Abstract

The paper sludge conditioning effects of waste polyester textile fibers as skeleton builders combined with ferric chloride (FeCl3) were evaluated and the sludge dewatering mechanism was explored. The catalytic effect of Fe-rich sludge biochar (Fe-SB) on enhancing sludge dewaterability was evaluated. Results showed the combined fiber-FeCl3 conditioning significantly promoted the sludge dewaterability compared with conditioner alone, leading to a 77.5% decrease in specific filtration resistance and a 68.9% increase in net yield. The decrease of extracellular polymeric substances (EPS) contents showed that the EPS were difficult to extract and sludge floc strength was enhanced as a result of chemical reactions such as complexation processes and charge neutralization. Hence, the enhancement of sludge dewaterability was primarily due to the sludge cake with a porous and incompressible structure formed by fiber and FeCl3, and the rigidity structure of fiber. Moreover, the Fe-SB prepared by fiber-FeCl3 conditioning sludge could effectively activate persulfate to enhance the sludge dewaterability, with water content of dewatered sludge decreasing by 14.6%. The Fe-SB had dual functions of the heterogeneous catalyst of persulfate and skeleton builder. This study presents a sludge recycling method that combined physicochemical conditioning and sludge biochar materials prepared by pyrolysis.

Download PDF

Full Article

Enhancing Paper Sludge Dewatering by Waste Polyester Fiber and FeCl3 for Preparation of Fe-rich Biochar

Xin Zhang,a,b,c,d Guolin Tong,c,d,* Yiheng Zhou,a Guoyi Li,a and Hui Zhang c,d

The paper sludge conditioning effects of waste polyester textile fibers as skeleton builders combined with ferric chloride (FeCl3) were evaluated and the sludge dewatering mechanism was explored. The catalytic effect of Fe-rich sludge biochar (Fe-SB) on enhancing sludge dewaterability was evaluated. Results showed the combined fiber-FeCl3 conditioning significantly promoted the sludge dewaterability compared with conditioner alone, leading to a 77.5% decrease in specific filtration resistance and a 68.9% increase in net yield. The decrease of extracellular polymeric substances (EPS) contents showed that the EPS were difficult to extract and sludge floc strength was enhanced as a result of chemical reactions such as complexation processes and charge neutralization. Hence, the enhancement of sludge dewaterability was primarily due to the sludge cake with a porous and incompressible structure formed by fiber and FeCl3, and the rigidity structure of fiber. Moreover, the Fe-SB prepared by fiber-FeCl3 conditioning sludge could effectively activate persulfate to enhance the sludge dewaterability, with water content of dewatered sludge decreasing by 14.6%. The Fe-SB had dual functions of the heterogeneous catalyst of persulfate and skeleton builder. This study presents a sludge recycling method that combined physicochemical conditioning and sludge biochar materials prepared by pyrolysis.

Keywords: Sludge dewaterability; Sludge biochar; Skeleton builder; Heterogeneous catalyst; Persulfate

Contact information: a: School of Environmental and Natural Resources, Zhejiang University of Science and Technology, Hangzhou, 310023 China; b: State Key Laboratory of Pulp and Paper Engineering, South China University of Technology, Guangzhou, 510640 China; c: Jiangsu Provincial Key Lab of Pulp and Paper Science and Technology, Nanjing Forestry University, Nanjing, 210037 China; d: Jiangsu Co-Innovation Center for Efficient Processing and Utilization of Forest Resources, Nanjing Forestry University, Nanjing, 210037 China; *Corresponding author: gtong@njfu.edu.cn

INTRODUCTION

A large amount of paper activated sludge (PAS) is produced in wastewater treatment plants associated with paper mills. The disposal cost of sludge cake is about 50% of the gross cost of treatment (Appels et al. 2008). The moisture content (MC) of PAS is higher than 90% (Zhang et al. 2018). The difficulties in sludge dewatering are related to the nature of the colloidal environment, which is influenced by several factors, such as extracellular polymeric substances (EPS), particle size, bound water, and zeta potential, etc. Sludge has high compressibility during the sludge compression and filtration stage, which hinders the various forms of water from being separated (Qi et al. 2011). Therefore, the proper and efficient dewatering method is key to cut down the amount of sludge, transportation, and drying costs.

Physical conditioners, often known as skeleton builders or filtration aids, can increase the sludge incompressibility and permeability by forming a porous and rigid cake structure (Qi et al. 2011; Mowla et al. 2013). Carbon-supported materials have been studied as physical conditioners to enhance the sludge dewaterability, including wood chips (Ding et al. 2014), biochar (Tao et al. 2019), sawdust (Luo et al. 2013), and fiber wastes (Yang et al. 2018). This type of physical conditioner is advantageous for sludge dewatering in several respects, such as the low mineral content and high heating value (Mowla et al. 2013), especially when the sludge cake is treated by incineration and thermal treatment. Nevertheless, physical conditioners alone can just decrease the MC of sludge cake only to a moderate degree. Flocculation is widely used before the mechanical dewatering stage to realize the sludge solid-water separation by bridging between particles and charge neutralization. Ferric chloride (FeCl3) is one of the most common and efficient inorganic flocculants. However, because the sludge compressibility is still higher after sludge conditioned with flocculant alone, the MC of cake can only be reduced to a certain value. Most researches have observed that the combination conditioning of physical conditioners and flocculants for sludge dewatering could effectively achieve higher solids content (Zhu et al. 2018b; Liang et al. 2019). Liang et al. (2019) used biochar as the filtration aid in conjunction with FeCl3 to reduce the MC of sludge cake to below 50% dry solid (DS). Among the most studies on sludge dewatering, the conditioner dosage was optimized with a constant sludge concentration, without considering the effect of different concentration on the optimal dose.

China has more than 0.02 billion tons of abandoned textiles every year, about 70% of which are chemical fiber textiles. Among them, polyester-based textiles are widely produced as shirts and socks and eventually turned into garbage and incineration for quick disposal (Nzihou 2010). They will inevitably induce serious environmental pollution if disposed of irrationally. It has been reported that longer fibers can make the sludge much easier to remove the water due to form of the rigid and incompressible structure in the dewatered sludge cake. Nittami et al. (2015) have studied the effects of compressibility of the synthetic fibers themselves on the sludge dewatering property. Employing waste polyester textiles (WPT) as skeleton builders in the sludge dewatering could cut down the costs related to the disposal of the fibers and sludge. However, few studies have focused on the effect and the optimum conditioning of WPT fibers combined with flocculant on sludge dewaterability. The combination conditioning of exogenous fiber and FeCl3 will have to produce a huge amount of Fe/fiber-rich dewatered sludge that will induce challenges for disposal.

