Abstract

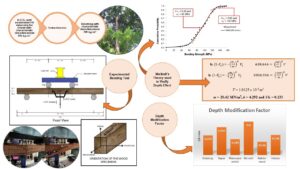

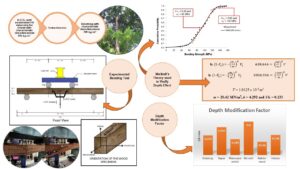

The design practice has shifted from permissible stress design to limit state design using Eurocode 5 (EC5), which introduces design strength optimization. However, the adoption of EC5 in Malaysia cannot be done directly due to the absence of design strength data for Malaysian timber species. This paper presents a study that evaluates the bending strength properties, moisture content, and density of kekatong (Cynometra malaccensis) timber specimens using the Weibull theory to produce 1/k values for the local timber species. The depth impact adjustment factors for kekatong timber had a value of 0.23, which is not far from the well-established 1/k value of 0.2 for softwood and temperate hardwood with characteristic densities below 700 kg/m3 in EC5. The study shows that the bending strength of local timber is affected by its volume, and the variation of bending strength at several probabilities is in close agreement with theoretical predictions. Overall, the study provides important insights for the design of timber structures using Malaysian timber species, which can be used to improve the safety and sustainability of timber structures.

Download PDF

Full Article

Depth Effect of Tropical Heavy Hardwood of Kekatong Species Towards EC5 using Weibull’s Theory

Nasroien Bambang Purwanto,a Norshariza Mohamad Bhkari,a,b,* Wei Chen Lum,c Zakiah Ahmad,a Anis Azmi,d Muhammad Amirul Akmal Rosli,a Nurul Faiizin Abdul Aziz,e and Nurul Izzatul Lydia Za’ba f

The design practice has shifted from permissible stress design to limit state design using Eurocode 5 (EC5), which introduces design strength optimization. However, the adoption of EC5 in Malaysia cannot be done directly due to the absence of design strength data for Malaysian timber species. This paper presents a study that evaluates the bending strength properties, moisture content, and density of kekatong (Cynometra malaccensis) timber specimens using the Weibull theory to produce 1/k values for the local timber species. The depth impact adjustment factors for kekatong timber had a value of 0.23, which is not far from the well-established 1/k value of 0.2 for softwood and temperate hardwood with characteristic densities below 700 kg/m3 in EC5. The study shows that the bending strength of local timber is affected by its volume, and the variation of bending strength at several probabilities is in close agreement with theoretical predictions. Overall, the study provides important insights for the design of timber structures using Malaysian timber species, which can be used to improve the safety and sustainability of timber structures.

DOI: 10.15376/biores.18.4.6882-6895

Keywords: Malaysian tropical hardwood; Eurocode 5; Bending strength; Weibull’s Theory; Depth effect; Depth modification factor

Contact information: a: School of Civil Engineering, College of Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, Malaysia; b: Institute for Infrastructure Engineering and Sustainable Management, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, Malaysia; c: Faculty of Bioengineering and Technology, Universiti Malaysia Kelantan, Jeli Campus, 17600 Jeli, Kelantan, Malaysia; d: Faculty of Engineering, Built Environment and Information Technology, MAHSA University 42610 Jenjarom, Kuala Langat, Selangor, Malaysia; e: School of Civil Engineering, College of Engineering, Universiti Teknologi MARA Cawangan Pahang, 26400 Bandar Tun Razak, Pahang, Malaysia; f: Faculty of Engineering and the Built Environment, SEGi University, Jalan Teknologi, Kota Damansara, 47810 Petaling Jaya, Selangor Darul Ehsan, Malaysia;

