Abstract

The demand for timber resources in the building industry has been increasing. Plantation Eucalyptus nitens is of interest because of its sustainable supply and potential for structural applications. However, few design standards cover strength values of plantation eucalypt timber, especially flexural failure below and above the fibre saturation point, which is an important mechanism of failure in bending members used in the building industry. Static bending tests were undertaken using a universal testing machine to examine nonlinear bending behaviour of 130 fibre managed E. nitens small clear wood samples at low and high moisture contents (MC). The mean bending modulus of rupture (MOR) was 80.7 MPa for low MC and 59.0 MPa for high MC. The high MC samples exhibited larger displacements at low ultimate loads, while the low MC samples showed abrupt failures at relatively small displacements with high ultimate loads. The design characteristic values for low and high MC E. nitens were 68.5 MPa and 39.8 MPa, respectively. This research demonstrates that fibre managed E. nitens timber is a promising timber for structural applications, especially when exposed to water, as the MOR reduction of E. nitens timber above FSP is relatively lower than those of P. radiata, which is a traditional construction material.

Download PDF

Full Article

Flexural Characteristics of Eucalyptus nitens Timber with High Moisture Content

Yingyao Cheng,a,b,* Gregory Nolan,b,c Damien Holloway,a Jaskiran Kaur,a Michael Lee,c and Andrew Chan a

The demand for timber resources in the building industry has been increasing. Plantation Eucalyptus nitens is of interest because of its sustainable supply and potential for structural applications. However, few design standards cover strength values of plantation eucalypt timber, especially flexural failure below and above the fibre saturation point, which is an important mechanism of failure in bending members used in the building industry. Static bending tests were undertaken using a universal testing machine to examine nonlinear bending behaviour of 130 fibre managed E. nitens small clear wood samples at low and high moisture contents (MC). The mean bending modulus of rupture (MOR) was 80.7 MPa for low MC and 59.0 MPa for high MC. The high MC samples exhibited larger displacements at low ultimate loads, while the low MC samples showed abrupt failures at relatively small displacements with high ultimate loads. The design characteristic values for low and high MC E. nitens were 68.5 MPa and 39.8 MPa, respectively. This research demonstrates that fibre managed E. nitens timber is a promising timber for structural applications, especially when exposed to water, as the MOR reduction of E. nitens timber above FSP is relatively lower than those of P. radiata, which is a traditional construction material.

Keywords: Eucalyptus; Static bending; High moisture content; Design characteristic value

Contact information: a: School of Engineering, University of Tasmania, Hobart, Australia; b: ARC Centre for Forest Value, University of Tasmania, Hobart, Australia; c: Centre for Sustainable Architecture with Wood, University of Tasmania, TAS 7001, Launceston Tasmania, Australia;

* Corresponding author: Yingyao.Cheng@utas.edu.au

INTRODUCTION

Timbers from fast-growing eucalypts are now considered to be building materials with extensive potential (Gilbert et al. 2017; Nocetti et al. 2017; Hein and Brancheriau 2018; Derikvand et al. 2019a, 2019b; Pagel et al. 2020); one such resource is plantation Eucalyptus nitens (Derikvand et al. 2019b, 2019c). For many practical applications, bending stiffness (modulus of elasticity, MOE) and strength (modulus of rupture, MOR) are of interest, as they determine the mechanical performance of timber members (Arnold 2009; Nocetti et al. 2015, 2016; Hein and Brancheriau 2018; Derikvand et al. 2019a; Brunetti et al. 2020). However, the stiffness and strength of wood can decrease significantly as moisture content (MC) increases above equilibrium (i.e., the fibre saturation point, FSP) (Nocetti et al. 2015; Aicher and Stapf 2016). The aim of this study was to determine the MOE and MOR values at low and high moisture contents in E. nitens timber, harvested from fibre managed (thinned and pruned) plantations. In this study, low MC means that MC is less than 15%, which is the normal situation for E. nitens timber as used in the building industry, and high MC means that the MC is above equilibrium, which is the extreme situation for E. nitens in structural applications when exposed to water. This information will be used to establish design characteristic values that can allow E. nitens to be used as a structural material, and in particular, for its potential application in a water-saturated state.

