Abstract

Recently, an intermittent hot-pressing process had been developed and applied to produce bamboo bundle laminated veneer lumber (BLVL) joints with lengths of more than 6 m. According to our previous studies, there was a major difference in the physical and mechanical performance of hot-pressing joints and at adjacent positions on the lumber. In this paper, heat transfer and the effects of various aging temperatures on the mechanical performance of the joints of intermittent hot-pressed BLVLs were studied. During the hot-pressing process, there were noticeable different temperature changes on the board. In addition, degradation of the modulus of elasticity (MOE) and modulus of rupture (MOR) values on the joints was greater than that on the adjacent positions of the BLVLs, and the degradation increased with increasing aging temperature. Because of the low interfacial bonding strength of the joints caused by the pre-curing effect during the hot-pressing process, the MOR was more sensitive to hydrothermal conditions. Therefore, when BLVLs produced by intermittent hot-pressing are used as engineering components, the joints should be well-designed and arranged to avoid being used in the same cross-section.

Download PDF

Full Article

Effects of Aging Temperature on Mechanical Performance of Bamboo Bundle Laminated Veneer Lumber Joints Prepared by Intermittent Hot Press Process

Fuming Chen,a,b Haidong Li,c Zehui Jiang,a and Ge Wang a,*

Recently, an intermittent hot-pressing process had been developed and applied to produce bamboo bundle laminated veneer lumber (BLVL) joints with lengths of more than 6 m. According to our previous studies, there was a major difference in the physical and mechanical performance of hot-pressing joints and at adjacent positions on the lumber. In this paper, heat transfer and the effects of various aging temperatures on the mechanical performance of the joints of intermittent hot-pressed BLVLs were studied. During the hot-pressing process, there were noticeable different temperature changes on the board. In addition, degradation of the modulus of elasticity (MOE) and modulus of rupture (MOR) values on the joints was greater than that on the adjacent positions of the BLVLs, and the degradation increased with increasing aging temperature. Because of the low interfacial bonding strength of the joints caused by the pre-curing effect during the hot-pressing process, the MOR was more sensitive to hydrothermal conditions. Therefore, when BLVLs produced by intermittent hot-pressing are used as engineering components, the joints should be well-designed and arranged to avoid being used in the same cross-section.

Keywords: Aging temperature; BLVL; Hot-pressing joints; Mechanical performances

Contact information: a: Department of Bamboo and Rattan Biomaterials, International Centre for Bamboo and Rattan, Beijing, China, 100102; b: Key Laboratory State Forestry Administration (SFA), Beijing, China, 100102; c: Henan Polytechnic University, Henan, P. R. China; *Corresponding author: wangge@icbr.ac.cn

INTRODUCTION

Environmental conservation and wood-based resource shortages have increased worldwide attention to bamboo as a preferred and sustainable building material because of its fast growth, environmental friendliness, reuse capability, and excellent mechanical properties compared with those of structural wood products (Nugroho and Ando 2001; Lugt et al. 2006; Hu and Pizzi 2013; Deng et al. 2014, 2016).

Bamboo-based construction and engineering materials have been extensively applied and investigated to obtain innovative products with desired mechanical and physical performance and for upgrading the process technologies (Chung and Yu 2002; Lee et al. 2003, 2012; Mahdavi et al. 2012; Sharma et al. 2015). Bamboo bundle laminated veneer lumber (BLVL) is a bamboo-based composite developed as a promising material for engineering applications because of advantages such as good dimensional stability, excellent mechanical performance, and a high resource yield ratio (over 90%) (Chen et al. 2013a; Jiang et al. 2013). Additionally, the methods used to study the changes in mechanical performance during the aging resistance test on bamboo-based products were adopted in previous works (Tomak et al. 2012; Yu et al. 2013; Huanga et al. 2014)

