Abstract

A combined process consisting of an enzymatic pretreatment of small poplar wood chips, followed by an ultrasonic treatment was proposed and performed. Under the ultrasonic action of cavitation, thermal, and mechanical effects, the two processes of pulping and bleaching can be completed in one procedure. Before the ultrasonic treatment assisted pulping, an enzyme pretreatment was used to destroy the bonds between the cellulose, hemicellulose, and lignin to make the subsequent ultrasonic treatment exhibit higher selectivity and efficiency. This provided a poplar ultrasonic assisted pulp (PUP) with a 75% yield. A further analysis of the pulp, utilizing a scanning electron microscope (SEM), showed the fine fibrillation degree of the fiber surface of PUP was comparable to the traditional poplar chemimechanical pulp (PMP) and poplar chemical pulp (PCP). Thermogravimetric analysis and Raman analysis showed that the final residue obtained from the PUP was 20%. In addition, a decorative base paper was successfully made using the poplar ultrasonic pulp, and the physical properties reached or exceeded the industry standard of decorative base paper.

Download PDF

Full Article

Enzymatic Assisted Ultrasonic Pretreatment’s Effect on Poplar Pulp Properties

Qinqin Zhang,a Ming Xu,a,b Liyan Xing,a Chao Dang,a Xiaoshuai Han,a and Jun Wen Pu a,*

A combined process consisting of an enzymatic pretreatment of small poplar wood chips, followed by an ultrasonic treatment was proposed and performed. Under the ultrasonic action of cavitation, thermal, and mechanical effects, the two processes of pulping and bleaching can be completed in one procedure. Before the ultrasonic treatment assisted pulping, an enzyme pretreatment was used to destroy the bonds between the cellulose, hemicellulose, and lignin to make the subsequent ultrasonic treatment exhibit higher selectivity and efficiency. This provided a poplar ultrasonic assisted pulp (PUP) with a 75% yield. A further analysis of the pulp, utilizing a scanning electron microscope (SEM), showed the fine fibrillation degree of the fiber surface of PUP was comparable to the traditional poplar chemimechanical pulp (PMP) and poplar chemical pulp (PCP). Thermogravimetric analysis and Raman analysis showed that the final residue obtained from the PUP was 20%. In addition, a decorative base paper was successfully made using the poplar ultrasonic pulp, and the physical properties reached or exceeded the industry standard of decorative base paper.

Keywords: Enzymatic pretreatment; Ultrasonic; Fiber morphology; Thermal stability; Decorative base paper

Contact information: a: MOE Key Laboratory of Wooden Material Science and Application, Beijing Forestry University, Beijing, 100083, PR China; b: Beijing Institute of Zhongke Ultrasonic Technology, Chaoyang District, Beijing, 100000, P.R. China *Corresponding author: 2219227472@qq.com

INTRODUCTION

It is widely known that papermaking industries compete in markets where the added value of products is low, and in addition, margins for papermakers are becoming lower daily. Therefore, the paper industries are constantly pursuing technological developments, trying to balance efficiency and production costs (Li 2016).

The physicochemical properties of ultrasonic acoustics is the object state of mechanical vibration (or energy) spread in the transmission medium in the form of ultrasonic soundwaves. Ultrasonic refers to having at least a frequency of at least 20 KHz, which means that the particle vibration per second is greater than 20,000 times beyond the general auditory frequency limit (16 KHz). The consequences of ultrasonic vibrations in the liquid include mechanical, thermal, and cavitation effects.

Considering the high energy and water requirements for conventional pulping of wood, different methods have been explored (Mander et al. 2013; Lei et al. 2013). Ultrasonic techniques have had wide application (O’Sullivan et al. 2016) and have shown broad application prospects in the pulp and papermaking industry. The applications of this technology in the process of pulping (Hesley et al. 1956; Subhedar and Gogate 2014) include, beating preparation of nanocrystalline cellulose (Li et al. 2011), carboxymethyl cellulose (Hivechi et al. 2015), and treatment of recycled fiber (Tatsumi et al. 2000; Subhedar et al. 2015) have been well documented.