The increasing demand for timber in the construction industry together with a shortage of supply from native forests has called for additional plantation resources (Crafford and Wessels 2016; Derikvand et al. 2016; Gilbert et al. 2017). A potential new resource is fast-growing plantation eucalypts; E. nitens is one option because of its sustainable supply and possible use in building applications (Derikvand et al. 2019b, 2019c; Pagel et al. 2020). To use such a resource as structural or engineered timber, its mechanical properties need to be known, so as to establish design codes and specifications (Derikvand et al. 2019c), although a number of previous studies have been undertaken to examine the physical properties of wood fibre (Medhurst et al. 2012; Zhao et al. 2020) or bending properties of sawn boards from E. nitens plantations (Derikvand et al. 2019a, 2019b). A visual grading method was applied to evaluate the strength grade of dimensioned E. nitens timber. However, this method was not always appropriate (Derikvand et al. 2019b), and more experimental work was needed.

The safety of timber structures is a major concern in construction. The strength of timber usually decreases as the MC increases, and in the case of high MC, the strength can decrease by a factor of up to 50% (Aicher and Stapf 2016). At the same time, wood has many mechanical failure modes: tensile failure; compressive failure; shear failure, and flexural failure (Polyanin and Manzhirov 2000). Flexural failure is particularly important in beams and in bending members in buildings, bridges, and foundations (Bal and Bektaş 2012; Gilbert et al. 2014; Derikvand et al. 2019a, 2019b). At present, few design standards cover flexural strength values for E. nitens timber, especially in the high MC range (Aicher and Stapf 2016; AS/NZS 4063 2010; ASTM D2899 2012). Lack of this information may lead to the unsafe use of E. nitens, especially where the timber is saturated. For example, timber piles immersed in soil near coast for a long time. For timber above the water table, water can be drawn into the wood by capillary action and can lead to moisture content in the piles above their fibre saturation point. Another example in which wood would become completely soaked in normal usage is when a timber houses in a flood zone. In such cases, the timber members may become immersed in flood water for a long time and became saturated with water. Bending properties in engineered E. nitens wood products proposed for design purposes must therefore be addressed for both low and high moisture content situations.

The design characteristic values for wood strength are key parameters in determining the safety of wood members in structural applications and these are generally determined by full-size and small clear sample testing (Gong et al. 2017). Full-size testing takes natural defects and size into consideration (Gong et al. 2017); test results are therefore close to reality. However, according to the design code for timber structures (AS/NZS 4063 2010; ASTM D2899 2012), design characteristic values are still based on small clear sample testing; therefore, for this study, small clear samples were used as a first step in the development of the design characteristic values for E. nitens timber at both low and high moisture contents.

This study uses national testing standards (ASTMD 143-09 2009) to examine the effects of high moisture content on the bending strength of wood from fibre-managed plantation-grown E. nitens. An experimental investigation on the MOR and MOE of commercial timber species, radiata pine (P. radiata), at both low and high moisture contents was also undertaken as a comparison. The specific objectives were to:

- Obtain load-displacement curves of fibre managed E. nitens samples in four-point bending for both low and high moisture contents;

- Determine the flexural characteristic (MOR and MOE) of fibre managed E. nitens samples for both low and high moisture contents; and

- Obtain the design characteristic values for fibre managed E. nitens bending samples for both low and high moisture contents.

EXPERIMENTAL

Materials

An experimental investigation of E. nitens was undertaken to obtain load and deflection curves in four-point bending tests, at both low and high moisture contents. Here, low moisture content means that the MC was less than 15%, also called “dry condition”. High MC means that the MC is above the fibre saturation point (FSP), also called “wet condition”. The FSP varies between species but is typically in the range 20 to 30% (Ross 2010; Dieste et al. 2013; Engelund et al. 2013; Nocetti et al. 2015; Aicher and Stapf 2016). The FSP for E. nitens is usually assumed be 30% (Dawson et al. 2020). MC for the “dry” and “wet” E. nitens samples tested in the present study were in the range from 9.7% to 12.6% for dry samples and from 57.9% to 124.3% for wet samples, with mean (COV) values of 12% (5.4%) and 86% (16.7%), respectively (Table 2). The MOE and MOR in bending at both high and low moisture contents were determined from these load-displacement curves. The test samples and methods are summarised in Table 1.

