Abstract

Densifying alfalfa into briquettes is one of the effective ways to increase its density and reduce the cost of storage and transportation. To explore the influence of vibration frequency on alfalfa briquetting, vibration-assisted compression tests with six vibration frequencies of 0, 9.52, 15.56, 21.24, 27.50, and 33.44 Hz were carried out. The results showed that the compression with vibration could reduce the maximum forming pressure and the energy consumption. The quality of alfalfa briquettes was improved compared with the compression without vibration. Within the range of test, when the vibration frequency was 21.24 Hz, the maximum pressure was the minimum, which was 5.83 MPa. In addition, the specific energy consumption was the lowest, which was 1374 J/g/cm3. The experimental results provided a basis for determining the optimum vibration parameters of alfalfa compression.

Download PDF

Full Article

Effect of Vibration Frequency on the Vibration-assisted Densification for Alfalfa

Haoyi Wang, Pei Wu,* Dongmei Xue, and Yanhua Ma

Densifying alfalfa into briquettes is one of the effective ways to increase its density and reduce the cost of storage and transportation. To explore the influence of vibration frequency on alfalfa briquetting, vibration-assisted compression tests with six vibration frequencies of 0, 9.52, 15.56, 21.24, 27.50, and 33.44 Hz were carried out. The results showed that the compression with vibration could reduce the maximum forming pressure and the energy consumption. The quality of alfalfa briquettes was improved compared with the compression without vibration. Within the range of test, when the vibration frequency was 21.24 Hz, the maximum pressure was the minimum, which was 5.83 MPa. In addition, the specific energy consumption was the lowest, which was 1374 J/g/cm3. The experimental results provided a basis for determining the optimum vibration parameters of alfalfa compression.

Keywords: Vibration-assisted; Frequency; Briquetting; Alfalfa; Biomass

Contact information: College of Mechanical & Electrical Engineering, Inner Mongolia Agricultural University, Hohhot, 010018, P.R. China; *Corresponding author: jdwupei@163.com

INTRODUCTION

Alfalfa is a leguminous crop that has abundant crude protein, vitamins, and amino acids. In recent years, alfalfa has become an excellent choice to feed livestock in densified form (Fan et al. 2009; Huang et al. 2011; Wang et al. 2017). However, the traditional pellet or briquette-making machines always have the problems of high energy consumption and low efficiency, which limits the process of alfalfa commercial circulation.

To solve this problem, many researchers have studied the factors influencing the biomass densification process and tried new methods to improve the traditional densifying process (Farla et al. 1997; Kaliyan and Morey 2009; Stelte et al. 2011; Tumuluru 2014; Jiang et al. 2016). Lam et al. (2015) proved that steam auxiliary process could increase the pellet density. Frodeson et al. (2019) studied how the polysaccharides were affected by changing moisture content during densification of biomass.

In recent years, some researchers have focused on ultrasonic vibration-assisted compression. This method can increase pellet quality and reduce energy consumption in biomass densification. In terms of increasing pellet quality, Zhang et al. (2010) investigated four levels of molding pressure (138, 206, 275, and 344 kPa) in ultrasonic vibration-assisted pelleting, a significant increase in pelleting density was found under the pressures from 138 to 344 kPa. Tang et al. (2012) reported that pellet crack size would become larger when ultrasonic power, molding pressure, pellet weight, and moisture content were higher, and when the pelleting time was longer. Song et al. (2015) showed that the pelleting density would increase with the increase of the ultrasonic power in the ultrasonic-assisted pelleting process. Zhang et al. (2018) put forward predictive models for pellet density and durability in ultrasonic vibration-assisted pelleting using multiple response surface methodology. In order to reduce energy consumption, Song et al. (2013, 2014) studied the effect of sieve size, pelleting pressure, ultrasonic power, and pellet weight on energy consumption, and proposed a predictive model for energy consumption in ultrasonic vibration-assisted pelleting of wheat straw using response surface methodology. Benavente and Fullana (2015) testified that a roasting pretreatment could reduce specific energy consumption in biomass densification process.