Conventional sludge disposal methods, such as landfill, land use, and incineration, would induce the waste of iron compounds and environmental pollution. Bolobajev et al. (2014) studied that the Fe-rich sludge derived from the Fenton process could be effectively reused as an iron source in advanced oxidation treatments for sewage processing. Moreover, considering the recovery of syngas energy and the reduction of sludge volume, the Fe-rich sludge biochar (Fe-SB) prepared by pyrolysis could also be effectively used in the wastewater treatment process (Hadi et al. 2015). The Fe-SB could be considered to be not only a productive iron source for the advanced oxidation process but also an effective absorbent of various pollutants due to its porous carbon structure (Xiao et al. 2020). Yu et al. (2019) studied that the Fe-SB prepared by polyferric sulfate could act as a persulfate catalyst to degrade tetracycline and pharmaceutical wastewater effectively. Waste polyester textiles have a higher carbon content of 64%, which is nearly equal to many raw materials preparing activated carbon. Thus, it is reasonable to presume that WPT can be one of the productive resources as a precursor of activated carbon (Yuan et al. 2018), with many advantages, such as lower cost and better eco-friendliness, than the other conventional activated carbons. The Fe/fiber-rich dewatered sludge cake can be used to produce multi-functional Fe-SB materials. Until now, some studies indicated that biochar could enhance the sludge dewaterability, in which the MC of dewatered sludge decreased to 70% DS (Wu et al. 2017; Wang et al. 2018). However, these studies still added the flocculant instead of reusing iron from Fe-SB, which resulted in the waste of iron. The feasibility and efficiency of conditioned sludge as a precursor of biochar to catalyze persulfate have not yet been studied.

In this study, a novel waste recycling method was proposed by using WPT as the skeleton builder and Fe-SB as the heterogeneous catalyst of persulfate to improve sludge dewaterability. The effect and mechanism on sludge dewaterability in the combination conditioning of fiber and FeCl3 were studied by sludge compressibility, zeta potential, Fourier transform infrared (FT-IR) spectrometry, microscopic structural analysis, and EPS classification. The possible catalytic ability of Fe-SB prepared from the Fe/fiber-rich sludge to improve the sludge dewaterability was also explored. This will provide a theoretical foundation of waste recycling.

EXPERIMENTAL

Materials

Activated sludge and exogenous fiber

The PAS was collected from a wastewater treatment plant in a pulp and paper company (Nantong, China) that produces bleached chemical wood pulp and high-level paper. To minimize the microbial activity, samples were transported to the lab in 2 h and kept at 4 °C and used for less than 5 d. The main sludge characteristics were total suspended solids (TSS) of 6.06 to 8.49 g/L, DS of 0.91 to 1.07%, the specific resistance to filtration (SRF) of 1.60 to 3.26 × 1012 m/kg, and a pH of 6.8 to 7.0.

The raw polyester fiber materials were purchased from an engineering fiber company (Huixiang Inc., Changsha, China) with a diameter of 20 ± 4 µm. They were adjusted into 3 mm in length by scissors and dried at 50 ± 5 °C to a constant weight before the experiment.

The WPT were polyester shirts and collected from the living areas (Nanjing, China). They were treated before being used as exogenous fiber in the study. The detailed process was as follows: the WPT were cut into small pieces with a size of 2 cm × 5 cm and refined to 30 °SR in a laboratory Hollander refiner. Moreover, the obtained WPT fibers were homogenized and fractionated with a Bauer-McNett classifier (Paper Testing Instruments Gmbh, Laakirchen, Austria) following TAPPI T233 cm-95 (1995) to obtain the fibers with different size. If possible, it is better to adopt the opening and crushing equipment to reduce the damage of the fiber.

Additionally, FeCl3 of chemical pure grade was bought from a chemical company (Guoyao Inc., Nanjing, China) and made the solution (20 g/L) before the experiment. All the tests were performed three times, and the results are shown as the average values.

Methods

Sludge conditioned by the fiber and FeCl3

The experiment was performed at room temperature (25 °C). To measure the optimal conditioning of fiber and FeCl3, a different fiber dosage (0 to 30% DS), fiber sizes (an average length (length weighted) of 0.53 to 3 mm), and different FeCl3 dosages (0 to 150 g/kg DS) were added into the sludge samples. Experimental procedures were as follows: sludge conditioning was conducted by a 300-mL beaker at first; then, the fiber and flocculant were added; sludge samples were stirred at 350 rpm for quick agitation (30 s) and 40 rpm for slow agitation (3 min) to keep dispersion fully. The combined fiber and FeCl3 conditioning was conducted with a different sequence of addition. The fiber-FeCl3 conditioning meant that the fiber was added first. The conditioned sludge sample (100 mL) was added into a standard Buchner funnel to carry out the sludge dewatering process until no filtrate came out or sludge cake fractured, and then the MC of the cake was measured.

Preliminary sludge conditioning experiment of Fe-SB as the persulfate catalyst

The sludge biochar was synthesized by pyrolysis at 800 °C for 2 h under nitrogen atmosphere at a heating rate of 10 °C/min in a tube furnace. Before the preparation of Fe-SB, the raw sludge was treated at the optimal fiber size and FeCl3 dosage. The obtained biochar materials were washed, dried, and grounded into 80-mesh for further experimentation.

The sludge oxidation experiment of Fe-SB was conducted with or without the addition of persulfate. Persulfate was added to condition the sludge sample at a dosage of 100 mg/g DS and agitated at 300 rpm for 10 min. Then, Fe-SB (5% DS) was added and agitated at 150 rpm for 15 min. To prevent free radicals, such as SO4 and OH, from oxidizing iron in lower valence rapidly, the reaction must be controlled.

Sludge Dewaterability Assessment

The sludge dewaterability was evaluated with the SRF and MC of sludge cake. The sludge SRF was measured based on the studies carried out by Qi et al. (2011).

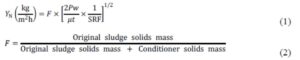

The sludge solids will increase inevitably with adding the skeleton builder. Thus, the net sludge solids yield (YN) was introduced to express the dewaterability mainly, supplemented by SRF (Qi et al. 2011). A higher YN meant that the sludge had better dewaterability. The YN can be calculated by Eq. 1,

where F is a correlation factor in Eq. 2, P is filtration pressure (Pa), w is equal to the ratio of weight of cake solids to filtrate volume as a constant (kg/m3), µ is the filtrate viscosity (Pa·S), and t is the filtration time.

