Abstract

An experimental method was developed in this investigation to evaluate the shear strength of adhesive bonds in solid wood materials. The new method was tested against the standard test methods described in ASTM D-905, EN 205, and EN 302-1. Specimens were constructed of Oriental Beech (Fagus orientalis L.) and bonded with three different wood adhesives. Using the proposed method in the study, unintentional errors in cutting and testing processes of the shear specimens were decreased, which led to a decrease in the variability of the results. The worst stability was observed in the data obtained when the EN 205 and ASTM D-905 standard methods were used.

Download PDF

Full Article

A Modified Method for Shear Strength Measurement of Adhesive Bonds in Solid Wood

Mohammad Derikvand,a,* and Halimeh Pangh b

An experimental method was developed in this investigation to evaluate the shear strength of adhesive bonds in solid wood materials. The new method was tested against the standard test methods described in ASTM D-905, EN 205, and EN 302-1. Specimens were constructed of Oriental Beech (Fagus orientalis L.) and bonded with three different wood adhesives. Using the proposed method in the study, unintentional errors in cutting and testing processes of the shear specimens were decreased, which led to a decrease in the variability of the results. The worst stability was observed in the data obtained when the EN 205 and ASTM D-905 standard methods were used.

Keywords: Adhesive bond strength; Lap joints; Polyurethane; Polyvinyl acetate; Shear test; Urea-formaldehyde; Wood adhesives; Wood shear failure

Contact information: a: Young Researchers and Elite Club, Andimeshk Branch, Islamic Azad University, Andimeshk, Iran; b: Department of Wood and Paper Science and Technology, College of Agriculture and Natural Resources, University of Tehran, Karaj, Iran; *Corresponding author: m.derikvand@ut.ac.ir

INTRODUCTION

Wood as an engineering material usually needs to be modified with respect to its physical and mechanical properties to suit different purposes. The dimensional stability and mechanical properties of wood can be improved by means of laminating. Cross-laminated timber (CLT) panels, plywood, glulam, and laminated veneer lumber (LVL) are examples of laminated (layered) wood composite materials that are widely used in the construction of wooden structures and buildings. Layered wood composite materials have a wide range of applications in the furniture industry as well. One of the most important steps in constructing such layered materials is choosing an appropriate adhesive to be used in the bonding process of wood materials. In this regard, adhesives have several chemical and mechanical characteristics that need to be considered, but the shear strength is one of the most important factors. In fact, the shear strength, as one of the most common interfacial stresses under service conditions (Pizzo et al. 2003; Serrano 2004), is commonly used as the reference parameter to compare the bond strength of different adhesives (Vick and Okkonen 1998; Örs et al. 2000; Serrano 2004; Burdurlu et al. 2006; Konnerth et al. 2006; Raftery et al. 2009; Lu et al. 2013; Bomba et al. 2014; Derikvand et al. 2014; Li et al. 2015; Šedivka et al. 2015).

