Abstract

Veneers are used as overlaying material for various types of composite substrates for the production of veneered panels and furniture. There is a strong correlation between color and quality for the acceptability of a product, which is currently an industrial preoccupation. The aim of the present study was to evaluate the color variability of veneers produced from high-quality European oak logs exhibiting the best production yield. Defect-free logs cut from a Quercus spp. forest in Romania were sliced into veneers. Color measurements were made at various locations on veneer sheets. All data were statistically analyzed. As expected, heartwood highly influenced the final color of decorative oak veneers, in which yellow and red were highlighted. The statistical analysis also revealed the homogeneity of lightness and yellow degree within the veneer collectivity. The color homogeneity within the sectors confirmed the wood quality for veneer production. Therefore, individual veneer sheets can be segregated based on color measurement to provide accurate results for sorting pieces of different colors.

Download PDF

Full Article

Evaluation of Color Variability of Oak Veneers for Sorting

Elena-Camelia Musat,a Emilia-Adela Salca,b,* Florin Dinulica,a Valentina D. Ciobanu,a and Adela-Eliza Dumitrascu c

Veneers are used as overlaying material for various types of composite substrates for the production of veneered panels and furniture. There is a strong correlation between color and quality for the acceptability of a product, which is currently an industrial preoccupation. The aim of the present study was to evaluate the color variability of veneers produced from high-quality European oak logs exhibiting the best production yield. Defect-free logs cut from a Quercus spp. forest in Romania were sliced into veneers. Color measurements were made at various locations on veneer sheets. All data were statistically analyzed. As expected, heartwood highly influenced the final color of decorative oak veneers, in which yellow and red were highlighted. The statistical analysis also revealed the homogeneity of lightness and yellow degree within the veneer collectivity. The color homogeneity within the sectors confirmed the wood quality for veneer production. Therefore, individual veneer sheets can be segregated based on color measurement to provide accurate results for sorting pieces of different colors.

Keywords: Decorative veneer; Oak; Wood Grading; Chromatic System; Slicing Yield

Contact information: a: Department of Silviculture and Forest Engineering, Transilvania University of Brasov, Sirul Beethoven 1, 500123, Brasov, Romania; b: Faculty of Wood Engineering, Transilvania University of Brasov, Universitatii 1, 500068, Brasov, Romania; c: Faculty of Technological Engineering and Industrial Management, Transilvania University of Brasov, Mihai Viteazul 5, 500174, Brasov, Romania; *Corresponding author: emilia.salca@unitbv.ro

INTRODUCTION

Wood presents extraordinary properties and can be considered an advanced natural polymer composite consisting of cellulose, hemicelluloses, lignin, and extractives (Walinder 2006). At first glance, color, gloss, and texture are easily observed both on raw and processed wood surfaces. The largest variations in wood color are associated with the extractives content of wood (Moya and Berrocal 2010; Gierlinger et al. 2004). The natural color of wood can be changed by biological alteration, boiling, steaming, heating, drying, chemical treatments, or by exposing it to sun rays (Kreber 1994; Nemeth et al. 2013).

According to Wiedenbeck et al. (2003), color can establish the commercial value of a given product. Moreover, color has been found to be very useful in detecting defects in wood (Brunner et al. 1990). The beauty of natural solid wood for cabinets can be successfully replaced by decorative natural veneers, which help maximize the use of rare and valuable timbers in furniture manufacturing (Ozarska 2003).

Most hardwood species can be cut into veneer. This is due to their lower lignin content, making them more thermoplastic than softwood (Lutz 1977). Hardwood veneer is therefore preferred for furniture production.

There is an extensive amount of literature concerning the color of wood. Wood discoloration can vary with genetic, environmental, or treatment conditions (Venet and Keller 1986; Hon and Shiraishi 1991; Klumpers et al. 1993; Mosedale et al. 1996). According to Janin (1987) and Zanetti et al. (2003), lightness is a very important criterion for oak wood grades; clear and bright wood is mostly appreciated. A negative correlation between wood lightness and sapwood width was found by Hoffmann (1987).

