Abstract

Merbau wood has been widely used in outdoor applications. However, it has a disadvantage in that its water-soluble extractives readily leach out and stain adjacent materials. Heat treatment is an efficient technique to solve this problem. In this study, the effects of heat treatment on the durability of merbau heartwood were investigated. Merbau heartwood blocks with and without heat treatment were exposed to subterranean termites (Coptotermes formosanus) according to ASTM D3345 (2008), and to brown-rot fungus (Gloeophyllum trabeum) and white-rot fungus (Trametes versicolor) according to ASTM D1413 (2007). The effect of heat treatment on the chemical changes in merbau heartwood and its extracts were investigated by means of Fourier transform infrared spectroscopy (FTIR) and gas chromatography – mass spectrometer (GC/MS). The results show that the extraction yields of merbau heartwood with heat treatment using various solvents significantly decreased. However, termite resistance and fungal resistance of merbau heartwood with and without heat treatment showed no obvious difference. FTIR spectra in the fingerprint region of merbau heartwood and its ethanol-benzene extracts did not show any significant difference between heat-treated and untreated samples. More constituents were identified from the ethanol-benzene extracts of merbau heartwood with heat treatment by means of GC/MS compared to those identified from the ethanol-benzene extracts of untreated merbau heartwood.

Download PDF

Full Article

Effects of Heat Treatment on Durability of Merbau Heartwood

Yuchao Liao,a Jianjing Wang,b Zhaohua Lu,c,* Jin Gu,a and Chuanshuang Hu a,*

Merbau wood has been widely used in outdoor applications. However, it has a disadvantage in that its water-soluble extractives readily leach out and stain adjacent materials. Heat treatment is an efficient technique to solve this problem. In this study, the effects of heat treatment on the durability of merbau heartwood were investigated. Merbau heartwood blocks with and without heat treatment were exposed to subterranean termites (Coptotermes formosanus) according to ASTM D3345 (2008), and to brown-rot fungus (Gloeophyllum trabeum) and white-rot fungus (Trametes versicolor) according to ASTM D1413 (2007). The effect of heat treatment on the chemical changes in merbau heartwood and its extracts were investigated by means of Fourier transform infrared spectroscopy (FTIR) and gas chromatography – mass spectrometer (GC/MS). The results show that the extraction yields of merbau heartwood with heat treatment using various solvents significantly decreased. However, termite resistance and fungal resistance of merbau heartwood with and without heat treatment showed no obvious difference. FTIR spectra in the fingerprint region of merbau heartwood and its ethanol-benzene extracts did not show any significant difference between heat-treated and untreated samples. More constituents were identified from the ethanol-benzene extracts of merbau heartwood with heat treatment by means of GC/MS compared to those identified from the ethanol-benzene extracts of untreated merbau heartwood.

Keywords: Heat treatment; Merbau heartwood; Fungal resistance; Termite resistance

Contact information: a: Dept. of Wood Science & Engineering, Faculty of Material and Energy, South China Agricultural University, Guangzhou 510642, P.R. of China, b: Guangdong Academy of Forestry, Guangzhou, P.R of China, 510642; c: Research Institute of Tropical Forestry, Chinese Academy of Forestry, Guangzhou, P.R of China, 510642; *Corresponding author: cshu@scau.edu.cn

INTRODUCTION

The genus Intsia comprises nine species, mostly distributed in Southeast Asia and the Pacific Islands (Thaman et al. 2011). Merbau (Intsia spp.) heartwood is widely used in outdoor applications because of its good mechanical properties, beautiful color, and texture, as well as its high natural durability. However, it has a disadvantage because its water-soluble extractives readily leach out and stain adjacent materials (Hu et al. 2012). In one of our previous studies, heat treatment was shown to be an efficient technique to solve this problem (Hu et al. 2012, 2013). Herein, the effects of heat treatment on the durability of merbau heartwood were investigated.