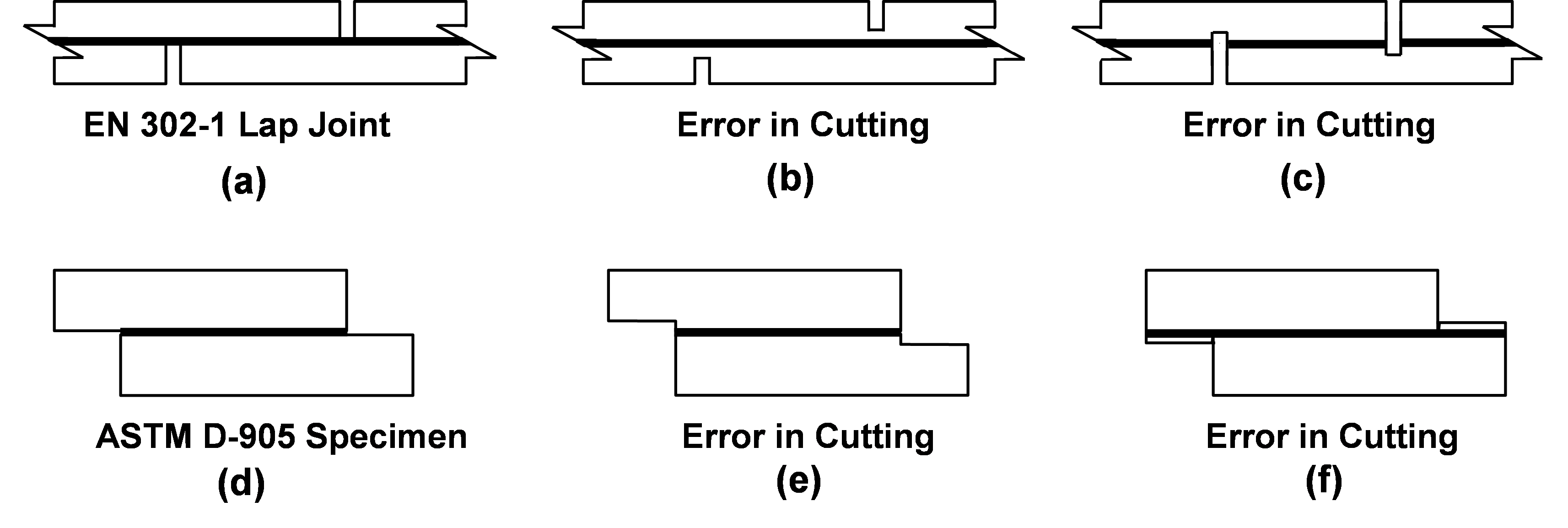

The shear strength of adhesively bonded wood is conventionally evaluated by means of standard test methods; the ASTM D-905 standard block shear specimens, the standard shear lap joint testing method corresponding to EN 205 (European Committee for Standardization 2003), and the EN 302-1 lap joint testing method (European Committee for Standardization 2013) are frequently used for the evaluation of adhesive bonds in solid wood materials. However, significant variability in the shear strength values could be associated with the standard methods. Part of this variability is related to the nature of wood as an orthotropic material as well as to the influence of wood variability (Pizzo et al. 2003). However, the majority of this variability and instability is related to errors in cutting, bonding, and testing processes of the standard test specimens (Karlsson and Wong 2004; Konnerth et al. 2006). Difficulties may arise with these standard methods during the preparation of identical test specimens. ASTM D-905 and EN 302-1 standard procedures, for example, are very sensitive to errors in cutting (Karlsson and Wong 2004) as well as to amount of adhesive applied to the test specimens (Raftery et al. 2008; Li et al. 2015). The most important errors in cutting EN 302-1 and ASTM D-905 specimens can be seen in Fig. 1.

Fig. 1. Common errors in cutting ASTM D-905 and EN 302-1 specimens (figure redrawn based on a concept by Karlsson and Wong 2004)

Such errors in cutting steps directly affect the stability of shear strength values obtained by the above-mentioned standard methods. It was reported that even if the cut is 0.5 mm too deep (Fig. 1, (c) and (e)) or too shallow (Fig. 1, (b) and (f)), the test results would not be comparable to an accurately cut specimen (Karlsson and Wong 2004). Furthermore, some types of errors may also appear during the process of testing of the specimens; horizontal displacements, for example, frequently occur during loading of the ASTM D-905, EN 302-1, and EN 205 shear specimens, which causes the applied load to move away from the bond line direction, negatively affecting the results.

Overall, although the standard methods described are generally accepted and frequently used for the evaluation of adhesive bond strength, there is a need for engineers/researchers to develop new techniques to prevent any unwanted errors in the manufacturing and testing processes of the specimens to improve the reliability of the results. Hence, a new method is proposed here to analyze the shear strength of adhesive bonds in solid wood materials. The new specimen geometry is, in fact, a modified version of the ASTM D-905 block shear specimens. The new method was tested against the standard methods described in ASTM D-905, EN 302-1, and EN 205.

MATERIALS AND METHODS

Materials

Wood

Shear specimens in the study were constructed of defect-free, straight grain Oriental Beech wood (Fagus orientalis L.) with an average moisture content of 12%. Specific gravity of the wood used was 0.69 ± 0.03, and its shear strength parallel to the grain was 14.9 ± 0.92 MPa (in accordance with the procedure of ASTM D-143 (1999)). Wood materials were carefully checked with respect to their slope of grain and surface quality. Any damaged specimen was removed from the process.

