Abstract

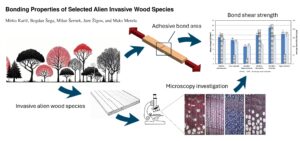

Invasive alien plant species pose a significant challenge to European ecosystems. They displace native vegetation, damage agricultural land, and annually cost the European economy billions of euros. Many of them are removed daily and mainly burned, although some of them produce lignocellulosic material that could be used in place of native wood species. In this study, the bonding properties of selected invasive wood species in Slovenia were tested using standard methods. Wood lamellas were produced according to the SIST EN 205 standard from Ailanthus altissima, Aesculus hippocastanum, Robinia pseudoacacia, Gleditsia triacanthos and Acer negundo and glued with polyvinyl acetate (PVAc) and one-component polyurethane (PU) adhesive. The results showed that selected wood species can be bonded well with both adhesives (bond shear strengths from 7.2 to 15.1 N/mm2), although there were large variations due to the heterogeneity of the wood material. The differences in the shear strength of the bonds were mainly due to the different densities of the wood (479 to 702 kg/m3) species and the high variability in material properties (for example porosity from 0.54 to 0.68 and shear strength in tangential direction from 11.2 to 21.1 N/mm2), which are related to the anatomical characteristics of the individual wood species.

Download PDF

Full Article

Bonding Properties of Selected Alien Invasive Wood Species

Mirko Kariž, Bogdan Šega, Milan Šernek, Jure Žigon, and Maks Merela *

Invasive alien plant species pose a significant challenge to European ecosystems. They displace native vegetation, damage agricultural land, and annually cost the European economy billions of euros. Many of them are removed daily and mainly burned, although some of them produce lignocellulosic material that could be used in place of native wood species. In this study, the bonding properties of selected invasive wood species in Slovenia were tested using standard methods. Wood lamellas were produced according to the SIST EN 205 standard from Ailanthus altissima, Aesculus hippocastanum, Robinia pseudoacacia, Gleditsia triacanthos and Acer negundo and glued with polyvinyl acetate (PVAc) and one-component polyurethane (PU) adhesive. The results showed that selected wood species can be bonded well with both adhesives (bond shear strengths from 7.2 to 15.1 N/mm2), although there were large variations due to the heterogeneity of the wood material. The differences in the shear strength of the bonds were mainly due to the different densities of the wood (479 to 702 kg/m3) species and the high variability in material properties (for example porosity from 0.54 to 0.68 and shear strength in tangential direction from 11.2 to 21.1 N/mm2), which are related to the anatomical characteristics of the individual wood species.

DOI: 10.15376/biores.19.2.3078-3094

Keywords: Invasive species; Wood anatomy; Wood bonding; Bond shear strength; Polyurethane adhesive; Polyvinyl acetate adhesive

Contact information: University of Ljubljana, Biotechnical Faculty, Jamnikarjeva ulica 101, 1000 Ljubljana, Slovenia; *Corresponding author: maks.merela@bf.uni-lj.si

GRAPHICAL ABSTRACT

INTRODUCTION

Alien (non-native) species are those that have been intentionally or unintentionally introduced by humans outside their original range. Of course, not all alien species are invasive. The first step to invasion is the introduction of the species, i.e., the plant has been moved by humans across a major geographical barrier into a new environment where it was not previously found. The next step is naturalisation, which begins when the abiotic and biotic barriers to survival and regular reproduction have been overcome. Invasion occurs when introduced plants begin to spread and reproduce in areas that are far from the places of introduction (Richardson et al. 2000). More than 12,000 alien species have already been discovered in Europe, of which around 15% are invasive and pose a serious threat to native species (European Commission 2014).

The spread of invasive alien plant species is one of the challenges facing local ecosystems. Invasive species displace native vegetation, destroy agricultural land, cause losses in agriculture, forestry, fisheries and tourism, damage infrastructure, and have a negative impact on human health (Kumar Rai and Singh 2020). All of this causes billions of euros of damage to the European economy every year. EU Regulation 1143/2014 on invasive alien species, which came into force on January 1, 2015, provides for three types of measures: prevention, early detection and rapid eradication, and management (EU Regulation No 1143/2014).

This approach is possible for species that are not locally distributed, but there are also some species that are already locally distributed and which could be used towards the production of qualitative or technical wood material. Many of them are removed on a daily basis and mainly burned, although some of them could be used instead of native species. However, the wood obtained from the alien species is not used because there is insufficient knowledge about its properties (Terzopoulou et al. 2023).

It is important to consider each species at the local level. For example, Ailanthus altissima is a native species that is widespread in China but is considered an undesirable invasive species in Europe and North America due to its aggressive invasive and pioneer-like characteristics (Brandner and Schickhofer 2010).

