Abstract

Oak wood (Quercus robur L.) was subjected to cyclic thermo-mechanical treatment (CTMT). The temperature of the press platens during the CTMT was either 100 °C or 150 °C. The equilibrium moisture content and the dimensional changes of the oak wood were examined when it was exposed to 9 to 98% relative humidity at 20 °C (± 2 °C). Densified oak wood had lower equilibrium moisture content than the non-densified wood for the relative humidity ranges examined. Furthermore, when the temperature of the thermo-mechanical modification was higher, the equilibrium moisture content of the wood was lower. Thermo-mechanical modified wood was characterised by higher swelling values in the radial direction than in the tangential direction. When the temperature of the CTMT was higher, the water absorption of the wood was lower. The number of treatment cycles significantly influenced the water absorption of the oak wood at its maximum saturation. After CTMT, changes were observed in oak wood, in particular, with regards to soluble substances in 1% NaOH and to chloroform-ethanol extractives.

Download PDF

Full Article

Chemical Composition and Selected Physical Properties of Oak Wood (Quercus robur L.) Modified by Cyclic Thermo-Mechanical Treatment

Agnieszka Laskowska,* Monika Marchwicka, Piotr Boruszewski, and Joanna Wyszyńska

Oak wood (Quercus robur L.) was subjected to cyclic thermo-mechanical treatment (CTMT). The temperature of the press platens during the CTMT was either 100 °C or 150 °C. The equilibrium moisture content and the dimensional changes of the oak wood were examined when it was exposed to 9 to 98% relative humidity at 20 °C (± 2 °C). Densified oak wood had lower equilibrium moisture content than the non-densified wood for the relative humidity ranges examined. Furthermore, when the temperature of the thermo-mechanical modification was higher, the equilibrium moisture content of the wood was lower. Thermo-mechanical modified wood was characterised by higher swelling values in the radial direction than in the tangential direction. When the temperature of the CTMT was higher, the water absorption of the wood was lower. The number of treatment cycles significantly influenced the water absorption of the oak wood at its maximum saturation. After CTMT, changes were observed in oak wood, in particular, with regards to soluble substances in 1% NaOH and to chloroform-ethanol extractives.

Keywords: Chemical composition; Densification; Equilibrium moisture content; European oak

Contact information: Faculty of Wood Technology, Warsaw University of Life Sciences – SGGW, Nowoursynowska Str. 159, 02-776 Warsaw, Poland;

* Corresponding author: agnieszka_laskowska@sggw.pl

INTRODUCTION

The primary purpose of thermo-mechanical treatment of wood is the production of high density materials for flooring (Fang et al. 2012a; Belt et al. 2013; Laskowska 2017). The susceptibility of wood to densification is due to its anatomical structure and chemical composition. Amorphous polymers (e.g., lignin and hemicelluloses) are viscoelastic materials that may behave both like liquids and elastic solid materials, depending on the time and temperature of the treatment. For isolated amorphous polymers, transition from a glassy state to a highly viscoelastic state is defined as the glass transition temperature (Tg). Many properties of the polymer change significantly when it passes its softening point, after which the wood becomes very susceptible to deformation (Kúdela and Rešetka 2012). The glass transition temperature is correlated with the moisture content of wood (Kultikova 1999; Hill et al. 2012; Ülker et al. 2012). The glass transition temperature is above 100 °C for dry hemicelluloses and lignin. Depending on the moisture content, the Tg for wet lignin is within the range of 60 °C to 100 °C, while for wet hemicelluloses, the Tg is within the range of 0 °C to 100 °C (Irvine 1984). Because of the high crystallinity of dried cellulose, the Tg value is 200 °C (Lindström et al. 1987; Kúdela and Rešetka 2012), but lower Tg values are noted for wet cellulose depending upon its moisture content. Hillis and Rozsa (1978) examined the impact of constituents of radiata pine on its softening and found that the moisture content lowered the softening point of the hemicelluloses and lignin. The authors discovered that the hemicelluloses were the first in the cell wall to be softened (at 54 to 56 °C), which lowered the “stiffness” of the wood. This enabled the wood fibres to change their cross-sectional shape when subjected to applied forces. Lignin in the cell wall and middle lamellae softens between 72 °C and 128 °C, which enables further cross-sectional movement within and between the wood fibres. In another research study, Hillis and Rozsa (1985) examined the softening curves of radiata pine (Pinus radiata D. Don) in different growth rings obtained from young trees. Softening points were determined at the level of 80 °C for hemicelluloses and 100 °C for lignin. The differences in the softening curves from the earlier findings were ascribed to different chemical properties of the hemicelluloses contained in the sapwood and heartwood.

