Abstract

Changbai larch (Larix olgensis Henry) is one of the main plantation species in the northern part of China, but so far its utilization has been limited to solid wood, pulping, and paper products. As part of a national initiative, the objective of this work was to develop a good understanding concerning how stand management practices affect larch wood and veneer properties. To cope with the variation of initial and final stand density, the term “relative thinning intensity (RTI)” was introduced to describe the effect of stand thinning on the resulting wood and veneer properties. Nine representative sample trees each from four stands were harvested, then trimmed and bucked. Six 1.25 m long bolts along the entire tree stem were systematically cut to peel 2.6 mm thick veneers. Clear wood specimens were also sawn from matched bolts for mechanical testing for the purpose of comparison and validation. The correlation between the main tree variables and properties of clear wood and veneer was analyzed, and the influence of RTI on key wood and veneer properties was examined and compared. A good correlation was found in density and modulus of elasticity (MOE) between larch clear wood and veneer, giving an R2 of 0.75 and 0.71, respectively. This indicates that veneering can be potentially used to characterize this larch species. The stand with the lowest RTI had the shortest rotation but yielded the best properties of both clear wood and veneer, which highlights the importance of stand management in terms of thinning.

Download PDF

Full Article

Characterizing Changbai Larch Through Veneering. Part 1: Effect of stand density

Suyong Huang,a Brad Jianhe Wang,b Jianxiong Lu,a,* Chunping Dai,b Yuancai Lei,c and Xiaomei Sun d

Changbai larch (Larix olgensis Henry) is one of the main plantation species in the northern part of China, but so far its utilization has been limited to solid wood, pulping, and paper products. As part of a national initiative, the objective of this work was to develop a good understanding concerning how stand management practices affect larch wood and veneer properties. To cope with the variation of initial and final stand density, the term “relative thinning intensity (RTI)” was introduced to describe the effect of stand thinning on the resulting wood and veneer properties. Nine representative sample trees each from four stands were harvested, then trimmed and bucked. Six 1.25 m long bolts along the entire tree stem were systematically cut to peel 2.6 mm thick veneers. Clear wood specimens were also sawn from matched bolts for mechanical testing for the purpose of comparison and validation. The correlation between the main tree variables and properties of clear wood and veneer was analyzed, and the influence of RTI on key wood and veneer properties was examined and compared. A good correlation was found in density and modulus of elasticity (MOE) between larch clear wood and veneer, giving an R2 of 0.75 and 0.71, respectively. This indicates that veneering can be potentially used to characterize this larch species. The stand with the lowest RTI had the shortest rotation but yielded the best properties of both clear wood and veneer, which highlights the importance of stand management in terms of thinning.

Keywords: Changbai larch; Stand density; Relative thinning intensity (RTI); Wood property; Veneering

Contact information: a: Research Institute of Wood Industry, Chinese Academy of Forestry (CAF), Beijing, P. R. China 100091; b: FPInnovations – Wood Products, 2665 East Mall, Vancouver, B.C., Canada V6T 1W5; c: Research Institute of Forest Resource Information Techniques, CAF, Beijing, P. R. China 100091; d: Research Institute of Forestry, CAF, Beijing, P. R. China 100091.

*Corresponding author: jianxiong@caf.ac.cn

INTRODUCTION

To protect natural resources and the environment for sustainable development, plantations have become the major source of timber supply in China for forest products such as solid wood, plywood, pulping, and paper. A good plantation species should produce not only high timber yield, but also the desired properties of wood for highly valued end products. Accelerating tree growth rate or shortening the rotation could potentially affect wood quality (Alteyrac et al. 2005). With the worldwide move towards intensive silviculture and shorter rotations, the quality of wood and end products from this changing resource has become a concern for the forest products industry (Knudson et al. 2006). It is important to understand how silvicultural treatments affect the quality of standing trees and wood obtained from them (Wang et al. 2005b). Stand management generally includes initial spacing (initial density), pre-commercial thinning, and commercial thinning, measured mainly by stand density at different stages, as well as rotation control and pruning. Tremendous work has been done to determine the effects of stand management on tree growth, stem shape, yield, wood chemical, physical, and mechanical properties of various species (Tong and Zhang 2005; Víquez et al. 2005; Guller 2007; Clark et al. 2008; Kumar et al. 2008; Peltola et al. 2009). For Taiwania (Taiwania cryptomerioides Hay.), thinning, particularly heavy thinning, resulted in lower wood quality (Wang et al.2005a; Lin et al. 2006). Increasing the thinning intensity led to a reduced mean wood density, tracheid length, and latewood proportion in the harvested wood of Norway spruce (Picea abies (L.) Karst) (Pape 1999; Cao et al. 2008). Initial spacing significantly influenced modulus of elasticity (MOE) of radiata pine (Pinus radiata D.) (Waghorn et al. 2007). Likewise, initial spacing had a significant effect on tree growth, wood density, fibre, and pulp properties of jack pine (Pinus banksiana L.), which could be improved through stand density regulation and moderate pre-commercial thinning (Kang et al. 2004). Compared with using a large initial spacing, use of a narrow initial spacing also significantly increased wood dynamic MOE (Lasserre et al. 2009). Heavy thinning or high thinning intensity decreased the basic density of the wood (Pape 1999; Cao et al. 2008), however, stand density did not appear to be consistently related to some chemical contents of plantation-grown loblolly pine (Pinus taeda L.) wood, such as Klason-lignin, holocellulose, or alpha-cellulose (Shupe et al. 1996).

