Abstract

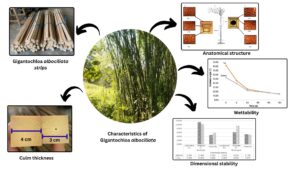

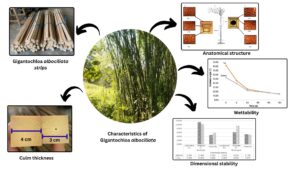

Thirteen bamboo species are reported to be in commercial use in Malaysia. However, Buluh madu (Gigantochloa albociliata) did not make to the list. As a species, G. albociliata is cultivated for its delicious bamboo shoot and is demonstrated to possess great potential to produce commercialised products such as laminated bamboo panel. Unlike common bamboo, which has hollow cylindrical culms, G. albociliata has thick culms at the base, with smaller hollow cavities at the top portion. Therefore, it can be easily converted into high-thickness strips, thus improving the processing efficiency of laminated bamboo. To validate this theory, the anatomical, chemical, physical, and mechanical properties of G. albociliata were evaluated. The round bamboo and strips from the top and bottom sections of the bamboo stem were tested. It was found that G. albociliata has a vascular bundle type similar to that of the Gigantochloa genus bamboo. The fibre in G. albociliata is long and strong. The top section of bamboo has longer fibres, a higher density, and a higher specific gravity than the bottom section. As a result, bamboo from the top section has greater bending strength than bamboo from the bottom section. The G. albociliata species was discovered to have high mechanical strength, dimensional stability, and good wettability, making it an ideal material for laminated products.

Download PDF

Full Article

Characterization of the Properties of Buluh Madu (Gigantochloa albociliata)

Siti Asiyah Kasdi,a Seng Hua Lee,b,* Paridah Md. Tahir,a,c,* Syeed Saifulazry Osman al-Edrus,a Sabiha Salim,c Muhammad Aizat Abd Ghani,e Balkis Fatomer A. Bakar,a,c Wei Chen Lum,f and Jun Zhang g

Thirteen bamboo species are reported to be in commercial use in Malaysia. However, Buluh madu (Gigantochloa albociliata) did not make to the list. As a species, G. albociliata is cultivated for its delicious bamboo shoot and is demonstrated to possess great potential to produce commercialised products such as laminated bamboo panel. Unlike common bamboo, which has hollow cylindrical culms, G. albociliata has thick culms at the base, with smaller hollow cavities at the top portion. Therefore, it can be easily converted into high-thickness strips, thus improving the processing efficiency of laminated bamboo. To validate this theory, the anatomical, chemical, physical, and mechanical properties of G. albociliata were evaluated. The round bamboo and strips from the top and bottom sections of the bamboo stem were tested. It was found that G. albociliata has a vascular bundle type similar to that of the Gigantochloa genus bamboo. The fibre in G. albociliata is long and strong. The top section of bamboo has longer fibres, a higher density, and a higher specific gravity than the bottom section. As a result, bamboo from the top section has greater bending strength than bamboo from the bottom section. The G. albociliata species was discovered to have high mechanical strength, dimensional stability, and good wettability, making it an ideal material for laminated products.

DOI: 10.15376/biores.18.4.8503-8514

Keywords: Gigantochloa albociliata; Specific gravity; Laminated bamboo; Chemical composition; Fibre morphology

Contact information: a: Institute of Tropical Forestry and Forest Product (INTROP), Universiti Putra Malaysia, 43400 UPM Serdang, Selangor, Malaysia; b: Department of Wood Industry, Faculty of Applied Sciences, Universiti Teknologi MARA Cawangan Pahang Kampus Jengka, 26400 Bandar Tun Razak, Pahang Malaysia; c: Faculty of Forestry and Environment, Universiti Putra Malaysia, 43400 UPM Serdang, Selangor, Malaysia; d: Institute of Ecosystem Science Borneo, Universiti Putra Malaysia Kampus Bintulu Sarawak, Nyabau Road, 97008 Bintulu, Sarawak, Malaysia; e: Faculty of Tropical Forestry, Universiti Malaysia Sabah, 88400 Kota Kinabalu, Sabah, Malaysia; f: Department of Bio and Natural Resource Technology, Faculty of Bioengineering and Technology, Universiti Malaysia Kelantan, 17600 Jeli, Kelantan, Malaysia; g: Yunnan Provincial Key Laboratory of Wood Adhesives and Glued Products, Southwest Forestry University, Kunming 650224, People’s Republics of China;