Moisture content plays an important role in the process of wood densification; it also determines the hygroscopic properties of wood at the same time. Several other factors contribute to this effect. Wood is a porous material. Moreover, wood as an organic material that is composed of carbohydrates (ca. 70 %), which are cellulose and hemicelluloses; these polysaccharides contain a large quantity of polar hydroxyl groups (Požgaj et al. 1993; Gindl et al. 2004). The wood components, especially polysaccharides, significantly determines its hygroscopic properties (Stamm and Millet 1941).

Thermo-mechanical treatment and its impact on the properties of wood have been the subject of several studies. Comprehensive data concerning the sorption properties of densified wood are lacking in the literature reports. However, much attention has been given to characterizing the dimensional changes of wood, which is the stress relaxation of wood after thermo-mechanical treatment; this phenomenon is known as spring-back (Xu and Tang 2012; Pelit et al. 2016). The set recovery (after water soaking) phenomenon has been analyzed (Blomberg et al. 2006; Fang et al. 2012b; Buchelt et al. 2014). In order to restrict this phenomenon, a number of processes have been developed in combination with thermo-mechanical treatment, i.e. thermal or hydrothermal treatment (Welzbacher et al. 2008; Hill et al. 2012; Laine et al. 2013). Kúdela and Rešetka (2012) stated that the reduction of wood hydrophilicity and permanent dimensional stabilisation of wood after pressing requires reaching the rubbery state of polymers. Reaching that state for lignin in wood with low moisture content is possible by using a pressing temperature between 180 °C and 200 °C (Inoue et al. 1998; Ito et al. 1998; Dwianto et al. 1999). However, it should be noted that the structural components of wood, in particular the hemicelluloses, may be degraded at this temperature (Schniewind 1989; İmirzi et al. 2014). As a consequence, thermo-mechanical treatment conducted at high temperatures may lower the thermo-mechanical properties of the modified wood (Ülker and Hiziroglu 2017). Moreover, using high modification temperatures is not justified due to the unfavourable economics.

Cyclic thermo-mechanical treatment (CTMT) is examined as part of the current study. A three-stage treatment cycle was repeated twice. This method was developed in order to improve the physical and mechanical properties of the wood. The impact of cyclic thermo-mechanical treatment on the chemical composition and selected physical properties of oak (Quercus robur L.) were determined. A temperature in the order of 100 °C to 150 °C is sufficient to soften amorphous polymers (lignin and hemicelluloses). Wood components may be degraded at a higher temperature. Therefore, the cyclic thermo-mechanical modification of oak wood was conducted at temperatures of 100 °C and 150 °C. An important aspect of the tests was to examine the equilibrium moisture content and dimensional changes of the densified oak wood in a controlled environment (i.e., at a specified temperature and at various relative humidities).

EXPERIMENTAL

Material

European oak (Quercus robur L.) was used for cyclic thermo-mechanical treatment. The dimensions of the samples were as follows: 130 mm (longitudinal), 80 mm (tangential), and 8.50 mm (radial). The European oak wood was obtained from central Poland. The surface of the wood samples was finished by planing. Then the samples were conditioned at 65% (± 5%) relative humidity and 20 °C (± 2 °C) in accordance to the ISO 13061-1 (2014) standard. The density of wood was determined in accordance to the ISO 13061-2 (2014) standard. Wood ground in a laboratory mill was used for chemical analyses. Subsequently, the ground wood was sieved in order to obtain the flour fraction between 0.5 and 1.0 mm. Four samples were used for each of the tests.

Methods

Cyclic thermo-mechanical treatment

Oak wood was subjected to cyclic thermo-mechanical treatment (CTMT). One treatment cycle consisted of three stages: I. heating the wood in a hydraulic press; II. wood densification; and III. cooling the wood samples in unheated hydraulic press without exerting pressure. The thermo-mechanical modification was carried out in one and in two cycles. The heating time was 120 s, the densification time was 120 s, and the cooling time of the wood in hydraulic press was 240 s. The treatment temperature was either 100 °C or 150 °C, and the unit pressure was set to 45 N/mm2. The cooling took place at 20 °C (± 2 °C) and 65% (± 5%) relative humidity. After the treatment, the wood samples were conditioned at normal conditions (i.e. 20 °C (± 2 °C) at 65% (± 5%) relative humidity) for 7 days.

