Abstract

In the 20 years since its invention in Europe, cross-laminated timber (CLT) has become a widely used construction material in parts of the old continent and has started to attract global attention. CLT possesses numerous advantages as a construction material, including its superior structural and environmental performance, as well as the speed and efficiency with which CLT buildings can be erected. In this study, European engineers were surveyed to learn about their current level of awareness of CLT, the major barriers to CLT adoption, and about the most pressing research needs to advance the use of CLT as a construction material. The study used a web-based survey with a convenience sample of 93 different kinds of timber and civil engineers and/or researchers, most of which belong to a European CLT research network. Results showed that participants think that, in general, the level of awareness about CLT among developers, construction managers, engineers, architects, and construction managers, is low. The majority of perceived barriers for CLT adoption involved its building code compatibility and the availability of technical information. The most pressing research needs for CLT development, according to respondents, are in the areas of structural performance and connections, moisture performance, and market research.

Download PDF

Full Article

Cross-Laminated Timber: Status and Research Needs in Europe

Omar Espinoza,a,* Vladimir Rodriguez Trujillo,b Maria Fernanda Laguarda Mallo,a and Urs Buehlmann c

In the 20 years since its invention in Europe, cross-laminated timber (CLT) has become a widely used construction material in parts of the old continent and has started to attract global attention. CLT possesses numerous advantages as a construction material, including its superior structural and environmental performance, as well as the speed and efficiency with which CLT buildings can be erected. In this study, European engineers were surveyed to learn about their current level of awareness of CLT, the major barriers to CLT adoption, and about the most pressing research needs to advance the use of CLT as a construction material. The study used a web-based survey with a convenience sample of 93 different kinds of timber and civil engineers and/or researchers, most of which belong to a European CLT research network. Results showed that participants think that, in general, the level of awareness about CLT among developers, construction managers, engineers, architects, and construction managers, is low. The majority of perceived barriers for CLT adoption involved its building code compatibility and the availability of technical information. The most pressing research needs for CLT development, according to respondents, are in the areas of structural performance and connections, moisture performance, and market research.

Keywords: Cross-laminated timber (CLT); Engineered wood products; Research needs

Contact information: a: Department of Bioproducts and Biosystems Engineering, University of Minnesota, St. Paul, MN, USA; b: Laboratory on Innovation and Technology for Architecture, Universitat Politècnica de Catalunya, Sant Cugat del Vallès; c: Department of Sustainable Biomaterials, Virginia Tech, Blacksburg, VA, USA; *Corresponding author: espinoza@umn.edu

INTRODUCTION

Cross-laminated timber (CLT) is a construction technology developed in Europe in the early 1990s, where it has since then become a widely used building material. In Europe, CLT successfully competes with steel, brick, and concrete in selected market segments, such as multi-family buildings. ANSI/APA PRG 320-2012 (2012) defines CLT as a “prefabricated engineered wood product made of at least three orthogonally bonded layers of solid-sawn lumber that are laminated by gluing of longitudinal and transverse layers with structural adhesives to form a solid rectangular-shaped element intended for roof, floor, or wall applications.” CLT panels are pre-fabricated, with openings for doors, windows, and ducts precision-cut by CNC routers. The prefinished panels are transported to the construction site and put into place with cranes and a small construction crew. Walls and floor systems are joined using metal connectors. Additional insulation layers can be applied to CLT walls and ceilings, or the surfaces can be left bare to take advantage of the warmth and aesthetics of wood. CLT’s attractiveness as a building system originates in part from the speed with which CLT buildings can be raised, resulting in considerable savings in labor and minimal disturbance to the site’s surroundings. Also, part of the attention given to CLT is due to its potential use in tall buildings; 9- and 10-story buildings have been erected, and taller buildings are in preparation (Lattke and Lehmann 2007; Hopkins 2012).

Global Production of CLT

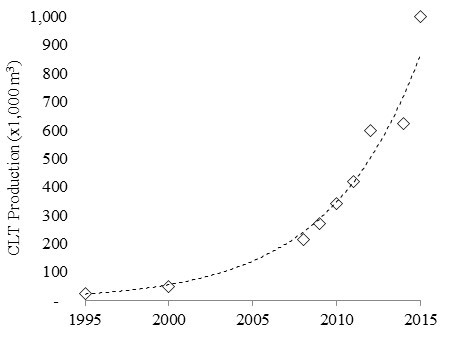

Since its market introduction in the early 1990s, production of CLT has grown at a rapid rate. Most estimates put global annual production of CLT at over 600,000 m3 for 2014 (Muszyński 2015; Plackner 2015), a number that is expected to reach one million m3 by 2016 as operations in Finland, Latvia, Japan, and the U.S. come on line. According to Plackner (2015), CLT production will potentially reach 3 million m3 within the next 10 years, with most of the growth expected to occur outside Western Europe. Figure 1 shows past, present, and estimated future production volume for CLT based on industry newsletters, company contacts, conference presentations, and industry experts.