* Corresponding author: nshariza@uitm.edu.my

GRAPHICAL ABSTRACT

INTRODUCTION

Wood, concrete, and steel are commonly used in construction. To understand how to design and construct structures with these materials, designers need to understand how materials respond to mechanical forces. However, testing equipment that can measure the characteristics of large building elements is rare and expensive. Therefore, measurements are often taken on small clear specimens, assuming that the results can be extrapolated to structural size. Strength properties of wood from small clear specimens are then corrected for variables such as moisture content and load duration, but this method does not account for growth defects like knots in structural timber. To accurately reflect the conditions in which timber is used in practice, it is important to test the structural size. This will establish a consistent basis for designing the timber structures (Lee et al. 2003). Bending strength is a crucial factor in designing wood structures because it directly impacts the structural integrity and safety of the construction. An alternative approach to justify the focus on bending strength is that these tests effectively encompass a combination of tensile and compressive phenomena simultaneously. Adequate bending strength ensures the structure’s abilities to support various loads without excessive deflection or failure. Clear wood, structural timber, and other wood-based materials can all be tested for the size effect. It is essential to establish a consistent basis for designing timber structures that can be accepted by the timber engineering and research community (Madsen 1990; Oh 2014; Baharin et al. 2020).

The Weibull distribution is a mathematical way to describe size effects. This theory is based on the weakest link, meaning that the overall strength of an object depends on its weakest section. The weakest link theory is used to model the correlation between density and dimension (width and depth) by calculating the k value. A mathematical model is created using this theory to study the impact of dimensions on the k value, which is compared to the EN 384 (2016) modification factor. However, this formula only applies to softwood and a few hardwood species with a characteristic density less than 700 kg/m3. In Malaysia, timber structure design follows permissible stress codes from MS 544: Part 2 and MS 544: Part 3. To maintain design continuity, as noted by Azmi et al. (2022), local designers are encouraged to adopt Eurocode 5 (EC5) limit state design principles for creating safe and cost-effective structures. However, due to potential variations in Malaysian tropical hardwood properties compared to other types of timber, the direct adoption of EC5 should be reconsidered and investigated. Therefore, Weibull’s theory is used to calculate the k value for kekatong (Cynometra malaccensis) with density of 1000 kg/m3. This study aims to determine if the modification factor of 1/k = 0.2 is applicable to tropical hardwoods with characteristic densities greater than 700 kg/m3.

Bohannan (1996) conducted the first study of Weibull brittle fracture applied to timber. The study revealed that larger wooden members, such as deep-bending and wide-tension members, are weaker than their smaller counterparts. Size effects on the strength of timber have also been linked to depth and length. Schneeweiß and Felber (2013) state that the bending strength of wood can be affected by size, whether it is a small or large specimen, because of its dependence on the ratio of span and depth. Probabilistic theories such as the Weibull strength theory are often used to describe statistically based size impacts on strength for lignocellulosic material like timber (Barrett et al. 1990). The weakest link theory suggests that the strength of a material is dependent on the size of the highly stressed volume and that a material is only as strong as its weakest link (Tannert et al. 2012; Schneeweiß and Felber 2013). Walley and Rogers (2022) mentioned that, when analyzing bending members, both the magnitude and location of stresses must be considered when applying the weakest link theory of strength. Timber beams consist of elements of length in the direction of bending stresses, and failure at any cross-section throughout the length leads to complete failure of the beam. This makes length a factor in statistical theory. A statistical strength theory based on the weakest link theory suggests that when subjected to bending, a chain is as strong as its weakest link (Takeda and Hashizume 1999). In addition, timber flaws vary along the length, so a two-parameter Weibull distribution is needed with zero strength for infinite size. Madsen and Buchanan (2011) mentioned size’s effects by considering bending, strength results are between tensile and compressive strength due to the mix of tension and compression. Wood is brittle in tension and ductile in compression, so bending failure can be either brittle or ductile. An ideal brittle material fails when a single particle fails (Köhler et al. 2009; Oh 2014). Buchanan (1983) and Fonselius (1997) mentioned that clear timber’s length had approximately the same effect on strength for both testing modes, but the depth’s effect was much greater for tension members than for bending members. Through using brittle fracture theory, the strength of timber in bending can be related to the strength in axial tension. A unified size-effect model based on the weakest link brittle fracture theory has been developed to represent statistical size effects in visually graded structural timber (Barrett et al. 1995). Probabilistic theories such as the Weibull strength theory adequately describe statistical based size impacts on the strength of lignocellulosic materials such as timber. The Weibull distribution is based on the weakest link theory, which states that a material fails when one of its small elements fails (Tannert et al. 2012). Schneeweiß and Felber (2013) mentioned that the strength of the material depends on the size of the highly stressed volume, and the strength in wood decreases when the stress volume increases due to weak locations in the wood. Weibull theory can compute the probability of failure of a single volume of timber subjected to bending stress when the stresses are known. To explain Weibull theory a single volume subjected to bending, consider a volume V of timber under distribution of bending stress σ. Weibull’s theory allows the computation of the probability of failure Fν of this volume V when the stresses are known. This probability is defined by Equation 1:

(1)

where V* is the reference volume, m, k, and σ0 are material constants, and σ0 represents the material’s minimum strength. Equation 1 uses three material constants, making it a “three-parameter” Weibull model. Assuming that σ0 = 0, a simplified, “two-parameter” model can be used. The assumption of zero minimum strength might seem implausible, but as demonstrated by Foschi and Barrett (1975), both models produce results that are roughly equivalent for failure probability greater than or equal to 0.05. The coefficient of variation of the material for a specific geometry and loading configuration is related to the parameter k.

Equation 1 changes to the following when the structural element is subject to uniform stresses and the “two-parameter” model is assumed, with reference volume V* set to 1.0 m3:

(2) or

(3)

Applying Eq. 3, considering the two volumes, V1 and V2, with corresponding strengths of σ1 and σ2, and V1 and V2 have an equal likelihood of failing under bending, thus:

(4) and

(5)

Equations 4 and 5, when combined, give Eq. 6 as shown below:

(6)

Equation 6 shows the relationship between two strengths and their respective volumes with the same probability of failure.

Existing literatures indicate, a lack of specific study regarding the verification of Weibull’s theory to represent the depth effect of Malaysian tropical hardwood under bending. Previous studies evaluated the size effects of structural size specimens from Malaysian hardwood timber and other countries, but they did not use Weibull’s theory to analyze and model the correlation between density and dimension while calculating the k value, which will be compared to the modification factor stipulated in EN 384:2016 (Takeda and Hashizume, 1999; Abu Bakar and Saleh 2005; Oh 2014; Zhou et al. 2015). Abu Bakar and Saleh (2005) verified the Weibull’s theory to local timber but strictly worked only on Meranti species under tension. Firmanti et al. (2005) evaluated the studies on the application of mechanical grading using flexural bending test for tropical timber in Indonesia and developed a parametric distribution, including the Weibull distribution. Zhou et al. (2015) and Oh (2014) investigated, the depth effect on bending strength using Chinese larch and Japanese larch as structural timbers. Additionally, a study by Takeda and Hashizume (1999), evaluated the effect of size on Chinese larch under tension.

Therefore, the objective of this study was to determine the bending strength properties of kekatong, a representative of Malaysian tropical hardwood with a density of 1000 kg/m3 and then created a mathematical model using Weibull’s theory to develop these dimensional impacts on the k value, which will be compared to the modification factor establish in EN 384 (2016).

EXPERIMENTAL

Experimental Evaluation

This study focused on a four-point bending test using tropical hardwood of kekatong with density 1000 kg/m3. A total of 84 specimens of structural size timber were tested under bending in accordance with the current version of EN 408 (2012). Three different depths were used i.e., 75 mm, 100 mm, and 125 mm. In accordance with EN408 (2012), h represents the depth of cross section in a bending test arrangement, meanwhile in EN384 (2016), h represents the depth in the adjustment factor formula. Depth in this context represents the beam thickness.