The compression ratio (CR) was calculated according to Eq. 1, where to is the original thickness (mm), and td is the thickness of wood after densification (mm):

(1)

Chemical composition

The wood meal flour was extracted for 10 h using a Soxhlet extractor, which used a chloroform-ethanol solvent mixture (93:7 v/v) (Antczak et al. 2006). The lignin, cellulose, and holocellulose contents were determined on the solvent-extracted wood meal. The amount of acid-insoluble lignin was determined in accordance to TAPPI T 222 om-15 (2015), and the amount of acid-soluble lignin was determined in accordance with the NREL/TP-510-42618 lab procedure (Sluiter et al. 2011) using a UV/Vis wavelength of 205 nm. The cellulose content was determined using the method described by Seifert (1960). The holocellulose content was determined by the acid chlorite delignification of the extracted wood meal using sodium chlorite in an acid medium as described by Wise et al. (1946). In brief, 1.5 g sodium chlorite was used with 1 g of wood flour; the acid chlorite delignification process was conducted for 4 h. The content of wood substances soluble in 1% NaOH was determined in accordance to TAPPI T 212 om-12 (2015).

The tests were conducted using analytical grades of sulfuric acid, acetic acid, hydrochloric acid, and chloroform that were obtained from Chempur (Piekary Śląskie, Poland). Methanol and p-dioxane were of reagent grade and were obtained from Chempur. Sodium hydroxide (analytical grade) was procured from Avantor Performance Materials Poland S.A. (Gliwice, Poland). Acetyloacetone and sodium chlorite were of reagent grade and were obtained from Sigma-Aldrich (Poznań, Poland). Ethanol (technical grade) was purchased from Linegal Chemicals (Warsaw, Poland).

Determination of the equilibrium moisture content and dimensional changes

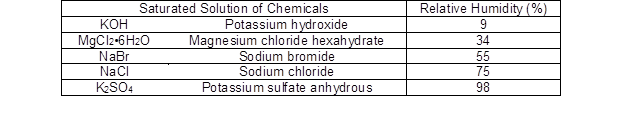

Wood samples with the dimensions of 80 mm (tangential) × 12 mm (longitudinal) were used for determining the equilibrium moisture content. The dimension of the wood samples in the radial direction (thickness) in the case of control samples was 8.67 (± 0.35) mm; in the case of modified samples, the sample thickness corresponded to the measured value after the thermo-mechanical treatment. The wood samples, after being dried to a moisture content of 0%, were placed into containers in which the relative humidity was 9 to 98% at 20 °C (± 2 °C). Wood conditioning at various relative humidity conditions was obtained using saturated solutions of chemicals, which are given in Table 1.

Table 1. Saturated Solutions of Chemicals Used to Obtain Appropriate Relative Humidity

Dimensional changes in the radial and tangential directions were determined. The dimensions of the samples were determined with an accuracy of ± 0.001 mm. Linear swelling for the radial (Sr) and tangential (St) directions were calculated as,The chemicals used in Table 1 were of proanalysis (p.a.) grade and were obtained from Chempur (Piekary Śląskie, Poland). Measurement of the equilibrium moisture content and dimensional changes of wood has been completed when the mass of the wood samples between three weighings at 48 h intervals was identical. The relative humidity was measured using an AZ 9871 anemometer (AZ Instrument Corp., Taichung City, Taiwan). One hundred-twenty samples were used for testing sorption (adsorption) properties.

(2)

(3)

where ro and to are the dimensions (mm) of the wood samples at oven-dry condition measured in the radial and tangential directions, respectively, and rc and tc are the dimensions (mm) of the wood samples conditioned at different relative humidities measured in the radial and tangential directions, respectively.

The volumetric swelling (VS) of the wood at different relative humidity values was determined as,

(4)

where Vo is the volume (mm3) of the wood samples at oven-dry condition, and Vc is the volume (mm3) of the wood samples conditioned at different relative humidities.

Water absorption measurement

Samples with the dimensions of 20 mm (tangential) × 20 mm (longitudinal) were used for the determination of water absorption. The thickness of the wood samples in the radial direction in the case of control samples was 8.67 mm (± 0.35 mm), whereas in the case of modified samples, it corresponded to the thickness of the sample after thermo-mechanical treatment. The wood samples were dried to constant mass at a temperature of 103 °C (± 2 °C). The samples were dried until the mass between two successive measurements did not differ by more than 0.2%. The samples were cooled to room temperature (20 °C (± 2 °C)) in a desiccator. Then, the samples were soaked in distilled water at a temperature of 20 °C (± 2 °C). The samples were weighed after 24 h of soaking in water. Additionally, the samples were weighed until no further change in mass occurred (maximum saturation point). Consequently, the water absorption of wood was determined after that time. The wood properties were determined for 20 control samples, and for each variant of the CTMT. Water absorption (WA) was calculated according to Eq. 5, where mo is the mass of the oven-dried wood (g), and mt is the mass of wood after soaking in water (g):

(5)

Statistical analysis

Statistical analyses were performed using STATISTICA version-12 software from StatSoft, Inc. (Tulsa, OK, USA). The statistical analysis of the results was carried out using a significance level (p) of 0.050. For some studied parameters, fitted curves were determined; the equation parameters for the fitted trends (y) and the coefficient of determination (R2) were ascertained.