Fig. 1. Global production of CLT, where the data for 2015 is a forecast (sources: for period 1990-2010, Schickhofer (2011); for period 2011-2015, Muszyński (2015)

Currently, production is heavily concentrated in central Europe, specifically the German-speaking countries, which hold just under 80% of the global installed production capacity as of 2015 (60% in Austria, 17% in Germany, and 3% in Switzerland (Plackner 2015)). Currently, the largest CLT manufacturer is Stora Enso, with two facilities in Austria with a combined capacity of 120,000 m3 (Manninen 2014).

CLT as a Building System

CLT is comparable and, in some aspects superior, to concrete or steel. As a building system, CLT allows long spans without intermediate supports. A CLT panel with seven layers and a total thickness of nine inches can be used to span approximately 25 feet (Karacabeyli and Douglas 2013). Variations of CLT, such as “cassette” or “folded” floors, allow for even greater spans (Crespell and Gagnon 2011). Regarding structural performance, CLT panels can be used as load-bearing plates and shear walls, in contrast to other wood-based engineered composite panel products (Steiger et al. 2008). CLT also has advantages regarding its fire performance because of the predictable burning properties of large-section wood structural elements (Forest Products Laboratory 2010). Furthermore, unlike a wood frame system, CLT constructions create limited concealed spaces, which reduces fire spread (Craft 2011). The seismic performance of CLT has been the subject of several studies. In one experiment, a seven-story building specimen was subjected to severe earthquake-like motions, equivalent to 7.2 on the Richter scale. CLT showed excellent seismic behavior, with maximum inter-story drifts of 1.5 in. and lateral deformation of less than 12 in. (Quenneville and Morris 2007). CLT also performs well in respect to environmental performance when compared to steel, brick, glass, plastics, or concrete (Lippke et al. 2004; Wilson et al. 2005; CORRIM 2010; Hubbard and Bowe 2010).

The environmental performance attributes of CLT originate mainly from the basic characteristics of wood, which have been demonstrated in numerous life-cycle assessments as being extremely favorable. Given sustainably managed forests, replacing steel, concrete, or plastics with wood as raw material reduces carbon emissions. A 2011 study by the U.S. Forest Service concluded that wood has superior environmental performance over other materials such as concrete or steel, even when the wood stems from diseased trees (Ritter et al. 2011). A number of independent studies compared the environmental performance of multi-story buildings built with CLT and concrete (John et al. 2008; Robertson et al. 2012; Chen 2012; Durlinger et al. 2013). These studies consistently concluded that CLT buildings had lower embodied energy than concrete-based buildings and superior performance compared with concrete and steel with respect to ozone depletion, global warming potential, and eutrophication (John et al. 2008; Robertson et al. 2012; Chen 2012; Durlinger et al. 2013). Furthermore, wood has the additional benefit of acting as a carbon sink (Bowyer et al. 2011). Lastly, tests in Canada showed that CLT’s volatile organic compounds and formaldehyde emissions can be below established standards (Robertson et al. 2012).

CLT Research Centers in Europe

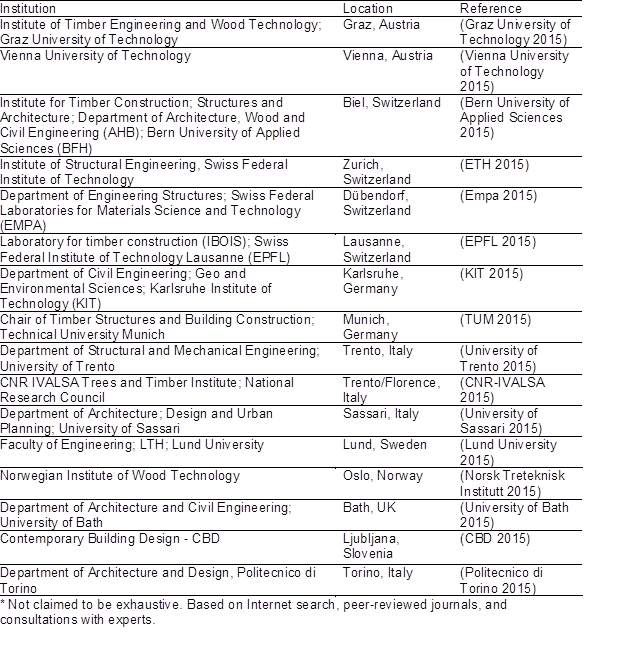

Development of modern CLT was the result of a joint effort by industry and academia (Crespell and Gagnon 2011), initiated in the early 1990s by the Swiss government as part of an effort to develop new markets for sawmill by-products. What followed was remarkable interest in the resulting material, CLT. In 2012 there were reportedly over 100 CLT projects in Europe (Mohammad et al. 2012), and considerable research activity in European institutions (Table 1).

