Abstract

Glycolaldehyde, produced from cracking of glucose, was tested as a substitute for formaldehyde in urea-based wood adhesives. Initially, different parameters (water content, aldehyde/urea-ratio, curing temperature, and time) were screened to identify the optimal curing conditions providing the highest bond strength. Afterwards, the system was reformulated as a 2-component system and compared to a urea-formaldehyde 2-component system, which showed a comparatively low strength of the resulting resin. Different hardeners were tested, and AlCl3 showed an 80% increase in bond strength for the resin compared to NH4Cl. Infrared and nuclear magnetic resonance analyses were performed to ensure formation of the desired aminal bond network, which showed that the hardener was essential for proper curing of the resin. Finally, a urea-glycolaldehyde-formaldehyde resin was tested that further indicated major differences between the reactivity of formaldehyde and glycolaldehyde.

Download PDF

Full Article

Evaluation of Glycolaldehyde as a Formaldehyde Substitute in Urea-based Wood Adhesives

Alexander Sandahl,a,* Lars Saaby Pedersen,b Esben Taarning,b and Anders Lindhardt a

Glycolaldehyde, produced from cracking of glucose, was tested as a substitute for formaldehyde in urea-based wood adhesives. Initially, different parameters (water content, aldehyde/urea-ratio, curing temperature, and time) were screened to identify the optimal curing conditions providing the highest bond strength. Afterwards, the system was reformulated as a 2-component system and compared to a urea-formaldehyde 2-component system, which showed a comparatively low strength of the resulting resin. Different hardeners were tested, and AlCl3 showed an 80% increase in bond strength for the resin compared to NH4Cl. Infrared and nuclear magnetic resonance analyses were performed to ensure formation of the desired aminal bond network, which showed that the hardener was essential for proper curing of the resin. Finally, a urea-glycolaldehyde-formaldehyde resin was tested that further indicated major differences between the reactivity of formaldehyde and glycolaldehyde.

DOI: 10.15376/biores.17.4.5769-5784

Keywords: Glycolaldehyde; Bond strength analysis; Urea-based wood adhesives; Bio-based chemicals

Contact information: a: Center for Product and Materials Chemistry, Danish Technological Institute, Kongsvang Alle 29, 8000, Aarhus C, Denmark; b: Biobased Chemicals, Haldor Topsoe A/S, Haldor Topsøes Allé 1, 2800, Kgs. Lyngby, Denmark; *Corresponding author: ales@teknologisk.dk

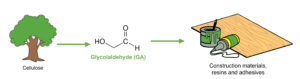

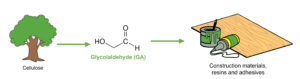

GRAPHICAL ABSTRACT

INTRODUCTION

Bio-based chemicals are potential key pieces in realizing the green transition to a low carbon economy through substitution of petrochemicals. They are a group of chemicals accessible through the chemical deconstruction of biomass that has received increased interest over the last decade. Recent academic and industrial focus has been identifying possible places in the chemical infrastructure where substitution of petrochemicals with bio-based chemicals may be beneficial (Schrittwieser et al. 2018; Dai et al. 2020; Xu et al. 2022).

In contrast to petrochemicals, bio-based chemicals (except for lipid-based) are often oxygen-rich, contain alcohols, ethers, ketones, and carboxylic acids, making them more hydrophilic than their petrochemical counterparts. Examples include lignin oligomers as substitutes for bisphenol A (Ferrini et al. 2017) in epoxy resins (Zhen et al. 2021), and polycarbonates (Koelewijn et al. 2017) or polyol in polyurethane (Pan and Saddler 2013). Generally, the bio-based (plastic) materials have inferior material properties compared to their petrochemical counterparts (Chung et al. 2013; Wang and Venditti 2015). However, these materials are still in their infancy in development, whereas materials based on petrochemicals have been optimized over the last hundred years for improved material properties (Rowan 2021).

It is important to keep exploring new bio-based materials as potential substitutes for petrochemical materials. From glucose it is possible to access glycolaldehyde (GA), a C2-aldehyde building block, by retro-aldol reactions through thermal cracking (Luebben and Raebiger 2015; Schandel et al. 2020). The authors propose that GA holds the potential to substitute for other petrochemical aldehydes (Faveere et al. 2019), specifically formaldehyde.

Formaldehyde is a petrochemical aldehyde and used in the production of different resins, e.g., urea-formaldehyde (UF), phenol-formaldehyde, and poly(oxomethylene) (POM). The resin UF is produced in large amounts (approximately 12 m tons annually, Mordor Intelligence 2020). It accounts for > 40% of the global formaldehyde consumption (Zhang 2018). Furthermore, the formaldehyde content in the resin is high (in the range 40 to 60 wt%), which increases the impact of formaldehyde substitution. Herein, the authors explore the possibility of substituting formaldehyde with GA in UF resins (Fig. 1).

Fig. 1. Formaldehyde (based on fossil resources) is currently used in various adhesives for wood-based construction materials that suffer from emission of free formaldehyde. Through substitution of formaldehyde with GA (bio-based) the emission is decreased due to the lowered vapor pressure of GA.