RESULTS AND DISCUSSION

The highest density value, 1116 ± 24 kg/m3, was observed for oak wood after two modification cycles performed at 150 °C; the modified wood density was increased by 71% when compared to non-densified wood (i.e. control). The compression ratio was 43%. Oak wood modified with one cycle at 100 °C had the lowest modified density of 1015 ± 18 kg/m3, which represented a 56% increase from the original wood density.

It was observed that when a higher temperature was used for CTMT, the higher was the density of the modified oak wood (Table 2). Oak wood after two cycles of thermo-mechanical treatment had a higher density than those after one cycle of treatment; the differences between these two groups were statistically significant based on the ANOVA (Fischer’s F-test; p < 0.050).

Table 2. Thickness, Density and Equilibrium Moisture Content of CTMT Oak Wood (Standard Deviation in Parentheses)

The equilibrium moisture content (EMC) of oak wood for a given relative humidity level is presented in Table 2. Densified oak wood was observed to have lower EMC values than non-densified wood (i.e. control). These observations are consistent with literature reports. Hill et al. (2012) densified Scots pine (Pinus sylvestris L.) at 150 °C for 1 h. The investigators found that densification, thermal modification, and their treatment combinations reduced the EMC of the wood samples over the relative humidity range of 0% to 95%. The authors observed, similar to this study, that when the modification temperature was higher, the lower was the equilibrium moisture content of the wood. No significant differences were found in this study in the EMC values of the oak wood if it was treated with one or two cycles of thermo-mechanical treatment.

The modification temperature affected the cellulose content (42%). However, changes in its percentage share in wood (Table 4) were minor (3 to 4%). The number of thermo-mechanical modification cycles significantly affected all the analysed oak wood components with the exception of lignin (Table 3). The number of thermo-mechanical modification cycles had the greatest impact on the amount of chloroform-ethanol extractives (94%), and the smallest on the holocellulose (37%). It is worth noting that changes in the percentage share of holocellulose in wood (Table 4) were minor (less than 1%). Changes were observed, in particular, in the amount of soluble substances in 1% NaOH and in the content of chloroform-ethanol extractives after CTMT (Table 4).

Densified oak wood contained more 1% NaOH soluble substances than non-densified wood. The differences ranged from 4% to 13% and were statistically significant (p < 0.050). A higher value of 1% NaOH soluble substances indicates wood degradation process. This is due to the fact that extractives, such as fatty acids, as well as a portion of lignin, hemicelluloses, and degraded cellulose, can dissolve in weak alkali solutions. An increase in the content of these substances occurs when the wood components are thermally degraded. Hemicelluloses are the most susceptible to degradation (Hoffmann 1981; Pettersen 1984; Fengel and Wegener 1989). İmirzi et al. (2014) reported that degradation starts with hemicelluloses from 120 °C, and the degree of degradation depends on the heating period. A number of phenomena occur as a result of hemicelluloses degradation, which include: (1) lower degrees of polymerization of the hemicelluloses; (2) disruption of hydrogen bonding and Van der Waals forces among the hemicellulose polymer strands; and (3) disruption of weak and covalent bonds between other wood constituents (e.g., lignin). These phenomena could have affected the EMC of oak wood. Cellulose and hemicelluloses are polymers composed of numerous polar hydroxyl groups (-OH). The lower the content of this compounds, the lower the affinity of wood to water and, consequently, the lower the equilibrium moisture content of wood (Morsing 2000; Kamke and Sizemore 2005).

Table 3. ANOVA Evaluation of the Factors Influencing the Chemical Composition of CTMT Oak Wood (Fischer’s F-test; p < 0.050)

Table 4. Chemical Composition of CTMT Oak Wood (Standard Deviation in Parentheses)

After the second cycle of treatment, irrespective of the CTMT temperature, the content of chloroform-ethanol extractives decreased significantly based on the t-test (p < 0.050). Some chloroform-ethanol extractives were volatilized during the second cycle of treatment. This indicates that longer thermo-mechanical treatment resulted in a decrease in the content of chloroform-ethanol extractives. It should be stated that the treatment time has a significant impact on the degradation of wood components (Fengel and Wegener 1989; Kultikova 1999). Mosedale et al. (1998) identified over 50 volatile compounds of diverse chemical types in oak wood (Quercus robur L.) extracts; over 30 of these compounds were quantified. Mészáros et al. (2007) found that the thermal degradation of wood extractives from Robinia pseudoacacia occurs at two stages: the first stage occurs between 130 °C and 250 °C, whereas the second stage takes place between 250 °C and 550 °C. The lower content of chloroform-ethanol extractives in oak wood subjected to the second cycle of treatment did not significantly affect the EMC of wood. Available literature data indicate that when the extractives contents are high, the lower is the equilibrium moisture content of the wood (Popper et al. 2006).

