Abstract

Linseed oil and shellac are natural, environmentally friendly materials with good water repellency. They were used to impregnate Chinese ash wood at room temperature (20 °C) using a vacuum-pressure procedure (consisting of three cycles of 0.01 MPa for 1.5 h and atmospheric pressure for 1.5 h) to improve the dimensional stability of wood. The effects of the impregnation treatment on wood color changes, dimensional stability, moisture absorption, and morphological characteristics were evaluated. The linseed oil and shellac treatment improved the dimensional stability of wood. Linseed oil and shellac displayed good permeability in Chinese ash wood, with weight gains of 21.7% and 19.0%, respectively, after impregnation. The swelling coefficients of treated wood in the tangential and radial directions decreased by 15 to 22%, indicating that impregnation improved the dimensional stability of wood. Linseed oil and shellac solidified and occluded the pits within the wood interior to prevent moisture absorption. This method can be used to improve the dimensional stability of a variety of wood products, such as buildings, furniture, and landscape architecture.

Download PDF

Full Article

A Comparative Study on the Effects of Linseed Oil and Shellac Treatment on the Hygroscopicity, Dimensional Stability, and Color Changes of Chinese Ash Wood

Mihaela Liu,c Xinwei Tu,c Xinyou Liu,a,b,c,* Zhihui Wu,a,c,* Jiufang Lv,a,b,c and Anca Maria Varodi d

Linseed oil and shellac are natural, environmentally friendly materials with good water repellency. They were used to impregnate Chinese ash wood at room temperature (20 °C) using a vacuum-pressure procedure (consisting of three cycles of 0.01 MPa for 1.5 h and atmospheric pressure for 1.5 h) to improve the dimensional stability of wood. The effects of the impregnation treatment on wood color changes, dimensional stability, moisture absorption, and morphological characteristics were evaluated. The linseed oil and shellac treatment improved the dimensional stability of wood. Linseed oil and shellac displayed good permeability in Chinese ash wood, with weight gains of 21.7% and 19.0%, respectively, after impregnation. The swelling coefficients of treated wood in the tangential and radial directions decreased by 15 to 22%, indicating that impregnation improved the dimensional stability of wood. Linseed oil and shellac solidified and occluded the pits within the wood interior to prevent moisture absorption. This method can be used to improve the dimensional stability of a variety of wood products, such as buildings, furniture, and landscape architecture.

Keywords: Linseed oil; Shellac; Hygroscopicity; Dimensional stability; Wood dimensional stability; Swelling coefficients

Contact information: a: Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, Nanjing Forestry University, Nanjing 210037, China; b: Nanjing Forestry University Academy of Chinese Ecological Progress and Forestry Studies Str. Longpan No.159, Nanjing, China; c: College of Furnishing and Industrial Design, Nanjing Forestry University, Str. Longpan No.159, Nanjing, China; d: Transilvania University of Brașov, Faculty of Wood Engineering, Romania

* Corresponding author: liu.xinyou@njfu.edu.cn, wzh550@sina.com

GRAPHICAL ABSTRACT

INTRODUCTION

Wood is a versatile and renewable natural biopolymer that is widely used in a variety of fields. Due to its aesthetic appearance and properties, it remains an indispensable product in daily life and culture (Chien et al. 2018). However, lignocellulosic materials often suffer from dimensional instability, photodegradation, combustibility, and biological degradation, which limit the use of wood in various applications. Many methods have been developed in recent decades to improve the dimensional stability, thermal stability, light stability, and biological resistance of wood, including steam-heat treatment (Saeed et al. 2016; Yin et al. 2017), acetylation and silylation (Ziegler et al. 2008), and alkoxysilane modification (Broda et al. 2018) among others. Thermal treatments may darken the original color of the wood and weaken its mechanical properties (Esteves et al. 2011; Popescu and Popescu 2013), whereas chemical modifications might be detrimental to the environment. Many of these modifications are also complex and consume large amounts of energy.

