Abstract

The effects of a three-layer structure and age on the mechanical properties of moso bamboo were investigated. The ages of 1-, 3-, and 5-year-old bamboo were chosen to make test samples, and specimens from each age of moso bamboo were divided into three groups (raw bamboo, bamboo removed from outer layer, and bamboo removed from inner layer) for evaluation of modulus of rupture and parallel-to-grain compressive strength. The regression analysis was completed to evaluate the relationship between mechanical properties and bamboo age. The results showed that the age of moso bamboo was positively correlated with the flexural and parallel-to-grain compressive strengths. The mechanical strength of moso bamboo increased with the increased age of moso bamboo. For the moso bamboo with same age, the flexural and parallel-to-grain compressive strengths decreased for the samples without bamboo outer layer. However, for the samples without bamboo inner layer, the parallel-to-grain compressive strength remained unchanged, but the flexural strength increased. The outer layer of bamboo with high toughness and flexibility played an important role during bending. However, the inner layer of bamboo is relatively brittle, which has negative effects on its flexural strength. These results provide an important basis for the bamboo used in engineering.

Download PDF

Full Article

Effects of Three-layer Structure and Age on Mechanical Properties of Moso Bamboo

Ge Han,a Rongrong Li,b and Chuangui Wang a,*

The effects of a three-layer structure and age on the mechanical properties of moso bamboo were investigated. The ages of 1-, 3-, and 5-year-old bamboo were chosen to make test samples, and specimens from each age of moso bamboo were divided into three groups (raw bamboo, bamboo removed from outer layer, and bamboo removed from inner layer) for evaluation of modulus of rupture and parallel-to-grain compressive strength. The regression analysis was completed to evaluate the relationship between mechanical properties and bamboo age. The results showed that the age of moso bamboo was positively correlated with the flexural and parallel-to-grain compressive strengths. The mechanical strength of moso bamboo increased with the increased age of moso bamboo. For the moso bamboo with same age, the flexural and parallel-to-grain compressive strengths decreased for the samples without bamboo outer layer. However, for the samples without bamboo inner layer, the parallel-to-grain compressive strength remained unchanged, but the flexural strength increased. The outer layer of bamboo with high toughness and flexibility played an important role during bending. However, the inner layer of bamboo is relatively brittle, which has negative effects on its flexural strength. These results provide an important basis for the bamboo used in engineering.

Keywords: Moso bamboo; Modulus of Rupture; Compressive strengths; Three-layer structure; Age

Contact information: a: School of Forestry and Landscape Architecture, Anhui Agricultural University, Hefei 230036, China; b: Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, Nanjing Forestry University, Nanjing 210037, China; *Corresponding author: nj230036@163.com

INTRODUCTION

China has abundant bamboo resources and ranks first in both the area of bamboo forest and the annual yield of bamboo produced in the world. Bamboos are one of the fast-growing and renewable non-timber plants with good mechanical properties. Normally, the 3- to 5-year-old bamboo could be harvested for manufacturing of some industrial products (Scurlock et al. 2000). Moreover, some physical properties (such as hardness, strength, and elasticity) of bamboo are better than those of wood-based materials. Reasonable utilization of bamboo has important economic and social benefits (Scurlock et al. 2000; Chele et al. 2012; Huang et al. 2012; Shao and Wang 2018).