However, these studies mainly focused on the ultrasonic vibration-assisted pelleting with the fixed vibration frequency of 20 kHz, and there were few studies on the effect of vibration frequency on the vibration-assisted densification process (Wu et al. 2014; Ma et al. 2016). Therefore, in this paper the densification experiments with different vibration frequencies were carried out, and the results will contribute to the explanation of the influence of vibration on alfalfa briquettes and energy consumption during densification.

EXPERIMENTAL

Materials

The alfalfa used in the tests was harvested in the suburb of Hohhot (Inner Mongolia, China). After being collected, the alfalfa was naturally dried to approximately 7% moisture content. Then, the material was crumbled into small particles using a 9RS-60 crumbling machine (manufactured in Machinery Plant of Inner Mongolia Agriculture University, Hohhot, China). Impurities were removed by forceps.

Particle size measured by the standard sieves was between 0.9 and 8 mm according to the GB/T 5917.1 (2008) standard. Moisture content of the alfalfa particles was obtained by calculating the ratio of the water weight contained and the total weight of the raw material according to the GB/T 36055 (2018). To obtain different moisture contents, the crumbled raw alfalfa was added with water and mixed sufficiently to adjust the moisture content to 16 to 18%. The moisture content of the alfalfa sample was measured with a GMK-3308 moisture content tester (G-WON Company Ltd., eoul, South Korea). After preparation, the sample material was bagged and stored for 48 h at room temperature.

Fig. 1. Bagged test material

Experimental System

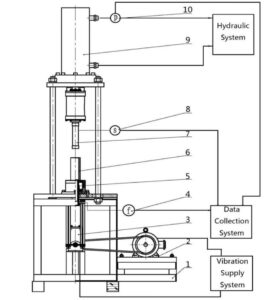

Figure 2 shows the experimental system for alfalfa vibration-assisted compression, in which a hydraulic system with the maximum pressure of 11 MPa, a vibration generating system, a briquetting system, and a data collection system were included. A die, used as the key part of the densification is with inlet diameter of 45 mm and outlet diameter of 40 mm, and the outlet of the die is connected to the rod board to impose the vibration to the compression material.

Fig. 2. Schematic diagram of the densifying test system: 1: Frame; 2: Motor; 3: Vibration device; 4: Accelerometer; 5: Die; 6: Barrel; 7: Punch; 8: Displacement sensor; 9: Hydraulic cylinder; 10: Pressure sensor

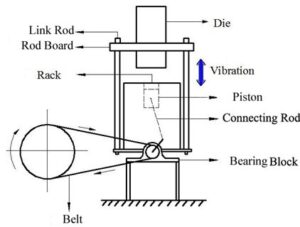

The vibration is generated by a crank-connecting rod mechanism, as shown in Fig. 3. The electromotor drives the crankshaft rotating through the belt, and then the rotating crankshaft drives the rack connected with the piston to perform the reciprocating motion and thus generating the vibration. Finally, the vibration of the rack is transmitted to the die through a link rod and board that was connected with the bottom of the die by a threaded connection.

A pressure sensor CYYZ11 (XinYi Company Ltd., Beijing, China) installed to the oil pipe inlet of the hydraulic system and a BM-300 displacement sensor (BESTNEW Company Ltd., Shenzhen, China) connected to the piston were used to detect the hydraulic pressure and punch displacement. The signals from these two sensors were collected simultaneously by a NI data acquisition board (National Instrument Company Ltd., Los Angeles, CA, USA), coordinated with LabVIEW2013 software (National Instrument Company Ltd., LabVIEW2013, Los Angeles, CA, USA). The vibration data were detected by a three-axis acceleration sensor Dytran3263A2 (Dytran Company Ltd., Chatsworth, California, USA) that was installed on top of the connecting board. The data was plotted by OriginPro8 software (OriginLab, Pro8, Northampton, MA, USA).