Previous studies showed that heat treatment could increase the resistance of some wood species with low natural durability against fungus and termites. Maritime pine, spruce, beech, and poplar measuring 5 cm by 10 cm by 200 cm were heat-treated at temperatures ranging from 200 to 260 °C for 1 to 24 h. The results showed that heat treatment may modify the durability from non-resistant to moderate/resistant species depending on the fungus species (Kamdem et al. 2002). The durability of heat-treated beech wood towards Coriolus versicolor was evaluated according to parameters including mass loss, wettability, and chemical composition. Degradation of hemicellulose associated with other chemical modifications appearing during heat treatment was thought to be the origin of improved durability (Hakkou et al. 2006). The effect of heat treatment temperature on the elemental composition of Scots pine (Pinus sylvestris) sapwood was investigated in the range of temperatures between 220 and 250 °C (Šušteršic et al. 2010). The results confirmed that chemical modifications of wood cell wall polymers were the main factors responsible for wood durability improvement against fungal decay after heat treatment. The influences of sunlight on the weathering degradation processes of heat-treated jack pine (Pinus banksiana) and birch (Betula papyrifera) were investigated (Huang et al. 2012, 2013). The results revealed that the photo-degradation of lignin and the presence of extractives played important roles in discoloration and wetting behavior of heat-treated samples during irradiation. Decay resistance against Basidiomycetes fungi of heat-treated Pinus roxburghii and Mangifera indica wood at different temperatures for different durations was examined by soil block bioassay method. The results revealed that the decay resistance against fungal attack could be improved with heat treatment (Kamdem et al. 2002; Hakkou et al. 2006; Esteves and Pereira 2009; Sini and Hannu 2009, 2010, 2015; Šušteršic et al. 2010; Tripathi et al. 2014).

It has been reported that higher extractive content leads to higher resistance to fungus and termites (Wang and Hart 1983; Syafii et al. 1987; Taylor et al. 2006; Antwi-Boasiako et al. 2010; Kirker et al. 2013). The natural durability and resistance against fungal attack varied with variations of the toxic extractives. The extractives and their contents may be varied during heat treatment. However, the effect of heat treatment on the durability of wood species with high natural durability has seldom been reported. The objective of this study was to evaluate the decay and termite resistance of heat-treated merbau heartwood.

EXPERIMENTAL

Materials

The gross density of approximately 50-year-old merbau (Intsia bijuga) heartwood, which was imported from Papua New Guinea, was 800 kg/m3. The moisture content was 12.4% after the kiln-dried lumber was conditioned for six months at 25 °C and 65% relative humidity.

Methods

Heat treatment

The heat treatment of merbau heartwood was conducted using an experimental oven under air atmosphere at 170 °C for 4 h according to our previous studies (Hu et al. 2012).

Determination of extractive contents

Heat-treated and untreated samples were ground to fine powder, which was able to pass a 250-μm sieve but to be retained on a 180-μm sieve (i.e., particle sizes of 180 to 250 μm) by a Wiley mill. The powdered samples (2 g) of merbau heartwood with and without heat treatment were extracted with various solvents (cold water, hot water, and ethanol-benzene, respectively), according to ASTM D1110 (2013) and ASTM D1107 (2013) to determine the extractives content. The organic solvent was evaporated at 40 °C in a rotary evaporator. All extracted samples were oven-dried at 103 ± 2 °C and reweighed. Each extraction was repeated five times. The extractives content was determined as follows,

![]()

where W1 and W2 are the initial and final oven-dried weights (g) before and after the extraction, respectively.

Termite resistance testing

Blocks of heat-treated merbau heartwood, untreated merbau heartwood, and masson pine (Pinus massoniana) measuring 6.4 mm [longitudinal (L)] × 25.4 mm [radial (R)] × 25.4 mm [tangential (T)] were exposed to subterranean termites (C. formosanus) , which were provided by Guangdong Academy of Forestry according to ASTM D3345 (2008) for the termite resistance test. Blocks were oven-dried and weighed; meanwhile, cylindrical test containers 80 mm in diameter and sand were sterilized before the test. Subterranean termites (1 ± 0.05 g, approximately 100 workers) were weighted and counted, then added to each container containing a block sample, 100 g of sand, and sufficient distilled water. All the containers were stored at 28 °C and 80% relative humidity in the dark for eight weeks. The test container was examined daily to remove the dead termites and reweighed weekly to keep the amount of water sufficient. The termite survival rate was calculated as follows,

![]()

where T1 and T2 are the numbers of termites alive at the beginning and the end of the test, respectively.

The percentage of weight loss during the termite resistance test was calculated as follows,

Weight loss (%) = [(M1–M2)/M1]100 (3)

where M1 and M2 are the initial and final oven-dried weights (g) of the blocks before and after the test, respectively.

Termite survival rate and weight loss were averaged from five replicates. The termite resistance was also classified into the following five rating categories: (10) sound, surface nibbles permitted; (9) light attack; (7) moderate attack, penetration; (4) heavy attack; and (0) failure based on the visual observation according to ASTM D3345 (2008).