The sludge MC and TSS were calculated according to standard methods (APHA 2012). The sludge compressibility was measured as the slope of a log-log plot of the SRF versus P (Zhao and Bache 2001). The compressibility was higher meaning that the sludge was prone to deformation, which was close to or greater than 1 for raw sludge.

Analytical Methods of Sludge Conditioning Process and Biochar Characteristics

The fiber properties of fiber length, coarseness, fiber width, curl index, and fine fiber content were measured with the fiber quality analyzer (FQA, OpTest Equipment Inc., Hawkesbury, Canada).

The microstructural characteristic was investigated by Classica optical microscopy (Motic, Xiamen, China) and Quanta 200 scanning electron microscopy (SEM, FEI Company, Hillsboro, OR, USA). The particle size of sludge floc was analyzed using a Topsizer laser diffraction particle size analyzer (OMEC Co., Shanghai, China) (Wu et al. 2017). After centrifugation at 3000 rpm for 5 min and filtration through the 0.45-µm membrane, the zeta potential in the sludge supernatant was measured by a Nanosizer ZS instrument (Malvern Co., Malvern, UK) at 25 °C (Wang et al. 2017). A heat extraction method was introduced to separate the soluble EPS (S-EPS), loosely bound EPS (LB-EPS), and the tightly bound EPS (TB-EPS) from sludge suspension (Zhen et al. 2012a). The proteins (PN) and polysaccharides (PS) contents in the sludge supernatant were measured by a UV spectrophotometer (PERSEE Inc., Beijing, China) using the modified Lowry method (Frølund et al. 1995) and the anthrone method (Wu et al. 2017), respectively. The sum of PN and PS content was considered as total EPS content (Wu et al. 2014). The filter sludge cake was dried in a freezer dryer (GIPP co., Shanghai, China) and ground into powder. The sludge chemical structure were tested quickly in the transmission mode by a VERTEX FT-IR spectrometer (Bruker Optics, Ettlingen, Germany) (range: 4000 to 400 cm-1) (Zhen et al. 2012b).

The functional groups analysis of biochar was the same as that of the sludge cake. The mineral phase of biochar was tested by a powder X-ray diffractometer (XRD, Philips, PAN Analytical B.V., Eindhoven, Netherlands) with Cu Kα radiation. The specific surface and the pore size distributions of the biochar were analyzed using a surface area analyzer (BK112-TB, JingWeiGaoBo Inc., Beijing, China) according to the nitrogen adsorption and desorption method.

In this study, analysis of variance was carried out by the software SPSS 22 (SPSS Inc., Beijing, China) and p < 0.05 was accepted as indicative of significant differences.

RESULTS AND DISCUSSION

Optimization of the Combined Fiber-FeCl3 Conditioning

The fiber dosage under different sludge TSS

Based on the raw polyester fibers with length in 3 mm, the effects of fiber dosage on sludge dewaterability under different sludge TSS are shown in Fig. 1. Herein, the SRF and YN were used to express the sludge dewaterability and filterability.

With the sludge TSS increasing from 7.37 to 16.07 g/L, the SRF decreased from 2.35 × 1012 m/kg to 1.62 × 1012 m/kg. The result studied by Christensen and Dick (1985) showed a similar trend. This showed that the initial sludge TSS had a greater impact on the SRF. The raw sludge had higher SRF and lower YN, showing poor dewaterability. At a lower sludge TSS of 7.37 g/L, an increasing fiber dosage from 0 to 20% DS clearly exhibited a better sludge dewatering property, corresponding to reduction by 50.9% in the SRF, while the YN increased by 19.7% (Fig. 1a). Afterwards, the sludge dewatering became worse when the fiber dosage increased continuously to 30% DS. Hence, the optimum fiber dosage was 20% DS. Moreover, similar changes were observed in the other sludge TSS. As shown in Fig. 1b, the curve of SRF was inconsistent with that of YN, which was also shown in the study of Ning et al. (2013). Then, the YN determined the optimum dewaterability. At the sludge TSS of 10 g/L and 16.066 g/L, the optimum fiber dosage was 10% DS and 5% DS, respectively (Fig. 1b and 1c). Overall, the higher sludge concentration was not good for the formation of sludge water channel from fiber and the optimum fiber dosage was lower.

Fig. 1. Effects of raw polyester dosage on SRF and YN under different sludge TSS: a: TSS of 7.37 g/L; b: TSS of 10 g/L; c: TSS of 16.07 g/L

Yang et al. (2018) observed that the SRF decreased 58% when the sludge was conditioned with jute fiber (30% DS) and cationic polyacrylamide (CPAM). However, under similar SRF reduction rate, the fiber dosage would be lower than 5% DS at the same sludge TSS and fiber length in this study. It could be concluded that the sludge dewaterability was associated with not only the fiber width but also the fiber type. At the optimum dosage, straight and curved fibers (Sen and De 1949) all were dispersed throughout the sludge cake, formed the rigid porous structure as skeletons during the sludge dewatering process, and in turn resulted in the better sludge dewaterability.

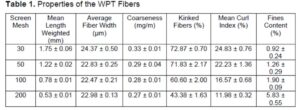

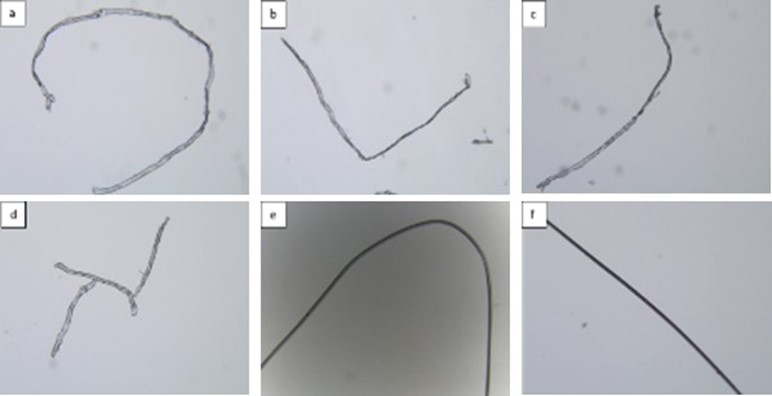

Fiber length and fibrillation

Figure S1 shows fiber microscopic images of WPT fiber after fractionation with different mesh screens, unbeaten WPT fiber, and raw polyester fiber. The raw polyester fiber and unbeaten WPT fiber had almost no curl and kink, smooth surface, and uniform width (Fig. S1 f and e). After being beaten, the fibers showed fibrillation, uneven width, and curl and kink (Fig. S1 a through d). To further evaluate the different fiber length fractions, fiber properties analysis was conducted (Table 1). After fractionation, as the average fiber length decreased from 1.75 mm to 0.53 mm, the curl index and kinking degree decreased, while the fines content increased. There were almost no differences in the fiber width and coarseness.