Recently, an intermittent hot-pressing process has been developed and applied to produce BLVLs with lengths greater than 6 m (Chen et al. 2013b). The term “intermittent”, as used in this article, means that the pressure and heat were applied discontinuously to successive sections of panel material, since the product was too long to fit all at once within the hot-press device. Studies on the physical and mechanical performances of intermittent hot-pressing-derived BLVLs have also been carried out. Experimental results showed that large-span BLVLs could be prepared by the intermittent hot-pressing process with mechanical properties that meet the requirements of 160-E superior products according to Chinese national standard GB/T 17657-2013 (Chen et al. 2016; GB/T 17657(2013)). Li et al. (2016) established an empirical 3-D model as a good predictor to track and monitor the variance of MOE of BLVLs. In addition, the aging treatment test showed that the phenol formaldehyde (PF) resin/polyvinyl acetate (PVAc) ratio had a noticeable influence on the mechanical degradation of BLVLs. Deng et al. (2016) found that the water absorption-swelling rate and weight gain rate of BLVLs decreased as the PF/PVAc ratio increased at 63 °C.

However, according to our previous studies, there was a noticeable difference in the physical and mechanical performance of hot-pressing joints and adjacent positions on the lumber. In this paper, heat transfer on the hot-pressing board and the hot-pressing joints were investigated by monitoring the temperature change during the hot-pressing process. Moreover, the effects of various aging temperatures on the mechanical performance of the joints of intermittent hot-pressing BLVLs were studied.

EXPERIMENTAL

Sample Preparation

Strips of Cizhu bamboo (Neosinocalamus affinis) aged three years from Yibin (China) were obtained by splitting the bamboo tubes longitudinally. They were then rolled and broomed into bamboo bundles by a self-developed untwisting machine. More details about the machine can be seen in our previous publications (Chen et al. 2013a, 2014). The BLVLs were prepared from bamboo bundle veneers by intermittent hot-pressing technology at a platen temperature of 130 °C for 16 min by an ordinary hot press with an area of 1220 × 2440 mm2.

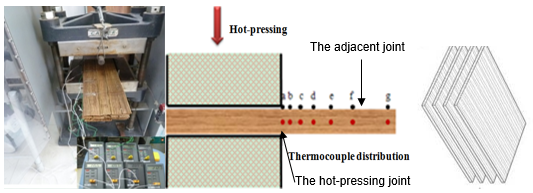

Fig. 1. Temperature monitoring during the intermittent hot-pressing process

The target dimensions and density were respectively 3000 × 1220 × 14 mm3 (length × width × thickness), and 1.0 g/cm3. The process and the parameters for BLVLs can be found in Chen et al. (2016). During the hot-pressing process, the temperatures on the surface and core of the hot-pressing joints and adjacent positions were respectively monitored by thermocouples, as shown in Fig. 1. The hot-pressing joints, the weakest parts of the BLVL, are located in connecting positions corresponding to twice hot-pressing, as shown in the point of a in Fig. 1.

Heat Transfer of BLVLs during the Hot-Pressing Process

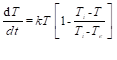

Bamboo is a viscoelastic anisotropic biomaterial (Majumdar et al. 2010; Huang et al. 2014). The heat transfer mechanism of bamboo-based composites during the hot-pressing process is very complicated because of major differences in cell structures, which affect their physical and chemical performances. The heat transfer rate depends on the density, thickness, moisture content, pressure pressing temperature, resin content, and other factors. Scholars (Yang 2001; Wang et al. 2005) have established some mathematical models through the study of physical parameters like the thermal conductivity, moisture diffusivity, and thermal diffusivity of materials. Through many experiments, it was found that the heat transfer of boards reflects the Malthus model shown in Eq. 1 (Zombori and Kamke 2001; Wang et al. 2005):

(1)

where Ti is the initial temperature; Te is the equilibrium temperature; Tt is the temperature at various time intervals; t is time; and k is the heat transfer coefficient.