Urea formaldehyde is a widely used wood adhesive in the production of particle boards, wood panels, and medium–density fiberboards (MDF). Its popularity stems from its reactivity window being compatible with biomaterials (temperature window for curing), formulation in aqueous dispersions, reasonable strength for many product classes, and low price. In contrast, the disadvantages include its low water resistance compared to other wood adhesives (e.g., phenol and melamine-based adhesives) (Dunky 1998) and the general employment of formaldehyde, a known carcinogen. Specifically, the emission of formaldehyde from the final wood product is a challenge for indoor use (Myers 1983; Böhm et al. 2012). Although the toxicity of GA is yet undetermined, its vapor pressure is much lower (Petitjean et al. 2010) than the vapor pressure of free formaldehyde, which is a gas at room temperature, thus making GA a preferable substitute by decreasing exposure through emission.

In recent decades, different approaches have been tested to reduce the emission of formaldehyde from formaldehyde-containing wood adhesives. Reductions can be achieved either by addition of formaldehyde scavengers that chemically bind free released formaldehyde (Costa et al. 2013) or through substitution of formaldehyde with other aldehydes to reduce the total amount of formaldehyde used in production. Examples include partial substitution with furfural (Zhang et al. 2014) and 5-hydroxymethylfurfural (HMF) (Esmaeili et al. 2017). However, these resins suffer from longer press times and high press temperatures for curing of the resin because of the decreased reactivity of these bio–based aldehydes (180 °C for HMF-substituted and 130 °C for furfural-substituted). The authors anticipate that GA may have higher reactivity than these aldehydes because of its smaller size and the neighboring heteroatom increasing electrophilicity of the aldehyde (Anh et al. 1973), and thus, hopefully milder curing conditions required. GA already is known to have a very high degree of hydration when dissolved in water (Kua et al. 2013) indicating a high reactivity, but not to the same degree as formaldehyde (Winkelman et al. 2002). Hopefully, the size and anticipated reactivity will allow GA to be a close substitute for formaldehyde in terms of curing conditions and properties of the cured resin. To our knowledge, this is the first example of a complete substitution of formaldehyde with a bio-based aldehyde in urea-based wood adhesives.

EXPERIMENTAL

Materials

Aluminum trichloride, urea, and sodium hydroxide were purchased from Merck Group (Darmstadt, Germany). Formaldehyde (37 wt% aqueous), ammonium chloride, ammonium sulfate, ammonium nitrate, ammonium phosphate dibasic, acetonitrile, and 2,5-dihydroxybenzoic acid were purchased from Th. Geyer GmbH & Co. KG (Renningen, Germany). Glycolaldehyde (as glycolaldehyde dimer, > 99% purity) was produced by Haldor Topsøe A/S (Kongens Lyngby, Denmark) via thermal cracking of glucose syrup. All chemicals were used as received.

Methods

The pH measurements were performed using a FisherbrandTM AccumetTM AB200 benchtop pH/conductivity meter (Thermo Fisher Scientific, Waltham, MA, USA), and bond strengths were measured using a TA.XTplusC texture analyser (Stable Micro Systems, Godalming, England) with a 50 kg load cell for tensile strength analysis. All tests were performed as triplicates, and data are reported as average values with related standard deviations.

Usually, urea-formaldehyde resins are prepared by the “alkaline-acid” method (Ferra et al. 2012) or “alkaline-acid-alkaline” method (Zhang et al. 2013) to increase the pot-life of the resin and ensure formation of pre-polymer species (Ormondroyd 2015). However, since GA is prone to undergo aldol reaction under alkaline conditions (Barsøe 2021), the resins were prepared under acidic conditions and used directly without any subsequent storage and later use.

For 1-component systems, resins were produced by dissolving urea (1.0 eq) in deionized water (dependent on water content) followed by addition glycolaldehyde (1.1 to 1.5 eq). The mixture was stirred at room temperature until all material had dissolved to produce the prepolymer mixture as a viscous transparent liquid. Hardener (NH4Cl, 2 wt%) was weighed into a vial, and the prepolymer mixture was added and shaken until the hardener had dissolved to produce the resin mixture for curing.

For 2-component systems, resins were produced by dissolving urea (1.0 eq) in deionized water (30 wt%) followed by addition of 37 wt% formaldehyde (1.3 eq) or glycolaldehyde (1.3 eq), whereafter pH was adjusted to pH = 8.0 using 0.1 M NaOH to produce the prepolymer mixtures. Hardeners were dissolved in deionized water with concentration of 30 wt% (heat may be necessary for dissolution). A total of 5 parts (v/v) of the prepolymer mixture were mixed with 1 part (v/v) of the hardener to produce the resin mixture for curing.