Corresponding authors: leesenghua@uitm.edu.my; parida@upm.edu.my

GRAPHICAL ABSTRACT

INTRODUCTION

The bamboo area in Peninsular Malaysia is estimated to be 421,722 ha, or about 7% of the forest land. According to reports, only 13 bamboo species out of 59 found in Peninsular Malaysia, primarily from the Bambusa, Gigantochloa, and Dendrocalamus genus, are commercially used (Siam et al. 2019). Among these, only two species, which are G. scortechinii and G. levis, have been widely reported to be suitable for the production of various panel products (Hanim et al. 2013). This is because the natural hollow cylindrical shape and thin wall of bamboo have prevented it to be used effectively, as converting the bamboo strip into an engineered bamboo panel would be time-consuming.

Buluh madu (G. albociliata) is a type of bamboo known for its delicious bamboo shoots. It is a native species to Thailand and Burma, where it is well known as “Phai rai” in Thailand and “Wa-hpyu-ka-le” in Burma (Duriyaprapan and Jansen 1995). It has been introduced to India and Indochina for agricultural and construction purposes. In Malaysia, G. albociliata was introduced and cultivated to fulfil the demand for honey bamboo shoots, as it is a favourite food of many, particularly in traditional Malay cuisine. This bamboo is utilized because harvesting requires only a short maturation period of about 8 months for the shoots and 3 to 4 years for the stems. The G. albociliata has advantageous characteristics for use as a construction material, with a height of 6 to 10 m, a long internode of 15 to 40 cm, and a thick culm of 1.5 to 3 cm (Johar Mohamed 2012). One of the most intriguing characteristics of G. albociliata is its thick culm wall when compared to other bamboo species. Thus, G. albociliata has advantages over other bamboo species as it can produce thick strips of > 20 mm. Theoretically, lamination efficiency improves, and less glue lines are required to achieve a specific thickness of the laminated panels.

Despite the potential shown by G. albociliata, a comprehensive study on the anatomical structure, fibre morphology, chemical structure, and physical and mechanical properties of the bamboo should be conducted. Understanding these characteristics is helpful in identifying appropriate processing techniques such as drying, preservation, and treatment procedures. The investigation into the chemical, physical, and mechanical properties of the bamboo species will provide information on the workability and glue spreading ability of the bamboo species were it to be used in the production of laminated panels. Thus far, no article reporting on the basic characteristics of G. albociliata has been published, to the best of the authors’ knowledge. Therefore, this study aimed to investigate the basic characteristics of G. albociliata and its potential in laminated panels production.

EXPERIMENTAL

Materials

Four-year-old G. albociliata was harvested from a plantation in Sik, Kedah. The harvested bamboo culm was divided into two parts: top and bottom. The bamboo’s bottom part begins one metre above the ground and extends to the first hollow internode. Meanwhile, the bamboo’s top is measured from the first hollow internode to the first branch of the stem. Most bottom parts of bamboo do not have a hollow round cavity (it is solid), and almost all top parts of bamboo have a hollow round cavity, with only a few having a cavity on one end and tapering to the other (no hole). The bamboo culm was used in its natural state and was designated as round bamboo. Meanwhile, the bamboo culm was run through a four-sided planer to obtain a 20 mm × 20 mm square strip. The properties of both round bamboo and strips were evaluated.