Fungal resistance testing

Blocks of heat-treated merbau heartwood, untreated merbau heartwood, masson pine sapwood, and Chinese white poplar sapwood (Populus tomentosa) measuring 19 mm (L) × 19 mm (R) × 19 mm (T) were exposed to brown-rot fungus (G. trabeum) and white-rot fungus (C. versicolor) according to ASTM D1413 (2007) for the test of decay resistance. masson pine and Chinese white poplar sapwood were used here to provide a basis for comparison. Blocks of masson pine sapwood measuring 3 mm (L) × 28 mm (R) × 35 mm (T) were used as feeder strips. Blocks were placed in glass jars, which contained a medium of 2 wt% malt extract and 1.5 wt% agar. The jars were incubated at 28 °C and 75% relative humidity for twelve weeks. The percentage of weight loss was calculated using the initial and final oven-dried weights of the sample blocks before and after the test using the above mentioned Eq. 3. The value was averaged from five replicates.

Fourier transform infrared spectroscopy (FTIR)

The effects of heat treatment on the chemical composition of merbau wood and its extractives were studied. The FTIR spectra of the powdered merbau heartwood and its extractives with and without heat treatment were obtained by means of a Spectrum 100 FT-IR spectrometer (PerkinElmer, USA) equipped with a triglycine sulfate (TGS) detector, mid-infrared (MIR) light source, and OptKBr beam splitter. Samples (1 mg) were dispersed into 100 mg of potassium bromide. They were finely ground and pressed to form pellets at 25 MPa. The spectrum of each sample was measured from 4000 to 400 cm-1 at a resolution of 4 cm-1 and 32 scans under transmission mode. PerkinElmer spectrum 10 was adopted to post-process the data.

Gas chromatography / mass spectroscopy (GC/MS)

Merbau heartwood powder samples with and without heat treatment (particle sizes 100 to 200 ) of 2.5 g were oven-dried and ultrasonically extracted with 30 mL of ethanol-benzene (1:2, v/v) for 6 h. Extractive solutions were analyzed by GC/MS on an Agilent 6890 (USA) gas chromatograph equipped with a split/splitless injector and a 5975 mass selective detector (MSD) to identify the constituents present in the extractives. The chromatography was performed on a 30 meter-long DB-5MS (0.25-mm inner diameter, 0.25- film thickness) capillary column (Agilent Technologies, USA) using helium as the carrier gas. The samples (1 ) were injected via the auto-injector with a 20:1 split ratio and 1.4 mL/min flow. Mass spectra were recorded over the 30 to 500 amu range at 1 scan/s, with an ionization voltage of 70 eV in electron impact (EI) mode and an ion source temperature of 230 °C. The injector port temperature was 290 °C, and the mass selective detector was operated at 300 °C.

The mass spectra of compounds were used to compare with those presented in the computer database (NIST08) and spectra published in the references as well as their GC retention times related to known compounds.

Statistical analysis

Means and standard deviations were calculated for extractives contents and weight loss for the decay resistance and termite resistance tests. One-way analysis of variance (ANOVA) was applied to evaluate the effects of heat treatment on fungal resistance and termite resistance of merbau heartwood using SPSS (SPSS 19.0, USA) software. Significant differences between variables were examined by means of the Duncan’s test at P = 0.05.

RESULTS AND DISCUSSION

Extractive Contents

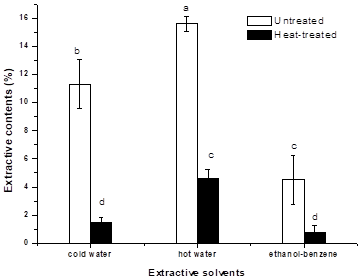

The extractive contents of merbau heartwood with and without heat treatment using various extractive solvents are shown in Fig. 1. The extraction yields of untreated samples were 15.6%, 11.3%, and 4.5%, while those of heat-treated samples were 4.6%, 1.5%, and 0.8% using hot water, cold water, and ethanol-toluene, respectively. The hot water extracts had the highest values and ethanol-benzene extractives had the lowest, with and without heat treatment. A higher amount of hot water extractives may indicate that samples contained much more polar extractives such as tannins, gums, sugar, starch, and coloring matters (Shebani et al. 2008). The extraction yields of merbau heartwood significantly decreased after heat treatment (p = 0.000).

Fig. 1. Extractive contents of merbau heartwood with and without heat treatment. Means (N = 5) with the same letter are not significantly different using Duncan’s test (*P < 0.05).