There is also interest in CLT internationally. In 2014, the joint World Conference on Timber Engineering and Forest Products in Quebec City, Canada, listed 8 sessions and over 56 presentations on CLT research (WCTE 2014), demonstrating global interest in CLT. Thus, as CLT today is being used globally, research into its use and advancement is also occurring on a global scale.

Research Objective

This study identified major research needs for the advancement and growth of CLT, as perceived by timber engineering experts in Europe. To accomplish this objective, European experts in timber engineering and CLT were surveyed to learn about their awareness, perceived barriers to adoption, and views on research needed to further develop market adoption of CLT.

Table 1. Research Institutions in Europe Conducting Research about CLT in 2015*

Research Methods

Given the large potential for expanded wood products use in the European building industry, a web-based target survey was conducted to collect the opinion of European CLT experts. Dillman’s tailored design methods for survey design and implementation were followed (Dillman et al. 2009). Web-surveys are increasingly common and are a cost-effective method to collect information (Rea 2005). Web-surveys, when carefully done, can generate response rates and quality of responses comparable to the more traditional method of mailed surveys (Kaplowitz et al. 2004). The targeted sampling approach chosen for this survey was a non-probability strategy, where researchers do not have certainty of whether all potential respondents have the same chance of selection (Rea 2005). Thus, generalizations from the results of this survey cannot be made for the entire population of interest. However, for this survey, targeted sampling was chosen over random sampling due to time and resource limitations and because of the existence of a limited set of current and valid addresses. Further details of the methodology employed for this study are explained below.

Questionnaire Development

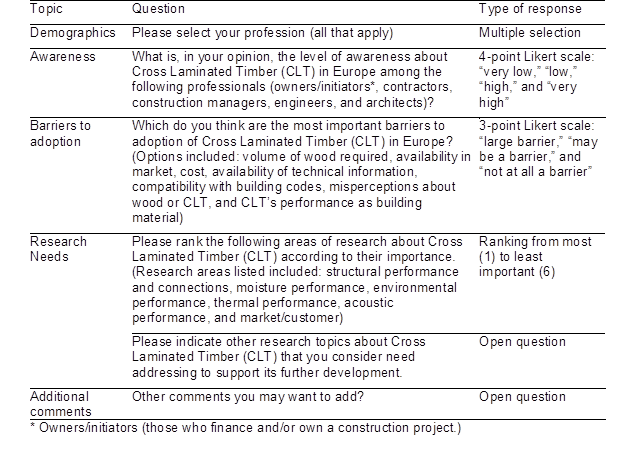

The survey instrument was developed in two steps: first, a list of topics led to an initial draft of the questionnaire based on the research objectives, which then was reviewed by experts from academia and industry. Following some minor adjustments based on feedback obtained, a web-enabled version of the questionnaire was created using the Qualtrics online survey software (Qualtrics 2014). Four additional experts (two from industry, two from academia) then reviewed this version of the questionnaire and their feedback shaped the final version of the questionnaire. Topics, questions, and response methods are listed in Table 2.

Table 2. Summary of Questionnaire Items

Sample Frame Development

For this survey, the population of interest was comprised of European experts in timber engineering as well as civil engineers and researchers with a focus on wood construction. A non-probability sampling strategy was adopted; therefore results and conclusions are only valid for the sample. Numerous experts on the list assembled were part of the program on European Cooperation in Science and Technology (COST), a “framework supporting trans-national cooperation among researchers, engineers, and scholars across Europe” (COST 2015a). Specifically, experts chosen belonged to the following COST groups: COST Action FP1402, a network on Structural Timber Design, with the objective of bridging research results and the needs of designers, industry, and regulators (COST 2015b) and the Management Committee of COST Action FP1101, “Assessment, reinforcement and monitoring of timber structures” (COST 2015c).

Experts included in the distribution list assembled worked in research and educational institutions, wood construction firms, manufacturing entities, state-funded laboratories, timber engineering consulting firms, private industry, industry associations, design and engineering firms, and in structural software companies. The final distribution list contained 93 names and addresses.

Survey Implementation

The survey was implemented following Dillman’s Tailored Design Method (Dillman et al. 2009). First, an email message was mailed to all names in the distribution list in late January of 2015 explaining the goals of the survey and containing a link to the questionnaire. Then, a first reminder was sent to non-respondents after one week and a second reminder after the second week. The survey was closed four weeks later and answers were collected in spreadsheet form for analysis.