Fig. 1. Swelling in radial (a) and tangential (b) directions of CTMT oak wood versus relative humidity

CTMT oak wood is characterised by higher swelling values in the radial direction than in the tangential direction (Fig. 1). These relations are the reverse to those observed for non-modified wood (Govorčin et al. 1998; Wagenführ 2007). This is due to the fact that oak wood was densified in the radial direction. Hence, the tendency of wood to undergo dimensional changes in the radial direction was greater than in the tangential direction. For densified oak wood, the ratio of swelling in the tangential direction to swelling in the radial direction (T/R) varied from 0.4 to 0.6, depending upon the relative humidity (Fig. 2b). For non-densified wood, the T/R ratio varied from 1.2 to 1.6, which depended upon the relative humidity. These observations are consistent with literature data (Wagenführ 2007). The number of cycles of thermo-mechanical treatment did not significantly affect the radial and tangential swelling. Fang et al. (2012b) observed that the increase in thickness of densified wood is caused by reversible and irreversible swelling. Reversible swelling is caused by the hygroscopic nature of wood, whilst the irreversible swelling is caused by the compression set recovery. Some authors have reported that the main cause of the compression set recovery is the elastic strain energy that is stored in the semicrystalline microfibrils and in the lignin of wood (Higashihara et al. 2000; Navi and Heger 2004). It is also noted that when the relative humidity was higher, the greater were the differences between the radial swelling of densified wood and non-densified wood, which were irrespective of the temperature of densification (Fig. 1a). Higher relative humidity conditions contributed to greater changes in the wood structure, which is mainly attributed to irreversible swelling.

Oak wood modified at 150 °C was observed to have lower swelling values than wood densified at 100 °C. The swelling in the radial direction of oak wood densified at 100 °C ranged from 1.6% to 12.2%, whereas that of oak wood densified at 150 °C ranged from 1.4% to 10.9%, which depended upon the relative humidity (Fig. 1a). The swelling in the tangential direction of oak wood densified at 100 °C varied from 0.8% to 7.2%, whereas in the case of oak wood densified at 150 °C it ranged from 0.6% to 6.9%, which depended upon on the relative humidity (Fig. 1b). These trends are attributed, in particular, to changes in contents of hemicelluloses during the thermo-mechanical treatment (Kocaefe et al. 2008; İmirzi et al. 2014). Fitted curves depicting the trends of oak wood swelling based on the relative humidity are presented in Table 5.

Fig. 2. Volumetric swelling (a) and T/R ratio (b) of CTMT oak wood versus the relative humidity

The volumetric swelling of non-densified oak wood varied from 1.5% to 12.2%, which depended upon the relative humidity. The volumetric swelling of densified oak wood was higher than that of non-densified wood. These observations are attributed to the higher values of radial swelling. The volumetric swelling of oak wood densified at 100 °C varied from 2.5% to 22.0%, whilst that of the oak wood densified at 150 °C varied from 1.9% to 20.8% (Fig. 2a). The number of cycles of thermo-mechanical treatment did not contribute significantly to the differences in volumetric swelling for the range of conditions examined. An important factor affecting volumetric swelling is the untreated wood density (Kord et al. 2010). In the tests conducted, the correlation between the density of the densified wood and volumetric swelling was statistically significant (p < 0.050) with an R2 value of 0.61. A higher density is associated with a greater content of cell walls, which leads to greater susceptibility to swelling.

Table 5. Fitted Curves Predicting the Swelling of Untreated and CTMT Oak Wood at Various Relative Humidity (RH) Values

Water absorption (WA) of non-densified oak wood after 24 h of water soaking and the maximum saturation value were 48.0% (± 0.7%) and 103.9% (± 0.8%), respectively (Fig. 3).

Fig. 3. Water absorption during the soaking of oak wood

The temperature of thermo-mechanical treatment had a significant impact on both the WA of oak wood after 24 h and the maximum WA at saturation (Table 6). The impact of the temperature of wood modification on WA was 78% at 100 °C and 25% at 150 °C. The number of treatment cycles significantly affected the WA of oak wood at maximum saturation with an impact of 55% (Table 6).