Termite Resistance

The effects of heat treatment on termiticidal activities of merbau wood against the subterranean termite C. formosanus was investigated. Weight losses, termite survival rates, and termite attack ratings according to visual observation are shown in Table 1.

Table 1. Weight Loss, Survival Rate, and Termite Attack Rate of Samples Exposed to C. formosanus

a Numbers in parentheses are standard deviations.

b Means (N = 5) within each column followed by the same letter are not significantly different using Duncan’s test (*P < 0.05).

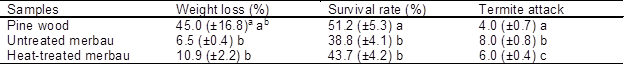

Masson pine sapwood was used as a positive control. The fact that its weight loss was 45.0% confirmed that the termites were active under the test conditions. Weight losses and survival rates of merbau heartwood with and without heat treatment were 10.9% and 6.5%, and 43.7% and 38.8%, respectively. The ANOVA analysis on weight losses (p = 0.59) and survival rates (p = 0.11) of merbau heartwood with and without heat treatment showed that the effect of heat treatment of merbau heartwood on termite resistance was not significant. It was reported that heat treatment was an ineffective way to increase the termite resistance of some wood species (Esteves and Pereira 2009). The termite attack ratings of merbau heartwood with and without heat treatment were 6.0 and 8.0, respectively. Visual observations after termite resistance testing are shown in Fig. 2. The termite destruction of the heat-treated sample was more serious. The visual observations were consistent with the weight loss and termite survival rate data.

Fig. 2. Visual observation of samples after termite attack: (a) pine wood; (b) untreated merbau heartwood; (c) heat-treated merbau heartwood

Fungal Resistance

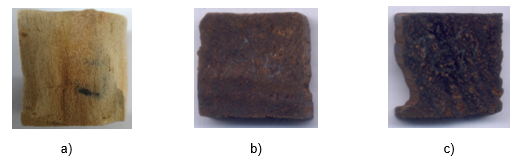

The effect of heat treatment on the fungal resistance of merbau heartwood against the brown-rot fungus G. trabeum and white-rot fungus C. versicolor was studied. Weight losses after fungal resistance testing are shown in Fig. 3.

Fig. 3. Mean weight loss of samples after exposure to brown-rot fungus (G. trabeum) and white-rot fungus (C. versicolor). Means (N = 5) with the same letter are not significantly different using Duncan’s test (*P < 0.05).

The weight losses of masson pine and poplar sapwoods were higher than 30.0%, which confirmed that the fungal tests were valid. Weight losses of merbau heartwood with and without heat treatment against the brown-rot fungus G. trabeum were 3.2% and 4.2%, while weight losses against the white-rot fungus C. versicolor were 3.3% and 4.2%, respectively. Weight losses without heat treatment were slightly higher than those with heat treatment against both brown-rot and white-rot fungus. The statistical analysis did not show significant differences between the heat-treated and untreated samples (p = 0.190).

Water-soluble extractives of merbau heartwood readily leach out and stain adjacent materials, which limits its outdoor applications (Hillis and Yazaki 1973). Heat treatment is an effective way to solve this problem because some water-soluble extractives with lower thermal stability will evaporate or chemically react (Hu et al. 2012). Heat treatment was also confirmed to increase the resistance of some wood species with low natural durability against fungus and termites (Kamdem et al. 2002; Hakkou et al. 2006; Šušteršic et al. 2010; Huang et al. 2012, 2013; Tripathi et al. 2014). Eight durable wood species exhibited higher weight loss against termite or fungi attack when their extractives were removed (Kirker et al. 2013). The results of the termite resistance test and fungal resistance test showed that heat treatment at 170 °C for 4 h did not affect the resistance of merbau heartwood to termite attack and decay by brown-rot and white-rot fungi, although the extractive contents significantly decreased after heat treatment (p = 0.000). The reason was thought to be the synergistic balance between the increase of the durability and the removal of the extracts with heat treatment. The quantity and type of extracts both have impact on the durability of the woods. During the heat treatment, toxic compounds may be generated and the water accessibility of the wood may decrease, providing protection for the heat-treated wood against bio-attack (Hakkou et al. 2006).

