Abstract

Molds in wet and warm environments often attack surfaces of products made from beech and other less or moderately durable woods. This paper presents the effects of the physical modification of beech wood with a CO2 laser having a constant power output of 45 W, using eight radiation doses from 7.8 to 75 J/cm2. Variations in laser activations created a scale of color changes in surfaces of beech wood determined in the CIE L*a*b* system, ranging from an apparently unaffected to totally dark due to carbonization effects. The surfaces of beech samples modified by laser were subsequently infected with the molds Aspergillus niger and Penicillium brevicompactum, and their growth on the top surfaces of beech samples was evaluated according to the standard STN 49 0604 (1980). The modified surfaces of beech wood exposed to higher CO2 laser powerful effects (i.e., radiation doses 25 J/cm2 and more) obtained evidently higher resistance to Aspergillus niger, but their resistance to Penicillium brevicompactum changed only minimally.

Download PDF

Full Article

The Impact of Laser Surface Modification of Beech Wood on its Color and Occurrence of Molds

Zuzana Vidholdová,a,* Ladislav Reinprecht,a and Rastislav Igaz b

Molds in wet and warm environments often attack surfaces of products made from beech and other less or moderately durable woods. This paper presents the effects of the physical modification of beech wood with a CO2 laser having a constant power output of 45 W, using eight radiation doses from 7.8 to 75 J/cm2. Variations in laser activations created a scale of color changes in surfaces of beech wood determined in the CIE L*a*b* system, ranging from an apparently unaffected to totally dark due to carbonization effects. The surfaces of beech samples modified by laser were subsequently infected with the molds Aspergillus niger and Penicillium brevicompactum, and their growth on the top surfaces of beech samples was evaluated according to the standard STN 49 0604 (1980). The modified surfaces of beech wood exposed to higher CO2 laser powerful effects (i.e., radiation doses 25 J/cm2 and more) obtained evidently higher resistance to Aspergillus niger, but their resistance to Penicillium brevicompactum changed only minimally.

Keywords: CO2 laser; Wood modification; Color; Molds

Contact information: a: Department of Mechanical Wood Technology, Faculty of Wood Sciences and Technology, Technical University in Zvolen, T. G. Masaryka 24, Zvolen, SK-960 53, Slovak Republic; b: Department of Physics, Electrical Engineering and Applied Mechanics, Faculty of Wood Sciences and Technology, Technical University in Zvolen, T. G. Masaryka 24, Zvolen, SK-960 53, Slovak Republic;

* Corresponding author: zuzana.vidholdova@tuzvo.sk

INTRODUCTION

Wood is a natural organic material. It has favourable characteristics in terms of sustainability, good physical and mechanical properties, workability, and enhanced energy recovery. However, wood products contain microbial-degradable carbohydrates and polar hydroxyls that absorb moisture from air; in moist environments they are often attacked by biological agents such as bacteria, molds, or decaying fungi (Reinprecht 2016). Biodegradation of wood products with molds is less dangerous in comparison to the effects of decaying fungi or insects. It occurs mainly on wood surfaces. On the other hand, it can cause various problems with wooden structures indoor and outdoor, including their undesirable appearance and detrimental effect on people’s health. Thus, prevention of mold growth on wooden materials is an important challenge.

Molds usually grow at temperatures from 0 to 50 °C and a relative air humidity of above 80% (Viitanen and Bjurman 1995). The intensity of mold growth depends on the environmental conditions and on the type of wooden material (Reinprecht and Broulíková 1987; Salminen et al. 2011; Karlsson et al. 2012; Vidholdová et al. 2015). Molds release millions of microscopic spores into the air. If these spores land on a wooden surface and environmental conditions are suitable for their sporulation, especially in wet and warm conditions, new molds will begin to grow. Molds can negatively affect the quality of air when producing volatile organic compounds and spores. High concentrations of spores may cause allergic reactions in sensitive individuals. Molds may also cause discoloration of wood surfaces, making them less aesthetically acceptable. The best way to prevent or stop the growth of molds on wood surfaces is to ensure a permanently dry environment.