Oak wood densified at 100 °C had a higher WA value after 24 h soaking in water than non-densified wood (i.e. increase of 50% at one cycle and 33% after two cycles of treatment). Wood modified at 150 °C was characterised by the same level of WA after 24 h soaking in water as non-densified wood. It is worth noting that WA for maximum saturation of the densified oak wood was lower than that of the non-densified wood. The WA of non-densified oak wood after 24 h soaking in water corresponded to 46% of the WA value at maximum saturation.

Table 6. ANOVA Evaluation of the Factors Influencing the Water Absorption of Oak Wood (Fischer’s F-test; p < 0.050)

The WA after 24 h soaking for oak wood densified at 100 °C was 73% of the WA value at maximum saturation. For oak wood densified at 150 °C, the WA at 24 h was 58% of the WA value at maximum saturation. Lower WA values noted for oak wood densified at 150 °C are a result of changes in the chemical components of wood after thermo-mechanical treatment. The content of soluble substances in 1% NaOH and chloroform-ethanol extractives changed. The WA of oak wood could also be influenced by changes to the wood structure. During densification at higher temperatures, the microvoids of wood close more “completely”. As a result, the access of water to the internal structure is made more difficult. Hill et al. (2012) noted that changes to the glassy polymer matrix are responsible for the water sorption hysteresis of wood when it is subjected to densification.

CONCLUSIONS

- Significant differences in the hygroscopic properties of unmodified and densified wood by CTMT were observed. When higher treatment temperatures were use, the lower was the equilibrium moisture content of the oak wood.

- Densified oak wood contained 4% to 13% more 1% NaOH soluble substances than non-densified wood, which varied depending upon the conditions of CTMT. This may affect the EMC of the oak wood.

- After the second cycle of treatment, irrespective of the treatment temperature, there was ca. 35% decrease in the amount of chloroform-ethanol extractives.

- CTMT oak wood was characterised by higher swelling values in the radial direction than in the tangential direction. For densified wood, the T/R ratio varied from 0.4 to 0.6, whereas for non-densified oak wood the T/R ratio varied from 1.2 to 1.6, which depended upon the relative humidity.

- The number of thermo-mechanical treatment cycles significantly affected the WA of oak wood at its maximum saturation value.

ACKNOWLEDGEMENTS

The authors thank Warsaw University of Life Sciences for their financial support.

REFERENCES CITED

Antczak, A., Radomski, A., and Zawadzki, J. (2006). “Benzene substitution in wood analysis,” Annals of Warsaw University of Life Sciences – SGGW, Forestry and Wood Technology 58, 15-19.

Belt, T., Rautkari, L., Laine, K., and Hill, C. A. S (2013). “Cupping behaviour of surface densified Scots pine wood: The effect of process parameters and correlation with density profile characteristics,” J. Mater. Sci. 48(18), 6426-6430. DOI: 10.1007/s10853-013-7443-1

Blomberg, J., Persson, B., and Bexell, U. (2006). “Effects of semi-isostatic densification on anatomy and cell-shape recovery on soaking,” Holzforschung 60(3), 322-331. DOI: 10.1515/HF.2006.052

Buchelt, B., Dietrich, T., and Wagenführ, A. (2014). “Testing of set recovery of unmodified and furfurylated densified wood by means of water storage and alternating climate tests,” Holzforschung 68(1), 23-28. DOI: 10.1515/hf-2013-0049

Dwianto, W., Morooka, T., Norimoto, M., and Kitajima, T. (1999). “Stress relaxation of Sugi (Cryptomeria japonica D. Don) wood in radial compression under high temperature steam,” Holzforschung 53(5), 541-546. DOI: 10.1515/HF.1999.089

Fang, Ch.-H., Blanchet, P., Cloutier, A., and Barbuta, C. (2012a). “Engineered wood flooring with a densified surface layer for heavy-duty use,” BioResources 7(4), 5843-5854. DOI: 10.15376/biores.7.4.5843-5854

Fang, Ch.-H., Mariotti, N., Cloutier, A., Koubaa, A., and Blanchet, P. (2012b). “Densification of wood veneers by compression combined with heat and steam,” Eur. J. Wood Wood Prod. 70(1-3), 155-163. DOI: 10.1007/s00107-011-0524-4

Fengel, D., and Wegener, G. (1989). Wood: Chemistry, Ultrastructure, Reactions, Walter de Gruyter, Berlin, Germany.

Gindl, M., Reiterer, A., Sinn, G., and Stanzl-Tschegg, S. E. (2004). “Effects of surface ageing on wettability, surface chemistry, and adhesion of wood,” Holz Roh Werkst 62(4), 273-280. DOI: 10.1007/s00107-004-0471-4

Govorčin, S., Sinkovič, T., and Trajkovič, J. (1998). “Distribution of properties in use for oak, beech and fir-wood in radial direction,” in: Wood Structure and Properties, S. Kurjatko and J. Kudela (eds.), Technica University in Zvolen, Slovakia, pp. 30-38.

