Abstract

To investigate the effect of pre-freezing treatment on the shrinkage properties and discoloration of Eucalyptus urophylla × Eucalyptus grandis wood, E. urophylla × E. grandis wood samples were treated by pre-freezing at -20 and -40 °C for 72 h and then dried to reach equilibrium moisture content at 12% and 8%, respectively. Color changes were measured by colorimeter and evaluated by diffuse reflectance visible (DRV) spectrometry; mechanical properties were also tested. The results showed that the shrinkage of Eucalyptus wood samples decreased after being pre-frozen, and the overall color change ΔE* increased by 6.11 when the treatment temperature changed from minus 20 to -40 °C. Absorption (ΔK/S) spectra in the range of 450 to 740 nm of the treatment samples exhibited flat-lined, which suggests that the color of wood stabilizes after being pre-frozen and dried. The tensile, compression and bending strengths decreased 4.74, 6.05, 1.18 after pre-freezing treatment at -40 °C, respectively. Pre-freezing treatment at -20 °C is better than that at -40 °C for improving the drying properties of E. urophylla × E. grandis wood.

Download PDF

Full Article

Effects of Pre-Freezing Prior to Drying upon Some Physical and Mechanical Properties of Eucalyptus urophylla × Eucalyptus grandis Wood

Hongda Liu, Jianmin Gao,* and Yao Chen*

To investigate the effect of pre-freezing treatment on the shrinkage properties and discoloration of Eucalyptus urophylla × Eucalyptus grandis wood, E. urophylla × E. grandis wood samples were treated by pre-freezing at -20 and -40 °C for 72 h and then dried to reach equilibrium moisture content at 12% and 8%, respectively. Color changes were measured by colorimeter and evaluated by diffuse reflectance visible (DRV) spectrometry; mechanical properties were also tested. The results showed that the shrinkage of Eucalyptus wood samples decreased after being pre-frozen, and the overall color change ΔE* increased by 6.11 when the treatment temperature changed from minus 20 to -40 °C. Absorption (ΔK/S) spectra in the range of 450 to 740 nm of the treatment samples exhibited flat-lined, which suggests that the color of wood stabilizes after being pre-frozen and dried. The tensile, compression and bending strengths decreased 4.74, 6.05, 1.18 after pre-freezing treatment at -40 °C, respectively. Pre-freezing treatment at -20 °C is better than that at -40 °C for improving the drying properties of E. urophylla × E. grandis wood.

Keywords: Pre-freezing; Eucalyptus; Shrinkage; Color; DRV

Contact information: MOE Key Laboratory of Wooden Material Science and Application, Beijing Forestry University, Beijing 100083, China; *Corresponding authors: jmgao@bjfu.edu.cn; ychen@bjfu.edu.cn

INTRODUCTION

Eucalyptus is one of the most important plantation tree species planted in south China. As a result of the superb growth rate, eucalyptus wood is widely used in many fields, such as the pulp and paper industry, outdoor construction, and interior decoration. However, many species of Eucalyptus tend to crack, collapse, and exhibit discoloration during drying, thus limiting the use of eucalyptus wood. The shrinkage of eucalyptus wood is related to its basic density, double fiber cell wall thickness, and proportion of ray parenchyma (Wu et al. 2005). There is a negative relationship between volumetric shrinkage and specific gravity and lignin and extractives contents in eucalyptus wood (Chafe 1986, 1987). Leonardon et al. (2009) used FTIR micro-spectroscopy to measure the chemical composition of wood, showing that the microfiber angle data predicts shrinkage when corrected for density. Drying wood at temperatures below the collapse threshold temperature can prevent collapse and differential shrinkage. The collapse threshold temperature is defined as the highest temperature at which a charge of wood can be dried to fiber saturation point (FSP) without resulting in collapse. Innes (1995) reported that the timber from two eucalyptus trees was successfully dried to 40% moisture content (MC) free of collapse, by drying at temperatures below 30 °C. The internal checking of eucalyptus wood is a result of differential shrinkage and collapse. With wood dried at 30 °C and 65% relative humidity(RH), internal checking was weakly negatively correlated with total external shrinkage and highly positively correlated with normal shrinkage, moisture content (Ilic 1999a).