Figure 2a shows that fiber length had different improved effects on sludge dewaterability by measuring the SRF and YN. The SRF and YN of unconditioned sludge were 1.60 × 1012 m/kg and 4.85 kg/(m2h), respectively. As the fiber length was decreased from 1.75 mm to 0.53 mm, the SRF decreased first and then increased. Correspondingly, the change of YN was the opposite. When the fiber length was decreased to 0.78 mm, the SRF and YN were 0.96 × 1012 m/kg and 5.30 kg/(m2h), with the maximum changes of 40.3% and 9.4%, respectively. As the average fiber length further lowered to 0.53 mm, however, the SRF increased 4.6% and YN decreased 1.7%.

Pulp refining will cause fiber fibrillation, which is related to the pilling off the fibrils from the fiber surface and the decreasing fiber strength. As shown in Fig. 2a, the dewaterability of paper sludge containing unrefined and refined fibers was evaluated. Compared with 3 mm unrefined fiber, the decreasing fiber length (1.75 mm) was bad for sludge dewatering, which was inconsistent with the effect of the following lower length. Therefore, fiber fibrillation can influence the sludge dewaterability due to the rigidity of fiber as skeletons.

Fig. 2. Effect of different fiber length (a: sludge TSS of 8.49 g/L, fiber dosage of 20% DS) and FeCl3 dosage (b: sludge TSS of 6.42 g/L, pH of 6.8) on sludge dewaterability

It has been reported that longer fibers can make the sludge much easier to remove the water than fine fibers due to the formation of the rigid and incompressible structure in the dewatered sludge cake (Nittami et al. 2015). However, this was inconsistent with the present findings that fiber length longer than 0.78 mm was bad for sludge dewatering. Longer fibers in the sludge were easy to be wound and flocculated, and difficult to form a better water channel, which was bad for sludge dewatering. Moreover, shorter fibers, known as the fines, would cause the pores of cake to clog and deteriorate the sludge dewaterability. This was in accordance with the results of Lu et al. (2011) using enzymes conditioning to promote the sludge dewatering. After cellulase pretreatment, the addition of shorter fibers increased 3 to 6 percentage points in cake solids, leading to the porosity reduction of sludge cake. In addition, poor rigidity was bad for sludge dewatering to maintain the water channels (Ning et al. 2013; Wu et al. 2017). Zhang et al. (2020b) also found the optimum pulp fiber length in the paper sludge dewatering. Therefore, to avoid the fiber fibrillation and increase the fiber strength, a large amount of WPT can be crushed after setting the optimum fiber length in a disintegrator in practice.

FeCl3 dosage

The SRF showed the effect of FeCl3 dosage on sludge dewatering (Fig. 2b). The dewaterability of raw sludge was worse with SRF of 3.21 × 1012 m/kg. When the FeCl3 dosage increased to 120 g/kg DS, the sludge dewatering performance was enhanced significantly with SRF decreasing 80.1%.

A large amount of fine sludge particles will tend to clog the pores of the cake and result in the porosity reduction of the sludge solids in the dewatering process (Mowla et al. 2013; Wei et al. 2018), which will in turn lead to a poor dewaterability. After adding FeCl3, multivalent iron cations can adsorb to flocs surfaces, reduce the electrostatic repulsion between negatively charged particles, e.g., flocs and single cells, and then aggregate into larger flocs. The efficient water-solid separation will be achieved in combination with mechanical dewatering device (Wu et al. 2017). Hence, the SRF decreased significantly and reached a certain value with the increasing flocculant dosage (Wei et al. 2018).

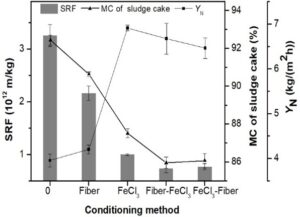

Sludge Dewaterability by the Combined Fiber-FeCl3 Conditioning

The effect of different conditioning methods on sludge dewaterability is presented in Fig. 3. The trends of SRF, MC of filtered cake, and YN were the same. The dewaterability of unconditioned sludge was worse with SRF of 3.26 × 1012 m/kg and MC of 92.4%. The combined conditioning of WPT fiber and FeCl3 enhanced the sludge filterability significantly. Additionally, it had the lowest SRF and MC of sludge cake that decreased 77.5% and 7%, respectively, while the highest YN increased 68.87% correspondingly. Figure 3 also indicates that fiber could get better sludge dewaterability only in combination with the flocculant. Therefore, under the same sludge dewaterability, physical conditioner can reduce the flocculant dosage to precondition the sludge sample (Zhu et al. 2018b; Guo et al. 2019).

Fig. 3. Effect of sludge conditioning on sludge dewaterability (sludge TSS of 6.91 g/L, 0.78 mm fiber dosage of 20% DS, FeCl3 dosage of 120 g/kg DS, pH of 7.0)

Several experiments were used to evaluate the effects of the adding order of FeCl3 and fiber on sludge dewaterability. Figure 3 showed that the order of addition had an insignificant influence on the SRF and YN. Compared with FeCl3-WPT fibers, the WPT fiber-FeCl3 resulted in a lower SRF (decreasing 4.52%) and a higher YN (increasing 3.31%), showing better dewaterability. When the sludge was conditioned by FeCl3 first, this reduced the opportunity to obtain a better structure between fiber and sludge particles. Moreover, the fiber could not be aggregated by FeCl3 and led to lower dewatering performance. Ning et al. (2013) observed that adding the TSIS before the polymer (CPAM) resulted in better sludge dewatering performance significantly, compared with the opposite order of addition.

Changes of Sludge Solids and Liquid with the Combined Fiber-FeCl3 Conditioning

Compressibility of sludge cake

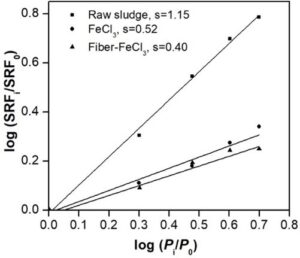

The sludge compressibility is one of the key properties to achieve solid-liquid separation effectively and then obtain the lower MC of sludge cake (Qi et al. 2011). Figure 4 presents the effects of fiber-FeCl3 conditioning on sludge compressibility. When the sludge sample was conditioned by FeCl3 alone, the cake compressibility remarkably declined from 1.15 in raw sludge to 0.52. After fiber-FeCl3 conditioning, it was reduced by 65.2% to 0.40. The addition of fibers would make incompressibility and permeability better in the filtered cake. Therefore, it was beneficial for sludge water removal through water channels formed by fibers.