Urea-glycol-aldehyde-formaldehyde (UGAF) resin was produced as the 2-component systems, however, with addition of GA before addition of formaldehyde. It should be noted that the water in the formaldehyde solution contributed to the water content in the resin, which was compensated for by using less water when mixing urea and glycolaldehyde, thus keeping the total water content constant at 30 wt%. A total of 20 µL resin was added to wooden beech sticks (length = 15 cm, thickness = 0.2 cm, width = 2.0 cm, rounded ends) and another wooden beech stick placed on top. The resin was cured in a preheated oven with an aluminum cylinder (diameter = 2.0 cm, height = 1.5 cm) and a 5 kg iron weight was placed on top of the sample to give a pressure of 0.156 N/mm2. The climate chamber used was a 10-L plastic bucket into which a beaker with 50 mL deionized water was placed. A Bosch BME280 humidity sensor (Bosch, Gerlingen, Germany) was used to monitor and ensure a constant relative humidity (RH) of 65% for over 1 month.

For characterization, resin was cured (500 mg) for 20 min at 100 °C in an aluminum container. Infrared (IR) spectra were recorded using an Agilent 4500a attenuated total reflectance-Fourier transform infrared (ATR-FTIR) spectrometer (Agilent Technologies, Santa Clara, CA, USA). Matrix-assisted laser desorption/ionization (MALDI) spectra were recorded using a Bruker Autoflex maX (Bruker, Billerica, MA, USA) in reflector positive ion mode. Samples were dissolved in water (10 mg/mL) and mixed in equal amounts with matrix solution. The matrix was prepared by dissolving 2,5-dihydroxybenzoic acid (DHB) in acetonitrile (20 mg/mL) followed by dilution with an equal volume 0.2 M NaCl to give a final concentration of 10 mg/mL DHB and 0.1 M NaCl. A total volume of 1.5 µL was applied to the MALDI plate. The m/z-values were calculated using Eq. 1,

m/z = M(Na+) + M(avg(urea, GA)) × #units + M(water) × #water (1)

where M is the respective molecular weights (M(avg(urea, GA)) = 60.05), #units is the number of urea and GA units combined, and #water is the number of associated water molecules. Carbon-13 nuclear magnetic resonance (13C NMR) spectra were recorded at 101 MHz on a Bruker BioSpin GmbH AscendTM 400 (Bruker, Billerica, MA, USA) and were calibrated using urea as spiked internal standard (162.50 ppm). For sample preparation, cured resin (500 mg) was dissolved in deionized water (0.50 mL) transferred to an NMR tube.

RESULTS AND DISCUSSION

1-Component System: Initial Parameter Screening

The study was initiated with screening of relevant parameters for curing the urea-glycolaldehyde (UGA) resin, i.e., determination of the effects from curing time, temperature, U/GA-ratio, and water content. The influence of the parameters was evaluated by bond strength determination and visual appearance of the fracture surface of the wood. In these initial tests, the resin is mixed as a 1-component adhesive (mixing of UGA and curing agent), without pH adjustment. The pot life of the uncured resin was more than 1 week, whereafter all samples began turning yellow.

Fig. 2. Optimization of parameters affecting the strength of the UGA-resin: (a) screening the effect of different water contents in the resin when curing at 100 °C using a U/GA-ratio of 1/1.3; water content of 30 wt% gave the highest strength; (b) screening the effect of different U/GA-ratios in the resin when curing at 100 °C and a water content of 30 wt%; a U/GA-ratio of 1/1.3 gave the highest strength; (c) screening the effect of different curing temperatures while having a water content of 30 wt% and 1.3 eq GA to urea; curing temperature of 100 °C for 10 min gave the highest strength

Initially, a U/GA-ratio of 1/1.3 was chosen for testing the effect of the water content in the resin and curing at 100 °C. The minimum required water content to keep the resin liquid at room temperature was 30 wt%. It is clear that the water content strongly affected the strength of the cured resin (Fig. 2a): a lesser amount of water used resulted in a higher strength, i.e., more resin equaled higher strength. Afterwards different U/GA-ratio were screened (Fig. 2b), and 1.3 eq GA showed the highest strength of the resin. This was likely a compromise between GA lost during curing (via thermal decomposition), flexibility, and amount of end groups, all of which increase with increasing amounts of GA. Furthermore, with increasing amounts of GA, the crosslinking density is expected to be lowered. Lastly, different curing temperatures were screened (Fig. 2c), and 100 °C was the optimal temperature, giving a bond strength of 1.36 MPa after curing for 10 min. At lower temperatures, the resin did not cure to completion, and at higher temperatures the GA likely underwent decomposition.

This also fits the visual appearance of the fracture surfaces (Fig. 3), where brown color evolution was observed when increasing curing temperature and time. This is not surprising, as GA is the retro-aldol product of glucose (Fig. 4a) and can perform aldol reactions giving carbohydrates (Fig. 4c) (Omran et al. 2020). These can undergo caramelization reactions upon heating (Woo et al. 2015) and thus formation of brown byproducts, which the nitrogen from urea may further catalyze through Maillard reactions (Maillard 1912). It was observed that curing temperature had a much larger effect on color formation than the curing time.

Fig. 3. An overview of the fracture surfaces after curing at different temperatures for different durations. It was observed that color evolution depends largely on the curing temperature and to a lesser extent the curing time.

