Abstract

The overall objective was to use waste plywood and medium density fiberboard (MDF) to manufacture a new type of board. The dimensional stability of board was improved by mechanical inhibition between laths along the thickness direction. Its modulus of rupture (MOR) and dimensional stability were tested to determine whether it satisfied the Chinese national standard. The innovational points lie in the treatment to improve dimensional stability and raw materials. The MOR of board manufactured with MDF was superior to that manufactured with plywood, although the MOR of MDF was lower than the MOR of plywood. The IT and DT of new manufactured boards decreased more than 33.48% compared to the raw materials. Besides, the warpage and thickness variation tended to be stabilized with cyclical tests continuing. This result indicated that the treatment of mechanical inhibition between laths along thickness direction could improve the dimensional stability of boards. In addition, MDF was a suitable raw material for the new board.

Download PDF

Full Article

Dimensional Stability of Board Manufactured with Wood-based Panel Laths

Jiebing Wang, Zhenzhong Gao, Dengyun Tu, Zesen He, Xishun Lin, and Jin Sun*

The overall objective was to use waste plywood and medium density fiberboard (MDF) to manufacture a new type of board. The dimensional stability of board was improved by mechanical inhibition between laths along the thickness direction. Its modulus of rupture (MOR) and dimensional stability were tested to determine whether it satisfied the Chinese national standard. The innovational points lie in the treatment to improve dimensional stability and raw materials. The MOR of board manufactured with MDF was superior to that manufactured with plywood, although the MOR of MDF was lower than the MOR of plywood. The IT and DT of new manufactured boards decreased more than 33.48% compared to the raw materials. Besides, the warpage and thickness variation tended to be stabilized with cyclical tests continuing. This result indicated that the treatment of mechanical inhibition between laths along thickness direction could improve the dimensional stability of boards. In addition, MDF was a suitable raw material for the new board.

Keywords: Medium density fiberboard (MDF); Plywood; Modulus of rupture (MOR); Dimensional stability

Contact information: Department of Wood Science and Technology, South China Agricultural University, Guangzhou, Guangdong, China; *Corresponding author: sunjinsci@163.com

INTRODUCTION

Wood-based panels are widely used in the furniture and construction industry. However, wood is susceptible to dimensional changes with changing relative humidity, and this susceptibility is also observed for wood-based panels (Mirski 2009). Thus, dimensional stability treatment of wood-based panel is important.

According to the treatment methods and effects, the wood processing methods that can be used to improve the dimensional stability can be divided into five categories: cross-lamination through mechanical inhibition between veneers; covering with a waterproof coating material; reduction of the hygroscopicity of wood; chemical crosslinking of wood’s cell constituents; and using chemicals to make the cell wall bulkier (Liu and Meng 2003).

Researchers have studied the different effects of heat treatment on spruce wood, radiate pinewood (Pinus radiata D. Don wood), and Douglas fir (Bekhta and Niemz 2003; Dubey et al. 2010; Dubey et al. 2011; Li et al. 2011). Their dimensional stabilities improved with the increasing of treatment temperature. The dimensional stability of wood composites can be significantly improved via acetylation of discrete layers within flakeboard and propionic anhydride (van Houts et al. 2003; Papadopoulos 2006). Besides, Kamke and Gabrielli (2008) researched the effect of different chemical modifications combined with viscoelastic thermal compression process on wood-based products. In addition, Candan et al. (2011) investigated the thickness swelling and linear expansion of oriented strandboard with fire retardant-treated veneer according to ASTM D1037-06 (2006). Dundar et al. (2009) investigated the dimensional stability of fire retardant-treated, veneer-laminated lumber. However, there has been little research on the dimensional stability of boards prepared through mechanical inhibition, except in the case of plywood with cross-lamination through mechanical inhibition between veneers.

Plywood and medium-density fiberboard are widely used in furniture, interior decoration, and other applications, generating large amounts of waste boards that are typically used as fuel. Such processing methods not only reduce their utility value, but also result in atmospheric pollution. Thus, it is necessary to solve this problem.

Wood-based product tends to exhibit thickness swelling (parallel to compression) instead of linear expansion (normal to compression) because of the release of compressive stresses, especially in a changing environment (Karr and Sun 2000). Thus, wood-based products will reduce thickness swelling by reducing the release of compressive stresses when they glue the structure together along the thickness direction. On the one hand, the overall objective of this study was to produce a new type of board with better dimensional stability through mechanical inhibition between laths along thickness direction and to test its performance to determine whether it meets Chinese national standards. On the other hand, waste plates, produced during the manufacture of plate furniture, were used as raw materials. The innovation points lay in the manufacturing methods and raw materials.