FTIR

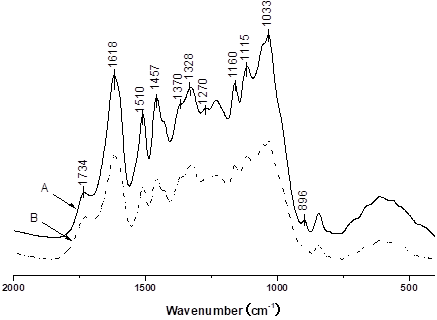

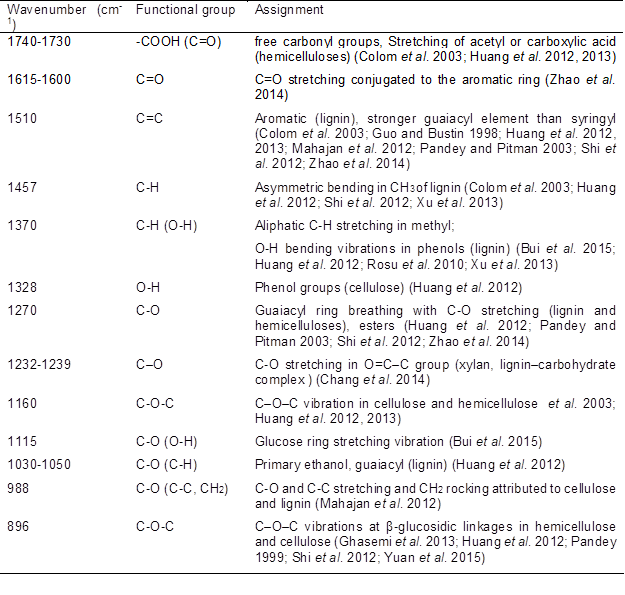

Chemical changes in merbau heartwood and its ethanol-benzene extracts with and without heat treatment were investigated by means of FTIR. FTIR bands in the fingerprint region of merbau wood powder with and without heat treatment after ethanol-benzene extraction and the ethanol-benzene extracts with and without heat treatment are shown in Figs. 4 and 5.

Fig. 4. FTIR spectra in fingerprint region of (A) untreated and (B) heat-treated merbau heartwood after ethanol-benzene extraction

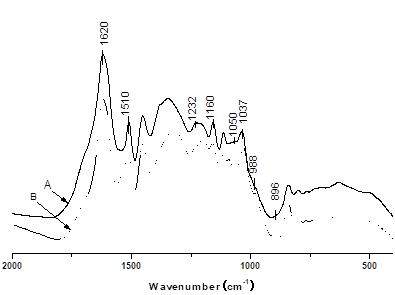

There are many well-defined peaks in the fingerprint region between 1800 and 800 cm-1, representing various functional groups. The peaks in the fingerprint region are assigned in Table 2.

Table 2. Band Assignments in FTIR Spectra of Merbau Heartwood and Its Ethanol-Benzene Extracts

The relative intensity of bands at 1734, 1615 to 1600, 1510, 1457, 1370, 1328, 1232 to 1239, 1160, 1115, 1030 to 1050, and 896 cm-1 showed no significant difference between the samples with and without heat treatment. The relative intensity of bands at 1270 cm-1, assigned to guaiacyl ring breathing with C-O stretching, was slightly lower in heat-treated samples, which indicates the untreated samples contained much more methoxyl groups in their lignin (Colom et al. 2003; Pandey and Pitman 2003; Huang et al. 2012b, 2013b; Mahajan et al. 2012; Shi et al. 2012; Zhao et al. 2014).

It can be observed from Fig. 5 that the relative intensity of the band at 1050 cm-1, assigned to C-O and C-H in ethanol and guaiacyl, was higher in the extracts without heat treatment, whereas the peak at 988 cm-1, assigned to C-O and C-C stretching and CH2 rocking, was higher in the extracts with heat treatment. The information from the FTIR spectra indicated that the major components of the merbau heart wood (i.e., cellulose, hemicellulose, and lignin) and its extracts did not change during the heat treatment.