Mazet et al. (1993) showed significant differences between the sapwood and heartwood of sessile oak and European oak regarding their photochemical behavior. The abundant amount of extractives in heartwood, such as ellagitannins, explains such behavior (Scalbert et al. 1987; Stich and Ebermann 1987). With vacuum drying, as an alternative drying method, it is possible to limit oak surface oxidation (Sandoval-Torres et al. 2010). Wood dried in a conventional dry kiln was not as bright as wood dried at a lower temperature in a vacuum, and reddish and blue stains also appeared (Resch et al. 2000).

Oak wood and veneer are well known to produce grey or black iron tannin stains, which can easily be removed with oxalic acid or by planing (Kreber 1994). Hydrothermal treatment may also be used to enhance wood properties and to achieve a more uniform color. A combined effect of steaming and heating at low temperature has been applied to modify the surface color of Turkey oak (Ferrari et al. 2013; Todaro et al. 2013).

There is a strong correlation between color and quality for the acceptability of a product, which is currently an industrial preoccupation. Color is an essential quality parameter for wooden products with a direct impact on their final value. Accurate colorimetric methods are currently used in industry to avoid the subjective visual evaluation of a product color.

Yield in veneer production represents one of the most important and efficient criteria to assess a company activity (Mitisor and Istrate 1982). Its rate depends on the manufacturing technology, the quality of raw material, and the product to be obtained (Morosanu 2011; Dumitrascu et al. 2013).

The losses in veneer production at different stages vary with log quality and diameter. The highest rate of green and clipper losses, approximately 22%, was found during peeling of Douglas-fir (Lutz 1977). Recovery rates higher than those for sawmilling were achieved for Eucalypt species by spindle-less lathe technology when green and gross recoveries of 68% to 77% and 54% to 65% were obtained (McGavin et al. 2014). Therefore favorable veneer recovery rates are to be obtained in addition to the best veneer quality.

Decorative veneers are produced in Romania using home-grown softwood and hardwood species such as silver fir, larch, oak, maple, walnut, cherry, pear, alder, ash, elm, and beech. Out of these species, European oak is considered the most valuable wood species. Out of 15,195,000 m3 volume of round wood, a total of 30,000 m3 of oak was used in Romania for the production of decorative veneers (I.N.S. 2013). In Romania, the wood of oak for decorative veneers is not in mass production, and the attentive tree identification is imposed. Sometimes trees can be up to 120 years old, and they can appear in different rates within a tree population.

The aim of the present study was to evaluate the color variability of veneers produced from high-quality European oak logs exhibiting the best production yield. These aspects are less known in our country and they do not appear in the specialty literature, but they represent a start point which is needed for the quality sorting of raw material in furniture manufacturing and panel products industry.

EXPERIMENTAL

Materials

Eight oak (Quercus robur) defect-free logs were selected for this study from a large group of oak logs cut from a Quercus spp. forest located in the Snagov region of Romania. They were all Q-A graded (sapwood width ≤ 3 cm) according to SR EN 1316-1 (2001) for further use in veneer production.

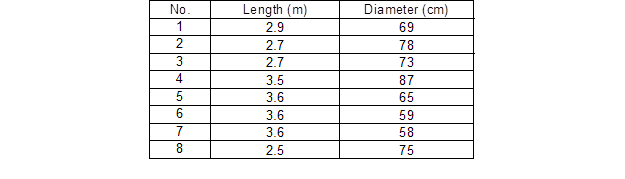

Their characteristics are presented in Table 1.

Table 1. Characterization of Oak Logs

Methods

The logs were debarked and were cut into flitches. Prior to veneer cutting, they were hydrothermally treated in hot water at 80 to 90 °C for 20 h. Logs were sliced into veneer sheets 0.55 mm thick. All veneer sheets were dried in three temperature steps: 100, 120, and 132 °C, in a GRENZEBACH dryer of GRENZEBACH BSH GmbH, Germany. The time of veneer drying of about 2 minutes was set according to the recommendations from specialty literature for such wood species and veneer thickness (Mitisor and Istrate 1982). The veneer final moisture content was approximately 12.6%.