Adhesives

In order to reduce any risk of drawing conclusions based on a specific type of adhesive, three different kinds of commonly employed adhesives in the wood industry were selected; namely, polyvinyl acetate (PVAc), two-component polyurethane (PU), and urea-formaldehyde (UF) adhesives. These adhesives are widely used in the construction of layered wood materials as well as in the manufacturing process of wooden structures and furniture. Some properties of the adhesives can be seen in Table 1.

Table 1. Some Characteristics of Adhesives Used in the Study

Specimen Description

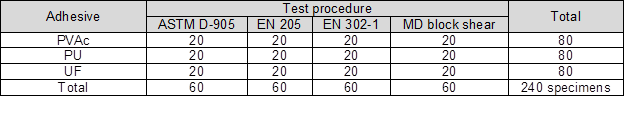

Four types of shear specimens were manufactured and tested in this study: a) ASTM D-905 block shear specimen, b) EN 205 single lap joint, c) EN 302-1 shear lap joint, and d) a new modified geometry of the ASTM D-905 block shear specimen (Fig. 2). The new shear specimens are referred to from here on in the text as “MD block shear specimens”.

All the test specimens were constructed in accordance with the procedure described in their respective standard method, as shown in Fig. 2. In all cases, the grain direction was parallel to the longitudinal axis of the specimens. A high speed table saw was used to cut the specimens. As the spread rate of adhesive affects the shear strength of adhesively bonded wood (Raftery et al. 2008; Li et al. 2015), the shear specimens were produced with a constant spread rate of 200 g·m-2. Any excess adhesive was carefully cleaned off from the edges and surfaces of the specimens using a wet brush. Following the assembly process, the shear specimens were immediately pressed using a uniform pressure of 0.8 MPa for 4 h. For each batch of the test specimens, bond line thickness was randomly measured in a microscope and was found to vary between 45 μm to 60 μm.

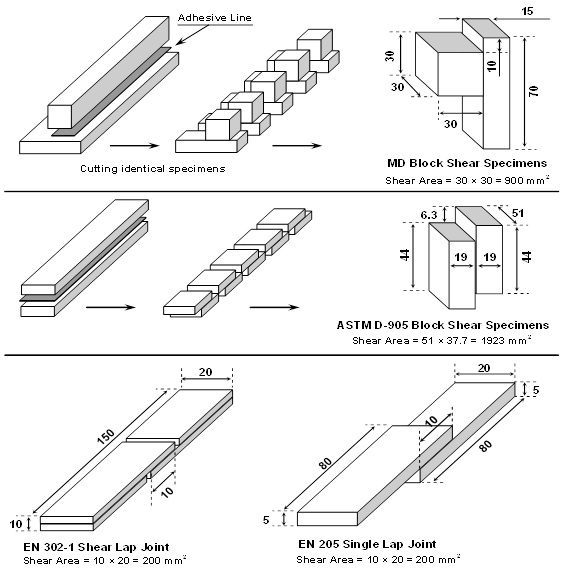

A factorial design of experiments was used to study the effect of test variables on the shear strength (3 levels for adhesive type factor and 4 levels for testing method factor). Overall, 20 replicates were produced and tested for each treatment shown in Table 2.

Table 2. Full Factorial Experimental Design

Fig. 2. Geometries and dimensions of ASTM D-905 block shear specimen, EN 205 single lap joint, EN 302-1 shear lap joint, and MD block shear specimen tested in the study

Test Procedures

All tests were conducted on shear specimens that had been reconditioned in a climatic chamber at a temperature of 20 ± 2 °C and a relative air humidity of 65 ± 5% for a week. The shear specimens were loaded in either tension (EN 205 and EN 302-1 specimens) or compression (MD and ASTM D-905 specimens) in accordance with their corresponding standard system, using for this purpose an INSTRON (model 4466, USA) testing machine with a load speed of 1 mm·min-1. Ultimate load at failure point was recorded for each specimen. The shear strength (τ) was then calculated as follows (Eq. 1),

![]() (1)

(1)

where ? is the shear strength (MPa), P is the ultimate applied load (N), and A is the shear area (mm2) (the shear area for each test specimen can be seen in Fig. 2).