Because T0 = Ti, Eq. 2, from the integral transformation of Eq. 1, can be used to calculate k:

(2)

(2)

Hydrothermal Aging Treatment on the Hot-pressing joints

Specimens with dimensions of 300 × 20 × 12.5 mm (length × width × thickness) were cut from the BLVLs, and the hot-pressing joints were located at the middle of every specimen. To observe the temperature influence on aging resistance, three groups of samples were respectively treated by different hydrothermal temperatures (18, 63, and 100 °C). Every sample was weighed before the treatment. Five repetitive samples were prepared for each tests. Equations for MOE-aging time curves in the joints and control samples in other adjacent parts of BLVL at various aging temperatures was fitted by using the software of SPSS 12.0.

Bending Test

After removing the test specimens from water, the surface was dried with filter paper and the sample was immediately weighed. To investigate the effects of aging temperature on the mechanical performance at the hot-pressing joints of BLVLs, 3-point bending tests were performed using an Instron 5582 (Instron Corporation, Norwood, MA) mechanical testing machine in accordance with Chinese National Standard GB/T 17657-2013(GB/T 17657(2013)). The test times were 0, 2, 6, 12, 18, and 22 h after hot-humid circling aged treatment. Modulus of elasticity (MOE) was evaluated in the range between 20% and 40% of the ultimate load. Modulus of rupture (MOR) corresponds to the maximum stress at failure. All tests were performed at 18 °C.

CT Scanning

The cross-section of the hot-pressing joints and adjacent positions after bending tests were analyzed by computed tomography (CT) scanning technology (BrightSpeed Excel Select, GE Co., Fairfield, America), which was originally designed for medical use. Digital images sized 512 × 512 Pixels were produced. The X-ray generator was set to 120 kV and 140 mA with a slice thickness interval between slices of 2.5 mm.

RESULTS AND DISCUSSION

Analysis of Heat Transfer on the Hot-Pressing Board and Hot-pressing Joints

Figure 2 shows the temperature changes on the hot-pressing board and the hot-pressing joints during the hot-pressing process. In Fig. 2a, the temperature of the surface and core layers of the board reached up to 120 °C and the resin began to cure rapidly at 11 and 15 min, respectively. The temperature of the surface layer approached the set temperature of 135 °C after 15 min, when the cooling process just started. The temperatures began to decline after 16 and 18 min, respectively. Additionally, at both the heating stage and cooling stage, the temperature of the core layer lagged approximately 2 min behind that of the surface layer.

Meanwhile, a complicated temperature change occurred on the hot-pressing joints. The temperature of the surface layer of the hot-pressing joints reached a maximum of 98.8 °C after 10 min, and the temperature remained steady until the cooling process started, as shown in Fig. 2b. Subsequently, the water inside the board evaporated and absorbed a lot of heat when it was close to 100 °C, which caused a decline in the temperature. The temperature of the core layer reached a maximum of 70 °C at 20 min, which is lower than the curing temperature of the adhesive. At 14 min after cooling, the surface and the core layers had the same temperature. During the intermittent hot-pressing process, the pre-curing of the adhesive on the surface layer takes place; this had little influence on the core layer, which possibly leads to low interfacial bonding strength on the joints.

Fig. 2. Temperature curves at various positions of surface and core layers of BLVLs

Effects of Various Hydrothermal Treatment Temperatures on MOE of BLVL Joints

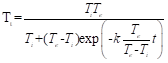

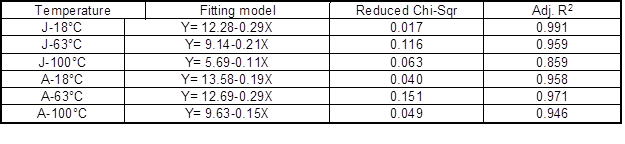

The MOE changes in the joints and adjacent positions of BLVLs impregnated at various aging temperatures are shown in Fig. 3. After 22 h of aging treatment at 18, 63, and 100 °C, the MOE values on the joints were reduced by 24.4%, 46.5%, and 67.4%, respectively. The corresponding MOE changes in the adjacent positions were respectively 12.7%, 43.8%, and 54.0%. It is obvious that the MOE on joints had a greater reduction than that on the adjacent positions. Furthermore, the MOE degradation rate showed an increasing trend with increasing aging temperature. The MOE of BLVLs first decreased rapidly with increasing aging time and then decreased more gradually, which was consistent with the trend of a negative exponential function. The curves of MOE on the joints and adjacent positions, as well as the aging time, were fitted according to a negative exponential equation, as shown in Table 1. It was confirmed that every fitting equation had a good accuracy because of the low Chi squared and high R2 values.

