Abstract

Oil palm biomass is readily available in Malaysia. However, its high lignin content makes it undesirable for further processing. Pretreatment is employed to reduce the amount of lignin. Many resources exist on pretreatment methods for lignocellulosic biomass, but there are few articles specifically on oil palm biomass. Therefore, this review focuses on pretreatment methods for oil palm biomass, comparing their main strengths and limitations. Furthermore, this review tabulates different pretreatment conditions utilized, combinations of pretreatment methods, the resulting yields, and the potential applicability in producing value-added products. Because the main limitation of pretreatment is the formation of toxic compounds such as furfural and hydroxymethylfurfural, this review also discusses chemical detoxification methods for oil palm biomass residues. According to this review, among all types of oil palm biomass, oil palm empty fruit brunch is the most widely studied, and alkaline pretreatment is the most popular of all pretreatment methods. Combination of pretreatment methods is suitable for biomass with greater lignin content, to increase delignification efficiency. Furthermore, a combination of overliming and activated carbon treatment removes the maximum amount of toxic by-products.

Download PDF

Full Article

Overview of Pretreatment Methods Employed on Oil Palm Biomass in Producing Value-added Products: A Review

Rushan Diyanilla,a Tuan Sherwyn Hamidon,a Lisman Suryanegara,b andM. Hazwan Hussin a,*

Oil palm biomass is readily available in Malaysia. However, its high lignin content makes it undesirable for further processing. Pretreatment is employed to reduce the amount of lignin. Many resources exist on pretreatment methods for lignocellulosic biomass, but there are few articles specifically on oil palm biomass. Therefore, this review focuses on pretreatment methods for oil palm biomass, comparing their main strengths and limitations. Furthermore, this review tabulates different pretreatment conditions utilized, combinations of pretreatment methods, the resulting yields, and the potential applicability in producing value-added products. Because the main limitation of pretreatment is the formation of toxic compounds such as furfural and hydroxymethylfurfural, this review also discusses chemical detoxification methods for oil palm biomass residues. According to this review, among all types of oil palm biomass, oil palm empty fruit brunch is the most widely studied, and alkaline pretreatment is the most popular of all pretreatment methods. Combination of pretreatment methods is suitable for biomass with greater lignin content, to increase delignification efficiency. Furthermore, a combination of overliming and activated carbon treatment removes the maximum amount of toxic by-products.

Keywords: Oil palm; Cellulose; Lignin; Pretreatment; Detoxification

Contact information: a: Materials Technology Research Group (MaTReC), School of Chemical Sciences, Universiti Sains Malaysia, 11800 Minden, Penang, Malaysia; b: Research Center for Biomaterials, Indonesian Institute of Sciences (LIPI), Jakarta, Indonesia;

* Corresponding author: mhh@usm.my; mhh.usm@gmail.com

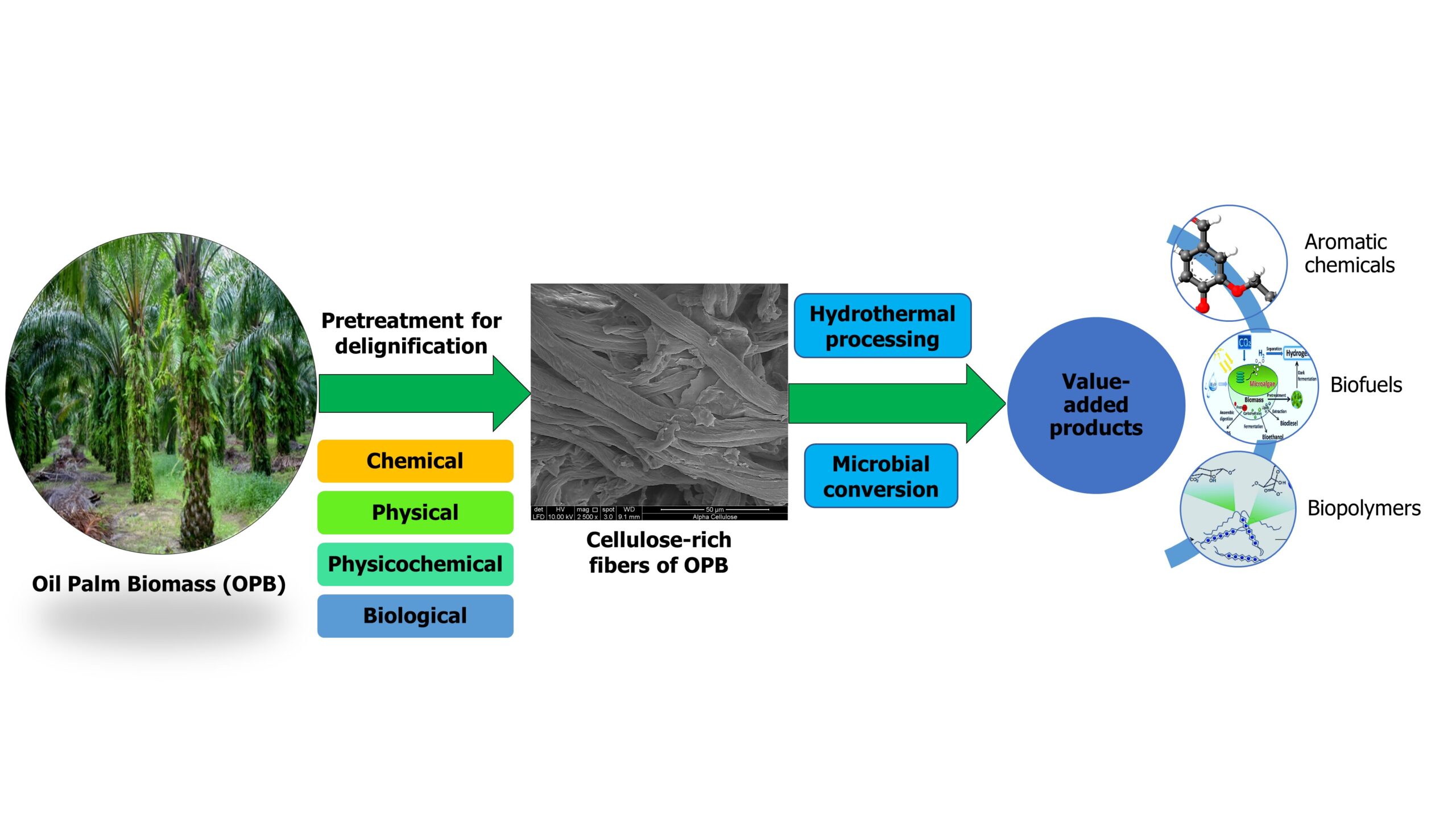

GRAPHICAL ABSTRACT

INTRODUCTION

Over the past decades, the world’s energy demand has been growing rapidly. Conventional energy resources such as coal, oil, petroleum, and natural gas are growing more scarce, and use of fossil fuels causes climate change (Tsegaye et al. 2019; Trache et al. 2020). Thus, available energy resources need to be conserved while exploring sustainable alternatives, such as conversion of renewable energy materials to biofuels (Medina et al. 2018). To that end, available resources should be utilized efficiently while overcoming challenges such as solid waste management, environmental pollution, the greenhouse effect, and energy demand (Manaf et al. 2018; Charnnok et al. 2019).

Currently, the oil palm industry in Malaysia generates more than 80 million tons (dry weight basis) of oil palm waste per year (Megashah et al. 2018a; Yiin et al. 2018a), and this figure is expected to increase by at least 40% in 2020 (Rupani et al. 2019). Corresponding to a proposed increase in oil palm plantations in Malaysia, annual oil palm production is expected to increase by up to 50 million tons by 2030 (Tahir et al. 2018). Palm kernel shell (PKS) (Lee et al. 2018), oil palm empty fruit bunch (OPEFB), oil palm frond (OPF), oil palm mesocarp fiber (OPMF), oil palm leaves (OPL), palm oil mill effluent (POME), palm kernel cake (PKC), and oil palm trunk (OPT) are the most generated co-products (Fig. 1) (Rafatullah et al. 2013; Brito et al. 2018; Chan et al. 2018). The total oil palm biomass residues (dry weight basis) (Fig. 2) available for replanting, pruning, and milling activities in Malaysia in 2017 was assessed 51.19 metric tons (MT) out of 101.02 MT of oil palm fresh fruit bunches (OPFFB) processed (Hamzah et al. 2019).

Meanwhile, researchers worldwide are performing new experiments to maximize the usage of oil palm biomass. So far, many studies have been performed on the technological advancements in the use of oil palm biomass for the production of biochar, polymers, and biofuels (Hassan et al. 2019; Hussin et al. 2020). With the increasing demand for alternatives to fossil fuels and the depletion of fossil fuel reservoirs, studies are proceeding toward the production of biofuels (Chang 2018). With the increase in population, demand for food sources has also increased. Therefore, the current interest is more towards the production of biofuels from non-edible sources (Razali et al. 2018). Consequently, biofuels produced from oil palm biomass have attracted the attention of many researchers.