Most of the potentially invasive species are not available in larger stem diameters and are therefore not commonly used for wood processing, mainly because the plants are removed at an early stage before they grow into larger trees. Their wood is only available in a limited form (limited boot diameters and lengths) and to avoid this limitation, several pieces must be joined together to make larger elements or products. Gluing is one of the methods used to join wood into larger formats or assemblies. Several wooden elements can be joined together to form composite materials that are used to make products (e.g., furniture and building structures). Wood can also be ground into smaller particles and used in particle boards and wood-plastic composites (Medved et al. 2020).

Wood, in general, is a high-strength porous material and thus a complex substrate for adhesive bonding (Frihart 2009). The bonding of wood is influenced by the type of glue/adhesive, the preparation of the wood (drying, planning), the microclimatic conditions (relative humidity and temperature), the bonding technology (pressure, time, temperature). However, the wood structure is something that cannot be changed, and the characteristics of the individual wood species are inevitable. Wood anatomy affects adhesive penetration, which is described as the flow of adhesive across the surface into the wood to fill the empty voids of the cells (lumina). The porosity (frequency and diameter of the cell lumina) has a major influence here. Filling the cell lumens ensures mechanical interlocking and increases the surface area for adhesive contact (Marra 1992). Many chemicals can penetrate the cell walls and the middle lamella and affect the physical and mechanical properties of the wood. Flowing of an adhesive into the lumina improves the mechanical interlocking, but has little effect on the swelling properties of the wood (Kamke and Lee 2007; Stokke and Groom 2008; Frihart 2009).

Wood is an anisotropic material due to its cellular structure, and there are three main xylotomical planes (transverse, radial, and tangential). The penetration of the adhesive into the radial or tangential surface is not the same for the same adhesive application technology (Ülker 2016). When gluing wood, these planes are important, but in practice usually gluing of wood is in combination of radial/tangential planes. The most important features are elongated tracheids in softwood species and vascular elements (vessels) and longitudinal fibers in hardwood species. The lumens of cells are large enough to provide a good path for the flow of liquid glue. The connecting pits are often sufficient to allow the flow of glue (Ülker 2016). Different wood properties, including porosity or sorption properties, affect the penetration of adhesive.

The reduction in penetration increases adhesive line thickness, which in case of foaming adhesives like PU, is a potential area for CO2 microbubbles to get trapped in cured adhesive. These microbubbles can act as a stress concentration point and failure starting point (Masoumi et al. 2023). Various manufacturing factors have an effect on the adhesive strength. In particular, the amount of adhesive and the pressure influence the thickness of the adhesive joint.

In order to achieve high shear strength, both effective penetration and thin adhesive joints are required (Masoumi et al. 2024). Also, the machining of the bonding surface has been shown to affect the penetration of the adhesive and the bond strength. Especially the wood interphase layer (Marra 1992) is affected by surface preparation (clear cutting with open cell lumens, cracks occurred during machining, deformed/weakened surface material). Better bond strength is achieved on surfaces with a clear cut, without excessive damaged/suppressed tissue.

Comparing the workability of the selected invasive alien species, according to Merhar, the best average surface quality grade for surface planing at low feed rates was obtained for Ailanthus altissima and Acer negundo (surface quality grade 1.1 and 1.3), but Robinia pseudoacacia showed a high proportion of torn out grains (surface quality grade 2.35) (Merhar et al. 2020). Wood surfaces with increased roughness can exhibit increased tensile bond strength due to enlarged bonding area, but on more open cells of the smoothed end-grain surfaces the pronounced starving of the bond line and thus decreased bond strength was observed (Follrich et al. 2010).

The strength of glued joints is very important for the strength of the end product (the construction) and depends on several factors: Adhesive properties, wood properties, surface preparation, bonding method, and intended use of the bonded joint (Marra 1992; Burdurlu et al. 2007; Tiryaki et al. 2015). In timber structures, the joints and connections are often the weakest points and require special attention. Wood bonding can be represented as a chain of links (adhesive film; intra-adhesive boundary layers; adhesive-wood interface; wood substrate and wood), whereby the strength of the chain depends on the weakest link. The properties of the individual layers (links) influence the final strength of the bond (Marra 1992).

Most of the research related to bonding of wood from alien invasive species in past was done only on more suitable and, in some countries, more common species, such as Robinia pseudoacacia (Konnerth et al. 2016; Vasiliki and Ioannis 2017)) or Ailanthus altissima. Robinia pseudoacacia has been found to bond well with one-component polyurethane adhesives but has poor compatibility with phenol-resorcinol-formaldehyde adhesives. Some species require modified pressing conditions (longer pressing time and higher pressure) to achieve better bonding strength or even the use of epoxy adhesive is recommended (Voulgaridis et al. 2012; Iždinský et al. 2020). In the case of Robinia pseudoacacia, the sanded surface and the use of a modified PUR adhesive with increased penetration had a positive effect on the shear strength of the bond (Holeček et al. 2023).

