Abstract

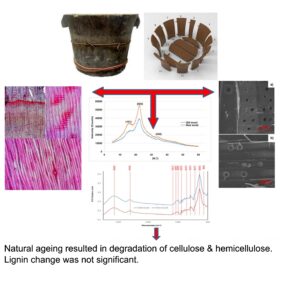

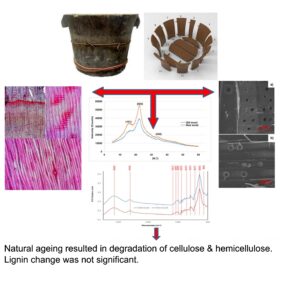

This study presents the results of a comprehensive investigation of a wooden rice bucket made in the 1860s. Macroscopy aspects and microscopic structure were conducted to identify the wood species. X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM) were also adopted to investigate the degradation degree of the rice bucket compared with a new wood sample from the same species. The results of the microscopic identification concluded that the rice bucket was made of Chinese fir (Cunninghamia lanceolata). The XRD pattern indicated that the crystallinity degree of cellulose in the wooden rice bucket decreased to 33.2% from 38.8% (new wood). The FTIR spectra revealed that natural ageing resulted in the degradation of cellulose and hemicellulose, and the change of lignin was not obvious.

Download PDF

Full Article

Characterization and Identification of Wooden Rice Bucket Made in 1860s

Xin Wei Tu,a,b Xin You Liu,a,b,c,* and Anca Maria Varodi c,*

This study presents the results of a comprehensive investigation of a wooden rice bucket made in the 1860s. Macroscopy aspects and microscopic structure were conducted to identify the wood species. X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM) were also adopted to investigate the degradation degree of the rice bucket compared with a new wood sample from the same species. The results of the microscopic identification concluded that the rice bucket was made of Chinese fir (Cunninghamia lanceolata). The XRD pattern indicated that the crystallinity degree of cellulose in the wooden rice bucket decreased to 33.2% from 38.8% (new wood). The FTIR spectra revealed that natural ageing resulted in the degradation of cellulose and hemicellulose, and the change of lignin was not obvious.

DOI: 10.15376/biores.17.4.6511-6520

Keywords: FTIR; Microscopy; Natural ageing; Old wood; SEM; XRD

Contact information: a: Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, Str. Longpan No. 159, Nanjing, China; b: College of Furnishing and Industrial Design, Nanjing Forestry University, Str. Longpan No. 159, Nanjing, China; c: The Faculty of Furniture Design and Wood Engineering, Transylvania University of Brasov, Str. Universității, No. 1, Brasov, Romania;

* Corresponding author: liu.xinyou@njfu.edu.cn; anca.varodi@unitbv.ro

GRAPHICAL ABSTRACT

INTRODUCTION

Wood is one of the earliest materials used by human beings, carrying the civilization of human development (Popescu et al. 2009; Ganne-Chédeville et al. 2012; Pop et al. 2020; Sun et al. 2022). Wood culture is deeply rooted in the soul and is one of the most representative cultural heritages in ancient China, transmitted through generations (Xie et al. 2015; Liu et al. 2019; Yin and Liu 2021). In ancient China, most furniture, houses, and tableware were made of wood (Qu et al. 2019; Sun et al. 2022), and wooden objects from ancient civilizations were considered precious and needed careful storage and study, as they were susceptible to fungi, bacteria, insects, and also different physical agents (Popescu et al. 2007; Fabri 2012; Popescu et al. 2013; Pop et al. 2020). It is also important to learn and study the manufacturing technique of these special old objects. With the enhancement of people’s awareness of the protection of historical relics, the restoration of ancient wood products has become necessary. One of the most important principles in the restoration process is to replace degraded wood with new wood from the same species, when it is necessary (Timar et al. 2012; Tamburini et al. 2014). To complete effective antiquation treatment of fresh wood, it is essential to understand the evolution of chemical composition of wood structure during natural ageing (Colombini et al. 2009; Zhao et al. 2019).