Malaysia is globally renowned for its palm cultivation, being the world’s second-largest palm oil producer and exporter (Tajuddin et al. 2019), accounting for more than 30% of world palm oil production and 37% of world exports in 2016 (Rizal et al. 2018a). Therefore, great amounts of oil palm biomass are generated annually and then thrown out or burnt without further utilization due to the lack of technology to utilize this material (Onoja et al. 2019). This situation worsens the biomass overload problem, wastes precious cellulose-rich resources, and can lead to serious environmental issues such as air pollution (Latif et al. 2019). Lignocellulosic biomass is the most readily available renewable green carbon source generated on earth and presents potential alternatives to petroleum-based commodity crops (Ahmad et al. 2018a; Tayyab et al. 2018). Lignocellulosic biomass provides raw materials for potential renewable energy sources due to its carbohydrate composition (Megashah et al. 2018b). It can be used to produce biofuels such as bioethanol, biobutanol (Espinosa et al. 2018), and biomethane (Medina et al. 2018), along with various other value-added products (Kamsani et al. 2018; Namondo et al. 2018). Second-generation bioethanol is the most advanced product generated from lignocellulosic biomass (Perrone et al. 2018).

As the name implies, lignocellulosic biomass contains lignin (aromatic biopolymer), as well as cellulose and hemicellulose (polysaccharides) as major components (Rizal et al. 2018a; Thamsee et al. 2019). Only the cellulose and hemicellulose are further converted to ethanol. However, due to the high amount of lignin present in the cell wall, utilization of oil produced from the palm is difficult. Lignins are complex structures that are resistant to further conversion (Cardona et al. 2018). Therefore, before the primary processing steps of enzymatic hydrolysis, fermentation, and distillation, some preparation steps are required to digest these resistant structures (i.e., to reduce biomass recalcitrance) and open them up for further conversion (Satlewal et al. 2018; Sukiran et al. 2018). These preparation steps (delignification) are known as pretreatment methods.

An effective pretreatment method alters the chemical composition of lignocellulosic biomass, its macrostructure, and its microstructure. Apart from delignification, pretreatment methods reduce the crystallinity of cellulose and improve the porosity of the lignocellulosic material (Noorshamsiana et al. 2017; Sasmal and Mohanty 2018). Moreover, a resourceful pretreatment technique must be cheap, be easy to operate, and form a substantial percentage of the yield (Tayyab et al. 2018). The pretreatment method should be selected based on the amount of lignin present in the studied oil palm biomass. Based on the research studies analyzed in this review article, the amount of lignin present in different types of oil palm biomass varies drastically (approximately 14% to 36%). The greatest amount of lignin is present in oil palm mesocarp (OPMF), and the lowest amount of lignin is present in OPEFB.

Fig. 1. Major oil palm biomass residues

Most of the studies performed on oil palm biomass are on OPEFB. Apart from OPEFB having the greatest availability, the ease of performing chemical reactions due to the lower lignin content may contribute to its popularity. However, due to the limited number of studies performed on PPF, it is difficult to compare the amounts of lignin observed in different studies. One notable feature found was the deviation in the lignin content of a specific type of biomass when comparing various studies. The cellulose, hemicellulose, and lignin contents of different types of oil palm biomass are summarized in Table 1, as different studies reported varied lignin contents even among a specific type of oil palm biomass. This result may be due to several factors, such as the area the plant is grown, the constituents of the soil, nutritional levels, and climatic changes, which affect the amount of lignin present in order to adapt to nature. Therefore, a researcher planning to work on a particular type of oil palm biomass should first analyze the lignin content before selecting the pretreatment method.

Table 1. Cellulose, Hemicellulose, and Lignin Contents of Different Types of Oil Palm Biomass

These pretreatment methods can be divided into three main categories: physical pretreatment, chemical pretreatment, and biological pretreatment (Nabilah-Jansar et al. 2018). Of these methods, physical pretreatment and chemical pretreatment are widely used (Hosseini Koupaie et al. 2019) due to their low cost and user-friendliness (Noorshamsiana et al. 2017). However, with increasing demand for the use of environmentally benign methods, researchers have started to shift towards biological pretreatment methods, mainly due to reduced energy consumption, better productivity, the formation of non-toxic compounds, and greater specificity (Arora et al. 2019; Tsegaye et al. 2019).

Acid treatment, alkaline treatment, and organic solvent treatment are chemical treatment methods (Moniruzzaman and Goto 2018). Milling, pyrolysis, and hydrothermal treatment are examples of physical pretreatment (Tang et al. 2018). Enzymatic treatment and treatment using microorganisms are biological pretreatment methods. In the production of biofuel, the choice of pretreatment method mainly depends on the nature of the biomass used, the generation of toxic inhibitors, and the amount of lignin present (Kumar et al. 2019). Also, special consideration should be given to cost-effectiveness and the effects on the final product and its composition (Kim 2018; Tayyab et al. 2018). Furthermore, ease of expanding to industrial scale should be given a high value.

Fig. 2. Availability of major oil palm biomass residues (dry weight) in Malaysia in 2017

Many review articles have been written on pretreatment methods in general. For instance, Rizal et al. (2018a) reviewed the pretreatment of oil palm biomass for fermentable sugar production. Even though their review study focused on different pretreatment techniques employed on oil palm biomass, the review paper does not reach beyond explaining post-production from fermentable sugars. Their study does not enlighten about the production of value-added products from fermentable sugars. Moreover, how each pretreatment technique affects the production of fermentable sugars has not been discussed. Apart from that, Rizal et al. (2018a) have not discussed each pretreatment method in detail. To the best of the present authors’ knowledge, there have been little to no studies regarding the various pretreatment techniques employed on oil palm biomass in the production of value-added products. There has been a need for in-depth review of literature detailing how each pretreatment technique influence the digestibility of oil palm biomass in valorizing them into value-added products including bioethanol, lactic acid, vanillic acid, biovanillin, biohydrogen, 2,3-butanediol, pyrolysis oil, protocatechuic acid, vanillin, cellulose nanocrystals, as antioxidants, and transparent paper production. Apart from conventional techniques, the present review also deliberates emerging pretreatment technologies employed on oil palm biomass as promising sustainable green pretreatment methods including microwave irradiation, ultrasonication, and ultra-high pressure. Additionally, this review focused on comparing the salient features and limitations of different pretreatment methods, while describing the different reaction conditions used on different types of oil palm biomass. Emphasis was also given to several detoxification methods for the removal of toxic by-products produced during the pretreatment process. Therefore, this review paper serves to highlight and discuss the vast potential of an effective pretreatment to overcome the recalcitrance of oil palm biomass and may guide researchers and practitioners in designing their setups according to their needs.

CHEMICAL PRETREATMENT

Of all the existing pretreatment methods, chemical pretreatments are the most widely used. Chemical pretreatments can be subdivided according to the type of chemical being used. As the name implies, the pretreatment is performed via a chemical reaction, which leads to the disruption of the bonds among cellulose, hemicellulose, and lignin (Noorshamsiana et al. 2017).

Fig. 3. Main chemical pretreatment methods employed on oil palm biomass

The main chemical pretreatment types are acid pretreatment, alkaline pretreatment, organosolvent pretreatment, deep eutectic solvent pretreatment, and ionic liquid pretreatment, as depicted in Fig. 3. For instance, Loow and Wu (2018) employed a novel approach studying the efficiency of transformation of OPF into pentose sugars (xylose and arabinose) using an inorganic salt pretreatment, CuSO4·5H2O, with the assistance of chemical additives (H2O2 and Na2S2O8). The study reflected the importance of using chemical additives with the inorganic salt pretreatment of OPF. The results showed that the addition of 4.5 vol% of Na2S2O8 during the CuSO4·5H2O pretreatment at 120 °C for 30 min was able to achieve a total pentose sugar yield up to approximately 40%. Table 2 lists some of the chemical pretreatment methods used on oil palm biomass, including the reaction conditions that were employed and the outcome of each technique.

Acid Pretreatment

Acid pretreatment can effectively alter the chemical structures of lignocellulose. Acids employed in acid pretreatment work as catalysts to hydrolyze carbohydrates (especially hemicellulose), thereby weakening the lignin-hemicellulose barrier (Risanto et al. 2018). Acid pretreatment can be performed using mild acids as well as concentrated acids (Zhai et al. 2018). However, the reaction conditions will be different according to the strength of the acid being used. Typically, concentrated acids (30% to 70%) are employed at temperatures less than 100 °C, while dilute acids (0.1% to 10%) are employed at temperatures between 120 and 200 °C (Sari et al. 2018). The common inorganic acids used for acid pretreatment are H2SO4, H3PO4, HNO3, and HCl (Manaf et al. 2018). Apart from inorganic acids, organic acids are also used for pretreatment and do not generate additional lignocellulose-derived compounds during the fermentation process. Organic acids such as formic acid, maleic acid, oxalic acid, acetic acid, and citric acid (Oktaviani et al. 2019) are used for chemical pretreatment. Shrinking-bed, batch percolation, plug flow, flow-through, and counter-current reactors are the types of reactors that can be used for acid pretreatment (Kapoor et al. 2018).