Chemical treatments of wood with fungicides can kill molds and preventively protect wood from future mold attacks. The surface modification of wood may involve the action of various chemicals and biological agents (e.g., enzymes), or physical energetic fields (e.g., electromagnetic radiation, plasma, laser irradiation, or electron bombardment), mainly to alter its surface chemistry and improve the compatibility between the wood surface and coatings or adhesives (Hill 2006). Some physical modifications of wood surfaces involve changes in their molecular structure a subsequent increase of their resistance against molds and other biological agents (Reinprecht 2016).

Carbon dioxide (CO2) laser irradiation is a method used to modify the surface properties of wood. The CO2 laser uses a mixture of three gases – CO2, N2, and He – as an active medium. The wavelength radiation ranges in the infrared spectral area from 9.1 to 11 μm (the most commonly used wavelength is 10.6 μm). This technology is typically used for industrial cutting, engraving, drilling, or marking (Chitu et al. 2003; Barcikowski et al. 2006; Wust et al. 2007; Petutschnigg et. al. 2013). The treated wooden material retains its original appearance, and the laser-irradiated area is covered with a layer of dark carbon and ash. For example, at cutting, the less dense woods, e.g., pine and other softwoods, can be cut with higher speeds than denser woods, e.g., oak, beech, hornbeam, etc. The laser cutting speed increases with decreasing wood moisture (Gajtanská et al. 2004).

Lasers wood treatments often induce changes in color (Lin et al. 2008; Kubovský and Babiak 2009; Petutschnigg et. al. 2013; Petru and Lunguleasa 2015), polysaccharides (Kačík et al. 2010; Kačík and Kubovský 2011), and lignin (Barcikowski et al. 2006; Kubovský et al. 2016). These changes are influenced by the laser power. Changes in the color and in the chemical and anatomical structure of the modified wood are usually the most intensive at the surfaces directly affected with the laser; they decrease and level off at a minimum distance of 35 to 40 μm (Barcikowski et al. 2006). The effect of CO2 laser treatment is mainly caused by thermal processes in wood and changes in the main wood components (Orech and Kleskenová 1975; Panzner et al. 1998).

It is well-known that the prevention of microbial attack or biofilm formation (e.g. from bacteria or other organisms) on wood surfaces is a highly desirable outcome from the ecological and healthy views. Physical modification of wood surfaces (e.g. by plasma or laser) could prevent the growth of bacteria and molds without a negative impact on people. The aim of this study was to determine changes in the color and in the activity of molds on surfaces of beech wood treated with different radiation doses of a CO2 laser.

EXPERIMENTAL

Wood Samples

Samples prepared from beech wood (Fagus sylvatica L.) had the dimensions of 50 mm × 20 mm × 5 mm (length × width × thickness). A total of 96 samples without knots and false hardwood were collected for the research (64 modified with CO2 laser = for testing the color and the mold resistance after modification; 32 reference = for testing the color and the mold resistance in a native state without modification).

All four side surfaces of each sample were brushed with epoxy resin (CHS-Epoxy 324) for its protection against water uptake from the surrounding environment, especially from agar soil during the mold test. Before starting the laser modification process, the top surface of each sample was sanded with sandpaper, grain size 60 and then 120, using a DREMEL®3000 grinder machine (Breda, Netherlands). Samples were conditioned at a temperature of 20 ± 1°C and a relative humidity of 60% for constant moisture.

Laser Irradiation

The CO2 laser irradiation of beech wood samples was performed using experimental laser equipment. This device consists of: (1) a sealed CO2 laser tube (Reci Laser Technology CO., Ltd, Beijing, China) with an outgoing beam diameter of 8.0 mm, wave length of 10.6 μm, and a maximum output power of 100 W, (2) CNC positioning table system (Formetal Piesok, Piesok, Slovakia) which allowed laser head positioning and raster scans of the laser beam, and (3) a special PC control system.