Fig. 5. FTIR spectra in fingerprint region of ethanol-benzene extracts of (A) untreated and (B) heat-treated merbau heartwood

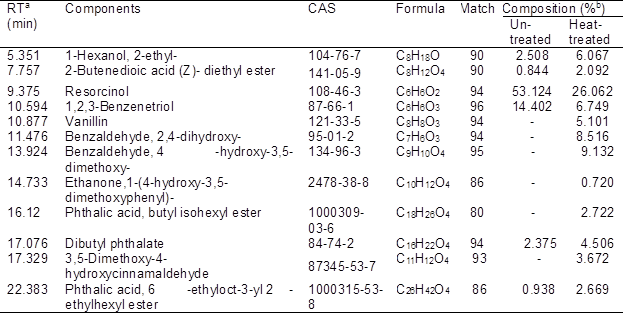

Gas Chromatography / Mass Spectroscopy (GC/MS)

Chemical constituents identified in the ethanol-benzene extracts of merbau heartwood with and without heat treatment are presented in Table 3. 1-Hexanol 2-ethyl-, 2-butenedioic acid (Z)-diethyl ester, resorcinol, 1,2,3-benzenetriol, dibutyl phthalate, and phthalic acid (6-ethyl-oct-3-yl 2-ethylhexyl ester) were the major constituents identified from the ethanol-benzene extracts of merbau heartwood with and without heat treatment. Resorcinol and 1,2,3-benzenetriol were the dominant constituents identified from the extracts of merbau heartwood without heat treatment; their compositions decreased from 53.12% and 14.4% to 26.06% and 6.75%, respectively, after heat treatment. From the analysis of extractive contents, the organic extractive content was decreased after heat treatment. Thus, the absolute amount of resorcinol and 1,2,3-benzenetriol in the heat-treated sample was less compared to the untreated sample, which indicated that some polyphenols in the extractives chemically reacted during the heat treatment. The relative compositions (%) of 1-hexanol,2-ethyl-(2.51%), 2-butenedioic acid (Z)-diethyl ester (0.84%), dibutyl phthalate (2.38%), and phthalic acid (0.94%) increased in the extracts of merbau heartwood with heat treatment.

There were some more constituents of vanillin (5.01%), benzaldehyde, 4-hydroxy-3,5-dimehtoxy- (9.13%), ethanone, 1-(4-hydroxy-3,5-dimethoxyphenyl)- (0.72%), phthalic acid (2.72%), and 3,5-dimethoxy-4-hydroxy-cinnamaldehyde, butyl isohexyl ester (3.67%) identified in extracts of merbau heart wood with heat treatment, which indicated new chemical compounds were generated during the heating process. However, these changes seemed to have little impact on the durability of the merbau heartwood, as indicated above.

Table 3. Identified Constituents of Ethanol-Toluene Extracts of Merbau Heartwood with and without Heat Treatment

a Retention time; the identified compounds are listed in the elution order from a non-polar capillary column.

b The % composition is the percentage calculated by means of the integral peak area divided by the total integral area.

CONCLUSIONS

Heat treatment is an effective technique for preventing the water-soluble extractives of merbau heartwood from leaching out and staining adjacent materials. The results showed that heat treatment had no significant impact on its high natural durability. The main findings of this study are as follows:

- The extraction yields of the merbau heartwood using cold water, hot water, and ethanol-benzene as solvents significantly decreased with heat treatment.

- Heat treatment at 170 °C for 4 h had no significant effects on termite resistance and fungal resistance of merbau heartwood.

- FTIR analysis of merbau heartwood and its ethanol-benzene extracts with and without heat treatment indicated the major chemical components of merbau heartwood did not change during the heat treatment process.

- 1-Hexanol, 2-ethyl-, 2-butenedioic acid (Z)-diethyl ester, resorcinol, 1,2,3-benzenetriol, dibutyl phthalate, and phthalic acid, 6-ethyloct-3-yl 2-ethylhexyl ester were identified from the extracts of merbau heartwood with and without heat treatment.

ACKNOWLEDGMENTS

The authors are grateful for the financial support from the Department of Education of Guangdong Province, P.R of China (Project No. YQ2013029).

REFERENCES CITED

Antwi-Boasiako, C., Barnett, J. R., and Pitman, A. J. (2010). “Relationship between total extractive content and durability of three tropical hardwoods exposed to Coriolus versicolor (Linnaeus) Quelet,” J. Ind. Acad. Wood Sci. 7(1), 9-13. DOI: 10.1007/s13196-010-0002-3

ASTM D1107-96 (2013). “Standard test method for ethanol-toluene solubility of wood,” ASTM International, West Conshohocken, PA. DOI: 10.1520/D1107

ASTM D1110-84 (2013). “Standard test methods for water solubility of wood,” ASTM International, West Conshohocken, PA. DOI: 10.1520/D1110

ASTM D1413-07e1 (2007). “Wood preservatives by laboratory soil-block cultures,” ASTM International, West Conshohocken, PA. DOI: 10.1520/D1413-07E01