In this study, the compressibility under fiber conditioning decreased 23.1%, which was similar to that of the study of Zhu et al. (2018a) (20.3%) and much more than that under biochar conditioning (11.9%) (Wu et al. 2017). Ning et al. (2013) found that the compressibility of TSIS-CPAM conditioning sludge was reduced 53.49% compared to that of flocculated sludge alone. The TSIS particles had irregular surfaces and more rigid lattice structures than the fibers, which could not easily deform. Meanwhile, the dosage of TSIS was 150% DS, which was higher than that in this study. Lastly, fiber was completely inert in the sludge dewatering, while the TSIS contained various metal cations that can occur the ion bridging and acid-base reaction with the sludge flocs, just like flocculant. Therefore, sludge incompressibility and dewaterability showed greater improvement.

Fig. 4. Effect of sludge conditioning on compressibility (sludge TSS of 6.91 g/L, 0.78 mm fiber dosage of 20% DS, FeCl3 dosage of 120 g/kg DS, pH of 7.0) (P0 is the basic filtration pressure and P0 = 0.01 MPa, Pi = 0.01, 0.02, 0.03, and 0.04 MPa)

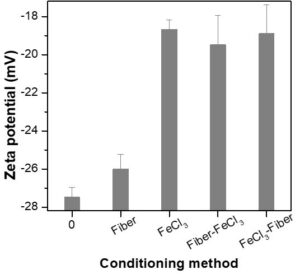

Zeta potential

The zeta potential is correlated with sludge dewatering (Liu et al. 2016). The zeta potential of the raw sludge was -27.5 mV, meaning that sludge flocs had a negative surface charge. Electrostatic repulsion existed between sludge particles and resulted in the relative stability of sludge system with poor dewatering (Qi et al. 2011). Figure 5 illustrates the zeta potential under different conditioning methods. After adding the flocculant, zeta potential increased to -18.8 mV, an increase of 32.0%. The ferric ion with positive charges in the flocculant could play the role of neutralization in the sludge system (Guo et al. 2019). The subsequent destabilization and aggregation happened between the sludge colloidal particles, leading to the increasing floc size and sludge dewatering performance (Xiao et al. 2017). However, the zeta potential of fiber conditioning sludge only increased 5.37% at the most compared with the raw sludge. Hence, it could be inferred that fibers did not exchange ions with the sludge flocs and did not influence the combination between sludge particles and water molecules.

Fig. 5. Effect of sludge conditioning on zeta potential (sludge TSS of 7.13 g/L, pH of 6.8, 0.78 mm fiber dosage of 20% DS, and FeCl3 dosage of 120 g/kg DS)

EPS content and FT-IR spectroscopic analysis

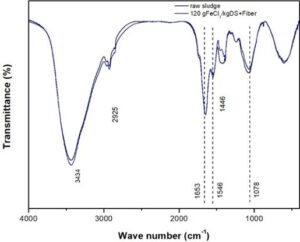

The transformation of EPS in sludge colloidal environment was very important to explain the mechanism of enhanced dewaterability. Figure 6 shows that when the sludge was conditioned by the combined fiber-FeCl3, PS contents increased insignificantly in S-EPS but decreased in LB-EPS and TB-EPS, while PN contents all decreased in S-EPS, LB-EPS, and TB-EPS, meaning that the total EPS extractabilities was reduced. The interaction between Fe3+ and EPS improved the strength of sludge floc, being consistent with the result of compressibility (Fig. 4). Higher floc strength resulted in the decrease of EPS extractability under centrifugal force and heating treatment. It was found that the factors of reducing PN concentration and increasing floc strength were important to improve sludge dewaterability (Zhang et al. 2020a). According to the FT-IR spectra (Fig. S2), after fiber-FeCl3 conditioning, the relative intensities of bands at 1653, 1546, and 1078 cm-1 remained unchanged. Considering the variation of zeta potential (Fig. 5), it can be deduced that the chemical reactions between FeCl3/fiber and EPS were not found. The biopolymer concentration was mostly influenced by the charge neutralization and complexation processes of FeCl3, leading to enhancing the sludge dewaterability finally.

Fig. 6. Biopolymers distribution and content in EPS (a) concentration of EPS components; (b) quantities of PN and PS

Microscopic structure

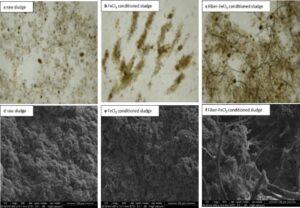

Figure S3 shows the photos of the sludge flocs structure before and after sludge conditioning. The raw sludge was compact without obvious pores or channels (Fig. S3a and S3d). When raw sludge was conditioned by FeCl3, the median sludge particle diameter increased 201.9%, because the sludge particles became unstable and flocculated into bigger sludge flocs through charge neutralization (Fig. S3b and S3e). As shown in Fig. S3c and S3f, the fiber was evenly distributed in the sludge flocs and the coarse surface, and the large pores and cracks were obviously observed. The fibers acted as skeletons between the flocs and formed the porous structure in the filtered cake (Nittami et al. 2015). Therefore, the pores and cracks produced by fiber would form many water removal channels and then the better cake incompressibility and permeability were obtained during sludge dewatering.

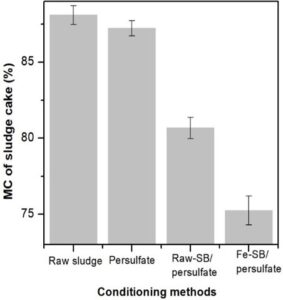

Preliminary Catalytic Ability Analysis of Fe-SB

To avoid a second pollution of exogenous fiber and find a proper disposal method of the huge number of Fe/fiber-rich sludge cake, the possibility of sludge biochar was tested as the persulfate catalyst. The effect of biochar/persulfate conditioning on sludge dewaterability is shown in Fig. 7. The sludge dewaterability was evaluated by MC of the sludge cake. The MC of raw sludge cake was 88.1%, indicating a poor dewaterability. Sludge conditioned with persulfate alone had an insignificant effect on the dewaterability, indicating the weak oxidation effect on sludge flocs. When the raw sludge biochar (Raw-SB) was combined with persulfate to pretreat sludge, MC decreased to 80.7%, a decrease of 8.4%. Furthermore, after the Fe-SB/persulfate conditioning, the MC of sludge cake decreased to 75.2% by 14.6%, showing a better dewaterability. It was demonstrated that Raw-SB could activate persulfate to degrade organic substances of sludge flocs as carbon-based functional materials (Thomas et al. 2008). Iron modified biochar could further increase the catalytic and activation capacity of persulfate to obtain the better sludge dewaterability (Wang et al. 2020). Homogeneous leached Fe2+ from Fe-SB resulted in more contribution on dewaterability, such that the dewaterability was reduced by 12.74% while that was reduced by 6.84% from heterogeneous iron bonded on biochar (Tao et al. 2019).