Determination of yield

Investigations of yield were performed considering the production losses for each step in veneer production: grading, sectioning, preparation, topping, cutting, drying, and trimming. The yield was determined based on total losses in veneer production with the following equation,

![]()

in which p is the sum of losses from each processing step.

Color measurement

The veneer sheets from the two logs that exhibited the best veneer yield and having the most reduced losses in production were selected. A total of 39 veneer sheets were subjected to color measurement by employing a Chroma Meter CR-400 device of Konika Minolta Inc., Japan. Following ISO 7724-2 (1984), 165 color measurements were made at various locations on veneer sheets. A database with statistical layered data classified according to each log number, the position within the log cross section (set through three variants: inner, middle, and outer third of log ray), the position of the sample as a function of sapwood and heartwood, and the veneer sample number was created. All data were processed using STATISTICA 7.0 (StatSoft). The Shapiro-Wilk test and the Kruskal-Wallis test were used for statistical analysis.

The color was evaluated with the CIELab chromatic system, which operates with the following parameters: lightness (L*), redness degree (a*), and yellowness degree (b*).

RESULTS AND DISCUSSION

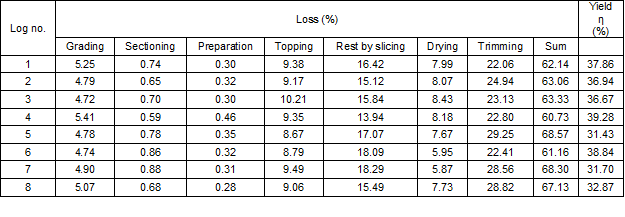

To estimate the yield of decorative veneers, the losses from each processing step of the technological flow were considered. They are presented in Table 2.

Table 2. Losses and Yield during Oak Veneer Production

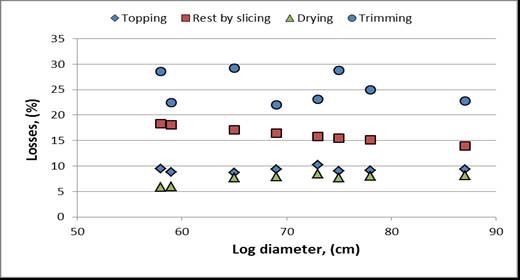

Production practice has established that the production yield of sliced veneers presents low values when compared to the rotary-cutting process. This is caused by losses when sawing the flitch and during trimming straight edges of sliced veneers. Figure 1 presents the variability of the most important losses as a function of log diameter.

Fig. 1. Losses during sliced veneer production as function of log diameter

Similar results for losses and yield were found in the literature. Total losses of 63.64% were determined for decorative veneers sliced from beech logs by Mitisor and Istrate (1982).

Two out of the eight logs cut into veneers, having diameters of 59 and 87 cm, presented the best yield and were selected for further color measurement.

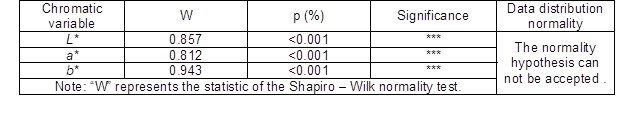

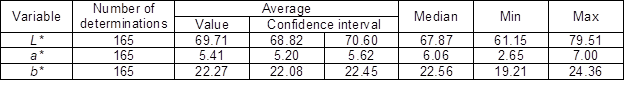

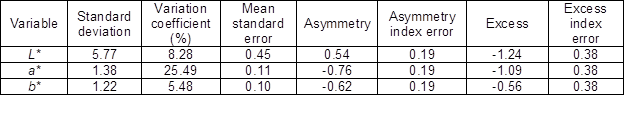

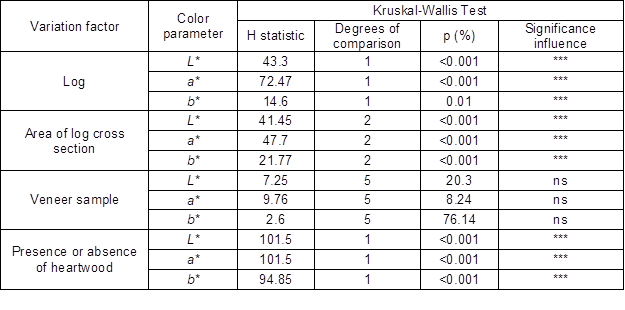

The measurements performed on veneers led to a raw database layered by log identification, the place within its cross section, and the sheet identification number. The data were statistically processed, and the indices of experimental distributions of chromaticity parameters were examined. Table 3 presents the validation of the statistical model.