Data Analysis and Results Validation

Data analysis was carried out using Microsoft Excel and IBM SPSS (Statistical Package for the Social Sciences) Statistics software. Descriptive statistics were calculated, and qualitative responses were coded and categorized for analysis. For validation, results from the survey were presented during a meeting in Karlsruhe, Germany, of a recently formed special working group within the COST Action framework, “Solid Timber Construction – Cross Laminated Timber” (COST Action FP1402 – Working Group 2). The stated objective of this working group is to “Collect, discuss, assess, harmonize and condense fragmented state-of-the-art concerning CLT with focus on testing and design (Brandner and Tomasi 2015).” Among other specific tasks, this group is working on the incorporation of CLT into the European standard (Eurocode 5 – Design of timber structures; JRC 2015), and the development of a European version of the CLT handbook, with expected publication in 2018.

Limitations

As with any research, there are limitations and potential sources of error that need to be considered when making inferences and generalizations from the results obtained. For this study, the most important limitation is that results cannot be generalized to the entire population, as a non-probability sampling strategy was adopted. The distribution list was developed based on the availability of e-mail addresses, and the number of respondents represents a small fraction of the population of interest. Furthermore, the answers provided by the respondents may reflect some of the biases characteristic of their occupations (for example, a fire engineer would be more likely to favor “fire performance” as a major research need). Also, all limitations inherent to any survey apply to this study, such as recall bias or different interpretation of response scales used (Alreck and Settle 2004; Dillman et al. 2009).

RESULTS AND DISCUSSION

Survey Implementation and Response

The survey was conducted in January and February of 2015. After the initial communication and two reminders, the survey was closed on February 23, 2015. Fifty-one usable responses were received out of 93 invitations sent, resulting in an adjusted response rate of 53.8% (accounting for one failed email). No incomplete responses were received, thus all answers were included in the analysis.

Respondents’ Demographics

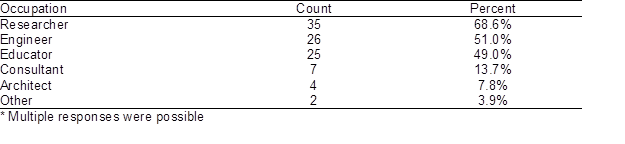

Table 3 lists the self-reported occupations and professions of respondents. Most of them indicated “researcher” as occupation (68.6% of respondents), followed by “engineer” (51.0%) and “educator” (49.0%), respectively. Numerous respondents reported more than one occupation, with the most common combinations being engineer and researcher (37.3%) and educator and researcher (31.4%). Lastly, 12 respondents (23.5%) indicated being an engineer, researcher, and educator. As for the geographic distribution of respondents, respondents were not concentrated geographically and were widely distributed over 25 European countries. However, most responses were received from Spain (10 responses, or 19.6% of responses), Sweden (5, or 9.8%), and Italy (4, or 7.8%).

Table 3. Respondents’ Self-Reported Occupations and Professions (N=51)

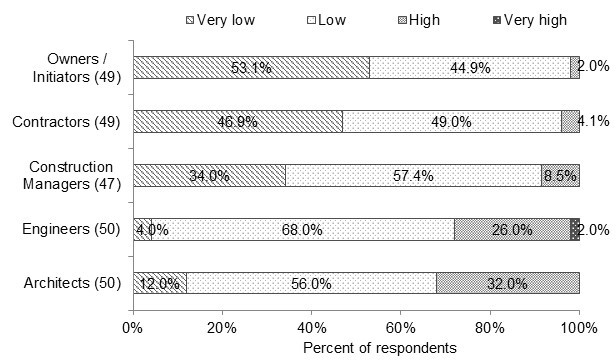

Perceived Level of Awareness

Respondents were asked about their perceptions of the level of awareness of CLT among building owners, contractors, construction managers, engineers, and architects. Results are shown in Fig. 2. According to the participants, the level of awareness is low for construction managers, contractors, and owners/initiators. In fact, 91.5%, 95.9%, and 98.0% of respondents, respectively, rate the awareness as “low” or “very low” for these professionals. These results are quite surprising, as CLT has been used in Europe for more than 20 years with extensive coverage in trade journals and in the news. However, awareness was rated higher for engineers and architects with 32.0% and 28.0% of respondents rating these professionals’ level of awareness “high” or “very high,” respectively.

Respondents were given the opportunity to add a professional category and rate the level of awareness among members of the category added. Only three participants suggested additional categories, including “research” (very high level of awareness), “general public” (very low awareness), and “builders of wood-based structures” (high awareness).