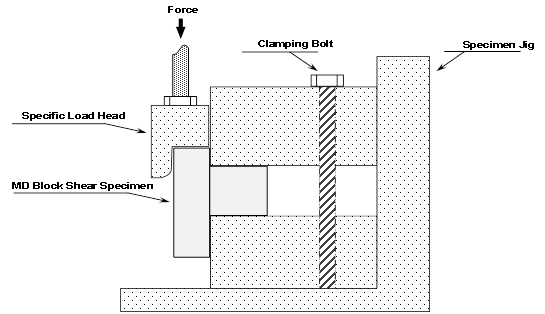

A specific test set-up was designed to evaluate the shear strength of the MD block shear specimens (Fig. 3). This apparatus makes it possible to apply a uniaxial load on the MD specimens (loading in the central area of bond line), which is the key parameter in performing an accurate evaluation of bond strength.

Fig. 3. Apparatus designed to evaluate the shear strength of MD block shear specimens

Data Analysis

Statistical analysis of the data obtained in the study was carried out using the Statistical Package for Social Science (SPSS) software (version 13.0; IBM, USA). A one-way analysis of variance (ANOVA) was performed on the data set to statistically determine the impact of adhesive type and testing method on shear strength. When the ANOVA showed an important difference among test factors, comparisons between means were made by the Duncan’s test.

RESULTS AND DISCUSSION

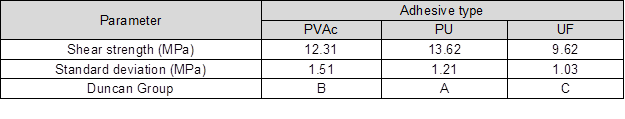

ASTM D-905 Block Shear Specimens

Average shear strength values of the ASTM D-905 block shear specimens bonded with different adhesives are given in Table 3. The difference between individual groups was evaluated by means of the Duncan’s test (Table 3). Based on the results, PU adhesive had meaningfully greater shear strength than either PVAc or UF adhesives. The specimens bonded with UF resin turned out to exhibit the worst shear strength capacities. Shallow wood failures were observed in the bonded surfaces of the specimens made with UF resin, whereas for the specimens bonded with either PVAc or PU adhesives the main failure mode was wood failure parallel to the grain.

Table 3. Average Shear Strength Values, Standard Deviation, and Duncan’s Test Results According to ASTM D-905

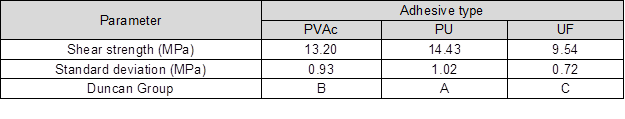

MD Block Shear Specimens

The MD block shear specimens delivered about the same results for the impact of adhesive type on shear strength as did the ASTM D-905 method (Table 4). Based on the results, the mean shear strength of PU adhesive was 9.3% higher than that of specimens bonded with PVAc adhesive. The lowest average shear strength value was obtained by specimens glued with UF adhesive. Overall, the specimens bonded with UF adhesive had 66% of the shear capacity of identical specimens bonded with PU adhesive. No eccentric loading (errors in testing process) was observed during testing of the MD specimens. Except for the specimens bonded with PU adhesive, the failure mode was mainly bond line failure. Overall, wood failure in the MD specimens was minor in comparison with that in the ASTM D-905 block shear specimens, which could be related to the test apparatuses used in the loading process of these specimens. The new loading system, used for testing of the MD specimens, provided an appropriate tool that made it possible to apply a vertical load on the central area of the adhesive line. Consequently, unlike the ASTM D-905 testing system, no horizontal displacement, or bending, occurred during testing of the MD block shear specimens and the exerted load did not move away from the bond line.

Table 4. Average Shear Strength Values, Standard Deviation, and Duncan’s Test Results According to the New Method

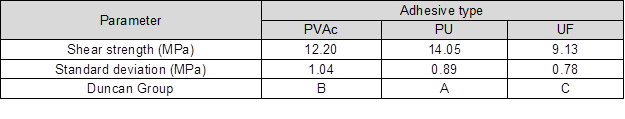

EN 205 Single Lap Joints

According to the results obtained, the highest average shear strength for the EN 205 testing system was achieved by the specimens glued by PU adhesive (Table 5). Specimens bonded with PVAc adhesive had 91% of the shear capacity of identical specimens bonded with PU adhesive. Likewise, specimens glued with UF adhesive had 67% of the shear strength of the PU specimens. Some kinds of horizontal displacement (an initial bending) appeared during loading of the EN 205 lap joint specimens; as a result, compared to the shear values obtained by either ASTM D-905 or MD block shear specimens, the EN 205 method underestimated the bond strength of the adhesives tested. In addition, except for the UF specimens, the failure mode was mainly wood failure.