Different from wood materials, bamboo has a hollow structure and quasi-cylindrical shape, which is periodically divided by diaphragms in the length direction (Tan et al. 2011; Chaowana et al. 2015). Its mechanical properties are much better than those of wood with the same density. Therefore, bamboo is an ideal material for construction, furniture, and some other related applications (Chen et al. 2020). Kumar et al. (2016) evaluated the influences of density and fiber direction on the mechanical properties of bamboo scrimber (such as compressive strength, tensile strength, shear strength, flexural strength, and elastic modulus for compression). The results revealed that all of the tested mechanical properties of bamboo scrimber varied significantly with changes in the density and fiber direction. Krause et al. (2016) studied the influence of microstructure on mechanical performances of bamboo. They found that the density determined the compressive strength and the tensile strength was affected by the volume fraction of the fibers. In addition, Gutierrez and Maluk (2020) found that the mechanical properties of bamboo was reduced at elevated temperatures, which had significant impact on the failure mechanisms and stress–strain curves. In the past decades, some studies have been conducted on the physical and chemical properties of bamboo that provided some basic data for the processing and utilization of bamboo (Amada and Untao 2001; Dixon and Gibson 2014; Jakovljevic and Lisjak 2019; Liu and Yang 2019; Gu et al. 2020; Wei et al. 2020). However, there is little information available in literature on the effects of bamboo inner and outer layers on its mechanical properties.

Bamboo stem is composed of three layers, called the inner layer, middle layer, and outer layer (Chand et al. 2006; Li et al. 2014). The outer layer is bamboo skin, which is thin relative to the cross section. The inner layer is the innermost part of stem, which does not have vascular bundles. Normally, the middle layer is the part with better performance that is used in manufacturing various kinds of bamboo products. Due to the special structure and difference in properties, the bamboo inner and outer layers are often removed and treated as processing residues in practical applications, which produces much waste. To rationalize the complete utilization of moso bamboo, this study took moso bamboo with different ages as the research material to reveal the influence of age and three-layers of structure on its mechanical properties. It will provide a scientific basis for the selection and utilization of moso bamboo at different ages.

EXPERIMENTAL

Materials

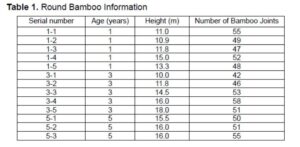

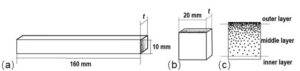

The moso bamboo (Phyllostachys heterocycla) was harvested in Jinzhai Anhui, China. The information of round bamboo is listed in Table 1. All the defect-free (which means no decay, no cracking, no moth eaten, etc.) samples were obtained from round bamboo at the height of 1.5 m and prepared according to Chinese standard GB/T 15780 (1995), as shown in Fig. 1. The sample dimensions of flexural strength and parallel-to-grain compressive strength tests were 160 mm × 10 mm × t mm (Longitudinal × Tangential × Radial) and 20 mm × 20 mm × t mm (Longitudinal × Tangential × Radial), respectively. Before mechanical strength testing, all the samples were dried and the moisture content was about 9.7 %. Figure 2 represents the schematic diagram of the samples.

Fig. 1. Flow chart of samples preparation

Fig. 2. Specimens used for MOR testing (a), Parallel-to-grain compressive strength testing (b), and divided cross section (c)

Experimental Methods

Thirty samples were prepared for flexural strength testing and parallel-to-grain compressive strength testing. The specimens were randomly divided into three groups. The first group contained raw bamboo samples (marked as RB). The dimensions of RB samples for flexural strength and parallel-to-grain compressive strength tests were 160 mm × 10 mm × t mm (Longitudinal × Tangential × Radial) and 20 mm × 20 mm × t mm (Longitudinal × Tangential × Radial), respectively. The second group of samples were obtained after removing the bamboo outer layer (marked as RO). The third group of samples were made from removing the bamboo inner layer (marked as RI). The samples used for testing parallel-to-grain compressive strength were prepared in the same way as the samples used for flexural strength testing. The parallel-to-grain compressive strength and flexural strength were measured according to Chinese standard GB/T 15780 (1995). Each experimental condition was repeated five times. During the testing, the relative humidity (RH) and temperature in the laboratory were about 50% and 20 ℃, respectively.