Acid pretreatment is widely used, as it has many advantages. Dilute acids are more suitable because there is no need to recycle; they have a high reaction rate and can be used for continuous production. In the subsequent steps, the use of dilute acids will lead to high glucan hydrolysis and high xylose production. Also, when dilute H3PO4 and H2SO4 are employed, the essential nutrients phosphorous (P) and sulfur (S) aid the fermentation (Kapoor et al. 2018). Furthermore, at low pH, microorganisms used in the subsequent steps are able to adjust to the environment (Singh et al. 2018). Organic acids are less toxic and produce comparatively fewer inhibitory compounds in the hydrolyzate, as well as minimal sugar degradation (Oktaviani et al. 2019).

Despite these advantages, there are some drawbacks to consider when using acid pretreatment. The main downside is that a severer pretreatment such as acid pretreatment would dissolve more cellulose and hemicellulose. Additionally, acid-catalyzed hydrolysis would lead to the degradation of fermentable sugars to form inhibitory products, including furfural and hydroxymethylfurfural (HMF). HMF and furfural diminish the yield of fermentable sugars in the pretreatment liquor and concurrently serve as fermentation inhibitors. These inhibitory products should be removed or reduced through detoxification before the sugars can be fermented into ethanol or other value-added products (Noparat et al. 2015). Acid pretreatment causes starch to degrade to form HMF under severer conditions. For an example, if OPT is subjected to acid pretreatment, starch loss would be inevitable (Eom et al. 2015). Moreover, there are other drawbacks, including the need to use individual reactors to withstand corrosion, increasing operational and maintenance costs. Subsequent detoxification, washing, and neutralizing should be done before further processing, which increases the time and cost (Noorshamsiana et al. 2017). Partial degradation of lignin forms phenolic compounds that will cause interference in the subsequent steps of hydrolysis. Highly acidic conditions may lead to further hydrolysis of hemicellulose into xylose, which can be further hydrolyzed to furfural and HMF. However, this can also be used to commercially synthesize furfural. Hastuti et al. (2018) extracted cellulose nanocrystals (CNCs) from OPEFB via hydrochloric acid pretreatment. They concluded that CNCs isolated by hydrochloric acid pretreatment persisted stably for more than 6 months without undergoing any sedimentation, demonstrating superior nano-dispersibility.

Oil palm empty fruit bunch is the most widely used type of biomass available from the oil palm tree. The reason for this may be the abundance of OPEFB upon palm oil extraction for other industrial applications. Mostly, dilute H2SO4, HNO3, and acetic acid have been applied as the acid pretreatment medium. According to Gonzales et al. (2019) and Thamsee et al. (2018), the glucose yield is reduced when using high temperatures for an extended time. Oil palm trunk is the next highly used oil palm biomass. Rattanaporn et al. (2018) achieved the greatest reducing sugar yield with the use of oxalic acid, compared to acetic acid and citric acid. According to the aforementioned studies, both PPF and OPF have been employed with dilute H2SO4 as the pretreatment agent. However, comparison of the results is difficult due to the limited number of studies conducted.

Noparat et al. (2015) employed dilute acid pretreatment on OPT biomass under varying conditions (temperature, acid concentration, and time) to improve enzymatic saccharification. A fractional factorial experiment design was adopted to investigate the pretreatment conditions needed to obtain high enzymatic digestibility. The data obtained indicated that mild acid pretreatment conserved more cellulose and hemicellulose; nevertheless, severe conditions were required to attain adequate enzymatic hydrolysis of OPT. According to their study, most of the hemicelluloses in OPT were removed through the acid pretreatment, while cellulose and lignin being more porous were easily hydrolyzed by cellulases into glucose. Effects of acid pretreatment and conditions on consequent enzymatic hydrolysis were evaluated upon hydrolyzing with the use of enzymes containing cellulase at a loading of 15 FPU/g cellulose and β-glucosidase at a loading of 30 CBU/g cellulose for 72 h. They found that pretreating with 3% H2SO4 for 40 min at 180 ºC attained the highest enzymatic hydrolysis (cellulose-to-glucose conversion yield) of ca. 80% along with the highest overall glucose recovery (50.8%), while 1% H2SO4 pretreatment for 20 min at 160 ºC achieved the lowest cellulose to glucose conversion yield of 22% upon 72 h of digestion. Insufficient enzymatic hydrolysis achieved at 1% H2SO4 signified that milder pretreatment conditions fails to remove an adequate amount of hemicelluloses from OPT. The higher the amount of remaining hemicelluloses upon pretreatment, the poorer would be the enzymatic digestibility of cellulose.

The approach of adopting organic acid pretreatment has attracted much attention among the researchers owing to its high potential to promote enzymatic saccharification of lignocellulosic biomass, as organic acids are much less hazardous and produce lesser inhibitory by-products of fermentation compared to other chemical pretreatments. Rattanaporn and co-workers (2018) employed organic acid (acetic acid, oxalic acid, and citric acid) pretreatment on OPT to investigate the effects of enzymatic saccharification and bioethanol production. Enzymatic hydrolysis was carried out for 72 h at 45 ℃ using 20 FPU of Celluclast® and 100 CBU of cellobiase along with 50 mM sodium citrate buffer (pH 4.7) and 200 µL of 2 M sodium azide. The relationship between pretreatment parameters and pretreatment efficiency in terms of released reducing sugar yield was determined using response surface methodology (RSM) with Box–Behnken experimental design. Organic acid concentration, pretreatment temperature, and pretreatment time variables primarily affect the efficacy of chemical pretreatment of OPT. According to the mathematical models, optimum pretreatment conditions to attain the highest released sugar content for acetic acid was 107.3 °C, 30 min, 8.23 wt%, for citric acid (131.92 °C, 58.92 min, 13.92 wt%) and for oxalic acid (100 °C, 60 min, 15 wt.%) in terms of pretreatment temperature, pretreatment time, and organic acid concentration, respectively. Response surface plots revealed the antagonistic effect of pretreatment parameters at a certain condition. Oxalic acid pretreated OPT biomass contained the highest amount of lignin upon enzymatic saccharification at 54.0%, followed by citric acid (52.7%) and acetic acid (51.8%) pretreatments. This trend corroborated with the trend attained for released reducing sugar yield, signifying that oxalic acid was the most suitable pretreatment to improve the efficiency of enzymatic saccharification. As the lignin content inhibits the fermentation process, it may perhaps be speculated that citric acid pretreatment might form less amount of inhibitory by-products of fermentation. Analyses of OPT biomass composition upon pretreatment (prior to saccharification) revealed that untreated OPT contained the least cellulose content (38.8%), followed by acetic acid (47.6%), citric acid (49.6%), and oxalic acid (52.1%) pretreated OPT. Upon saccharification, hemicellulose and cellulose contents of pretreated OPT were reduced significantly even compared to untreated sample, validating its efficiency. Oxalic acid pretreatment yielded the highest enzymatic saccharification efficiency (1.80 mg/mL reducing sugars), followed by citric acid (1.23 mg/mL) and acetic acid (1.03 mg/mL) under optimal pretreatment conditions. Based on RSM, oxalic acid pretreated OPT released the maximum reducing sugar of 144 mg/g-pretreated biomass at the optimum condition. The effect of organic acid pretreatment in producing an improved ethanol yield was investigated by bioethanol fermentation of enzymatically hydrolyzed pretreated OPT using Saccharomyces cerevisiae TISTR 5606. The fermentation process was carried out in a batch at 32 °C for 60 h. Citric acid pretreatment attained the highest ethanol yield (16.27 ± 1.03 g/L), followed by acetic acid (13.69 ± 0.84 g/L) and oxalic acid (13.28 ± 0.26 g/L). All three organic acid pretreated hydrolysates achieved a much higher ethanol production than the untreated OPT hydrolysate (8.33 ± 0.22 g/L). Even though citric acid produced the highest ethanol concentration, oxalic acid pretreatment was found to be the most effective in enhancing enzymatic saccharification of OPT. Thus, obtained data indicated that selecting a suitable organic acid to pretreat oil palm biomass is crucial in enhancing the saccharification efficiency and bioethanol fermentation production yield.

Removal of hemicellulose from oil palm biomass can be attained with the use of dilute acid pretreatment, which increases the accessibility of enzymes or microbes to cellulose in enhancing the biomass digestion.

Alkali Pretreatment

Alkali pretreatment is performed mainly by hydroxides such as NaOH, H2O2, NH4OH (Ab Rahim et al. 2018), KOH, and Ca(OH)2 (Ouyang et al. 2018). Potassium hydroxide can selectively remove xylene (Noorshamsiana et al. 2017), whereas Ca(OH)2 is inexpensive and safe to use. Alkaline pretreatment followed by acid pretreatment can produce more pure cellulose. In the alkaline pretreatment, a saponification reaction occurs in which the intermolecular ester linkage between hemicellulose and lignin is broken down. Therefore, the lignin is solubilized, and cellulose is easily exposed to enzymatic hydrolysis in the further steps (Sari et al. 2018).