In recent decades, the study of archaeological and aged wood has attracted extensive attention (Popescu et al. 2005, 2006). Wood undergoes a certain continuous degradation process in the environment over time (through simultaneous biological, chemical, or physical attacks). The degradation process causes damage in the old wood structure and its mechanical properties and thus results in the loss of wood heritage. Some researchers (Chen and Guo 2016, 2017) evaluated the mechanical properties of ancient wood in an old temple with nondestructive testing methods and the results indicated that there were significant linear correlations between the variant resistance and wood density. Li et al. (2019) also reported a significant correlation between micro-drilling resistance and wood density. Outdoor natural ageing is more aggressive and can be considered an important means to study the effects of different ageing factors on wood properties. It is well known that moisture is one of the most important factors that affect outdoor wood degradation (Timar and Beldean 2006; Friedrich 2018; Aydın and Aydın 2020). Natural ageing reduces wood thermal resistance, caused by a decrease in holocellulose content (Zachar et al. 2021). Popescu studied ancient wood with different natural ageing time using different physical-chemical methods, such as Fourier transform infrared (FTIR) spectroscopy, X-ray diffraction (XRD), and X-ray photoelectron spectroscopy (XPS), and the results showed that with the increase of ageing specimens, the carbonyl groups of wood gradually decreased, and the proportion of lignin increased. This is due to the degradation of hemicellulose, which was mainly manifested in the decomposition of polyxylan (Popescu et al. 2006, 2007, 2009, and 2013).

Decay mechanisms related to wood fungi, such as brown rot, soft rot (Ascomycetes), and white rot (Basidiomycetes), has a specific type of wood damage via decomposing cellulose, hemicelluloses, and also lignin (Broda and Mazela 2016; Pop et al. 2020). This kind of degradation can be observed at the chemical and microscopic level and also at the macroscopic level (Fackler and Schwanninger 2012; Brischke et al. 2014; Walsh-Korb and Avérous 2019).

This work aimed to analyze the material characteristics of an old wooden tableware (rice bucket). Microscopic investigation was used to identify the wood species. Various analyses including FTIR, XRD, and scanning electron microscopy (SEM) were employed to determine the difference between new wood and ancient/old wood. These works provide valuable guidelines for understanding wood natural ageing to provide artificial aged wood for restoration in replacing the destroyed pieces/wooden objects lost in ancient China.

EXPERIMENTAL

Materials

In this study, approximately 160-year-old wood samples were taken from an old rice bucket obtained from a Chinese antiques collector in Ningbo City, China. This object had been stored indoors without sunlight exposure, where the environment conditions were not monitored as is required for this type of old artifact (Fig. 1a).

The rice bucket was an important wooden tableware, widely used in southern China. The profile of the bucket is surrounded by 11 vertical plates linked with 24 pieces of possible bamboo sticks (Fig. 1c). The upper diameter is 270 mm, the lower diameter is 200 mm, and the height is 164 mm. There are two handles protruding 40 mm at 110 mm height. The bottom of the bucket is on a side panel inlaid with six boards.

The initial moisture content was 12.2 ± 1.7% (measured in line with GB/T 1931 (2009) standard), which is consistent with the indoor storage condition.

After surface cleaning (Fig. 1b), three small wooden samples coded P1 through P3 were extracted from hidden areas of different plates, from the bottom of the rice bucket, where the degradation appeared to be more intense.

Fig. 1. Case study: rice bucket made of Chinese fir (Cunninghamia lanceolata) wood: a. general initial aspect; b. inside view of the initial conservation state of wood material due to degradation after cleaning; c. schematics appearance of the hypothetical dismantling rice bucket of the same type.

Methods

Microscopic identification

For better identification of the wooden species, macroscopic characteristics of samples were detected under a 10x magnifying glass. It can be observed that the samples have well delimited annual rings, and a narrow band of late wood, with a light yellow brown color. It can be concluded that this wood should belong to softwood.

To plasticize the extracted samples, they were boiled in distilled water for approximately 6 h until the sample sank into the water. The sample was then transferred to a mixture of glycerin and ethanol (1:4) for preservation. The plasticized samples were sliced into 30 μm slices in transversal, radial, and tangential sections with a microtome. To increase the contrast of the microscopic image, the slices are stained in with safranine and washed with water prior to observation. The thin, stained, transparent slices were observed in transmitted light at different magnifications (40 to 100x) under an optical microscope Zeiss Axio Scope A1 microscope (Carl Zeiss AG, Oberkochen, Germany) fitted with software of AxioVision Rel.4.8 (Carl Zeiss AG, Oberkochen, Germany).