Fig. 3. Schematic diagram of the operating principles

Methods

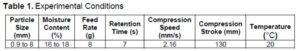

For researching the effect of vibration frequency on densification process, six levels of vibration frequency conditions were set in the experiment: 0, 9.52, 15.56, 21.24, 27.50, and 33.44 Hz. The other experimental conditions are shown in Table 1.

Through adjusting the motor rotation, the six levels of vibration frequency mentioned above were obtained for the tests. The compression punch moved from the highest point to the lowest point, and then returned, which is defined as one stroke. Each test was repeated for 12 strokes. Signals of displacement of the compressed punch, pressure in the hydraulic cylinder, and vibration from the exciting device were collected by a displacement sensor, a pressure transmitter, and an acceleration sensor, respectively.

The density of alfalfa briquette was measured by the following method: using a Vernier caliper (accuracy: 0.02 mm, and range: 150 mm, Harbin Measuring & Cutting Tool Group Company Ltd., Harbin, China) to measure the diameter d (mm) as well as the length l (mm) of the briquette at three different locations, and the mean values were calculated. The density of briquette ρ (g/cm3) is defined by Eq. 1:

![]()

Relaxation ratio was used to explain the relaxation degree of briquette, its formula is defined by Eq. 2,

Relaxation ratio = Extrusion density / Relaxation density (2)

where the extrusion density (g/cm3) is the density of alfalfa briquette within 2 min after extrusion and relaxation density (g/cm3) is the density of alfalfa briquette within 168 h after extrusion.

RESULTS AND DISCUSSION

Figures 4a and 4b show the pressure-time and displacement-time curves of compression without assisted vibration and with vibration frequency of 21.24 Hz. The compression process under two working conditions was almost the same, which can be divided into five stages.

The first stage was AB (pre-compression stage). Due to the low bulk density of alfalfa at this stage, the required pressure was low and increased slowly. The second was BC (compression stage), in which the material was further compressed and viscoelastic deformation occurred, with the increase of density and the material squeezed into the narrow section of the die, the required pressure increased rapidly. The third stage was the CD (extrusion stage), in which the alfalfa log began to squeeze out, indicating that the pressure had reached the maximum static friction force between the material and die surface, and the static friction turned into the kinetic friction. Thus, the pressure decreased and displacement increased, until the punch reached the end of the die. The fourth stage was DE (shape-preservation stage), in which the punch stopped at the maximum displacement for a period of time, and the pressure decreased gradually. The last was EF (punch-return stage), in which the punch returned and the cycle of compression was completed.

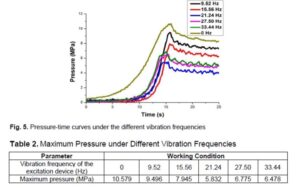

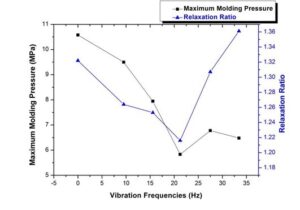

The maximum pressure required in the densifying process is an important parameter to estimate energy consumption. The pressure is mainly determined by compression resistance, which includes deformation resistance, the friction between the compressed material and inner wall of the die. When vibration frequency was varied, the maximum pressure of alfalfa compression also varied, as shown in Table 2. The pressure-time curves under six vibration frequencies had the same changing trend, as shown in Figure 5. By comparison of alfalfa compression without assisted vibration, it was found that alfalfa compressed with assisted vibration had a smaller maximum molding pressure. This might be due to the fact that the material to be compressed was mainly subjected to shear stress during compression and the greater friction needed to be overcome when without assisted vibration, indicating that the vibration could decrease the resistance of densification.