It has been proposed that the ultrasound-assisted reactions in aqueous solutions involve free-radical mechanisms because of the formation of hydroxyl radicals (HO·) with oxidation capabilities (Weissler 1959, 1962; Anbar and Pecht 1964; Reifsneider and Spurlock 1973; Mead et al. 1975; McKee et al. 1977). These proposals of free-radical formation have been confirmed via spin-trapping techniques (Makino et al. 1982, 1983)

Enzymatic treatments have gained recognition in the pulp and papermaking industry because they are stereo specific, nontoxic, environment friendly, and energy conserving alternatives (Madhu and Chakraborty 2017). Cellulase can be a safer alternative to the toxic chlorinated compounds used in the bleaching of pulp (Li et al. 2010; Goluguri et al. 2012; Woldesenbet et al. 2012). Cellulase pretreatment also can improve the efficiency of the chemical extraction of lignin from pulp and minimize the requirement of chlorine dioxide (ClO2) (hazardous chemical) (Damiano et al. 2003; Ayyachamy and Vatsala 2007). These enzymatic treatments provide a promising tool for the selective removal of hemicellulose as well as the precise adjustment of the pulp intrinsic viscosity due to hydrolytic cleavage of the cellulose macromolecules (Hutterer et al. 2017)

In this study, the authors created a new pulping process, cellulase pretreatment assisted by ultrasonication. Analysis showed that the PUP fibers had better performance. The morphology and properties of PUP fibers were studied through scanning electron microscopy (SEM), thermogravimetric analysis, Fourier transform infrared (FT-IR) spectral analysis, Raman analysis, and handsheets properties testing.

EXPERIMENTAL

Materials

Poplar chemical pulp (PUP) pulped by an alkaline anthraquinone (AQ) process and poplar chemimechanical pulp (PMP) was supplied by Henglian Co., Ltd. (Shandong, China). Poplar wood chips were supplied by Beijing Institute of Zhongke Ultrasonic Technology (Beijing, China). Cationic polyacrylamide (CPAM) (molecular weight of 8 million g/mol, charge density of 2.47 mmol/g), alkyl ketene dimmer (AKD), titanium dioxide (TiO2), xylanase enzymes, xylose, ammonia, sodium dodecyl sulfonate, and magnesium sulfate were supplied by Kebaiao Chemical Co., Ltd. (Beijing, China). All of the solvents and chemicals used in this study are commercially available in the market and were used directly without further purification.

Methods

In order to get PUP, the poplar wood chips were first cut into small pieces with lengths of approximately 1 cm to 3 cm and then pulped in a covered 5-L ultrasonic reactor (Beijing Institute of Zhongke Ultrasonic Technology, Beijing, China) (Self-products) after a bio-treatment. The bio-treatment was conducted using xylanase enzymes with an added amount of 90 IU/g in a water bath shaker at 45°C for 4 h (Sunson, Beijing, China). Then, the ultrasonic reaction was performed at a mass concentration of 8% for 2 h and an ultrasonic frequency of 18 kHz, at room temperature and pressure under constant stirring. The temperature rose to 90 °C, and ammonia (6%), sodium dodecyl sulfonate (0.2%), and magnesium sulfate (1%) were added. All of the amounts of solvents and chemicals used in this study were based on dry mass relative to wood material. The PUP with a Kappa number of 11.2 were measured according to ISO standard (GB/T 1546 (2004)) with good yield values of approximately 75%.

Xylanase activity was measured by the DNS method (Li et al. 2001), and the xylanase activity was calculated based on the equation:

in which P refers to the xylanase activity (U/g); r is the xylose concentration (μg/mL); the relative molecular weight of xylose was 150.14 g/mol; t is the reaction time (min); and D is the dilution factor.

SEM analysis

The fiber of different pulps were sprayed with gold and used for SEM analysis. A US 8020 model (Hitachi, Kyoto, Japan) scanning electron microscope was used to observe the samples. The samples containing the prepared transverse and radial faces were mounted on aluminum stubs with conductive adhesive tape. The working conditions were as follows: working distance of 20 mm, accelerating voltage of 1 kV, and an illuminating current of 0.7 nA. At least five different fibers from the same sample were scanned several times, and the replicated images were chosen and presented.

