Abstract

Paper pulp was produced by the kraft method using sorghum (Sorghum bicolor × S. bicolor sudanense) as the fibrous raw material. Two groups were cooked using active alkali at 10% and 14%. For each group, five sulfite ratios (0, 4, 8, 12, and 16%) were used, making a total of 10 different groups that were cooked. A literature study was conducted to determine the cooking temperature, the time needed to reach the maximum temperature, and the duration of cooking time at the maximum temperature. A total of 30 batches of paper were obtained from pulps without beating and from pulps beaten at values of 35 ± 2 °SR and 50 ± 2 °SR (Schopper Riegler) freeness. The aim was to determine the most suitable alkali and sulfite ratios by conducting standard tests for the yield, kappa number, and viscosity of the screened pulps and for the papers obtained from these pulps. The highest screened yield of cooked pulp was obtained under conditions of 14% active alkali and 12% sulfite. Since the mechanical properties of the paper obtained from this pulp were satisfactory when compared with those in the literature, it was concluded that these ratios could be recommended as a condition for cooking.

Download PDF

Full Article

Determination of Alkali and Sulfite Ratios in Paper Pulp Produced from Sorghum Stalks via the Kraft Method

Ayhan Gençer * and Ceyda Hatıl

Paper pulp was produced by the kraft method using sorghum (Sorghum bicolor × S. bicolor sudanense) as the fibrous raw material. Two groups were cooked using active alkali at 10% and 14%. For each group, five sulfite ratios (0, 4, 8, 12, and 16%) were used, making a total of 10 different groups that were cooked. A literature study was conducted to determine the cooking temperature, the time needed to reach the maximum temperature, and the duration of cooking time at the maximum temperature. A total of 30 batches of paper were obtained from pulps without beating and from pulps beaten at values of 35 ± 2 °SR and 50 ± 2 °SR (Schopper Riegler) freeness. The aim was to determine the most suitable alkali and sulfite ratios by conducting standard tests for the yield, kappa number, and viscosity of the screened pulps and for the papers obtained from these pulps. The highest screened yield of cooked pulp was obtained under conditions of 14% active alkali and 12% sulfite. Since the mechanical properties of the paper obtained from this pulp were satisfactory when compared with those in the literature, it was concluded that these ratios could be recommended as a condition for cooking.

Keywords: Sorghum sudanense; Kraft method; Alkali-sulfidity ratio; Pulp yield; Paper production

Contact information: Forest Industry Engineering, Faculty of Forestry, Bartin University, 74100 Bartin, Turkey; *Corresponding author: ayhangencer61@hotmail.com

INTRODUCTION

At the time paper was invented, annual plants were preferred in order to make processing easier. As a result, annual plants have been used for centuries in traditional papermaking. However, after the invention of the printing press, there was a great demand for paper, and the need for the development of the paper industry arose accordingly. In Europe, this industrialization began with the development of paper pulp production methods using chemical means. A number of methods were tried, and the kraft method was found to be suitable both technically and economically. The kraft method is widely used today in the production of paper pulp. In those early years, abundant wood raw materials were used with this method in Europe. With the expansion of paper production and the increase in demand for wood raw materials, paper production from annual plants has made a comeback in the economic agenda of some countries with limited forest resources. For this reason, the production of paper from spontaneously growing or cultivated annual and perennial plants has become widespread over an extended geographical area.