There are advantages and disadvantages to alkaline pretreatment. It can be operated at low temperature and pressure, thus consuming less energy. It leads to cellulose swelling and reduces the crystallinity, consequently increasing the surface area for enzymatic reactions (Baruah et al. 2018). Moreover, alkaline pretreatment leads to lignin structural changes and removal of acetyl groups and uronic acid substitutes of the hemicellulose, thereby increasing carbohydrate accessibility to further enzymatic hydrolysis. Alkaline pretreatment is more effective in removing lignin. However, as a result of alkaline pretreatment, limited solubilization of hemicellulose is achieved and the process degrades less sugar (Kapoor et al. 2018). When NH3 is used for chemical pretreatment, it causes selective delignification and also can be recovered easily due to high volatility. Moreover, on an industrial scale, effective and easy recovery could indirectly reduce costs (Latif et al. 2018). However, alkaline pretreatment is only suitable for biomass with low lignin content.

Among the disadvantages of alkaline pretreatment, alkali salts can be converted to irrecoverable salts and may get absorbed by the biomass, making them difficult to recover (Noorshamsiana et al. 2017). Also, it requires a longer reaction time, and some hemicellulose is dissolved, which leads to loss of biomass. Alkaline pretreatment necessitates extensive washing and neutralizing before proceeding to further enzymatic hydrolysis (Kapoor et al. 2018).

Sodium hydroxide is the most widely used alkali pretreatment agent. According to Waluyo et al. (2018), lignin content decreased by 5.3% after being soaked in 15% NaOH for 24 h. In a similar study, Chavalparit et al. (2018) were able to reduce the lignin content by 10.2% by soaking OPEFB in 5% NaOH for 48 h. By comparing these two studies it may be concluded that, despite decreasing the concentration of NaOH, the percentage of lignin removed can be increased by increasing the reaction time. In another study, Razali et al. (2018) were able to reduce the lignin content by 18.3%. The pretreatment method they employed was soaking OPEFB in 2% NaOH for 4 h, followed by autoclaving at 121 °C for 5 min. They were able to decrease the lignin content even further by applying heat and pressure, followed by the alkaline treatment. Similarly, studies performed using alkaline pretreatment and OPF as a raw material have demonstrated a high delignification percentage with high temperatures (Ahmad Sobri et al. 2019; Mahmood et al. 2019).

Kunasundari et al. (2017) pretreated sap from felled OPT using alkaline precipitation in view of enhancing the sugar fermentability for the efficient production of lactic acid. Their study aimed at fermentative lactic acid production under non-sterilized conditions through a novel Gram-positive bacterium Bacillus coagulans strain 191. This strain was used to ferment diverse sugars accompanied with yeast extract to form lactic acid. It is understood that alkaline precipitation is efficient in detoxifying a fermentative medium. They found out that alkaline pretreatment effectively removed fermentation inhibitors from the sap of OPT to achieve a high productivity of lactic acid. It was revealed that alkaline pretreatment (using 2 M NaOH) carried out at higher pH (8 to 10) provided efficient fermentation by B. coagulans strain 191, which resulted in highly productive lactic acid yield. At pH 9 and 24 h of fermentation, lactic acid reached the highest concentration at 63.3 g/L and yield of 0.92 g per g of total sugars. In the absence of alkaline pretreatment, a lower lactic acid yield was obtained, attributed to the formation of inhibitory products. The screening of optimal temperature for the growth of strain 191 (incubation) was found to be 55 °C for 72 h, responsible for the production of highest yield of lactic acid. The yield of lactic acid and consumption of glucose reached 80 to 88% when the culture medium of strain 191 was sustained at pH 5.0 to 6.0. For alkaline precipitation pretreatment, lowering the time duration of fermentation from 48 h to 24 h maximized the productivity of lactic acid from 0.89 to 2.64 g/L/h (h = fermentation time). Interestingly, alkaline precipitation (pH 8 to 10) was able to detoxify inhibitory compounds in improving lactic acid fermentation by B. coagulans strain 191. It was revealed that the degradation of total sugars upon alkaline precipitation was not substantial (6.1 to 22%). Although the total sugar degradation was not significant, alkaline precipitation method could be optimized to achieve an improved detoxification by altering the reaction conditions including reaction temperature and employing other alternate forms of alkali.

Alkali pretreatment alters or removes lignin from the biomass to cleave lignin-carbohydrate bonds in enhancing the accessible surface area and porosity in pretreated oil palm biomass. Thus, alkali pretreatment increases the digestion of cellulose to obtain a high sugar yield, which can be converted to value-added products.

Organosolvent Pretreatment

Organosolvents are organic solvents such as ethanol, methanol, acetone, glycerol, aqueous phenol, ethylene glycol, triethylene glycol, and aqueous n-butanol. These reactions are performed at temperatures between 150 °C and 200 °C. In these reactions, these solvents increase the pore size of the biomass, which increases the accessibility of the biomass to further reactions. Also, internal bonds are hydrolyzed, which leads to disruption of the biomass. The use of acids or bases as catalysts increases the reaction rate (Kapoor et al. 2018).

The main advantage of this method is that solvents, such as ethanol, are inexpensive, can operate at low boiling points, and are less toxic. Furthermore, high-quality and low-molecular-weight lignin can be isolated from the organosolv process under mild conditions. However, organic solvents may be hazardous when handled in large quantities and are highly flammable. To prevent the precipitation of lignin before washing the biomass with water, it should be washed with organic solvents, which makes this process expensive (de Menezes Nogueira et al. 2019).

Organosolvent pretreatment with aqueous ethanol degraded 27.7% of lignin in a study by Mardawati et al. (2018). However, in another study, Chin et al. (2019) achieved greater delignification by using a catalyst concurrently with 50% aqueous ethanol. They used NaOH, H2SO4, and FeCl3 as catalysts, separately. Of the catalysts used, NaOH yielded the greatest delignification (67.2%).

Nurfahmi et al. (2016) investigated the effect of organosolvent pretreatment and acid hydrolysis process on OPEFB in producing bioethanol. Organosolvent pretreatment was carried out with the use of aqueous ethanol at varying concentration (35, 55, and 75% vol), reaction temperature (80, 100, and 120 °C) and reaction time (30, 60, and 90 min). Organosolvent pretreatment is effective in unbounding the linkage between lignin and hemicellulose. Aqueous ethanol was employed in this study as the solvent owing to its low cost and ease of recovery. Their study demonstrated that increased ethanol concentration enhanced the degradation of lignin content, promoting cellulose and hemicellulose to able to convert into sugars through acid hydrolysis. Acid hydrolysis was performed at 1% (v/v) H2SO4 at 90 °C with a reaction time 30 min to evaluate the influence of organosolvent pretreatment on overall sugar yield. Effect of pretreatment temperature at 35% vol. ethanol concentration depicted that heating temperature was positively correlated with overall sugar yield, in which 60 min of heating time attained the highest release of sugar from OPEFB. The optimal yield of overall sugar yield (98.9 mg/L) was obtained at 120 °C pretreatment temperature, 55% vol. ethanol concentration, together with 60 min reaction time. In terms of lignin content, higher pretreatment temperature resulted in lower lignin composition, which promotes delignification rate, thereby resulting in a higher sugar yield. Since hemicellulose degrades at around 180 °C, it is not advisable to heat treat at elevated temperatures. Moreover, pretreating for a longer time could dissolve a certain amount of hemicellulose, which lowers the total sugar yield. Pretreatment at 35% and 55% (v/v) ethanol concentration positively affected the sugar yield, conforming to the disruption of ether linkage between hemicellulose and lignin, enabling more cellulose and hemicellulose to convert into sugars. On the basis of acid hydrolysis on sugar yield, mild acid concentration appears to be the suitable choice to mitigate the formation of hydrolysis inhibitory compounds (including furfural, HMF, formic acid and acetic acid), thereby increasing the bioethanol yield.

Deep Eutectic Solvents / Low-transition-temperature Mixture Pretreatment

One of the main complications in pretreatment methods is their ineffectiveness in removing lignin due to their low solubility. Consequently, researchers have shifted their interest toward the applicability of deep eutectic solvents (also known as low-transition-temperature mixtures), which are novel, eco-friendly solvents (green solvents). Because deep eutectic solvents share similar physicochemical properties with ionic liquids, these promising green solvents have recently gained widespread scientific interest for the pretreatment of lignocellulosic biomass (Thi and Lee 2019). Despite their similar physicochemical properties, a deep eutectic solvent costs 80% less than a similarly effective ionic liquid, which has been a deciding factor for the replacement of ionic liquids with deep eutectic solvents. Furthermore, deep eutectic solvents considerably enhance the enzymatic hydrolysis performance of the pretreated oil palm biomass (Tajuddin et al. 2019).