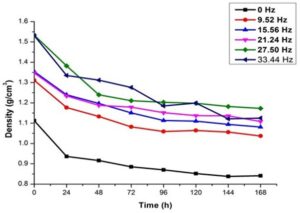

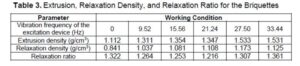

Because of stress relaxation, the density of the briquette gradually decreased after being removed from the die. In this experiment, the density of the briquette was measured every 24 h after the briquettes were extruded out of the die, and the time-density curves of the briquette made under different vibration frequencies are shown in Fig. 6. It was noticed that the density of the briquette decreased rapidly at the beginning, and then slowed down gradually with time; the smaller the density difference between two adjacent measurements, the slower the stress relaxation, and the density variation was relatively small at the frequency 21.24 Hz.

Fig. 6. The density-time curve of the briquette after extrusion

The relaxation ratio is usually used to indicate the degree of relaxation of the briquette. In Table 3, except for 33.44 Hz, the relaxation ratio of alfalfa briquette with assisted vibration was less than that without assisted vibration, showing that the assisted vibration influenced the decrease of briquette deformation recovery. The reason might be that the assisted vibration helped to improve the moving and filling of material particles during compression. Meanwhile, the elastic restitution deformation of material particles was reduced, and a part of the internal stress was uniformed or eliminated, resulted in the alfalfa briquette kept a high density after a long storage time.

Vibration frequency was an important parameter affecting the compression effect. When the assisted-vibration frequency was close to the natural frequency of the compressed material, it was easy to produce resonance and make particles easily to enter each other’s pores. The assisted vibration facilitated the rearrangement of alfalfa particles and helped the material to form an aggregate-density structure.

Combined with the experimental results of the influence of vibration frequency on the maximum pressure and relaxation ratio, within the range of vibration frequencies generated in this experiment, when the vibration frequency increased, the maximum molding pressure and the relaxation ratio decreased at first and then increased, as shown in Fig. 7. When the assisted-vibration frequency was at 21.24 Hz, the relaxation ratio and the maximum pressure were relatively small, at 1.216 and 5.832 MPa, respectively.

Fig. 7. The curves of vibration frequency versus the maximum pressure and relaxation ratio

When the vibration frequency was below 21.24 Hz, with the increase of vibration frequency, the vibration energy acting on the compressed material increased gradually, and smaller pressure could be needed to compress the alfalfa into a more dense briquette. When the vibration frequency was at 21.24 Hz, the vibration energy was fully utilized, and a better compression effect was achieved.

It could be concluded that the natural frequency of compressed alfalfa was about 21.24 Hz; when the vibration frequency was higher than 21.24 Hz, especially up to 33.44 Hz, the stabilization time of vibration was short, which was disadvantageous to the vibration-assisted compression. In addition, the equipment was shaking greatly, so the relaxation of alfalfa briquette was relatively large.

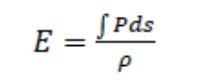

Specific energy consumption, which is defined as the energy consumed by compressing the unit density of material, is an important indicator to evaluate the rationality of biomass densifying process (Hu et al. 2013). The formula is shown in Eq. 3,

where, E (J/g/cm3) is the specific energy consumption, P (N) is the pressure of hydraulic system, S (m) is the displacement of compression piston, and ρ (g/cm3) is the relaxation density.

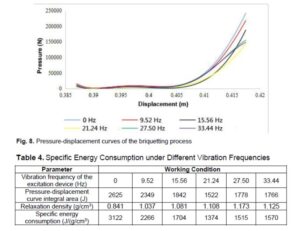

In software OriginPro8, the area between the pressure-displacement curve and the abscissa under different vibration frequencies could be calculated, which indicated the energy consumption in the alfalfa briquetting process, as shown in Fig. 8. The energy consumption of compression for alfalfa with assisted vibration was less than that of compression without vibration.

Moreover, the specific energy consumption of alfalfa briquetting decreased at first and then increased with the increase of frequency. In this test, when the vibration-assisted frequency was at 21.24 Hz, the experiment system had the minimum specific energy consumption, which was 1374 J (g/cm3), as shown in Table 4.