Table 5. Average Shear Strength Values, Standard Deviation, and Duncan’s Test Results According to EN 205

EN 302-1 Shear Lap Joints

In the case of EN 302-1 testing system, the highest shear capacity was also found for PU adhesive (Table 6). Overall, PVAc adhesive had 87% of the shear strength of comparable specimens glued with the PU adhesive. Similarly, UF adhesive had 65% of the shear capacity of the PU adhesive.

During loading of the EN 302-1 lap joint specimens, horizontal displacements in the joint elements were minor in contrast to the EN 205 specimens. However, in all cases, the EN 302-1 testing system underestimated the shear capacities of the adhesives tested. Furthermore, although considerable amount of failures in wood materials was observed in the specimens bonded with PVAc adhesive, the EN 302-1 lap joint specimens failed mostly in the bond line.

Table 6. Average Shear Strength Values, Standard Deviation, and Duncan’s Test Results According to EN 302-1

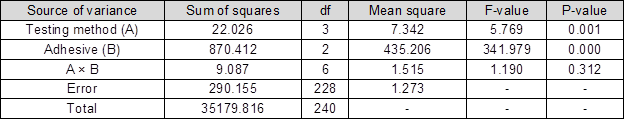

Statistical Analysis Results

Based on the ANOVA results, the effect of testing method and type of adhesive on shear strength was significant at a 95% level of confidence (Table 7). The interaction effect of the factors was not significant, which indicates that the four methods studied had about the same capabilities to determine the impact of adhesive type on shear strength.

Table 7. Results of ANOVA for the Overall Impact of Adhesive Type and Testing Method on the Shear Strength of Adhesively Bonded Wood

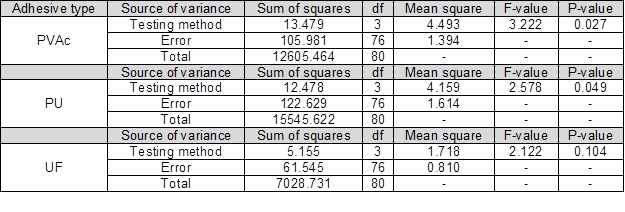

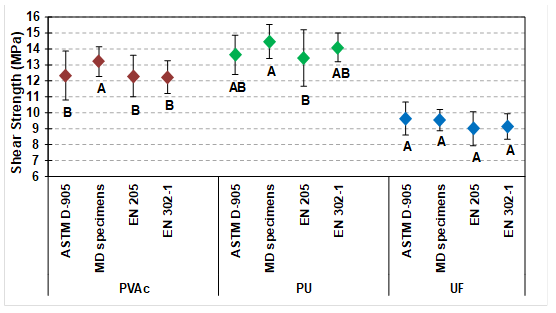

When the ANOVA was reperformed on the data set to determine the impact of testing method on shear strength of each adhesive type separately (Table 8), similar results were obtained, indicating significant impact of testing method, with a 95% level of confidence, on the shear strength of specimens glued with either PVAc or PU adhesives. However, testing method had no important impact on the shear strength of UF adhesive (P-value > 0.05). The Duncan’s test results with respect to the impact of testing method on the shear strength of each adhesive are illustrated in Fig. 4.