FT-IR measurements

The FTIR analysis was performed using a Tensor 27 (Bruker, Shanghai, China). And 1.0 g of samples was mixed with 100 mg of kBr. The scanning range used was 4000 to 400cm-1, with a resolution of 2 cm-1, and a total accumulation of 32 scans.

Thermal gravimetric analysis (TGA)

The thermal stabilities of the samples were measured using a thermogravimetric analyzer (DTG-60, Shimadzu, Japan) and heated from 10 °C to 800 °C at a rate of 10 °C/ min-1 in nitrogen atmosphere.

Raman spectroscopy

Raman spectra were collected from 500 cm-1 to 2000 cm-1 using a micro-Raman spectrometer, Jobin Yvon LabRam 300 (Jobin Yvon, Beijing, China) with an excitation wavelength of 633 nm.

Handsheet preparation and measurements

The ultrasonic assisted poplar pulp and poplar chemical pulp was beat to 38°SR using a KRK semi-auto beating machine (Kyoto, Japan) with a pulp content of 1.57% for 30 min, respectively. This was mixed according to the ultrasonic assisted poplar pulp: poplar chemical pulp mixing ratio, which was 3:7.TiO2 filler was used to improve the opacity of decorative base paper, and the amount was 32% based on the oven dried weight pulp. A total of 0.25% of AKD sizing agent (as the solid mass of the AKD emulsion) and 0.3% of CPAM (0.1% water solution) was added. All of the chemical dosages were as solid mass percentages based on pulp fibers. Laboratory paper sheets (handsheets) were formed with a sheet former and than cured for 2 h at 105 °C. At least five strips of each handsheet were tested, and all the data presented was the average of these tests.

Each handsheet was cut into 15 cm wide strips before testing. The tensile properties were studied by using a Lloyd instruments universal testing machine (Ametek, LRX, Shanghai, China). The water content, ash content, permeability, and expansion ratio were measured according to ISO standards (GB/T 462 (2003), GB/T 742 (2003), GB/T 24989 (2010), and GB/T 459 (2002). Handsheets were made using a KRK laboratory handsheet former (Kyoto, Japan).

RESULTS AND DISCUSSION

Bio-treatment Analysis

According to Fig. 1 and Table 1, the xylanase showed the highest activity at pH =8.

Fig. 1. Xylose standard curve

Table 1. Xylanase Enzyme Activity with Different pH

Figure 2 shows the surface morphology of fiber treated with the xylanase showed more smoother than the original fiber, and a small amount of holes appeared on the fibers, and xylanase can degrade xylan and LCC, which was beneficial to the removal of lignin. The poly pentose content of xylanase treatment pulp decreased from 12.93% to 7.69%, which means that the dissolution of the hemicellulose, and the enzyme acts by degrading hemicellulose in the fiber, making the fiber cell wall loose and allowing lignin to be extracted easily (Wen 2012). The gap between cellulose and lignin provides the position for subsequent ultrasound action.

Fig. 2. SEM images of Fiber treated with xylanase

Results for the content of xylose polymers and oligomers (poly-pentose) are shown in Table 2.

Table 2. Poly-pentose Content after Xylanase Pretreatment

SEM Analysis

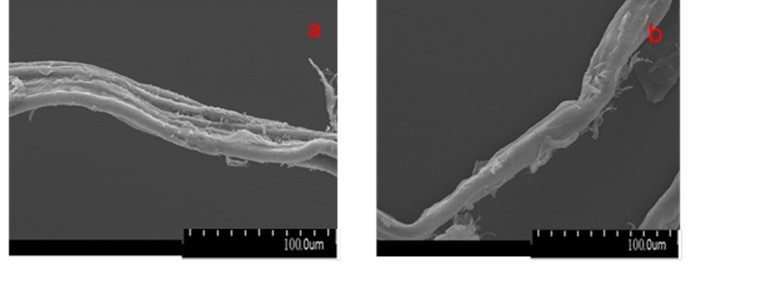

The fibrillation of PUP fiber (Fig. 3a) was more obvious than the others (Fig. 3b, c), which may be attributed to the strong mechanical effect of ultrasound on the cell walls. The fibrillation makes the cell wall structure accessible for further chemical reactions (Levente et al. 2008). Ultrasound-assisted pulping method finished the pulping and bleaching process in one procedure, such that the PCP and PUP pulps had approximately the same appearance (Fig. 3d).