As E. nitens is currently used for wood pulp in industry, E. nitens samples are not available in the market. E. nitens boards were specially ordered from the industry partner, Britton Timbers (Smithton TAS, Australia). The samples were cut from well-defined tangential, radial, and transverse faces of E. nitens boards. The boards were randomly selected from different logs at a local mill and were originally from a 16-year-old E. nitens pulpwood plantation located in the Woolnorth region of NE Tasmania, Australia, which has a maximum altitude of 190 m.

These were compared with P. radiata samples for the same dimension, cut from P. radiata boards with same feature. The P. radiata boards were purchased from a local trader (McKay Timber, Glenorchy TAS, Australia).

In total, 130 small clear E. nitens samples were used in the four-point bending tests. Half of them had a low moisture content (i.e., 65 dry samples) and the other half had a high moisture content (65 wet samples). The dry samples were from boards dried in an industrial hardwood kiln and then stored indoors 20 °C and 65% relative humidity (RH) for 3 months, while the wet samples were soaked in deionised water for 3 months to make sure they were fully saturated. They were then tested within one day of removal from the water to make sure the wet samples were in a MC value above FSP. A simple soaking process (normal soaking) was used to increase the MC of the timber samples (Arnold 2009), i.e., samples were simply placed into a large container filled with water and a heavy weight placed on the samples to keep them fully submerged.

In this study 100 P. radiata samples were used. Fifty were tested at dry condition and the rest were tested at wet condition, which used the same soaking process as the E. nitens samples. Moisture content (MC) for dry samples is below the fibre saturation point (FSP), whilst wet is above. The FSP for P. radiata is 21 to 30% (Ross 2010). Moisture content distribution for P. radiata was provided in Fig. 1 compared with E. nitens samples.

Fig. 1. Boxplot of MC for P. radiata samples compared with E. nitens samples

Testing Facilities and Procedure

The support frame consisted of a four-point bending test frame with 3 spans of 120 mm each (Fig. 2). These tests were performed on a universal testing machine (Hounsfield H50KM 50 kN, serial number H50KM/669; Tinius Olsen Ltd., Surrey, UK). Prior to testing, the weights and dimensions of the samples were measured to determine their densities and volumes at testing time.

Fig. 2. Schematic diagram of four-point bending

The tests were conducted at roughly 20 °C, and the RH was in the range of 50% to 70%. Immediately after testing, small pieces from each sample were cut and oven dried for 72 h to determine moisture content according to AS/NZS 1080.1 (2012).

The samples had five types of the test sample direction, as they have annual growth ring angles of 0°, 30°, 45°, 60° or 90° in the cross section defined by wood handbook (Ross 2010). Each annual growth ring angle had 26 samples for E. nitens and 20 samples for P. radiata, while half was dry samples (MC < 15%), and the other half was wet samples (MC > FSP).

Data Analysis

MOE and MOR

Material properties of timber in bending (MOE and MOR) were calculated according to Eqs. 1 and 2, respectively.

(2)

Moisture content and basic density

The moisture content (MC) of the samples was calculated using AS/NZS 1080.1 (2012), while basic density was calculated using Eq. 3 (Derikvand et al. 2019c),

(3)

where b is basic density (kg/m3), M is the mass of the test piece after oven drying (kg), V is the volume of test piece before oven-drying (m3), and MC is the moisture content (%).

Moisture adjustment factor of completely water-saturated state to dry

A moisture adjustment factor (Nocetti et al. 2015), F(MC), is defined as showing the relative influence of moisture on MOR compared with a reference MC, usually at 12%. Moisture modification factor above FSP, Eq. 4, is given by,

(4)

where c is constant depending on experimental results.

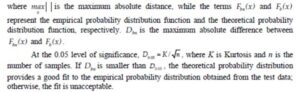

Statistical analyses were undertaken using Matlab (The MathWorks Inc., version 2018a, Natick, MA, USA). Theoretical probability functions of normal distribution and lognormal distribution were applied to fit the probability distributions of MOR for dry and wet samples. A Kolmogorov–Smirnov test (K–S test) was applied to evaluate the fit between the theoretical probability distribution and the empirical probability distribution obtained from the experimental data, as it is sensitive to differences in both the location and shape of the probability distribution functions (Bryc 1995). The formula for the K–S test can be expressed as follows,

(5)

RESULTS AND DISCUSSION

Load-displacement Curves

Figure 3 presents typical load-displacement behaviour for small clear E. nitens and P. radiata samples at the loading point, i.e., the one-third point. The dry samples exhibited a more extensive linear phase in the load-displacement curve with sudden brittle ruptures compared with the wet samples (Figs. 3a and 3b).