Methods

Determination of anatomical structure and fibre morphology

The method outlined by Latif Mohmod and Tamizi Mustafa (1992) were adopted to determine the anatomical studies on the types of vascular bundles and their distributions. Bamboo sample blocks of size (10 mm × 10 mm × culm wall thickness) were observed using a wireless digital microscope (Koolertron Wireless WiFi Digital USB Microscope (1000x magnification); Koolertron, Shenzhen, China). Bamboo strips from lower and upper sections were chipped into a matchstick size and macerated using a mixture of 30% hydrogen peroxide: glacial acetic acid (1:1 ratio) and placed in a water bath at 70 °C for 3 to 4 h. A higher temperature and longer time were needed to ensure that all the lignin had dissolved and the cellulose fibres appeared whitish. The maceration solution was then washed in distilled water until all traces of the acid disappeared. The cellulose fibres were then placed in the vials and gently agitated to give sufficient separation. The vials were then half-filled with distilled water and secured with a cap. The macerated fibres were then spread on the glass slide before drops of safranin-O was added. A cover slip was applied on the slide. The quantitative measurements of the fibre length, fibre width, fibre lumen diameter, and fibre cell wall thickness from each top and bottom sections of G. albociliata were conducted. The quantitative measurement was made using an optical microscope, and at least 50 fibres were measured. From the fibre measurement, the Runkle ratio, coefficient of suppleness, and Felting Power or L/D factor were calculated using the formulas below:

Runkel ratio = 2w/ l (1)

Coefficient of suppleness = (l x 100) / D (2)

Felting Power or L/D ratio = L / D (3)

where w is fibre wall thickness (μm), l is lumen diameter (μm), D is fibre width (μm), and L is fibre length (mm).

Determination of chemical composition

Fresh felled bamboo was divided into top and bottom sections and chipped before drying in an oven at 60 °C for three days. The sample was then powdered using a Fritsch pulverisette with a sieved size of 0.25 mm. TAPPI test method T257 (1993) was used to determine the chemical composition of G. albociliata.

Determination of moisture content and specific gravity

Gigantochloa albociliata’s moisture content and specific gravity were determined using ISO 22157 (2019). A small section measuring approximately 30 mm (round sample) and 60 mm (strip sample) in length was cut. The section was cut at the internode to remove any defects or failures (away from the node). The sections were then dried in an oven at 103 ± 2 °C for more than 24 h, or until the weight was constant. The moisture content of the bamboo was then calculated based on the difference of its initial weight and oven-dried weight while the specific gravity was calculated by dividing the density of bamboo with the density of water.

Determination of dimensional stability

Gigantochloa albociliata’s dimensional stability was tested in accordance with Indian Standard (IS) 6874 (2008). Each sample’s radial, longitudinal, and tangential sections were marked and measured with digital Vernier calipers. All samples were dried in an oven and kept at 103 ± 2 °C for 48 h. The shrinkage test was performed under conditions that progressed from green to oven dry. The difference in initial and final dimensions on the radial, longitudinal, and tangential planes was used to calculate the bamboo shrinkage percentages. The samples were placed in a water saturated environment until a constant weight was reached, at which point the swelling percentage was calculated.

Determination of mechanical properties

Static bending of the round bamboo and strip was conducted according to an in-house testing method by Forest Research Institute Malaysia (FRIM). The bamboo measured approximately 1000 mm in length. The test employed a three-point loading method with an 800-mm span. Throughout the test, a constant loading speed of 6.6 mm/min was used. The Shimadzu Universal Testing Machine (AG-1/100KN AG-IS; Shimadzu Corporation, Kyoto, Japan) and the Shimadzu software TrapeziumX were used. The Trapezium software calculated the modulus of elasticity (MOE) and modulus of rupture (MOR) using basic engineering principles.

Determination of wettability

Prior to testing, bamboo strips (20 mm × 20 mm × 4 mm) were conditioned at 20 ± 2 °C for a week. A total of 0.02 mg distilled water was dropped onto the outermost layer of the bamboo strips using the sessile drop technique. The bamboo green has already been removed by four-sided planer. Using dpiMAX software (DataPhysics Instruments, version 1, Filderstadt, Germany), the angle formed between the droplet and the bamboo surface was measured at 0 s, 2 s, 30 s, 60 s, 90 s, and 120 s.