Although it is not very common in industrial settings, a wide variety of annual plants can be used to produce paper and other beneficial products. For example, it has been suggested that sorghum stalks are suitable for sugar production (Herrera et al. 2003). Similarly, when necessary, annual plants can be used in fiberboard production. For example, medium-density fiberboard (MDF) produced from cotton stalks have mechanical properties that can compete with boards obtained from hardwood trees (Gençer et al. 2001). Considering that the screened pulp yields obtained by the soda anthraquinone method are from lignocellulosic materials such as wheat straw, barley straw, rye straw, reed, corn stalk, tobacco stalk, cotton stalk, sunflower stalk, and hemp, Ateş et al. (2015) suggested that raw materials other than tobacco stalk and cotton stalk could be economically evaluated in the production of paper pulp using chemical methods. Paper produced using broomcorn stalks (Gençer 2015) and the sorghum-sudangrass hybrid grown in Turkey was found to have optical, mechanical, and physical properties similar to that produced from hardwood trees (Gençer and Şahin 2015). The pulp obtained from woad (Isatis tinctoria L.) plant stalks can be used as a substitute for the pulp obtained from wheat stalks according to one study (Cömlekcioglu et al. 2016). Gülsoy and Şimşir (2018) stated that the pulps obtained via the kraft method from fern stalks were at a level capable to compete with those of common non-wood annuals, aspen, and eucalyptus. Saeed et al. (2018) observed that paper pulp made from the annual castor bean plant provided an acceptable yield, exhibited moderate viscosity, and was bleachable. However, not every fibrous material may be suitable for paper production. For example, rosemary stalks are not suitable for paper pulp production due to the average value of their alpha cellulose (Odabaş et al. 2017). In addition, as in the case of all the annual plants in sorghum gathering, drying and storage may pose difficulties. However, drying and storage difficulties may also occur in the case of wood which is an organic substance. In order for a raw material to be used in paper production, the morphological properties, as well as the chemical properties must be appropriate for the formation of paper. In addition, economic conditions must be met, including criteria such as being inexpensive, sufficient in quantity, and capable of being harvested. The amount of raw material to be obtained from a unit area of cultivated plants must be high and it must be easy to harvest. Otherwise, it cannot compete economically with wood raw materials.

Among cultivated annual plants, sorghum is one that can be adapted to both tropical and temperate zones and can yield high energy and biomass (1.40 to 1.54 ton /1000 m2) (Keskin et al. 2005; Dutra et al. 2013). Since the biomass yield is high and harvesting with machines is easy, sorghum can be considered an alternative to wood raw material as a fiber source.

As in the case of every field, with the increase in demand for raw materials, the paper industry continues to search for new resources that can serve as substitutes. In plantation forestry, the time required for the maintenance of forest trees is extensive, with fast-growing species taking 10 to 12 years of operation life to produce new raw material resources. Nevertheless, the demand for wood continues to increase in the forest industry, and since it is expensive to produce paper from wood, the competitive power of the paper manufacturers is decreased. This predicament, which occurs in the cycle of supply and demand, leads to the need to access the raw material in a shorter period of time. For this reason, the evaluation of annual crops in the production of paper pulp is an alternative solution to the problem. The stalks are obtained as an agricultural by-product, with the main production goals being cereals, etc. The quality of the stalks and the amount per unit area remain of secondary importance in the grain harvesting methods. This reduces the quality of the raw materials and increases the cost of collecting them. For this reason, annual plants with high biomass can be an alternative source. To this purpose, sorghum (Sorghum bicolor x S. bicolor var. sudanense) grown by direct seeding was used as the raw material in this study.

In general, the NaOH method is used in the production of paper pulp from annual plants. The pulps obtained by this method have high bleachability properties, while the pulps obtained by the kraft method are darker and more durable. Determining the active alkali and sulfidity ratios in pulp production by kraft method is important in order to determine the strength characteristics and yield of the pulp to be obtained. Casey (1960) indicated that increased sulfidity in the kraft method increases the pulp yield. In this study, the aim was to determine the active alkali-sulfite ratios in the production of paper pulp from sorghum stalks using the kraft method.

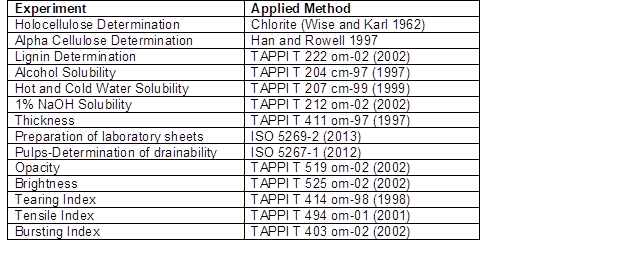

EXPERIMENTAL

Sorghum stalks were obtained from seeds planted in Bartin, Turkey in 2017. Using local hand tools, harvesting was carried out 110 days after sowing. After separating the seeds, the stalks were dried in a semi-open shed. The stalks were cut in 5 cm lengths and, under laboratory conditions, their basic components and some of their solubility properties were determined. The paper pulps produced and the papers obtained from them were subjected to relevant standard tests (Table 1).