Fig. 3. Load-displacement curves of E. nitens in bending compared with P. radiata samples, (a) E. nitens samples and (b) P. radiata samples. “Dry” means that the MC of the samples is less than 15%. “Wet” means that the MC of the samples is above FSP, approximately 30%. The wet samples were immersed in water for 3 months to let the samples be as saturated as possible.

A distinctly different ductile bending behaviour in wet samples was observed in the load–displacement curves. The wet samples exhibited considerably larger displacements at lower maximum loads, while the dry samples showed relatively small displacements just beyond the proportional limit, connected with somewhat higher maximum loads. This reveals that the samples become more flexible after absorbing water compared with the brittle and sudden failure in dry samples.

A significant difference in the value of ultimate loads and the displacement at ultimate load can be seen when comparing E. nitens and P. radiata samples at high MC. The P. radiata samples exhibited more ductile character, i.e., they attained the higher value of displacement at their ultimate load (before the curve goes down) than E. nitens. This is because P. radiata is a soft wood, and the loading nose penetrated the sample (Fig. 4), causing bearing failure during testing and affecting the load and displacement curves. This was observed in most of the P. radiata samples at high MC.

Fig. 4. Bearing failure for P. radiata samples, (a) penetration of loading nose during testing; (b) impression of loading nose

Failure Modes

Although the failure was initiated in different areas in various samples, two types of failure were most frequently observed during testing: combined compression with tension failure (Fig. 5a, b) and bending tension failure (Fig. 5c, d).

Fig. 5. Failure modes of the four-point bending E. nitens samples; dry samples (a, c); wet samples (b, d); combined compression with tension failure (a, b); bending tension failure (c, d). The values of MC on the photos are the specific MC of the testing samples shown in the photos. The 86% is a mean value of MC for the wet samples.

All the dry samples of E. nitens, (i.e., with MC less than 15%), showed a sudden tensile rupture (Fig. 5a, c), which is consistent with typical observations for clear timber beams (ASTMD 143-09 2009; Ross 2010; Bal and Bektaş 2012; Derikvand et al. 2019c). Once a tensile rupture occurred, it propagated rapidly throughout the test sample. The current study firstly examined the nonlinear bending behaviour of wet E. nitens samples and found ductile failure behaviours comparable to behaviour in the dry samples with the cracks remaining localised (Fig. 5b, d). This is due to the water present in the wet samples providing lubrication between the grain fibres, allowing them to slide easily from one state to another at a microscopic level, while undergoing shear deformation, thus allowing a redistribution of local stresses. Similar failure modes were found for P. radiata.

For combined compression with tension failure mode, three phases of bending failure were observed: The first, an elastic phase indicates that neither the tensile stress nor the compressive stress is larger than its ultimate value and the corresponding deformation can be fully recovered. The next phase was compression failure, when compressive strength was reached in the compressive side of the sample (i.e., the top surface) while the tensile stress was less than its ultimate values. At this time, compression failure appeared in the compressive side of the sample and the neutral axis shifted toward its tensile side (i.e., the bottom surface). In other areas of the samples that were under bending-induced tension and compression, the material was loaded elastically. The third phase, tension failure appearance with crack initiation, was characterised by the appearance and development of cracks in the tensile side of the samples when the tensile strength was reached. These cracks caused the neutral axis to shift toward the compression side. This three-phase failure behaviour, which was found in both dry and wet test samples, was generally found in good quality test specimens where the tensile capacity was higher than the compressive capacity.

For the bending tensile failure mode, the only phases observed were the elastic phase and the crack initiation phase (on the tensile surface of the test specimen). This failure mode, characterised by brittle failure of the tensile side, without a yielding on the compressive side, was usually observed in test specimens having a slight grain angle. After cracks were initiated, they developed along the grain.

Basic Density, MOE, and MOR

There was acceptable agreement with values of basic density measured with previous studies (Farrell et al. 2008; Derikvand et al. 2019c). The average values of the basic density from both dry and wet plantation E. nitens samples were 520.4 kg/m3 and 496.9 kg/m3, respectively (Table 2). It also was found that the mean values for basic density were close to that reported by Farrell et al. (2008) for wet samples and Derikvand et al. (2019c) for dry samples, with the difference less than 5%.