Color and shrinkage are both important concerns for wood value. Wood discoloration is a complex phenomenon, primarily affected by heat, light, physiological and biochemical reactions, and microorganisms (Sandoval-Torres et al. 2010). Wood consists of cellulose, hemicelluloses, lignin, and extractives. The discoloration of wood during drying is commonly associated with the extractives and lignin. The extractives of eucalyptus wood contain alcohols, alkanes, esters, and acids (Zhang et al. 2012). Generally, heartwood has significantly more extractives than sapwood in eucalyptus wood; these differences in the content of extractives are also dependent on the species and proportion of heartwood (Morais and Pereira 2011). Vanclay et al. (2008) reported that heartwood color in Eucalyptus dunnii wood, especially its lightness, was correlated with tree size, and the large color differences between sapwood and heartwood may be correlated with high radial shrinkage. The wood color in young Eucalyptus grandis is redder and more saturated because of the faster growth rates (Wilkins and Stamp 1990).

Eucalyptus wood has been modified to improve its drying quality by such processes as pre-steaming (Alexiou et al. 1990), pre-boiling (Chafe 1993), and pre-freezing. The wood of high moisture content (up to 250%) was successfully pre-frozen without damage, but part of softwood and hardwood species still exhibited some drying defects (Erickson et al. 1966). Pre-freezing produces marked reductions in shrinkage, collapse, and drying degradation of the heartwood of eucalypts; however, no significant improvement regarding internal checking was obtained (Ilic 1999b). Pre-freezing wood for 12 to 24 h at -20 °C appears to be the most practicable conditions for eucalyptus wood (Ilic 1995). There was less change in wood strength when spruce wood was subjected to freezing at -10 °C/h. However, all mechanical properties of spruce wood were reduced when freezing at a lower rate of -1 °C/h (Szmutku et al. 2013). The effect of extractives was responsible for the shrinkage of wood. It was reported that the shrinkage of black walnut was reduced after extractives were removed by cold-water extraction (Erickson and Peterson 1969). The flexural creep was even lower in prefrozen samples, which may explain why shrinkage and collapse are reduced via the effect on rheological properties of the wood (Erickson and Sauer 1969). The progressive loss of moisture due to the escape of water molecules leads to a reduction of volume of the cell wall or shrinkage (Erickson et al. 1968).

A new process that involves pre-freezing the wood to -20 and -40 °C allows for many changes to take place that not only reduce the shrinkage of timber, but also reduce the change in color. However, no studies have been carried out to determine the effect of pre-freezing on the color of eucalypts; thus, our study is aimed at investigating the effect of pre-freezing treatment of eucalypts on the color change, shrinkage, and mechanical properties.

EXPERIMENTAL

Materials

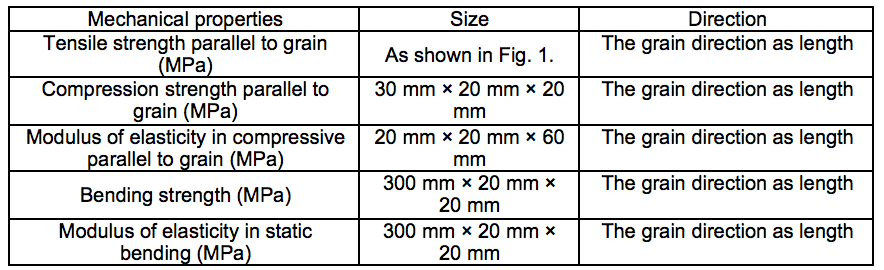

Six- to 10-year-old Eucalyptus urophylla × Eucalyptus grandis wood was harvested from Guang Xi province, China. The logs from these trees were stored outdoors, protected from weathering, for approximately six months in Beijing, China. Heartwood was selected as the tested wood. The basic density of the tested wood is 0.45 g/cm3. 150 cores (initial MC = 40%) were divided into 20 mm × 20 mm × 20 mm sections to determine the shrinkage and color, and 30 species (initial MC = 40%) were used for mechanical testing according to the national standard. The GB/T standards identical to ISO standards were used to determine physical and mechanical properties of wood. The size of species for experiments involving mechanical properties are shown in Table 1.