A shift has recently taken place in the focus of much research from tree growth rate to end product traits. Some efforts have been made to find the inherent linkage between the stand management and end products. As a result of this effort, it was found that the effect of silvicultural treatments could be negligible for some properties of end products, such as loblolly pine particleboard and medium density fiberboard (MDF) (Shupe et al. 1999), but this was not the case with solid wood or lumber. Higher quality lumber could be produced from denser black spruce (Picea mariana (Mill.) B.S.P.) plantations with appropriate thinning (Tong et al. 2009). Nevertheless, most research has been limited to only clear wood or lumber properties (Zhang et al. 2002). At present, veneer products, such as parallel strand lumber (Parallam) and laminated veneer lumber (LVL), are classified as engineered wood products for structural use. They generally have a higher market value than lumber and pulp. Those products can overcome the deficiency of solid wood by removing strength-reducing defects such as knots and decay before gluing and layup to achieve uniform stiffness and strength for engineered applications. However, very limited work is available concerning the effect of silvicultural treatments or stand management on properties of veneer and resulting veneer products (Knudson et al. 2006; Wang et al. 2011).

Changbai larch (Larix olgensis Henry) is one of the most important commercial plantation species in the northern part of China. This species has a high growth rate and high survival rate due to its strong resistance to pests, diseases, and inclement weather (Liu 2004). With an increasing volume of plantations reaching rotation age, this species has become one of the major fiber stocks in China. It is generally very knotty, which could affect the appearance grades and some mechanical properties of end products, so pulp has been the predominant industrial application for this species (Li 2001; Sun and Pang 2005; Wang et al. 2006), followed by lumber (He et al. 2009). Traditionally, forest resources are mainly characterized through tests on clear wood and full size lumber (Tong and Zhang 2006; Wang and Dai 2011). While growth characteristics of this larch species in China have been well documented, little is known about its veneer properties in relation to its stand management and tree growth. Virtually no effort has been undertaken to use this species for manufacturing veneer-based products, particularly LVL.

To maximize the value return from larch plantations in China, a national research program was recently initiated to characterize this resource through veneering with regard to stand density, growth rate, and stem position and to determine its suitability for veneer products such as plywood and LVL. As part of the initiative, the key objective of this work was to investigate the effect of the stand density on clear wood and veneer properties. This work was specifically designed to characterize this larch resource via veneering along with traditional clear wood testing. By analyzing the correlation of main properties between clear wood and veneer, the effectiveness of veneering for larch resource characterization can be identified. By determining the properties of clear wood and veneer in relation to stand density, diameter at breast height (DBH) and stem position, a cost-effective stand management strategy can be established and an accurate resource assessment can be realized. As a result, the best product potential from this resource can be determined in relation to an optimum stand management strategy.

MATERIALS AND METHODS

Tree Samples and Cutting

In this study, the sample trees were obtained from Mengjiagang Forestry Center, Jiamusi, Heilongjiang province, China. This site is located in the Xiaoxinganling Mountain zone (Long. 130˚32’E-130˚52’E; Lat. 46˚20’N-46˚30’N). The site belongs to the East Asian continental monsoon climate zone, which has an altitude of 250 m and approximately 120 frost-free days. The average annual rainfall and sunshine time are about 550 mm and 1955 hours, respectively. The two temperature extremes recorded are 35.6 ºC (highest) and -34.7 ºC (lowest), with an average temperature of 2.7 ºC.

