Abstract

Microwave (MW) treatment is an environmentally friendly and time-saving technique with great potential for generating wood-impregnation innovations. In this study, a microwave-assisted impregnation (MWAI) approach was developed to achieve adequate retention and fixing of alkaline copper quaternary (ACQ) in refractory spruce wood. The synergistic effect of MW pre- and post-treatments in the impregnation procedure on wood’s compressive strength (CS) and copper leaching resistance and valence conversion was investigated. In conclusion, high-intensity MW pre-treatment and low-intensity MW post-treatment provided optimum results for the fixation of copper. Based on the results of the copper conversion assays, the same MWAI procedure is also predicted to give high biological efficiency.

Download PDF

Full Article

Effect of Microwave-Assisted Impregnation on the Leaching Resistance of ACQ in Refractory Spruce Wood

Kübra Gündüz Vaydoğan,a,* and Hamiyet Şahin Kol b

Microwave (MW) treatment is an environmentally friendly and time-saving technique with great potential for generating wood-impregnation innovations. In this study, a microwave-assisted impregnation (MWAI) approach was developed to achieve adequate retention and fixing of alkaline copper quaternary (ACQ) in refractory spruce wood. The synergistic effect of MW pre- and post-treatments in the impregnation procedure on wood’s compressive strength (CS) and copper leaching resistance and valence conversion was investigated. In conclusion, high-intensity MW pre-treatment and low-intensity MW post-treatment provided optimum results for the fixation of copper. Based on the results of the copper conversion assays, the same MWAI procedure is also predicted to give high biological efficiency.

DOI: 10.15376/biores.19.1.1229-1244

Keywords: Spruce; ACQ; Microwave; Fixation; Leaching resistance

Contact information: a: Department of Forest Engineering, Karabuk University, P. O. Box 78200, Karabuk, Turkey; b: Department of Environmental Engineering, Karabuk University, P. O. Box 78200, Karabuk, Turkey; *Corresponding author: kubragunduz@karabuk.edu.tr

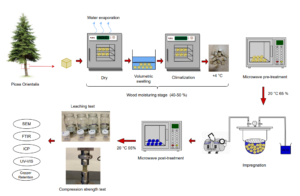

GRAPHICAL ABSTRACT

INTRODUCTION

The service life of wooden products relies on the natural durability of wood species, as well as on their methods of chemical and modifying protection and on their exposure conditions. Chemically, wood protection with preservatives is the most common approach to extending its life; the preservatives, such as insects and fungicides, are typically impregnated into the wood’s depth. The effectiveness of wood preservatives and their impact on the environment are nowadays significant. The optimization of wood pretreatment and its chemical impregnation technology is crucial (Reinprecht 2016).

Spruce has low natural durability and is known for its low permeability, essentially because of the aspiration of a significant portion of the bordered pits during drying (Dashti et al. 2013). In spruce wood, very low permeability and shallow preservative uptake are major issues in the impregnation process (Yıldız et al. 2010; Bakır et al. 2022). The current circumstances have necessitated the incorporation of such wood species within the industry. A supply-demand mismatch of wood material is growing due to rapid worldwide deforestation and population growth.

Alkaline copper quaternary (ACQ) is a widely used wood preservative in commercial applications. It is suitable for contact with aboveground interior construction, aboveground exterior buildings, and ground contact-sawn wood product usage (Evans 2003; Freeman et al. 2003; Mazela et al. 2003; Hasan et al. 2010). Two active ingredients, which may differ within specified limits, are present in each type of ACQ: copper oxide (62 to 71%) as fungicide and a quaternary ammonium compound (29 to 38%) for insecticidal purposes (Mai and Militz 2007). However, wood protection with ACQ often requires high concentrations due to problems with poor copper fixation. In this case significant copper (Cu) leaching occurs, causing considerable monetary losses and environmental concerns (Tascioglu et al. 2005; Ung and Cooper 2005; Temiz et al. 2006).

Various modification techniques have been implemented in recent years to enhance the impregnation properties of refractory wood species; these include steaming (Dashti et al. 2012), incising (Pang et al. 2017), drilling (Kortsalioudakis et al. 2015), microwave (Kol and Cayır 2021; 2023), and bio-incising (Bakir et al. 2022). Additionally, several methods have been described in the literature for enhancing the leaching resistance of Cu based chemicals from wood, including hot water (Yu et al. 2009a), hot air (Yu et al. 2009b), temperature (Tascioglu et al. 2008), and microwave (Yu et al. 2010). Among them, microwave (MW) technology has lately gained popularity in the world for wood modification processes, especially for impregnation innovations. Microwave-assisted impregnation (MWAI) is a very helpful and innovative choice if it is intended to impregnate refractory spruce wood with ACQ. Microwaves have a very high potential and appeal in achieving the desired modification with their versatile, fast, energy-saving, and selective heating aspects. In contrast to traditional heating methods, MW heating involves the absorption of electromagnetic waves by the medium, with rapid conversion into heat energy. Meanwhile, MW radiation can selectively transfer energy to polar molecules within the material, resulting in a simultaneous increase in temperature. This is because the microwaves contacting the substance cause the ions and dipoles within the material to rotate in the opposite direction. Thus, energy from electromagnetic waves is converted into heat inside of the material by the friction of molecules. This results in a temperature gradient from the materials on the inside to the outside, moving in the same direction as the released volatiles (Wang et al. 2022; Qu et al. 2023). The distinctive working mechanism makes MW treatment attractive for modifying wood.