Fig. 3. MOE change in the joints and adjacent positions of BLVL impregnated at various aging temperatures

Table 1. Fitting Equations for MOE vs. Aging Time in the Joints and Adjacent Parts of BLVL at Various Aging Temperatures

As shown in Fig. 4, the relationship between MOE and water absorption ratio was linear on the joints and the adjacent parts of BLVLs under various aging temperatures. However, the R2 (0.85) values of the equation on the joints treated at 100 °C were far less than others, as seen in the corresponding fitting linear equations (Table 2). To some extent, these results imply that under high temperature, the stiffness damage on the joints was related not only to the water absorption deformation, but also to the interfacial bonding and microcracks between PF resin and bamboo fibers.According to the thermodynamic theory, the kinetic energy of water molecules increases with increasing temperature. Thus, under high-temperature conditions, the aging damage and water absorption ratio also increased because of the increase in migration of water molecules into the board. Because of the low interfacial bonding strength of the joints caused by the pre-curing effect during the hot-pressing process, the bamboo fibers and resin were more vulnerable to aging damage and deformation under the hydrothermal aging conditions, which further resulted in stiffness reduction and strength damage.

Fig. 4. Linear fitting equation for MOE and water abortion ratio of BLVLs impregnated at various water temperatures: (a) intermittent hot-pressing joints; (b) adjacent positions

Table 2. Fitting Equations for MOE vs. Water Absorption Rate in the Joints and Adjacent Parts of BLVLs

Effects of Hydrothermal Treatment Temperature on the Strength Degradation of BLVL JointsNote: J represents the joint; A means the adjacent position.

The hydrothermal treatment not only is able to degrade the stiffness of BLVLs, but it also can damage their mechanical strength, as shown in the authors’ previous studies (Li et al.2016). As shown in Fig. 5, the MOR decreased with increasing aging time at an aging temperature of 63 °C. After 22 h of aging treatment, the MOR and its decreasing ratio on the joints were 59 MPa and 50%, respectively. However, those on the adjacent parts were respectively 94 MPa and 31.2%.

Fig. 5. MOR vs. aging time for joints and adjacent parts at 63 °C

Figure 6 shows CT images after 22 h of aging treatment at 63 °C. There were long micro-cracks visible at the joints because of the water molecules that were absorbed because of the low interfacial bonding strength on the joints. When the internal stress was further released, a large number of microcracks were generated and aggregated.

Fig. 6. Classic CT images of the cross-sections of the hot-pressing joints and adjacent positions

There was also a linear relationship observed between MOR and water absorption ratio, as shown in Fig. 7.

Fig. 7. MOR vs. water absorption for the joints and adjacent parts at 63 °C

After 22 h of aging treatment at 18, 63, and 100 °C, the reduced rates of MOR on the joints were respectively 33.6%, 48.2%, and 50.2%. However, those on the adjacent positions were respectively 20.8%, 27.7%, and 34.8%, as shown in Fig. 8. It could also be found that the degradation of MOR on the joints was more than that on the adjacent parts of BLVLs. Additionally, the degradation increased with increasing aging temperature. As mentioned above, because of the low interfacial bonding strength on the joints caused by the pre-curing effect during the hot-pressing process, the MOR was more sensitive to the hydrothermal conditions. Therefore, when BLVLs produced by the intermittent hot-pressing process are used as engineering components, the joints should be well designed and arranged to avoid being used in the same cross-section.