Linseed oil and shellac are natural, inexpensive, non-toxic coatings that are widely used in wooden crafts due to their hardness, gloss, and ability to form water barrier films (Farag and Leopold 2007; Kasote et al. 2013; Anastasiua et al. 2016; Weththimuni et al. 2016). Linseed oil is used to manufacture paints, varnishes, inks, soaps, and many other products. Shellac has been applied in a variety of products (e.g., pharmaceuticals, food treatments, children’s toys, and electrical insulation) because of its thermoplasticity, insulating properties, and low toxicity (Bai et al. 2002; The et al. 2008).

Despite these applications, linseed oil and shellac rarely have been used to improve the hygroscopicity of wood products. Thus, the aim of this paper is to use environmentally-friendly modifiers (linseed oil and shellac) and a low-energy consumption process to impregnate Chinese ash at room temperature to improve its dimensional stability and hygroscopicity, while retaining its initial color after treatment. The results will broadly expand its applications in diverse fields. Therefore, the effects of treatment on the hygroscopicity, dimensional stability, and color changes were examined.

EXPERIMENTAL

Sample Preparation

Chinese ash (Fraxinus mandshurica), commonly cultivated in northeast China, was sourced from Liaoning Province, China. The test specimens were prepared from sapwood with dimensions of 20 × 20 × 20 mm (length × width × thickness) and an initial moisture content of 75 ± 5% according to GB/T 1931 (2009) (Zhao et al. 2009). All specimens were dried at 103 °C.

Wood Impregnation with Linseed Oil and Shellac

Linseed oil (Fabryo Company) was purchased from Conrep Shop (Brasov, Romania). Shellac (98% purity, wax free) and ethanol (90%) were purchased from Chuxiong DES Shellac Co., Ltd. (Chuxiong, Yunnan). Linseed oil and shellac ethanol solution (20% g/mL) were used to impregnate wood samples in a vacuum chamber (Shanghai Laboratory Instrumental Works Co., Ltd., Shanghai, China). Twenty dry specimens were weighed, immersed in these liquids, and treated in a vacuum chamber at a pressure of 0.01 MPa at room temperature (20 °C) for 1.5 h. Afterward, the pressure was equilibrated to atmospheric pressure for 1.5 h, and the reverse process was performed three times to impregnate the samples with linseed oil and shellac. Residual liquid was removed from the specimen surfaces. The control group was not impregnated with linseed oil or shellac. After treatment, the specimens were naturally dried for 7 days until ethanol completely evaporated. They were then dried at 103 °C, and their oven-dried weight was measured.

Color Measurements

Pre- and post-treatment surface color measurements on the tangential sections of all specimens were performed using an AvaSpec-USB2 spectrometer (Avantes, Netherlands) equipped with an integrating AVA sphere with a diameter of 80 mm. Measurements were made using a D65 standard illuminant and a 10° standard observer. The reflectance percentage, collected at 10 nm intervals over the visible spectrum (400 to 700 nm), was converted into the CIELab color system.

The resultant pre- and post-treatment color coordinates were lightness L* (from 0 for black to 100 for white), redness a* (from negative values for green, to positive values for red on the green-red axis), and yellowness b* (from negative values for blue, to positive values for yellow on the blue-yellow axis).

The color differences between treated and control samples were calculated based on Eq. 1,

(1)

where L*,

a*, and

b* are the differences between the pre- and post-treatment values of L*, a*, and b*, respectively. Low

E values corresponded to a small color difference.

Weight Percentage Gain (WPG)

The WPG was determined based on the weight before and after impregnation and was calculated using Eq. 2,

(2)

where w0 is the oven-dried weight of specimens before treatment (g), and ww denotes the oven-dried weight of specimens after treatment (g).

Estimation of Wood Dimensional Stability

Swelling tests were performed according to the GB/T 1931 (2009) standard. The treated and control groups were oven-dried and stored in a climate-controlled chamber at 20 °C at 65% humidity to reach the equilibrium moisture content (EMC). The dimensions and weights of the specimens were measured before and after conditioning, and the swelling coefficient was calculated using Eq. 3,

(3)

where a is the swelling coefficient (radial, tangential, or longitudinal), l0 denotes the initial specimen dimension, and lw represents the dimension after conditioning.