Table. 1. The Size of Wood for Mechanical Properties Experiments

Fig. 1. Dimensional specifications for evaluation of tensile strength parallel to grain

Methods

Pre-freezing and drying treatment

The weights and dimensions of all tested samples were measured before treatment. Of the three groups, one was chosen as control and the other samples underwent pre-freezing for 72 h at -20 or -40 °C by household refrigerator and 596 litres of vertical cryogenic refrigerator, respectively. Some research data indicated (Ilic 1995) that being kept frozen in a freezer for 72 h could change the structure of wood. The rate of temperature decrease for freezing was -10 °C/h. After pre-freezing, 50 specimens of the samples were dried to a theoretical MC of 12% in a climate chamber at 30 °C and 65% humidity to examine the shrinkage and color variation; the other 50 samples were dried at 60 °C to a MC of 8% in a drying oven to investigate the change in color. All the samples were oven-dried at 103±2 °C until the weight of the segments remained unchanged. The weights and dimensions of the treated samples were then measured again.

Shrinkage measurement

Radial shrinkage (RS), tangential shrinkage (TS), and longitudinal shrinkage (LS) were calculated using Eq. 1. Volumetric shrinkage (VS) was calculated using Eq. 2,

S = (1)

where, S represents the shrinkage from saturation to air-dried state, D40% represents the saturated dimensions, and D12% represents the wood dimensions when dried to a MC of 12%.

VS = (2)

In Eq. 2, VS represents the volumetric shrinkage, V40% represents the saturated volume, and D12%represents the wood volume when dried to a MC of 12%.

Color measurement

A Konica Minolta CM-2300d Chroma Meter (Minolta Corporation, Ramsey, NJ, USA) was used to measure color parameters with a C standard illuminant, according to the CIELAB color system. The CIELAB color system is a three-dimensional color space measuring the lightness (L*) of the sample and color coordinates (a* and b*). L* represents the reflectance of a sample and ranges between 0 (black) and 100 (white). An increase in L* means the color has faded or has become lighter (+ΔL* = lightening); a decrease in L* means the color has darkened (-ΔL* = darkening). The color coordinates a* and b* do not have a specific range. The coordinate a* is defined as the red/green (+a* or –a*) coordinate; b* is defined as the yellow/blue (+b* or –b*) coordinate (Vanclay et al. 2008). In this study, ΔL*, Δa*, and Δb* were calculated according to Eqs. (3 through 5). The corresponding total color change (ΔE*) was calculated using Eq. 6 (Oltean et al. 2007). ΔE* was used to assess how each board differed from the control (Pincelli et al. 2012). Color was measured at three locations on each sample, and five replicates were used.

ΔL*= L* treated – L*untreated (3)

Δa*= a*treated– a*untreated (4)

Δb*= b* treated – b*untreated (5)

ΔE*= (6)

Spectral measurement

Spectral measurements in the range of 360 to 650 nm were performed with a CM-2300d spectrophotometer manufactured by Konica Minolta company, using cellulose filter paper as the standard. The reflectance spectra were converted into K/S spectra using the Kubelka-Munk equation,

K/S= (7)

where K represents the absorption coefficient and S represents the scattering coefficient; the K/Sspectra as a function of wavelength is used to identify the apparent absorption maxima. R∞ (between 0 and 1) is the measured reflectance of the sample divided by the measured reflectance of the standard (

∞ means the layer is so thick that further increasing the thickness does not change the reflectance) (Chen et al. 2014). Spectral changes resulting from pre-freezing treatment and drying at 30 and 60 °C were characterized by the spectra of ΔK/S.

Mechanical properties measurement

Mechanical properties of the tested wood were measured as per China National Standards GB/T 1938 (2009), GB/T 1935 (2009), GB/T 1936.1 (2009), GB/T 1936.2- (2009), and GB/T 15777 (1995). The mechanical properties of the tested wood included tensile strength parallel to the grain, compression strength parallel to the grain, modulus of elasticity in compression parallel to the grain, bending strength, and modulus of elasticity in static bending.