Table 1. Tests Applied to Sorghum Stalks, Obtained Pulps, and Papers

The chlorite method (Wise and Karl 1962) was used in the maceration of the sorghum stalks. Fiber measurements were made with a Visopan light microscope. From these measurements, values were derived for the slenderness ratio: fiber length / fiber width, the flexibility ratio: (lumen width / fiber width) / 100 and the Runkel ratio: 2 × wall thickness / lumen width. Generally, the lignin content of herbaceous plants is lower than that of wood and woody plants. For this reason, the cooking conditions of herbaceous plants are more moderate. Casey (1960) stated that high-quality pulps were obtained from annual plants cooked for 2 h under moderate conditions using 12% NaOH. However, not every herbaceous plant is transformed into a pulp under moderate conditions. One of the factors affecting the fibrillation during delignification is the lignin ratio. In the production of paper pulp by chemical means, lignin-rich fibrous materials require a higher cooking temperature, a longer cooking time, and a higher chemical content. Deniz et al. (2017) reported a cooking temperature of 165 °C in the production of paper pulp from bamboo and Gülsoy and Şimşir (2018) carried out the production of paper pulp from fern stalks at 170 ºC via the kraft method. Table 2 shows that the ratio of lignin in both of these raw materials is considerably higher than that of sorghum stalks. Gençer and Şahin (2015) stated that sorghum stalks containing 13% lignin cooked with 14% NaOH for 2 h at 130 °C produced pulp that could compete with hardwood pulps. For these reasons, 155 ± 2 °C, near the lowest cooking temperature for the kraft method, was chosen for this study. At a constant cooking temperature, 10 batches were cooked at ratios of 10 and 14% of the active alkali (Na2S) and at varying ratios of sulfidity (0, 4, 8, 12, and 16%) compared to the full dry-stem weight. The time taken to reach the maximum cooking temperature was 60 min, and the cooking time at the maximum temperature was 60 min, totaling 120 min. The standard values in Table 1 were applied to the pulps obtained after cooking and to the papers obtained from these pulps. The beating process was made in a Hollander beater to 35 ± 2 °SR, and 50 ± 2 °SR and the handsheets were produced to be 70 g/m2.

RESULTS AND DISCUSSION

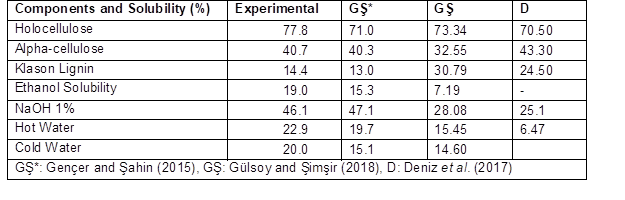

In the production of paper pulp using chemical means, prior knowledge of the basic components such as lignin, alpha cellulose, and holocellulose and some solubility values of the lignocellulosic materials is important for economical and quality pulp production. For this reason, some chemical components and solubility values of the sorghum stalks compared to other findings in the literature are given in Table 2.

Table 2. Comparison of Some Chemical Components and Solubility Values of Sorghum Stalks vs. Other Literature Findings

Compared with the annual plants in Table 2, the sorghum stalks had a lower lignin ratio, and paper pulp could be produced by using lower amounts of chemicals than with the others. Agnihotri et al. (2010) found that when the sugar beet core was removed, the rates of holocellulose, alpha cellulose, and lignin in the depithed sugar beet bagasse were 71.03%, 42.34%, and 21.7%, respectively.

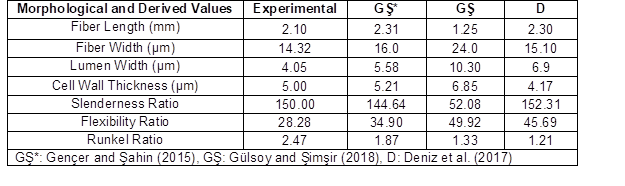

Table 3. Some Morphological Characteristics of Sorghum Stalks and their Derived Values

In the production of paper from any pulp, the knowledge of the morphological properties of the raw material from which the pulp was obtained can be helpful for achieving the characteristics of the paper to be produced. Table 3 shows some morphological characteristics of the sorghum stalks and their derived values.