Fig. 2. Perceived level of awareness among different occupations (number of respondents in parentheses)

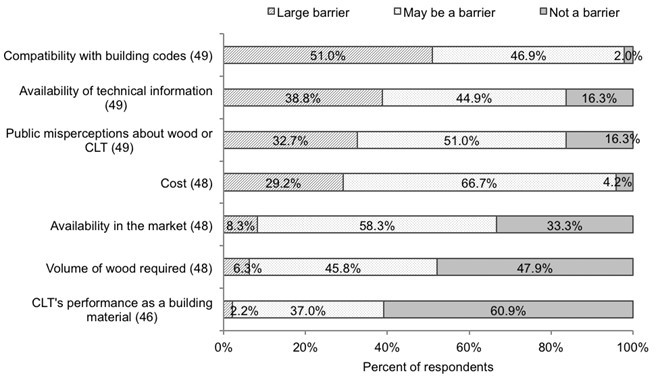

Perceived Barriers for CLT Adoption

The third question in the survey asked respondents to rate a list of potential barriers to the adoption of CLT in Europe. Results can be seen in Fig. 3. Barriers to CLT adoption in Europe perceived by respondents were “compatibility with building code;” which 51.0% of respondents considered a “large barrier,” followed by “availability of technical information,” “misperceptions about wood or CLT,” and “cost” (38.8%, 32.7%, and 29.2% of respondents, respectively). “Availability in the market” and “volume of wood required for CLT” were considered potential barriers (58.3% and 45.8% rated these factors as “may be a barrier,” respectively). Lastly, 60.9% of respondents indicated that CLT’s performance as a building material is “not at all a barrier.”

These results can be contrasted with those from recent research in the United States, where a nationwide survey of architects was conducted (Laguarda-Mallo and Espinoza 2015, 2014). U.S. architects coincided with European engineers in that building code compatibility is a large barrier (in the U.S. study, just under 90% of respondents deemed building code compatibility as large or potential barrier). Results were similar for cost and availability of technical information. Perceptions differed, however, for availability of CLT, with 94% and 67% of U.S. architects and European engineers, respectively, considering availability of CLT a large or potential barrier. This more pronounced concern for the availability of CLT in the U.S. is not surprising, as CLT is not yet readily available in the U.S. In fact, currently, only one manufacturer (Smartlam) produces CLT panels, and only a handful of projects have been built with imported CLT at the time of writing.

Fig. 3. Perceived barriers to adoption (number of respondents in parentheses)

Respondents were given the opportunity to indicate barriers not listed, in the “other” category. Seven participants entered suggestions, including: fear of drawbacks of wood as material (fire damage, decay, insect damage), thermal performance, lack of experience in design of CLT buildings, high cost (for residential buildings), fire performance (in tall buildings), calculation of connections, and lack of awareness by the public. All these barriers mentioned were considered as large barriers.

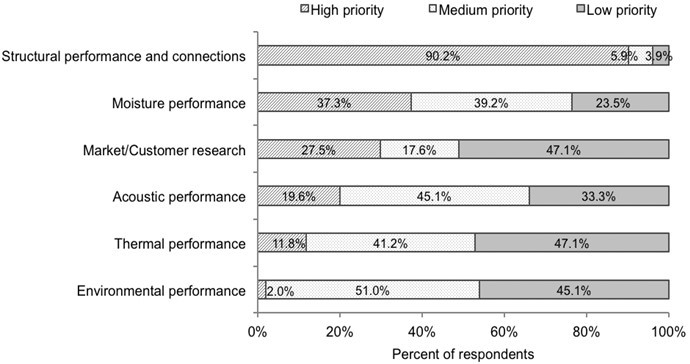

Research Needs

The fourth question in this survey asked about research needs related to CLT. Participants were presented with a list of six potential research topics and asked to rank these topics in order of importance. Results for this question are summarized in Fig. 4. To facilitate the interpretation, answers were grouped into three options: first and second ranked were grouped into a “high priority” category, third and fourth into a “medium priority” category, and items ranked fifth and sixth were grouped into a “low priority” category. Just over 90% of respondents indicated that “structural performance and connections” were the most important research needs. Of all respondents, 76.5%, 64.7%, and 45.1%, respectively, regarded “moisture performance,” “market/customer research,” and “acoustic performance” as medium or high research priority. Interestingly, 96.1% of respondents indicated that “environmental performance” is a “medium” to “low” research priority. This was not expected, given that the environmental aspects of CLT are repeatedly mentioned as one of its biggest selling points. It can be speculated that for Europeans, where the environmental advantages of constructing with wood have been heavily promoted for the last 20 years or more, that respondents did not feel a need for much more effort in that area. Another unexpected result is that structural performance was the subject identified as the area of greatest research need, whereas the same topic was rated as the least important barrier to wider adoption. One potential explanation for this apparent contradiction is the structural engineering research background of most respondents.