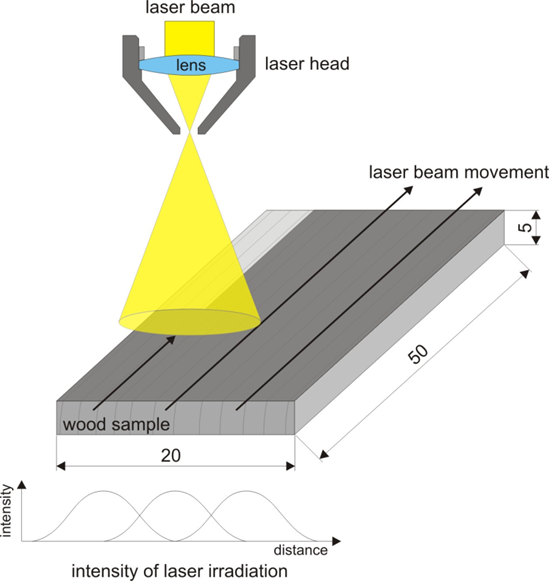

Fig. 1. The scheme of the laser treatment on the beech wood surface.

The samples were placed away from the lens focus, at a distance of 127 mm below the focus point. The unfocused beam diameter on the surface of samples at this distance was 10 mm. The output power of the laser beam was set on 45 W in CW mode. Laser power was determined using equipment Coherent Radiation Model 201 (Coherent Inc., Santa Clara, CA, USA). The spread laser beam stroked on the surface of the individual beech wood sample perpendicularly, and the laser head carriage moved along the width (axis x) at a determined scanning speed. To achieve a uniform irradiation over the whole surface of the sample, each sample was irradiated with three parallel passes of the laser beam (Fig. 1). A parallel band system was created on the surfaces of the first group of samples. The speed of the laser irradiation was increased, and the whole process was repeated on another group of samples. Individual groups of samples were irradiated with a particular value of eight scanning speeds from 6 to 58 mm/s. The irradiation doses H (Table 1) were calculated from the laser beam parameters and scanning speed according to Eq. 1,

where (W) is effective power of laser beam on the surface of sample, (s) is time of irradiation of one pass (the proportion of sample width (m) and scanning speed (m/s)), and (m2) is the area of one pass. The same method has been used e.g. by Kubovský and Babiak (2009).

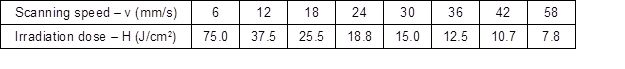

Table 1. Irradiation Doses Depending on the Scanning Speeds

Color Analysis

The colors of the wood surfaces were analysed according to the CIE L*a*b* color system using a Color Reader CR-10 (Konica Minolta, Osaka, Japan). This device is based on a D65 light source that simulates daylight, and its sensor head is 8 mm in diameter. In the native state and after laser treatment, the color coordinates L* (darkness: white – black), a* (red – green), and b* (yellow – blue) of each sample were measured in the center of its top surface (20 mm × 50 mm). Measurements were performed for samples conditioned at a temperature of 20 ± 1 °C and 60% relative humidity. The L*, a* and b* values were used to calculate the total color change ΔE* according to Eq. 2,

where ΔL* is L*laser – L*native, Δa* is a*laser – a*native, and Δb* is b*laser – b*native.

Mold Test

Two microscopic fungi, Aspergillus niger Tiegh. and Penicillium brevicompactum Dierck, were used for the mold test of beech wood samples. The top surfaces of samples were treated as follows: (1) modified with CO2 laser of a different irradiation dose and (2) unmodified (reference). The samples were tested in Petri dishes for 28 days at 20 ± 2 °C, according to the Standard STN 49 0604 (1980). Before the mold test, the samples were sterilized 1 h with the UV light (30 W), placed into Petri dishes (two modified pieces and one reference piece per one dish were filled with 3 to 4 mm thick layer of the Czapek-Dox agar) on sterilized matts, and subsequently inoculated with a water spore suspension of the given mold species.

The growth activity of molds (GAM) on the top side (20 mm × 50 mm) of the laser modified and reference beech wood samples was carried out visually (using a table magnifying glass having 5× magnification) after the 7th, 14th, 21th, and 28th day. Assessing the mold growth on the tested wood was done under different inclination angles from 15° to 90° with the aim to correctly identify the presence and intensity of mold growth – mainly of the dark spores of Aspergillus niger on darker surfaces irradiated with higher doses of laser. The GAM on the top surfaces of samples was determined on a scale from 0 to 4 (by STN 49 0604 1980), such that 0 = no mold on the surface; 1 = mold up to 10 % of surface; 2 = mold up to 25% of surface; 3 = mold up to 50% of surface; and 4 = mold more than 50% of surface.