Table 8. Results of ANOVA for the Effect of Testing Method on the Shear Strength of Each Adhesive Separately

Fig. 4. Average shear strength of adhesives tested in the study; Latin letters indicate Duncan Group for each adhesive type at a 95% level of confidence

On the basis of the Duncan’s test results, the four testing procedures showed about the same average values for the shear strength of the UF adhesive, which had much less shear strength capacity than either PVAc or PU adhesives (Fig. 4). However, the average shear strength values of PVAc adhesive measured by the four methods were significantly different. Similarly, there was a significant difference between the testing methods in determining the shear capacity of PU adhesive. These results tend to indicate that the impact of testing procedure on bond strength analysis is more important when the shear strength of an adhesive is almost equal to or exceeds the shear strength parallel to the grain of wood (the shear strength of Beech wood used was 14.9 MPa). This phenomenon may be attributed to the failure mode of these specimens. For the ASTM D-905 specimens, for example, most failures occurred in the wood next to the adhesive line. Similarly, the failure mode of the EN 205 specimens was mainly wood failure parallel to the grain. Hence, it could be maintained that when the shear strength of an adhesive is high (like that of PU or PVAc adhesives), wood shear strength is predominantly tested by the standard methods instead of the bond strength; this argument is in agreement with the results of Konnerth et al. (2006).

Overall, combining the data obtained by different groups, the highest shear strength was obtained with the MD block shear specimens. The ASTM D-905 specimens were characterized by the second highest average shear strength. The lowest shear strength values were also obtained with the EN 205 and EN 302-1 specimens. Because of the specific geometry of the EN 205 and EN 302-1 lap joint specimens, an initial bending (or horizontal displacement) is very likely to happen during loading of these specimens which leads to lower measured shear strength of the bond line.

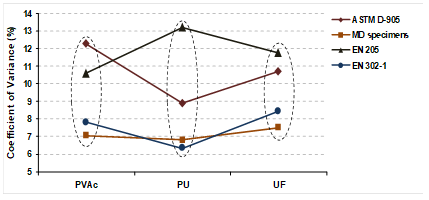

Variability in shear strength values

An important factor to compare the variability (or stability) of different testing procedures is the relative standard deviation, or, coefficient of variance (COV). The COV is a simple criterion that determines the repeatability of an assay. When the value of COV is lower, it indicates that the data set has high stability and less variability. The coefficient of variance (COV) values for the results obtained in the study can be seen in Fig. 5.

Fig. 5. Coefficient of variance (COV) of shear strength results according to type of adhesive and testing method

As shown in Fig. 5, the EN 205 single lap joint testing method (average COV = 11.9%) and ASTM D-905 block shear testing system (average COV = 10.8%) turned out to exhibit the highest variability, whereas the MD block shear specimens (average COV = 7.1%) and EN 302-1 (average COV = 7.5%) were characterized by the lowest variability. There was a meaningful difference between the COV values of the ASTM D-905 and the modified version of this standard (the MD specimens). The shear area of the ASTM D-905 block shear specimens was 1923 mm2, which is more than 2 times greater than that in the MD specimens (900 mm2). It is well known that the shear stress distribution in an adhesively bonded joint tends to be more uniform as the size of the bond area decreases (Serrano 2004); hence, apart from the high proportion of wood failure in the ASTM D-905 testing system and its negative effect on the stability of the data, variability in the results obtained by the ASTM D-905 method could be related to its larger area of bondline.

CONCLUSIONS

- The new method developed in the study showed an excellent capability to determine the shear strength of adhesive bonds in solid wood materials. The process of manufacturing of the test specimens is very simple with the new testing system. As a result, unintentional errors in cutting identical test specimens was decreased and no moments (or horizontal displacements) appeared during loading of the specimens. Consequently, the stability of the data obtained improved significantly, in contrast to the results obtained by the other standard systems studied. Hence, if measuring the gross values of shear strength is the main objective of the testing, the new method is strongly recommended.

- Based on the results, the impact of testing method on the estimation of adhesive bond strength is more significant when the ultimate shear strength of the adhesive bond reaches the shear strength parallel to the grain of wood. In addition, testing method has much less influence when the adhesive bond strength is low.

- The worst stability was obtained by EN 205 and ASTM D-905 standard methods. Furthermore, in specimens bonded with either PU or PVAc adhesives, which were characterized by the highest shear strength values, the two methods delivered results rather on the wood shear failure than on adhesive line strength.

REFERENCES CITED

ASTM D-143. (1999). “Standard test methods for small clear specimens of timber,” The American Society of Testing and Materials, USA.

ASTM D-905. (1998). “Standard test method for strength properties of adhesive bonds in shear by compression loading,” The American Society of Testing and Materials, USA.