Improving wood permeability is one of the MW treatment’s most important goals. Wood permeability in the radial and longitudinal directions can be increased thousands of times in species believed to be impermeable to liquids. The MW field creates vibrations in the polar molecules of the moist wood, most notably its water molecules. Thus, the water in wood is heated to generate high-temperature, high-pressure steam. When steam leaves the wood, it ruptures the structure and creates spaces. This makes new pathways for liquids and vapors to move through easily (Peyskens et al. 1984; Singh et al. 2016; Mascarenhas et al. 2021). Under internal steam pressure, the pit membranes in cell walls, aspirated pits, and weak ray cells rupture and delaminate. Increased MW intensity increases internal steam pressure, forming more voids in the radial-longitudinal planes (Torgovnikov and Vinden 2009, 2010; He et al. 2014; Terziev et al. 2020; Mascarenhas et al. 2021; Weng et al. 2021; Wang et al. 2022). Thus, high-energy intensity significantly increases the uptake of the preservatives; however, it can cause excessive damage to the microstructure and reduce the strength properties (Machado 2006; Torgovnikov and Vinden 2010; Hermoso and Vega 2016; Ganguly et al. 2021). The optimizing initial moisture content (MC) of wood and MW energy intensity are critical parameters in the modification efficiency. Suppose significantly higher preservative retentions, which are generally used in manufacturing new wooden material, are not desired. In that case, it is sufficient to create an outward diffused vapor pressure, which only acts on the weak links, such as the pit membranes, forming radial channels through which preservatives can easily pass. Previous research indicated that a microwave energy intensity of 250 to 1200 MJ/m3 is sufficient to improve the penetration and uptake of preservatives in wood, depending on the intrinsic properties of wood and the initial MC (Torgovnikov and Vinden 2010). The optimal initial MC of the wood has been proposed to be in the 40 to 60% range to balance the strength loss and energy loss during the MW modification to improve the impregnation. Because excessive MC in the wood necessitates greater energy, on the other hand, strength losses become more obvious when MC levels fall below the fiber-saturated point (Jiang et al. 2006; He et al. 2014).

Reaching the sufficient uptake of preservatives with MW pre-treatment of wood does not guarantee better biological durability of impregnated wood. In addition, it must be clear how well MW energy intensity between 250 and 1200 MJ/m3 works to improve the leaching of preservatives. A comprehensive literature review showed that the amount of copper leaching in ACQ-treated wood after MW pre-treatment was not clarified clearly. The fixation of ACQ is achieved through a process of strong ion exchange, specifically targeting anionic carboxyl and phenolic sites present in hemicelluloses and lignin. Additionally, ACQ forms stable but weaker complexes with other groups of lignin or hemicellulose (Kamdem and Zhang 2000; Zhang and Kamdem 2000; Ruddick et al. 2001; Ruddick 2003). If the MW intensity is high, then the active component may be readily leached from the wood because of more structural deformation, or its leaching may decrease as the preservative penetrates deeper into the wood. After high MW intensity pre-treatment of wood, the number of anionic sites in wood necessary for ACQ fixing may rise, or these sites may become more readily accessible.

In addition, the fixation rate and extent of ACQ to wood cells have also been reported to be enhanced by MW post-treatment following impregnation. According to the literature, achieving this goal requires a MW energy intensity of 100 to 200 MJ/m3 (Cao and 004; Yu et al. 2010). Copper fixation depends on time, temperature, and solution concentration, requiring several weeks to equilibrate at room temperature (Tascioglu et al. 2005; Ung and Cooper 2005). In post-treatment processes, as the temperature increases, the fixation extent increases, but above 70 °C, the biological efficiency decreases due to the conversion of copper (Tascıoglu et al. 2008). Monovalent copper is less soluble and, less effective against fungi compared with divalent copper. The conversion of divalent copper to monovalent copper increases with increasing temperature Cui 1999; Zhang and Kamdem 1999; Barnes et al. 2000). During the MW post-treatment, the applied MW energy accelerates the copper and wood reactions, which require energy and moisture content. An increase in MW energy intensity provides more power for the excitation of polar molecules and intermolecular frictions; hence, the temperature increase rate increases, and the moisture in the wood cells quickly vaporizes (Yu et al. 2010). Moisture vaporization would facilitate the mobility of reacting components. In the fixation process, the rate of the temperature is another critical factor. It is possible to reach high temperatures in a short time in microwave post-treatment. However, the effect of the high temperature reached in a short time in microwave processing on the fixation of ACQ is unknown. The conversion of divalent copper may not be changed negatively by short-time microwave post-treatment.

This study aimed to make spruce with low permeability usable outdoors with ACQ, which has a leaching problem, with the MWAI system. The synergistic effects of MW pre- and post-treatment on the retention and fixation of ACQ into spruce wood were investigated. The effect of ACQ impregnation assisted by MW pre- and post-treatment on the compressive strength of spruce was also investigated. The MW energy intensity has been optimized to minimize copper leaching while maintaining the strength qualities of treated spruce wood. Another objective was to estimate the biological durability of wood by clarifying the impact of the MWAI approach on copper valence conversion. This makes it possible to assess how microwave-assisted ACQ impregnation affects spruce’s service area framework and service life.