Statistical Analysis

Analysis of variance (ANOVA) was performed to test the differences in the growth of mold activity among the different trials within the group (combination of irradiation dose, mold species, and duration of mold test) at a 0.05 significance level using Statistica v. 12 software (StatSoft CR, s.r.o., Prague, Czech Republic).

RESULTS AND DISCUSSION

Color Changes of the Laser-Treated Beech Wood Surfaces

During the laser modification of the beech wood samples, their top surfaces created heat-affected zones. By visual inspection, the wood surfaces showed a different color appearance depending on the intensity of the laser treatment (Fig. 2). It was clear that due to the laser modification the beech wood, surfaces became darker with traces of charring.

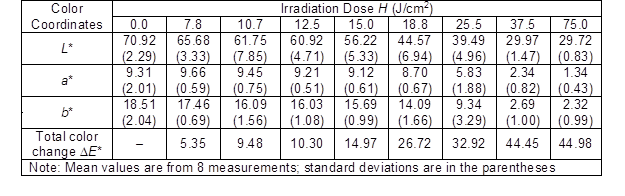

The CIE L*a*b* color analyses demonstrated gradual darkening of the laser-treated samples with increasing irradiation dose, as indicated by decreased L* values (Table 2). The table also shows the values of color coordinates a* and b* of the native and with laser-modified beech wood samples, together with their total color changes ΔE*.

Fig. 2. Laser treated beech wood surfaces with different irradiation doses H (J/cm2).

Table 2. Measured Values of L*, a*, b*, and the Total Color Change ∆E* after the Laser-Treatment of Beech Wood Surfaces

Generally, the color changes of the laser-modified beech wood samples were influenced by the irradiation dose (Table 2). Samples after modification became darker when lightness L* decreased from 70.92 (unmodified surface) to 29.72 (surface modified with irradiation dose 75 J/cm2). Due to the laser modification, there was a transition from red to green shades (a* changed from 9.31 to 1.34). Similarly, there was a transition from yellow to blue (b* changed from 18.51 to 2.32). With increasing of the laser-irradiation dose the total color difference ΔE* continued to grow for modified samples from 5.35 to 44.98. This parameter showed almost a continuous increase, while its values were mainly affected by changes of the L*. This result was consistent with other reports where wood surface color changes were analysed after laser treatments (Lin et al. 2008; Kubovský and Babiak 2009; Petutschnigg et. al. 2013; Petru and Lunguleasa 2015; Kubovský et al. 2016).