ASTM D3345-08 (2008). “Laboratory evaluation of wood and other cellulosic materials for resistance to termites,” ASTM International, West Conshohocken, PA. DOI: 10.1520/D3345-08

Bui, N. Q., Fongarland, P., Rataboul, F., Dartiguelongue, C., Charon, N., Vallée, C., and Essayem, N. (2015). “FTIR as a simple tool to quantify unconverted lignin from chars in biomass liquefaction process: Application to SC ethanol liquefaction of pine wood,” Fuel Process Technol. 134, 378-386. DOI: 10.1016/j.fuproc.2015.02.020

Chang, S., Salmén, L., Olsson, A., and Clair, B. (2014). “Deposition and organisation of cell wall polymers during maturation of poplar tension wood by FTIR microspectroscopy,” Planta 239(1), 243-254. DOI: 10.1007/s00425-013-1980-3

Colom, X., Carrillo, F., Nogués, F., and Garriga, P. (2003). “Structural analysis of photodegraded wood by means of FTIR spectroscopy,” Polym. Degrad. Stabil. 80(3), 543-549. DOI: 10.1016/S0141-3910(03)00051-X

Esteves, B. M., and Pereira, H. M. (2009). “Wood modification by heat treatment: A review,” BioResources 4(1), 370-404. DOI: 10.15376/biores.4.1.370-404

Ghasemi, E., Ghorbani, G. R., Khorvash, M., Emami, M. R., and Karimi, K. (2013). “Chemical composition, cell wall features and degradability of stem, leaf blade and sheath in untreated and alkali-treated rice straw,” Animal 7(7), 1106-1112. DOI: 10.1017/S1751731113000256

Guo, Y., and Bustin, R. M. (1998). “FTIR spectroscopy and reflectance of modern charcoals and fungal decayed woods: Implications for studies of inertinite in coals,” Int. J. Coal Geol. 37(1), 29-53. DOI: 10.1016/S0166-5162(98)00019-6

Hakkou, M., Pétrissans, M., Gérardin, P., and Zoulalian, A. (2006). “Investigations of the reasons for fungal durability of heat-treated beech wood,” Polym. Degrad. Stabil. 91(2), 393-397. DOI: 10.1016/j.polymdegradstab.2005.04.042

Hillis, W. E., and Yazaki, Y. (1973). “Polyphenols of Intsia heartwoods,” Phytochemistry 12(10), 2491-2495. DOI: 10.1016/0031-9422(73)80461-3

Hu, C., Jiang, G., Xiao, M., Zhou, J., and Yi, Z. (2012). “Effects of heat treatment on water-soluble extractives and color changes of merbau heartwood,” J. Wood Sci. 58(5), 465-469. DOI: 10.1007/s10086-012-1265-7

Hu, C. S., Jiang, G. F., Zhou, J. H., Xiao, M., and Yi, Z. (2013). “Effects of the thickness of the heat-treated wood specimen on water-soluble extractives and mechanical properties of merbau heartwood,” BioResources 8(1), 603-611. DOI: 10.15376/biores.8.1.603-611

Huang, X., Kocaefe, D., Kocaefe, Y., Boluk, Y., and Pichette, A. (2012). “Study of the degradation behavior of heat-treated jack pine (Pinus banksiana) under artificial sunlight irradiation,” Polym. Degrad. Stabil. 97(7), 1197-1214. DOI: 10.1016/j.polymdegradstab.2012.03.022

Huang, X., Kocaefe, D., Kocaefe, Y., Boluk, Y., and Krause, C. (2013). “Structural analysis of heat-treated birch (Betula papyrifera) surface during artificial weathering,” Appl. Surf. Sci. 264(1), 117-127. DOI: 10.1016/j.apsusc.2012.09.137

Kamdem, D. P., Pizzi, A., and Jermannaud, A. (2002). “Durability of heat-treated wood,” Holz Roh Werkst. 60(1), 1-6. DOI: 10.1007/s00107-001-0261-1

Kirker, G. T., Blodgett, A. B., Arango, R. A., Lebow, P. K., and Clausen, C. A. (2013). “The role of extractives in naturally durable wood species,” Int. Biodeter. Biodegr. 82(8), 53-58. DOI: 10.1016/j.ibiod.2013.03.007

Mahajan, S., Jeremic, D., Goacher, R. E., and Master, E. R. (2012). “Mode of coniferous wood decay by the white rot fungus Phanerochaete carnosa as elucidated by FTIR and ToF-SIMS,” Appl. Microbiol. Biot. 94(5), 1303-1311. DOI: 10.1007/s00253-011-3830-1