Fig. 4. Ranking of research needs (N=51). Ranked 1st and 2nd: high priority; 3rd and 4th: medium priority; and 5th and 6th: low priority

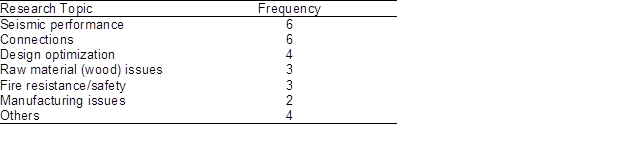

As with previous questions, participants had the opportunity to add research needs that they consider important. In total, 20 participants suggested research topics. Several themes were mentioned more than once and are aggregated in Table 4.

Table 4. Research Topics Suggested by Respondents

The most common topics in need of research suggested by respondents in an open-ended question were seismic performance, connections, and design. Raw material issues included effect of grain direction on joint performance and the use of alternative and local species for CLT. Manufacturing issues included were: optimization of CNC cutting of CLT panels, perforation rates of connections, and modular fabrication. “Others” included the development of building systems, use of CLT panels as beams, using CLT for tall buildings, and durability.

Open Question

Lastly, respondents were asked to add any comments about the topic of this survey. Only five participants volunteered comments ranging on the visual appearance of CLT design to limitations to CLT use. One respondent wrote, “Timber availability, building tradition, and clients’ perception varies a lot from country to country in Europe […]. In Portugal, timber is expensive. Therefore, if it’s going to be used it should be seen and appreciated. But exposed CLT structures are not always very attractive, nor suitable to elaborated architectural design and raise fire […] concerns. Besides, timber durability in Southern Europe climates and thermal performance of low-weight buildings in summer conditions are [a] great issues in these countries.”

CONCLUSIONS

Cross-laminated timber (CLT) is an innovative wood-based building product, with significant economic and environmental advantages over traditional building materials. CLT buildings effectively store large amounts of carbon and have been shown to produce lower emissions than construction executed in concrete or steel. Furthermore, the prefabricated nature of CLT allows effective and efficient construction and minimal disruption to site surroundings. Structurally, research has shown that CLT can compete and even outperform more traditional materials. These advantages have resulted in exponential growth in CLT production, primarily in Central Europe (Fig. 1). Although production and construction is still highly concentrated in this area, interest is growing in other parts of the world including Australia, New Zealand, Japan, and North America. In a similar way, research activity on CLT structural design, properties, and testing has grown rapidly. In this study, European experts in timber engineering, civil engineering, and research voiced their perceptions about (a) the level of awareness about CLT in the construction community in Europe, (b) their views on the most pressing research needs for CLT, and also about (c) the perceived barriers to CLT adoption in Europe. The major findings are summarized below.

- Respondents deemed the perceived level of awareness of CLT in the European construction industry as low, particularly among engineers and architects. These two groups were rated as having low or very low levels of awareness (72 and 68%, respectively, were ranked in these two groups by the respondents). However, awareness was perceived to be lower for owners, contractors, and construction managers.

- The major barriers to CLT adoption, according to participants, were building code compatibility (51.0% considered it a large barrier to adoption), availability of technical information (38.8%), public misperceptions about wood (32.7%), and cost (29.2%). CLT availability and volume of wood required for its construction were perceived as potential barriers by 58.3% and 45.8% of respondents, respectively. Lastly, CLT’s performance as building material was not considered a barrier by 60.9% of engineers.

- The most important research needs, according to survey participants, were CLT structural performance and connections (90.2% considered this as “high priority”), followed by moisture performance (37.3%) and market research (27.5%). CLT’s thermal (11.8%) and environmental performance (2.0%) do not seem to be a high priority research need for European timber engineers.

Results from this study apply only to the participants because of the non-probability sampling strategy adopted. Generalizations to the entire European CLT professional community thus cannot be made. Further research includes expanding the geographical scope to North America and other regions around the globe, as wells as an in-depth analysis of the research needs considered most urgent by European experts.

REFERENCES CITED

Alreck, P. L., and Settle, R. B. (2004). The Survey Research Handbook, 3rd Ed., Vol. XXV, McGraw-Hill, Irwin, Boston, MA.

ANSI/APA PRG 320-2012. (2012). “Standard for performance-rated cross-laminated timber,” American National Standards Institute, Washington, DC.

Bern University of Applied Sciences. (2015). “Department of Architecture, Wood and Civil Engineering,” Retrieved April 10, 2015, from http://www.bfh.ch/en/bfh/the_six_departments/.