Table 1. Parameters for Kekatong’s Specimens for Bending Test

Note: h* is the depth of bending specimen

The timber pieces were graded by a certified grader following BS 5756 (2011) and MS 1714 (2003) standards. Only timber pieces graded as hardwood structural (HS) were used for this study. To conduct the bending test for the structural size specimens, the machine setup was adjusted based on the size of the specimens. Nine different dimensions were used in this study, as listed in Table 1. A four-point bending test was set up according to EN 408 (2012) as shown in Fig. 1.

Fig. 1. Test specimens for bending test

According to ASTM D198 (2015), the specimens with depth-to-width ratio (d/b) of three or greater shall be provided lateral support located about halfway between the reaction and load point. Each of the supports must allow vertical movement without frictional restraint as well as, the lateral support must be restricted for lateral displacement. In this study, the d/b ratio for specimens with depth 125 mm and breadth 30 mm was 4.167, while for specimens with depth 125 mm and breadth 40 mm, the value was 3.125. These two sizes of timber specimens used lateral support when tested under bending test. A preliminary test was also conducted to identify the loading rate for each configuration (i.e., dimension of the samples) so that the maximum load, Fmax, was reached within 300 ± 120s. Different loading rates were recorded. Two linear variable displacement transducers (LVDT) were used to measure the local modulus of elasticity (Em,l) and global modulus of elasticity (Em,g). Both LVDT were placed at a central gauge length located centrally on the front and back of the specimens with different directions to read the modulus of elasticity (MOE). To minimize any local indentation, small steel plates were inserted in between the specimen and the loading head. The span of the samples was 18 times the sample’s depth. In this study, the loading speed was adjusted so that the ultimate failure load was reached within 300 ± 120s. The samples were tested using a universal testing machine (UTM) (IPC Global, Boronia, Australia) with load capacity of 50 klbf until total failure. The modulus of elasticity (MOE) and modulus of rupture (MOR) of each sample were calculated. The MOR measures the maximum load-carrying capacity of the timber, which includes both compression and tension parallel to the grain (Adnie Baharin et al. 2020). The MOE strongly correlates with the strength properties of the material and was measured by local deflection between the loads. A comparison between global and local deflection was made to verify the MOE value.

In deriving the strength properties of timbers in structural size, many factors need to be considered, such as moisture content, the grain directions, the grading rule, number of specimens, dimensions, etc. All of these parameters may influence the strength properties of timber. Therefore, modification needs to be applied when the parameters of the structural timber used are not the same as stipulated in the standard. However, the suitability of the modifications on the strength properties of Malaysian tropical hardwood is still not fully verified. Thus, Weibull’s theory was used to explain the size effect on strength values and MOE of kekatong. When a material is stressed, it can break or fail, and this characteristic is important for safety. Even materials that behave elastically will eventually fail under enough stress. Based on the observation of Bodig and Jayne (1982), there are six types of failure in bending parallel to the grain. The first type is simple tension, which is caused by a direct pulling force in two parts of the wood parallel to the grain. The second type is cross-grained tension, which happens when a tensile force acts obliquely to the grain, and results in diagonal, spiral, or other types of cross-grain fractures on the underside of the specimen. Tough wood can experience splintering tension failure, which is characterized by numerous small tension failures and a splintery break. Brittle tension failure is the fourth type and results in a clean break.

Evaluation of Bending Strength Characteristics Value

After experimental testing, the timber specimens tested were cut into three mid-span sections to determine the moisture content according to EN 13183-1 (2002). The bending strength calculated using basic formula in BS EN 408:19.3 (Eq. 17), to estimate the bending stress in a beam under simple bending. To obtain the cumulative probability idealization for local timber of kekatong using the brittle fracture theory, the values from MOR obtained from experimental test were sorted out in accordance with the 5 kN interval of bending strength. In accordance with standard BS EN 408:9.3 (Eq. 1) was used to calculate the local modulus of elasticity in bending. The global modulus of elasticity was calculated using the formula in BS EN 408:10.3 (Eq.2).