Another important measure, MOE, ranged from 10.0 to 13.2 GPa for dry samples and from 6.4 to 11.6 GPa for wet samples, with mean values of 11.8 and 9.5 GPa, respectively (Fig. 5 and Table 2). The MOR values were in the range of 62.2 to 100.3 MPa for dry samples and 23.9 to 87.7 MPa for wet samples, with mean values of 80.7 and 59.0 MPa, respectively. These lie in the ranges of those of Farrell et al. (2008) and Hein and Brancheriau (2018) for high moisture samples and for low moisture samples, respectively (Fig. 5). The coefficients of variation (COV) for MOE and MOR in both dry and wet samples were also examined. The COVs of MOR and MOE for dry samples were lower than the corresponding cases provided by the Wood Handbook (Ross 2010) and Hein and Brancheriau (2018) (Table 2). These lower COVs were due to the samples being cut from the same boards and being defect-free, with clear samples being selected to avoid the influences of non-uniformities in the wood samples, as studied in the Wood Handbook (Ross 2010), Farrell et al. (2008), and Hein and Brancheriau (2018). The COVs of MOR and MOE for wet samples were higher than those for dry samples due to the wet samples covering a broad moisture range. Therefore, this study is shown to be reasonable and repeatable data for plantation-grown E. nitens.

Significant influence from high MC was found on the MOR and MOE of samples for E. nitens and P. radiata in this study (Fig. 6). The high MC correlates with low values of MOR and MOE. At high MC, the maximum MOR among the group of P. radiata samples was less than those in the group of E. nitens, while they are close for dry samples, indicating a higher value of the mean moisture adjustment factor above FSP for E. nitens.

Fig. 6. Boxplot of MOE and MOR for E. nitens samples compared with other studies on plantation eucalypt species, H18 (Hein and Brancheriau 2018), F08 (Farrell et al. 2008), and P. radiata samples: (a) MOE; (b) MOR

Linear Regression Models for MOE-MOR

The regression statistics between the MOE and MOR of E. nitens samples for dry and wet conditions are presented in Table 3, comparing with the P. radiata samples.

Positive correlations between MOE and MOR for the two species at both dry and wet conditions were found. In other words, MOR increased with an increase in MOE. Linear-regression models were also developed in the study and showed that more than 48% of variations in the MOR for dry E. nitens samples and 41% of variations in the MOR for wet E. nitens samples could be explained by their MOE values (Table 3).

The relationship between MOE and MOR for P. radiata samples showed a weak correlation (R2 = 0.47 for dry and R2 = 0.34 for wet), implying that MOE of E. nitens affects its MOR more significantly compared with softwood species, P. radiata, in this study. The similarity between the regression models for both dry and wet samples indicates that the MOR of E. nitens samples can be predicted from their MOE below and above FSP.

Characteristic Values and Moisture Adjustment Factors Above FSP

For many practical applications, the MOR is of interest, as it indicates the mechanical performance of timber bending members. The empirical probability distributions of MOR of E. nitens in both dry and wet states were determined from the test data to assess its suitability for use in building structures. The results of the K-S test are presented in Table 4, in which different data sets had different critical (D0.05) and maximum (Dbn) absolute difference values.

With the exception of Wet-E (F08), which showed only the normal probability distribution fitted the testing data, both theoretical probability distributions fitted the experimental data; however, the normal probability distribution showed a better fit as it had smaller maximum absolute difference. An additional check has been undertaken using Anderson-Darling (A-D) Test. It gives more weight to the tails than does the K-S test (Anderson and Darling 1952; Anderson and Darling 1954; Stephens 1974). By putting the same data through the A-D test, all the experimental data were confirmed to fit a normal distribution (Fig. 7).

Fig. 7. The result of Anderson-Darling (A-D) Test for normal distribution of MOR from plantation eucalypt samples; dry samples (a, c); wet samples (b, d); A-D Test for the MOR from authors’ testing (a, b); A-D Test for the MOR from values given in other research, (c) Hein and Brancheriau (2018) and (d) Farrell et al. (2008). If squared distance A2 is less than critical value at the 0.05 level of significance, the data fit the normal distribution, otherwise, the fit is unacceptable.