Deep eutectic solvents are a new generation of green solvents that can overcome the significant drawbacks of ionic liquids due to being cost-effective, biodegradable, eco-friendly, easy to synthesize, and reusable (Yiin et al. 2018a). They are ionic fluids of two or three compounds linked through hydrogen bonds, forming a eutectic mixture that has a melting point lower than any of its components. Generally obtained by mixing quaternary ammonium salts with metal salts, they are capable of forming bonds with complex halide ions (Satlewal et al. 2018). They are biodegradable but require specialized knowledge to handle and synthesize. In a study by Thi and Lee (2019), a maximum reducing sugar yield of 20.7% was achieved using choline chloride and lactic acid (1:2 molar ratio) as the low-transition-temperature mixture. Attaining a high glucose yield is attributed to the severe disruption of lignin and hemicellulose in OPEFB biomass, as illustrated by SEM and FTIR analyses. Degradation of lignin and removal of hemicellulose exposes the cellulose content to enzymatic hydrolysis. The study highlighted that (choline chloride: lactic acid) deep eutectic solvent pretreatment is more effective compared to alkali and acid pretreatments in terms of mitigating sugar loss, economic viability, and eco-friendliness. Tan et al. (2018) observed a maximum delignification of 88% using a choline chloride and lactic acid low-transition-temperature mixture. Therefore, the above studies imply that a low-transition-temperature mixture of choline chloride and lactic acid is effective for greater reducing sugar yield and delignification.

Zulkefli et al. (2017) applied deep eutectic solvent (DES) pretreatment on OPT to optimize its enzymatic hydrolysis. The study utilized choline chloride and ethylammonium chloride ammonium salts, and hydrogen bond donor solvents of glycerol, ethylene glycol and urea to prepare DESs with 1:2 molar ratio of ammonium salt: hydrogen bond donor. Ethylammonium chloride: ethylene glycol (1:2) deep eutectic solvent imparted the highest efficacy on OPT pretreatment among all the tested DESs. Applying the most suited DES heated at 100 °C for 48 h resulted in the highest OPT biomass dissolution (58%) with the removal of 83% of hemicellulose and 42% of lignin. FTIR analysis revealed that ethylammonium chloride: ethylene glycol (1:2) DES rendered the most pronounced structural alterations in OPT, signifying the highest delignification (corresponds to a greater hydroxyl bond disruption) as opposed to other DESs. Moreover, ethylammonium chloride: ethylene glycol pretreatment medium attained the optimum glucose conversion of 74% (50 °C for 24 h) with 50 FPU/g of Celluclast and 100 CBU/mL of Novozyme 188. Removal of hemicellulose through DES pretreatment exposes cellulose, thus allowing enzymes to reach its reaction sites. It is vital to effectively remove hemicellulose and lignin in the biomass structure in order to provide ease of access for the enzymes to cellulose. Higher degradation of hemicellulose is due to its less thermodynamic stability as opposed to both lignin and cellulose, which allows DESs to easily solubilize hemicellulose.

Ionic Liquids

Ionic liquids (IL) are molten salts with a melting point less than 100 °C (Ahmad et al. 2018c). They are exploited as solvents and/or co-solvents and have potential for the pretreatment of lignocellulosic biomass due to being eco-friendly and recyclable in comparison to volatile organic compounds. Ionic liquids contain an organic cation, which can be imidazolium, pyridinium, aliphatic ammonium, alkylated phosphonium, or sulfonium, along with an organic or inorganic anion (Moniruzzaman and Goto 2018). Ionic liquids can undergo a wide range of intermolecular interactions with lignocellulosic biomass under mild processing conditions with relatively low energy input, fulfilling a crucial requirement for sustainable processing of lignocelluloses to generate biofuels and value-added chemicals. They are safe and non-toxic (i.e., green solvents) and possess low volatility, substantial thermal stability (Ahmad et al. 2018c), high solvating power, and high chemical stability (Mahmood et al. 2018; Rashid et al. 2018).

Ionic liquids can promote biomass decrystallization by disrupting the hydrogen bond linkages between the cellulose microfibers, which improves digestibility of the biomass, enhances surface area and porosity (Abraham et al. 2020). They can dissolve cellulose, though the dissolving properties depend on the cation used (Azizan et al. 2019). As the length of the alkyl chain increases, the solubility of cellulose progressively decreases. Dissolution of cellulose increases in the presence of electron-withdrawing groups in the alkyl chains of IL cations (Baruah et al. 2018). Although these liquids can be recycled, the process is costly, and they are toxic to microorganisms and enzymes used in the further hydrolysis steps. Mahmood et al. (2018) reported that ionic liquid pretreatment, using 1-butyl-3-methylimidazolium chloride ([BMIM][Cl]) and 1-ethyl-3-methylimid-azolium acetate ([EMIM][OAc]), of OPF at high solids loading improved the thermal stability and altered the chemical composition by partially removing hemicellulose and lignin impurities, even though it did not increase the crystallinity of the OPF.

Mahmood et al. (2019) pretreated crude oil palm biomass using [BMIM][Cl] and 1-ethyl-3-methylimidazolium diethyl phosphate ([EMIM][DEP]) ionic liquids and discovered an increase in the cellulosic content of the crude oil palm biomass and an improvement in its thermal stability. The ionic-liquid-pretreated crude oil palm biomass demonstrated a high entropy change (∆S) (-194.7, and -196.7 J/mol for [BMIM][Cl] and ([EMIM][DEP]), respectively), suggesting a more disordered lignocellulosic structure, which showcases imidazolium-based ILs’ ability to break down its structure. The study highlighted that ILs utilized provide greater delignification ability of oil palm biomass compared to acid, alkali and liquid hot water pretreatment methods. IL pretreatment improved the cellulosic fraction of oil palm biomass, which in turn increased its thermal stability. Imidazolium-based IL pretreatment not only opens up the complex oil palm biomass structure, but it also activates and improves the degrees of freedom of rotation and vibration of the structure compared to untreated OPB samples. [BMIM][Cl] and [EMIM][DEP] pretreated OPB resulted in higher ΔG° values (208.0 kJ/mol and 210.9 kJ/mol, respectively) compared to untreated OPB (188.9 kJ/mol), suggesting that IL pretreatment could have shifted OPB samples to a higher energy state compared to its thermodynamic equilibrium, providing more thermodynamic stability. Obtaining higher ΔH° values for IL pretreated OPB necessitates higher thermal energy for their degradation compared to untreated OPB. Increased ΔH° values attribute to an increment in cellulosic content and a reduction in the crystallinity of IL-pretreated OPB fibers. Their findings indicated the potential applicability of ionic liquids in agriculture for the pretreatment of lignocellulosic biomass wastes to generate biofuels with an environmentally benign technique.

Of all ionic liquid pretreatment agents, those with acetate are among the most widely studied. Abu Darim et al. (2018), Azmi et al. (2018), and Mahmood et al. (2018) studied the use of ([EMIM][OAc]) in different ratios with OPF and different reaction temperatures. They reported that lignin content and crystallinity index decreased by a reasonable amount. Elgharbawy et al. (2018) demonstrated that choline acetate is more effective in delignification than choline butanoate.

Typically, enzymes obtained from naturally occurring fungi, or enzymes formed through genetically engineered fungi are utilized for enzymatic delignification to be employed in aqueous media. Nevertheless, degradation of lignin in aqueous media proceed quite slowly, which can be attributed to ineffective enzyme approachability to the biomass surface to degrade lignin. Thus, researchers have overcome this issue with the use of ionic liquid pretreatment before carrying out enzymatic delignification. For instance, Financie and co-workers (2016) applied the ionic liquids [EMIM][DEP] and [EMIM][OAC] for pretreatment at different temperatures (70 to 100 °C for 4 h) prior to enzymatic delignification of OPF to achieve an enhanced enzymatic delignification efficiency. [EMIM][DEP] was chosen as the most suited IL due to its low viscosity and excellent hydrogen bonding acceptor capability, which in turn provides superior ability to dissolve OPF fibers (Elgharbawy et al. 2016). Moreover, they investigated the effect of IL pretreatment temperature and time on OPF and found that upon pretreatment, OPF resulted in a noticeably lower lignin content as opposed to untreated OPF. OPF pretreated with [EMIM][DEP] at 100 °C for 4 h achieved the highest delignification at 68.8%, followed by 90 °C for 4 h (ca. 45.8%). Elgharbawy et al. (2016) in their review paper noted that pretreatment temperature plays an important role in affecting the yield of reducing sugars released from lignocellulosic biomass, which in turn influences the valorization of lignocellulosic biomass into biofuels. Nevertheless, OPF pretreated at 100 °C showed a lower holocellulose content in comparison to 90 °C pretreatment owing to the degradation of cellulose and hemicellulose at higher pretreatment temperature. Thus, 90 °C and 4 h pretreatment condition was selected for consequent enzymatic hydrolysis to result in OPF with high cellulose content.

Financie and co-workers (2016) attained OPF samples rich in cellulose, corroborating to a high thermal stability in comparison to the untreated OPF. Derivative thermogravimetric (DTG) analysis revealed that OPF pretreated with [EMIM][DEP] ionic liquid at 90 °C for 4 h recorded a maximum degradation temperature (Tmax) of 357.9 °C, while untreated OPF showed a Tmax of 331.2 °C. According to previous studies (Zhang et al. 2014; Financie et al. 2016; Mahmood et al. 2016; Mohtar et al. 2017; Liu et al. 2020), increased thermal stability of ionic liquid pretreated lignocellulosic biomass justifies an increased delignification and cellulosic content, and a reduction in hemicellulose content. Enzymatic hydrolysis was carried out with laccase as an enzyme in sodium acetate buffer (pH 4.5) at 50 °C for 24 h. IL pretreatment with subsequent enzymatic delignification resulted in an α-cellulose content of 68.1 wt% (up from 45.7%), whereas hemicellulose and lignin content was reduced to 12.1% and 8.5% (weight %), respectively. It was noted that enhanced delignification efficiency can be attributed to the ease of enzyme access to the swollen OPF pretreated with the ionic liquid, which opens up more accessible surface area for enzymes. The study explicitly suggested that combining ionic liquid pretreatment followed by enzymatic hydrolysis could deliver a platform to valorize OPF into bioenergy and biomaterials (biocomposites and textiles).