Data analysis

All data were analysed using one-way analysis of variance (ANOVA), and Duncan’s multiple range test (DMRT) was used to determine the significant difference between variables.

RESULTS AND DISCUSSION

Anatomical Structure

Figure 1 shows the anatomical structure of G. albociliata at different sections of the bamboo stem. Along the stem, one can see that the bottom part of the bamboo is solid, and hole is non-existent. The hole became detectable as the point of observation moved towards the top of the stem and grew larger along with the height of the bamboo. According to the study by Siam et al. (2019) and Liese (1985), the type of vascular bundle distribution of G. albociliata is a mixture of type III and type IV. The top part of G. albociliata was comprised of type III vascular bundle, while the bottom part was comprised of type IV vascular bundle. There was a distinction between the top and bottom sections of the bamboo, as two fibre strands were identified at the bottom and a single fibre strand at the top. Grosser and Liese (1971) discovered that the type IV vascular bundle of Gigantochloa was always combined with the type III vascular bundle, particularly at the base internodes.

The vascular bundle is also longer and smaller in the outer layer but shorter and larger in the inner layer, resulting in a denser vascular bundle in the outer layer than the inner layer. It can be seen that the size of vascular bundle distribution decreases from bottom to top. The shape of vascular bundle is also seen as roundish and oval at the top section compared to the bottom of the bamboo. This is because of the reducing cell wall thickness within the culm height (Grosser and Liese 1971). Aside from shrinking in shape and size within the culm height, it can also be seen that the number of vascular bundles decreases from bottom to top but becomes tightly packed together at the top of the bamboo. As a result, higher density at the top section is expected.

Fig. 1. a) Morphology of G. albociliata; b) vascular bundle of G. albociliata at bottom section at 7x magnification; and c) vascular bundle of G. albociliata at top section at 7x magnification

Fibre Morphology

Table 1 compares the means of fibre length, width, lumen width, cell wall thickness, Runkle ratio, coefficient of suppleness, and L/D ratio of G. albociliata between sections. The G. albociliata fibre width ranges from 26.81 to 28.79 µm, with a higher value at the bottom. This finding is consistent with the trend of bamboo species studied by Siam et al. (2019), with the exception of G. ligulata and B. vulgaris, which have larger fibre width. This finding supports the findings of Liese (1998), who discovered that fibre is typically thicker at the bottom.

The fibre length of G. albociliata is 2.01 mm and 1.96 mm at the top and bottom sections, respectively, and it can be classified as long fibre (> 1.9 mm), as reported by Kiaei et al. (2014). The cell wall thickness is significantly greater at the bottom (3.15 µm) than at the top (2.93 µm), as is the Runkel ratio, which is 0.66 at the bottom compared to 0.54 at the top.

Meanwhile, the top part of the bamboo has a significantly higher suppleness coefficient and L/D ratio than the bottom part. G. albociliata’s fibre length and lumen width are not significant between sections, and it is shorter and smaller than other bamboo species previously reported (Wahab et al. 2010; Siam et al. 2019; Khantayanuwong et al. 2023). According to Granholm et al. (2010), thick-walled fibres have a Runkel ratio greater than 1, while thin-walled fibres have a Runkel ratio less than 1. Fibres with a Runkel ratio greater than 1 are expected to have low mechanical strength. In this study, the G. albociliata fibres have a Runkel ratio between 0.54 and 0.66, indicating that they have good mechanical properties.