Higashihara, T., Morooka, T., and Norimoto, M. (2000). “Permanent fixation of transversely compressed wood by steaming and its mechanism,” Mokuzai Gakkaishi 46(4), 291-297.

Hill, C. A. S., Ramsay, J., Keating, B., Laine, K., Rautkari, L., Hughes, M., and Constant, B. (2012). “The water vapour sorption properties of thermally modified and densified wood,” J. Mater. Sci. 47(7), 3191-3197. DOI: 10.1007/s10853-011-6154-8

Hillis, W. E., and Rozsa, A. N. (1978). “The softening temperatures of wood,” Holzforschung 32(2), 68-73. DOI: 10.1515/hfsg.1978.32.2.68

Hillis, W. E., and Rozsa, A. N. (1985). “High temperature and chemical effects on wood stability. Part 2. The effect of heat on the softening of radiata pine,” Wood Sci. Technol. 19(1), 57-66. DOI: 10.1007/bf00354753

Hoffmann, P. (1981). “Chemical wood analysis as a means of characterizing archaeological wood,” in: Proceedings of the ICOM Waterlogged Wood Working Group Conference, Ottawa, Canada, pp. 69-72.

Inoue, M., Kodama, J., Yamamoto, Y., and Norimoto, M. (1998). “Dimensional. stabilization of compressed wood using high-frequency heating,” Mokuzai Gakkaishi 44(6), 410-416.

Irvine, G. M. (1984). “The glass transitions of lignin and hemicellulose and their measurement by differential thermal analysis,” Tappi J. 67(5), 118-121.

ISO 13061-1 (2014). “Physical and mechanical properties of wood – Test methods for small clear wood specimens. Part 1: Determination of moisture content for physical and mechanical tests,” International Organization for Standardization, Geneva, Switzerland.

ISO 13061-2 (2014). “Physical and mechanical properties of wood – Test methods for small clear wood specimens. Part 2: Determination of density for physical and mechanical tests,” International Organization for Standardization, Geneva, Switzerland.

Ito, Y., Tanahashi, M., Shigematsu, M., Shinoda, Y., and Ohta, Ch. (1998). “Compressive-molding of wood by high-pressure steam-treatment: Part 1. Development of compressively molded squares from thinnings,” Holzforschung 52(2), 211-216. DOI: 10.1515/hfsg.1998.52.2.211

İmirzi, H. Ö., Ülker, O., and Burdurlu, E. (2014). “Effect of densification temperature and some surfacing techniques on the surface roughness of densified Scots pine (Pinus sylvestrisL.),” BioResources 9(1), 191-209. DOI: 10.15376/biores.9.1.191-209

Kamke, F. A., and Sizemore, H. (2005). “Viscoelastic thermal compression of wood,” United States Patent No. US 7,404,422 B2

Kocaefe, D., Poncsak, S., Doré, G., and Younsi, R. (2008). “Effect of heat treatment on the wettability of white ash and soft maple by water,” Holz Roh Werkst 66(5), 355-361. DOI: 10.1007/s00107-008-0233-9

Kord, B., Kialashaki, A., and Kord, B. (2010). “The within-tree variation in wood density and shrinkage, and their relationship in Populus euramericana,” Turk. J. Agric. For. 34, 121-126. DOI: 10.3906/tar-0903-14

Kultikova, E. V. (1999). Structure and Properties Relationships of Densified Wood, Master’s Thesis, Virginia Tech, Blacksburg, VA, USA.

Kúdela, J., and Rešetka, M. (2012). “Influence of pressing parameters on dimensional stability and selected properties of pressed beech wood. I. Dimensional stability and density,” Acta Facultatis Xylologiae Zvolen 54(1), 15-24.

Laine, K., Rautkari, L., Hughes, M., and Kutnar, A. (2013). “Reducing the set-recovery of surface densified Scots pine wood by hydrothermal post-treatment,” Eur. J. Wood Wood Prod.71(1), 17-23. DOI: 10.1007/s00107-012-0647-2

Laskowska, A. (2017). “The influence of process parameters on the density profile and hardness of surface-densified birch wood (Betula pendula Roth),” BioResources 12(3), 6011-6023. DOI: 10.15376/biores.12.3.6011-6023

Lindström, T., Tulonen, J., and Kolseth, P. (1987). “Swelling and mechanical properties of cellulose hydrogels. Part VI. Dynamic mechanical properties,” Holzforschung 41(4), 225-230. DOI: 10.1515/hfsg.1987.41.4.225

Mészáros, E., Jakab, E., and Várhegyi, G. (2007). “TG/MS, Py-GC/MS and THM-GC/MS study of the composition and thermal behavior of extractive components of Robinia pseudoacacia,” J. Anal. Appl. Pyrolysis 79(1-2), 61-70. DOI: 10.1016/j.jaap.2006.12.007

Morsing, N. (2000). Densification of Wood. The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to the Grain, Ph.D. Dissertation, Department of Structural Engineering and Materials, Technical University of Denmark, Kongens Lyngby.