Moisture Absorption (MA)

Specimens were placed in a chamber set to 20 °C and 65% humidity to reach the EMC according to the GB/T 1931 (2009) standard. Following conditioning in the climate chamber, the MA was calculated using Eq. 4,

(4)

where wb (wa) denotes the weight of the specimens before (after) conditioning in the climate chamber (g).

Morphological Characteristics

The surface shapes of the samples were assessed based on their morphologies using a scanning electron microscope (SEM, Quanta 200, FEI Company, Eindhoven, Netherlands) to investigate variations in their physical structures.

RESULTS AND DISCUSSION

Post-treatment Color Changes

The measured color data (mean of 20 values) for control and treated wood samples are summarized in Table 1. Chinese ash is a white-yellow wood with pre-treatment color parameters of L* = 70.3, a* = 6.5, and b* = 17.6. Post-treatment, L* slightly decreased, while a* and b* slightly increased. The color difference values were 1.3 and 1.4 after linseed oil and shellac treatment, which were much smaller than heat-treated wood (Sivrikaya et al. 2019). According to the correlation between ΔE, the calculated color differences, and changes visible to the human eye (Allegretti et al 2008), these color differences are the smallest visible differences.

Table 1. Color Measurements using the CIELab system for the Control and Treated Wood Samples: L*, a*, b* Coordinates (average values ± standard deviations) and the Calculated Global Color Differences ∆E

Weight Percentage Gain (WPG%)

The weight percentage gain (WPG%) indicates the net weight of the wood after impregnation by linseed oil or shellac, and the value depends on the permeability of these liquids inside Chinese ash wood. The oven-dried weight of untreated specimens was 4.30 g, and the average oven-dried weight after treatment with linseed was about 5.24 g. The WPG% was 21.7%, which is similar to retention values in previous studies (Can and Sivrikaya 2017, 2019). The average oven-dried weight after treatment with shellac was 5.12 g, and the WPG% was 19.0%.