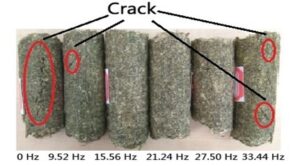

As shown in Fig. 9, the appearance of the alfalfa briquettes made under different vibration frequencies was observed after two months. It was found that the cracks of the alfalfa briquette made without assisted vibration were obvious. The cracks were long and big because of the heat from the friction between alfalfa briquette and die surface as well as the uneven internal stress. Although there were still cracks on the surface of the alfalfa briquettes prepared under other working conditions, the cracks were relatively small, and the overall surface was relatively smooth. Thus, it was concluded that the assisted vibration could make heat transmission and internal stress uniform.

Fig. 9. Appearances of alfalfa briquette at different vibration frequencies after two months

CONCLUSIONS

Assisted vibration can effectively reduce the maximum molding pressure and the specific energy consumption of the compression process and can improve the quality of alfalfa briquettes.

With the increase of assisted-vibration frequency, the maximum molding pressure, specific energy consumption, and relaxation ratio were decreased first and then increased. When vibration frequency was around 21.24 Hz, the maximum molding pressure, specific energy consumption, and relaxation ratio had smaller values in this test, so the optimum vibration frequency of alfalfa compression may be around 21.24 Hz.

ACKNOWLEDGEMENTS

The authors thankfully acknowledge the funding support through the National Natural Science Foundation of China (Grant No.32060771, No.31860666) and the project of the 2013 Inner Mongolia “Grassland excellence team” (Neizutongzi[2014]27) for carrying out this research work.

REFERENCES CITED

Benavente, V., and Fullana, A. (2015). “Torrefaction of olive mill waste,” Biomass and Bioenergy 73, 186-194. DOI: 10.1016/j.biombioe.2014.12.020

Fan, W. N., Wang, C. Z., Shi, P. F., Yan, X. B., Xu, B., and Yang, L. L. (2009). “Progress situation on research and application of alfalfa in animal diet,” Pratacultural Science 26, 81-86.

Farla, J., Blok, K., and Schipper, L. (1997). “Energy efficiency developments in the pulp and paper industry: A cross-country comparison using physical production data,” Energy Policy 25(7-9), 745-758. DOI: 10.1016/s0301-4215(97)00065-7

Frodeson, S., Henriksson, G., and Berghel, J. (2019). “Effects of moisture content during densification of biomass pellets, focusing on polysaccharide substances,” Biomass and Bioenergy 122, 322-330. DOI: 10.1016/j.biombioe.2019.01.048

GB/T 5917.1 (2008). “Two-sieve screening method— Determination of feed particle size,” Standardization Administration of China, Beijing, China.

GB/T 36055 (2018). “Method for analysis of forestry biomass—Determination of moisture content,” Standardization Administration of China, Beijing, China.

Hu, J., Lei, T., Sheng, S., and Zhang, Q. (2013). “Specific energy consumption regression and process parameters optimization in wet-briquetting of rice straw at normal temperature,” BioResources 8(1), 663-675. DOI: 10.15376/biores.8.1.633-675

Huang, X., Wan, F., Huang, J., Wu, J., and Zhang, K. (2011). “Parameter optimization of granulated alfalfa pelleting process based on extrusion simulation experiment,” Transactions of the Chinese Society of Agricultural Engineering 27(11) 354-358. (In Chinese) DOI: 10.3969/j.issn.1002-6819.2011.11.066

Jiang, L., Yuan, X., Xiao, Z., Liang, J., Li, H., Cao, L., Wang, H., Chen, X., and Zeng, G. (2016). “A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties,” Energy Conversion and Management 126, 509-515. DOI: 10.1016/j.enconman.2016.08.035

Kaliyan, N., and Morey, R. V. (2009). “Factors affecting strength and durability of densified biomass products,” Biomass and Bioenergy 33(3), 337-359. DOI: 10.1016/j.biombioe.2008.08.005