Table 3. Verification of the Experimental Distribution Normality of the Chromatic Variables

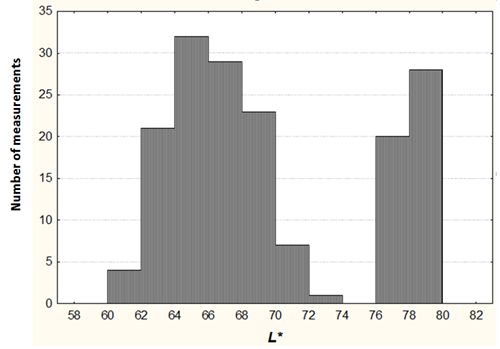

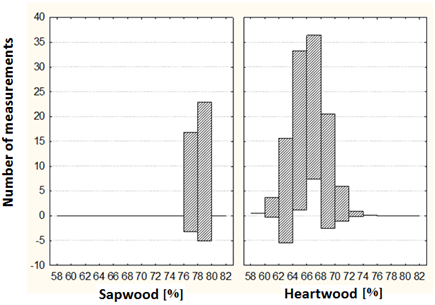

The chromaticity parameters did not follow a normal distribution. Therefore, as a result, their processing received a non-parametric handling. The experimental distribution of lightness degree showed a bi-modular character, having maximum values at 64 to 66 and 78 to 80, respectively (Fig. 2). This denoted the great color segregation under the heartwood influence.