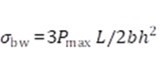

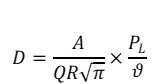

Modulus of rupture

The modulus of rupture in the tangential direction was tested by three-point bending method with a span of 120 mm. The loading was performed at a uniform speed, and the samples were destroyed within 1 ± 0.5 min. Immediately after the flexural strength test, a bamboo block with the length of 30 mm was intercepted near the failure point of the sample to measure the moisture content. The modulus of rupture (MOR) can be calculated using the following Eq. 1, where is modulus of rupture (MPa) of the sample with moisture content of W (%), is the failure load (N), L is the span between two supports with a value of 120 mm, b is width of sample (mm), and h is the height of sample (mm).

where is modulus of rupture (MPa) of the sample with moisture content of W (%), is the failure load (N), L is the span between two supports with a value of 120 mm, b is width of sample (mm), and h is the height of sample (mm).

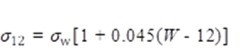

When the moisture content of the sample was at 12%, the MOR was calculated according to the following Eq. 2,

where is ultimate flexural strength of the sample with the moisture content of 12% (MPa), and W is the moisture content of the sample (%).

Parallel-to-grain compressive strength

Firstly, the thickness of bamboo wall was measured at the midpoint of the sample. Secondly, the sample was placed in the center of the spherical sliding support of the testing machine and the compressive direction is parallel to the fiber direction. Finally, the sample was broken within 1 ± 0.5 min with a uniform speed and its water content was immediately measured. The parallel-to-grain compressive strength was calculated using the following Eq. 3,

where is the parallel-to-grain compressive strength (MPa) of the sample with the moisture content of W (%), is the failure load (N), b is the width of sample (mm), and t is the thickness of sample (mm).

When the moisture content was 12%, the parallel-to-grain compressive strength was calculated according to the following Eq. 4,

where is the parallel-to-grain compressive strength (MPa) of the sample with the moisture content of 12% and W is the moisture content of the sample (%) (Chen et al. 2020).

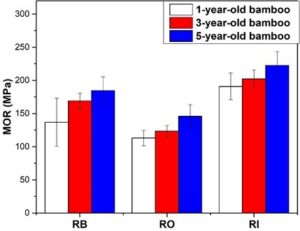

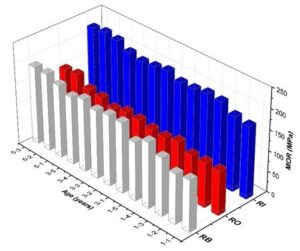

Fig. 3. Changes in MOR values with bamboo age

Fig. 4. MOR of each bamboo sample under three experimental groups with age

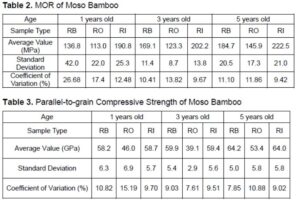

The MOR of moso bamboo showed a trend of gradual increase with increasing age of sample (Fig. 4). The MOR of 5-year-old samples was the highest, but its value with the 1-year-old samples was the lowest. This was because the mechanical properties of bamboo had not reached the peak, and the bamboo cell tissue is still in the stage of continuous strengthening before reaching 5 years. The effects of age on MOR of bamboo indicated good agreement with previous research (Okahisa et al. 2017).