Bomba, J., Šedivka, P., Böhm, M., and Devera, M. (2014). “Influence of moisture content on the bond strength and water resistance of bonded wood joints,” BioResources 9(3), 5208-5218. DOI: 10.15376/biores.9.3.5208-5218

Burdurlu, E., Kiliҫ, Y., Eli’Bol, G. C., and Kiliҫ, M. (2006). “Shear strength of Calabrian pine (Pinus brutia (Ten.)) bonded with polyurethane and polyvinyl acetate adhesives,” Journal of Applied Polymer Science 100(6), 4856-4867. DOI: 10.1002/app.23000

Derikvand, M., Ebrahimi, G., and Tajvidi, M. (2014). “A feasibility study of using two-component polyurethane adhesive in constructing wooden structures,” Journal of Forestry Research 25, 477-482. DOI: 10.1007/s11676-013-0425-y

EN 205 (2003). “Adhesives. Wood adhesives for non-structural applications. Determination of tensile shear strength of lap joints,” European Committee for Standardization.

EN 302-1 (2013). “Adhesives for load-bearing timber structures – Test methods – Part 1: Determination of longitudinal tensile shear strength,” European Committee for Standardization.

Karlsson, S., and Wong, M. (2004). “Experimental evaluation of the test methods EN 302-1 and ASTM D905 for wood-adhesive bonds,” Master’s Dissertation, Division of Structural Mechanic, Lund University, S-221 00 Lund, Sweden, p. 72.

Konnerth, J., Gindl, W., Harm, M., and Müller, U. (2006). “Comparing dry bond strength of spruce and beech wood glued with different adhesives by means of scarf- and lap joint testing method,” Holz als Roh- und Werkstoff 64, 269-271. DOI: 10.1007/s00107-006-0104-1

Li, R., Guo, X., Ekevad, M., Marklund, B., and Cao, P. (2015). “Investigation of glueline shear strength of pine wood bonded with PVAc by response surface methodology,” BioResources 10(3), 3831-3838. DOI: 10.15376/biores.10.3.3831-3838

Lu, W., Hu, Y., Yao, J., and Li, Y. (2013). “Optimization and simulation research of tensile properties of wood lap joint,” BioResources 8(1), 1409-1419. DOI: 10.15376/biores.8.1.1409-1419

Örs, Y., Atar, M., and Özҫifҫi, A. (2000). “Bonding strength of poly (vinyl acetate)-based adhesives in some wood materials treated with impregnation,” Journal of Applied Polymer Science 76, 1472-1479. DOI: 10.1002/(SICI)1097-4628(20000531)76:9<1472::AID-APP11>3.0.CO;2-0

Pizzo, B., Lavisci, P., Misani, C., Triboulot, P., and Macchioni, N. (2003). “Measuring the shear strength ratio of glued joints within the same specimen,” Holz als Roh- und Werkstoff 61, 273–280. DOI: 10.1007/S00107-003-0386-5

Raftery, G. M., Harte, A.M., and Rodd, P. D. (2008). “Qualification of wood adhesives for structural softwood glulam with large juvenile wood content,” Journal of the Institute of Wood Science 18(1), 24-34. DOI: 10.1179/wsc.2008.18.1.24

Raftery, G. M., Harte, A.M., and Rodd, P. D. (2009). “Bond quality at the FRP-wood interface using wood-laminating adhesives,” International Journal of Adhesion & Adhesives 29, 101-110. DOI: 10.1016/j.ijadhadh.2008.01.006

Šedivka, P., Bomba, J., Böhm, M., and Boška, P. (2015). “Influence of temperature on the strength of bonded joints,” BioResources 10(3), 3999-4010. DOI: 10.15376/biores.10.3.3999-4010

Serrano, E. (2004). “A numerical study of the shear-strength-predicting capabilities of test specimens for wood–adhesive bonds,” International Journal of Adhesion & Adhesives 24, 23-35. DOI: 10.1016/S143-7496(03)00096-4

Vick, C. B., and Okkonen, E. A. (1998). “Strength and durability of one-part polyurethane adhesive bonds to wood,” Forest Products Journal 48, 71-76.

Article submitted: August 11, 2015; Peer review completed: October 24, 2015; Revised version received and accepted: October 27, 2015; Published: November 17, 2015.

DOI: 10.15376/biores.11.1.354-364