X-ray diffraction

Based on the results of microscopic identification, new wood of uniform species was prepared to compare the crystallinity degree of cellulose in the old wood samples. The new wood and the old wood were dried and ground into 80-mesh powder. A total of 10 samples (5 new wooden samples and 5 old wooden samples from P1 through P3) were pressed into thin slices at room temperature. The XRD spectra of these wood samples were obtained by in situ XRD using the X‘Pert Pro Multipurpose Diffractometer (PANalytical, Almelo, Netherlands) equipped with a Rigaku Smart Lab 9kWXRD system (Shimadzu Corporation, Kyoto, Japan). The function of scattering intensity and scattering angle was measured by θ-2θ scanning. The intensity was measured as a function of the scattering angle 2θ with a θ-2θ scan. The angle range was 5 to 60° and the scanning speed was 2°/min. The spectra presented are averages of 5 measurements for both new wood and old wood. According the Segal method, a degree crystallinity of cellulose was determined with the height of the (002) peak (I002, 2θ = 22.8°), and the minimum between the (002) and (101) peaks (IAM, 2θ = 18°) using the following equation,

(1)

where CRx (%) stands for degree crystallinity of cellulose, I200 represents both crystalline and amorphous material, and IAM represents only amorphous material.

Chemical structure analysis

The FTIR spectra were obtained for both new and old wood samples under direct transmittance with the standard FTIR spectrometer (Tensor 27, Bruker, Ettlingen, Germany) within the 700 to 4000 cm−1 range at a 4.0 cm−1 resolution for altogether 32 scans. After aligning the light equipment, the authors collected background spectra before measurement. The spectra presented are averages of six measurements for each wood samples.

Morphological characteristics

To investigate physical structures for inspecting the possible changes of physical aspects of new and old wood samples, this work employed the environmental SEM (Quanta 200, FEI Company, Eindhoven, Netherlands) to observe the surface shapes of wood specimens by measuring electrical conductivity. Wood samples were prepared by applying a sputter gold coating (2 nm) using Gold Palladium SEM Annular Sputtering by adopting the target 2″ ID × 3″ OD × 0.1 mm Anatech (SC502-314; Quorum Technologies, Ltd., Watford, UK). The bombarding voltage used for SEM was 20.0 kV.

RESULTS AND DISCUSSION

Microscopic Identification

Wood species identification was based on the wood microscopic identification keys. The investigated samples appear to be coniferous species, with delimited annual rings and a slightly wavy contour characteristic, which is an important feature of the Cunninghamia species (Fig. 2a). The tracheid dimensions of early wood are larger than those of late wood and were measured on radial direction. The obtained results, 21 to 34.6 to 52.4 μm in the earlywood and 6.8 to 16.2 to 24.6 μm in the latewood are complying with usual limits mentioned by literature for fir species (Sun et al. 2020; Wagenführ and Wagenführ 2021). Moreover, no resinous channels were observed. The tangential section (Fig. 2b) shows that the rays of the investigated sample are mainly single row rays composed of 4 to 12 cells, and occasionally there are spindle-shaped rays.

The micrograph (Fig. 2c) of the investigated sample on the radial section shows that tracheids did not show any helical thickenings and their bordered pits are aligned in single rows. The cross field pitting was visible on the radial sections, which refers to the type of pits characteristic from communication between rays and axial tracheids. Combining the information of the microscopic images with the information of the macroscopic aspects and origin of the wooden rice bucket, the wood species was Chinese fir (Cunninghamia lanceolata).