This finding was consistent with previous research for other species, for example P. radiata species (AS/NZS 4063 2010). Basic statistical parameters and the characteristic values of lognormal distribution and normal distribution for Eucalyptus timber are shown in Table 4. For the better fitting probability distribution, i.e., normal distribution, suggested design characteristic values of fibre managed plantation-grown small clear E. nitens samples for dry and wet conditions were 68.5 and 39.8 MPa, respectively.

The moisture adjustment factor of completely water-saturated state to dry for fibre managed plantation E. nitens in this study was at 0.58 at a 5% percentile level and 0.73 at mean level (Table 4 and Fig 8), respectively, while the mean moisture adjustment factor above FSP for P. radiata was 0.55, which was close to that provided in the Wood Handbook (Ross 2010), in which this the moisture adjustment factor was 0.52 at mean level for P. radiata. The moisture adjustment factor of E. nitens at the mean level was relevantly higher than P. radiata, and other hardwood species, such as Mora, F(MC > FSP)mean = 0.57 (Ross 2010), and other softwood species, for example Spruce F(MC > FSP)mean = 0.53 (Ross 2010), implying a potential use of E. nitens by the building industry, especially where the timber is vulnerable to water.

Fig. 8. Relationship of MORMC/ MOR12 vs.MC for E. nitens timber. S.D. = Standard deviation.

CONCLUSIONS

- This study determined the mechanical bending strength of E. nitens from fibre-managed plantation at both low and high moisture contents. It was found that fibre-managed plantation E. nitens is promising to use as a structural material. The bending strength values were obtained by performing four-point bending tests with a universal testing machine, and samples were from a 16-year-old fibre managed E. nitens sourced from Tasmania, Australia. Similar tests were undertaken on P. radiata for comparison.

- Load and displacement curves for E. nitens samples in bending were determined. Dry samples, in general, failed by brittle fracture with a sudden tensile rupture in the timber, while wet samples featured larger displacements at lower maximum loads and failed by ductile failure with several drops in their load-displacement curves, indicating alternating periods of rupture and hardening.

- The mean and variation of material properties for E. nitens, such as MOE and MOR, at both low and high moisture contents were determined. The agreement between the data in this study and findings reported by other research (Farrell et al. 2008; Hein and Brancheriau 2018) on plantation Eucalyptus timber for low and high moisture contents showed that the results of E. nitens in these tests are reasonable for both low and high moisture content states.

- For design purposes, linear-regression models were developed based on the correlations between MOR and MOE of the E. nitens in low and high MC and compared with the models for P. radiata samples. The correlation between MOR and MOE was also sufficiently good to allow estimates of MOR from its MOE of E. nitens to be obtained.

- The bending strength probability distributions of E. nitens at both low and high moisture contents were estimated. The normal distribution showed a better fit and was selected to determine design characteristic values presented in this paper. The design characteristic values for small clear E. nitens samples with low and high moisture contents were 68.5 and 39.8 MPa, respectively.

- Significant influence from high MC was found on the MOR and MOE of samples for E. nitens in this study. The high MC links with low values of MOR and MOE. The test results for small clear E. nitens wood in four-point bending provided moisture modification factors above FSP for 0.58 and 0.73 at the 5th percentile and mean strength level, respectively, which was relevantly higher than those of P. radiata.

- The results showed that fibre managed plantation E. nitens shows promise as a material to be used in the construction industry for bending members especially in water saturated conditions. However, there is still a lack of knowledge on the mechanical properties of full-size E. nitens timber with consideration of knots and defects at high moisture content, further work could include experimental work on full-size E. nitens timber to facilitate using this resource in a fully water-saturated state for building applications.

ACKNOWLEDGMENTS

The authors are grateful for the help and support of the technicians, Mr. Andrew Bylett, and Mr. Calverly Gerard in the workshop at the University of Tasmania. The first author also would like to thank Ms. Barbara Meyer, Dr. Chris Beadle, and Dr. Mohammad Derikvand for fruitful discussions.

This research was funded by Tasmania Graduate Research Scholarship, University of Tasmania, Australia is acknowledged. The additional support from the Australian Research Council, Centre for Forest Value, and University of Tasmania, TAS, Australia, grant number IC150100004.