Fig. 2. Histogram of lightness degree for oak veneers

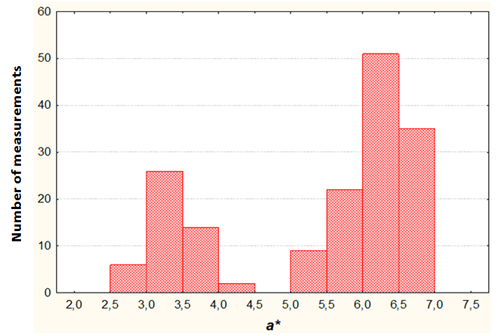

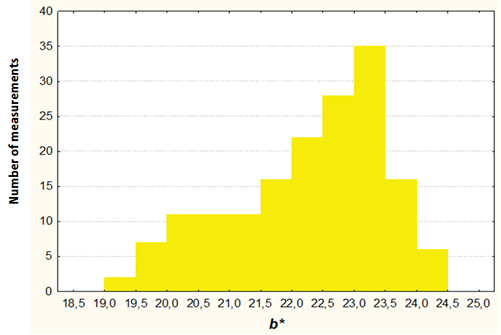

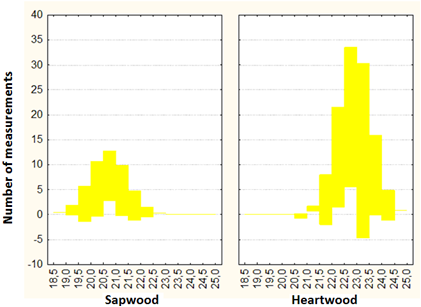

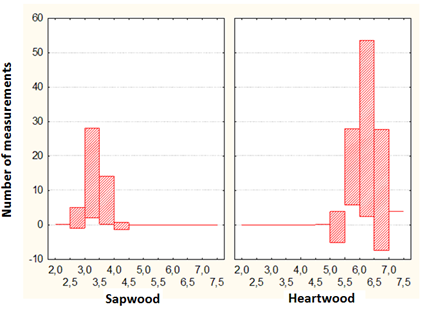

The experimental distribution of redness degree showed an extreme bi-modular character, having maximum values at 3 to 3.5 and 6 to 6.5, respectively (Fig. 3). This denoted the color layering as function of wood structure. High redness degree values referred to and characterized the heartwood of samples. The experimental distribution of yellowness degree (Fig. 4) presented a strong asymmetry to the right, which influenced the color tendency to migrate through more consistent yellow tones specific to high-quality oak wood for veneers. Resch et al. (2000), who studied oak trees from various locations in Germany, Austria and France, found similar CIELab values for 0.6-mm-thick oak veneers dried at 150 °C: L* = 63.9, a* = 7.6 and b* = 23.7.

Fig. 3. Histogram of redness degree for oak veneers

Fig. 4. Histogram of yellowness degree for oak veneers

Statistical indicators of experimental distributions are presented in Tables 4 and 5. The color variables L* and a* for oak veneers presented a bimodal character for the distribution of values which were not layered at the first evaluation, and that suggested the sapwood and heartwood influence upon veneer color.

Table 4. Statistical Values of Chromatic Parameters

Table 5. Statistical Indicators of Experimental Distributions

The color parameters, such as lightness degree and yellowness degree, are homogeneously distributed within the collectivity of performed measurements. The variation coefficient presented lower values than 30%. The variable a* is the single one which presents a high level of variability. Such statement suggests that the oak veneers color is segregated only through the redness degree.

As a result, the central tendency of distributions is accurately indicated by average values. The lightness, for example, contributed 70% to the complete veneer color. The statistical significance of influence of some independent variables on the wood color parameters for the analyzed veneers is presented in Table 6.

Table 6. Descriptive Statistics of Color Parameters

The matrix of transgression probabilities associated with the individual sectors highlighted that the strongest influence on lightness degree was due to the median sector of the log cross section. The variability among samples regarding the veneer layering was recorded in the third median part of log diameter. The matrix of transgression probabilities associated with the individual sectors highlighted that the strongest influence on redness degree was due to the median sector of the log diameter. The variations of yellowness degree with log diameter were produced in the outer sectors. The differences among samples regarding the chromatic parameters were not significant. Therefore, color was relatively homogeneous within the log, which confirmed the wood quality for decorative veneer production.

The heartwood presence constitutes an influencing decisive factor for the chromatic aspect of veneers. All the chromatic parameters were significantly layered according to the type of structure imposed by the heartwood presence. The veneer lightness was more pronounced and more homogeneously distributed in two classes within the sapwood (Fig. 5). According to the position of the sample within the log cross section, the yellowness layering conducted to the normalization of distribution. In heartwood, the yellowness degree was also highlighted simultaneously with the redness degree, as shown in Figs. 6 and 7. The yellowness module migrated from 20.5 to 21 in sapwood and from 22.5 to 23 in heartwood. The redness coordinate is more pronounced in heartwood compared with sapwood.

Fig. 5. Histogram of lightness degree layered by sapwood and heartwood

The results obtained in this study agree with other studies performed on oak wood. Mosedale et al. (1996) studied oak trees native in Germany and they mentioned the following CIELab values for oak sapwood: L* = 81.1, a* = 9.2, and b* = 22.9. The heartwood values were L* = 67.8, a* = 10.5, and b* = 23.4.

Such evidences highlighted by Resch et al. (2000) and Mosedale et al. (1996) were supported by a certain geographical possible variability of oak wood color.

Fig. 6. Histogram of yellowness degree layered by sapwood and heartwood

Fig. 7. Histogram of redness degree layered by sapwood and heartwood

CONCLUSIONS

- The veneer yield was highly influenced by losses during the sawing of flitches, veneer cutting, and trimming the edges of sliced oak veneers. The obtained yields showed the accuracy of the veneer technology used for decorative veneers.

- Heartwood highly influenced the final color of decorative oak veneers, in which yellow and red were highlighted. The distribution tendency of yellowness degree had a shift to the right through more intense degrees specific to oak veneers.