RESULTS AND DISCUSSION

Relationship Between Shrinkage and Pre-Freezing Treatment

The samples were pre-frozen for 72 h at -20 or -40 °C and then dried to 12% MC. The other group were dried to 12% MC at 30 °C with 65% humidity as control. Although several studies have been shown that the drying rate of some hardwoods appears to increase by pre-freezing before or early in the kiln drying period (Ilic 1995). The pre-freezing treatment slowed down the drying rate in the present study. The different drying rates can also be attributed to the different pretreatment temperatures. It is possible that water in wood cells could not be frozen entirely at -20 °C, whereas it was more thoroughly frozen at -40 °C, so that the drying process takes a little longer.

Average values of TS, RS, LS, and VS of the air-dried wood samples before and after pre-freezing and drying to an EMC of 12% are summarized in Table 2. The TS, RS, and VS decreased after pre-freezing treatment, while no obvious change can be seen for LS. The shrinkage of eucalyptus wood decreased by 0.62%, 0.2%, and 0.82% for TS, RS, and VS, respectively, after pre-freezing at -20 °C compared with the control. The shrinkage of eucalyptus wood decreased by 0.19%, 0.12%, and 0.68% for TS, RS, and VS, respectively, after pre-freezing at -40 °C compared with the control. This indicates that pre-freezing treatment at -20 °C had a more positive effect on the decrease in shrinkage of eucalyptus wood. Many explanations have been proposed to explain why pre-freezing produces a reduction in shrinkage. The primary explanation involves the transformation of water to ice, which results in an expansion of the lumen, thereby spreading a compressive stress to the cell walls. This, along with the moisture loss, makes the cells more rigid, thus reducing the shrinkage of wood. Another explanation is that some types of wood extractives move into the cell walls during freezing and may play a part in strengthening the cell walls (Ilic 1995).

Table 2. Shrinkage of E. urophylla× E. grandis Wood Before and After Pre-Freezing Treatment

Relationship Between Color and Pre-Freezing Treatment

The color parameters L*, a*, b*, Δa*, Δb*, ΔL*, and ΔE* of the pre-freezed samples after drying to an EMC of 12% at 30 °C are shown in Table 3 and Fig. 2. The color parameters of the pre-freezed samples after oven drying to a MC of 8% at 60 °C are shown in Table 4 and Fig. 3.

After drying at 30 °C, the L* value of samples subjected to pre-freezing at -20 °C decreased, while the L* value of those pre-frozen at -40 °C increased when compared to the control. There was no significant change in a* values for any pre-frozen samples. The b* value decreased slightly when pre-freezing treated at -20ᵒ C. However, the b* value increased significantly after pre-freezing treatment at -40 °C when compared to the control (Table 3). Figure 2 shows that the value of ΔL* was negative and decreased after pre-freezing treatment at -40 °C, which indicates that the wood turned dark gradually after pre-freezing and drying. The value of Δa* changed only slightly after treatment, i.e., the red-green color of wood remained stable. The value of Δb* decreased after pre-freezing treatment, i.e., the wood turned blue gradually after pre-freezing at -40 °C. The value of ΔE* increased after treatment (Fig. 2).

Table 3. CIEL*a*b* Parameters of E. urophylla× E. grandis Wood after Drying at 30 °C

Fig. 2. CIEL*a*b* parameters of E. urophylla× E. grandis wood samples dried at 30 °C

Table 4 shows the color parameters L*, a*, and b* of the pre-frozen samples after drying at 60 °C. The ΔL* of wood decreased after pre-freezing at -40 °C and drying at 60 °C. The red-green value remained unchanged after drying. The yellow-blue value increased after the treatment; the wood turned blue gradually after pre-treatment. The chromatic aberration of wood significantly increased after pre-freezing at -40 °C compared with the other two groups (Fig. 3), but all of the color parameters changed only slightly, which indicated that the color stability of eucalyptus wood was very good after pre-freezing treatment.