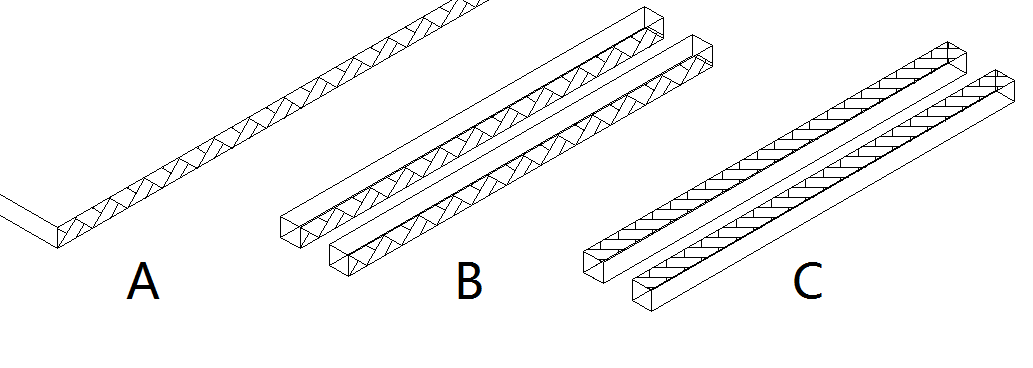

Fig. 1. Step of manufacturing: raw material (A), gluing (B), and assembling after rotating around the axis direction by 90°(C)

EXPERIMENTAL

Materials

Raw Materials

The density, modulus of rupture (MOR), increase in thickness (IT), and decrease in thickness (DT) of plywood, with the dimensions of 2440 by 1220 by 15 mm3, were 0.522 g/cm3, 18.47 MPa, 1.111%, and 1.172%, respectively. This plywood was used as material of core layers after being cut into laths. The density, MOR, IT, and DT of MDF, with the dimensions of 2440 by 1220 by 15 mm3, were 0.654 g/cm3, 14.41 MPa, 2.851%, and 2.374%, respectively. This was used as material of core layers after being cut into laths. The density, MOR, IT, and DT of plywood, with the dimensions of 2440 by 1220 by 3 mm3, were 0.552 g/cm3, 56.98 MPa, 0.694%, and 0.925%, respectively. This was used as face veneer. In this study, polyvinyl acetate was used as an adhesive and methylene diphenyl diisocyanate (MDI) was used as a curing agent.

Board manufacturing

The plywood and MDF with 15 mm thickness were cut into laths with dimensions of 1220 by 17 by 15 mm3 using a circular saw. Then they were smoothed with dimensions of 1220 by 16 by 15 mm3 using a thickness sanding machine. Next, they were cut into the required lengths, including 300, 150, and 75 mm. At the same time, the face veneers were cut to obtain plates with dimensions of 310 by 310 by 3 mm3.

The single spread was generally 100 to 120 g/m2. The mixing proportion of polyvinyl acetate and MDI was 100:15. Stirring was done with a glass rod after weighing.

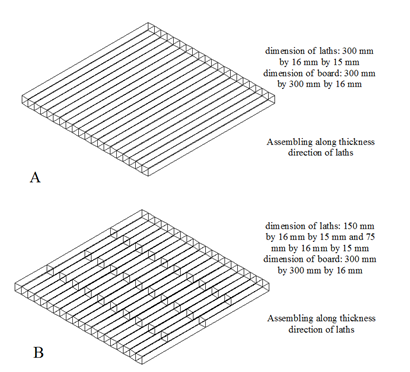

One side of laths with 16 mm width, as well as face veneers, was single-side glued. The standard laths were shaped to form core layer with dimensions of 300 by 300 by 16 mm3 after gluing (Fig. 1-B) and rotating around the axis direction by 90° (Fig. 1-C). In other words, the laths were assembled along the thickness direction of laths. The core layer was cold-pressed into a plate (300 by 300 by 22 mm3) under the condition of 1 MPa for 2 min after face veneers were adhered to both sides. In this study, two assembly modes were adopted. To express this, abbreviations were used to denote the two assembly modes (AM 1 and AM 2), as shown in Fig. 2.

The plates were cut to obtain different test specimens according to GB/T 17657-1999 (1999).