The aim of this study was to test the bonding of selected alien invasive wood species in Slovenia. The specimens were available in a suitable size to perform bonding tests with two adhesives commonly used in wood processing. The results could be used to suggest possible uses for the wood of the species presented, thus giving them new uses and added value.

EXPERIMENTAL

Materials

Wood

Selected wood species were used in this study: Tree of heaven (Ailanthus altissima), horse chestnut (Aesculus hippocastanum), black locust (Robinia pseudoacacia), honey locust (Gleditsia triacanthos), and box elder maple (Acer negundo). All of these species are on Slovenia’s list of invasive alien species and their presence and spread should be monitored and regulated. The use of this raw material for new products promotes the removal of these species from the natural environment and the expansion of their use. After harvesting, the logs were first processed into boards and planks and then dried in the air and in technical drying chambers (Plavčak et al. 2019; Merela et al. 2020). Slides for microscopy investigation of selected species were prepared according to methodology decribed in Čufar et al. 2022.

Adhesives

Two different types of adhesives were used due to their contrasting curing mechanism: Polyvinyl acetate adhesive (PVAc) and polyurethane adhesive (PU). These two cold-curing adhesives were chosen because of their different curing mechanisms: PVAc cures mainly by removal of water and PU cures by a chemical reaction between the isocyanate groups of the adhesive and the hydroxyl (–OH) groups in wood and water. PVAc adhesive Mekol D3 produced by Mitol Sežana, Slovenia, was used with adhesive viscosity at 23 °C (ISO 2555-Brookfield RVT, spindle 5/20 rpm) 7,000 to 10,000 mPa·s and density 1.05 to 1.15 g/cm3 (manufacturer data). The PU adhesive Mitopur E45, was produced by Mitol Sežana, Slovenia, with viscosity at 23 °C (ISO 2555-Brookfield RVT, spindle 5/20 rpm) 5,500 to 9,000 mPa.s, density 1.1 g/cm3, and solids content 98 to 100%.

Methods

Wood bonding and conditioning

The samples for tensile shear strength of adhesive bonds were prepared and conditioned according to standard method, described in standards SIST EN 205 (2016) and SIST EN 204 (2016).

First, 5 mm thick radially cut wood lamellas were prepared from kiln-dried boards with 8% moisture content. The bonding surface of lamellas was planed with thickness planer. The planer head had been fitted with 4 regular blades and the feed rate was 5 m/min before bonding to ensure a fresh, uncontaminated surface for bonding. With same machine and feed rate, the knife marks of 1.1 mm were measured on the surface (Merhar et al. 2020).The dimensions of the samples (length) were changed from standard requirements (from 120 to 150 mm) in order to obtain as many samples as possible from the available material, but the shear area corresponded to the standard (20 × 10 mm). Common European beech (Fagus sylvatica L.) wood samples were also prepared and glued as control and comparison samples.

The amount of applied adhesive was 180 g/m2. No primer was used before adhesive application. The PU-bonded surfaces were sprayed with water mist before bonding, in accordance with the manufacturer’s recommendations for bonding wood with a moisture content of less than 15%. The lamellas were pressed in a conventional press at room temperature with a pressure of 0.8 N/mm2. The pressing time was 90 min (the adhesive manufacturer recommends a minimum pressing time of 30 min for PVAc and 30 to 45 min for PU).

The glued lamellae were then placed in a conditioning chamber (20 °C, 65% RH) and after one week were cut into test specimens for adhesive shear strength testing. Three different conditioning sequences were used for the samples (numbering according to the standard SIST EN 204 2016):

- Conditioning sequence 1: testing dry samples after 7 days conditioning in standard climate

- Conditioning sequence 3: testing wet samples after 7 days conditioning in standard climate and 4 days soaking in water at room temperature

- Conditioning sequence 4: testing dry samples after 7 days conditioning in standard climate, 4 days soaking in water at room temperature, 7 days conditioning in standard climate.

Fig. 1. Shear strength testing on universal testing machine (left) and visual evaluation of shear area percentage of wood failure after test (right) – outside samples- Robinia pseudoacacia and inner samples -Acer negundo

Determining the bond shear strength and percentage of wood failure

The tensile shear strength test was performed by following the standard procedure (SIST EN 205 2016) on the universal testing machine Z005 (ZwickRoell GmbH, Ulm, Germany). The samples were clamped in a test fixture and the bond was subjected to tensile loading at a test speed of 50 mm/min until breakage occurred.