- The sector of its cross section that the veneers were cut from and the heartwood presence had a significant influence on the log’s chromatic parameters.

- The statistical analysis revealed the homogeneity of lightness and yellow degree within the veneer collectivity. The homogeneity of color within the sectors confirmed the wood quality for veneer production.

- Findings in this work showed that individual veneer sheets can be segregated based on color measurement to provide accurate results for sorting pieces of different colors.

ACKNOWLEDGMENTS

This study was supported by the Sectoral Operational Programme Human Resources Development (SOP HRD), financed from the European Social Fund and by the Romanian Government under the project number POSDRU/159/1.5/S/134378.

The authors acknowledge the support offered by Dr. Eng. Ciprian Morosanu from Losan Company and the Forest Products Laboratory from Transilvania University of Brasov in Romania.

REFERENCES CITED

Brunner, C. C., Shaw, G. B., Butler, D. A., and Funck, J. W. (1990). “Using color in machine vision systems for wood processing,” Wood and Fiber Science 22(4), 413-428.

Dumitrascu, E.-A., Ciobanu, V. D., and Lepadatescu, B. (2013). “Valorization of wood resources for the cutting of decorative veneer in the context of sustainable development of Romanian forests,” BioResources 8(3), 4298-4311. DOI: 10.15376/biores.8.3.4298-4311

Ferrari, S., Allegretti, O., Cuccui, I., Morretti, N., Marra, M., and Todaro, L. (2013). “A revaluation of Turkey oak wood (Quercus cerris (L.)) through combined steaming and thermo-vacuum treatments,” BioResources 8(4), 5051-5066. DOI: 10.15376/biores.8.4.5051-5066

Gierlinger, N., Jacques, D., Gradner, M., Wimmer, R., Schwanninger, M., Rozenberg, P., and Pâques, L. E. (2004). “Color of larch heartwood and relationships to extractives and brown-rot decay resistance,” Trees 18(1), 102-108. DOI: 10.1007/s00468-003-0290-y

Hoffmann, P. (1987). “Mesure de la variabilite de la couleur du bois. Méthodologie et influence de l’anatomie du plan ligneux et de la variation angulaire du debit,” DEA Sciences du bois, Universite de Nancy I, Station de Recherches sur la Qualite des Bois, INRA-CRF, nancy-Champenoux, 74 p.

Hon, D. N. S., and Shiraishi, N. (1991). Wood and Cellulose Chemistry, Marcel Dekker, New York, 1020 pp.

ISO 7724-2 (1984). “Paints and varnishes. Colorimetry. Part 2: Color measurement,” International Organization for Standardization, Geneva, Switzerland.

Janin, G. (1987). “Mesure de la couleur du bois; Intérêt forestier et industriel,” Annals of Forest Science 44(4), 455-472. DOI: 10.1051/forest:19870405

Klumpers, J., Janin, G., Becker, M., and Lévy, G. (1993). “The influences of age, extractive content and soil water on wood color in oak: The possible genetic determination of wood color,” Annals of Forest Science 50(1993), 403s-409s. DOI: 10.1051/forest:19930746

Kreber, B. (1994). “Understanding wood discoloration helps maximize wood profits,” Western Dry Kiln Association, Corvallis, OR.

Lutz, J. F. (1977). “Wood veneer: Log selection, cutting, and drying,” Technical Bulletin 1577, U.S. Department of Agriculture.

Mazet, J. F., Triboulot, M. C., Janin, G., Merlin, A., and Deglise, X. (1993). “Modifications de la couleur du bois de chenes europeens expose a la lumiere solaire,” Annals of Forest Science 50(2), 119-146. DOI: 10.1051/forest:19930202

McGavin, R. L., Bailleres, H., Lane, F., Blackburn, D., Vega, M., and Ozarska, B. (2014). “Veneer recovery analysis of plantation eucalypt species using spindleless lathe technology,” BioResources 9(1), 613-627. DOI: 10.15376/biores.9.1.613-627

Mitisor, A., and Istrate, V. (1982). Technology of Veneers, Plywood and Fibreboards (In Romanian: Tehnologia Furnirelor, Placajelor si Placilor din Fibre de Lemn), Technical Publishing House, Bucharest, Romania, 324 pp.