Fig. 3(a & b). SEM images of a) PUP; b) PMP c) PCP; and d) 1:PCP 2: PUP

Fig. 3(c & d). SEM images of a) PUP; b) PMP c) PCP; and d) 1:PCP 2: PUP

Fig. 4. FT-IR spectra of PCP (a) and PUP (b)

FT-IR Spectral Analysis

For PUP, a strong band at 1450 cm-1 was attributed to C=C in the benzene skeleton vibration in the spectra of poplar ultrasonic pulp (Fig. 4). These results were consistent with the previous FT-IR spectral studies of poplar pulp shown by Ma et al. (2012). However, there was also a strong absorption band at 1504 cm-1 and 1465 cm-1 for the stretching vibrations of the benzene skeleton vibration, which may have been related to the thermal, mechanical and cavitation effect, and thus further analysis was performed.

TGA Analysis

As shown in Fig. 5, a small amount of mass was lost in both samples during heating up to 100 °C, and this was attributed to the evaporation of water. The extent of degradation of PUP and PCP after heating to 800 °C was 80% and 88%, respectively, and there may have been thermal degradation of organic molecules that contained H and C. And the final residue obtained from the PCP and PUP was 12% and 20%, so, the residues of PUP were obviously more than those of PCP. Then Raman spectroscopy technology was used to further explore the heat resistance performance.

Fig. 5. The TGA and DrTGA curves of PCP, and PU

Raman Analysis

As shown in Fig. 6, the Raman spectrum of ultrasonic assisted poplar pulp ash revealed that although the fluorescence background signal was very strong, a relatively strong D-band at 1315.11 cm-1 and a G-band at 1518.15 cm-1 were observed. In addition, the ratio of intensities of ID/IG was 1.07. This indicated the presence of more defects or amorphous carbon as compared with sp2 hybridization in the ash, similar to the graphite character, which was attributed to highly disordered carbon atoms. The authors infer that a graphite-like material may be produced, but further research will be needed to determine the exact composition of the detected presence.

Fig. 6. Raman spectrum of ultrasonic assisted poplar pulp

Application in the Making of Decorative Base Paper

The above analysis focused on the new technology of enzymatic assisted ultrasonic poplar pulp, but using this new application, a successful preparation of decorative base paper that adhered to the complex requirements of the national standard was created. As shown in Table 3, the new technology of pulp processing had great prospects for development in multiple applications.

Table 3. Properties of Decorative Base Paper

Notes: Reference: The industry standard of decorative paper for wood-based panels (LY/T 1831(2009))’

CONCLUSIONS

- The enzymatic pretreatment of poplar chips increased selectivity for the subsequent ultrasonic treatment, the pulp yield reached approximately 75%.

- The residual amount of PUP was 20% after heating to 800°C. It was possible to produce a graphite-like material with good heat resistance by FT-IR and Raman analysis.

- The decorative base paper was made successfully with PUP and all kinds of parameters reached or exceeded the industry standard.

ACKNOWLEDGEMENTS

This work was sponsored by the Special Fund for Beijing Common Construction Project and Beijing Forestry University, Grant No. 2016HXKFCLXY0016.