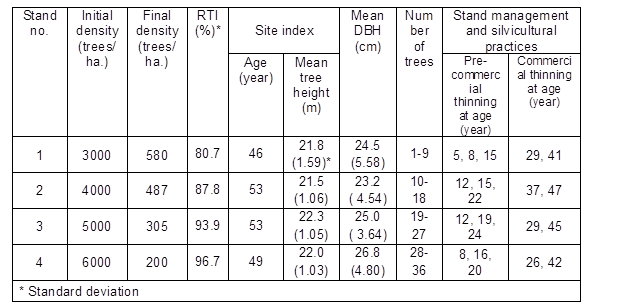

Four typical stands were selected with varying initial spacing (or density), final density, and stand management practices. Those stands had an age of 46 to 53 years and received 3 pre-commercial thinnings and 2 commercial thinnings. After a series of thinning operations, the order of the final stand density in magnitude was reversed as compared to that of the initial stand density. Meanwhile, the timing of the pre-commercial thinning and commercial thinning was not exactly the same, signifying the complexity of the stand history. Nine representative trees were systematically selected from each stand, three each from large (30 cm), medium (25 cm), and small (20 cm) DBH classes, respectively. They were harvested, trimmed, and bucked. Six 1.25 m long bolts were systematically cut along the entire stem to peel 2.6 mm thick veneer. The live crown width, length, and DBH were measured from each tree before felling, and the northern orientation was marked. After felling, the total height and diameter of the five biggest branches were measured as well as the diameter at different tree heights for calculating the tree taper. Clear wood specimens were also sawn from matched bolts for mechanical testing to permit comparison and validation and subsequent evaluation of product options.

Table 1 shows the characteristics of the 9 sample trees from each stand with the mean DBH and tree height. In addition to those 36 trees (Table 1), 5 more trees were randomly felled from those stands for the purpose of model validation, which will be addressed in a subsequent paper.

Table 1. Sampling Schemes and Stand Characteristics of Larch Trees

The main tree variables, such as the DBH, tree height, branch height, crown width, tree taper, and mean diameter of the 5 biggest branches, were recorded for each tree. Among those, the tree taper was calculated as individual tree height over its diameter difference at the two ends (with bark). For the four stands, although the initial stand density was systematically planned from 3,000 to 6,000 trees/ha, the final density differed due to the variation of thinning history and intensity (Table 1).

Relative Thinning Intensity (RTI)

To cope with the variation of initial spacing and final stand density, the term “relative thinning intensity (RTI)” was introduced to hereafter quantify this difference in stand thinning for a direct comparison and describe the effect of the stand thinning on resulting wood and veneer properties.

(1)

As shown in Fig. 1, each tree was bucked into 6 segments with a mark from butt to top (crown) along the entire stem to indicate its stem position. Among which, the first segment (1300 mm from the butt) was right on the breast height for basic density measurement and veneer processing. Then, the 5 consecutive segments 2 to 6 were cross cut with a length of 2500 mm. After that, all segments were transported to the Chinese Academy of Forestry (CAF) in Beijing. In the pilot plant, each segment (from 2 to 6) was further cross cut to obtain 5 disks, starting from the bottom and labeled A to E for determining various wood characteristics. Disk A (30 mm thick) was used to determine chemical properties such as pH, acid, and alkali buffer values; disk B (30 mm thick) provided the sapwood and heartwood area ratio; disk C (50 mm thick) was used to observe anatomical symptoms such as annual ring width; section D (1250 mm long) was used to determine clear wood macro- and micro- mechanical properties, and section E (1250 mm long) was used for veneering.

Fig. 1. Bucking and cross cutting of one sample tree

Clear Wood Tests

For each section D, specimens were prepared from the 2nd to 6th segment to test main clear wood properties such as density, bending MOE, bending modulus of rupture (MOR), and compression MOR. The density measurement was performed at an oven dry condition with a specimen size of 20 mm x 20 mm x 20 mm in accordance with GB/T 1933-2009 (equivalent to International Organization for Standardization (ISO) 3131). The bending tests followed GB/T 1936.2-2009 for MOE and GB/T 1936.1-2009 for MOR (equivalent to ISO 3349 and ISO 3133, respectively) with a specimen size of 300 mm x 20 mm x 20 mm. The loading rate used was 1-3 mm/min for MOE and 5-10 mm/min for MOR. The compression tests were conducted following GB/T 1935-2009 (ISO 3787 equivalent) with a specimen size of 30 mm × 20 mm x 20 mm. The values of bending MOE, MOR, and compression MOR were calibrated to a moisture content (MC) level of 12%. For each section, 3 to 6 specimens were generally taken from sapwood to heartwood depending on the log diameter (ISO 3129). The total numbers of specimens were 581, 837, 1046 for density, bending MOE (MOR) and compression MOR, respectively.