Fig. 7. Effect of biochar/persulfate on sludge dewaterability (sludge TSS of 7.13 g/L)

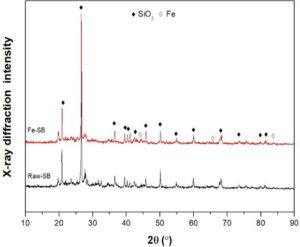

Fig. 8. The XRD spectra of Raw-SB and Fe-SB

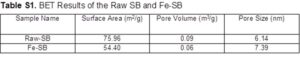

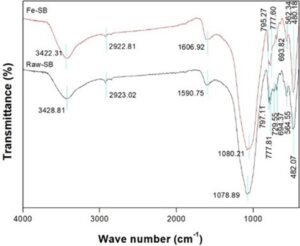

As shown in Table S1, the surface area of Raw-SB and Fe-SB were 76.0 m2/g and 54.4 m2/g, respectively. Iron could decrease the surface area and pore volume of Fe-SB because iron compounds might locate in the voids and block the passages (Chen et al. 2019). As presented in Fig. S4, the FT-IR spectra of Fe-SB showed similar peak information as Raw-SB, demonstrating that the combination fiber-FeCl3 conditioning would insignificantly change the surface functional groups of Fe-SB. However, the peak position of Fe-SB was slightly shifted, which was mainly caused by the iron-binding on the carbon surface. In addition, the fingerprint peak approximately 729 cm-1 disappeared in the Fe-SB, belonging to the C-H group on the carbon ring, which might be related to the higher iron content and carbon chain decomposition of Fe-SB (Tan et al. 2019). The XRD analyses of Raw-SB and Fe-SB are presented in Fig. 8. There were some obvious diffraction peaks for two biochar materials that were relevant to the SiO2 crystal. A new phase of zero-valent iron (44.673°, 65.021°, and 82.33°) appeared in the Fe-SB samples, which in turn resulted in the persulfate activation as the carbon-supported iron catalyst to improve sludge dewaterability.

DISCUSSION

In this study, sludge conditioned with WPT fiber and FeCl3 improved the sludge solid content, and thus sludge had lower SRF and higher YN than the sludge conditioned with FeCl3 alone. When sludge was conditioned with the WPT fiber and flocculant, the SEM images in Fig. S3 also revealed that voids and huge cracks lay in the cake to form the water drainage passage; the compressibility of the cake in Fig. 4 and the extractability of EPS in Fig. 6 decreased remarkably, but the FT-IR spectra in Fig. S2 almost remained unchanged. In Fig. 5, the zeta potential of fiber conditioning sludge was changed insignificantly, not like FeCl3 conditioning. In addition, the beating treatment of WPT fiber was bad for the fiber rigidity, and then sludge dewaterability decreased in Fig. 2a. Therefore, the improvement of sludge dewaterability was due to the more porous and incompressible structure in the filtered cake formed by fiber and flocculant, together with the rigidity of the fiber itself.

The preliminary catalysis experiment demonstrated in this study that the Fe-SB prepared by fiber-FeCl3 conditioning sludge cake could effectively activate persulfate to improve the sludge dewaterability, with MC of sludge cake decreasing 14.6%. Previous studies have illustrated that iron catalysts immobilized on carbonaceous materials could be one of the heterogeneous catalysts to activate persulfate for the production of hydroxyl and sulfate radicals, due to their superior biocompatibility, larger surface area, higher stability, and physicochemical properties (Xiao et al. 2020). Yu et al. (2019) synthesized a set of magnetic and nitrogenous supported biochar materials, which could degrade tetracycline efficiently with the larger surface area, compared with many other typical carbon catalysts, such as wood biochar and graphitic carbon, as a result of the synergistic effect of carbon, nitrogen, and iron species in which carbon worked with the electron transport medium. In addition, many studies showed that sludge biochar could enhance the incompressibility and permeability of filtered cakes, make water in the sludge easily removable, and then improve the sludge dewaterability. In a word, biochar played the role of the skeleton builder. To comprehend the activating mechanism of Fe-SB/persulfate, further experiment conditions must be tested in the future.

CONCLUSIONS

In this study, a novel waste recycling method was developed by using waste polyester textiles (WPT) as the skeleton builder and iron-containing sludge biochar (Fe-SB) as the heterogeneous catalyst of persulfate to improve sludge dewaterability. The combined fiber-FeCl3 conditioning significantly promoted the sludge dewaterability compared with conditioner alone, leading to the specific resistance to filtration decreasing 77.5%, the moisture content of sludge cake decreasing 7%, the filtration time decreasing 57.9%, and the net yield increasing 68.9%. The chemical reaction was not found between fibers and sludge flocs by the FT-IR spectrum and zeta potential analysis. The decrease of EPS contents were attributed to the more difficult extractability and bigger sludge floc strength. Hence, the enhancement of sludge dewaterability was primarily due to the sludge cake with a porous and low compressible structure formed by fiber and FeCl3, and the rigidity structure of fiber itself. The Fe-SB prepared by fiber-FeCl3 conditioning sludge cake could effectively activate persulfate to enhance the sludge dewaterability, with water content of dewatered sludge decreasing by 14.6%. This study presented a sludge recycling method that combined physicochemical conditioning and sludge biochar materials prepared by the pyrolysis process.

ACKNOWLEDGMENTS

This research was supported by grants from the Open Foundation of State Key Laboratory of Pulp and Paper Engineering at South China University of Technology (No. 202006), the Natural Science Foundation of Zhejiang Province in China (No. LY21C160004), the general research project of Education department in Zhejiang province (No. Y202044548), and the Priority Academic Program Development of Jiangsu Higher Education Institution (PAPD).

REFERENCES CITED

American Public Health Association (APHA) (2012). Standard Methods for the Examination of Water and Wastewater, 22nd Ed., American Public Health Association, Washington, D.C, USA.