Table 1. Fibre Length, Fibre Width, Lumen Width, Cell Wall Thickness, Runkle Ratio, Coefficient of Suppleness, and L/D ratio of G. albociliata at Top and Bottom Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

Chemical Compositions

Table 2 shows the chemical compositions of top and bottom parts of the G. albociliata. With the exception of cold-water solubility, there was no significant difference in chemical composition between the top and bottom parts of the bamboo. The cold water solubility test measures extraneous components that are insoluble in cold water, such as tannins, sugars, and colouring matter. The mean chemical compositions of G. albociliata for cold water solubility at top and bottom were 11.67% and 14.33%, respectively. This means that the bottom part of G. albociliata may contain significantly higher tannin and sugar than the top part. Although they did not differ significantly, the bottom part of G. albociliata also had a higher mean value for hot water solubility (10.00% vs. 8.33%), ethanol-toluene extractives (4.43% vs. 4.25%), α-cellulose (46.3% vs. 44.3%), lignin (28.3% vs. 25.3%), and ash content (5.00% vs. 4.00%) than the top part of G. albociliata. In contrast, the top part of G. albociliata was found to have higher hemicellulose content than the bottom part.

Table 2. Chemical Compositions of G. albociliata of Different Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

The bottom had a higher extractive content of alcohol-toluene (4.43%) than the top (4.25%). The value was higher than that found in Yusoff et al. (2021), which ranges from 1.01% to 2.09%. High alcohol toluene extractive frequently associates with bamboo maturity and increases resistance to biological attack. The top part of the bamboo had the highest holocellulose content of 85.7%, while the bottom part had a lower holocellulose content of 83.3%. According to Yusoff et al. (2021), a lower holocellulose content at the bottom could be due to a high extractive and ash content. Furthermore, the dense distribution of vascular bundles at the top section of bamboo suggests a higher holocellulose content (Li et al. 2007). The alpha-cellulose of this bamboo (44.33% for top and 46.33% for bottom) is higher than the alpha-cellulose of the same bamboo reported by Yusoff et al. (2021), which was 42.9%. Meanwhile, Wahab et al. (2013) reported that the alpha cellulose content of four cultivated Gigantochloa bamboos ranged from 33.80% to 51.6%.

Lignin content of G. albociliata in this study was 25.3% to 28.3% for top and bottom sections, respectively. According to Yusoff et al. (2021), bamboo with a high lignin content is a good building material because it has a high heating value and structural rigidity. Norul Hisham et al. (2006) previously reported that the lignin content of G. scortechinii ranged from 23.4% to 29.0%, which is quite similar to the G. albociliata in this study. The ash content observed in this study is 4.00% to 5.00%, which is higher than other studies (1.59% to 1.87%) (Yusoff et al. 2021). According to Yusoff et al. (2021), higher ash content indicated higher silica content at the epidermis, and this could be a problem during the processing as silica tend to blunt the blade.

Physical Properties

As indicated in Tables 3 and 4, moisture content at the bottom is significantly higher than the top part for both round and strip bamboo. The higher moisture content of bamboo at the bottom is due to the size of the vascular bundle at the bottom being larger than the top, as shown in Fig. 1 and reported by Grosser and Liese (1971). The specific gravity of G. albociliata round bamboo is higher at the top (0.72) than the bottom (0.69). Similar observation was made on the bamboo strips where strips from the top section (0.64) were higher than the bottom section (0.60). This is similar to the study reported by Suchart and Thaipetch (2004) with specific gravity of G. albociliata ranging from 0.62 to 0.68. Despite this, it has a lower specific gravity (0.74 to 0.90) than G. levis, which was studied by Osman et al. (2022). Figure 1(b) shows that the number of vascular bundles increases and becomes tighter together from the bottom to the top. This may be the reason that round bamboo and the strip from the top section has higher specific gravity than that of the bottom section.