Veneer Peeling and Tests

Each 1250 mm long section E (bolt) from segments 1-6 was transported to a plywood mill for veneer processing. The bolts were conditioned in a pond at 60 ºC for 48 hours before peeling with an industrial lathe equipped with a nose bar. The lathe settings were: horizontal gap = 2 mm, pitch angle = 89.5º, and vertical gap = 1.2 mm. The core drop size was 38 mm. The target veneer thickness was 2.6 mm (about 1/10 inch). Each veneer ribbon was clipped into 600 mm sheets in width sequentially from sap (bark) to core (pith). Then each sheet was coded with a number in combination with tree number, segment number, and veneer sheet number for easy identification. After that, each sheet was dried using a press dryer with a temperature of 120 to 130 ºC. A total drying time of about 15 min was used to achieve a target veneer MC of 3 to 6%, which is ideal for gluing. The dryer was opened once to evaporate steam after pressing about 7 min.

All dry sheets were shipped back to CAF in Beijing for ultrasonic tests. Each sheet was fed through a full scale Metriguard 2800 veneer tester (Metriguard Inc. 2012). This tester uses a variety of property measurements for sorting veneer. These may include ultrasonic propagation time (UPT), density, or dynamic MOE. The density is measured by microwave cavity resonators. The data for each sheet were then downloaded from the tester for further analysis. The total number of veneer sheets was 2291 for density, UPT and dynamic MOE measurements. Note that the veneer dynamic MOE is computed as follows,

(2)

where ρ is veneer density and L is the span for the UPT measurement.

Statistical Analysis

Data were first plotted for population cumulative distribution of each of clear wood and veneer properties. The t-test was used to examine the difference in mean value of each property between any two of stands. Meanwhile, the mean values of each of tree-level variable and properties were calculated to establish a correlation table using a built-in Microsoft ExcelTMstatistical tool. Further, the mean value and its standard deviation of each property were tabulated in terms of stands.

Property Correlation Between Clear Wood and Veneer

For each stand, the cumulative distribution function (CDF) of each clear wood and veneer property was constructed. On a tree basis, the mean property values of clear wood and veneer were computed. The correlation was established for density and MOE between clear wood and veneer for a total of 36 trees, 9 trees per stand. Note that targeted clearwood specimens were oven-dried, whereas the MC of veneer sheet was 3 to 6% for LVL manufacture.

Although the targeted MC was different for clear wood and veneer, the inherent property correlation was worthwhile to explore. Such correlation analysis can help validate the results by each other and thus demonstrate the feasibility of resource characterization through veneering.

RESULTS AND DISCUSSION

Correlation Between Tree Variables and Clear Wood Properties

A correlation table (Table 2) was established to describe how the clear wood properties are affected by the main tree variables, which include the following six: DBH, tree height, branch height, crown width, tree taper, and mean diameter of 5 biggest branches. The clear wood properties contain wood bending MOE and MOR, and compression MOR.

Table 2. Correlation between Larch Clear Wood Properties and Tree Variables

Overall, the correlation between the tree variables and clear wood mechanical properties was weak, with a maximum coefficient of merely 0.28 (Table 2). No single tree variable was found to remarkably affect clear wood bending MOE, bending MOR, and compression MOR. While it was weak, the DBH had a positive correlation with clear wood compression MOR, but a negative correlation with clear wood bending MOE and MOR. During tree growth, a tree with larger DBH could develop higher wood compression strength in order to provide a stronger support for the stem.

Among the six tree variables, DBH seemed to be the key one that positively correlated with the mean diameter of the 5 biggest branches, tree taper, tree height, and crown width in descending order from good to moderate (Table 2). The tree height had a moderately good and positive correlation with the mean diameter of the 5 biggest branches and tree taper. The crown width was also well and positively correlated with the mean diameter of the 5 biggest branches and tree taper. A larger tree taper or a larger diameter of branches meant a wider spread of the crown. In addition, the tree taper had a positive correlation with the mean diameter of 5 biggest branches, indicating that a larger tree taper is often associated with larger branches. This result is consistent with that obtained from other studies (Zhang et al. 2005).

Among the three clear wood properties, the clear wood bending MOE was moderately correlated with both bending MOR and compression MOR. The higher the bending MOE, the higher the bending and compression MOR.

Properties of Clear Wood Under Different Thinning Intensities

Table 3 summarizes the clear wood properties in terms of stands with different thinning intensities. The RTI was calculated for each stand. Stand 1 had the lowest RTI, indicating the weakest thinning intensity. The RTI increased from stand 1 (80.7%) to stand 4 (96.7%). In general, each property of clear wood tended to decrease with increasing RTI. It seemed that stand 2 had the largest variation in all three clear wood properties. There existed a large within-stand variation in each of the clear wood properties. The within-stand variation seemed to be much higher than the between-stand variation. The coefficient of variation (CV) ranged from 10.8 to 17.5% for density, 21.3 to 25.2% for bending MOE, 21.6 to 25.2% for bending MOR, and 17.7 to 20.6% for compression MOR. In view of such a large variation of clear wood basic properties, either log sorting or lumber grading may be necessary for structural applications of this plantation species.