Lam, P. S., Lam, P. Y., Sokhansanj, S., Lim, C. J., Bi, X. T., Stephen, J. D., Pribowo, A., and Marbee, W. E. (2015). “Steam explosion of oil palm residues for the production of durable pellets,” Applied Energy 141, 160-166. DOI: 10.1016/j.apenergy.2014.12.029

Ma, Y., Wu, P., Zhang, Y., Xuan, C., and Su, H. (2016). “Effect of vibration during compression on the process of making biomass briquettes,” BioResources 11(1), 2597-2606. DOI: 10.15376/biores.11.1.2597-2606

Song, X., Zhang, M., Deines, T. W., Zhang, P., Pei, Z. J. (2013). “Energy consumption study in ultrasonic vibration-assisted pelleting of wheat straw for cellulosic biofuel manufacturing,” International Journal of Manufacturing Research 8(2), 135-149. DOI: 10.1504/IJMR.2013.053284

Song, X., Zhang, M., Pei, Z. J., and Wang, D. (2014). “Ultrasonic vibration-assisted pelleting of wheat straw: A predictive model for energy consumption using response surface methodology,” Ultrasonics 54(1), 305-311. DOI: 10.1016/j.ultras.2013.06.013

Song, X., Zhang, M., Pei, Z. J., and Wang, D. (2015). “Ultrasonic vibration-assisted (UV-A) pelleting of wheat straw: A constitutive model for pellet density,” Ultrasonics 60, 117-125. DOI: 10.1016/j.ultras.2015.03.002

Stelte, W., Holm, J. K., Sanadi, A. R., Barsberg, S., Ahrenfeldt, J., and Henriksen, U. B. (2011). “Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions,” Fuel 90(11), 3285-3290. DOI: 10.1016/j.fuel.2011.05.011

Tang, Y., Zhang, P., Liu, D., Pei, Z. J., and Cong, W. (2012). “Ultrasonic vibration-assisted pelleting of cellulosic biomass for biofuel manufacturing: A study on pellet cracks,” Journal of Manufacturing Science and Engineering 134(5), 1-8. DOI: 10.1115/1.4007467

Tumuluru, J. S. (2014). “Effect of process variables on the density and durability of the pellets made from high moisture corn stover,” Biosystems Engineering 119, 44-57. DOI: 10.1016/j.biosystemseng.2013.11.012

Wang, Y., Huang, X., and Wu, J. (2017). “Numerical simulation and verification of flow field in ring die pellet mill at different process parameters for alfalfa,” Transaction of Chinese Society of Agricultural Engineering 33(21), 267-274. (In Chinese) DOI: 10.11975/j.issn.1002-6819.2017.21.033

Wu, P., Ma, Y., Chen, Y., Zhang, Y., and Wang, H. (2014). “Vibration-assisted compaction of biomass,” BioResources 9(3), 3857-3868. DOI: 10.15376/biores.9.3.3857-3868

Zhang, Q., Shi, Z., Zhang, P., Zhang, M., Li, Z., Chen, X., and Zhou, J. (2018). “Ultrasonic-assisted pelleting of sorghum stalk predictive models for pellet density and durability using multiple response surface methodology,” Energies 11(5), Article ID 1214. DOI: 10.3390/en11051214

Zhang, Q., Zhang, P. F., Deines, T., Pei, Z. J., Wang, D., and Wu, X. (2010). “Ultrasonic vibration assisted pelleting of sorghum: Effects of pressure and ultrasonic power,” in: International Manufacturing Science and Engineering Conference, ASME, Erie, PA, USA, pp. 129-135. DOI: 10.1115/MSEC2010-34173

Article submitted: July 19, 2020; Peer review completed: December 5, 2020; Revised version received and accepted: January 18, 2021; Published: January 22, 2021.

DOI: 10.15376/biores.16.1.1863-1874