In summary, the resin appears to be sensitive towards changes in water content and curing temperature. Furthermore, different competing reactions (Fig. 4b-c) may be operating during heating giving rise to brown color formation and decreased strength of the resin. The highest observed tensile strength is likely an optimal balance between these reactions.

Fig. 4. Different reactions with glycolaldehyde: (a) heating of glucose to produce glycolaldehyde through retro aldol reaction, (b) reaction between urea and glycolaldehyde to give a urea-methylol intermediate followed curing to a resin upon heating, (c) side reaction of glycolaldehyde through aldol reaction to produce C4 and larger carbohydrates, which eventually caramelize during extended heating

2-Component Systems

The next step of the study was to compare the performance of the UGA-resin to a reference UF-resin. Because UF-resins are formulated as 2-component systems, the UGA-resin had to be formulated in a similar manner to compare the resins.

The UGA was prepared with 30 wt% water without hardener, and pH was adjusted to pH = 8 for this mixture. The pH of the solution was however not stable, and 24 h later, it dropped to pH = 5.5. This indicated that the aldehyde had undergone a base-catalyzed Cannizaro reaction (Haas et al. 2020) or oxidation from oxygen, yielding glycolic acid responsible for the pH change. When preparing UF resins, this step is usually performed to ensure prepolymer formation (urea-methylol species) and extend the pot-life because the UF resin cures rapidly at room temperature under acidic conditions and curing is inhibited under alkaline conditions (Sun et al. 2014).

It was observed that the UF-resin had a 3.2 times higher strength than UGA. Furthermore, the strength of UGA as a 2-component system decreased compared to the 1-component system. However, this can be explained by the addition of water added from the hardener mix giving a final water content of 37 wt% before curing. The results fit with data from the 1-component system giving lower bond strengths than UGA with 40 wt% water and higher than UGA with 30 wt% water.

Table 1. Initial Results and Comparison of 2-Component Systems Using NH4Cl as Hardener

Until now, the commonly used hardener NH4Cl has been used for curing the resin. Because this is a new resin, other hardeners may give higher bond strengths. Therefore, the authors screened different inorganic acidic salts to see how they affect the bond strength. The pH was also measured after mixing the hardener and UGA to see if any correlations between pH and bond strength existed (Fig. 5).

Fig. 5. Strength of 2-component UGA-resin cured with different hardeners shown against pH of the mixtures before curing (samples were cured for 10 min at 100 °C)

As the data suggest, there were no immediate correlations between pH of the solution and the resulting bond strength after curing. It was observed that NH4Cl gave the lowest bond strength. When switched to AlCl3 or NH4NO3, an 80% increase in bond strength was observed. The large variation between the different ammonium salts implies that the counterion has an important but unknown effect. Furthermore, AlCl3 may act as a Lewis acid towards GA activation or bind water through complexation, thereby encouraging other curing mechanisms than for ammonium salts. It should be noted that it if hardener is left out from the formulation, the UGA-resin gave no adhesion between the wood samples.

Water resistance of the cured UGA-resin (with NH4Cl as hardener) was also tested by storing six samples in a climate chamber for 30 days at 20 °C and 65% RH. Of these samples, only one was intact for bond strength analysis, resulting in a bond strength of 0.54 MPa. The other five samples broke before or when trying to place the samples in the tensile strength analyzer. This indicates that the resin was hydrophilic and had little to no water resistance. Notably, these conditions are the minimum requirements for service class 1 adhesives to be used under dry conditions (cf. EN 1995-1-1 (2004).

Characterization of the UGA-resin

To monitor the curing process and specifically formation of the desired aminal bonds in the resin, IR spectroscopy was performed in combination with 13C NMR spectroscopy and MALDI mass spectrometry. Results from IR spectroscopy of the UGA resin before and after curing (Fig. 6) showed the greatest changes in vibrations related to the urea functional group. Before curing Amide I (C=O stretch, 1632 cm-1) and Amide II (N-H bend, 1538 cm-1) had similar peak intensities. After curing, the intensity of Amide II had decreased noticeably compared to Amide I, indicating loss of N-H groups through reaction at urea-N during curing. Furthermore, a series of peaks in the range 1500 to 1400 cm-1 appeared, which may be assigned to aminal formation (Pavia et al. 2015; Dey et al. 2019).

Fig. 6. IR spectra of uncured UGA without addition of NH4Cl (dashed line) and UGA cured for 20 min at 100 °C with addition of NH4Cl (bold line)

The 13C NMR spectra were recorded (Fig. 7a through 7i) to identify the carbon atoms present in the resin. The chemical shifts can be related to different chemical groups bound to carbon and thus different chemical bonds (Table 2).

Table 2. Overview of Chemical Bonds in UF and UGA Resins and the Expected Range of 13C NMR Chemical Shifts.

For the uncured UGA-resin, various peaks were observed (Fig. 7c) in the region from 50 to 105 ppm corresponding to various aliphatic carbons with heteroatoms bound. These signals belong to different isomers of glycolaldehyde hydrates and dimers (Kua et al. 2013) as well as UGA adducts (hemiaminals). Three peaks around 160 ppm (Fig. 7b) were observed corresponding to free urea (162.50 ppm) and urea with 1 and 2 substitutions fitting with prepolymer formation (hemiaminal formation from reaction between urea-N and the aldehyde of glycolaldehyde). The aldehyde peak at 204.49 ppm suggests that some unreacted glycolaldehyde was still present in the solution (Collins and George 1971).