Table 3. Specific Gravity, Moisture Content, and Density of G. albociliata Round Bamboo of Different Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

Table 4. Specific Gravity, Moisture Content, and Density of G. albociliata Strips of Different Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

Dimensional Stability

Figure 2 depicts the percentage of swelling and shrinkage of G. albociliata strips of the bottom and top portions. The tangential swelling is greater in the bottom strips, while the longitudinal and radial swelling is greater in the top strips. In contrast, the top strips have greater longitudinal and tangential shrinkage but less radial shrinkage than bottom strips. Only tangential shrinkage differed statistically between top and bottom strips. Tangential shrinkage can cause bamboo to lose its original shape, resulting in width and curvature changes. This type of shrinkage can have an impact on the stability and fit of bamboo in applications such as laminated products. However, the shrinkage values of G. albociliata in this study were lower than those reported for G. scortechinii in other studies (Wahab et al. 2013; Anokye et al. 2014). This could imply that G. albociliata is more stable than G. scortechinii.

Fig. 2. Swelling and shrinkage of G. albociliata strips of different sections

Mechanical Properties

Tables 5 and 6 show that the MOE and MOR of top bamboo are higher than those of bottom bamboo for both round bamboo and strips. Higher MOE and MOR values on the top of the bamboo could be related to factors such as higher cellulose content and specific gravity, as shown in Tables 2, 3, and 4. According to Sorieul et al. (2016), increased hemicellulose influences the flexibility and elasticity of the cell wall, which in turn influences the mechanical properties of the material. The value of MOE of G. albociliata strip is also higher than the split bamboo reported by Siam et al. (2019). Bamboo from the top section has higher mechanical properties than that of bottom section, which possibly can be attributed to the higher fibre length and L/D ratio as well as lower Runkel ratio. When compared to other species, the MOE of G. albociliata strips is higher than G. thoii (13185 N/mm2), B. vulgaris (12104 N/mm2), and G. scortechinii (10800 N/mm2). The MOR of G. albociliata strip (Table 6) is considered lower than the other 13 commercial Malaysian bamboo species but the value is comparable to that of B. bluemeana, B. heterostachya, and G. scortechinii split (Siam et al. 2019). It is worth mentioning that round G. albociliata show promising MOR values with range of 178 to 181 N/mm2, which is considerably high.

Table 5. MOR and MOE of G. albociliata Round Bamboo of Different Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

Table 6. MOR and MOE of G. albociliata Strips of Different Sections

Note: Number in parentheses refers to standard deviation. Within the same column, means followed by letter a or b are significantly different at p ≤ 0.05.

Wettability

Wettability through contact angle analysis is essential for determining surface characterisation and material performance. These measurements make it possible to develop appropriate application and surface modification strategies for this bamboo, focusing on glueability and bond formation. Figure 3 shows the contact angle of different parts of G. albociliata against time.

Fig. 3. Contact angle against time of G. albociliata strips of different sections

Bamboo from the top section initially had higher contact angle (82.5°) than the lower section (53.21°). However, as time passed, the contact angle of both sections became almost the same after 30 s. At 120 s, both sections had contact angle of approximately 15°. G. albociliata has a smaller contact angle at 2 s than D. sericeus (46.60°), as reported by Chaowana et al. (2015) and G. levis (53 to 64.7°), as reported by Faizal et al. (2015). These findings indicated that G. albociliata has greater wettability than both D. sericeus and G. levis, as evidenced by a lower contact angle. It also demonstrates G. albociliata‘s suitability for use in laminated products, as the glue spreading ability would be advantageous due to high wettability.

CONCLUSIONS

- Buluh madu (G. albociliata) has a vascular bundle distribution of a mixture of Type III and Type IV, similar to the bamboo of other members of the Gigantochloa genus. The size of vascular bundle distribution decreases from the bottom to top of the bamboo stem. The outer layer of the bamboo has a denser distribution of vascular bundle than inner layer.

- G. albociliata has long fibres. The top section of bamboo has longer fibre, coefficient of suppleness, and L/D ratio, but lower fibre width, cell well thickness, and Runkle ratio than the bottom section.

- Chemical composition of the top and bottom section of bamboo did not differ significantly except for cold-water solubility, where bottom section may contain significantly higher tannin and sugar than the top section.