REFERENCES CITED

Aicher, S., and Stapf, G. (2016). “Compressive strength parallel to the fiber of spruce with high moisture content,” European Journal of Wood and Wood Products 74(4), 527-542. DOI: 10.1007/s00107-015-1004-z

Anderson, T. W., and Darling, D. A. (1952). “Asymptotic theory of certain “goodness-of-fit” criteria based on stochastic processes,” Annals of Mathematical Statistics 23, 193-212. DOI:10.1214/aoms/1177729437

Anderson, T. W., and Darling, D. A. (1954). “A test of goodness-of-Fit,” Journal of the American Statistical Association 49, 765-769. DOI:10.2307/2281537

Arnold, M. (2009). “Effect of moisture on the bending properties of thermally modified beech and spruce,” Journal of Materials Science 45(3), 669-680. DOI: 10.1007/s10853-009-3984-8

AS/NZS 1080.1 (2012). “Timber—Methods of test—Moisture content,” Standards Australia, Sydney, Australia.

AS/NZS 4063 (2010). “Characterization of structural timber Part 1: Test method,” Standards Australia, Sydney, Australia.

ASTM D143-09 (2009). “Standard test methods for small clear specimens of timber,” ASTM International, West Conshohocken, PA, USA.

ASTM D2899 (2012). “Standard practice for establishing allowable stresses for round timber piles,” ASTM International, West Conshohocken, PA, USA.

Bal, B. C., and Bektaş, İ. (2012). “The effects of some factors on the impact bending strength of laminated veneer lumber,” BioResources 7(4), 5855-5863. DOI: 10.15376/biores.7.4.5855-5863

Brol, J., and Wdowiak-Postulak, A. (2019). “Old timber reinforcement with FRPs,” Materials 12(24), Article ID 4197. DOI: 10.3390/ma12244197

Brunetti, M., Nocetti, M., Pizzo, B., Aminti, G., Cremonini, C., Negro, F., Zanuttini, R., Romagnoli, M., and Scarascia Mugnozza, G. (2020). “Structural products made of beech wood: Quality assessment of the raw material,” European Journal of Wood and Wood Products 78(5), 961-970. DOI: 10.1007/s00107-020-01542-9

Bryc, W. (1995). The Normal Distribution: Characterizations with Applications, Vol. 100, Springer-Verlag, New York, NY, USA.

Crafford, P. L., and Wessels, C. B. (2016). “The potential of young, green finger-jointed Eucalyptus grandis lumber for roof truss manufacturing,” Southern Forests: A Journal of Forest Science 78(1), 61-71. DOI: 10.2989/20702620.2015.1108618

Dawson, B. S. W., Pearson, H., Kimberley, M. O., Davy, B., and Dickson, A. R. (2020). “Effect of supercritical CO2 treatment and kiln drying on collapse in Eucalyptus nitens wood,” European Journal of Wood and Wood Products 78, 209-217. DOI: 10.1007/s00107-020-01500-5

Derikvand, M., Jiao, H., Kotlarewski, N., Lee, M., Chan, A., and Nolan, G. (2019a). “Bending performance of nail-laminated timber constructed of fast-grown plantation eucalypt,” European Journal of Wood and Wood Products 77(3), 421-437. DOI: 10.1007/s00107-019-01408-9

Derikvand, M., Kotlarewski, N., Lee, M., Jiao, H., Chan, A., and Nolan, G. (2019b). “Short-term and long-term bending properties of nail-laminated timber constructed of fast-grown plantation eucalypt,” Construction and Building Materials 211, 952-964. DOI: 10.1016/j.conbuildmat.2019.03.305

Derikvand, M., Kotlarewski, N., Lee, M., Jiao, H., and Nolan, G. (2019c). “Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown Eucalyptus nitens H. Deane & Maiden lumber,” Forests 10(2), Article Number 194. DOI: 10.3390/f10020194

Derikvand, M., Nolan, G., Jiao, H., and Kotlarewski, N. (2016). “What to do with structurally low-grade wood from Australia’s plantation eucalyptus; building application?,” BioResources 12(1), 4-7. DOI: 10.15376/biores.12.1.4-7

Dieste, A., Rodríguez, K., and Baño, V. (2013). “Wood–water relations of chestnut wood used for structural purposes,” European Journal of Wood and Wood Products 71(1), 133-134. DOI: 10.1007/s00107-012-0627-6

Engelund, E. T., Thygesen, L. G., Svensson, S., and Hill, C. A. S. (2013). “A critical discussion of the physics of wood–water interactions,” Wood Science and Technology 47(1), 141-161. DOI: 10.1007/s00226-012-0514-7

Farrell, R., Innes, T., and Nolan, G. (2008). “Sorting plantation Eucalyptus nitens logs with acoustic wave velocity,” Forest & Wood Products Australia (FWPA): Victoria, Australia, (https://www.fwpa.com.au/images/processing/FWPA_PN07%203018_ acoustic_sorting.pdf), Accessed 18 July 2020.