Upon curing for 20 min without addition of hardener, a few changes were observed in the region for aliphatic carbon atoms (Fig. 7f). Importantly, the aldehyde peak at 204.49 ppm was lost, indicating that reactions with the aldehyde occurred. However, the remaining part of the spectra were close to identical when hardener was omitted.

With addition of hardener (2 wt% NH4Cl), the spectrum changes (Fig. 7g) compared to curing without hardener. The area around 160 ppm (Fig. 7h) contains wide peaks corresponding to many different substituted urea-species. A shift to lower values (156 to 158 ppm) indicated tri- and tetra-substitution of urea along with uron formation (Park et al. 2008). The most important changes were observed for the aliphatic carbons (Fig 6i). Acetals and hemiacetals (85 to 105 ppm) were completely lost and a new group of peaks in the range 50 to 58 ppm appeared corresponding to the desired aminal peaks. Furthermore, the number of peaks increased noticeably, indicating an inhomogeneous structure with many similar chemical groups that is characteristic for thermoset polymers (Schäfer et al. 2020).

Therefore, the hardener was essential for curing the resin. When hardener was left out of the resin, it was not possible to measure the bond strength, as the samples broke before it could be measured (data not shown), indicating that the aminal network was correlated to crosslinking, giving the resin its strength.

Fig. 7. 13C NMR spectra of UGA: (a) through (c) uncured UGA without addition of NH4Cl, (d) through (f) UGA cured for 20 min at 100 °C without addition of NH4Cl, (g) through (i) UGA cured for 20 min at 100 °C with addition of NH4Cl

No peaks were observed corresponding to carbon with unsaturation. Because the resin became colored, it would be expected that the color was attributed to unsaturated compounds. Therefore, the colored compounds must only be present in low concentrations and thus not detectable by 13C NMR.

It is important to note that the cured resin was completely soluble in water, which was also the NMR solvent. In general, UF-resins and thermosets are insoluble in water, but the addition of the extra hydroxymethyl groups may be enough to give solubility, for this urea-based resin. Furthermore, the bonds in cured UGA do not hydrolyze when dissolved, meaning that the actual cured material dissolved. This high aqueous solubility of the cured resin also fits the observation that the resin lost its bonding to wood when stored under 65% RH for over 30 days. However, only few water-soluble thermosets are known, and it is unlikely that a highly crosslinked polymer readily dissolves in water.

Therefore, MALDI mass spectrometry was performed to gain insight into the length of the polymer (Fig. 8). Urea and GA are close in mass (60.06 Da for urea, 60.05 for GA) and are only distinguishable with high resolution mass spectrometry techniques. Thus, it is only possible to assign the total number of units (urea and GA combined) comprised in the oligomers with MALDI. The observed oligomers spanned a range from dimers to 12-mers with a varying number of water molecules associated with the ionization and detection process. Notably, up to 7 water molecules were found associated with a dimer (m/z = 268.8), thus exceeding the possible number of covalently bound water molecules through, e.g., hydration of GA, and must therefore be non-covalently associated. As observed, the number of associated water molecules decreased with increasing oligomer length, indicating the desired condensation between urea and GA with release of water upon formation of the aminal bond. However, the highest observed m/z-value corresponded to a 12-mer, meaning that the polymerization did not run to completion. As discussed earlier, increasing the reaction time further decreases bond strength of the final resin (Fig. 2), thus indicating the inability to form longer polymers when curing the resin under the applied conditions, possibly because of side reactions (Fig. 4c) or simply too low reactivity of the components.

Fig. 8. MALDI spectrum of cured UGA-resin (cured at 100 °C with NH4Cl for 20 min); the peaks were assigned with the total number of units in the oligomer and assignment of each peak is further elaborated in the table.

It is necessary to have a sufficiently high reactivity of unreacted monomers during polymerization, as the concentration of monomers decrease with increasing polymer length. The lower reactivity of GA compared to formaldehyde may be a reason for the observation of shorter oligomers in contrast to MALDI analysis of UF, where masses were observed in the range of 1000 to 5000 Da (Gavrilović-Grmuša et al. 2010; Jeong and Park 2019).

UGAF Resin

A last series of experiments was performed to observe the effect of mixing formaldehyde with glycolaldehyde to a urea-glycolaldehyde-formaldehyde resin and to gain insight into reactivity differences between GA and formaldehyde. Here the amount of formaldehyde in the resin was increased while keeping the total molar aldehyde content constant (Fig. 9a and 9b).

Fig. 9. Results from formaldehyde substitution in UGA: (a) bond strength of cured UGAF resin with increasing the formaldehyde content. The resin was cured at 100 °C for 10 min with 2 wt% NH4Cl. The (molar) aldehyde content was kept constant at 1.3 eq to urea. (b) Pictures of UGAF resins with increasing formaldehyde content after storing 1 week at room temperature (without addition of NH4Cl). Resin containing 10% CH2O formed a transparent viscous liquid, while 30% CH2O and 50% CH2O gave a white cloudy gel, and 70% CH2O and 90% CH2O yielded hard solid that looked like white plastic.