EXPERIMENTAL

Oriental spruce [Picea orientalis (L.) Link.] wood grown in the Black Sea Region of Turkey was used for this study. During the impregnation process, (ACQ) Korasit® KS2 (KG n.d.) was utilized. This product is a water-soluble chromate and boron-free wood preservative. Ingredients included a monoethanolamine (MEA) solution, N,N-Didecyl-Nmethylpoly(oxyethyl) ammonium propionate, copper(II) carbonate copper (II) hydroxide (1:1), ethanediol. Concentration of preservative was determined according to the manufacturer’s suggestions as 2%.

Methods

Samples preparation

Samples of 19*19*19 mm3 for leaching resistance and 20*20*30 mm3 for compression strength were prepared from the sapwood region of air-dried spruce wood (MC of 12-15%). Straight-grained, defect-free wood samples, kept in air-dry condition at a relative humidity of 65% and a temperature of 20 °C, were then oven-dried at 103 °C until they reached constant weight. They were divided into six groups according to the experimental design, considering their oven dry weight (Table 1). Two groups consisted of those pre-treated with MW at low (labeled L1) and high microwave intensity levels (labeled H1), two others were pre-treated with MW at low and high levels and then impregnated with ACQ (respectively labeled L1-L2 and L1-H2), and the remaining two groups were impregnated with ACQ after MW pre-treatment at low and high levels and then post-treated with MW at low and high levels (respectively labeled H1-L2 and H1-H2). Ten replicates were used for each group. Initially, all grouped samples were kept in distilled water for about 10 days until they reached constant volume and subsequently left to dry again at a relative humidity of 65% and a temperature of 20 °C in the climatization cabinet. MC of samples was determined by frequently weighing the samples left to dry. The samples reaching the target initial MC (approximately 40 to 50%) were covered with stretch film and kept at 4 °C to prevent them from getting moisture until the MW pre-treatment.

Table 1. Experimental Design

Microwave pre-treatment

The MW pre-treatment was performed at a frequency of 2.45 GHz using a Samsung CM1929 Microwave heating device. The samples were subjected to two different MW pre-treatments at low and high energy density levels labeled L1 and H1, respectively. To obtain the desired energies, the pre-treatment processes determined depending on the MW power and volume of the samples were calculated based on the formula given in Eq. 1,

E = P × t V (1)

where E is the energy (MJ/m3), P is the MW power (W), t is the total exposure time (h), and V is the sample volume (m3).

The weights of all samples were determined just before MW pre-treatment. Ten samples were exposed to the MW at one time. MW exposure time was calculated by the above formulas (Eq.1) based on sample volumes. After MW pre-treatment, the samples were again weighed and conditioned at a relative humidity of 65% and a temperature of 20 °C. The MW pre- and post-treatment program is given in Table 2.

Table 2. Microwave pre- and Post-treatment Programs

Impregnation

MW pre-treated samples were impregnated with ACQ. Firstly, the weights of the samples were weighed (T1) before impregnation. The samples were impregnated by the vacuum method. Before the prepared impregnation material was transferred to the desiccator containing the samples, a vacuum of 660 mm Hg was applied to the samples for 30 min, and then ACQ was added to the system. The system was then brought back to atmospheric pressure, and the specimens were left for a further 24 h in the solution. Finally, any leftover solution on the surface of the samples was cleaned, and the weights of the samples (T2) were determined. After the impregnation, the preservative retention was calculated according to Eqs. 2 and 3.

G = T2 – T1 (2)

where T2 is the sample weight after the impregnation (g), and T1 is the sample weight before the impregnation (g).

(3)

In Eq. 3, R is the amount of wood preservative that was retained in the wood sample (kg/m3), C is the mass (g) of preservative in 100 g of the 2% treating solution, and V is the volume of the sample (cm3).

Microwave post-treatment

The two group’s samples pre-treated with MW at low and high levels and impregnated with ACQ (L1 and H2) were air-dried at 20 °C and 65% relative humidity. The other four group samples after impregnation were directly subjected to MW post-treated low and high levels (Table 2). MW post-treatment was carried out in the MW oven used for the pre-treatment process. Ten samples were exposed to the MW at one time. The initial and final MC of samples were determined by weighing the samples before and after MW heating. The surface temperature of the samples was determined using a non-contact thermometer (Dixell XT 110C-5C1TU) after just MW post-treatment. Following this, the samples were kept in the climatization cabinet at 20 °C temperature and 65% relative humidity until they reached constant weight.

Scanning electron microscopy (SEM) and energy-dispersive x-ray spectroscopy (EDX) analysis

The microstructure of samples and the placement and distribution of the ACQ in samples after MWAI processes were examined using SEM-EDX. Cross and radial sections (10 µm thick) were then cut using a sliding microtome with a classical microtome blade. The sectioned specimens were coated with gold (Au) in the coating device and observed with the SEM-EDX.

Compressive strength (CS) test

CS in parallel with the grain test was applied to the samples to determine the changes in the strength properties of the wood by MW pre- and post-treatment. It was carried out according to the TS 2595 (1977) standard for samples with dimensions of 20*20*30 mm3.