The bond shear strength was calculated according to Eq. 1,

(1)

where 𝜏 is the bond shear strength (MPa), Fmax the applied maximum force (N), l is the length of the bonded test surface (mm), and b is the width of the bonded test surface (mm). The percentage of wood failure was determined visually with an accuracy of 10%. The results were analysed using Microsoft Excel and the PSPP software.

The bond strength depends on several factors from adhesion between wood and adhesive, adhesive properties, and wood properties (Marra 1992). The properties of the wooden slats have a major influence on the shear strength of the joint. The lamellas used for the tests were made from logs with smaller diameters, so that the lamellas were not ideally cut radially and some of them also showed greater differences in the width of the annual rings, wood defects, and a more heterogeneous wood structure with more tyloses and discolorations (Plavčak et al. 2019).

Microscopic anatomical analyses revealed structure and important vessel elements lumina diameter of selected species (Fig. 2). Early wood vessel diameters are larger and were measured on cross sections. Average tangential vessel diameters were calculated: Robinia pseudoacacia – 175 µm, Acer negundo – 53 µm, Aesculus hippocastanum – 33 µm, Gleditsia triacanthos – 198 µm, Ailanthus altissima – 229 µm, and Fagus sylvatica – 56 µm. Bond shear strength of tested tree species and adhesives for conditioning sequence 1 correlated perfectly with vessel diameters (Fig. 3). Correlation was positive for both the adhesives polyvinyl acetate adhesive (PVAc) and polyurethane adhesive (PU). Correlation was also fine for bond shear strength for conditioning in sequence 4, except in case of Robinia pseudoacacia for PU adhesive. The presence of tyloses in cell lumina may prevent sufficient penetration of PU adhesive into vessel lumina.

Fig. 2. Wood anatomy of analyzed species; rows from top to bottom are cross, radial, and tangential sections. Species from left to right: Robinia pseudoacacia, Acer negundo, Aesculus hippocastanum, Gleditsia triacanthos and Ailanthus altissima

Different wood species also exhibit different machinability and thus surface characteristics (Merhar et al. 2020). The quality of the cut surface (open cell lumina of deformed/damaged tissue) has an effect on wettability, adhesive penetration, mechanical anchoring of the adhesive, and thus on bond strength (Ugulino and Hernández 2017). Due to growth defects in the wood used from smaller diameter logs, there were also some tear-outs in the planing before bonding, which could cause uneven bondline thickness and also reduce the actual contact area. Some species also exhibited greater deformation of the rough- cut lamellas during the conditioning stage prior to planing and bonding, which can lead to slight differences in adhesive layer thickness and also tension in the bonds due to uneven surfaces. The greater thickness of the adhesive layer has a negative effect on the strength of the bonded joint. This could be the reason for higher deviations in some results.

In wood species with a high proportion of low-molecular extractives (e.g., Robinia pseudoacacia), the strength of adhesive bonds depends on the time between mechanical surface preparation and bonding. If this time is too long, then the extractives migrate to the surface, which impairs the quality of the bond or slows the curing of the adhesive (Roffael 2016; Bockel et al. 2018). During the bonding process, the time between surface planing, adhesive application, and pressure application was kept to 30 min to minimize this effect.

Ailanthus altissima bonded with PVAc adhesive showed the highest shear strength of the dry samples (15.1 N/mm2), and the lowest strength was measured for samples of Aesculus hippocastanum (7.5 N/mm2 for PU and 7.2 N/mm2 for PVAc adhesive). There were statistically significant differences (ANOVA, F=34.93, p=0.000) between wood species, except between Gleditsia and beech (average value around 12 N/mm2) (LSD, p=0.532). PVAc adhesives exhibited higher strengths than PU adhesives for all wood species, with the exception of Aesculus hippocastanum, where the higher strength was achieved when bonded with PU adhesive.

The bindings from beech wood served as a reference and had shear strengths of more than 10 N/mm2. Similar or higher strengths are considered “good bonding strength” and are sufficient for use in woodworking. Samples of Robinia, Gleditsia (samples glued with PVAc) and Ailanthus showed similar or even higher strengths and are therefore considered to form quality bonds.

Fig. 3. Bond shear strength of tested tree species and adhesives for conditioning sequence 1 and average vessel diameter of used wood species

For conditioning sequence 3, the samples were soaked in water for 4 days prior to testing. The bonds were exposed to water, which affected the adhesive but also caused wood swelling and thus creating stresses in bonds, which could break some bonds and reduce joint strength. The highest bond shear strength in this case was achieved with Aesculus hippocastanum (5.8 N/mm2) and Gleditsia triacanthos (5.6 N/mm2), both bonded with PU (Fig. 4). Samples bonded with PU showed higher strengths compared to PVAc (with the exception of the Robinia samples), which was to be expected due to the adhesive properties. PU cures by a chemical reaction and is more water resistant than PVAc, which cures by removing water. Gleditsia (PVAc) and Robinia (PU) had the lowest bond shear strength, but still higher than the reference sample of beech. The minimum value for the standard bond strength requirements for conditioning sequence 3 was 2 N/mm2.