Fig. 2. Assembly mode 1(A) and assembly mode 2 (B) of core layer

Methods

Transverse modulus of rupture (MOR)

The MOR of the specimens was tested according to the 3-points bending test of GB/T 17657-1999 (1999). Samples with 200 by 50 by 22 mm3 were cut perpendicular to axial direction of laths. Every manufactured board required the testing of six samples.

Increase in thickness (IT) and decrease in thickness (DT)

The IT and DT of each specimen was tested at 85 ± 5% relative humidity (RH) and 35 ± 5% RH according to GB/T 17657-1999 (1999). Every manufactured board required the testing of eight samples. Half of these were cut perpendicular to the laths’ length direction, while the others were cut parallel to laths’ length direction.

Dimensional stability caused by cyclical changes in relative humidity

The detection method was based on the hygrothermal treatments of Mirski (2009). The length and width of the specimens were 300 ± 1 mm.

First, the specimens were placed in a constant temperature and humidity testing machine (CTHTM) until their masses were constant under the conditions of 25 ± 2 °C and 65 ± 5% relative humidity (RH). Then, the thickness of specimens was tested as follows: the average thickness of four points was considered the specimen thickness. Every manufactured board required the testing of two samples.

Second, the specimens were put on the CTHTM for 12 h under the conditions of 25 ± 2 °C and 95 ± 5% RH. Their thickness and warpage were tested. Warpage was the maximum value of the ratio of maximum chord height of concave and the diagonal in the same plane, tested according to GB/T standard 5849-2006 (2006).

Third, the specimens were put on the CTHTM for 12 h under the conditions of 25 ± 2 °C and 35 ± 5% RH. Their thickness and warpage were tested once again.

The second and third steps were repeated two times again.

RESULTS AND DISCUSSION

Transverse Modulus of Rupture (MOR)

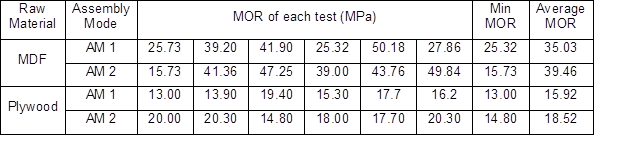

According to the standard for blockboard in GB/T 5849-2006 (2006), the average MOR value should be no less than 15 MPa and the minimum value should be at least 12 MPa. As shown in Table 1, the minimum average value and minimum value of samples were 15.92 and 13 MPa, respectively, which met the standard. The board was similar to blockboard except for the material of the core layer. Therefore, the board could be applied as blockboard.

Table 1. MOR of Tested Boards

The MOR of the boards manufactured by MDF was obviously superior to that of the boards manufactured with plywood, although the MOR of plywood (18.47 MPa) was superior to the MOR of MDF (14.41 MPa). That was attributed to the fact that laths of plywood were smoother than laths of MDF, affecting adhesion property of boards. Also, the plywood tended to slide between veneers. Besides, this phenomenon showed that the destruction of samples was mostly due to the wood materials but not the adhesive. The key distinction between different kinds of samples was the interaction within the laths and the adhesive limit between the laths. Compare to assembly mode of MOR values, AM 2 was superior to AM 1. Thus, shorter laths provided more adhesive and better strength. The overall test results also reflected this.

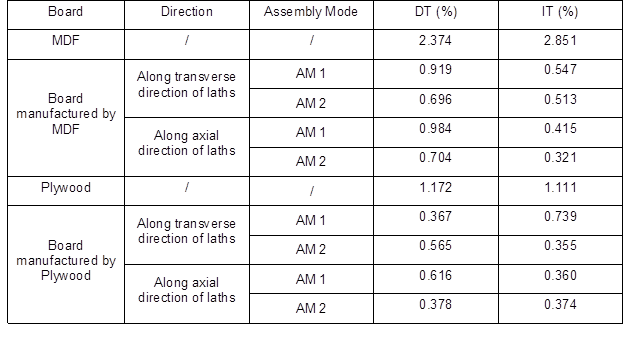

Table 2. DT and IT of Tested Boards

Increase in Thickness (IT) and Decrease in Thickness (DT)