It was noteworthy that the addition of up to 50% formaldehyde only increased the bond strength by 0.3 MPa and the subsequent addition (> 50%) of formaldehyde had a larger effect on the bond strength. It appears that two different regions exist: ≤ 50% formaldehyde and >50% formaldehyde content (Fig. 9a). With ≤ 50% formaldehyde it did not contribute to increasing the strength; however, the solutions turned cloudy white after 1 week but had properties as soft gels (Fig. 9b). This is likely due to the formation of UF-oligomers that are insoluble in water (Ormondroyd 2015) because formaldehyde is more reactive than GA and therefore condenses first with urea. Bond strength may therefore be dependent on GA crosslinking the UF-oligomers during curing in this region. In the > 50% region, formaldehyde may be able to crosslink UF-oligomers during curing, thus resulting in a substantial increase in bond strength when adding more formaldehyde, being able to crosslink the oligomers. From this it appears that formaldehyde delivers a strong crosslink giving the resin its strength, whereas GA has a crosslink with lower strength, either from lowered crosslink density or as a result of poorer mechanical properties when incorporating GA into the polymer. As observed earlier, this reflects the different reactivities of the two aldehydes, whereby the more reactive aldehyde gives a higher bonder strength.

In perspective, the differences between UGA and UF resembled those between POM and poly(ethyleneglycol) (PEG), which are similar in chemical structures but have different material properties: POM is a hard, water-insoluble plastic and PEG is a water-miscible liquid. In this manner, UF resembles POM and UGA resembles PEG, where these differences emerge through the addition of an extra hydroxymethyl group to UF.

This report serves as an initial exploratory study for the use of GA in urea-based wood adhesives. Because UF resin is a highly optimized material and synthesis of UGA was based on specific UF synthesis protocols, it is not reasonable to compare and rate UGAs properties against those of UF. If given the same time for optimization as UF has been given, UGA materials with desirable properties for certain purposes may be obtained, but they are unlikely to resemble those of UF.

CONCLUSIONS

In this paper, glycolaldehyde (GA) was explored as a bio-based substitute for formaldehyde in urea-based wood adhesives with the following conclusions:

- The GA was able to react with urea through aminal bond formation giving a urea-glycolaldehyde (UGA)-resin. The strength of the resin was highly dependent on the curing temperature, water content, and choice of hardener.

- The properties of UGA were not comparable to those of urea-formaldehyde (UF); UF has low pot-life and short curing times, whereas UGA has a long pot-life (> 1 week) and curing time (10 min) to achieve maximum bond strength, which is only 43% (when using AlCl3 as hardener) of the reference UF-resin. This reflects the reactivity of the two aldehydes: formaldehyde is a highly reactive electrophile, whereas GA is less reactive. Furthermore, GA adds hydrophilicity to the resin, thus decreasing its water resistance, whereas UF is usually a water-insoluble resin. The low bond strength and water solubility of UGA may be partly due to the incomplete polymerization of the resin and the hydroxyl group of GA, making it more hydrophilic than formaldehyde-based adhesives.

- Thus, UGA is not a good direct substitute for UF, but its water solubility may be useful in other applications.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Danish Environmental Protection Agency, Case No. 2020-15416

REFERENCES CITED

Anh, N. T., Eisenstein, O., Lefour, J. M., and Tran Huu Dau, M. E. (1973). “Orbital factors and asymmetric induction,” J. Am. Chem. Soc. 95(18), 6146-6147. DOI: 10.1021/ja00799a068

Barsøe, L. R. (2021). “From biomass to rare sugars: Chromatographic and in-situ NMR spectroscopic kinetic analysis and practical implementation,” Master Thesis, Technical University of Denmark

Böhm, M., Salem, M. Z., and Srba, J. (2012). “Formaldehyde emission monitoring from a variety of solid wood, plywood, blockboard and flooring products manufactured for building and furnishing materials,” J. Hazard. Mater. 221-222, 68-79. DOI: 10.1016/j.jhazmat.2012.04.013

Chung, Y. L., Olsson, J. V., Li, R. J., Frank, C. W., Waymouth, R. M., Billington, S. L., and Sattely, E. S. (2013). “A renewable lignin–lactide copolymer and application in biobased composites,” ACS Sustain. Chem. Eng. 1(10), 1231-1238. DOI: 10.1021/sc4000835

Collins, G. C. S., and George, W. O. (1971). “Nuclear magnetic resonance spectra of glycolaldehyde,” J. Chem. Soc. B 1352-1355. DOI: 10.1039/J29710001352

Costa, N. A., Pereira, J., Ferra, J., Cruz, P., Martins, J., Magalhães, F. D., Mendes, A., and Carvalho, L. H. (2013). “Scavengers for achieving zero formaldehyde emission of wood-based panels,” Wood Sci. Technol. 47(6), 1261-1272. DOI: 10.1007/s00226-013-0573-4