Conditioning sequence 4 comprises 7 days conditioning in a normal climate, 4 days soaking in water at room temperature and 7 days conditioning in a normal climate. The minimum value for the adhesive strength in conditioning sequence 4 required by the standard is 8 N/mm2. As the samples are dried after soaking in water, these values are higher than for conditioning sequence 3, but lower than for conditioning sequence 1, as the bonds were exposed to soaking in water and the swelling and shrinkage of wood.

Fig. 4. Bond shear strength of tested tree species and adhesives for conditioning sequence 3

This type of test specimen simulates real-life application situations in which wood joints can be exposed to water and then dried and should retain most of their strength to remain usable. Robinia glued with PVAc had the highest shear strength (12.7 N/mm2) and Robinia glued with PU adhesive had the lowest (3.7 N/mm2). The PVAc adhesives showed higher values than PU adhesives (except Aesculus) (Fig. 5).

Fig. 5. Bond shear strength of tested tree species and adhesives for conditioning sequence 4

The percentage of wood failure (Table 1) shows whether the bonding failed due to poor adhesion problems (0% wood failure) or whether the bonding was successful, and the strength of the bond is higher than the strength of the wood – in which case the fracture occurs in the wood (100% wood failure). To evaluate the quality of the bonding, both the shear strength and the percentage of wood failure should be considered. For example, Aesculus hippocastanum showed lower shear strengths (7.2 and 7.5 N/mm2), but the percentage of wood failure was 100%. This indicates that the bonding was good, the bond strength was higher than the wood strength, and the fracture occurred in the wood material. However, the strength of wood (compared to other wood species) was lower and so was the strength of the bond.

Table 1. Percentage of Wood Failure of Tested Tree Species and Adhesives for Different Conditioning Sequences

In Robinia, Gleditsia and Ailanthus, the percentage of wood failure in PU was significantly lower, but the standard deviation of these values was high (Table 1). This could indicate poorer bonding, but due to the high bond strengths, it is probably due to thicker or unevenly thick bonds (the lamellae were not perfectly radially cut and twisted during conditioning prior to bonding and therefore could not be perfectly planned) or even to extractives in the wood affecting the curing of the adhesive. Some tear out also occurred during the planning of these timbers and in this case the glued surface was not perfect.

The percentage of wood failure in wet samples was almost 0% for all samples (Table 1), except for Aesculus hippocastanum (22%), which means that the bonds in the adhesive failed. The stresses caused by the moisture penetration of the wood and the resulting swelling affect the adhesive joints, which fail during loading.

There were higher differences in percentage of wood failure together with high standard deviations for most of the tested groups (Table 1). The percentages of wood failure were as expected higher after conditioning sequence 3 and lower after conditioning sequence 1.

Comparing the bond strength of wet (conditioning sequence 3) and dry (conditioning sequence 1) samples (Fig. 6), the bonds lost more than 2/3 of their strength after soaking in water, with the exception of Aesculus and Gleditsia, which lost only 23% and 31% of their dry strength, respectively. A smaller decrease in strength was found by PU adhesive (except for Robinia), which was expected due to the adhesive properties (chemical reaction). The resulting bonds should be more water resistant than those prepared with PVAc, which cures by removing solvents (mainly water).

Fig. 6. Strength comparison: wet samples (preparation 3) vs dry samples (preparation 1)

The shear strength of the bond depends to a large extent on the wood properties, especially the density, which is strongly correlated with the mechanical properties of the wood. The densities of the tested wood species varied considerably (see Table 2), from 479 kg/m3 (Aesculus hippocastanum) to 702 kg/m3 (Gleditsia triacanthos – heartwood).

Table 2. Average Wood Density, Standard Deviation in Brackets

Wood species with lower wood densities were found to have lower bond strengths (Fig. 7). The bond strength increased with increasing density up to around 600 kg/m3, after which it no longer increased. The reason for this could lie in the penetration of the adhesive, which is lower at higher densities. Robinia and Gleditsia with higher densities also had the lowest porosity and therefore probably lower penetration.

Fig. 7. Bond shear strength vs wood species density

The bond strength also depends on the strength of the wood. If there is a high percentage of wood failure, the measured shear strength is actually the shear strength of the wood, since the fracture occurs in the wood tissue. The shear strength of the bond increases with the wood shear strength (Fig. 8), only Gleditsia falls out of the trend – but these samples also show less wood failure (PU 42%, and PVAc at 88%).