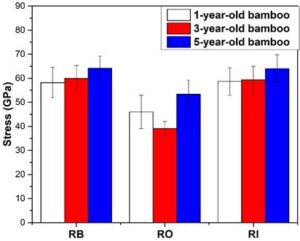

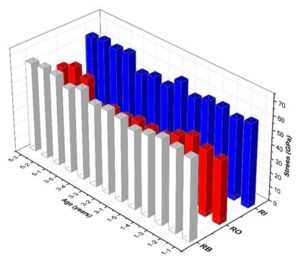

Parallel-to-grain Compressive Strength

The variation in parallel-to-grain compressive strength with bamboo age indicated a different trend from MOR. Compared to RB, the parallel-to-grain compressive strength of RO with ages of 1, 3, and 5 years decreased about 21.0%, 34.7%, and 15.3%, respectively. However, the change in parallel-to-grain compressive strength of RI with ages of 1, 3, and 5 years was not noticeable (Fig. 5). Noticeably, the outer layer of moso bamboo played an important role in parallel-to-grain compressive strength and had greater influence on parallel-to-grain compressive strength than MOR of bamboo materials, while the inner layer of the bamboo played a negligible role. In these three groups of samples, the parallel-to-grain compressive strength of RO decreased noticeably (Fig. 5). However, the parallel-to-grain compressive strength of RI did not change noticeably. This indicated that the parallel-to-grain compressive strength of bamboo inner layer was very close to that of the raw bamboo.

For the index of bamboo age, the parallel-to-grain compressive strengths of 1-, 3-, and 5-year-old bamboo samples showed a small increase. This result is similar to the study of Li (2009) that the mechanical properties of bamboo gradually increased with increasing of age.

Fig. 5. Changes in the parallel-to-grain compressive strength of different samples

Fig. 6. Parallel-to-grain compressive strength of each bamboo under three conditions

Discussion

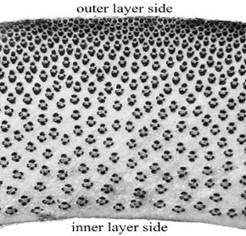

The mechanical properties of moso bamboo are mainly affected by the composition and distribution of the vascular bundles and parenchyma tissues (Parameswaran and Liese 1976; Liese 1987; Kanzawa et al. 2011). The mechanical properties of moso bamboo varied with the change of the distribution and the shape of vascular bundles protected by bundle sheaths. From bamboo outer layer to inner layer, the distribution density of vascular bundles decreased the volume of vascular bundles and the content of parenchyma cells increased. However, parenchyma tissues, which consisted of thin-walled parenchyma cells, contribute little to the rigidity of bamboo. Bamboo inner layer is composed of multilayered thick-walled sclereids with relatively high density, but its texture is brittle and the toughness is poor. Therefore, the flexural strength of RI was increased while the parallel-to-grain compressive strength was almost unchanged.

In Fig. 7, it can be clearly observed that the vascular bundles near the bamboo inner layer are sparse and relatively large. In contrast, the vascular bundles in the bamboo outer layer are dense and small (Kanzawa et al. 2011). Vascular bundles are composed of metaxylem vessel and sheaths of sclerenchyma fiber that amount to approximately 40% of the mass and 60% to 70% of the weight of the bamboo culm. It is commonly known that fiber-reinforced structure enhances the flexibility of bamboo. The fiber bundles play an important role when bamboo is subject to bending, which not only strengthen bamboo, but also restrict crack propagation and delay fracture (Xie et al. 2016; Chen et al. 2019b). Therefore, the mechanical strength of samples without outer layer decreased apparently.

Fig. 7. Typical transverse cross-sectional features of moso bamboo

CONCLUSIONS

This study focused on the effects of 3-layer structure and age on the mechanical properties of moso bamboo. The special structure of moso bamboo has significant effects on the properties of each part, which directly affects the preparation process and properties of bamboo composite materials. This research will help to guide the rational use of different layers during the structure design of bamboo composite materials, which will have positive effects on improving bamboo utilization rate. And reasonable cutting of bamboo in different years also plays an important role in bamboo planting efficiency and sustainable utilization of bamboo forest. The detail conclusions are shown as follows:

- In consideration of economic benefits, the industrial use of moso bamboo age is generally 3 to 5 years old. In the selected samples, the results of parallel-to-grain compressive strength and MOR values showed that the mechanical properties of 5 years-old moso bamboo was highest, and then followed 1 and 3 years-old moso bamboo.

- The three-layers of structure also had noticeable effects on bamboo mechanical properties. The removal of bamboo outer layer reduced the parallel-to-grain compressive strength and MOR values. In addition, the removal of bamboo inner layer had little effect on parallel-to-grain compressive strength.