Dai, L., Wang, Y., Liu, Y., He, C., Ruan, R., Yu, Z., Jiang, L., Zeng, Z., and Wu, Q. (2020). “A review on selective production of value-added chemicals via catalytic pyrolysis of lignocellulosic biomass,” Sci. Total Environ. 749, article ID142386. DOI: 10.1016/j.scitotenv.2020.142386

Dey, D., Murmu, N. C., and Banerjee, P. (2019). “Tailor-made synthesis of an melamine-based aminal hydrophobic polymer for selective adsorption of toxic organic pollutants: An initiative towards wastewater purification,” RSC Adv. 9(13), 7469-7478. DOI: 10.1039/C9RA00453J

Dunky, M. (1998). ”Urea-formaldehyde (UF) adhesive resins for wood,” Int. J. Adhes. Adhes. 18(2), 95-107. DOI: 10.1016/S0143-7496(97)00054-7

EN 1995-1-1 (2004). “Design of timber structures – Part 1-1: General – Common rules and rules for buildings,” European Committee for Standardization, Brussels, Belgium.

Esmaeili, N., Zohuriaan-Mehr, M. J., Mohajeri, S., Kabiri, K., and Bouhendi, H. (2017). “Hydroxymethyl furfural-modified urea–formaldehyde resin: Synthesis and proper-ties,” Eur. J. Wood Wood Prod. 75(1), 71-80. DOI: 10.1007/s00107-016-1072-8

Faveere, W., Mihaylov, T., Pelckmans, M., Moonen, K., Gillis-D’Hamers, F., Bosschaerts, R., Pierloot, K., and Sels, B. F. (2019). “Glycolaldehyde as a bio-based C2 platform chemical: Catalytic reductive amination of vicinal hydroxyl aldehydes,” ACS Cat. 10(1), 391-404. DOI: 10.1021/acscatal.9b02437

Ferra, J. M., Henriques, A., Mendes, A. M., Costa, M. R. N., Carvalho, L. H., and Magalhães, F. D. (2012). “Comparison of UF synthesis by alkaline‐acid and strongly acid processes,” J. Appl. Polym. Sci. 123(3), 1764-1772. DOI: 10.1002/app.34642

Ferrini, P., Koelewijn, S. F., Van Aelst, J., Nuttens, N., and Sels, B. F. (2017). “Zeolites as sustainable catalysts for the selective synthesis of renewable bisphenols from lignin‐derived monomers,” ChemSusChem 10(10), 2249-2257. DOI: 10.1002/cssc.201700338

Gavrilović-Grmuša, I., Nešković, O., Điporović-Momćilović, M., and Popović, M. (2010). “Molar-mass distribution of urea–formaldehyde resins of different degrees of polymerisation by MALDI-TOF mass spectrometry,” J. Serb. Chem. Soc. 75(5), 689-701, DOI: 10.2298/JSC091030036G

Haas, M., Lamour, S., Christ, S. B., and Trapp, O. (2020). “Mineral-mediated carbohydrate synthesis by mechanical forces in a primordial geochemical setting,” Comm. Chem. 3(1), 1-6. DOI: 10.1038/s42004-020-00387-w

Jeong, B. and Park, B-D. (2019). “Effect of molecular weight of urea–formaldehyde resins on their cure kinetics, interphase, penetration into wood, and adhesion in bonding wood,” Wood Sci. Technol. 53, 665-685, DOI: 10.1007/s00226-019-01092-1

Koelewijn, S. F., Van den Bosch, S., Renders, T., Schutyser, W., Lagrain, B., Smet, M., Thomas, J., Dehaen, W., Van Puyvelde, P., Witters, H., et al. (2017). “Sustainable bisphenols from renewable softwood lignin feedstock for polycarbonates and cyanate ester resins,” Green Chem. 19(11), 2561-2570. DOI: 10.1039/C7GC00776K

Kua, J., Galloway, M. M., Millage, K. D., Avila, J. E., and De Haan, D. O. (2013). “Glycolaldehyde monomer and oligomer equilibria in aqueous solution: Comparing computational chemistry and NMR data,” J. Phys. Chem. 117(14), 2997-3008. DOI: 10.1021/jp312202j

Luebben, S. D., and Raebiger, J. W. (2015). “A novel renewable thermoplastic polyacetal by polymerization of glycolaldehyde dimer, a major product of the fast pyrolysis of cellulosic feedstock,” in: Green Polymer Chemistry: Biobased Materials and Biocatalysis, American Chemical Society, Washington D.C., USA, pp. 305-328.

Maillard, L. C. (1912). “Action of amino acids on sugars. Formation of melanoidins in a methodical way,” Compte-Rendu de L’academie des Sciences 154, 66-68.

Myers, G. E. (1983). “Formaldehyde emission from particleboard and plywood paneling: Measurement, mechanism, and product standards,” For. Prod. J. 33(5), 27-37. DOI:

Omran, A., Menor-Salvan, C., Springsteen, G., and Pasek, M. (2020). “The messy alkaline formose reaction and its link to metabolism,” Life 10(125), DOI: 10.3390/life10080125

Ormondroyd, G. A. (2015). “Adhesives for wood composites,” in: Wood Composites, Woodhead Publishing, Sawston, England, pp. 47-66.