Leaching test

The leaching test was carried out according to the AWPA E11 (2006) standard to determine the effect of MW pre- and post-treatment on the leaching of copper on ACQ-impregnated samples. Samples of 19*19*19 mm3 (RxTxL) dimensions were prepared as 6 repetitions for each group. They were placed in a jar, added 300 mL of distilled water, and subjected to leaching. After that, the water in the jars was replaced at 6, 24, and 48 h and thereafter at 48-h intervals for a total of 14 days. After homogenous mixing of the leaching water at the specified hours, 100 mL of it was taken and stored in a large container. At the end of 14 days, the collected water was again homogeneously mixed and 100 ml of it was taken and analyzed. The copper content in the water was determined using an inductively coupled plasma mass spectrometry (ICP-MS).

Determination of copper penetration in the wood structure

Copper penetration was then determined by applying Chrome azurol S solution, a colour indicator of copper, via spraying. This procedure is based on the AWPA A69-18 standard method (AWPA 2021). To assess copper retention, wood samples were cross-sectioned in the middle. Visual determination of the area of copper retention in wood was performed.

Attenuated total reflectance – Fourier transform infrared spectroscopy (ATR-FTIR)

The chemical interaction between ACQ and wood cell wall after MW pre- and post-treatment was performed using imaging ATR-FTIR microscopy. Samples were ground and then measured. The spectrum of each sample was obtained at a wavelength of 700 to 4000 cm-1 with a resolution of 4 cm-1.

Copper valence conversion by UV/VIS

Ultraviolet-Visible Spectroscopy (UV- VIS) analysis was performed to determine the effect of MW pre- and post-treatment on copper conversion. The percentage of copper conversion was expressed as the percentage of copper reduced from cupric copper (Cu (II)) to cuprous copper (Cu (I)), based on the ratio of cuprous copper to the total copper content in the samples. The total copper content in the treated samples was determined by the Inductively Coupled Plasma (ICP) analysis of the digested samples. After treatments, samples were analyzed for Cu-I content using a colorimetric method based on the chemical reaction between cuprous ion (Cu) and 0.10% 2,2-biquinoline in glacial acetic acid (Cui 1999). The wood samples were ground. Following the grinding process, the wood samples were sieved through a 40-mesh. Particles less than 40 mesh were taken in and then air-dried. Firstly, the 2,2’-biquinoline reagent was prepared at room temperature by dissolving about 0.25 g of 2,2’ biquinoline in 250 mL of glacial acetic acid. Approximately 5 mL of 2,2-biquinoline reagent was used to extract 0.05 g wood by shaking a water bath for 6 h at room temperature. After 6 h of shaking, it was centrifuged for 15 min. After centrifugation, the supernatant was analyzed by a UV-VIS spectrophotometer. The absorbance of the solution was measured at 540 nm, which is the wavelength of the maximum absorbance for the Cu (I)-2,2’-biquinoline complex in glacial acetic acid. Measurements were repeated until they obtained constant results to ensure that all the available cuprous ions from the treated wood had been extracted. The measured values were used because it was observed that there had been no change by the conclusion of the seventh day. Calibration curves were prepared using 0 to 50 ppm Cu-I standard solutions prepared by dissolving cuprous oxide in 2,2-biquinoline reagent.

RESULTS AND DISCUSSION

Effect of Microwave-Assisted Impregnation on Microstructure

SEM micrographs obtained from cross-sections of MW-pretreated wood showed that the tracheid cell walls were somewhat deformed, crumpled, and delaminated. Also, the intercellular layer of ray cells had micro-cracks (Fig. 1a-b). When comparing low- and high-intensity MW, the former caused marginally less damage (Fig. 1a vs. 1b). As shown by radial section micrographs (Fig. 1c-d), there was longitudinal lamella delamination between adjacent tracheids (Fig. 1d), and a significant number of the aspirated bordering pit membranes had ruptured (Fig. 1c). Excessive deformations were not expected in this study because the evaluation was limited to MW levels projected to provide the necessary modifications for the impregnation process. Similar results were also observed in other studies (Weng et al. 2020; Sahin Kol and Cayır 2021; Ganguly et al. 2021). Changes in the microstructure of the wood with MW pretreatment, as described in this case, may not significantly affect its mechanical properties but may facilitate impregnation treatment because the wood preservative flows more easily through the ruptured bordered pits and ray cells.

SEM-EDX was utilized to determine the presence and location of copper in the wood structure (Fig. 2a, b). The copper location in the wood was found to be comparatively similar at both high and low energy levels. The radial section micrographs illustrate a notable degree of uniform localization of copper within the wood. Figure 2 (c, d) shows the passageways created for ACQ by rupturing the membranes in the aspirated-bordered pit by steam explosion and the location of ACQ in a ruptured bordered pit.

Fig. 1. SEM micrographs of MW pretreated samples, L1 (a,c) and H1 (b,d). a,b are showing micro-cracks in cross section; c is showing ruptured aspirated pit membranes in radial section; d is showing delamination in middle lamella in radial section.