One of the most important factors in paper strength is the fiber length of the raw material used in pulp production. The fiber length in the sorghum stalks was measured as 2.10 mm. Gulsoy and Tufek (2013) measured 2.4 mm and 1.1 mm in maritime pine and European aspen woods, respectively. In this study, it was significant that the fiber length of the sorghum stalks was between the lengths of hardwood and softwood fibers, shorter than that of bamboo stalks, but longer than that of fern stalks. Considering the values derived from the morphological measurements of the sorghum stalks, the flexibility and Runkel ratios were low. However, since the slenderness ratio, which is one of the most important criteria in paper strength, was quite high, obtaining paper with high mechanical properties was deemed possible. Table 4 shows some of the characteristics of the pulp obtained from the sorghum stalks.

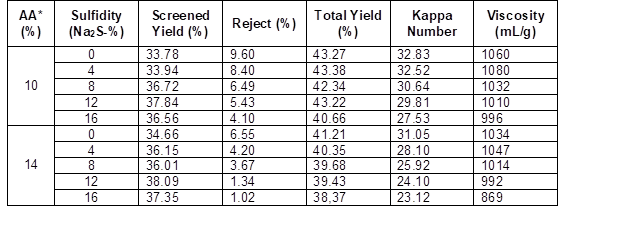

Table 4. Some Characteristics of Pulp Obtained from Sorghum Stalks

*AA: Active alkali

In this study, the highest yield (38.9%) was obtained under conditions of 14% active alkali (AA) and 12% sulfite. Casey (1960) stated that a yield of 35 to 45% for screened crop stalk pulp is reasonable. Deniz et al. (2017) achieved a yield of 47.1% for bamboo using the kraft method with 14% AA and 25% sulfite and a cooking process of 120 min. However, the ratio of alpha cellulose in the bamboo was 43.3%, while that of the sorghum was calculated as 40.7%. A high proportion of alpha cellulose has a positive effect on the pulp yield in the production of paper pulp using chemical means. In addition, they obtained a kappa number of 37.3 and viscosity values of 1210 (mL/g) in the pulps. Gülsoy and Şimşir (2018) reported a yield of 34.4% from fern stalks containing 32.6% alpha cellulose by using the kraft method with 25% AA (as Na2O) and 30% sulfite and cooking at 170 °C. Deniz et al. (2004) achieved a 42% screened yield, kappa number of 31 and 1114 mL/g SCAN viscosity from wheat straw containing 38.2% alpha cellulose, and 15.30% lignin by using 14% AA and 20% sulfite at a maximum temperature of 160 °C.

The amount of active alkali (NaOH) and sodium sulfide (Na2S) used in the cooking process increased the delignification rate. For this reason, the kappa number of the pulp decreased. The viscosity values of the pulps decreased due to the carbohydrate reactions of the increasing NaOH and Na2S ratios. A high viscosity value is an indication of the strength of the pulp. A reduction in the kappa number means a reduction in the amount of lignin remaining in the pulp. Pulps with a low kappa number are easier to bleach than those with a high kappa number. Therefore, this factor should be considered when determining cooking conditions.

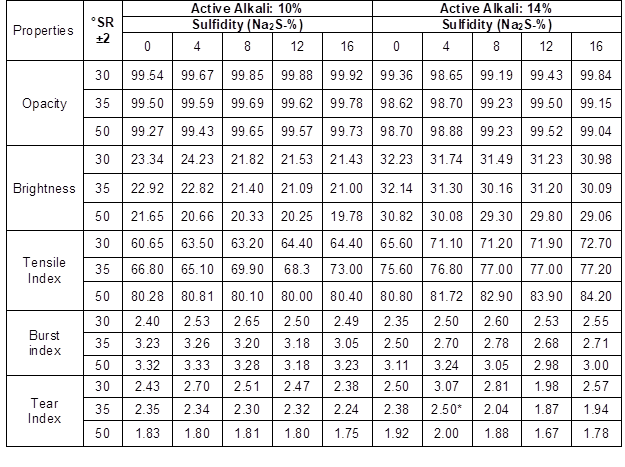

In Table 5, some mechanical and optical values of the papers obtained from the pulps produced by the kraft method from the sorghum stalks are shown at different levels of freeness.