Table 3. Mechanical Properties of Larch Clear Wood in Relation to Stands

Figure 2 shows the CDF of clear wood properties in terms of stands. The density of wood samples generally ranged from 400 to 900 kg/m3. There was a significant overlapping in density between stand 1 and stand 2, and between stand 3 and stand 4 as well. The t-test showed that there was no significant difference of the clear wood mean density between stand 1 and stand 2, and between stand 3 and stand 4 (p > 0.05). However, stand 1 and stand 2 had a significantly higher mean density than stand 3 and stand 4 (p < 0.05). Note that the former had an RTI lower than 90% whereas the latter had an RTI higher than 90%. The results indicated that the thinning intensity may have a negative effect on wood density.

Fig. 2. CDF of the four larch clear wood properties in terms of stands

For each stand, the clear wood bending MOE and MOR ranged from 7 to 27 GPa, and 40 to 180 MPa, respectively. Likewise, the clear wood compression MOR also varied significantly with a range from 35 to 85 MPa. Among the four stands, stand 1 had the highest clear wood mean bending MOE and compression MOR (Table 3), but there was no significant difference among the other three stands (p > 0.05). Also, there was no significant difference in clear wood mean compression MOR between stand 1 and stand 2, and between stand 3 and stand 4 (p > 0.05). Stand 1 and stand 2 had a higher wood mean compression MOR than stand 3 and stand 4 (p < 0.05). As far as wood mechanical properties are concerned, stand 1 and stand 2 had more advantageous properties than stand 3 and stand 4. Overall, stand 1 was superior to stand 2. This trend was essentially in agreement with the order of the RTI. Within the scope of this study, the wood mechanical properties decreased with increasing thinning intensity (or RTI). For this species, the RTI could be used to quantify the effect of the variation of thinning intensity resulting from different initial spacing densities and final density.

Properties of Veneer Under Different Thinning Intensities

Table 4 shows the correlation between the main tree variables and veneer properties. This analysis used the same tree variables employed in the clear wood analysis (Table 2). However, veneer properties included dynamic MOE, UPT, and density, as measured non-destructively by the Metriguard production line grader.

In general, the correlation between the six tree variables and three veneer properties remained weak (Table 4), but was slightly better than that obtained for the clear wood (Table 2). Based on Table 4, no single tree variable was found to significantly

Table 4. Correlation Between Larch Veneer Properties and Tree Variables

affect veneer UPT, density, and dynamic MOE. Overall, the DBH remained the key tree variable affecting veneer properties, with a positive correlation to veneer UPT and a negative correlation to veneer density and dynamic MOE. This result is consistent with that obtained from other studies (Zubizarreta Gerendiain et al. 2007), which indicated that a faster growth rate is often associated with a lighter and weaker wood. While exhibiting a weak correlation, the crown width affected veneer UPT, followed by the DBH, and tree taper in a descending order. This implies that an increase of the above three tree variables resulting from a faster tree growth could lead to an increase of veneer UPT. Note that veneer UPT is mainly affected by wood grain angle, veneer MC, temperature, and defects such as knots, decay, and cracks (Metriguard, Inc.). Assuming veneer density is constant, a larger UPT is often associated with a lower dynamic MOE.

Among the three veneer properties, the veneer dynamic MOE was positively correlated with veneer density but negatively correlated with veneer UPT (Table 4). Based on the correlation (Table 4), for this larch species, veneer density seemed to play a more important role than veneer UPT in determining veneer dynamic MOE.

Table 5. Properties of Larch Veneer in Relation to Stands

Table 5 summarizes the veneer properties in terms of stands with various thinning intensities. The definition of the RTI remained the same as its value increased from stand 1 (80.7%) to stand 4 (96.7%). For each stand, the total number of veneer sheets was also calculated, reflecting a measure of veneer yield. The same number of trees harvested from each stand resulted in different veneer yields, mainly due to the difference in the tree mean DBH (Table 1). The CV ranged from 8.6 to 12.1% for density, 7.0 to 7.9% for UPT, 12.9 to 13.4% for dynamic MOE.

Note that stand 1 had the shortest rotation age, namely 46 years as compared to 49 or 53 years for the other 3 stands, but did not generate the smallest mean DBH (Table 1). This observation indicated that for this plantation species, a short rotation would not necessarily result in reduced wood properties (Table 3) and veneer properties and lowered veneer yield (Table 5) if the pre-commercial or commercial thinning and intensity are appropriate. Therefore, it is essential for forest managers and wood scientists to work together to find an optimum stand management strategy to balance the veneer yield and veneer properties. In general, veneer density and dynamic MOE tended to decrease with increasing RTI. However, there was no consistent trend for veneer UPT from stand 1 to stand 4 (Table 5).