Previous studies have demonstrated that the yellow color is associated with the presence of chromophores in the lignin and extractives, as well as organometallic compounds in extractives (Pincelli et al. 2012), and the lightness decrease is related to chemical changes to glucose, hemicelluloses, and lignin when treated at high temperatures (Esteves et al. 2007). The present study suggests that the pre-freezing treatment did not change the structure of lignin or extractives related to wood color. On the other hand, it reduced the chemical interactions in the wood, thus enhancing the stability of eucalyptus wood color. Pre-freezing at -20 °C was better than that at -40 °C with respect to the color stability of eucalyptus wood.

Table 4. CIEL*a*b* Parameters of E. urophylla× E. grandis Wood after Drying at 60 °C

Fig. 3. CIE L*a*b* parameters of E. urophylla× E. grandis wood samples dried at 60 °C

Diffuse Reflectance Visible Spectroscopy (DRV)

The relationship between wavelength and spectral reflectance before and after drying at different temperatures is shown in Figs. 4 and 5.

As demonstrated in Fig. 4, the value of ΔK/S was negative in the range of 360 to 400 nm after drying at 30 °C to a MC of 12%. The group pre-frozen at -20 °C showed a peak at 520 nm, which is responsible for the red color of the sample. Absorption of the three groups tend to flatten in the 600- to 740-nm region, which indicates that the color of wood was stable and essentially unchanged.

After pre-freezing at -20 °C followed by drying at 60 °C (Fig. 5), the samples showed higher absorption in the range of 360 to 400 nm compared with the control. The group pre-frozen at -40 °C showed a peak at 410 nm, which was responsible for the yellow color of the sample. The most reasonable interpretation of these results is that the increased absorption was due to the formation of components with conjugated double-bond structures, including quinoid structures. This would cause the color of eucalyptus wood to shift toward yellow (Chen et al. 2013). Absorption of the samples with or without pre-freezing showed broad absorption in the range of 450 to 740 nm, which suggests that the color of wood became more stable and basically remain unchanged.

Fig. 4. ΔK/S spectra of E. urophylla× E. grandis wood samples dried at 30 °C

Fig. 5. ΔK/S spectra of E. urophylla× E. grandis wood samples dried at 60 °C

Relationship Between Mechanical Properties and Pre-Freezing Treatment

The mechanical properties of wood after the pre-freezing treatment were tested and analyzed (Table 5). The standard deviation are in parentheses. The standard deviation of the data used to measure the degree of deviation from the arithmetic mean. The smaller the standard deviation, the less the average value of these values deviate, and vice versa. The tensile strength parallel to the grain of E. urophylla × E. grandis wood decreased by 2.38 MPa and 4.74 MPa after pre-freezing at -20 and -40 °C, respectively. Compression strength parallel to the grain decreased by 2.87 MPa and 6.05 MPa after pre-freezing at minus 20 and -40 °C, respectively. The modulus of elasticity in compression parallel to the grain decreased by 1315.49 MPa and 1531.21 MPa after pre-freezing at -20 and -40 °C, respectively. Bending strength decreased by 0.8 MPa and 1.18 MPa after pre-freezing at minus 20 and -40 °C, respectively. The modulus of elasticity in static bending decreased by 903.42 MPa and 1188.37 MPa after pre-freezing at -20 and -40 °C. The most likely reason for these results is that the strength of cellulose and hemicelluloses decreased and the frozen of free water causing a damage in the cell wall structure, which resulted in the decreased of the tensile strength parallel to grain, bending strength, and modulus of elasticity in static bending of E. urophylla × E. grandis wood. The frozen water occupied a certain space in the wood that was difficult to be compressed. This led to a decrease in compression strength parallel to the grain and compressive modulus of elasticity of E. urophylla× E. grandis wood.

Table 5. Mechanical Properties of E. urophylla× E. grandis Wood after Pre-Freezing Treatment

CONCLUSIONS

- Pre-freezing is an environmentally friendly wood treatment method. The shrinkage of eucalyptus wood decreased after pre-freezing treatment. It is likely that when liquid water is transformed to ice during pre-freezing treatment, it results in an expansion of the lumen. This spreads a compressive stress to the cell walls, which makes the cell more rigid and reduces the shrinkage of eucalyptus wood.