Growth Activity of Molds on the Laser-Treated Beech Wood Surfaces

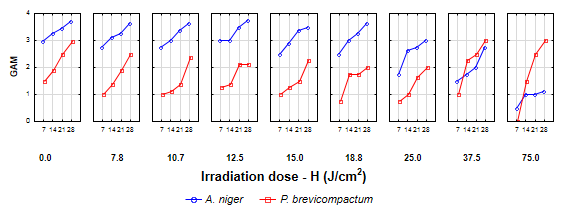

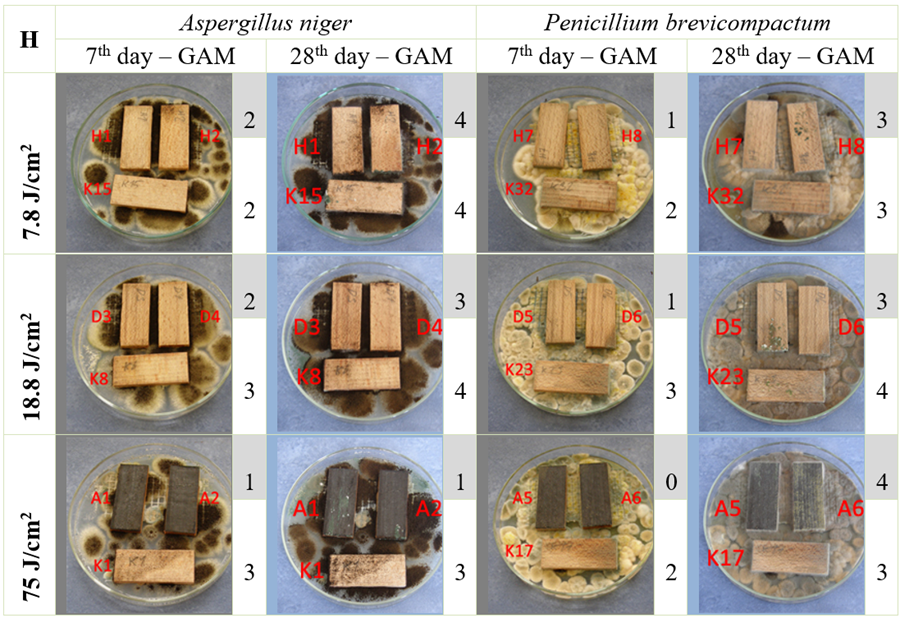

Surfaces of the laser-treated beech wood samples were more or less susceptible to the growth activity of molds (GAM). The mold growth intensity partly differed in relation to the intensity of the laser treatments; however, the lower radiation doses did not restrict the GAM significantly (Figs. 3 and 4).

Fig. 3. The GAM – Aspergillus niger and Penicillium brevicompactum – on the top surfaces of laser treated beech wood samples was tested from the 7th to 28th day. Note: Mean values are from 4 measurements.

With increased irradiation dose from 7.8 to 18.8 J/cm2, there was no apparent change in the minimal resistance of beech wood surfaces to the mold Aspergillus niger (in the 28th day the GAM was usually 4, or less often 3) (Fig. 3). However, there were significant decreases in the GAM at irradiation doses from 25 to 75 J/cm2, and for the highest irradiation dose (75 J/cm2), the GAM was approximately 1 at the end of the test. On wood surfaces having a charring layer (caused at higher intensities of the laser treatment), there was only a slight and infrequent occurrence of this mold species (less than 10%). This is consistent with previous work (Reinprecht and Vidholdová 2008), where OHT-thermowoods had evidently better resistance against the mold Aspergillus niger at higher treatment temperatures and prolonged times (the best at 220 °C/6 h). Kocaefe et al. (2007) also reported that mold resistance of wood is improved by heat treatment in terms of a higher temperature and processing time.

In contrast, the growth of Penicillium brevicompactum was lower both on the surfaces of the reference beech wood samples (in the 28th day the mean GAM was 3.0) and the laser treated ones (in the 28th day the mean GAM was between 2.0 and 3.0) (Fig. 3). The GAM did not apparently change due to the laser modification processes. Using the highest laser irradiation doses (37.5 and 75 J/cm2, i.e., when surfaces were covered with a charring layer), the surfaces of modified beech wood samples had a comparable resistance to growing activity of this mold species with reference samples (Fig. 4). This result contradicts that obtained for the mold Aspergillus niger; its activity decreased on wood surfaces containing a charring layer (Figs. 3 and 4).

Fig. 4. The GAM (1 – 4) of Aspergillus niger and Penicillium brevicompactum on: (A) surfaces of selected beech wood samples treated with the laser irradiation doses of 7.8, 18.8, and 75 J/cm2 (see two samples in the Petri dish), and (B) on surfaces of selected reference samples (see one sample oriented transverse in the same Petri dish). Note: Grey shading was used for two laser treated samples and white shading for one reference sample.