Bowyer, J., Bratkovich, S., Frank, M., Fernholz, K., Howe, J., and Stai, S. (2011). Managing Forests for Carbon Mitigation, Dovetail Partners, Inc., Minneapolis, MN.

Brandner, R., and Tomasi, R. (2015). “Solid timber construction – Cross laminated timber: Working program,” 1st Workshop COST Action FP1402 [PowerPoint Presentation], Karlsruhe, Germany.

CBD. (2015). “Contemporary building design (CBD),” Retrieved April 10, 2015, from http://www.cbd.si.

Chen, Y. (2012). “Comparison of environmental performance of a five-storey building built with cross-laminated timber and concrete,” Sustainable Building Science Program, University of British Columbia – Department of Wood Science, Vancouver, BC, Canada.

CNR-IVALSA. (2015). “Trees and timber institute,” Retrieved April 10, 2015, from http://www.ivalsa.cnr.it/en/.

CORRIM. (2010). “The consortium for research on renewable industrial materials,” Retrieved October 19, 2010, from http://www.corrim.org/.

COST. (2015a). “European cooperation in science and technology (COST),” Retrieved April 18, 2015, from http://www.cost.eu.

COST. (2015b). “FPS COST action FP1402 – Basis of structural timber design – From research to standards,” Retrieved April 18, 2015, from http://www.cost.eu/COST_Actions/fps/Actions/FP1402.

COST. (2015c). “COST Action FP1101 – Forests, their products and services (FPS),” Retrieved April 18, 2015, from http://www.costfp1101.eu.

Craft, S. (2011). “Fire performance of CLT assemblies,” Cross Laminated Timber Symposium, FPInnovations, Vancouver, BC, Canada, February 8-9 [PowerPoint Presentation].

Crespell, P., and Gagnon, S. (2011). “Cross-laminated timber: A primer,” [PowerPoint Presentation], FPInnovations, Vancouver, BC, Canada.

Dillman, D. A., Smyth, J. D., and Christian, L. M. (2009). Internet, Mail, and Mixed-Mode Surveys: The Tailored Design Method (Third Ed.), Wiley, New York.

Durlinger, B., Crossin, E., and Wong, J. (2013). “Life cycle assessment of a cross laminated timber building,” Market Access, Forest and Wood Products Australia. Melbourne, Australia.

Empa. (2015). “Department of Civil and Mechanical Engineering,” Retrieved April 17, 2015, from http://www.empa.ch/plugin/template/empa/51/1414/—/l=2/changeLang=true/lartid=1414/orga=/type=/theme=/bestellbar=/new_abt=/uacc=.

EPFL. (2015). “Laboratory for timber constructions ibois,” Retrieved April 17, 2015, from http://ibois.epfl.ch/page-10874.html.

ETH. (2015). “Institute of structural engineering (IBK),” Retrieved April 10, 2015, from http://www.ibk.ethz.ch/index_EN.

Forest Products Laboratory. (2010). Wood Handbook, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI.

Graz University of Technology. (2015). “Institute of timber engineering and wood technology,” Retrieved April 10, 2015, from http://portal.tugraz.at/portal/page/portal/TU_Graz/Einrichtungen/Institute/Homepages

Hopkins, P. (2012). “Timber challenges steel as the new apartment building stock,” The Sydney Morning Herald, Retrieved from http://www.smh.com.au/business/property/timber-challenges-steel-as-the-new-apartment-building-block-20120715-2243v.html.

Hubbard, S. S., and Bowe, S. A. (2010). “A gate-to-gate life-cycle inventory of solid hardwood flooring in the Eastern US,” Wood and Fiber Science 42(CORRIM Special Issue), 79-89.

John, S., Nebel, B., Perez, N., and Buchanan, A. (2008). “Environmental impacts of multi-storey buildings using different construction materials,” University of Canterbury – Department of Civil and Natural Resources Engineering, Christchurch, New Zealand.

JRC. (2015). “EN 1995: Design of timber structures,” Retrieved April 18, 2015, from http://eurocodes.jrc.ec.europa.eu/showpage.php?id=135.

Kaplowitz, M. D., Hadlock, T. D., and Levine, R. (2004). “A comparison of web and mail survey response rates,” Public Opinion Quarterly 68(1), 94-101.

Karacabeyli, E., and Douglas, B. (eds.). (2013). Cross-Laminated Timber Handbook, FPInnovations and Binational Softwood Lumber Council, Pointe-Claire, QC, Canada.

KIT. (2015). “Department of Civil Engineering, Geo and Environmental sciences,” Retrieved April 10, 2015, from http://www.bgu.kit.edu/english/index.php.