- The outer layer of bamboo with high toughness and flexibility played an important role when bamboo was subjected to bending. The inner layer of bamboo had a certain amount of compressive strength, but poor flexural strength.

ACKNOWLEDGMENTS

The authors are grateful for the support from the “12th Five-Year” National Science and Technology Support Plan project (2015BAD04B0302).

REFERENCES CITED

Amada, S., and Untao, S. (2001). “Fracture properties of bamboo,” Composites Part B: Engineering 32(5), 449-457. DOI: 10.1016/S1359-8368(01)00022-1

Chand, N., Jain, D., and Nigrawal, A. (2006). “Investigation on gradient dielectric characteristics of bamboo (Dendrocalamus strictus),” Journal of Applied Polymer Science 102(4), 3489-3494. DOI: 10.1002/app.24564

Chaowana, P., Barbu, M. C., and Fruhwald, A. (2015). “Bamboo – A functionally graded composite material,” Forest Products Journal 65(3-4), S48-S53.

Chele, E.-S., Ricardo, M.-C., Ana, P.-M., and Teresa, M.-R. (2012). “Bamboo, from traditional crafts to contemporary design and architecture,” Procedia – Social and Behavioral Sciences 51, 77-781. DOI: 10.1016/j.sbspro.2012.08.239

Chen, M., Ye, L., Li, H., Wang, G., Chen, Q., Fang, C., Dai, C., and Fei, B. (2020). “Flexural strength and ductility of moso bamboo,” Construction and Building Materials 246, Article ID 118418. DOI: 10.1016/j.conbuildmat.2020.118418

Chen, M. L., Ye, L., Wang, G., Fang, C. H., Dai, C. P., and Fei, B. H. (2019a). “Fracture modes of bamboo fiber bundles in three-point bending,” Cellulose 26(13-14), 8101-8108. DOI: 10.1007/s10570-019-02631-6

Chen, Q., Dai, C., Fang, C., Chen, M., Zhang, S., Liu, R., Liu, X., and Fei, B. (2019b). “Mode I interlaminar fracture toughness behavior and mechanisms of bamboo,” Materials & Design 183, Article ID 108132. DOI: 10.1016/j.matdes.2019.108132

Dixon, P. G., and Gibson, L. J. (2014). “The structure and mechanics of Moso bamboo material,” J. Royal Society Interface 11(99), 1-12. DOI: 10.1098/rsif.2014.0321

GB/T 15780 (1995). “Testing methods for physical and mechanical properties of bamboos,” Standardization Administration of China, Beijing, China.

Gu, S., Zhang, W., Ding, L., Cheng, H., and Wang, G. (2020). “Effect of utilization of fiberglass cloth in laminated bamboo sliver lumber on its strength and toughness,” J. Forestry Engineering 5(2), 144-150. DOI: 10.13360/ j.issn.2096-1359.201901009

Gutierrez, M., and Maluk, C. (2020). “Mechanical behaviour of bamboo at elevated temperatures – Experimental studies,” Engineering Structures 220, Article ID 110997. DOI: 10.1016/j.engstruct.2020.110997

Huang, Y. H., Fei, B. H., Yu, Y., and Zhao, R. J. (2012). “Plant age effect on mechanical properties of moso bamboo (Phyllostachys Heterocycla Var. Pubescens) single fibers,” Wood and Fiber Science 44(2), 196-201. DOI: 10.1007/s10086-011-1229-3

Jakovljevic, S., and Lisjak, D. (2019). “Investigation into the effects of humidity on the mechanical and physical properties of bamboo,” Construction and Building Materials 194, 386-396. DOI: 10.1016/j.conbuildmat.2018.11.030

Kanzawa, E., Aoyagi, S., and Nakano, T. (2011). “Vascular bundle shape in cross-section and relaxation properties of Moso bamboo (Phyllostachys pubescens),” Mater. Sci. & Eng. C: Mater. Biol. Appl. 31(5), 1050-1054. DOI: 10.1016/j.msec.2011.03.004