Table 2 shows the test results for IT and DT. Generally speaking, IT and DT of boards manufactured with plywood were smaller than that manufactured with MDF. That was because plywood was manufactured with cross-lamination through mechanical inhibition between veneers. IT and DT of boards manufactured with plywood were reduced by more than 33.48% and 47.44% compare to raw material (1.111% and 1.172%). The IT and DT of boards manufactured with MDF were reduced by more than 80.81% and 58.55% compared to the raw material (2.851% and 2.374%). Thus, the dimensional stability of the boards was obviously improved. Besides, AM 2 was overall found to be superior to AM 1. The IT and DT values of the samples along transverse direction of laths were greater than the corresponding values along the axial direction of the laths. The main reason for this was the restriction of the adhesive, which stopped vapor from entering the laths. The research of Karr et al. (2000) showed that resin binder content was the most significant factor affecting the strawboard dimensional stability in their tested parameter range. Therefore, board manufactured using shorter laths could better prohibit vapor from entering laths. Thus, these boards should have less thickness variation. In addition, IT and DT values of boards were no more than 1%, which was superior to the research of Połeć et al. (2012). In their research, the values of the longitudinal and transverse thickness swelling or shrinkage of the WPC oscillated only between 0 and 2.3% compared to values of between 4 and 14% for the solid woods. However, there was little difference in the test results of boards from different assembly modes because of the small dimensions of the board and little difference in the lengths of the laths. Therefore, further study is needed.

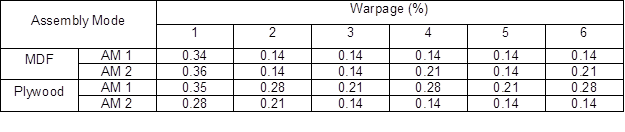

Dimensional Stability Caused by Cyclical Changes in Relative Humidity

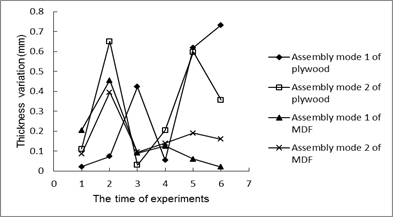

Thickness variation was defined as the difference value between adjacent thickness values. Figure 3 and Table 3 showed the thickness variation and warpage of the various boards caused by cyclical changes in relative humidity. The first value of thickness variation of the boards manufactured with plywood was superior to that of boards manufactured with MDF, which was in agreement with the results of IT and DT (Table 2). The thickness variation values of MDF were smaller than Mirski’s (2010) test results with the minimum value of 0.88 mm, although the testing environment was more extreme than his testing environment varying from 65 RH to 30 RH and from 65 RH to 85 RH. Besides, the thickness variation of the boards manufactured with MDF tended to be stabilized compared to that of boards manufactured with plywood. That was attributed to isotropic properties of MDF. In addition, this indicates that a high pressing rate (density) could improve the board’s hydrophobic properties, which is in agreement with Mirski (2009). As shown in Table 3, the warpage of boards tended to be stabilized with cyclical changes in relative humidity continuing. However, the differences of warpage values caused by materials and assembly modes were little.

Fig. 3. Thickness variation of different boards caused by cyclical changes in relative humidity (thickness variation was the difference value between adjacent thickness values)

According to the thickness variation requirements for blockboard in GB/T 5849-2006 (2006), the thickness variation was no more than 0.8 mm when the surface of board was not sanded before testing and its thickness was more than 16 mm. Therefore, the boards met the standard.

According to the warpage requirements for blockboard in GB/T 5849-2006 (2006), the warpage was no more than 0.3%. Several experimental data points did not meet the standard, but the gap was little (no more than 0.06%). First, the dimension of the board (300 by 300 mm2) was so small that the variation in these results was large. Second, the water resistance of the adhesive was weak, which affected the warpage and thickness variation. Third, the poor quality of raw materials, with high IT and DT, affected the warpage. Most importantly, testing environment was more extreme than the standard with untreated condition. Thus, the warpage would be improved when considering more such influential factors.

Table 3. Warpage of Various Boards Caused by Cyclical Changes in RH

The preparation of boards with lower adhesive and shorter laths will be researched in the future. In addition, the laths of core layer can be assembled as the cross-lamination of veneers for plywood.

CONCLUSIONS

- The MOR of board manufactured with MDF was obviously superior to that manufactured with plywood, although the MOR of the MDF was lower than the MOR of the plywood. Besides, AM 2 was superior to AM 1.

- The IT and DT of new manufactured boards were decreased by more than 33.48% compared to raw materials, and improvement of MDF was better than that of plywood. Besides, the board manufactured with MDF tended to be stabilized with the continuation of cyclical tests. These findings indicated that the treatment to provide mechanical inhibition between laths along the thickness direction was able to obviously improve the dimensional stability of boards. In addition, MDF was a suitable raw material for the new board.