Figure 3 shows the CDF of larch veneer properties in terms of stands. Similar to the clear wood, there existed a large variation in the veneer properties of each stand. Again, the within-stand variation seemed to be much higher than the between-stand variation. Under the circumstance of such a large variation of veneer properties, veneer stress grading is deemed necessary for structural applications of larch veneer. The veneer density generally ranged from 400 to 700 kg/m3. There was a significant overlapping in the mean density between stand 1 and stand 2, and between stand 3 and stand 4. Similar to the clear wood, no significant difference in the mean veneer density was found between stand 1 and 2 or between stand 3 and 4 (p > 0.05). However, stand 1 and stand 2 had a significantly higher mean density than the stand 3 and stand 4 (p < 0.05). This result is consistent with that obtained from the clear wood.

Stand 1 had the smallest veneer UPT and highest dynamic MOE among the four stands (Table 5). Due to a significant overlapping, statistically there was no significant difference in mean veneer UPT and dynamic MOE for the other three stands (p > 0.05). As a result, stand 1 with the smallest RTI yielded the best veneer properties. This result is also consistent with that obtained from the clear wood tests.

Based on the stand samples taken for this study, the properties of the larch clear wood and veneer decreased consistently with increasing relative thinning intensity (RTI) from stand 1 to stand 4; however, the difference in those properties between any two of the three stands from 2 to 4 was not statistically significant at the p = 0.05 level.

Correlation Between Larch Clear Wood and Veneer

Figure 4 shows the CDF of density population for larch clear wood and veneer with the data combined from all four stands. For the clear wood tests, only 3 to 6 specimens were generally taken from sapwood to heartwood, depending on the log diameter (ISO 3129). For the veneer tests, all sheets from sapwood to heartwood (except the core) were used in the CDF plot. By comparison, larch clear wood had a consistently higher density than larch veneer. This is probably due to the following two reasons: 1) the section of clear wood tests (section D) was always below the section of veneer tests (section E), and the density of lower sections tended to be higher than that of higher sections; and 2) the difference in sampling and sampling number.

Fig. 3. CDF of the three larch veneer properties in terms of stands

Fig. 4. Comparison between larch clear wood and veneer density populations

Fig. 5. Correlation of larch clear wood density and veneer density

Figure 5 shows the correlation of density between the larch clear wood and veneer on a tree basis. The correlation was reasonably good, giving an R2 of 0.75.

Similarly, Fig. 6 shows the population CDF of larch veneer dynamic MOE and clear wood bending MOE with the data combined from all four stands. By comparison, larch clear wood had a consistently higher MOE than larch veneer. This could be due to the effect of knots, MC, specimen size, specimen number, testing configurations and methods, or any other number of variables. Unlike the clear wood tests, the veneer tests involved knots, as well as larger and much more numerous specimens. Knots generally had a negative effect on wood and veneer mechanical properties (Nusret 2006). Also, veneer properties were calculated as the grand average of all sheets whereas clear wood properties were the average of a limited number of specimens. In addition, the clear wood testing used small specimens and a short span, whereas the veneer testing employed a wheel span of 1.2 m from the ultrasonic measurement. As shown in Figure 7, on a tree basis, the correlation of MOE between the larch clear wood and veneer was also reasonably good, giving an R2 of 0.71.

Fig. 6. Comparison between larch clear wood bending MOE and veneer dynamic MOE populations

Fig. 7. Correlation of larch clear wood bending MOE and veneer dynamic MOE

In summary, the clear wood exhibited higher density and MOE than the veneer counterpart. Nevertheless, the good correlation between the clear wood and veneer demonstrated that resource characterization through veneering is viable and cost effective, since it can be rapidly and directly performed on the production line (Wang and Dai 2012). Through veneering, information on wood properties can be collected non-destructively on a large scale, and the effects of the stand, rotation age, DBH, stem position, sapwood or heartwood, and juvenile or mature wood on veneer properties can be identified as well. As a result, the best product potential and rotation age can be determined to maximize the value recovery.

CONCLUSIONS

Among the four managed Changbai larch stands, stand 1 with the lowest RTI had the best clear wood and veneer properties due to the lightest thinning. Thus, the RTI could be potentially used to describe the complexity of stand management for this species with varying initial density and final density, and help characterize the effect of stand management on clear wood and veneer properties.

A good correlation was found between the larch clear wood and veneer in terms of both density and MOE. Larch clear wood exhibited higher density and MOE than its larch veneer counterpart, which could be due to the combined effect of sampling, sampling positions, knots, specimen number and size, or test configurations. This work on larch validated that veneering is a viable approach for resource characterization. With this approach, wood properties can be measured on a large scale non-destructively, which appears to be more cost-effective as compared to the clear wood tests.