Fig. 8. Comparison of MOR for joints and adjacent positions after 22 h under various aging temperatures

CONCLUSIONS

In this study, heat transfer on hot-pressed boards and hot-pressing joints was investigated. The effects of various aging temperatures on the mechanical performance of the joints of intermittent hot-pressed BLVLs were also studied. The main conclusions from this study are as follows:

- According to the temperature changes during the intermittent hot-pressing process, whether at the heating stage or at the cooling stage, the temperature on the core layer lagged approximately 2 min behind that on the surface layer. In addition, pre-curing of the adhesive occurred on the surface layer, and this had little influence on the core layer. The pre-curing effect led to a low interfacial bonding strength on the joints.

- According to the changes in mechanical performance of the joints and adjacent parts of BLVLs treated at various aging temperatures, it was obvious that the MOE and MOR values on joints had a greater degradation than those on the adjacent parts. Additionally, the degradation rate showed an increasing trend with increasing aging temperature.

ACKOWLEDGEMENTS

The authors are grateful for the financial support of the Fundamental Research Funds for the International Centre for Bamboo and Rattan (1632017015) and China State Forestry Administration Forestry Science and Technology Promotion Program (2017-29).

REFERENCES CITED

Chen, F., Jiang, Z., Deng, J., Wang, G., Zhang, D., Zhao, Q., and Shi, S. Q. (2013a). “Evaluation of the uniformity of density and mechanical properties of bamboo-bundle laminated veneer lumber (BLVL),” BioResources 9(1), 554-565. DOI: 10.15376/biores.9.1.554-565

Chen, F., Jiang, Z., Wang, G., Shi, S. Q., and Liu, X. (2013b). “Bamboo bundle corrugated laminated composites (BCLC). Part I. Three dimensional stability in response to corrugating effect,” Journal of Adhesion 89(3), 225-238. DOI: 10.1080/00218464.2013.739044

Chen, F., Deng, J., Cheng, H., Li, H., Jiang, Z., Wang, G., Zhao, Q., and Shi, S. Q. (2014). “Impact properties of bamboo bundle laminated veneer lumber by preprocessing densification technology,” Journal of Wood Science 60(6), 421-427. DOI: 10.1007/s10086-014-1424-0

Chen, F., Jiang, Z., Wang, G., Li, H., Smith, L. M., and Shi, S. Q. (2016). “The bending properties of bamboo bundle laminated veneer lumber (BLVL) double beams,” Construction and Building Materials 119, 145-151. DOI: 10.1016/j.conbuildmat.2016.03.114

Chung, K. F., and Yu, W. K. (2002). “Mechanical properties of structural bamboo for bamboo scaffoldings,” Engineering Structures 24 (4), 429-442. DOI: 10.1016/s0141-0296(01)00110-9

Deng, J., Chen, F., Wang, G., Qin, D., Zhang, X., and Feng, X. (2014). “Hygrothermal aging properties, molding and abrasion resistance of bamboo keyboard,” European Journal of Wood Products 72 (5): 659-667. DOI: 10.1007/s00107-014-0828-2

Deng, J., Chen, F., Li, H., Wang, G., and Shi, S.Q. (2016). “The effect of PF/PVAC weight ratio and ambient temperature on moisture absorption performance of bamboo-bundle laminated veneer lumber,” Polymer Composites 37(3): 955-962. DOI: 10.1002/ pc.23255GB/T 17657(2013). “Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels,” Standardization Administration of China, Beijing, P.R. China.

Hu, J. B., and Pizzi, A. (2013). “Wood-bamboo-wood laminated composite lumber jointed by linear vibration-friction welding,” European Journal of Wood and Wood Products 71(5), 683–686. DOI: 10.1007/s00107-013-0714-3

Huang, X.Y., Xie, J. L., Qi, J. Q., Hao, J. F., and Zhou, N. (2014a). “Effect of accelerated aging on selected physical and mechanical properties of Bambusa rigida bamboo,” European Journal of Wood and Wood Products 72(4), 547-549. DOI: 10.1007/s00107-014-0796-6

Huang, P., Chang, W.S., Shea, A., Ansell, M.P. and Lawrence, M. (2014b). “Non-homogeneous thermal properties of bamboo,” in: Materials and Joints in Timber Structures, Aicher, S., Reinhardt, H. W., and Garrecht, H. (eds.), Springer: 657-664. DOI: 10.1007/978-94-007-7811-5