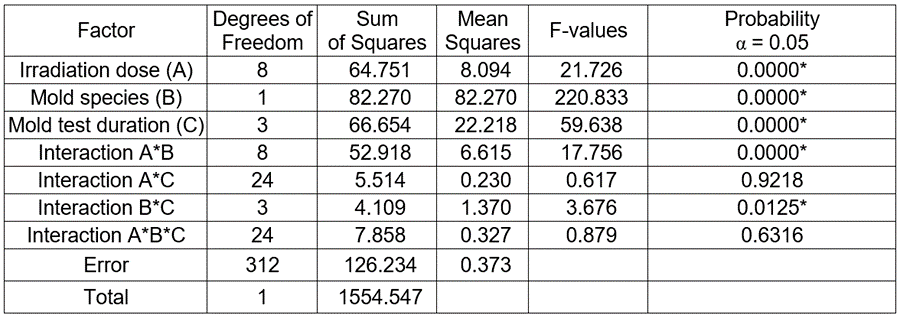

Table 3. Analysis of Variance for Results of the Growth Activity of Molds (GAM)

* Significant difference

From the statistical analyses of the GAM values, it is evident that all monitored factors at the mold tests (irradiation dose, species of mold, and duration of the mold test) had a statistically significant effect (a= 0.05) on the growth of molds on the laser modified wood surfaces (Table 3). Statistically significant were also the interaction effects between the irradiation dose and the mold species. This confirmed the finding from visual assessment that at higher irradiation doses inhibited growth of Aspergillus niger, but not of Penicillium brevicompactum. On contrary, the interactions between the irradiation dose and mold test duration, or between the irradiation dose, mold species and mold test duration were not significant.

CONCLUSIONS

- An increase of the laser irradiation doses from 7.8 to 75 J/cm2 caused a more evident charring of the beech wood surfaces.

- The color of the laser-irradiated samples, determined in the CIE L*a*b* system, gradually became darker (L* decreased from 70.92 to 29.72), more green (a* changed from 9.31 to 1.34), and more blue (b* changed from 18.51 to 2.32).

- In practice, the color tones of wood surfaces can be adjusted using different laser parameters.

- The laser treatment of beech wood surfaces had only a mild or no inhibition effect against the growth activity of molds. At higher irradiation doses, inhibition was evident only against the mold Aspergillus niger, but not against Penicillium brevicompactum.

- Generally, the anti-mold effect of the laser modification of wood surfaces can be probably specific for various species of molds, depending on: (1) their optimal and critical environmental conditions, and (2) changes in the trophic factors of wood during the modification process – charring, creation of monosaccharides, etc.

ACKNOWLEDGMENTS

This work was supported by the Slovak Research and Development Agency under the contract No. APVV-0200-12. The authors also thank Mr. Richard Šemoda for technical assistance.

REFERENCES CITED

Barcikowski, S., Koch, G., and Odermatt, J. (2006). “Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites,” Holz als Roh- und Werkstoff 64, 94-103. DOI: 10.1007/s00107-005-0028-1

Gajtanská, M., Christov, I., and Igaz, R. (2004). Lasers and their Exploration in Industry, Technická Univerzita vo Zvolene. (in Slovak)

Hill, C. A. S. (2006). Wood Modification: Chemical, Thermal and Other Processes, John Wiley & Sons, Ltd, Chichester, UK. DOI: 10.1002/0470021748

Chitu, L., Cernat, R., Bucatica, I., Puiu, A., and Dumitras, D. C. (2003). “Improved technologies for marking of different materials,” Laser Physic 13(8), 1108-1111.

Kačík, F., and Kubovský, F. (2011). “Chemical changes of beech wood due to CO2 laser irradiation,” Journal of Photochemistry and Photobiology A: Chemistry 222(1), 105-110. 10.1016/j.jphotochem.2011.05.008.

Kačík, F., Kubovský, I., Jamnický, I., and Sivák, J. (2010). “Changes of saccharides due to CO2 laser irradiation of maple wood,” Acta Facultatis Xylologiae Zvolen 52(1), 33-40.

Karlsson, O., Yang, Q., Sehlstedt-Persson, M., and Morén, T. (2012). “Heat treatments of high temperature dried Norway spruce boards: Saccharides and furfurals in sapwood surfaces,” BioResources 7 (2), 2284-2299. DOI: 10.15376/biores.7.2.2284-2299

Kocaefe, D., Shi, J. L, Yang, D. Q., and Zhang, J. (2007). “Preliminary study of thermal treatment effects on mold growth of selected Quebec wood species,” Forest Products Journal 57(12), 30-33.