Pandey, K. K., and Pitman, A. J. (2003). “FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi,” Int. Biodeter. Biodegr. 52(3), 151-160. DOI: 10.1016/S0964-8305(03)00052-0

Pandey, K. K. (1999). “A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy,” J. Appl. Polym. Sci. 71(12), 1969-1975. DOI: 10.1002/(SICI)1097-4628(19990321)71:12<1969::AID-APP6>3.0.CO;2-D

Rosu, D., Teaca, C., Bodirlau, R., and Rosu, L. (2010). “FTIR and color change of the modified wood as a result of artificial light irradiation,” J. Photochem. Photobiol. B 99(3), 144-149. DOI: 10.1016/j.jphotobiol.2010.03.010

Sini, M. K., and Hannu, V. (2009). “Decay resistance of sapwood and heartwood of untreated and thermally modified Scots pine and Norway spruce compared with some other wood species,” Wood Mater. Sci. Eng. 4(3-4), 105-114. DOI: 10.1080/17480270903326140

Sini, M. K., and Hannu, V. (2010). “Effect of fungal exposure on the strength of thermally modified Norway spruce and Scots Pine,” Wood Mater. Sci. Eng. 5(1), 13-23 DOI: 10.1080/17480271003786738

Sini, M. K., and Hannu, V. (2015). “Durability of thermally modified sapwood and heartwood of Scots pine and Norway spruce in the modified double layer test,” Wood Mater. Sci. Eng. DOI: 10.1080/17480271003786738

Shebani, A. N., van Reenen, A. J., and Meincken, M. (2008). “The effect of wood extractives on the thermal stability of different wood species,” Thermochim. Acta 471(1), 43-50. DOI: 10.1016/j.tca.2008.02.020

Shi, J., Xing, D., and Lia, J. (2012). “FTIR studies of the changes in wood chemistry from wood forming tissue under inclined treatment,” Energy Procedia 16(Part B), 758-762. DOI: 10.1016/j.egypro.2012.01.122

Šušteršic, Ž., Mohareb, A., Chaouch, M., Pétrissans, M., Petrič, M., and Gérardin, P. (2010). “Prediction of the decay resistance of heat treated wood on the basis of its elemental composition,” Polym. Degrad. Stabil. 95(1), 94-97. DOI: 10.1016/j.polymdegradstab.2009.10.013

Syafii, W., Samejima, M., and Yoshimoto, T. (1987). “The role of extractives in decay resistance of ulin wood,” Bull. Tokyo Univ. For. 77, 1-8.

Taylor, A. M., Gartner, B. L., Morrell, J. J., and Tsunoda, K. (2006). “Effects of heartwood extractive fractions of Thuja plicata and Chamaecyparis nootkatensis on wood degradation by termites or fungi,” J. Wood Sci. 52(2), 147-153. DOI: 10.1007/s10086-005-0743-6

Tripathi, S., Pant, H., and Kashyap, A. K. (2014). “Decay resistance against basidiomycetes fungi of heat-treated Pinus roxburghii and Mangifera indica wood,” J. Trop. For. Sci. 26(2), 203-207.

Wang, S., and Hart, J. H. (1983). “Heartwood extractives of Maclura pomifera and their role in decay resistance,” Wood Fiber Sci. 15(4), 290-301.

Xu, G., Wang, L., Liu, J., and Wu, J. (2013). “FTIR and XPS analysis of the changes in bamboo chemical structure decayed by white-rot and brown-rot fungi,” Appl. Surf Sci. 280(8), 799-805. DOI: 10.1016/j.apsusc.2013.05.065

Yuan, C., Liu, B., and Liu, H. (2015). “Characterization of hydroxypropyl-β-cyclodextrins with different substitution patterns via FTIR, GC–MS, and TG–DTA,” Carbohyd. Polym. 118, 36-40. DOI: 10.1016/j.carbpol.2014.10.070

Zhao, J., Wang, X., W., Hu, J., Liu, Q., Shen, D. K., and Xiao, R. (2014). “Thermal degradation of softwood lignin and hardwood lignin by TG-FTIR and Py-GC/MS,” Polym. Degrad. Stabil. 108(SI), 133-138. DOI: 10.1016/j.polymdegradstab.2014.06.006

Article submitted: September 12, 2015; Peer review completed: October 16, 2015; Revised version received and accepted: October 28, 2015; Published: November 18, 2015.

DOI: 10.15376/biores.11.1.426-438