Fig. 2. Micrographs of investigated sample in transversal (a), tangential (b), and radial (c) sections

X-ray Diffraction

Cellulose is the skeleton material of the wood cell wall, which is divided into crystalline zones and non-crystalline zones. Crystallinity of cellulose refers to the percentage of crystalline regions in cellulose microfilaments with crystalline and amorphous regions. X-ray diffractometer is commonly used for measuring the crystallinity of wood cellulose. Figure 3 shows that there are three diffraction peaks at 2θ of 18°, 22.5°, and 35°, corresponding to (101), (002), and (040) crystal planes, respectively. There is a maximum diffraction peak of (002) near 2θ = 22.8°, and an extremely small value near 2θ = 18°. The intensity of diffraction peaks for old (naturally aged) Chinese fir is considerably decreased, which is due to the major loss of hemicellulose and also loss of cellulose. According to Eq. 1 the calculated degree crystallinity of cellulose for old wood is 33.2%, and for new wood 38.8%, value which is in accordance with literature (Sun et al. 2020). The crystallinity of ancient wood decreases, which is due to the loss of cellulose, which leads to reduced crystallinity (Popescu et al. 2006).

Fig. 3. X-ray diffraction pattern of old and new Chinese fir

FTIR Analysis

As shown in Fig. 4, in the band of 3400 cm−1 corresponding to the stretching vibration of hydroxyl (-OH) (Song et al. 2017; Yang 2021), the spectrum of old wood decreased slightly, indicating that dehydration occurred during the natural ageing process. The FTIR peak at 1735 cm−1 was due to the C=O tensile vibration of xylan. The ancient wood samples do not show an absorption peak near 1735 cm−1, which belonged to the stretching vibration of the carbon-oxygen double bond of xylan acetyl group (CH3C=O) (Sharma et al. 2019), indicating that the hemicellulose and cellulose content in the ancient wood samples was low.

The stretching vibration of the conjugated carbonyl group at 1602 cm−1 on the side chain of the structural unit showed that the characteristic peak of naturally aged Chinese fir was still evident, meaning that lignin was only slightly degraded, which is in correlation with previous literature (Zhao et al. 2019).

Fig. 4. FTIR spectra for old and new Chinese fire wood

Morphology

To assess potential changes in physical structure due to natural ageing, a SEM micrograph was used to see the difference of wood samples, as shown in Fig. 5. Compared with new wood, most of the pits in the old wood were broken, while those pits in the new wood were intact. It is possible that the degradation of cellulose in the cell wall weakened the strength of the pits and caused them to break (Sun et al. 2022).

Fig. 5. SEM micrographs of old and new wood samples at 1400X magnification (a. old wood, b. new wood)

CONCLUSIONS

- The species was identified as Chinese fir (Cunninghamia lanceolata) by microscopic identification, indicating that Cunninghamia lanceolata can be used as an important wood for wooden tableware by Chinese people in the Yangtze River Basin.

- Compared with the new wood, after 160 years of natural ageing, the degree crystallinity of cellulose of the old Chinese fir decreased from 38.8% to 33.2%.

- Differences in FTIR spectroscopy indicated that chemical changes occurred during natural ageing, likely the deacetylation of hemicellulose.

- A comparison of the morphological characteristics of old and new wood samples revealed that most pits are broken during the process of natural ageing, caused by the deacetylation of hemicellulose and cellulose.

ACKNOWLEDGMENTS

This work was supported by the Universities philosophy and Social Science research project of Jiangsu Province (Grant No. 2021SJA0133), the Nanjing Forestry University Foundation for Basic Research (Grant No. 163104127), the National Key R&D Program of China (Grant No. 2016YFD0600704), and the Priority Academic Program Development (PAPD) of Jiangsu Province, and the China Scholarship Council (CSC) scholarship.

REFERENCES CITED

Aydın, M., and Aydın, T. Y. (2020). “Moisture dependent elastic properties of naturally aged black pine wood,” Construction and Building Materials 262, article ID 120752. DOI: 10.1016/j.conbuildmat.2020.120752

Brischke, C., Welzbacher, C. R., Gellerich, A., Bollmus, S., Humar, M., Plaschkies, K., Scheiding, W., Alfredsen, G., Van Acker, J., and De Windt, I. (2014). “Wood natural durability testing under laboratory conditions: Results from a round-robin test,” European Journal of Wood and Wood Products 72, 129-133. DOI: 10.1007/s00107-013-0764-6

Broda, M., and Mazela, B. (2016). “Cultural heritage – Research into innovative solutions and methods for historic wood conservation,” in: Proceedings of the 47th IRG Annual Meeting, Lisbon, Portugal, pp. 1-14.