A significant variation existed in properties of Changbai larch clear wood and veneer within each stand. The within-stand variation seemed to be higher than the between-stand variation. Thus, further work is needed to characterize the effect of within-stand tree growth characteristics, particularly DBH class and stem position, on larch clear wood and veneer properties.

ACKNOWLEDGEMENTS

This work was part of a research program sponsored by the Special Overseas Cooperation Fund for Chinese Academy of Forestry (CAFYBB2008008) and the National Natural Science Foundation of China (No. 30825034). The part of clear wood testing was also supported by the fund for Chinese Academy of Forestry (CAFINT2009C07). The authors would like to thank FPInnovations for their cooperation, particularly Dr. Gerry Middleton and Mr. Dave Munro for their help and advice. We sincerely thank Dr. Rongjun Zhao, Dr. Xinting Xing, and research assistants Weiwei Shangguan and Yali Shao for their participation in sampling trees and conducting clear wood tests. We also thank Dr. Dongsheng Chen for providing stand information. We further thank the staff from Sanli Company for their help in veneer peeling and the management team at the Mengjiagang Forest Centre for their assistance in field work and log conversion.

REFERENCES CITED

Alteyrac, J., Zhang, S. Y., and Cloutier, A. (2005). “Influence of stand density on ring width and wood density at different sampling heights in black spruce,” Wood Fiber Sci. 37(1), 83-94.

Cao, T. J., Valsta, L., Härkönen, S., Saranpää, P., and Mäkelä, A. (2008). “Effects of thinning and fertilization on wood properties and economic returns for Norway spruce,” Forest Ecology and Management 256(6), 1280-1289.

Clark, III, A., Jordan, L., Schimleck, L., and Daniels, R. F. (2008). “Effect of initial planting spacing on wood properties of unthinned loblolly pine at age 21,” J. For. Prod. 58(10), 78-83.

Guller, B. (2007) “The effects of thinning treatments on density, MOE, MOR and maximum crushing strength of Pinus brutia Ten. wood,” Ann For. Sci. 64(4), 467-475.

He, L., Wang X., Zhao D., Yan C., and Shi L.C. (2009). “Research on classification by appearance of larch timber and vibration inspection tests,” Forestry Machinery & Woodworking Equipment, 37(10), 24-26.

International Organization for Standardization (ISO) 3129, (1975). Wood-Sampling Methods and General Requirements for Physical and Mechanical Tests.

International Organization for Standardization (ISO) 3131, (1975). Wood- Determination of Density for Physical and Mechanical Tests.

International Organization for Standardization (ISO) 3133, (1975). Wood- Determination of Ultimate Strength in Static Bending.

International Organization for Standardization (ISO) 3349, (1975). Wood- Determination of Modulus of Elasticity in Static Bending.

International Organization for Standardization (ISO) 3787, (1976). Wood- Test Methods-Determination of Ultimate Stress in Compression Parallel to Grain.

Kang, K. Y., Zhang, S. Y., and Mansfield, S. D. (2004). “The effects of initial spacing on wood density, fibre and pulp properties in jack pine (Pinus banksiana Lamb.),” Holzforschung58(5), 455-463.

Knudson, R. M., Wang, B. J., and Zhang, S. Y. (2006). “Properties of veneer and veneer-based products from genetically improved white spruce plantations,” Wood Fiber Sci. 38(1), 17-27.

Kumar, S., Burdon, R. D., Stovold, G. T., and Gea, L. D. (2008). “Implications of selection history on genetic architecture of growth, form, and wood-quality traits in Pinus radiate,” Can. J. For. Res. 38(9), 2372-2381.

Lasserre, J. P., Mason, E. G., Watt, M. S., and Moore, J. R. (2009). “Influence of initial planting spacing and genotype on microfibril angle, wood density, fibril properties and modulus of elasticity in Pinus radiata D. Don corewood,” Forest Ecology and Management 258(9), 1924-1931.

Li, F. S. (2001) “Effect of cultivation measures on economic benefit of Larix olgensis pulp forest,” J. For. Res. 12(3), 179-182.

Lin, C. J., Wang, S. Y., Yung, T. H., and Tsai, M. J. (2006). “Compressive strength of young Taiwania (Taiwania cryptomerioides) trees grown with different thinning and pruning treatments,” J. Wood Sci. 52(4), 337-341.

Liu, Y. X. (2004). Compilation of Properties and Utilization of Wood Produced From Northerneast Part of China, Chemical Industry Press, Beijing.

Metriguard Inc. (2012) Veneer Testers, http://www.metriguard.com/catalog/5%20-%2016%20Veneer%20Testers.pdf

Nusret, A., Goker, Y., and Dundar, T. (2006). “Effect of knots on the physical and mechanical properties of scots pine (Pinus sylvestris L.),” Wood Research 51(3), 51-58.