According to EN 384 (2016), when testing wood, certain values need to be estimated. To estimate the characteristic strength and density values, the fifth percentile of the ranked samples is used. Fifth percentile in EN 384 (2016) is used for the structural size specimens, as it provides a conservative and reliable estimate of wood properties, accounting for natural variability of the material and ensures a safety margin in design and engineering applications. To estimate the MOE value, the mean value is used. If the width of the specimens does not meet the required width of 150 mm, adjustments need to be made to the bending and tensile strength values. The wood being tested should have a moisture content of about 12%. If it does not, adjustments need to be made to the MOE and density values. To determine the characteristic value of the strength, MOE, and density, the 5th percentile of each sub sample needs to be calculated and compared. The minimum value is then used as the characteristic value, and adjustments are made as needed. Finally, the density is corrected in accordance with EN 384 (2016) and EC5 (2008) design requirements. After adjusting for moisture content, the 5th percentile values were calculated for each sub-sample. The sub-sample was the size of the samples that were tested, and the 5th percentile value is an estimate of a characteristic of the overall group. This value is based on strength, resistance, density, and stiffness. There are two methods to determine this value in EN 384 (2016) and EN 14358 (2016). The EN 384 (2016) method includes a depth factor, but it only applies to characteristic densities less than 700 kg/m3. Because the characteristic density used in this study was greater than 700 kg/m3, a series of bending tests were conducted to validate the EN 384 (2016) depth factor.

RESULTS AND DISCUSSION

Table 2 summarizes the mean values for each kekatong specimen under bending test. From the table, it is evident that the moisture contents of all bending specimens tested were considered dry, as the values were below 19%. For dry condition timber, this is acceptable, because the coefficient of variation (COV) was below 30%.

Table 2. Summary of Mean Value

Note: Value of St. Deviation*; Value Coefficient of Variation**

Kekatong specimens with the size of 30x75x1500 mm3 exhibited the highest bending strength of 110 N/mm2, while the lowest bending strength was demonstrated by the kekatong specimens with size of 30x125x2500 mm3, which is 66.03 N/mm2. This result shows that increasing the depth of the timber specimen can reduce the ultimate bending strength. The characteristic density for kekatong from the bending specimens was 921 kg/m3, which is greater than 700 kg/m3.

As shown in Table 2, high value standard of deviations indicates that the values were spread out over a wide range from the mean. Timber is a natural material, and even within the same grade and moisture content, there can be inherent variability in the mechanical properties. The higher standard deviation value observed in this study may be attributed to certain factors such as the condition in which the trees grow and the age during the trees were harvested, which were the limitation of this study. However, it is important to note that the timber specimens had been visually graded, and the moisture content of the specimens was regulated in these studies to help reduce the properties deviation. Future research should take into consideration that trees sourced from different origins could result in slight differences in strength characteristics. Four common failure modes as shown in Fig. 2 were observed in the experimental bending test. In the previous section of failure characteristic in bending, the causes of failure were explained. There were two types of tensile ruptures, which were simple tension and cross-grained tension ruptures. Based on EN14358 (2016), the cause of the tension ruptures normally occurs in high density timber as kekatong, which has density of 1000 kg/m3, as the tension and compression failure occur simultaneously and lead to the specimen’s fractures at the neutral axis. Further, the presence of cross grain in timber and a low moisture content also affects the types of failure mode that happen.

Fig. 2. Failure mode of bending structural specimen: (a) Simple tension rupture, (b) Cross-grained tension rupture, (c) Splintering tension rupture, and (d) Brittle tension rupture

Based on the bending strength value obtained from the experimental test, the value from MOR was categorized at every 5 kN interval of bending strength. The number of specimens at every 5 kN interval of bending strength was counted. Table 3 shows the categorized cumulative probability for Kekatong specimen loaded in bending.