- After pre-freezing treatment, the color of eucalyptus wood changed less during drying. This may occur because the oxidation reaction of extractives was blocked when the mobility of the water in the lumen decreased. However, the color change during high-temperature heat treatment after pre-freezing should be further studied.

- The tensile strength parallel to grain, compression strength parallel to the grain, bending strength, and modulus of elasticity in static bending of E. urophylla × E. grandis wood decreased after pre-freezing treatment.

- Pre-freezing treatment is a method that can enhance the dimensional stability and increase the color stability of eucalyptus wood. Pre-freezing at -20 °C is better than that at -40 °C for improving the shrinkage and color of E. urophylla × E. grandis wood.

ACKNOWLEDGMENTS

Financial support from the Fundamental Research Funds for the Central Universities (YX2014-03), the National Natural Science Foundation of China (series project 31400498) and the Scientific Research Foundation for Returned Scholars, Ministry of Education of China(Grant No. 14JIX-01) are gratefully acknowledged.

REFERENCES CITED

Alexiou, P. N., Wilkins, A. P., and Hartley, J. (1990). “Effect of pre-steaming on drying rate, wood anatomy and shrinkage of regrowth Eucalyptus pilularis Sm,” Wood Science and Technology 24(1), 103-110. DOI:10.1007/BF00225310.

Chafe, S. C. (1986). “Collapse, volumetric shrinkage, specific gravity and extractives in Eucalyptusand other species Part 1: The shrinkage/specific gravity ratio,” Wood Science and Technology 20(4), 293-307.

Chafe, S. C. (1987). “Collapse, volumetric shrinkage, specific gravity and extractives in Eucalyptusand other species Part 2: The influence of wood extractives,” Wood Science and Technology 21(1), 27-41. DOI: 10.1007/BF00349715.

Chafe, S. C. (1993). “The effect of boiling on shrinkage, collapse and other wood-water properties in core segments of Eucalyptus regnans E Muell,” Wood Science and Technology 27(3), 205-217. DOI: 10.1007/BF00192817.

Chen, Y., Tshabalala, M. A., Gao, J. M., Stark, N. M., and Fan, Y. M. (2014). “Color and surface chemistry changes of extracted wood flour after heating at 120 °C,” Wood Science and Technology48(1), 137-150. DOI: 10.1007/s00226-013-0582-3.

Esteves, B., Velez Marques, A., Domingos, I., and Pereira, H. (2007). “Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood,” Wood Science and Technology 42(5), 369-384. DOI: 10.1007/s00226-007-0157-2.

Erickson, R. W., Haygreen, J., and Hossfeld, R. (1966). “Drying prefrozen redwood with limited data on other species,” Forest Prod. J. 16(8), 57-65.

Erickson, H. D., Schmidt, R. N., and Laing, J. R. (1968). “Freeze-drying and wood shrinkage,” Forest Prod. J. 18(6), 63-68.

Erickson, R. W., and Peterson, H. D. (1969). “The influence of prefreezing and cold water extraction on the shrinkage of wood,” Forest Prod. J. 19(4), 53-57.

Erickson, R. W., and Sauer, D. J. (1969). “Flexural creep behaviour of redwood heartwood during drying from the green state,” Forest Prod. J. 19(12), 45-51.

GB/T 1936.1 (2009). “Method of testing in bending strength of wood,” Standardization Administration of the People’s Republic of China, Beijing.

GB/T 1936.2 (2009). “Method for determination of the modulus of elasticity in static bending of wood,” Standardiz. Admin. of the People’s Republic of China, Beijing.

GB/T 1938 (2009). “Method of testing in tensile strength parallel to grain of wood,” Standardization Administration of the People’s Republic of China, Beijing.

GB/T 1953 (2009). “Method of testing in compressive strength parallel to grain of wood,” Standardization Administration of the People’s Republic of China, Beijing.