Ozonolysis

Ozonolysis is a chemical pretreatment method that employs ozone and mild operating conditions, offering high specificity in the delignification process (Perrone et al. 2018). In these types of reactions, the amount of water present in the biomass is a crucial factor that controls the reaction. Ozonolysis can be performed at ambient temperature and pressure; more importantly, it does not produce inhibitory compounds (Kapoor et al. 2018). Ozone has a short half-life and can decompose quickly, and it is also a corrosion hazard. Thus, it is not suitable for long-distance transportation and is typically generated on-site for use in ozonolysis. Another downside of ozonolysis is that ozone production requires high energy input (Rahman and Amin 2019).

Omar and Amin (2016) studied the multi-response optimization of OPF pretreatment by ozonolysis. It was discovered that ozonolysis pretreatment on OPF was effective in lignin degradation (up to 84.9%) and enhanced total reducing sugar recovery (up to 99.9%). The effect of particle size of OPF, reaction time, flowrate of ozone, moisture content variables along with their influence on degradation of lignin and total reducing sugar recovery were investigated by response surface methodology (RSM) based on Box-Behnken experimental design. RSM results revealed that during the ozonolysis process, moisture content-reaction time interaction imparted the biggest influence on total reducing sugar recovery, whereas particle size-moisture interaction influenced primarily on lignin degradation. Moreover, it was revealed that bigger particle size of OPF improved both the degradation of lignin and the total reducing sugar recovery. The multi-response optimization for optimum lignin degradation and the total reducing sugar recovery was achieved employing the desirability function (represented by the desirability profiles). Based on the desirability profiles, the optimal conditions for total reducing sugar recovery and degradation of lignin were; 75 min of reaction time, 0.8 mm of particle size, 105 mL/min of ozone flowrate, and 40 wt% of moisture content obtained through 19.5% of ozone consumption. They achieved a comparable levulinic acid (initial chemical to produce ethyl levulinate and γ-valerolactone for commercial applications) yield to that of commercial cellulose through ozonolysis-pretreated OPF, affirming an effective lignin degradation. Thus, the authors suggested that their study could aid future studies in improving the effectiveness of biorefinery processes.

Mardawati et al. (2019) performed a similar study on optimization of moisture content, particle size, and reaction time of OPEFB through ozonolysis pretreatment. They aimed to assess the effectiveness of ozone for the delignification of OPEFB by studying the effect of 30, 40, and 50% moisture content, 20, 40, and 60 mesh particle size, and 30, 45, and 60 min reaction time as well as their relationship with lignin degradation, reducing sugar yield, and holocellulose content, evaluated through RSM based on Box Behnken. They found out that the optimum conditions to attain an efficient lignin and hemicellulose degradation upon ozonolysis were; 50% moisture content, 40 mesh particle size, and a reaction time of 30 min. The data obtained revealed that ozonolysis was effective in delignifying lignin up to 63.9%, gaining a cellulose content of up to 41.0% and a reducing sugar yield up to 0.59 g/L. Thus, ozonolysis pretreatment reduced the lignin and hemicellulose content of OPEFB without reducing the cellulose content. In the absence of ozonolysis pretreatment, OPEFB hydrolysate produced a reducing sugar yield of mere 0.08 g/L, signifying the importance of an effective pretreatment such as ozonolysis to improve enzymatic hydrolysis. It was observed that a combined increment in moisture content (50%) and reaction time of ozonolysis (60 min) at 40 mesh particle size increased the reducing sugar yield (0.59 g/L) in comparison to reducing both the moisture content (30%) and reaction time (30 min) at 40 mesh particle size, which achieved a reducing sugar concentration of 0.33 g/L. Pertaining to the effect on cellulose content, 20 to 40 mesh particle size of OPEFB increased the cellulose content in comparison to 60 mesh particle size.

Table 2. Overview of Various Chemical Pretreatment Methods Employed on Oil Palm Biomass and Their Potential Applications

PHYSICAL PRETREATMENT

The purpose of physical pretreatment is to decrease the particle size, thereby decreasing the crystalline structure and degree of polymerization and increasing the surface area, aiding the enzymatic hydrolysis in later steps (Nabilah-Jansar et al. 2018; Rizal et al. 2018a). Thus, physical pretreatments increase the accessible area of lignocellulosic biomass (Tian et al. 2018). Milling, microwave treatment, extrusion, and ultrasonication are physical (mechanical) pretreatments (Ahmad et al. 2018a). After physical pretreatment, subsequent processes are more productive and easier to perform. Physical pretreatments are eco-friendly and rarely produce any toxic materials. However, drawbacks include high energy use for the operation of machinery (thus, being expensive) and an inability to be used on a large scale (Cardona et al. 2018). Table 3 lists various physical pretreatment methods used on oil palm biomass, their reaction conditions, and outcomes, while Fig. 4. depicts major physical pretreatment methods employed on oil palm biomass and their strengths.

Milling

Milling can dramatically reduce particle size to 0.2 mm (Moreno et al. 2019) and reduce the crystallinity of biomass (Baruah et al. 2018). It also leads to improved enzymatic hydrolysis and enhances the degree of polymerization. Milling does not give rise to any toxic or inhibitory compounds and does not require any harmful chemicals, making it a green approach (Moreno et al. 2019). Milling pretreatment techniques include ball milling, two-roll milling, colloid milling, rod milling, vibratory milling, hammer milling, and wet disk milling. Ball milling can loosen the cellulose structure, thereby retaining the micro-fiber structure in the hydrogen bond fracture (Tian et al. 2018). Shortcomings of milling pretreatment are high energy consumption during the process and the capital cost of mechanical equipment (Kapoor et al. 2018).

Yusof et al. (2018) evaluated the environmental impact of bioethanol production from wet disc milling pretreated OPF. The study discovered that the most substantial environmental impact arises from the recovery procedure of sugar, contributing to more than 90% of the overall impact. This pronounced environmental impact is due to the requirement of enormous power by wet disc milling pretreatment. Since wet disc milling is a physical pretreatment method, the resultant biomass particle size would be quite small along with enhanced defibrillation, reflecting to an increased biomass surface area. Pronounced surface area through milling pretreatment enhances the accessibility of enzymes to lignocellulosic biomass, which promotes enzymatic digestibility to attain a high yield.

Zahari and co-workers (2014) compared wet disc milling and hammer milling as pretreatment methods on OPF to produce fermentable sugars. Fermentable sugar yield profiles from saccharified wet disc milled-OPF and hammer milled-OPF affirmed that wet disc milling contributes to an enhanced sugar release. Wet disc milled-OPF released the maximum glucose content with a concentration of 0.469 g per gram of OPF as opposed to 0.273 g of glucose per gram of OPF released through hammer milling. They manifested that the distinct disparity in sugar recovery can be attributed to the mode of action of the two milling pretreatments. Hammer milling engages the downsizing of lignocellulosic fiber length through cutting, whereas wet disc milling affects the reduction of fiber length utilizing two milling stones, which not only shortens the fiber particle size, but also applies shear force onto biomass fiber. Additionally, water employed in wet disc milling aids in reducing the distance between two milling stones to the barest minimum. Thus, wet disc milling produces refined microfibrils, which assists in easing the saccharification process. Saccharification of wet disc milled-OPF fibers using cellulase (20 FPU/g loading, 48 h, 0.05 M acetate buffer) demonstrated that 95% of holocellulose composition was bio-converted into fermentable sugars compared to 60% of bioconversion with hammer milled-OPF. They proposed that reducing sugars derived from efficient utilization of OPF through wet disc milling pretreatment could be employed in the sustainable production of poly(3-hydroxybutyrate) bioplastic and bioethanol. Efficient utilization of oil palm biomass residues assists in minimizing the wastes generated at plantations, which benefit industries from accomplishing zero emission targets.

Although reduction of particle size through milling pretreatment could promote digestibility of oil palm biomass, the energy demand related to particle size reduction is quite significant, which exceeds the cost of particle size reduction.

Extrusion

The basis of extrusion is decreasing the particle size by rotating one or two screws in a tight barrel at high temperature (Peinemann and Pleissner 2020). The raw materials are passed through the barrel under high temperatures (>300 °C), where the action of the screws breaks down the lignocellulose biomass, and the high temperature causes chemical changes in the biomass. The design of the screws, the rotational speed, and the temperature within the barrel are the main parameters controlling the extrusion pre-treatment (Gatt et al. 2018).