REFERENCES CITED

Anbar, M., and Pecht, I. (1964). “On the sonochemical formation of hydrogen peroxide in water,” The Journal of Chemistry 68(2), 352-355. DOI: 10.1021/j100784a025

Ayyachamy, M., and Vatsala, T. M. (2007). “Production and partial characterization of cellulase free xylanase by Bacillus subtilis C01 using agri-residues and its application in biobleaching of nonwoody plant pulps,” Letters in Applied Microbiology 45, 467-472. DOI: 10.1111/j.1472-765X.2007.02223.x

Damiano, V. B., Bocchini, D. A., Gomes, E., and da, Silva. R. (2003). “Application of crude xylanase from Bacillus licheniformis 77-2 to the bleaching of eucalyptus kraft pulp,” World Journal of Microbiology and Biotechnology19, 139-144. DOI: 10.1016/j.ijbiomac.2017.01.054

GB/T 459 (2002). “Paper and board – Determination of dimensional instability,” Standardization Administration of China, Beijing, China.

GB/T 462 (2003). “Paper and board-Determination of moisture content,” Standardization Administration of China, Beijing, China.

GB/T 742 (2003). “Paper, board and pulp-Determination of residue (ash) on ignition at 900°C,” Standardization Administration of China, Beijing, China.

GB/T 1546 (2004). “Pulps-determination of Kappa number,” Standardization Administration of China, Beijing, China.

GB/T 24989 (2010). “Decorative base paper,” Standardization Administration of China, Beijing, China.

Goluguri, B. R., Thulluri, C., Cherupally, M., Nidadavolu, N., Achuthananda, D., Mangamuri, L. N., and Addepally, U. (2012). “Potential of thermo and alkali stable xylanases from Thielaviopsisbasicola (MTCC-1467) in biobleaching of wood kraft pulp,” Applied Biochemistry and Biotechnology 167, 2369-2380. DOI: 10.1007/s12010-012-9765-x

Hivechi, A., Bahrami, S. H., Arami, M., and Karimi, A. (2015). “Ultrasonic mediated production of carboxymethyl cellulose: Optimization of conditions using response surface methodology,” Carbohydrate Polymers 134, 278-284. DOI: http://dx.doi.org/doi:10.1016/j.carbpol.2015.07.045

Hivechi, A., Bahrami, S. H., Arami, M., and Karimi. (2015) “Ultrasonic mediated production of carboxymethyl cellulose: Optimization of conditions using response surface methodology,” Carbohydrate Polymers 134, 278-284. DOI: 10.1016/j.carbpol.2015.07.045

Hesley, H. J., Patterson, S. S., and Van Huysen, G. (1956). “Pulp reaction to ultrasonic Cavity preparation; Preliminary report,” United States Armed Forces Medical Journal 7(5), 685.

Hutterer, C., Kliba, G, and Punz, M. (2017). “Enzymatic pulp upgrade for producing high-value cellulose out of a Kraft paper pulp,” Enzyme & Microbial Technology. DOI: 10.1016/j.enzmictec.2017.03.014

Ju, T., Achenbach, J. D., Jacobs, L. J., Guimaraes, M., and Qu, J. (2017). “Ultrasonic nondestructive evaluation of alkali–silica reaction damage in concrete prism samples,” Materials and Structures 50(1), 60. DOI: 10.1617/s11527-016-0869-6

Lei, M., Zhang, H. J., Li, J. G., and Duan, J. L. (2013). “Characteristics of poplar preconditioning followed by refining chemical treatment alkaline peroxide mechanical pulp fiber fractions and their effects on formation and properties of high-yield pulp containing paper,” Ind. Eng. Chem. Res 52 (11), 4083-4088. DOI: 10.1021/ie3024356

Levente, C., Attila, L., and Andras, W. (2008). “Sonochemically modified wheat straw for pulp and papermaking to increase its economical performance and reduce environmental issues,” BioResources 3(1), 91-97.