- The differences of warpage values caused by materials and assembly modes were little. Besides, the warpage and thickness variations tended to become stabilized with the continuation of cyclical testing.

ACKNOWLEDGMENTS

This study was supported by the Nonprofit Industry Research Program of State Quality Inspection Administration of China (2012104006-8).

REFERENCES CITED

ASTM D1037-06 (2006). “Standard test methods for evaluating properties of wood-base fiber and particle panel materials,” ASTM International, West Conshohocken, PA.

Bekhta, P., and Niemz, P. (2003). “Effects of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood,” Holzforschung 57(5), 539-546. DOI: 10.1515/HF.2003.080

Candan, Z., Ayrilmis, N., and Akbulut, T. (2011). “Dimensional stability performance of fire retardant treated veneer-oriented strandboard composites,” BioResources 6(1), 308-316. DOI: 10.15376/biores.6.1.308-316

Dubey, M. K., Pang, S. H., and Walker, J. (2010). “Color and dimensional stability of oil heat-treated radiata pinewood after accelerated UV weathering,” Forest Products Journal 60(5), 453-459. DOI: 10.13073/0015-7473-60.5.453

Dubey, M. K., Pang, S. H., and Walker, J. (2011). “Changes in chemistry, color, dimensional stability and fungal resistance of Pinus radiata D. Don wood with oil heat-treatment,” Holzforschung 66(1), 49-57. DOI: 10.1515/HF.2011.117

Dundar, T., Ayrilmis, N., Candan, Z., and Sahin, H. T. (2009). “Dimensional stability of fire-retardant-treated laminated veneer lumber,” Forest Products Journal 59(11/12), 73-79. DOI: 10.13073/0015-7473-60.5.453

GB/T 5849 (2006). “Blockboard,” Chinese National Standardization Management Committee, China.

GB/T 17657 (1999). “Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels,” State Bureau of Quality and Technical Supervision, China.

Kamke, F. A., and Gabrielli, C. (2008). “Treatment of chemically modified wood with VTC process to improve dimensional stability,” Forest Products Journal 58(12), 82-86.

Karr, G. S., Cheng, E., and Sun, X. S. (2000). “Physical properties of strawboard as affected by processing parameters,” Industrial Crops and Products 12(1), 19-24. DOI: 10.1016/S0926-6690(99)00041-2

Karr, G. S., and Sun, X. S. (2000). “Strawboard from vapor phase acetylation of wheat straw,” Industrial Crops and Products 11(1), 31-41. DOI: 10.1016/S0926-6690(99)00031-X

Li, X. J., Cai, Z. H. Y., Mou, Q. Y., and Wu, Y. Q. (2011). “Effects of treatment on some physical properties of Douglas Fir (Pseudotsuga menziesii) wood,” Advanced Materials Research 197-198, 90-95. DOI: 10.4028/www.scientific.net/AMR.197-198.90

Liu, P. Y., and Meng, G. Z. H. (2003). “Treatment for wood dimensional stability,” China Wood Industry 17(2), 24-26.

Mirski, R. (2009). “The effect of variable environmental conditions on dimensional changes in thin wood-based materials. Part I. Absorption changes,” Electronic Journal of Polish Agricultural Universities 12(4), 4.

Mirski, R. (2010). “The effect of variable environmental conditions on dimensional changes in thin wood-based materials. Part II. Desorption changes,” Electronic Journal of Polish Agricultural Universities 13(3), 13.

Papadopoulos, A. (2006). “Chemical modification of pine wood with propionic anhydride: Effect on decay resistance and sorption of water vapour,” BioResources 1(1), 67-74. DOI: 10.15376/biores.1.1.67-74

Połec´, I. A., Hine, P. J., Bonner, M., Ward, I. M., Barton, D. C. (2012). “Hydro and thermal stability of die drawn wood polymer composites in comparison to solid wood,” Composites Science and Technology 72(12), 1436-1442.

van Houts, J. H., Winistorfer, P. M., and Wang, S. Q. (2003). “Improving dimensional stability by acetylation of discrete layers within flakeboard,” Forest Products Journal 53(1), 82-88.

Article submitted: April 6, 2015; Peer review completed: July 30, 2015; Revised version received: September 24, 2015; Accepted: September 25, 2015; Published: November 10, 2015.

DOI: 10.15376/biores.11.1.174-181