The anatomical aspects of wood that affect its porosity are complicated and have a major impact on adhesive performance. Porosity can have both positive and negative effects on adhesive performance (Frihart 2016). The cell lumina allow rapid flow of a liquid adhesive into the large early wood lumina in softwoods and vascular elements in hardwoods, which improves the mechanical interlocking of the adhesive, but excessive flow of the adhesive into the wood lumina pulls the adhesive away from the glue line; this can lead to inadequate bonding of the two surfaces and a starved glue line. Cell wall porosity effects adhesive infiltration in cell walls. Lower molecular weight and polar components of adhesives can infiltrate the cell wall structure and affect wood behaviour when exposed to moisture and thus also effect on bond strengths. The reduced swelling of wood will lower the strain at the interface due to wood swelling; thus, less force is applied to the adhesive at the interface.

Fig. 8. Bond shear strength vs wood shear strength (tan direction)

Fig. 9. Bond shear strength vs wood porosity

The penetration of adhesive into the wood can be divided into two groups: gross penetration and cell wall penetration. In the case of gross penetration, the liquid adhesive flows into the porous structure of the wood and mainly fills the cell lumina (Ülker 2016). Hydrodynamic flow and capillary action could be explained as gross penetration. Cell-wall penetration occurs when adhesive diffuses into the cell wall or flows into micro fissures. In wood, the least resistance to hydrodynamic flow is in the longitudinal direction, following the lumens in the long and slender tracheid of softwood, or through the vessels of hardwoods. Since vessels are connected end-to-end with perforation plates and there is no pit membrane, this cell type dominates the penetration of adhesives in hardwoods. All of the potential adhesion mechanisms (mechanical interlocking, covalent bonding, secondary chemical bonds, etc.) are influenced by penetration. Since all the tested species were hardwood species, the penetration depended mainly on their cell sizes and the orientation of their bonding lamellas.

The values of bond shear strength are comparable to values obtained with previous research. For example, Robinia PU bonds in our research showed 9.6 N/mm2, whereas Konnerth et al. (2016) determined 11.7 N/mm2; Jauernig (1997) determined 10.5 N/mm2, and Voulgaridis et al. (2012) reported 13.3 N/mm2. For Ailanthus PU bonds the present research showed 11 N/mm2, which is very similar to 10.4 N/mm2 of Brandner and Schickhofer (2010). In addition, the Ailanthus PVAc bonds were 15 N/mm2, while Panayotov et al. (2011) determined it to be 13.1 N/mm2.

All species showed quite good bonding as well as good adhesive strength for dry samples. The lowest strength was observed for Aesculus, but this was to be expected due to its lower density (Gorišek et al. 2019; Merhar et al. 2020). For bonding wood that is exposed to wetting by water, PU adhesive is more recommendable, as higher strength values were obtained than with PVAc. Aesculus showed quite high strength values for bonding with PU, which was not expected, and further tests should be carried out to investigate the reason for this.

Particular attention should also be paid to the homogeneity of the wood properties of invasive species. The wood lamellae were not perfectly uniform in density and showed several growth defects. This led to higher variability and higher standard deviations. Also, some results showed “unexplained” results. For example, the strength of some samples after conditioning sequence 4 showed higher values than the samples after conditioning sequence 1 (for example Robinia glued with PVAc). Further tests should be carried out with more samples to verify these results.

- All tested wood species obtained from selected alien invasive species showed quite good adhesion in dry samples. The lowest adhesive strength was measured for Aesculus hippocastanum, which also had the lowest wood density as well as the smallest vessel diameter. Samples of Ailanthus altissima had the highest adhesive strength, although Robinia pseudoacacia and Gleditsia triacanthos had a higher wood density. It is assumed that the main reason for this is the biggest cell lumina were detected for Ailanthus altissima. PVAc adhesives showed higher strengths than PU adhesives for all wood species, with the exception of Aesculus hippocastanum, where the highest strength was achieved with PU adhesives. This finding is also related to big vessel lumina. Generally, bond shear strength corelated well with vessel lumina diameter. Species with larger vessels had significantly greater bond strength.

- After soaking in water for 4 days (conditioning sequence 3), the highest bond shear strength was shown by Aesculus hippocastanum and Gleditsia triacanthos (species with biggest vessel diameters), both bonded with PU, which lost 23 to 31% on initial dry strength, compared to the rest of the specimens, which lost around 60% of its initial strength. A lower decrease in strength after this treatment was noticed for PU adhesives (except for Robinia), which was expected due to adhesive properties. The highest bond strength after conditioning sequence 4 (7 days conditioning in standard climate, 4 days soaking in water at room temperature and 7 days conditioning in standard climate) was exhibited by Robinia bonded with PVAc and the lowest was by Robinia bonded with PU adhesive. This phenomenon was attributed to the presence of tyloses in vessel lumina, which hindered adequate penetration of the adhesive. The PVAc adhesive bonds showed higher values than PU (except Aesculus) for this treatment.