Gilbert, B. P., Bailleres, H., Fischer, M. F., Zhang, H., and McGavin, R. L. (2017). “Mechanical properties of rotary veneers recovered from early to midrotation subtropical-hardwood plantation logs for veneer-based composite applications,” Journal of Materials in Civil Engineering 29(10), Article ID 04017194. DOI: 10.1061/(ASCE)MT.1943-5533.0002055

Gilbert, B. P., Underhill, I. D., Bailleres, H., El Hanandeh, A., and McGavin, R. L. (2014). “Veneer based composite hollow utility poles manufactured from hardwood plantation thinned trees,” Construction and Building Materials 66, 458-466. DOI: 10.1016/j.conbuildmat.2014.05.093

Gong, Y., Wu, G., Luo, X., Wang, Z., Jiang, J., and Ren, H. (2017). “Research on design value of compressive strength for Chinese fir dimension lumber based on full-size testing,” Journal of Wood Science 63(1), 56-64. DOI: 10.1007/s10086-016-1592-1

Hein, P. R. G., and Brancheriau, L. (2018). “Comparison between three-point and four-point flexural tests to determine wood strength of Eucalyptus specimens,” Maderas. Ciencia y Tecnología 20(3), 333-342. DOI: 10.4067/s0718-221×2018005003401

Medhurst, J., Downes, G., Ottenschlaeger, M., Harwood, C., Evans, R., and Beadle, C. (2012). “Intra-specific competition and the radial development of wood density, microfibril angle and modulus of elasticity in plantation-grown Eucalyptus nitens,” Trees 26(6), 1771-1780. DOI: 10.1007/s00468-012-0746-z

Nocetti, M., Brunetti, M., and Bacher, M. (2015). “Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber,” European Journal of Wood and Wood Products 73(1), 51-60. DOI: 10.1007/s00107-014-0861-1

Nocetti, M., Brunetti, M., and Bacher, M. J. M. (2016). “Efficiency of the machine grading of chestnut structural timber: Prediction of strength classes by dry and wet measurements,” Materials and Structures 49(11), 4439-4450. DOI: 10.1617/s11527-016-0799-3

Nocetti, M., Pröller, M., Brunetti, M., Dowse, G. P., and Wessels, C. B. (2017). “Investigating the potential of strength grading green Eucalyptus grandis lumber using multi-sensor technology,” BioResources 12(4), 9273-9286. DOI: 10.15376/biores.12.4.9273-9286

Pagel, C. L., Lenner, R., and Wessels, C. B. (2020). “Investigation into material resistance factors and properties of young, engineered Eucalyptus grandis timber,” Construction and Building Materials 230, Article ID 117059. DOI: 10.1016/j.conbuildmat.2019.117059

Polyanin, A. D., and Manzhirov, A. D. (2000). Timber: Its Nature and Behaviour, CRC Press, Boca Raton, FL, USA.

Ross, R. J. (2010). Wood Handbook: Wood as an Engineering Material (Report No. FPL-GTR-190), USDA Forest Service, Forest Products Laboratory, Madison, WI, USA.

Stephens, M. A. (1974). “EDF statistics for goodness of fit and some comparisons,” Journal of the American Statistical Association 69, 730-737. DOI:10.2307/2286009.

Zhao, C., Hu, Z., Wang, C., Yue, F., Li, S., Zhang, H., and Lu, F. (2020). “Profiling of the formation of lignin-derived monomers and dimers from eucalyptus alkali lignin,” Green Chemistry 2020(22), 7366-7375. DOI: 10.1039/D0GC01658F

Article submitted: December 31, 2020; Peer review completed: January 24, 2021; Revised version received and accepted: February 26, 2021; Published: March 2, 2021.

DOI: 10.15376/biores.16.2.2921-2936