Table 5. Some Mechanical and Optical Properties of Papers Obtained from Sorghum Stalks

Deniz et al. (2017) obtained a burst index of 5.13 (kPa.m2/g), a tensile index of 64.0 (Nm/g), and a tear index of 5.27 (mNm2/g) in the papers produced from bamboo via the kraft method. The tensile index values were higher in the papers obtained from sorghum stalks than in the paper from bamboo and these values were increased by beating in all paper groups. When high-value tensile index paper production is desired, the pulps can be beaten up to 50°SR.

The average tearing index was higher in all groups of paper obtained from unbeaten pulps than in the paper groups from the beaten pulps. If the aim is high-tear index paper production, the initial degrees of freeness may be sufficient for all pulps. Similarly, since the initial degrees of freeness of the pulps are sufficient to produce high-burst index paper, beating may not need to be applied.

Some bleaching occurs on the surface of the fibers with the delignification during cooking after the lignin in the middle lamella and fiber surfaces pass throughout the solution. With the beating process, the opacity and brightness values decreased in all paper groups. A similar phenomenon was reported to occur in paper production from bamboo using the kraft method (Deniz et al. 2017). The reason for this is that with the beating, part of the lignin in the fiber wall becomes visible as a result of fibrillation. Due to the dark-colored structure of the lignin, there is a decrease in the brightness value of the paper. When fibers are finished with beating, the end result is a low opacity value. Unbeaten pulp should be used to obtain papers with high-opacity and brightness values.

The present study obtained the highest yield (38.9%) under the conditions of 14% AA and 12% sulfite. These can be regarded as ideal cooking conditions, with the physical, optical, and mechanical properties of the paper produced from these pulps being competitive with those obtained via the kraft method using similar raw materials.

CONCLUSIONS

The method described in this report is suitable for the production of paper pulp, since the yield obtained by cooking sorghum-sudangrass hybrid (Sorghum bicolor × S. bicolor var. sudanense) via the kraft method was at a satisfactory level.

With determination of the 14% active alkali and 12% sulfidity ratios, the highest screened pulp yield was obtained under conditions of a paper pulp cooking temperature of 155 ± 2 °C, with 60 min needed to reach the maximum cooking temperature and 60 min cooking time at the maximum temperature, for a total cooking process time of 120 min. Therefore, these rates can be regarded as ideal cooking conditions.

From the standard pulp and paper tests, the sorghum-sudangrass hybrid was shown to be a raw material that can compete with other fiber resources in the production of paper pulp using the kraft method.

The short cooking time, low cooking temperature, and minimal chemical waste are the important advantages of paper pulp production from sorghum compared to other herbaceous plants mentioned in the literature.

REFERENCES CITED

Agnihotri, S., Dutt, D., and Tyagi, C. H. (2010). “Complete characterization of bagasse of early species of Saccharum officinerum-CO 89003 for pulp and paper making,” BioResources 5(2), 1197-1214. DOI: 10.15376/biores.5.2.1197-1214

Ateş, S., Deniz, İ., Kırcı, H., Atik, C., and Okan, O. T. (2015). “Comparison of pulping and bleaching behavior of some agricultural residues,” Turk. J. Agric. For. 39, 144-153. DOI: 10.3906/tar-1403-41

Casey, J. P. (1960). Pulp and Paper Chemistry and Chemical Technology III, Wiley, New York, NY, pp. 1029-1063.

Comlekcioglu, N., Tutuş, A., Cicekler, M., Canak, A., and Zengin, G. (2016). Investigation of Isatis tinctoria and Isatis buschiana stalks as raw materials for pulp and paper production,” Drvna Industrija 67(3) 249-255. DOI: 10.5552/drind.2016.1542

Deniz, İ., Kırcı, H., and Ates, S. (2004). “Optimisation of wheat straw Triticum durum kraft pulping,” Ind. Crop. Prod. 19, 237-243. DOI: 10.1016/j.indcrop.2003.10.011

Deniz, I., Okan, O. T., Serdar, B., and Şahin, H. İ. (2017). “Kraft and modified kraft pulping of bamboo (Phyllostachys bambusoides),” Drewno 60(200), 79-94. DOI: 10.12841/wood.1644-3985.224.05

Dutra, E. D., Barbosa Neto, A. G., Souza, R. B. D., Morais Junior, M. A., Tabosa, J. N., and Cezar, M. R. S. (2013). “Ethanol production from the steam juice of different sweet sorghum cultivars in the state of Pernanbuco, Northeast of Brazil,” Sugar Technology 15(3), 316-321. DOI: 10.1007/s12355-013-0240-y

Gençer, A., Eroğlu, H., and Özen, R. (2001). “Medium density fiberboard manufacturing from cotton stalks,” Inpaper International (2), 26-28.