Chen, Y., and Guo, W. (2016). “Mechanical properties evaluation of two wood species of ancient timber structure with nondestructive testing methods,” BioResources 11(3), 6600-6612. DOI: 10.15376/biores.11.3.6600-6612

Chen, Y., and Guo, W. (2017). “Nondestructive evaluation and reliability analysis for determining the mechanical properties of old wood of ancient timber structure,” BioResources 12(2), 2310-2325. DOI: 10.15376/biores.12.2.2310-2325

Colombini, M. P., Lucejko, J. J., Modugno, F., Orlandi, M., Tolppa, E. L., and Zoia, L. (2009). “A multi-analytical study of degradation of lignin in archaeological waterlogged wood,” Talanta 80(1), 61-70. DOI: 10.1016/j.talanta.2009.06.024

Fabri, B. (2012). “Wood artefacts,” in: Science and Conservation for Museum Collections, B. Fabbri (ed.), Nardini Editore, Firenze, Italy, pp. 293-320.

Fackler, K., and Schwanninger, M. (2012). “How spectroscopy and microspectroscopy of degraded wood contribute to understand fungal wood decay,” Applied Microbiology and Biotechnology 96, 587-599. DOI: 10.1007/s00253-012-4369-5

Friedrich, D. (2018). “Comparative study on artificial and natural weathering of wood-polymer compounds: A comprehensive literature review,” Case Studies in Construction Materials 9, Article ID e00196. DOI: 10.1016/j.cscm.2018.e00196

Ganne-Chédeville, C., Jääskeläinen, A. S., Froidevaux, J., Hughes, M., and Navi, P. (2012). “Natural and artificial ageing of spruce wood as observed by FTIR-ATR and UVRR spectroscopy,” Holzforschung 66(2), 163-170. DOI: 10.1515/HF.2011.148

GB/T 1931 (2009). “Wood moisture content measuring method – Wood-determination of moisture content for physical and mechanical test,” Standardization Administration of China, Beijing, China.

Liu, X. Y., Timar, M. C., and Varodi, A. M. (2019). “A comparative study on the artificial UV and natural ageing of beeswax and Chinese wax and influence of wax finishing on the ageing of Chinese Ash (Fraxinus mandshurica) wood surfaces,” Journal of Photochemistry and Photobiology B: Biology 201, article ID 111607. DOI: 10.1016/j.jphotobiol.2019.111607

Pop, D. M., Timar, M. C., Beldean, E. C., and Varodi, A. M. (2020). “Combined testing approach to evaluate the antifungal efficiency of clove (Eugenia caryophyllata) essential oil for potential application in wood conservation,” BioResources 15(4), 9474-9489. DOI: 10.15376/biores.15.4.9474-9489

Popescu, C. M., Sakata, Y., Popescu, M. C., Osaka, A., and Vasile, C. (2005). “Degradation of lime wood painting supports,” E-Preservation Science 2, 19-29.

Popescu, C., Vasile, C., Popescu, M., Singurel, G., Popa, V. I., and Munteanu, B. S. (2006). “Analytical methods for lignin characterization. II. Spectroscopic studies,” Cellulose Chemistry and Technology 40(8), 597-622.

Popescu, C. M., Dobele, G., Rossinskaja, G., Dizhbite, T., and Vasile, C. (2007). “Degradation of lime wood painting supports: Evaluation of changes in the structure of aged lime wood by different physico-chemical methods,” Journal of Analytical and Applied Pyrolysis 79(1-2), 71-77. DOI: 10.1016/j.jaap.2006.12.014

Popescu, C. M., Tibirna, C. M., and Vasile, C. (2009). “XPS characterization of naturally aged wood,” Applied Surface Science 256(5), 1355-1360. DOI: 10.1016/j.apsusc.2009.08.087

Popescu, C. M., and Hill, C. A. (2013). “The water vapour adsorption–desorption behaviour of naturally aged Tilia cordata Mill. wood,” Polymer Degradation and Stability 98(9), 1804-1813. DOI: 10.1016/j.polymdegradstab.2013.05.021