Pan, X., and Saddler, J. N. (2013). “Effect of replacing polyol by organosolv and kraft lignin on the property and structure of rigid polyurethane foam,” Biotechnol. Biofuels 6(1), 1-10. DOI: 10.1186/1754-6834-6-12

Park, B. D., Lee, S. M., and Park, J. Y. (2008). “13C-NMR spectroscopy of urea-formaldehyde resin adhesives with different formaldehyde/urea mole ratios,” J. Korean Wood Sci. Technol. 36(2), 63-72. DOI: 10.5658/WOOD.2008.36.2.063

Pavia, D. L., Lampman, G. M., Kriz, G. S. and Vyvyan, J. R. (2015). Introduction to Spectroscopy, 5th Edition, Cengage Learning, Boston, MA, USA.

Petitjean, M., Reyès-Pérez, E., Pérez, D., Mirabel, P., and Le Calve, S. (2010). “Vapor pressure measurements of hydroxyacetaldehyde and hydroxyacetone in the temperature range (273 to 356) K,” J. Chem. Eng. Data 55(2), 852-855. DOI: 10.1021/je9004905

Rowan, S. J. (2021). “100th anniversary of macromolecular science viewpoints,” ACS Macro. Lett. 10(4), 466-468. DOI: 10.1021/acsmacrolett.0c00789

Schandel, C. B., Høj, M., Osmundsen, C. M., Jensen, A. D., amd Taarning, E. (2020). “Thermal cracking of sugars for the production of glycolaldehyde and other small oxygenates,” ChemSusChem 13(4), 688-692. DOI: 10.1002/cssc.201902887

Schäfer, T., Buntkowsky, G., and Gutmann, T. (2020). “Solid-state nuclear magnetic resonance as a versatile tool to identify the main chemical components of epoxy-based thermosets,” ACS Omega 5(10), 5412-5420. DOI: 10.1021/acsomega.9b04482

Schrittwieser, J. H., Velikogne, S., Hall, M., and Kroutil, W. (2018). “Artificial biocatalytic linear cascades for preparation of organic molecules,” Chem. Rev. 118(1), 270-348. DOI: 10.1021/acs.chemrev.7b00033

Sun, Q. N., Hse, C. Y., and Shupe, T. F. (2014). “Effect of different catalysts on urea–formaldehyde resin synthesis,” J. Appl. Polym. Sci. 131(16), article ID 40644. DOI: 10.1002/APP.40644

Wang, C., and Venditti, R. A. (2015). “UV cross-linkable lignin thermoplastic graft copolymers,” ACS Sustain. Chem. Eng. 3(8), 1839-1845. DOI: 10.1021/acssuschemeng.5b00416

Winkelman, J. G. M., Voorwinde, O. K., Ottens, M., Beenackers, A. A. C. M., and Janssen, L. P. B. M. (2002). “Kinetics and chemical equilibrium of the hydration of formaldehyde,” Chem. Eng. Sci. 57, 4067-4076, DOI: 10.1016/S0009-2509(02)00358-5

Woo, K. S., Kim, H. Y., Hwang, I. G., Lee, S. H., and Jeong, H. S. (2015). “Characteristics of the thermal degradation of glucose and maltose solutions,” Prev. Nutr. Food Sci. 20(2), article no. 102. DOI: 10.3746/pnf.2015.20.2.102

Xu, Z. M., Luo, J., and Huang, Y. B. (2022). “Recent advances in the chemical valorization of cellulose and its derivatives into ester compounds,” Green Chem. 24(10), 3895-3921. DOI: 10.1039/D2GC00377E

Zhang, J. Z., Wang, X. M., Zhang, S. F., Gao, Q., and Li, J. Z. (2013). “Effects of melamine addition stage on the performance and curing behavior of melamine-urea-formaldehyde (MUF) resin,” BioResources 8(4), 5500–5514. DOI: 10.15376/biores.8.4.5500-5514

Zhang, J., Chen, H., Pizzi, A., Li, Y., Gao, Q., and Li, J. (2014). “Characterization and application of urea-formaldehyde-furfural co-condensed resins as wood adhesives,” BioResources 9(4), 6267-6276. DOI: 10.15376/biores.9.4.6267-6276

Zhang, L. (2018). “Formaldehyde: Exposure, toxicity and health effects,” Royal Society of Chemistry 37, 1-19. DOI: 10.1039/9781788010269

Zhen, X., Li, H., Xu, Z., Wang, Q., Zhu, S., Wang, Z., and Yuan, Z. (2021). “Facile synthesis of lignin-based epoxy resins with excellent thermal-mechanical performance,” Int. J. Biol. Macromol. 182, 276-285. DOI: 10.1016/j.ijbiomac.2021.03.203

Article submitted: May 19, 2022; Peer review completed: July 17, 2022; Revised version received and accepted: August 2, 2022; Published: August 16, 2022.

DOI: 10.15376/biores.17.4.5769-5784