Fig. 2. SEM-EDX micrographs of MWAI-treated wood (a,b) Copper presence in lumen of tracheids, (c,d) ruptured bordered pit and location of copper in a ruptured bordered pit

Effect of Microwave-Assisted Impregnation on Compression Strength

Table 3 shows the compressive strength (CS) of treated samples in different MWAI processes. Upon analysis of the data, it is evident that the CS of all treated samples exhibited a notable similarity. The small irregular differences in CS values between MW treatments can be attributed to the anisotropic properties of the wood rather than the different MW treatment itself, as they did not show a pattern distinct enough to be deciphered. Based on these findings, it can be said that the application of MWAI treatments did not have a significant detrimental effect on the strength of the wood. These findings are also compatible with SEM micrographs showing structural degradation after MW pretreatment (Fig. 1). In addition to being successful in opening largely closed pit openings, MW treatments did not cause significant structural damage to the fibers, as shown by SEM results (Fig. 1). Based on these data, it can be concluded that the moderate deformations of the tracheids and rays, along with the deformations of the bordered pits, were enough to ensure the flow of impregnation chemicals without sacrificing mechanical qualities. Given that this study mainly focused on energy levels that were predicted to enhance permeability, significant decreases in CS were not anticipated. Although the study findings are consistent with the literature, the change in CS value is slightly lower in our study. Kol and Çayır (2021) investigated the effect of MW pretreatment applied at two different power and energy intensities on the CS of spruce wood and obtained a decrease in the range of 1.7% to 2.9% and stated that this decrease was insignificantly small. Balboni (2018) applied microwave at low and high level energy density to Eucalyptus wood samples and reported a 10% reduction in their results. Machado (2006) applied microwaves at two different energy densities to oak wood samples and observed approximately 10% and 20% reduction in compressive strength values. Changes in the rate of decrease in the CS value in the literature can be attributed to changes in the initial MC and energy density of the samples.

The CS results revealed that the low and high MWAI treatments utilized in this study, both pre-and post-treatments, as well as the combined effect of the two, did not result in a substantial loss in the mechanical strength of the wood. The insignificance of the cumulative MWAI treatment on wood strength indicates that the impregnant flow paths created by the MW pre-treatment were sufficient for water evaporation in the MW post-treatment and that the high energy intensity used in the post-treatment did not cause further deformation.

Table 3. Compression Strength of MW-treated Wood

Effect of Microwave-Assisted Impregnation on Copper Leaching

Prior to the MW pre-treatment, the average MC of the samples was 54%. However, after subjecting the samples to MW pre-treatment at low- and high energy levels, the MC was reduced to 47% (L1) and 22% (H1) respectively. Following impregnation, the average moisture content (MC) of MW pre-treated samples was 111%. However, after MW post-treatment with low and high energy levels, the MC was reduced to 91% and 46%, respectively. The effects of the pre-and post-treatments on the MC of wood were similar, with the low MW treatments causing a decrease of approximately 15% and the high MW treatment causing a decrease of 59%. High MW treatment effectively achieved the necessary MC in less time in MWAI. The study findings revealed that when high energy levels were applied, wood’s MC reduced dramatically both pre-and post-treatment. It is obvious that at high MW level, the ability to swiftly reduce humidity to low levels while achieving the appropriate impregnation modification without compromising resistance is a desired result.

The average ACQ retention amounts of all samples treated under different MWAI conditions before leaching experiments were quite similar, at approximately 7%. Under the impregnation conditions applied, it was possible to reach the targeted 7 kg/m3, which is needed for the outdoor environment of the samples at low and high MW intensities. Low MW energy intensity provided the desired amount of retention for the outdoor environment, and high-energy intensity is not necessary for considering only the amount of retention.

The amounts of copper leached from the MW-treated samples are given in Fig. 3. In high-intensity MW pre-treatment, the amount of copper leached from wood was lower. The results indicate that high intensity of MW pre-treatment was more effective in reducing copper leaching. This is interpreted as the penetration of ACQs reaching deeper due to the somewhat high structural deformations caused by the high MW intensity level compared to the low MW intensity after MW pre-treatment (Fig. 4). Deeply penetrated Cu in high-intensity MW treated wood was more difficult to remove from wood, and thus the amount of Cu remaining in high-intensity treated wood was higher than in low-intensity treated wood. It is also possible that the various micro-cracks created by MW pre-treatment only in the tracheids and ray cells, without creating excessive structural distortions (Fig. 1a,b) may create more adsorption sites for copper and quat or facilitate copper and quat access to the sites. Therefore, as a result of intensive pretreatment, Cu can both penetrate further and may react more with wood components. Figure 5 shows the FTIR spectrum of the MW-treated samples under different conditions. The bands of 895, 1370, 1425, and 2900 cm-1 are bands of C-H in cellulose (Liu et al. 2019). The band at 3300 cm-1 represents the OH stretching vibration in hemicelluloses and lignin (Esteves et al. 2013; Xing and Li 2014; Kubovský et al. 2020). The band at 1027 cm-1 shows the C-O stress in cellulose and hemicellulose. When the FTIR spectra of the samples were analyzed, significant changes were observed at the peak depths of 1027, 2900, and 3300 cm-1. This was interpreted as MWAI processes increasing the complexation of ACQ with the cell wall. Both MW pretreatment alone and the combined effect of MW pre- and post-treatment individually play an effective role in the complexation of ACQ with the cell wall components.