Wood Dimensional Stability

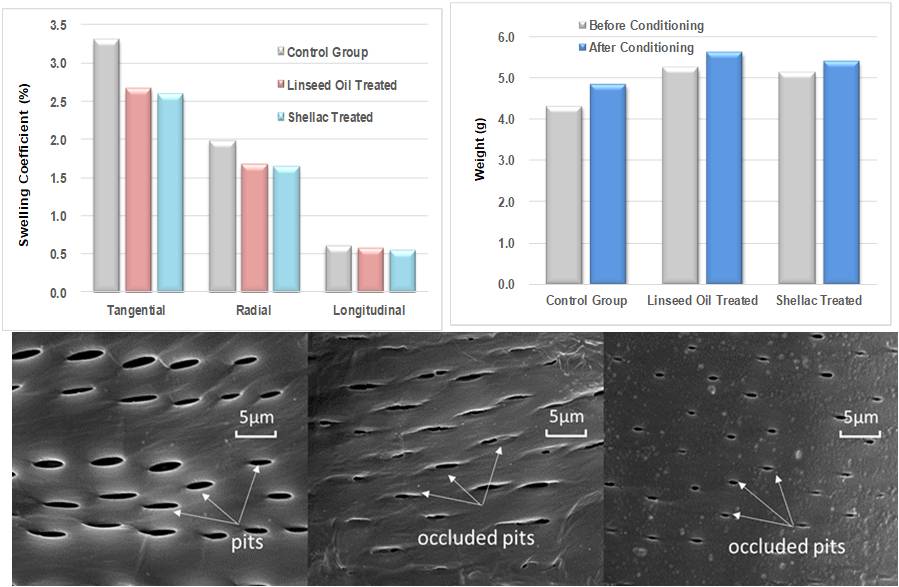

The dimensional stability of wood affects its utilization and quality and depends on the tree species, tree age, and age of the wood. The tangential and radial swelling coefficients are more sensitive than those in the longitudinal direction, and they are thus the most important factors for estimating the dimensional stability of wood. Figure 1 shows that the impregnation treatment influences the dimensional stability of wood. The average tangential, radial, and longitudinal swelling coefficients of the control group were 3.31%, 1.98%, and 0.62%, respectively; those of the linseed-treated group were 2.67%, 1.68%, and 0.58%. Those of the shellac-treated group were 2.59%, 1.65%, and 0.56%, respectively. Compared with the control group, the tangential swelling coefficient decreased by 19.3% after linseed treatment and 21.8% after shellac treatment. The average values of the radial swelling coefficients for the control, linseed oil, and shellac-treated groups were 1.98%, 1.68%, and 1.65%, respectively. Compared with the control group, the radial swelling coefficient of the linseed oil group was 15.2% lower, and the shellac group was 16.7% lower. The average longitudinal swelling coefficients for the control, linseed oil, and shellac-treated groups were 0.62%, 0.58%, and 0.56%, respectively. Therefore, the linseed oil and shellac treatments decreased the wood swelling coefficients in the tangential and radial directions without significantly affecting the wood swelling coefficients in the longitudinal direction.

Fig. 1. Swelling coefficients in different directions for the control, linseed oil, and shellac-treated groups

Moisture Absorption (MA)

The moisture content of wood has a significant impact on its stability when it reaches the fiber saturation point. To reveal the effect of shellac solution impregnation on the dimension stability, the hydrophilicity of wood was evaluated by measuring the moisture absorption (MA). Figure 2 illustrates the weights of specimens before and after conditioning in the climate chamber at 20 °C and 65% humidity.

Fig. 2. Weights of the specimens before and after conditioning

The MA values for the samples after conditioning were 7.0% for the linseed oil-treated specimens, 5.1% for the shellac-treated specimens, and 12.0% for the control group. Compared with the control group, the MA of the linseed oil-treated group was 41.5% lower, while the MA for the shellac-treated group was 57.5% lower. The results show that linseed oil and shellac treatment markedly decreased the MA of wood, which should increase its dimensional stability.

Morphology

The SEM micrographs of the treated samples and those of the control group (Fig. 3) show that linseed oil and shellac treatment greatly influenced the tissue structure of the samples and that the wood was impregnated with linseed oil and the shellac solution. Pits, which serve as the main moisture passageways to the wood interior (Panov et al. 2010) were occluded in the treated groups, which prevented MA when the wood product was exposed to moisture, thereby improving its dimensional stability. Therefore, linseed and shellac prevented MA when they impregnated the wood interior, which also improved the dimensional stability of wood.

Fig. 3. SEM micrographs (magnification 4000X) of the control group (left), linseed oil treatment group (middle), and the shellac treatment group (right)

CONCLUSIONS

- Treatment by either linseed oil or shellac impregnation improved the stability of Chinese ash wood.

- Linseed oil and shellac solution displayed good permeability in Chinese ash wood, and the weight percentage gain (WPG%) reached 21.7% after linseed oil impregnation and 19.0% after shellac impregnation.

- After linseed oil and shellac treatment, the swelling coefficients of wood in the tangential and radial directions decreased markedly, which improved the dimensional stability of wood.

- The impregnation of linseed oil and shellac occluded pits in the wood (which are the main water passageways into the wood) and solidified in the wood interior, which can prevent moisture absorption during the utilization of wood products.

ACKNOWLEDGMENTS

This work was supported by Project from International Cooperation Joint Laboratory for Production, Education, Research and Application of Ecological Health Care on Home Furnishing, the Nanjing Forestry University Foundation for Basic Research (Grant No. 163104127), the National Key R & D Program of China (Grant No. 2016YFD0600704), and the Priority Academic Program Development (PAPD) of Jiangsu Province, China.

REFERENCES CITED

Allegretti, O., Cividini, R., and Travan, L. (2008). “Drying process for white beech,” Pro Ligno 4(1), 11-19.

Anastasiua, A. E., Chiraa, N. A., Banu, I., Ionescu, N., Stana,R., and Roscaa, S. I. (2016). “Oil productivity of seven Romanian linseed varieties as affected by weather conditions,” Industrial Crops and Products 86, 219-230. DOI: 10.1016/j.indcrop.2016.03.051

Bai, J., Hagenmaier R. D., and Baldwin, E. A. (2002). “Volatile response of four apple varieties with different coatings during marketing at room temperature,” Journal of Agricultural and Food Chemistry 50(26), 7660-7668. DOI: 10.1021/jf020543n

Broda, M., Majka, J., Olek, W., and Mazela B. (2018). “Dimensional stability and hygroscopic properties of waterlogged archaeological wood treated with alkoxysilanes,” International Biodeterioration & Biodegradation 133, 34-41. DOI: 10.1016/j.ibiod.2018.06.007

Can, A., and Sivrikaya, H. (2019). “Surface characterization of wood treated with boron compounds combined with water repellents,” Color Research & Application 44(3), 462-472.