There are two types of extrusion machines: single-screw extruders and twin-screw extruders (Ariffin et al. 2018). Extrusion increases accessibility of cellulose and does not produce inhibitors such as furfural and HMF, so washing and detoxification are not needed. Extrusion can easily be scaled up to commercial-scale operations, as it can operate continuously and is eco-friendly, and modifications can be made according to needs (Tayyab et al. 2018). The main drawback of this method is the very high energy consumption of the process (Peinemann and Pleissner 2020).

Gatt et al. (2018) pointed out that extrusion with an enzyme cocktail, known as bioextrusion, is one of the reactive extrusion configurations and a novel pretreatment technique. Bioextrusion introduces enzymes to the medium as biocatalysts during the extrusion pretreatment. However, bioextrusion pretreatment suffers from two major drawbacks, which are insufficient residence time (typically 1 to 5 min) and difficulties in temperature regulation during the pretreatment. Their review study highlighted that bioextrusion of lignocellulosic biomass results in a higher sugar production yield. Since bioextrusion is still an evolving pretreatment technique, bioextrusion of lignocellulosic biomass has yet to gain increased attention among researchers. Vandenbossche et al. (2014) investigated a novel OPEFB deconstruction process with an alkaline pretreatment and bioextrusion in a twin-screw extruder. It was shown that deconstruction process of OPEFB did not produce any toxic byproducts retarding the saccharification. They pointed out the benefits of the novel process can be ascribed to the utilization of minimal energy through the operation at a low temperature, requirement of low water content, and being able to rapidly perform the deconstruction process. Bioextrusion was carried out through the introduction of an enzyme cocktail (cellulase and hemicellulase) into the extruder, which then undergoes successive compression (through mechanical pressure) and relaxation to enable the accessibility of enzyme cocktail into OPEFB, ensuring an ultimate contact. The study emphasized that the addition of saccharification enzymes into the extruder upon alkaline pretreatment assisted in the disruption of OPEFB fibers. The authors observed a significant increment in cellulose content compared to lignin and hemicellulose composition, which corresponds to the production of fine OPEFB fibers upon bioextrusion. Enzymatic hydrolysis yield of only 26% was attained due to the presence of a high amount of lignin in OPEFB. It can be concluded that combining alkaline pretreatment with bioextrusion has potential applicability in an OPEFB-based biorefinery for ethanol production, which could be further enhanced by optimizing pretreatment conditions.

Microwave Pretreatment

Microwave pretreatment is an emerging technique that employs a heating method beyond traditional heating (Tian et al. 2018). In this method, the biomass is exposed to electromagnetic radiation, which induces collisions of polar molecules within the biomass, producing heat by dielectric heating (López-Linares et al. 2019). The generated heat can disrupt complex lignocellulosic structures (Hassan et al. 2018). Microwave pretreatment is easy to operate and requires minimal space. Moreover, it consumes less energy and can yield high temperatures within a short time (Bichot et al. 2020). It does not produce any inhibitory products and is non-toxic, so it is eco-friendly (Bichot et al. 2019). To attain efficient hydrolysis, microwave heating can be coupled with acids and alkaline compounds (López-Linares et al. 2019). One such organic dicarboxylic acid that can be combined with microwave heating is maleic acid, which generates less inhibitory products compared to sulfuric acid, as it selectively hydrolyzes β-(1,4) bonds (Fatriasari et al. 2018).

Fatriasari et al. (2018) studied the effects of microwave pretreatment conditions (temperature, irradiation time, and maleic acid concentration) on the enzymatic hydrolysis performance of OPEFB in producing bioethanol. They found that microwave pretreatment temperature had the greatest effect on bioethanol production, as opposed to irradiation time and maleic acid concentration. Microwave pretreatment was conducted within a temperature range of 160 to 200 ℃ with 2.5 min of irradiation time. The effect of pretreatment temperature at 2.5 min irradiation time revealed that as the irradiation temperature increased, pulp recovery reduced, owing to the loss of chemical components consequent to pretreatment. OPEFB pretreated at 190 ℃ recorded the highest cellulose composition (57.5%). Since microwave irradiation causes oil palm biomass fibers to become disrupted and removes lignin and hemicellulose content, severe pretreatment above 190 ℃ according to this study attained the lowest cellulose content (44.0%) due to the degradation of cellulose. Up to 190 ℃ heating temperature, the reducing sugar yield increased, but it declined at 200 ℃, corroborating to the trend observed in alpha cellulose content. An optimal reducing sugar yield of 47.2% was achieved upon pretreatment at 190 ℃. The reduction of reducing sugar yield above 190 ℃ could be attributed to their degradation into inhibitory compounds including 5-HMF and furfural. The effect of irradiation time (at 190 ℃) on cellulose content showed a directly proportional correlation apart from 10 min irradiation. Longer irradiation time could effectively remove more amorphous phase to provide a higher cellulose content. On the other hand, pulp recovery declined with increasing irradiation time. Prolonged irradiation time resulted in a poor reducing sugar yield although hemicellulose and lignin removal was high. Thus, they suggested that the removal of lignin and hemicellulose contributes only to enhance the digestibility of OPEFB. However, microwave pretreatment is not feasible at the commercial scale, as it requires much expert knowledge and high initial costs for the machines if expanded to a large scale.

Ultrasonication

Currently, one of the most novel approaches of oil palm biomass pretreatment and delignification is based on energy irradiation methods including ultrasound (Ofori-Boateng and Lee 2014; Budiman and Wu 2016; Yasim-Anuar et al. 2018; Ong et al. 2019; Isa et al. 2020). Ultrasonication employs a combination of mechanical vibration and sonochemical effects on lignocellulosic biomass (Debiagi et al. 2020). In this process, ultrasonic radiation in the frequency range of 10 to 20 MHz is passed through the biomass, causing chemical and physical effects and producing cavities in the biomass. The disruption of the network structure causes the separation of cellulose, hemicellulose, and lignin (Baruah et al. 2018). Several factors govern the effectiveness of the ultrasonic treatment, such as the frequency of the ultrasonic radiation, the duration for which the radiation is passed through the biomass, and whether the radiation is supplied continuously or as a pulse (Ahmad et al. 2018c; Baruah et al. 2018).

The bubbles generated in the cavitation process also help to increase the surface area, thereby increasing the amount of cellulose available for cellulose enzymes. This is suitable for biomass with a small particle size. Ultrasonication can be coupled with other pretreatment methods to increase efficiency and reduce costs. However, if the ultrasonic radiation is provided for an extended period, it causes adverse effects (Kapoor et al. 2018).

Since palm oil mill effluent (POME) contains a high amount of insoluble organic matter (4 to 5% total solids) and a high concentration chemical oxygen demand (COD), the application of POME can serve as a raw material, being a cost effective approach at the same time to produce biogas has attracted increased interest among researchers. At present, there is limited research converging on improving the production of biogas from POME through ultrasonication pretreatment at different mesophilic temperatures. Even though biogas production could be achieved through anaerobic treatment of POME, the difficulty of solubilizing organic compounds in POME retards the process. Thus, several research studies have been carried out in improving the solubility of organic solids in POME with the application of ultrasound pretreatment.

Wong et al. (2018a) employed anaerobic digestion upon ultrasonication pretreatment of POME owing to its cost effectiveness and capability to produce biogas. They pointed out that ultrasonication is a viable pretreatment to disintegrate insoluble organic matter in POME, where they found that low frequency ultrasound significantly improved the solubilization of POME, signifying the plausibility to employ ultrasonication with anaerobic digestion in pretreating POME to improve biogas production. It was highlighted that solubilization of organic content in POME directly affects the anaerobic digestion rate as well as the yield of biomethane. According to their study, the concentration of soluble COD in POME can be used as a quantitative measure to evaluate the effectiveness of a pretreatment application. Ultrasonication density of 0.88 W/mL and 16.20 min of ultrasonication time resulted in 16.1% solubilization of organic matter and attained a soluble COD concentration of 31,700 mg/L.

Isa and co-workers (2020) studied the use of ultrasonication pretreatment in improving anaerobic digestion of palm oil mill effluent (POME) and biogas production. Conversion of POME waste into biogas was carried out by employing ultrasound at temperatures in the range of 25 to 45 ℃. The study investigated the effect of ultrasonication on the POME organic matter disintegration and the removal of COD in order to increase the biogas and methane yield. Biological treatment was conducted using anaerobic sequencing batch reactors at various temperatures in the mesophilic range with ultrasonic radiation of 20 kHz, supply power of 500 W, 16.2 min ultrasonication time, and 0.88 W/mL of ultrasonication density. Their study revealed that ultrasonication pretreatment is a potent pretreatment in enhancing biogas production and obtain a higher disintegration of POME (breaks the organic matter into simple organics) in the temperature range between 30 and 35 °C. Introducing ultrasonicated POME into the anaerobic sequencing batch reactor operated at 30 °C experienced the highest removal efficiency of COD at 95%. Houtmeyers et al. (2014) elaborated that during the application of ultrasound pretreatment on POME, cavitation microbubbles are formed, which become bigger in size until they burst upon attaining a critical size. During the bursting of microbubbles, the energy released causes water to decompose, forming reactive radicals (Zhang et al. 2018). These reactive radicals disintegrate organic matter. Wong et al. (2018b) emphasized that the mechanical, thermal and sonochemical effects generated through ultrasound irradiation expedite and ease the anerobic biodegradation owing to the effective solubilization of insoluble organics in POME. Thus, ultrasonication endured POME results in high concentration of simple organics. Isa et al. (2020) observed that sonicated POME fed anaerobic sequencing batch reactor functioned at 30 °C achieved a 21.5% increment in methane yield along with the production of the maximum amount of biogas (3465 mL). Wong et al. (2018b) suggested that an increased anerobic digestion rate can be attributed to the reduction in particle size of organics in POME which in turn improves their surface area for an efficient microbial degradation. Thus, it can be concluded that ultrasound pretreatment converts insoluble organic matter in POME into simpler structures for easy digestion, which promotes the production of biogas.