Li, X., She, Y., Sun, B., Song, H., Zhu, Y., Lv, Y., and Song, H. (2010). “Purification and characterization of a cellulase-free, thermostable xylanase from Streptomyces rameus L2001 and its biobleaching effect on wheat straw pulp,” Biochemical Engineering 52(1), 71-78. DOI: 10.1016/j.bej.2010.07.006

Li, W., Wang, R., and Liu, S. (2011). “Nanocrystalline cellulose prepared from softwood kraft pulp via ultrasonic-assisted acid hydrolysis,” BioResources 6(4), 4271-4281. DOI: 10.15376/biores.6.4.4271-4281

Li, W., Wang. R., and Liu, S. (2011). “Catalytic graphitization of hardwood acetic acid lignin with nickel acetate,” Journal of Wood Science 49(2), 188-192. DOI: 10.1007/s100860300030

Li, Y. (2016). “Detailed analysis of the UV-adjustment techniques used in paper and graphic industries,” Color Research & Application 35(9), 1-8.

Madhu, A., and Chakraborty, D. J. N. (2017). “Developments in application of enzymes for textile processing,” Journal of Cleaner Production 145, 114-133.

McKee, J. R., Christman, C. L., O’Brien Jr., W. D., and Wang, S. Y. (1977). “Effects of ultrasound on nucleic acid bases,” Biochemistry 16(21), 4651-4654. DOI: 10.1021/bi00640a019

Mead, E. L., Sutherland, R. G., and Verrall, R. E. (1975). “The ultrasonic degradation of thymine,” Canadian Journal of Chemistry 53(16), 2394-2399. DOI: 10.1139/v75-338

Makino, K., Mossoba, M. M., and Risez, P. (1982). “Chemical effects of ultrasound on aqueous solutions. Evidence for hydroxyl and hydrogen free radicals (·OH and ·H) by spin trapping,” Journal of the American Chemical Society 104(12), 3537-3539. DOI: 10.1021/ja00376a064

Makino, K., Mossoba, M. M., and Risez, P. (1983). “Formation of OH and H in aqueous solutions by ultrasound using clinical equipment,” Radiation Research 96(2), 416-421. DOI: 10.1021/ja00376a064

Reifsneider, S. B., and Sperlock, L. A. (1973). “Chemistry of ultrasound. II. Irradiative behavior of aliphatic aldehydes and carboxylic acids in an aqueous medium,” Journal of the American Chemical Society 95(2), 299-305. DOI: 10.1021/ja00783a001

Subhedar, P. B., and Gogate, P. R. (2014). “Alkaline and ultrasound assisted alkaline pretreatment for intensification of delignification process from sustainable raw-material,”Ultrasonics Sonochemistry 21(1), 216-225. DOI: 10.1016/j.ultsonch.2013.08.001

Subhedar, P. B., Babu, N. R., and Gogate, P. R. (2015). “Intensification of enzymatic hydrolysis of waste newspaper using ultrasound for fermentable sugar production,” Ultrasonics Sonochemistry 22, 326-332. DOI: 10.1016/j.ultsonch.2014.07.005

Tatsumi, D., Higashihara, T., Kawamura, S. Y., and Matsumoto, T. (2000). “Ultrasonic treatment to improve the quality of recycled pulp fiber,” Journal of Wood Science 46(5), 405-409. DOI: 10.1007/BF00776405

Weissler, A. (1959). “Formation of hydrogen peroxide by ultrasonic waves: Free radicals,” Journal of American Chemical Society 81(5), 1077-1081. DOI: 10.1021/ja01514a015

Weissler, A. (1962). “Ultrasonic hydroxylation in a fluorescence analysis for microgram quantities of benzoic acid,” Nature 193, 1070. DOI: 10.1038/1931070a0

Wen, X. L. (2012). “Advances in the application of biotechnology in pulping and bleaching processes,” Heilongjiang Papermaking 35 (1), 20-23.

Woldesenbet, F., Virk, A. P., Gupta, N., and Sharma, P. (2012). “Effect of microwave irradiation on xylanase production from wheat bran and biobleaching of eucalyptus kraft pulp,” Applied Biochemistry and Biotechnology 167, 100-108. DOI: 10.1007/s12010-012-9663-2

Article submitted: May 2, 2017; July 7, 2017; Revised version received: July 22, 2017; Accepted: July 23, 2017; Published: August 1, 2017.

DOI: 10.15376/biores.12.3.6832-6843