- Wood of alien invasive species is usually cut down before the trees reach a log dimension suitable for industrial processing. Because of the fast growth, growth conditions that are not optimal, and that people often cut and prune these trees, the wood of invasive species often includes many growth defects, greater differences in the width of the annual rings, and a high variability of material properties. In this study, issues were observed, which is why the results showed high deviations. The selected wood species showed relatively good gluing properties, but the higher variability of material properties and consequently the high variability of bond strengths should be considered when developing products made of wood from alien invasive species.

ACKNOWLEDGMENTS

The authors acknowledge the financial support of the Slovenian Research and Innovation Agency within the programs P4-0015 and P4-0430 and project J4-50131, as well as project Applause (UIA02-228) co-financed by the European Regional Development Fund through the Urban Innovative Actions Initiative.

REFERENCES CITED

Bockel, S., Mayer, I., Konnerth, J., Niemz, P., Swaboda, C., Beyer, M., Harling, S., Weiland, G., Bieri, N., and Pichelin, F. (2018). “Influence of wood extractives on two-component polyurethane adhesive for structural hardwood bonding,” J. Adhes. 94 (10), 829-845. DOI: 10.1080/00218464.2017.1389279

Brandner, R., and Schickhofer, G. (2010). “Tree-of-Heaven (Ailanthus altissima): Enormous and wide potential neglected by the Western civilisation,” 11th World Conf. Timber Eng. 2010, WCTE 2010, 2 (January 2010), 1576-1582.

Burdurlu, E., Usta I., Kiliç Y., and Ulupinar, M. (2007). “The effect on shear strength of different surfacing techniques in oriental beech (Fagus orientalis Lipsky) and scotch pine (Pinus sylvestris L.) bonded joints,” J. Adhes. Sci. Technol. 21 (3-4), 319-330. DOI: 10.1163/156856107780684611

Čufar, K., Beeckman H., Frelih M., Krže L., Hubau W., and Merela M. (2022). “Wood identification in objects of Bambuti people from the Congo in the collection of the Slovene ethnographic museum,” Wood. 71(2), 5-24. DOI: 10.26614/les-wood.2022.v71n02a04

European Commission (2014). Invasive Alien Species: a European Response, Publications Office of the European Union, Luxembourg.

Follrich, J., O. Vay, S. Veigel, and U. Müller. (2010). “Bond strength of end-grain joints and its dependence on surface roughness and adhesive spread,” J. Wood Sci. 56(5), 429-434. DOI: 10.1007/S10086-010-1118-1/METRICS.

Frihart, C. R. (2009). “Adhesive groups and how they relate to the durability of bonded wood,” J. Adhes. Sci. Technol. 23(4), 601-617. DOI: 10.1163/156856108X379137

Frihart, C. R. (2016). “Adhesive penetration of wood and its effect on bond strength,” in: 39th Annu. Meet. Adhes. Soc., San Antonio, Texas.

Gorišek, Ž., Merela M., Straže A., Krže L., Planinšič J., Čufar K., and Plavčak (2019). “Laboratory analysis of suitability for processing into wood product for 17 woody IAPS: physical-mechanical properties & drying characteristics,” Ljubljana: UIA02-228 APPLAUSE.

Holeček, T., A. Sikora, P. Šedivka, D. Cvejn, D. Sládek, J. Bárta, and R. Lagaňa. (2023). “Novel hybrid polymer adhesives for laminated materials based on hardwood.” Compos. Struct. 308, article 116684. DOI: 10.1016/J.COMPSTRUCT.2023.116684

Iždinský, J., Reinprecht L., Sedliačik J., Kúdela J., and Kučerová, V. (2020). “Bonding of selected hardwoods with PVAc adhesive,” Applied Sci. 11(1), article 67. DOI: 10.3390/app11010067

Jauernig, H. (1997). “Untersuchungen über die Verklebung von Robinie bei höheren Holzfeuchten,” Diplom Holzwirt, Fachbereich Biologie der Universität Hamburg.

Kamke, F. A., and Lee, J. N. (2007). “Adhesive penetration in wood—A review,” Wood and Fiber Science 39(2), 205-220.

Konnerth, J., Kluge M., Schweizer G., Miljković M., and Gindl-Altmutter, W. (2016). “Survey of selected adhesive bonding properties of nine European softwood and hardwood species,” Eur. J. Wood Wood Prod. 74(6), 809-819. DOI: 10.1007/s00107-016-1087-1.