Table 3. Cumulative Probability of Failure for Kekatong’s Specimen Loaded in Bending

Fig. 3. Cumulative probability idealization for local timber of kekatong using brittle fracture theory

The cumulative number of specimens and cumulative probability were also calculated and tabulated in Table 3. From Table 3, a graph of the cumulative probability versus bending strength is plotted through part of the Weibull’s weakest link theory and shown in Fig. 3.

Identification of Weibull’s parameters for Local Timber

The identification of the parameters k and m were based on two cumulative probabilities, which are 0.48 and 0.95, as given in Table 3. The value of 0.48 was determined as point of gradient in the elastic region under bending, while 0.95 was determined as the yield point in the elastic to plastic transition zone. Currently, the technical method of determining the values on the transition zone between elastic and plastic regions is to locate a “morphological turning point” by a visual and manual evaluation. The morphological turning point is considered the target yield point to identify the transition zone.

Through substituting the value of Fν1 = 0.48 and σ1 = 92 MPa, and correspondingly, substituting the value of Fν2 = 0.95 and σ2 = 132 MPa into the Eq. 3 of the Weibull’s theory, it will give:

(8)

It was assumed that the bending stress was uniform within the shaded area of bending specimen as shown in Fig. 1. The shaded area showed where the stresses were uniform and the volume was calculated, V = 1.0125 x 10-3 m3. This value may be substituted in both Eq. 7 and 8 to be simplified. Because both equations can be solved simultaneously, it will give value for m = 20.42 MN/m2 and k = 4.292.

The values of m and k represent Weibull’s parameters for local timber, from which Weibull’s cumulative curve was plotted using Eq. 2 and shown in Fig. 3. Because the experiment used nine different specimen sizes, the value of m varied according to their volume, while k remained constant. The experimental data is dispersed around the expected curve, and for kekatong with a volume of 1.0125×10-3 m3, plausible values for m and k were 20.42 MN/m2 and 4.292, respectively.

According to Table 4, in order to observe the trend in the values of the Weibull’s parameter for tropical hardwood timber, additional secondary data from Firmanti et al. (2005) were utilized.

Table 4. Summary of Value m, k, and 1/k for Kekatong and the Other Hardwood Timber (Firmanti et al. 2005)

A comparison with the values of the Weibull’s parameter for kekatong revealed that the other tropical hardwood timber, which is generally known to have a lower density, displayed higher values of the Weibull’s parameter.

Lower density tends to have higher k values, indicating broader distribution of strength. Higher density may have lower k values, as its strength value tends to be clustered around central value. Furthermore, lower density also gives higher m values from uniform and aligned fibers structures which contributes to higher strength and less variation in strength values. In contrast, hardwood timber with higher density typically has more complex and irregular fiber arrangement, leading to lower m values as the strength distribution tends to be more dispersed. However, it is important to mention that certain hardwood species from Firmanti et al. (2005) as kapur, meranti, and falcata may deviate from the observed trend due to the absence of precise density values for each species in the studies. As a result, the density provided here is based on the general average density at 19% moisture content.

According to EC5, the strength value of bending elements with depths and widths other than 150 mm must be adjusted using the modification factor given in EN384 (2016). However, the modification factor formula given in EN384 (2016) is specified for softwood and temperate hardwood with characteristic densities less than 700 kg/m3 and has an established 1/k value of 0.2. As the characteristic density value of kekatong is 921 kg/m3, it gives k value of 4.29. Consequently, the established value of 1/k is 0.23, which demonstrates that Weibull’s theory can be used to verify and represent the depth effect of this study. Nonetheless, it is still too early to deduce its applicability for other Malaysian tropical hardwood with characteristic density greater 700 kg/m3.

Based on the studies by Firmanti et al. (2005), it is important to note that tropical timber typically exhibits characteristic density higher than 700 kg/m3, although this specific information was not explicitly mentioned. Upon verification using Weibull’s theory, the obtained 1/k value also closely aligns with 0.2. It has been demonstrated that Weibull’s hypothesis of brittle fracture can be tested using specimens of any size of local or hardwood timber.