GB/T 15777 (1995). “Method for determination of the modulus of elasticity in compressive parallel to grain of wood,” Standardization Administration of the People’s Republic of China, Beijing.

Ilic, J. (1995). “Advantages of prefreezing for reducing shrinkage-related degrade in eucalypts: General considerations and review of the literature,” Wood Science and Technology 29(4), 277-285.DOI: 10.1007/BF00202087.

Ilic, J. (1999a). “Influence of prefreezing on shrinkage-related degrade in Eucalyptus regnans F. Muell,” Holz als Roh- und Werkstoff 57(4), 241-245. DOI:10.1007/s001070050049.

Ilic, J. (1999b). “Shrinkage-related degrade and its association with some physical properties in Eucalyptus regnans F. Muell,” Wood Science and Technology 33(5), 425-437. DOI: 10.1007/s002260050127.

Innes, T. C. (1995). “Collapse free pre-drying of Eucalyptus regnans F. Muell,” Holz als Roh- und Werkstoff 53(6), 403-406. DOI: 10.1007/s001070050119.

Leonardon, M., Altaner, C. M., Vihermaa, L., and Jarvis, M. C. (2009). “Wood shrinkage: Influence of anatomy, cell wall architecture, chemical composition and cambial age,” European Journal of Wood and Wood Products 68(1), 87-94. DOI: 10.1007/s00107-009-0355-8.

Morais, M. C., and Pereira, H. (2011). “Variation of extractives content in heartwood and sapwood of Eucalyptus globulus trees,” Wood Science and Technology 46(4), 709-719. DOI: 10.1007/s00226-011-0438-7.

Oltean, L., Teischinger, A., and Hansmann, C. (2007). “Wood surface discolouration due to simulated indoor sunlight exposure,” Holz als Roh- und Werkstoff 66(1), 51-56. DOI: 10.1007/s00107-007-0201-9.

Pincelli, A. L. P. S. M., de Moura, L. F., Brito, J. O. (2012). “Effect of thermal rectification on colors of Eucalyptus saligna and Pinus caribaea woods,” Maderas-Ciencia y Tecnologia 14(2), 239-248. DOI: 10.4067/S0718-221X2012000200010.

Sandoval-Torres, S., Jomaa, W., Marc, F., and Puiggali, J. R. (2010). “Causes of color changes in wood during drying,” Forestry Studies in China 12(4), 167-175. DOI: 10.1007/s11632-010-0404-8.

Szmutku, M. B., Campean, M., and Porojan, M. (2013). “Strength reduction of spruce wood through slow freezing,” European Journal of Wood and Wood Products 71(2), 205-210. DOI: 10.1007/s00107-013-0667-6.

Vanclay, J. K., Henson, M., and Palmer, G. (2008). “Color variation and correlations in Eucalyptusdunnii sawnwood,” Journal of Wood Science 54(6), 431-435. DOI: 10.1007/s10086-008-0977-1.

Wilkins, A. P., and Stamp, C. M. (1990). “Relationship between wood colour, silvicultural treatment and rate of growth in Eucalyptus grandis Hill (Maiden),” Wood Science and Technology 24(4), 297-304. DOI: 10.1007/BF00227050.

Wu, Y.-q., Hayashi, K., Liu, Y., Cai Y.-c., Sugimori, M., and Luo J.-j. (2005). “Collapse type shrinkage characteristics in plantation-grown eucalypts: I. Correlations of basic density and some structural indices with shrinkage and collapse properties,” Journal of Forestry Research (Harbin) 16(2), 83-88. DOI: 10.1007/BF02857895.

Zhang, B., Wu, S.-b., and Guo, D.-l. (2012). “The effect of methylbenzene/ethanol ratios on chemical composition of extractives from Eucalyptus grandis,” Forestry Studies in China 14(3), 235-239. DOI: 10.1007/s11632-012-0311-2.

Article submitted: Nov. 24, 2014; Peer review completed: Feb. 16, 2015; Revised version received and accepted: June 12, 2015; Published: August 10, 2015.

DOI: 10.15376/biores.10.4.6417-6427