Leaching test results showed that MW post-treatment enhanced somewhat the leaching resistance of ACQ from wood (Fig. 3). The lowest leached copper was in H1-H2 samples; the highest was obtained in L1 samples. The use of MW as a post-treatment was supposed to improve leaching resistance. Generally, the leached Cu decreases with increasing post-treatment temperature, as noted by others (Tascıoglu et al. 2008). In this study, temperature of up to 95 °C achieved during post-treatment is just for a short length of time. According to the findings, even a short-term temperature increases by MW contributed to enhanced copper leaching strength. Also, it is noteworthy that both amounts of MW energy used in post-treatment gave similar results. This phenomenon can be attributed to the utilization of intense MW energy to decrease the moisture level in the impregnated wood which has high MC (111%). As follows: excessive MC in the wood necessitates greater energy and low MW treatments caused a decrease of approximately 15% and the high MW treatment caused a decrease of 59%.

Therefore, the study showed that for the leaching resistance of copper in the MWAI process, high MW density is better when only MW pretreatment is involved, and when both MW pretreatment and posttreatment are involved, high MW pretreatment and low MW posttreatment are more effective.

Fig. 3. Amount of leached copper from MW-treated wood

Fig. 4. Penetration depth of ACQ in MW treated wood (A) in tangential sections (B) in radial sections

Fig. 5. FTIR spectra of MW-treated wood

Effect of Microwave-Assisted Impregnation on Copper Valence Conversion

In L1, L1-L2, and L1-H2 group samples, Cu I form was 13.3%, 8.95%, and 10.17%, respectively. The Cu I content of samples H1, H1-L2 and H1-H2 was 9.32%, 7.33% and 8.70%, respectively. When the Cu valence conversion of the samples post-conditioned in air after MW pretreatment (L1 and H1) was compared, it was observed that the samples with higher MW intensities contained less Cu I. Also, the finding demonstrated that MW post-treatment reduced the conversion of Cu II. When high and low post-treatments are compared, the Cu I form was lowest in the low post-treatment. In the present study, the temperatures during the low and high levels post-treatment were found to be 68 and 95 °C, respectively. This can be explained by the lower temperature reached in low-intensity MW post-treatment. According to the literature, the amount of Cu I increases with increasing post-treatment temperature (Ruddick 2003; Tascıoğlu et al. 2008).

The copper I form is more stable than the copper II form but is biologically less effective (Zhang and Kamdem 1999). The findings of copper conversion suggest that in the MWAI approach, high MW level pretreatment and low MW post-treatment provide a higher Cu II proportion and thus can improve the bio resistance of wood. Focusing on the chemistry of the tested system, it is difficult to draw definitive conclusions due to the existence of various possible mechanisms in redox balance; for example, wood resins, besides the carbohydrates of the wood can act as reducing agents, while available air might function as an oxidizing agent. Further studies are needed to elucidate the mechanisms effective in the conversion of copper in the tested system.

CONCLUSIONS

- The microwave-assisted impregnation (MWAI) system did not cause a significant decrease in the compressive strength of spruce.

- The application of high-intensity microwave (MW) pre-treatment enhanced the efficacy of Cu leaching reduction. Both the high and low MW post-treatment intensities in the MWAI system exhibited similar lowering effects on Cu leaching.

- Both MW pretreatment alone and the combined effect of MW pre- and post-treatment were found to allow for the complexation of ACQ with the cell wall components. The study concluded that the application of high MW intensity yielded better outcomes when only MW pretreatment was employed. Additionally, it was found that the combination of high MW pretreatment and low MW post-treatment proved to be more effective in the MWAI system.

- The Cu I form decreased as the energy intensity of the MW pre-treatment increased. The combination of high MW pre-treatment and low MW post-treatment proved to be more effective in enhancing the biological durability of spruce wood.

REFERENCES CITED

AWPA A 69-18 (2021). “Standard method to determine the penetration of copper containing preservatives,” American Wood Protection Association, Birmingham, AL, USA.

AWPA E 11 (2006). “Standard method of determining the leachability of wood preservatives,” American Wood Protection Association, Birmingham, AL, USA.

Bakir, D., Kartal, S. N., Terzi, E., and Dogu, A. D. (2022). “The effects of bioincising by Physisporinus vitreus on CuO retention and copper element leaching in oriental spruce wood,” Maderas. Ciencia y tecnología 24(27), 1-14. DOI: 10.4067/s0718-221×2022000100427

Barnes, H. M., Kamdem, D. P., and Freeman, M. H. (2000). “Copper naphthenate-treated southern pine pole stubs in field exposure. Part II: chemical characterization of full size pole stubs 12 years after treatment,” International Research Group on Wood Preservation.

Cao, J., and Kamdem, D. P. (2004). “Microwave treatment to accelerate fixation of copper-ethanolamine (Cu-EA) treated wood,” Holzforschung 58, 569-571.

Cui, W. (1999). Biological Performance of Cuprous and Cupric Copper against Wood Decay Fungi, Master’s Thesis, University of Michigan.

Dashti, H., Tarmian, A., Faezipour, M., Hedjazi, S., and Shahverdi, M. (2013). “Mass transfer through microwave-treated fir wood (Abies alba L.): A gymnosperm species with torus margo pit membrane,” Drying Technology 31(3), 359-364. DOI: 10.1080/07373937.2012.736908

Dashti, H., Tarmian, A., Faezipour, M., Hedjazi, S., and Shahverdi, M. (2012). “Effect of pre-steaming on mass transfer properties of fir wood (Abies alba L.): A gymnosperm species with torus margo pit membrane,” BioResources 7, 1907-1918.