The bending strength of structural timber of kekatong specimens ranged from 37 to 157 MPa for the same volume of timber structure, depending on timber characteristics such as density, defects, and growth attributes. Some specimens may exhibit more ductility before failure, thus leading to different deformation behavior. This outcome demonstrates the inhomogeneous nature of timber properties in bending.

CONCLUSIONS

- Cumulative probability curve for kekatong can be effectively represented using the Weibull’s cumulative curve.

- Local or hardwood timber can be used to verify Weibull’s theory of brittle fracture.

- The values for m and k for tropical hardwood of kekatong with density of 1000 kg/m3, are 20.4 MN/m2 and 4.29, respectively. These values were found to be lower than the m and k of hardwood timber with lower density than kekatong.

- The modification factor value of 0.2 stated in EC5 which was originally established for timber species with a characteristic density below 700 kg/m3, remains acceptable for design when using timber species with a characteristic density above 700 kg/m3.

- The property of timber was inhomogeneous in bending because it exhibited different deformation behavior when exposed to external loading.

- The depth and volume of a timber structure had an impact on its bending strength.

- Malaysian tropical hardwoods having different density can be tested to verify Weibull’s theory.

ACKNOWLEDGMENTS

The authors would like to thank Jabatan Pendidikan Tinggi, Kementerian Pengajian Tinggi, Malaysia, for supporting and funding this research, under Fundamental Research Grant Scheme (FRGS), Grant No. FRGS/1/2021/TK0/UITM/02/89. This research also was supported by School of Civil Engineering, College of Engineering, Universiti Teknologi MARA (UiTM) Shah Alam, Malaysia.

REFERENCES CITED

Abu Bakar, S., and Saleh, A. L. (2005). “Verification of Weibull’s theory of brittle fracture to meranti’s timber loaded in tension parallel to the grain,” Jurnal Teknologi 43(1), 27-33. DOI: 10.11113/jt.v43.764

Azmi, A., Ahmad, Z., Chen, L. W., Baharin, A., Za’ba, N. I. L., Bhkari, N. M., and Seng, H. L., (2022). “Compressive strength characteristic values of nine structural sized Malaysian tropical hardwoods,” Forests 13(8), article 1172. DOI: 10.3390/f13081172

ASTM D198 (-2015). “Standard test method of static tests of lumber in structural sizes,” ASTM International, West Conshohocken, PA, USA.

Baharin, A., Ahmad, Z., and Chen, L. W. (2020). “Bending strength properties of Keruing and light red Meranti in structural size in accordance with Eurocode 5,” International Journal of Innovative Technology and Exploring Engineering 9(4), 1323-1327. DOI: 10.35940/ijitee.c8362.029420

Barrett, J. D., and Fewell, A. R. (1990). “Size factors for the bending and tension strength of structural lumber,” in: Proceedings of the 23rd Meeting, International Council for Research and Innovation in Building and Construction, Working Commission W 18A – Timber Structures, CIB-W18, Paper No. 23-10-3, Lisbon, Portugal.

Barrett, J. D., Lam, F., and Lau, W. (1995). “Size effects in visually graded softwood structural lumber,” Journal of Materials in Civil Engineering 7(1), 19-30. DOI: 10.1061/(asce)0899-1561(1995)7:1(19)

Bodig, J., and Jayne, B. A. (1982). Mechanics of Wood and Wood Composites, Van Nostrand Reinhold Co., New York, NY, USA.

Bohannan, B. (1966). Effect of Size on Bending Strength of Wood Members (FPL 56. Corpus ID: 35761942), USDA Forest Service, Washington, D.C., USA.

EN 384 (2016). “Structural timber – Determination of characteristics values of mechanical properties and density,” European Committee for Standardization, Brussels, Belgium.

EN 408 (2012). “Timber structures: Structural timber and glue laminated timber – Determination of some physical and mechanical properties,” European Committee for Standardization, Brussels, Belgium.