- Round bamboo and strips from the top section have higher specific gravity and density than the bottom section and therefore higher mechanical strength. The swelling and shrinkage properties of G. albociliata may imply that this bamboo has better dimensional stability than G. scortechinii.

- G. albociliata has good wettability when compared to other bamboo species as shown by its lower contact angle. Coupled with its good strength properties and dimensional stability, it has a great potential to be processed into laminae for laminated bamboo panels production.

- The results of this study show that G. albociliata has a high potential for being processed into laminae for laminated panel manufacture. One of the most noticeable features is that the culms are solid at the bottom portion of the plant, with hollows appearing as they move towards the top. Owing to the large culm diameter and the absence of holes, using the bottom portion shortens the processing time. Meanwhile, despite having small hollow structures, the upper portion displays more promising qualities for being processed into laminae because of its superior mechanical properties. However, more research is needed to establish the implications of the hollow structures on the performance of the laminated panel, both aesthetically and mechanically.

ACKNOWLEDGMENTS

This study was financially supported by the Higher Education Center of Excellence (HICoE) Phase 2 grant (Project title: Mill production of laminated bamboo board from buluh madu (Gigantochloa albociliata) for structural applications, project code: 800-3/8/HICoEF2/2023/5210010) provided by the Malaysian Ministry of Higher Education (MOHE).

REFERENCES CITED

Anokye, R., Kalong, R. M., Bakar, E. S., Ratnasingam, J., Jawaid, M., and Awang, K. (2014). “Variations in moisture content affect the shrinkage of Gigantochloa scortechinii and Bambusa vulgaris at different heights of the bamboo culm,” BioResources 9(4), 7484-7493. DOI: 10.15376/biores.9.4.7484-7493

Chaowana, P., Jindawong, K., and Sungkaew, S. (2015). “Adhesion and bonding performance of laminated bamboo lumber made from Dendrocalamus sericeus,” in: 10th World Bamboo Congress, Damyang, South Korea.

Duriyaprapan, S., and Jansen, P.C.M. (1995). “Bambusa bambos (L.) Voss,” in: Plant Resources of South-East Asia. Bamboos, S. Dransfiled, and E. A. Widjaja (eds.), Backhuyes, Leiden, Netherlands.

Faizal, W., Wahid, A. B., Ahmad, M., and Rahmat, M. (2015). “Contact angle of different portion of beting bamboo (Gigantochloa levis) treated with maleic anhydride for composite materials,” International Journal of Mechanical and Production Engineering 3(10), 68-70.

Granholm, K., Harju, L., and Ivaska, A. (2010). “Desorption of metal ions from kraft pulps, Part 1. Chelation of hardwood and softwood kraft pulp with EDTA,” BioResources 5(1), 206-226. DOI: 10.15376/biores.5.1.206-226

Grosser, D., and Liese, W. (1971). “On the anatomy of Asian bamboos, with special reference to their vascular bundles,” Wood Science and Technology 5, 290-312. DOI: 10.1007/BF00365061

Hanim, A. R., Zaidon, A., Anwar, U. M. K., and Rafidah, S. (2013). “Effects of chemical treatments on durability properties of Gigantochloa scortechinii strips and ply-bamboo,” Asian Journal of Biological Sciences 6(3), 153-160. DOI: 10.3923/ajbs.2013.153.160

IS 6874 (2008). “Method of tests for bamboo,” Bureau of Indian Standards, Old Delhi, India

ISO 22157 (2019). “Bamboo structures,” International Organization for Standardization, Geneva, Switzerland.

Johar Mohamed (2012). Effect of Silvicultural Treatments on Buluh Madu (Gigantochloa albociliata) (Munro) Kurz) for Shoot Production, Master’s Thesis, Universiti Putra Malaysia, Selangor, Malaysia.