Krause, J. Q., Silva, F. D., Ghavami, K., Gomes, O. D. M., and Toledo, R. D. (2016). “On the influence of Dendrocalamus giganteus bamboo microstructure on its mechanical behavior,” Construction and Building Materials 127, 199-209. DOI: 10.1016/j.conbuildmat.2016.09.104

Kumar, A., Vlach, T., Laiblova, L., Hrouda, M., Kasal, B., Tywoniak, J., and Hajek, P. (2016). “Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties,” Construction and Building Materials 127, 815-827. DOI: 10.1016/j.conbuildmat.2016.10.069

Li, X. Z. (2009). Research on Mechanics and Failure Properties of Moso Bamboo, Master’s Thesis, Chinese Academy of Forestry, Beijing, China.

Li, Z. Q., Jiang, Z. H., Fei, B. H., Cai, Z. Y., and Pan, X. J. (2014). “Comparison of bamboo green, timber and yellow in sulfite, sulfuric acid and sodium hydroxide pretreatments for enzymatic saccharification,” Bioresource Technology 151, 91-99. DOI: 10.1016/j.biortech.2013.10.060

Liese, W. (1987). “Research on bamboo,” Wood Science and Technology 21(3), 189-209. DOI: 10.1007/BF00351391

Liu, H., and Yang, L. (2019). “Bending performance of bamboo-laminated LVL composite beam,” Journal of Forestry Engineering 4(1), 45-50. DOI: 10.13360/j.issn.2096-1359.2019.01.007

Lo, T. Y., Cui, H. Z., and Leung, H. C. (2004). “The effect of fiber density on strength capacity of bamboo,” Materials Letters 58(21), 2595-2598. DOI: 10.1016/j.matlet.2004.03.029

Okahisa, Y., Kojiro, K., Kiryu, T., Oki, T., Furuta, Y., and Hongo, C. (2017). “Nanostructural changes in bamboo cell walls with aging and their possible effects on mechanical properties,” Journal of Materials Science 53(6), 3972-3980. DOI: 10.1007/s10853-017-1886-8

Parameswaran, N., and Liese, W. (1976). “On the fine structure of bamboo fibres,” Wood Science and Technology 10(4), 231-246. DOI: 10.1007/BF00350830

Scurlock, J. M. O., Dayton, D. C., and Hames, B. (2000). “Bamboo: An overlooked biomass resource?,” Biomass and Bioenergy 19(4), 229-244. DOI: 10.1016/S0961-9534(00)00038-6

Shao, Z., and Wang, F. (2018). “Mechanical characteristics of bamboo structure and its components,” in: The Fracture Mechanics of Plant Materials, Springer, Singapore, pp. 125-146. DOI: 10.1007/978-981-10-9017-2_7

Tan, T., Rahbar, N., Allameh, S. M., Kwofie, S., Dissmore, D., Ghavami, K., and Soboyejo, W. O. (2011). “Mechanical properties of functionally graded hierarchical bamboo structures,” Acta Biomaterialia 7(10), 3796-3803. DOI: 10.1016/j.actbio.2011.06.008

Wei, X., Chen, F., and Wang, G. (2020). “Flexibility characterization of bamboo slivers through winding-based bending stiffness method,” Journal of Forestry Engineering 5(2), 48-53. DOI: 10.13360/ j.issn.2096-1359.201905046

Xie, J., Qi, J., Hu, T., De Hoop, C. F., Hse, C. Y., and Shupe, T. F. (2016). “Effect of fabricated density and bamboo species on physical–mechanical properties of bamboo fiber bundle reinforced composites,” Journal of Materials Science 51(16), 7480-7490. DOI: 10.1007/s10853-016-0024-3

Article submitted: November 18, 2020; Peer review completed: January 24, 2021; Revised version received and accepted: February 3, 2021; Published: February 8, 2021.

DOI: 10.15376/biores.16.2.2406-2415