Mosedale, J. R., Feuillat, F., Baumes, R., Dupouey, J.-L., and Puech, J.-L. (1998). “Variability of wood extractives among Quercus robur and Quercus petraea trees from mixed stands and their relation to wood anatomy and leaf morphology,” Can. J. For. Res. 28(7), 994-1006. DOI: 10.1139/x98-066

Navi, P., and Heger, F. (2004). “Combined densification and thermo-hydro-mechanical processing of wood,” MRS Bulletin 29(5), 332-336. DOI: 10.1557/mrs2004.100

Pelit, H., Budakçı, M., and Sönmez, A. (2016). “Effects of heat post-treatment on dimensional stability and water absorption behaviours of mechanically densified Uludağ fir and black poplar woods,” BioResources 11(2), 3215-3229. DOI: 10.15376/biores.11.2.3215-3229

Pettersen, R. C. (1984). “The chemical composition of wood,” in: The Chemistry of Solid Wood. Advances in Chemistry Series No. 207, R. M. Rowell (ed.), American Chemical Society, Washington, D.C., pp. 57-126.

Popper, R., Niemz, P., and Torres, M. (2006). “Einfluss des Extraktstoffanteils ausgewählter fremdländischer Holzarten auf deren Gleichgewichtsfeuchte,” Holz Roh Werkst 64(6), 491-496. DOI: 10.1007/s00107-006-0132-x

Požgaj, A., Chowanec, D., Kurjatko, S., and Babiak, M. (1993). Štruktúra a Vlasnosti Dreva [Structure and properties of wood], Príroda, Bratislava, Slovakia.

Schniewind, A. P. (1989). Concise Encyclopedia of Wood and Wood-Based Materials, Pergamon Press, Oxford, UK.

Seifert, K. (1960). “Zur Frage der Cellulose-Schnellbestimmung nach der Acetylacetone-Methode,” Das Papier 14, 104-106.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluitter, J., Templeton, D., and Crocker, D. (2011). Determination of Structural Carbohydrates and Lignin in Biomass, Laboratory Analytical Procedure (LAP), Technical Report NREL/TP-510-42618, National Renewable Energy Laboratory (NREL), U.S. Dept. of Energy, Golden, CO, (http://www.nrel.gov/biomass/pdfs/42618.pdf).

Stamm, A. J., and Millett, M. A. (1941). “The internal surface of cellulosic materials,” J. Phys. Chem. 45(1), 43-54. DOI: 10.1021/j150406a004

TAPPI T 212 om-12. (2015). “One percent sodium hydroxide solubility of wood and pulp,” TAPPI Press, Atlanta, GA, USA.

TAPPI T 222 om-15. (2015). “Acid-insoluble lignin in wood and pulp,” TAPPI Press, Atlanta, GA, USA.

Ülker, O., İmirzi, Ö., and Burdurlu, E. (2012). “The effect of densification temperature on some physical and mechanical properties of Scots pine (Pinus sylvestris L.),” BioResources 7(4), 5581-5592. DOI: 10.15376/biores.7.4.5581-5592

Ülker, O., and Hiziroglu, S. (2017). “Some properties of densified eastern red cedar as function of heat and pressure,” Materials 10(11), 1275. DOI: 10.3390/ma10111275

Wagenführ, R. (2007). Holzatlas [The Atlas of Wood], Fachbuchverlag Leipzig, München, Germany.

Welzbacher, C. R., Wehsener, J., Rapp, A. O., and Haller, P. (2008). “Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale – Dimensional stability and durability aspects,” Holz Roh Werkst 66(1), 39-49. DOI: 10.1007/s00107-007-0198-0

Wise, L. E., Murphy, M., and D’Addieco, A. A. (1946). “Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses,” Paper Trade J. 122(2), 35-43.

Xu, X., and Tang, Z. (2012). “Vertical compression rate profile and dimensional stability of surface-densified plantation poplar wood,” Lignocellulose 1(1), 45-54.

Article submitted: June 14, 2018; Peer review completed: August 19, 2018; Revised version received and accepted: September 18, 2018; Published: October 25, 2018.

DOI: 10.15376/biores.13.4.9005-9019