Jiang, Z., Chen, F., Wang, G., Liu, X., Shi, Q.S., Yu, Z. (2013). “Bamboo bundle corru-gated laminated composites (BCLC). Part II. Damage analysis under low velocity impact loading,” BioResources 8(1), 923-932. DOI: 10.15376/biores.8.1.923-932

Lee, A. W. C., and Liu, Y. (2003). “Selected physical properties of commercial bamboo flooring,” Forest Products Journal 53(6), 23-26. DOI: 10.4028/www.scientific.net/amr.744.366

Lee, C. H., Chung, M. J., Lin, C. H., and Yang, T. H. (2012). “Effects of layered structure on the physical and mechanical properties of laminated moso bamboo (Phyllosachys edulis) flooring,” Construction and Building Materials 28(1), 31-35. DOI: 10.1016/j.conbuildmat.2011.08.038

Li, H., Chen, F., Xian, Y., Deng, J., Wang, G., and Cheng, H. (2016). “An empirical model for predicting the mechanical properties degradation of bamboo bundle lamin-ated veneer lumber (BLVL) by hygrothermal aging treatment,” European Journal of Wood and Wood Products 75(4), 553-560. DOI: 10.1007/s00107-016-1100-8

Lugt, P. V. D., Dobbelsteen, A. A. J. F., and Janssen, J. J. A. (2006). “An environmental, economic and practical assessment of bamboo as a building material for supporting structures,” Construction and Building Materials 20(9), 648-656. DOI: 10.1016/j.conbuildmat.2005.02.023

Mahdavi, M., Clouston, P. L., and Arwade, S. R. (2012). “A low-technology approach toward fabrication of laminated bamboo lumber,” Construction and Building Materials 29(4), 257-262. DOI: 10.1016/j.conbuildmat.2011.10.046

Majumdar, A., Mukhopadhyay, S., and Yadav, R. (2010). “Thermal properties of knitted fabrics made from cotton and regenerated bamboo cellulosic fibres,” International Journal of Thermal Sciences 49(10), 2042-2048. DOI: 10.1016/jijthermalsci.2010.05.017

Nugroho, N., and Ando, N. (2001). “Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber,” Journal of Wood Science 47(3), 237-242. DOI: 10.1007/bf01171228

Sharma, B., Gatόo, A., Bock, M., and Ramage, M. (2015). “Engineered bamboo for structural applications,” Construction and Building Materials 81, 66-73. DOI: 10.1016/j.conbuildmat.2015.01.077

Tomak, E. D., Topaloglu, E., Ay, N., and Yildiz, U. C. (2012). “Effect of accelerated aging on some physical and mechanical properties of bamboo,” Wood Science and Technology 46(5), 905-918. DOI: 10.1007/s00226-011-0454-7

Wang, P., Li, P., and Tao, Y. (2005). “Study on heat transfer model and visualization of numerical algorithm about wood veneer during hot-pressing,” Trans. Materials and Heat Treatment 26(1), 90-92. DOI: 10.3969/j.issn.1009-6246.2005.01.022

Yang, Q. (2001). “Theoretical expressions of wood thermal parameter,” Journal of Fujian College of Forestry 21(4): 329-331. DOI: 10.1007/bf02867212

Yu, X., Zhu, R., and Yu, W. (2013). “Durability of structural bamboo laminated lumber,” Journal of Northeast Forestry University 41(4), 104-107. DOI: 10.3969/j.issn.1000-5382.2013.04.024

Zombori, G. B., and Kamke, F. A. (2001). “Simulation of the mat formation process,” Neural Computation 13(4), 799-815. DOI: 10.3724/sp.j.1011.2008.00869

Article submitted: January 24, 2017; Peer review completed: April 24, 2017; Revised version received and accepted; July 10, 2017; Published: July 25, 2017.

DOI: 10.15376/biores.12.3.6568-6578