Qu, L., Wang, Z., Qian, J., He, Z., and Yi, S. (2019). “Effect of combined aluminum-silicon synergistic impregnation and heat treatment on the thermal stability, chemical components, and morphology of wood,” BioResources 14(1), 349-362. DOI: 10.15376/biores.14.1.349-362

Sharma, P. R., Sharma, S. K., Antoine, R., and Hsiao, B. S. (2019). “Efficient removal of arsenic using zinc oxide nanocrystal-decorated regenerated microfibrillated cellulose scaffolds,” ACS Sustainable Chemistry & Engineering 7(6), 6140-6151. DOI: 10.1021/acssuschemeng.8b06356

Song, P., Xu, Z., Dargusch, M. S., Chen, Z. G., Wang, H., and Guo, Q. (2017). “Granular nanostructure: A facile biomimetic strategy for the design of supertough polymeric materials with high ductility and strength,” Advanced Materials 29(46), article ID 1704661. DOI: 10.1002/adma.201704661

Sun, H., Jia, R., Wu, Y-H., Zhou, L., Liu, S-Q., and Wang, Y-R. (2020). “Rapid detection of microstructural characteristics of heartwood and sapwood of Chinese fir clones,” Spectroscopy and Spectral Analysis 40(1), 184-188.

Sun, G. R., He, Y. R., and Wu, Z. H. (2022). “Effects of thermal treatment on the dimensional stability and chemical constituents of new and aged camphorwood,” BioResources 17(3), 4186-4195. DOI: 10.15376/biores.17.3.4186-4195

Tamburini, D., Łucejko, J. J., Modugno, F., and Colombini, M. P. (2014). “Characterisation of archaeological waterlogged wood from herculaneum by pyrolysis and mass spectrometry,” International Biodeterioration & Biodegradation 86(Part B), 142–149. DOI: 10.1016/j.ibiod.2013.06.024

Timar, M. C., and Beldean, E. (2006). “Aspects of wood degradation revealed by a modified L-joint test,” Bulletin of Transilvania University of Brasov 13(48), pp. 335-342.

Timar, M. C., Gurău, L., and Porojan, M. (2012). “Wood species identification, a challenge of scientific conservation,” International Journal of Conservation Science 3(1), 11-22.

Wagenführ, R., and Wagenführ, A. (2021). Holzatlas, Hanser Fachbuchverlag, Munich, Germany.

Walsh-Korb, Z., and Avérous, L. (2019). “Recent developments in the conservation of materials properties of historical wood,” Progress in Materials Science 102, 167-221. DOI: 10.1016/j.pmatsci.2018.12.001

Xie, J., Qi, J., Huang, X., Zhou, N., and Hu, Y. (2015). “Comparative analysis of modern and ancient buried Phoebe zhennan wood: Surface color, chemical components, infrared spectroscopy, and essential oil composition,” Journal of Forestry Research 26(2), 501-507. DOI: 10.1007/s11676-015-0034-z

Yang, L. (2021). “Effect of temperature and pressure of supercritical CO2 on dewatering, shrinkage and stresses of Eucalyptus wood,” Applied Sciences 11(18), article no. 8730. DOI: 10.3390/app11188730

Yin, Q., and Liu, H. H. (2021). “Drying stress and strain of wood: A review,” Applied Sciences 11(11), article no. 5023. DOI: 10.3390/app11115023

Zachar, M., Čabalová, I., Kačíková, D., and Jurczyková, T. (2021). “Effect of natural ageing on oak wood fire resistance,” Polymers 13(13), article no. 2059. DOI: 10.3390/polym13132059

Zhao, C., Zhang, X., Liu, L., Yu, Y., Zheng, W., and Song, P. (2019). “Probing chemical changes in holocellulose and lignin of timbers in ancient buildings,” Polymers 11(5), article no. 809. DOI: 10.3390/polym11050809

Article submitted: July 22, 2022; Peer review completed: Sept. 24, 2022; Revised version received and accepted: September 27, 2022; Published: October 5, 2022.

DOI: 10.15376/biores.17.4.6511-6520