Laguarda-Mallo, M. F., and Espinoza, O. (2015). “Awareness, perceptions and willingness to adopt cross-laminated timber in the United States,” Journal of Cleaner Production 94, 198-210. DOI:10.1016/j.jclepro.2015.01.090

Laguarda-Mallo, M. F., and Espinoza, O. (2014). “Outlook for cross-laminated timber in the United States,” BioResources 9(4), 7427-7443. DOI: 10.15376/biores.9.4.7427-7443

Lattke, F., and Lehmann, S. (2007). “Multi-storey timber constructions: Recent trends,” J. Green Building 2(1), 119-130. DOI: 10.3992/jgb.7.3.131

Lippke, B., Wilson, J., Perez-Garcia, J., Bowyer, J., and Meil, J. (2004). “CORRIM: Life-cycle environmental performance of renewable building materials,” Forest Products Journal 54(6), 8-19.

Lund University. (2015). “Faculty of engineering (LTH),” Retrieved April 10, 2015, from http://www.lth.se/english.

Manninen, H. (2014). “Long-term outlook for engineered wood products in Europe,” European Forest Institute, Joensuu, Finland.

Mohammad, M., Gagnon, S., Douglas, B., and Podesto, L. (2012). “Introduction to cross laminated timber,” Wood Design Focus 22(2), 3-12.

Muszyński, L. (2015). “The CLT talk,” 2015 Small Log Conference [PowerPoint Presentation], Forest Business Network, Coeur d’Alene, ID.

Norsk Treteknisk Institutt. (2015). “Norwegian institute of wood technology,” Retrieved April 10, 2015, from http://www.treteknisk.com/fullstory.aspx?m=1463.

Plackner, H. (2015). “Brettsperrholz wlichst global,” Holzkurier 2015, 12-13.

Politecnico di Torino. (2015). “Department of architecture and design,” Retrieved April 10, 2015, from http://www.polito.it.

Qualtrics. (2014). “Qualtrics survey software,” Qualtrics, LLC, Provo, Utah. Retrieved from http://www.qualtrics.com/.

Quenneville, P., and Morris, H. (2007). “Japan Kobe earthquake shake table simulation – The earthquake performance of multi-storey cross laminated timber buildings,” New Zealand Timber Design Journal 15(4), 3-8.

Rea, L. M. (2005). Designing and Conducting Survey Research: A Comprehensive Guide, 3rd ed., Vol. XVI, Jossey-Bass, San Francisco, CA.

Ritter, M. A., Skog, K., and Bergman, R. (2011). “Science supporting the economic and environmental benefits of using wood and wood products in green building construction,” U.S. Forest Service, Washington, DC.

Robertson, A. B., Lam, F. C. F., and Cole, R. J. (2012). “A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete,” Buildings 2012(2), 245-270.

Schickhofer, G. (2011). “CLT – European experiences,” [PowerPoint Presentation] Cross Laminated Timber Symposium, February 8-9, FPInnovations, Vancouver, BC, Canada.

Steiger, R., Gülzow, A., and Gsell, D. (2008). “Non destructive evaluation of elastic material properties of crosslaminated timber (CLT),” paper presented at the Conference COST E53, 29-30 October 2008, Delft, The Netherlands. http://www.coste53.net/downloads/Delft/Presentations/COSTE53-Conference_Delft_Steiger_Guelzow_Gsell.pdf.

TUM. (2015). “Department of architecture,” Retrieved April 10, 2015, from https://www.ar.tum.de/en/home/.

University of Bath. (2015). “Department of Architecture and Civil Engineering,” Retrieved April 10, 2015, from http://www.bath.ac.uk/ace/.

University of Sassari. (2015). “Faculty of architecture,” Retrieved April 10, 2015, from http://ww2.architettura.uniss.it/article/archive/49.

University of Trento. (2015). “Department of Civil, Environmental and Mechanical Engineering,” Retrieved April 10, 2015, from http://web.unitn.it/en/dicam.

Vienna University of Technology. (2015). “Vienna University of Technology,” Retrieved April 10, 2015, from https://www.tuwien.ac.at/en/tuwien_home/.

WCTE. (2014). “World conference on timber engineering,” Retrieved April 19, 2015, from http://www.wcte2014.ca/default.aspx?p=1980&l=en.

Wilson, J. B., Lippke, B., Comnick, J., Johnson, L. R., Perez-Garcia, J., Dancer, E. R., and Puettmann, M. E. (eds.) (2005). Special Issue: The Environmental Performance of Renewable Building Materials in the Context of Residential Construction (Vol. 37), Society of Wood Science and Technology, Monona, WI.

Article submitted: July 27, 2015; Peer review completed: October 16, 2015; Revised version received and accepted: October 21, 2015; Published: November 16, 2015.

DOI: 10.15376/biores.11.1.281-295