Esteves, B., Velez Marques, A., Domingos, I., and Pereira, H. (2013). “Chemical changes of heat treated pine and eucalypt wood monitored by FTIR,” Maderas. Ciencia y Tecnología 15(2), 245-258. DOI: 10.4067/S0718-221X2013005000020

Evans, F.G. (2003). “Field test results after nine years for CCA and ACQ-D preservative treated wood fixed in different climates,” in: 31st Annual Meeting of the International Research Group of Wood Preservation, Stockholm, Sweden.

Freeman, M. H., Shupe, T. F., and Vlosky, R. P. (2003). “Past, present, and future of the wood preservation industry,” Forest Products Journal 53(10), 8-15.

Ganguly, S., Balzano, A., Petrič, M., Kržišnik, D., Tripathi, S., Žigon, J., and Merela, M. (2021). “Effects of different energy intensities of microwave treatment on heartwood and sapwood microstructures in Norway spruce,” Forests 12(5), article 598. DOI: 10.3390/f12050598

Hasan, A. R., Hu, L., Solo-Gabriele H. M., Fieber, L., Cai, Y., and Townsend, T. G. (2010). “Field-scale leaching of arsenic, chromium and copper from weathered treated wood,” Environ. Pollut. 158, 1479-1486. DOI: 10.1016/j.envpol.2009.12.027

He, S., Lin, L., Fu, F., Zhou, Y., and Fan, M. (2014). “Microwave treatment for enhancing the liquid permeability of Chinese fir,” BioResources 9(2), 1924-1938.

Jiang, T., Zhou, Z. F., and Wang, Q. W. (2006). “Effects of intensive microwave irradiation on the permeability of larch wood,” Scientia Silvae Sinicae 42(11), 87-92. DOI: 10.3321/j.issn:1001-7488.2006.11.016

Kamdem, D. P., and Zhang, J. (2000). “Contribution of wood components on the absorption of copper amine,” International Research Group on Wood Preservation Stockholm, Sweden Doc. IRG/WP 00-30216

Kol, H. Ş., and Çayır, B. (2021). “Increasing the impregnability of oriental spruce wood via microwave pretreatment,” BioResources 16(2), 2513-2523. DOI: 10.15376/biores.16.2.2513-2523

Kol, H. Ş., and Çayır, B. (2023). “The effects of increasing preservative uptake by microwave pre-treatment on the microstructure and mechanical properties of Oriental spruce wood,” Wood Material Science & Engineering, 18(2), 732-738. DOI:10.1080/17480272.2022.2077656

Kortsalioudakis, N., Petrakis, P., Moustaizis, S., Voulgaridis, E., Adamopoulos, S., Karastergiou, S., and Passialis, C. (2015). “An application of a laser drilling technique to fir and spruce wood specimens to improve their permeability,” The 7th International Scientific and Technical Conference, Innovations in Forest Industry and Engineering Design.

Kubovský, I., Kačíková, D., and Kačík, F. (2020). “Structural changes of oak wood main components caused by thermal modification,” Polymers 12(2), 485. DOI: 10.3390/polym12020485

Liu, Z., Wang, X., Zhang, Y., Wen, L., Zheng, L., and Cai, L. (2019). “Flow rate and fixation of ACQ-D preservative in poplar living tree after injection,” Wood Science and Technology 53, 373-391. DOI: 10.1007/s00226-019-01079-y

Machado, J. S. (2006). “Effect of microwave treatment on oak compression strength,” Silva Lusitana 14(1), 51-58. ISSN 0870-6352.

Mai, C., and Militz, H. (2007). “Chapter 13. Wood preservatives,” in: Wood Production, Wood Technology, and Biotechnological Impacts, U. Kües (ed.), Göttingen University Press. DOI: 10.17875/gup2007-262 259.

Mascarenhas, F. J. R., Dias, A. M. P. G., and Christoforo, A. L. (2021). “State of the art of microwave treatment of wood: literature review,” Forests 12, article 745. DOI: 10.3390/f12060745.

Mazela, B., Polus, I., and Hoffmann, S. K. (2003). “Biological test, AAS and EPR study of copper monoethanolamine complex with quaternary ammonium compounds as a wood preservative,” in: The 34th Annual Meeting of the International Research Group of Wood Preservation, Brisbane, Australia.

Pang, S. J., Oh, J. K., Hong, J. P., Lee, S. J., and Lee, J. J. (2017). “Effect of incising on the long-term biodeterioration resistance of alkaline copper quaternary (ACQ) treated wood,” European Journal of Wood and Wood Products 75, 777-783. DOI: 10.1007/s00107-016-1151-x

Peyskens, E., de Pourcq, M., Stevens, M., and Schalck, J. (1984). “Dielectric properties of softwood species at microwave frequencies,” Wood Sci. Technol. 18, 267-280. DOI: 10.1007/BF00353363

Qu, J., Liu, R., Bi, X., Li, Z., Li, K., Hu, Q., Zhang, X., Zhang, G., Ma, S., and Zhang, Y. (2023). “Remediation of atrazine contaminated soil by microwave activated persulfate system: Performance, mechanism and DFT calculation,” Journal of Cleaner Production 399, article 136546. DOI:10.1016/j.jclepro.2023.136546

Reinprecht, L. (2016). Wood Deterioration, Protection and Maintenance, John Wiley & Sons, Hoboken, NJ, USA.