Khantayanuwong, S., Yimlamai, P., Chitbanyong, K., Wanitpinyo, K., Pisutpiched, S., Sungkaew, S., Sukyai, P., and Puangsin, B. (2023). “Fiber morphology, chemical composition, and properties of kraft pulping handsheet made from four Thailand bamboo species,” Journal of Natural Fibers 20(1), article ID 2150924. DOI: 10.1080/15440478.2022.2150924

Kiaei, M., Tajik, M., and Vaysi, R. (2014). “Chemical and biometrical properties of plum wood and its application in pulp and paper production,” Maderas. Ciencia y Tecnología 16(3), 313-322. DOI: 10.4067/S0718-221X2014005000024

Latif Mohmod, A., and Tamizi Mustafa, M. (1992). “Variation in anatomical properties of three Malaysian bamboos from natural stands,” Journal of Tropical Forest Science 5(1), 90-96.

Li, X. B., Shupe, T. F., Peter, G. F., Hse, C. Y., and Eberhardt, T. L. (2007). “Chemical changes with maturation of the bamboo species Phyllostachys pubescens,” Journal of Tropical Forest Science 19(1), 6-12.

Liese, W. (1985). “Anatomy and properties of bamboo,” in: Proceeding of the International Bamboo Workshop, Hangzhou, China, pp. 196–208.

Liese, W. (1998). The Anatomy of Bamboo Culms, Technical Report, International Network for Bamboo and Rattan (INBAR), Beijing, China.

Norul Hisham, H., Othman, S., Rokiah, H., Abd Latif, M., Ani, S., and Mohd Tamizi, M. (2006). “Characterization of bamboo Gigantochloa scortechinii at different ages,” Journal of Tropical Forest Science 18(4), 236-242.

Osman, S., Ahmad, M., Zakaria, M. N., Zakaria, A. M., Ibrahim, Z., Abu, F., Bahari, S. A., and Wan Jaafar, W. N. R. (2022). “Bamboo as future bio-industrial material: Physical behaviour and bending strength of Malaysia’s Beting bamboo (Gigantochloa levis),” IOP Conference Series: Earth and Environmental Science 951, article ID 012001. DOI: 10.1088/1755-1315/951/1/012001

Sorieul, M., Dickson, A., Hill, S. J., and Pearson, H. (2016). “Plant fibre: Molecular structure and biomechanical properties, of a complex living material, influencing its deconstruction towards a biobased composite,” Materials 9(8), article 618. DOI: 10.3390/ma9080618

Siam, N. A., Uyup, M. K. A., Husain, H., Mohmod, A. L., and Awalludin, M. F. (2019). “Anatomical, physical, and mechanical properties of thirteen Malaysian bamboo species,” BioResources 14(2), 3925-3943. DOI: 10.15376/biores.14.2.3925-3943

TAPPI T257 (1993). “Sampling and preparing wood for analysis,” TAPPI Press, Atlanta, GA, USA.

Wahab, R., Mustafa, M. T., Salam, M. A., Sudin, M., Samsi, H. W., and Rasat, M. S. M. (2013). “Chemical composition of four cultivated tropical bamboo in genus Gigantochloa,” Journal of Agricultural Science 5(8), 66-75. DOI: 10.5539/jas.v5n8p66

Wahab, R., Mustafa, M. T., Sulaiman, O., and Mohamed, A. (2010). “Anatomical and physical properties of cultivated two- and four-year-old Bambusa vulgaris,” Sains Malaysiana 39(4), 571-579.

Yusoff, M. S. R., Bahari, S. A., Haliffuddin, R. M. A. A., Zakaria, M. N., Jamaluddin, M. A., and Rashid, N. H. M. N. (2021). “Chemical contents and thermal stability of Madu bamboo (Gigantochloa albociliata) for natural-bonded fiber composites,” IOP Conference Series: Earth and Environmental Science 644(1), Article ID 012009. DOI: 10.1088/1755-1315/644/1/012009

Article submitted: September 16, 2023; Peer review completed: October 7, 2023; Revised version received and accepted: October 17, 2023; Published: October 27, 2023.

DOI: 10.15376/biores.18.4.8503-8514