Appels, L., Baeyens, J., Degrève, J., and Dewil, R. (2008). “Principles and potential of the anaerobic digestion of waste-activated sludge,” Progress in Energy and Combustion Science 34(6), 755-781. DOI: 10.1016/j.pecs.2008.06.002

Bolobajev, J., Kattel, E., Viisimaa, M., Goi, A., Trapido, M., Tenno, T., and Dulova, N. (2014). “Reuse of ferric sludge as an iron source for the Fenton-based process in wastewater treatment,” Chemical Engineering Journal 255, 8-13. DOI: 10.1016/j.cej.2014.06.018

Chen, Y., Bai, S., Li, R., Su, G., Duan, X., Wang, S., Ren, N., and Ho, S. (2019). “Magnetic biochar catalysts from anaerobic digested sludge: Production, application and environment impact,” Environment International 126, 302-308. DOI: 10.1016/j.envint.2019.02.032

Christensen, G. L., and Dick, R. I. (1985). “Specific resistance measurements: Methods and procedures,” Journal of Environmental Engineering 111(3), 258-271. DOI: 10.1061/(ASCE)0733-9372(1985)111:3(258)

Ding, A., Qu, F., Liang, H., Guo, S., Ren, Y., Xu, G., and Li, G. (2014). “Effect of adding wood chips on sewage sludge dewatering in a pilot-scale plate-and-frame filter press process,” RSC Advances 4(47), 24762-24768. DOI: 10.1039/c4ra03584d

Frølund, B., Griebe, T., and Nielsen, P. H. 1995). “Enzymatic activity in the activated-sludge floc matrix,” Applied Microbiology and Biotechnology 43(4), 755-761. DOI: 10.1007/BF00164784

Guo, S., Liang, H., Bai, L., Qu, F., Ding, A., Ji, B., Wang, X., and Li, G. (2019). “Synergistic effects of wheat straw powder and persulfate/Fe(II) on enhancing sludge dewaterability,” Chemosphere 215, 333-341. DOI: 10.1016/j.chemosphere.2018.10.008

Hadi, P., Xu, M., Ning, C., Sze, K., and McKay, G. (2015). “A critical review on preparation, characterization and utilization of sludge-derived activated carbons for wastewater treatment,” Chemical Engineering Journal 260, 895-906. DOI: 10.1016/j.cej.2014.08.088

Liang, J., Huang, J., Zhang, S., Yang, X., Huang, S., Zheng, L., Ye, M., and Sun, S. (2019). “A highly efficient conditioning process to improve sludge dewaterability by combining calcium hypochlorite oxidation, ferric coagulant re-flocculation, and walnut shell skeleton construction,” Chemical Engineering Journal 361, 1462-1478. DOI: 10.1016/j.cej.2018.10.143

Liu, J., Wei, Y., Li, K., Tong, J., Wang, Y., and Jia, R. (2016). “Microwave-acid pretreatment: A potential process for enhancing sludge dewaterability,” Water Research 90, 225-234. DOI: 10.1016/j.watres.2015.12.012

Lu, J., Rao, S., Le, T., Mora, S., and Banerjee, S. (2011). “Increasing cake solids of cellulosic sludge through enzyme-assisted dewatering,” Process Biochemistry 46(1), 353-357. DOI: 10.1016/j.procbio.2010.09.008

Luo, H., Ning, X., Liang, X., Feng, Y., and Liu, J. (2013). “Effects of sawdust-CPAM on textile dyeing sludge dewaterability and filter cake properties,” Bioresource Technology 139, 330-336. DOI: 10.1016/j.biortech.2013.04.035

Mowla, D., Tran, H. N., and Allen, D. G. (2013). “A review of the properties of biosludge and its relevance to enhanced dewatering processes,” Biomass & Bioenergy 58, 365-378. DOI: 10.1016/j.biombioe.2013.09.002

Ning, X., Luo, H., Liang, X., Lin, M., and Liang, X. (2013). “Effects of tannery sludge incineration slag pretreatment on sludge dewaterability,” Chemical Engineering Journal 221, 1-7. DOI: 10.1016/j.cej.2013.01.106

Nittami, T., Uematsu, K., Nabatame, R., Kondo, K., Takeda, M., and Matsumoto, K. (2015). “Effect of compressibility of synthetic fibers as conditioning materials on dewatering of activated sludge,” Chemical Engineering Journal 268, 86-91. DOI: 10.1016/j.cej.2015.01.032

Nzihou, A. (2010). “Waste and biomass valorization,” Waste and Biomass Valorization 1(1), 1-2. DOI: 10.1007/s12649-010-9013-y

Qi, Y., Thapa, K. B., and Hoadley, A. F. A. (2011). “Application of filtration aids for improving sludge dewatering properties – A review,” Chemical Engineering Journal 171(2), 373-384. DOI: 10.1016/j.cej.2011.04.060

Sen, M. K., and De, R. N. (1949). “Helical fibrillar arrangements in jute,” Nature 164(4172), 670. DOI: 10.1038/164670a0

Tao, S., Yang, J., Hou, H., Liang, S., Xiao, K., Qiu, J., Hu, J., Liu, B., Yu, W., and Deng, H. (2019). “Enhanced sludge dewatering via homogeneous and heterogeneous Fenton reactions initiated by Fe-rich biochar derived from sludge,” Chemical Engineering Journal 372, 966-977. DOI: 10.1016/j.cej.2019.05.002

TAPPI T233-95 (1995). “Fiber length of pulp by classification,” TAPPI Press, Atlanta, GA USA.

Thomas, A., Fischer, A., Goettmann, F., Antonietti, M., Müller, J., Schlögl, R., and Carlsson, J. M. (2008). “Graphitic carbon nitride materials: Variation of structure and morphology and their use as metal-free catalysts,” Journal of Materials Chemistry 18, 4893-4908. DOI: 10.1039/b800274f

Wang, H., Ma, Y., Wang, H., Hu, H., Yang, H., and Zeng, R. J. (2017). “Applying rheological analysis to better understand the mechanism of acid conditioning on activated sludge dewatering,” Water Research 122, 398-406. DOI: 10.1016/j.watres.2017.05.002

Wang, N., Zhang, W., Cao, B., Yang, P., Cui, F., and Wang, D. (2018). “Advanced anaerobic digested sludge dewaterability enhancement using sludge based activated carbon (SBAC) in combination with organic polymers,” Chemical Engineering Journal 350, 660-672. DOI: 10.1016/j.cej.2018.06.026

Wang, S., Liu, Y., and Wang, J. (2020). “Iron and sulfur co-doped graphite carbon nitride (FeOy/S-g-C3N4) for activating peroxymonosulfate to enhance sulfamethoxazole degradation,” Chemical Engineering Journal 382, Article ID 122836. DOI: 10.1016/j.cej.2019.122836