Kubovský, I., and Babiak, M. (2009). “Color changes induced by CO2 laser irradiation of wood surface,” Wood Research 54(3), 61-66.

Kubovský, I., Kačík, F., and Reinprecht, L. (2016). “The impact of UV radiation on the change of color and composition of the surface of lime wood treated with a CO2 laser,” Journal of Photochemistry and Photobiology A: Chemistry 322, 60-66. DOI: 10.1016/j.jphotochem.2016.02.022

Lin, C. J., Wang, Y. C., Lin, L. D., Chiou, C. R., Wang, Y. N., and Tsai, M. J. (2008). “Effects of feed speed ratio and laser power on engraved depth and color difference of Moso bamboo lamina,” Journal of Materials Processing Technology 198(1-3), 419-425. DOI: 10.1016/j.jmatprotec.2007.07.020

Orech, T., and Kleskenová, M. (1975). Untersuchungen über die Holzbearbeitung mit Laserstrahlen,” Drevo 30, 324.

Panzner, M. Wiedemann, G. Henneberg, K. Fischer, R. Wittke, T., and Dietsch, R. (1998). “Experimental investigation of the laser ablation process on wood surfaces,” Applied Surface Science 127-129, 787-792. DOI: 10.1016/S0169-4332(97)00743-5

Petru, A., and Lunguleasa, A. (2015). “Effects of the laser power on wood coloration,” in: International Conference of Scientific Paper AFASES 2015, Brasov, Romania

(http://www.afahc.ro/ro/afases/2015/afases_2015/mediu/Petru_Lunguleasa.pdf).

Petutschnigg, A., Stöckler, M., Steinwendner, F., Schnepps, J., Gütler, H., Blinzer, J., Holzer, H., and Schnabel, T. (2013). “Laser treatment of wood surfaces for ski cores: An experimental parameter study,” Advances in Materials Science and Engineering 1-7. DOI: 10.1155/2013/123085

Reinprecht, L. (2016). Wood Deterioration, Protection and Maintenance, John Wiley & Sons, Ltd, Chichester, UK. DOI: 10.1002/9781119106500.ch4

Reinprecht, L., and Broulíková, J. (1987). “Microbial corrosion of phenol-plastic compressed materials,” Plasty a Kaučuk 24(9), 275-278. (in Slovak)

Reinprecht, L., and Vidholdová, Z. (2008). “Mould resistance, water resistance and mechanical properties of OHT-thermowoods,” in: Sustainability through New Technologies for Enhanced Wood Durability: Socio-economic perspectives of treated wood for the common European market, Final Conference Proceeding of Cost Action E37 – Bordeaux, Gent University, Belgium, pp. 159-165.

Salminen, K., Peuhkuri, R., Lähdesmäki, K., Viitanen, H., Vinha, J., Paajanen, L., Iitti, H., Ojanen, T., and Strander, T. (2011). “Mould growth in building materials in laboratory and field experiments,” in: Proceedings 9th Nordic Symposium on Building Physics NSB 2011, Tampere, Finland, pp. 859-866.

STN 49 0604 (1980). “Wood protection. Methods of determination of biocidal properties of wood preservatives,” The Slovak Office of Standards, Metrology and Testing, Bratislava, Slovak Republic.

Vidholdová, Z., Iždinský, J., Reinprecht, L., and Krokošová, J. (2015). “Activity of bacteria and molds on surfaces of commercial wooden composites,” Materials Science Forum 818, 190-193. DOI: 10.4028/www.scientific.net/MSF.818.190

Viitanen, H., and Bjurman, J. (1995). “Mould growth on wood under fluctuating humidity conditions,” Material und Organismen 29(1), 27-46.

Wust, H., Haller, P., and Wiedemann, G. (2007). “Experimental study of the effect of a laser beam on the morphology of wood surfaces,” in: Proceeding of International Symposium on Wood Machining, Lausanne, Switzerland, pp. 183-192.

Article submitted: November 30, 2016; Peer review completed: February 2, 2017; Revised version received: April 13, 2017; Accepted: April 15, 2017; Published: April 24, 2017.

DOI: 10.15376/biores.12.2.4177-4186