Budiman and Wu (2016) performed ultrasonic irradiation on POME in view of enhancing photofermentative biohydrogen production. The influence of ultrasound amplitude (30 to 90%) and retention time of ultrasonication (5 to 60 min) on biohydrogen production yield and COD removal were evaluated. They found that the optimum ultrasonication conditions to pretreat POME were 70% amplitude and 45 min of retention time. It was observed that under optimal conditions (at 30 °C), cumulative COD removal of 36.9% and an 8.72 mL H2/mLmedium biohydrogen production were attained. The data obtained confirmed that ultrasonication was effective in solubilizing complex organic content in POME. They noted that ultrasonicated POME significantly improved biohydrogen yield as opposed to untreated POME, where increasing ultrasonication amplitude resulted in a reduction of both lignin and cellulose content. Moreover, the study revealed that improvement of the biohydrogen yield was the highest for sonicated POME using high ultrasound energy inputs (775 and 997 J/mL), conforming to enhanced surface area of the substrate (i.e. improved bioavailability) upon ultrasonication. The authors emphasized that swift internal heating prompted the solubilization of complex organics into the liquid phase. Based on their study, it can be concluded that extreme ultrasonication pretreatment conditions do not enhance biohydrogen production.

High enzymatic hydrolysis rate and significant improvement of sugar recovery

Improves enzymatic hydrolysis and enhances degree of polymerization

Fig. 4. Major physical pretreatment methods employed on oil palm biomass and their strengths

Table 3. Overview of Various Physical Pretreatment Methods Employed on Oil Palm Biomass and Their Potential Applications

PHYSICOCHEMICAL PRETREATMENT

Physicochemical pretreatment combines chemical pretreatment with physical pretreatment for an improved pretreatment with decreased reaction time and increased efficiency of delignification. Physicochemical pretreatments include steam explosion, superheated steam (SHS) pretreatment, ammonia fiber expansion, liquid hot water treatment, carbon dioxide explosion, and wet oxidation (Ahmad et al. 2018a). Table 4 describes previous literature on different physicochemical pretreatment methods for oil palm biomass, including the reaction conditions that were employed and the outcome of each technique.

Steam Explosion

Steam explosion pretreatment is an efficient method for the disruption of cellulose crystallinity and removal of hemicellulose (Ouyang et al. 2018; Siramon et al. 2018). In this process, high-pressure saturated steam is allowed to penetrate the biomass (Choopakar et al. 2018). The steam has a temperature between 150 °C and 260 °C and is trapped at a pressure between 0.69 MPa and 4.83 MPa for approximately 30 s to 20 min. The pressure is then suddenly released, making the water molecules leak out and causing an explosion. This explosion is capable of breaking the glycosidic bonds between cellulose and hemicellulose, as well as bonds between hemicellulose and lignin (Pangsang et al. 2019). The hemicellulose is converted to fermentable sugars and produces organic acids, which are capable of further hydrolyzing hemicellulose. Therefore, this process is considered an autohydrolysis process (Noorshamsiana et al. 2017). The chemical effect of this process is caused by the acetyl groups of hemicellulose, which cause the autohydrolysis that causes chemical changes in the biomass.

Furthermore, water acts as an acid at high temperatures, which also aids in the chemical changes. The breakdown of hemicellulose exposes more cellulose for cellulase and leads to an increase in enzymatic activity (Kapoor et al. 2018). Reaction time, the moisture content of the biomass (Ahmad et al. 2018c), steam temperature, the type of biomass used, and the particle size of the biomass are some factors that govern this process. The process is cost-effective and is easily performed on a pilot scale (Kapoor et al. 2018). The energy input is low, and, as the chemicals are auto-generated, there is no need for recycling. Moreover, this has minimum environmental impact and is suitable for further microbial treatment, as acidic conditions are being used (Tayyab et al. 2018). However, the high temperatures can lead to partial degradation of hemicellulose, and some amount of cellulose is also hydrolyzed. Also, fermentation inhibitors may be produced (Surya et al. 2018), which can hinder further steps. Therefore, washing is needed before the subsequent steps, which also removes some amount of soluble sugars (Boon et al. 2019).

Medina et al. (2016) demonstrated a biorefinery approach with steam explosion pretreatment of OPEFB under autocatalytic conditions. The optimal efficacy was obtained pretreating OPEFB at 195 °C for 6 min, which enhanced the cellulose content by 24% together with a hemicellulose reduction of 68%. Screening of pretreatment conditions disclosed that increased pretreatment severity negatively affected the OPEFB solid recovery. However, pretreated OPEFB at 212 °C for 8 min attained a 12% increment in cellulose composition. Conversely, raising the pretreatment temperature resulted in an enhanced degradation of hemicellulose. Obtaining cellulose rich and hemicellulose deficient oil palm biomass fibers after an effective pretreatment is vital for successive biotransformation in producing value-added products including bioethanol, organic acids and biobutanol. FTIR analysis revealed that with increased pretreatment temperature, the intensity of IR peaks at 1461 and 1415 cm−1 increased, which is related to the increase in cellulose content. Moreover, with increased pretreatment severity, the intensity of the band positioned at 1098 cm-1 (corresponds to β-glycosidic bonds) decreased, which indicates the loss of β-linked hemicelluloses. Compositional analysis of pretreated OPEFB demonstrated that the cellulose content after steam explosion pretreatment above 195 °C declined gradually, owing to the formation of fermentative inhibitory compounds including HMF, furfural, and acetic acid. The efficacy of pretreatment with respect to promotion of enzymatic hydrolysis of OPEFB showed that severe pretreatment conditions enhanced the hydrolysis. Pretreatment performed at 195 °C for 6 min yielded the highest enzymatic hydrolysis of 33.4% along with a glucose concentration of 4.18 g/L. Enzymatic digestibility and glucose yield obtained at 195 °C showed a more than two-fold increase in comparison to pretreatment at 175 °C and 185 °C. They found out that hydrolysates contained fermentable sugars (glucose, arabinose, and xylose) as well as significant amounts of acetic acid. Their study suggested that steam explosion pretreatment could be utilized in producing liquid hydrolysates rich fermentable sugars from OPEFB upon a successive separation step to remove inhibitory compounds, which promotes the sustainability of OPEFB-based biorefineries.

SHS Pretreatment

Superheated steam pretreatment, a type of steam pretreatment, is effective in disrupting the structural arrangement of lignocellulosic components. Superheated steam is dry steam that is produced by adding heat to wet steam. The additional heat helps the saturated steam to reach the boiling point of the liquid at a lower pressure compared to steam explosion pretreatment (Rizal et al. 2018b). Similar to steam explosion, this method also employs high-temperature steam, but it does not use high pressure. This method can modify the structure of the fibers, allowing them to be more exposed to enzyme reactions in the downstream steps. Superheated steam pretreatment is a novel, eco-friendly method and can be paired to increase efficiency (Noorshamsiana et al. 2017). A high amount of hemicellulose from the lignocellulosic fiber can be removed efficiently by SHS pretreatment, as the hemicellulose degrades at a temperature just greater than 180 °C, making it less thermally stable than cellulose and lignin (Rizal et al. 2018a). Benefits of SHS pretreatment include its high drying rate, low energy consumption, high productivity, and environmentally benign nature, as it is performed at atmospheric pressure (Norrrahim et al. 2018).

Several studies have been conducted on the use of SHS with laccase pretreatment. Heating OPEFB with SHS at 180 °C for 60 min, followed by enzyme degradation through laccase produced by Trametes versicolor (100 U/g substrate), was able to remove 38.7% of lignin (Rizal et al. 2018b). The same reaction performed with the SHS at 190 °C for 60 min, followed by degradation through laccase produced by T. versicolor (400 U/g substrate), was able to remove a slightly greater amount of lignin (39.6%), implying that the changes in temperature and substrate concentration had little effect on the delignification process. They found that increased temperature gave rise to the degradation of acetyl groups in hemicellulose, forming acetic acid, whereas hexose and pentose sugars degraded into furfural and HMF. A greater decrease of hemicellulose upon pretreating with superheated steam resulted in an improved lignin and cellulose content, which made the structural arrangement weaker. This observation was backed up by attaining an increased glucose content upon the saccharification of the SHS pretreated OPEFB sample. Sun et al. (2016) noted that the efficiency of saccharification largely depends on the effectiveness of the applied pretreatment.