Wei, H., Gao, B., Ren, J., Li, A., and Yang, H. (2018). “Coagulation/flocculation in dewatering of sludge: A review,” Water Research 143, 608-631. DOI: 10.1016/j.watres.2018.07.029

Wu, C., Zhang, G., Zhang, P., and Chang, C. (2014). “Disintegration of excess activated sludge with potassium permanganate: Feasibility, mechanisms and parameter optimization,” Chemical Engineering Journal 240, 420-425. DOI: 10.1016/j.cej.2013.12.011

Wu, Y., Zhang, P., Zeng, G., Liu, J., Ye, J., Zhang, H., Fang, W., Li, Y., and Fang, Y. (2017). “Combined sludge conditioning of micro-disintegration, floc reconstruction and skeleton building (KMnO4 /FeCl3 /Biochar) for enhancement of waste activated sludge dewaterability,” Journal of the Taiwan Institute of Chemical Engineers 74, 121-128. DOI: 10.1016/j.jtice.2017.02.004

Xiao, K., Chen, Y., Jiang, X., Yang, Q., Seow, W. Y., Zhu, W., and Zhou, Y. (2017). “Variations in physical, chemical and biological properties in relation to sludge dewaterability under Fe (II) – Oxone conditioning,” Water Research 109, 13-23. DOI: 10.1016/j.watres.2016.11.034

Xiao, S., Cheng, M., Zhong, H., Liu, Z., Liu, Y., Yang, X., and Liang, Q. (2020). “Iron-mediated activation of persulfate and peroxymonosulfate in both homogeneous and heterogeneous ways: A review,” Chemical Engineering Journal 384, Article ID 123265. DOI: 10.1016/j.cej.2019.123265

Yang, J., Chen, S., and Li, H. (2018). “Dewatering sewage sludge by a combination of hydrogen peroxide, jute fiber wastes and cationic polyacrylamide,” International Biodeterioration & Biodegradation 128, 78-84. DOI: 10.1016/j.ibiod.2016.10.027

Yuan, Z., Xu, Z., Zhang, D., Chen, W., Huang, Y., Zhang, T., Tian, D., Deng, H., Zhou, Y., and Sun, Z. (2018). “Mesoporous activated carbons synthesized by pyrolysis of waste polyester textiles mixed with Mg-containing compounds and their Cr(VI) adsorption,” Colloids and Surfaces A: Physicochemical and Engineering Aspects 549, 86-93. DOI: 10.1016/j.colsurfa.2018.04.008

Yu, J., Tang, L., Pang, Y., Zeng, G., Wang, J., Deng, Y., Liu, Y., Feng, H., Chen, S., and Ren, X. (2019). “Magnetic nitrogen-doped sludge-derived biochar catalysts for persulfate activation: Internal electron transfer mechanism,” Chemical Engineering Journal 364, 146-159. DOI: 10.1016/j.cej.2019.01.163

Zhang, W., Tang, M., Yang, P., and Wang, D. (2020a). “Micro-interfacial mechanisms on sludge dewaterability enhancement using cerium chloride for preparation of carbon-based functional material,” Journal of Hazardous Materials 386, Article ID 121930. DOI: 10.1016/j.jhazmat.2019.121930

Zhang, W., Wu, J., Weng, L., Zhang, H., Zhang, J., and Wu, A. (2020b). “Understanding the role of cellulose fiber on the dewaterability of simulated pulp and paper mill sludge,” Science of The Total Environment 702, Article ID 134376. DOI: 10.1016/j.scitotenv.2019.134376

Zhang, X., Cai, H., Shen, J., and Zhang, H. (2018). “Effects of potassium permanganate conditioning on dewatering and rheological behavior of pulping activated sludge: Mechanism and feasibility,” RSC Advances 8(72), 41172-41180. DOI: 10.1039/c8ra07822j

Zhao, Y. Q., and Bache, D. H. (2001). “Conditioning of alum sludge with polymer and gypsum,” Colloids and Surfaces A: Physicochemical and Engineering Aspects 194(1-3), 213-220. DOI: 10.1016/S0927-7757(01)00788-9

Zhen, G., Lu, X., Li, Y., Zhao, Y., Wang, B., Song, Y., Chai, X., Niu, D., and Cao, X. (2012a). “Novel insights into enhanced dewaterability of waste activated sludge by Fe(II)-activated persulfate oxidation,” Bioresource Technology 119, 7-14. DOI: 10.1016/j.biortech.2012.05.115

Zhen, G., Lu, X., Wang, B., Zhao, Y., Chai, X., Niu, D., Zhao, A., Li, Y., Song, Y., and Cao, X. (2012b). “Synergetic pretreatment of waste activated sludge by Fe(II)-activated persulfate oxidation under mild temperature for enhanced dewaterability,” Bioresource Technology 124, 29-36. DOI: 10.1016/j.biortech.2012.08.039

Zhu, C., Li, F., Zhang, P., Ye, J., Lu, P., and Wang, H. (2018a). “Combined sludge conditioning with NaCl-cationic polyacrylamide-rice husk powders to improve sludge dewaterability,” Powder Technology 336, 191-198. DOI: 10.1016/j.powtec.2018.05.042

Zhu, C., Zhang, P., Wang, H., and Ye, J. (2018b). “Conditioning of sewage sludge via combined ultrasonication-flocculation-skeleton building to improve sludge dewaterability,” Ultrasonics Sonochemistry 40, 353-360. DOI: 10.1016/j.ultsonch.2017.07.028

Article submitted: December 2, 2020; Peer review completed: January 24, 2021; Revised version received and accepted: February 2, 2021; Published: February 3, 2021.

DOI: 10.15376/biores.16.2.2326-2345

SUPPLEMENTARY INFORMATION

Fig. S1. Fiber optical microphotographs of WPT fibers after fractionation and raw polyester fiber (10 × 10 times): a, b, c, and d at 30-, 50-, 100-, and 200-mesh screen, respectively; e and f show the fiber morphology of unbeaten WPT fiber and raw polyester fiber, respectively

Fig. S2. The FT-IR spectra of the raw sludge and conditioned sludge cake with FeCl3 and fiber

Fig. S3. (a through c) Sludge flocs tested by optical microscope (4 × 10 times); (d through f) sludge cake tested by SEM (400 times) (sludge TSS of 7.13 g/L, 0.78 mm fiber dosage of 20% DS, and FeCl3 dosage of 120 g/kg DS)

Fig. S4. The FT-IR spectra of the raw SB and Fe-SB