Gençer, A. (2015). “Research on the suitability of broomcorn stalks for paper production and the effects, of hot water pre-treatment on paper’s properties,” Journal of Multidisciplinary Engineering Science and Technology 2(8), 2089-2092.

Gençer, A., and Şahin, M. (2015). “Identifying the conditions required for the NaOH method for producing pulp and paper from sorghum grown in Turkey. BioResources 10(2), 2850-2858. DOI: 10.15376/biores.10.2.2850-2858

Gulsoy, S. K., and Tufek, S. (2013). “Effect of mixing ratio of Pinus pinaster and Populus tremula on kraft pulp and paper properties,” Ind. Eng. Chem. Res. 52(6), 2304-2308. DOI: 10.1021/ie302709e

Gülsoy, S. K., and Şimşir, S. (2018). “Chemical composition, fiber morphology, and kraft pulping of bracken stalks (Pteridium aquilinum (L.) Kuhn) Drvna Industrija 69(1), 23-33. DOI: 10.5552/drind.2018.1725

Han, J. S., and Rowell, J. S. (1997). “Chemical composition of agrobased fibers, chapter 5,” in: Paper and Composites from Agrobased Reources, R. M. Rowell, R. A. Young, and J. K. Rowell (eds.), CRS Press Inc., New York, NY, pp. 83-134.

Herrera, A., Téllez-Luis, S. J., Ramírez, J. A., and Vázquez, M. (2003). “Production of xylose from sorghum straw using hydrochloric acid,” J. Cereal Sci. 37, 267-274. DOI: 10.1006/jcrs.2002.0510

ISO 5269-2 (2013). “Pulps – Preparation of laboratory sheets for physical testing. Part 2: Rapid Köthem method,” International Organization for Standardization, Geneva, Switzerland.

ISO 5267-1, (2012). “Pulps – Determination of drainability Part I: Schopper Reigler method,” International Organization for Standardization, Geneva, Switzerland.

Keskin, B., Yılmaz, İ. H., and Akdeniz, H. (2005). “Yield end yield component of forage sorghum hybrid (Sorghum bicolor x Sorghum sudanense Mtapf.) as influenced by variates and maturity,” Atatürk Üniv. Zir. Fak. Derg. 36(2), 145-150.

Odabaş, S. Z., Ateş, N., and Cavunt, A. (2017). “Utilization of rosemary (Rosmarinus officinalis L.) stalks in pulp and paper production,” Turkish Journal of Forestry 18(2), 155-159. DOI: 10.18182/tjf.310094

TAPPI 411 om–97, (1997). “Thickness (caliper) of paper, paperboard, and combined board,” TAPPI Press, Atlanta, GA.

TAPPI 412 om–02, (2002). “Moisture in pulp, paper and paperboard,” TAPPI Press, Atlanta, GA.

TAPPI 414 om–98, (1998). “Internal tearing resistance of paper (Elmendorf-type method),” TAPPI Press, Atlanta, GA.

TAPPI 403 om–02, (2002). “Bursting strength of paper,” TAPPI Press, Atlanta, GA.

TAPPI T494 om–01, (2001). “Tensile properties of paper and paperboard (using constant rate of elongation apparatus),” TAPPI Press, Atlanta, GA.

TAPPI T519 om–02, (2002). “Diffuse opacity of paper (d/0 paper backing),” TAPPI Press, Atlanta, GA.

TAPPI T525 om–02, (2002). “Diffuse brightness of pulp (d/0),” TAPPI Press, Atlanta, GA.

Wise, L. E., and Karl, H. L. (1962). Cellulose and Hemicellulose in Pulp and Paper Science and Technology, McGraw Hill, New York, NY.

Article submitted: September 18, 2018; Peer review completed: November 18, 2018; Revisions accepted: December 6, 2018; Published: December 11, 2018.

DOI: 10.15376/biores.14.1.922-930