Pape, R. (1999). “Effects of thinning regime on the wood properties and stem quality of Picea abies,” Scandinavian Journal of Forest Research 14(1), 38-50.

Peltola, H., Gort, J., Pulkkinen, P., Zubizarreta G. A., Karppinen, J., and Ikonen, V. P. (2009). “Difference in growth and wood density traits in scots pine (Pinus sylvestris L.) genetic grown at different spacing and sites,” Silva Fennica 43(3), 339-354.

Shupe, T. F., Hse, C. Y., Choong, E. T., and Groom L. H. (1999). “Effect of silvicultural practice and wood type on loblolly pine particleboard and medium density fiberboard properties,” Holzforschung 53(2), 215-222.

Shupe, T. F., Choong, E. T., and Yang, C. H. (1996). “The effect of silvicultural treatment on the chemical composition of plantation-grown loblolly pine wood,” Wood Fiber Sci. 28(3), 295-300.

Sun, S. F., and Pang, Y. M. (2005). “Study on management of pulpwood plantation of Larix Olgensis,” Forest Resources Management (3), 51-54.

Tong, Q. J., and Zhang, S. Y. (2005). “Impact of initial spacing and precommercial thinning on jack pine tree growth and stem quality,” For. Chron. 81(3), 418-428.

Tong, Q. J., and Zhang, S. Y. (2006). “Modelling jack pine lumber value recovery in relation to tree characteristics using Optitek simulation,” Forest Prod. J. 56(1), 66-72.

Tong, Q. J., Fleming, R. L., Tanguay, F., and Zhang, S Y. (2009). “Wood and lumber properties from unthinned and precommercially thinned black spruce plantations,” Wood Fiber Sci.41(2), 168-179.

Tong, Q. J., Tanguay, F., and Zhang, S. Y. (2011). “Impact of commercial thinning on annual radial growth and wood density in plantation-grown black spruce,” Wood Fiber Sci. 43(3), 311-325.

Víquez, E., and Pérez, D. (2005). “Effect of pruning on tree growth, yield and wood properties of Tectona grandis plantations in Costa Rica,” Silva Fennica 39(3), 381-390.

Waghorn, M. J., Mason, E. G., and Watt, M. S. (2007). “Influence of initial stand density and genotype on longitudinal variation on modulus of elasticity for 17-year-old Pinus radiate,” Forest Ecology and Management 252(1-3), 67-72.

Wang, B. J. and Dai, C. (2005). “Hot-pressing stress graded aspen veneer for laminated veneer lumber (LVL),” Holzforschung 59(1), 10-17.

Wang, B. J. and Dai, C. (2012). “Systematic resource characterization through veneering and non-destructive testing,” Submitted to Wood and Fiber Science, 20 pp.

Wang, S. L., Wen, J., Yang, Z., and Ma, F. M. (2006). “Effects site conditions on industrial fiber plantations of Larix olgensis,” J. For. Res. 17(3), 255-258.

Wang, S. Y., Lin, C. J., and Chiu, C. M. (2005). “Evaluation of wood quality of Taiwania trees grown with different thinning and pruning treatments using ultrasonic-wave testing,” Wood Fiber Sci. 37(2), 192-200.

Wang, S. Y., Lin, C. J., Chiu, C. M., Chen, J. H., and Yung, T. H. (2005). “Dynamic modulus of elasticity and bending properties of young Taiwania trees grown with different thinning and pruning treatments,” J. Wood Sci. 51(1), 1-6.

Zhang, J. H., Zhang, S. G., Shi, S. L., Hu, H. R., and Zhang, S. Z. (2004). “Paper-making properties of Larix kaempferi pulpwood,” Journal of Beijing Forestry University 26(5), 71-74.

Zhang, S. Y., Chauret, G., Ren, H. Q., and Desjardins, R. (2002). “Impact of initial spacing on plantation Black spruce lumber grade yield, bending properties, and MSR yield,” Wood Fiber Sci. 34(3), 460-475.

Zhang, S.Y., Lei, Y.C., Bowling, C. (2005) “Quantifying stem quality characteristics in relation to initial spacing and modeling their relationship with tree characteristics in black spruce (Picea mariana),” Northern Journal of Applied Forestry, 22(2), 85-93.

Zubizarreta Gerendiain, A. Peltola, H., Pulkkinen, P., Jaatinen, R., Pappinen, A., and Kellomäki, S. (2007) “Differences in growth and wood property traits in cloned Norway spruce (Picea abies),” Canadian Journal of Forest Research 37(12), 2600-2611.

Article submitted: January 9, 2012; Peer review completed: February 26, 2012; Revised version received: April 4, 2012; Accepted: April 19, 2012; Published: April 30, 2012.