EN 1995-1-1:2004+A1 (2008). “Eurocode 5: Design of timber structures,” European Committee for Standardization, Brussels, Belgium.

BS 5756:2007+A1 (2011). “Visual strength grading of hardwood. Specification,” British Standards Institute, London, UK.

EN 13183-1 (2002). “Moisture content of a piece of sawn timber – Part 1: Determination by oven dry method,” European Committee for Standardization, Brussels, Belgium.

EN 14358 (2016). “Density timber structures – Calculation and verification of characteristics values,” European Committee for Standardization, Brussels, Belgium.

Firmanti, A., Bachtiar, E., T., Surjokusumo, S., Komatsu, K., and Kawai, S. (2005). “Mechanical stress grading of tropical timbers without regard to species,” Journal of Wood Science 51(4), 339-347. DOI: 10.1007/s10086-004-0661-z

Fonselius, M. (1997). “Effect of size on the bending strength of laminated veneer lumber,” Wood Science and Technology 31, 399-413. DOI: 10.1007/BF00702562

Foschi, R. O., and Barrett, J. D. (1975). “Longitudinal shear strength of Douglas-fir,” Canadian Journal of Civil Engineering 3(2), 198-208. DOI: 10.1139/l76-020

Köhler, J., Sandomeer, M., Isaaksson, T., and Källsner, B. (2009). “Modelling the bending strength of timber components – Implications to test standards,” in: International Council for Research and Innovation in Building and Construction – Working Commission W18 – Timber Structures, CIB-W18 Papers 43-5-1, Nelson, New Zealand.

Lee, J., Kim, G., Kim, K., and Oh, J. (2003). “Distribution characteristics of bending properties for visual graded lumber of Japanese larch,” Journal of the Korean Wood Science and Technology 31, 72-79.

Madsen, B. (1990). “Size effect in defect-free Douglas-fir,” Canadian Journal of Civil Engineering 17(2), 238-242. DOI: 10.1139/l90-029

Madsen, B., and Buchanan, A. (2011). “Size effects in timber explained by a modified weakest link theory,” Canadian Journal of Civil Engineering 13(2), 218-232. DOI: 10.1139/l86-030

MS 1714 (2003). “Specification for visual strength grading of tropical hardwood timber,” Department of Standards Malaysia, Cyberjaya, Malaysia.

Oh, S. C. (2014). “Estimation of depth effect on the bending strength of domestic Japanese larch structural lumber using Weibull weakest link theory,” Journal of the Korean Wood Science and Technology 42(2), 112–118. DOI: 10.5658/WOOD.2014.42.2.112

Schneeweiß, G., and Felber, S. (2013). “Review on the bending strength of wood and influencing factors,” American Journal of Materials Science 3(3), 41-54. DOI: 10.5923/j.materials.20130303.01

Takeda, T., and Hashizume, T. (1999). “Differences of tensile strength distribution between mechanically high-grade and low-grade Japanese larch lumber II: Effect of knots on tensile strength distribution,” Journal of Wood Science 45(3), 207-212. DOI: 10.1007/BF01177727

Tannert, T., Franke, S., and Quenneville, P. (2012). “Comparison of test methods to determine Weibull parameters for wood,” in: World Conference on Timber Engineering, Session 46, Standards 1, Auckland, New Zealand, pp. 13–20.

Walley, S. M., and Rogers, S. J. (2022). “Is wood a material? Taking the size effect seriously,” Biomaterials 15(15), article 5403. DOI: 10.3390/ma15155403

Zhou, H., Han, L., Ren, H., and Lu, J. (2015). “Size effect on strength properties of Chinese larch dimension lumber,” BioResources 10(2), 3790-3797. DOI: 10.15376/biores.10.2.3790-3797

Article submitted April 10, 2023; Peer review completed: July 15, 2023; Revised version received and accepted: July 28, 2023; Published: August 8, 2023.

DOI: 10.15376/biores.18.4.6882-6895