Ruddick, J. N. R. (2003). “Basic copper wood preservatives, preservative depletion: Factors which influence loss,” Proc. Can. Wood Preserv. Assoc. 24, 26-59.

Ruddick, J. N. R., Xie, C., and Herring, F. G. (2001). “Fixation of amine copper preservatives Part 1: Reaction of vanillin, a lignin model compound with monoethanolamine copper sulphate solution,” Holzforschung 55(6), 585-589. DOI: 10.1515/HF.2001.095

Singh, R., Krishna, B. B., Kumar, J., and Bhaskar, T. (2016). “Opportunities for utilization of non-conventional energy sources for biomass pretreatment,” Bioresource Technology 199, 398-407. DOI: 10.1016/j.biortech.2015.08.117.

Tascioglu, C., Cooper, P., and Ung, T. (2008). “Effects of fixation temperature and environment on copper speciation in ACQ treated red pine,” Holzforschung 62(3), 289-293. DOI: 10.1515/HF.2008.035

Tascioglu, C., Cooper, P. A., and Ung, Y. Y. (2005). “Rate and extent of adsorption of ACQ preservative components in wood,” Holzforschung 59, 574-580. DOI:10.1515/HF.2005.094

Temiz, A., Yildiz, U.C., and Nilsson, T. (2006). “Comparison of copper emission rates from wood treated with different preservatives to the environment,” Building and Environment 41(7), 910-914. DOI: 10.1016/j.buildenv.2005.04.001

Terziev, N., Daniel, G., Torgovnikov, G., and Vinden, P. (2020). “Effect of microwave treatment on the wood structure of Norway spruce and radiata pine,” BioResources 15(3), 5616-5626. DOI: 10.4067/s0718-221×2022000100427

Torgovnikov, G., and Vinden, P. (2009). “High-intensity microwave wood modification for increasing permeability,” Forest Products Journal 59, 84-92.

Torgovnikov, G., and Vinden, P. (2010). “Microwave wood modification technology and its applications,” Forest Products Journal 60, 173-182. DOI: 10.13073/0015-7473-60.2.173

TS 2595 (1977). “Wood. Determination of ultimate stress in compression parallel to grain,” Turkish Standard Institution, Ankara, Turkey.

Ung, Y. T., and Cooper, P. A. (2005). “Copper stabilization in ACQ treated wood – Retention, temperature and species effects,” Holz Roh Werkstoff 63, 186-191. DOI: 10.1007/s00107-004-0555-1

Wang, Z., Xu, E., Fu, F., Lin, L., and Yi, S. (2022). “Characterization of wood cell walls treated by high-intensity microwaves: Effects on physicochemical structures and micromechanical properties,” Industrial Crops and Products 187, article 115341. DOI: 10.1016/j.indcrop.2022.115341

Weng, X., Zhou, Y., Fu, Z., Gao, X., Zhou, F., and Fu, F. (2020). “Effects of microwave treatment on microstructure of Chinese fir,” Forests, 11(7), 772. DOI:10.3390/f11070772

Weng, X., Zhou, Y., Fu, Z., Gao, X., Zhou, F., and Jiang, J. (2021). “Effects of microwave pretreatment on drying of 50 mm-thickness Chinese fir lumber,” J. Wood Sci. 67, 1-9. DOI: 10.1186/s10086-021-01942-2

Xing, D., and Li, J. (2014). “Effects of heat treatment on thermal decomposition and combustion performance of Larix spp. wood,” BioResources 9(3), 4274-4287. DOI: 10.15376/biores.9.3.4274-4287

Ye, M., and Morrell, J. J. (2015). “Effect of treatment post fixation practices on copper migration from alkaline-copper-treated Douglas-fir lumber,” Wood and Fiber Science 47(4), 391-398.

Yildiz, S., Yildiz, Ü., Dizman, E., Temiz, A., and Gezer, E. (2010). “The effects of preacid treatment on preservative retention and compression strength of refractory spruce wood impregnated with CCA and ACQ,” Wood Research 56(3), 93-104.

Yu, L. L., Gao, W., Cao, J. Z., and Tang, Z. Z. (2010). “Effects of microwave post-treatments on leaching resistance of ACQ-D treated Chinese fir,” Forestry Studies in China 12, 1-8. DOI 10.1007/s11632-010-0008-3

Yu, L., Cao, J., Cooper, P. A., and Tang, Z. (2009a). “Effects of hot water posttreatment on accelerating copper fixation in ACQ-D-treated Chinese fir,” Wood and Fiber Science 236-244.

Yu, L., Cao, J., Cooper, P. A., and Ung, Y. T. (2009b). “Effect of hot air post-treatments on copper leaching resistance in ACQ-D treated Chinese fir,” European Journal of Wood and Wood Products 67(4), 457-463.

Zhang, J., and Kamdem, D. P. (1999). “FTIR characterization of copper ethanolamine-wood interaction,” in: 30th Annual Meeting of the International Research Group on Wood Preservation, Rosenheim, Germany.

Zhang, J., and Kamdem, D. P. (2000). “FTIR characterization of copper ethanolamine—wood interaction for wood preservation,” Holzforschung 54(2), 119-122. DOI: 10.1515/HF.2000.020

Article submitted: October 28, 2023; Peer review completed: December 2, 2023; Revised version received and accepted: December 20, 2023; Published: January 4, 2024.

DOI: 10.15376/biores.19.1.1229-1244