Morosanu, C. (2011). Study Regarding the Quality of Wood from European Oak and Sessile Oak Having as Destination Aesthetic Veneers, Ph.D. dissertation, Transilvania University of Brasov, Romania.

Mosedale, J. R., Charrier, B., and Janin, G. (1996). “Genetic control of wood color, density and heartwood ellagitannin concentration in European oak (Quercus petraea and Q. Robur),” Forestry 69(2), 111-124. DOI: 10.1093/forestry/69.2.111

Moya, R., and Berrocal, A. (2010). “Wood color variation in sapwood and heartwood of young trees of Tectona grandis and its relationship with plantation characteristics, site, and decay resistance,” Annals of Forest Science 67(1), 109-122. DOI: 10.1051/forest/2009088

Nemeth, R., Ott, A., Takats, P., and Bak, M. (2013). “The effect of moisture content and drying temperature on the color of two poplars and Robinia wood,” BioResources 8(2), 2974-2083. DOI: 10.15376/biores.8.2.2074-2083

Ozarska, B. (2003). “A manual for decorative wood veneering technology,” Project No. PN01.1600, prepared for the Forest and Wood Products Research and Development Corporation and funded by the Australian Government, ISBN 1920883002.

Resch, H., Hansmann, C., and Pokorny, M. (2000). “The color of wood from white oak,” Forschung-Entwicklung 1, 13-15.

Sandoval-Torres, S., Jomaa, W., Marc, F., and Puiggali, J. R. (2010). “Color alteration and chemistry changes in oak wood (Quercus pedunculata (Ehrh)) during plain vacuum drying,” Wood Science and Technology 46(1-3), 177-191. DOI: 10.1007/s00226-010-0381-z

Scalbert, A., Monties, B., and Janin, G. (1987). “Comparaison de méthodes de dosage des tanins: Application à des bois de différentes espèces,” Actes du 2ème Colloque Sciences et Industries du Bois, Nancy, France, Vol. 2, pp. 261-268.

SR EN 1316-1 (2001). “Hardwood round timber-Qualitative classification. Part 1: Oak and Beech,” ASRO, Bucharest.

Stich, K., and Ebermann, R. (1987). “Oak peroxydase: Relationship with polyphenoloxydase,” Holzforschung 41(1), 19-21. DOI: 10.1515/hfsg.1987.41.1.19

Todaro, L., Dichicco, P., Morretti, N., and D’Auria, M. (2013). “Effect of combined steam and heat treatments on extractives and lignin in sapwood and heartwood of Turkey oak (Quercus cerris (L.)) wood,” BioResources 8(2), 1718-1730. DOI: 10.15376/biores.8.2.1718-1730

Venet, J., and Keller, R. (1986). Identification et Classement des Bois Francais, 2nd Ed., ENGREF, Nancy, France.

Walinder, M. (2006). “The new journal Wood Material Science and Engineering,” Wood Material Science and Engineering 1(1), 2-3. DOI: 10.1080/17480270600687026

Wiedenbeck, J., Wiemann, M., Alderman, D., Baumgras, J., and Luppold, W. (2003). “Defining hardwood veneer log quality attributes,” Northern Research Station, USDA Forest Service, Newtown Square, PA.

I.N.S. (2013). Available at: http://www.insse.ro/cms/ro/content/volumul-de-lemn-exploatat. Accessed on: 23 February 2015.

Zanetti, M., Mothe, F., Merlin, A., Janin, G., LeMoguedec, G., and Goncalez, J. (2003). “Conséquences du vieillissement du bois de chêne sessile (Quercus petraea (Matt. Leibl)) sur sa perception esthétique par les utilisateurs,” Annals of Forest Science 60(1), 61-68. DOI: 10.1051/forest:2002074

Article submitted: September 14, 2015; Peer review completed: October 24, 2015; Revised version received: November 9, 2015; Accepted: November 10, 2015; Published: November 24, 2015.

DOI: 10.15376/biores.11.1.573-584