Kumar Rai, P., and Singh, J. S. (2020). “Invasive alien plant species: Their impact on environment, ecosystem services and human health,” Ecol. Indic. 111, article 106020. DOI: 10.1016/J.ECOLIND.2019.106020.

Marra, A. (1992). Technology of Wood Bonding: Principles in Practice, Van Nostrand Reinhold, New York.

Medved, S., Tomec, D. K., Balzano, A., and Merela, M. (2020). “Alien wood species as a resource for wood-plastic composites,” Appl. Sci.11 (1), 1-16. DOI: 10.3390/APP11010044.

Merela, M., Thaler, N., Balzano, A., and Plavčak, D. (2020)). “Optimal surface preparation for wood anatomy research of invasive species by scanning electron microscopy,” Drv. Ind. 71(2), 117-127. DOI: 10.5552/drvind.2020.1958

Merhar, M., D. Gornik Bučar, and Merela. M. (2020). “Machinability research of the most common invasive tree species in Slovenia,” Forests 11(7), 752. DOI: 10.3390/f11070752

Panayotov, P., Kalmukov K., and Panayotov, M. (2011). “Biological and wood properties of Ailanthus altissima (Mill.) Swingle,” Forestry ideas 17(2), 122-130.

Plavčak, D., Gorišek, Ž., Straže, A., and Merela, M. (2019). “Drying characteristics of wood of invasive tree species growing in an urban environment,” Les/Wood 68(2), 31-43. DOI: 10.26614/les-wood.2019.v68n02a03

Regulation (EU) no 1143/2014 of the European parliament and of the council of 22 October 2014 on the prevention and management of the introduction and spread of invasive alien species. (2014). Official Journal of the European Union, L317/35. https://eur-lex.europa.eu/eli/reg/2014/1143/oj

Richardson, D. M., Pyšek, P., Rejmánek, M., Barbour, M. G., Dane Panetta, F., and West, C. J. (2000). “Naturalization and invasion of alien plants: Concepts and definitions,” Divers. Distrib. 6(2), 93-107. DOI: 10.1046/j.1472-4642.2000.00083.x

Roffael, E. (2016). “Significance of wood extractives for wood bonding,” Appl. Microbiol. Biotechnol. 100(4), 1589-1596. DOI: 10.1007/s00253-015-7207-8

SIST EN 204 (2016). “Classification of thermoplastic wood adhesives for non-structural applications,” European Committee for Standardization, Brussels, Belgium.

SIST EN 205 (2016). “Adhesives – Wood adhesives for non-structural applications – Determination of tensile shear strength of lap joints,” European Committee for Standardization, Brussels, Belgium.

Stokke, D., and Groom, L. (2008). “Characterization of the cellulosic cell wall,”

Terzopoulou, P., V. Kamperidou, and I. Barboutis. (2023). “Utilization potential of tree-of-heaven species biomass—A review,” Appl. Sci. 13(16), article 9185. Multidisciplinary Digital Publishing Institute. DOI: 10.3390/APP13169185.

Tiryaki, S., Bardak, S., and Bardak, T. (2015). “Experimental investigation and prediction of bonding strength of Oriental beech (Fagus orientalis Lipsky) bonded with polyvinyl acetate adhesive,” Journal of Adhesion Science and Technology 29 (23), 2521-2536. DOI: 10.1080/01694243.2015.1072989

Ugulino, B., and Hernández, R. E. (2017). “Assessment of surface properties and solvent-borne coating performance of red oak wood produced by peripheral planing,” Eur. J. Wood Wood Prod. 75(4), 581-593. DOI: 10.1007/S00107-016-1090-6

Ülker, O. (2016). “Wood adhesives and bonding theory,” in: Adhesives – Applications and Properties, A. Rudawska (ed.), IntechOpen. DOI: 10.5772/65759

Vasiliki, K., and Ioannis, B. (2017). “Bondability of black locust (Robinia pseudoacacia) and beech wood (Fagus sylvatica) with polyvinyl acetate and polyurethane adhesives,” Cienc. y Tecnol. 19(1), 87-94. DOI: 10.4067/S0718-221X2017005000008

Voulgaridis, E., Passialis, C., Negri, M., Michele, All S., and Stergios Adamopoulos, I. (2012). “Shear bond strength of black locust wood glued with three adhesive systems,” Wood Res. 57(3), 489-496.

Article submitted: February 20, 2024; Peer review completed: March 9, 2024; Revised version received and accepted: March 18, 2024; Published: March 28, 2024.

DOI: 10.15376/biores.19.2.3078-3094