Can, A., and Sivrikaya, H. (2017). “Combined effects of copper and oil treatment on the properties of Scots pine wood,” Drewno 60(199), 89-103.

Chien, Y., Yang, T., Hung, K., Li, C., Xu, J., and Wu, J. (2018). “Effects of heat treatment on the chemical compositions and thermal decomposition kinetics of Japanese cedar and beech wood,” Polymer Degradation and Stability 158, 220-227. DOI: 10.1016/j.polymdegradstab.2018.11.003

Esteves, B., Videira, R., and Pereira, H. (2011). “Chemistry and ecotoxicity of heat-treated pine wood extractives,” Wood Science and Technology 45(4), 661-676. DOI: 10.1007/s00226-010-0356-0

Farag, Y., and Leopold, C. S. (2007). “Physicochemical properties of various shellac types,” Dissolution Technologies 16(2), 33-39. DOI: 10.14227/DT160209P33

GB/T 1931 (2009). “Determination of wood moisture content,” Standardization Administration of China, Beijing, China.

Kasote, D. M., Badhe, Y. S., and Hegde, M. V. (2013). “Effect of mechanical press oil extraction processing on quality of linseed oil,” Industrial Crops and Products 42, 10-13. DOI: 10.1016/j.indcrop.2012.05.015

Panov, D., Terziev, N., and Daniel, G. (2010). “Using plant oils as hydrophobic substances for wood protection,” International Research Group on Wood Protection, Biarritz, France.

Popescu, C. M., and Popescu, M. C. (2013). “A near infrared spectroscopic study of the structural modifications of lime (Tilia cordata Mill.) wood during hydro-thermal treatment,” Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy 115, 227-233. DOI: 10.1016/j.saa.2013.06.002

Saeed, M. A., Andrews, G. E., Phylaktou, H. N., and Gibbs, B. M. (2016). “Raw and steam exploded pine wood: Possible enhanced reactivity with gasification hydrogen,” International Journal of Hydrogen Energy 41(37), 16566-16576. DOI: 10.1016/j.ijhydene.2016.05.121

Sivrikaya, H., Tesarova, D., Jerabkova, E., and Can, A. (2019). “Color change and emission of volatile organic compounds from scots pine exposed to heat and vacuum-heat treatment,” Journal of Building Engineering 26, 100918

The, D. P., Debeaufort, F., Luu, D., and Voilley, A. (2008). “Moisture barrier, wetting and mechanical properties of shellac/agar or shellac/cassava starch bilayer bio-membrane for food applications,” Journal of Membrane Science 325(1), 277-283. DOI: 10.1016/j.memsci.2008.07.052

Weththimuni, M. L., Capsoni, D., Malagodi, M., Milanese, C., and Licchelli, M. (2016). “Shellac/nanoparticles dispersions as protective materials for wood,” Applied Physics A 122, 1058. DOI: 10.1007/s00339-016-0577-7

Yin, J. P., Yuan, T. Q., Lu, Y., Song, K. L., Li, H. Y., Zhao, G. J., and Yin, Y. F. (2017). “Effect of compression combined with steam treatment on the porosity, chemical composition and cellulose crystalline structure of wood cell walls,” Carbohydrate Polymers 155, 163-172. DOI: 10.1016/j.carbpol.2016.08.013

Ziegler, I. M., Tánczos, I., Hórvölgyi, Z., and Agoston, B. (2008). “Water-repellent acylated and silylated wood samples and their surface analytical characterization,” Colloids and Surfaces A-Physicochemical and Engineering Aspects 319, 204-212. DOI: 10.1016/j.colsurfa.2007.06.063

Article submitted: July 7, 2020; Peer review completed: August 29, 2020; Revised version received and accepted: September 2, 2020; Published: September 7, 2020.

DOI: 10.15376/biores.15.4.8085-8092