Abstract

Vegetal fibers from different sources, including wood fibers and plant-derived fibers, together with polymer plastics per se (natural, synthetic, and their blends), as well as their combinations as composite materials may generate significant amounts of wastes. These will undergo degradation process under exposure to different environmental factors including microorganisms, climatic changes – e.g. droughts, oxygen, temperature, soil dynamics, UV radiation, etc. This survey offers a concise review of degradation under environmental conditions, mainly after in-soil exposure, of waste made of polymer materials and natural fibers. It also describes the most common methods for evaluation of bioconversion and degradation, as well as the structural properties after degradation (e.g. macroscopic investigation; weight loss; spectrometry – UV, FTIR, NMR; X-ray diffraction for crystalline changes; SEM microscopy; and thermal stability).

Download PDF

Full Article

In-Soil Degradation of Polymer Materials Waste –A Survey of Different Approaches in Relation with Environmental Impact

Carmen-Alice Teacă,a,* Mauruşa-Elena Ignat,a Marioara Nechifor,b Fulga Tanasă,b and Leonard Ignat a

Vegetal fibers from different sources, including wood fibers and plant-derived fibers, together with polymer plastics per se (natural, synthetic, and their blends), as well as their combinations as composite materials may generate significant amounts of wastes. These will undergo degradation process under exposure to different environmental factors including microorganisms, climatic changes – e.g. droughts, oxygen, temperature, soil dynamics, UV radiation, etc. This survey offers a concise review of degradation under environmental conditions, mainly after in-soil exposure, of waste made of polymer materials and natural fibers. It also describes the most common methods for evaluation of bioconversion and degradation, as well as the structural properties after degradation (e.g. macroscopic investigation; weight loss; spectrometry – UV, FTIR, NMR; X-ray diffraction for crystalline changes; SEM microscopy; and thermal stability).

DOI: 10.15376/biores.18.1.Teaca

Keywords: Wastes; Wood fibers; Plant fibers; Polymers; Wood-polymer composites; Plant fibers-polymer composites; Degradation; Environmental impact; Evaluation of degradation

Contact information: a: Center of Advanced Research in Bionanoconjugates and Biopolymers, “Petru Poni” Institute of Macromolecular Chemistry, 41A Grigore-Ghica Vodă Alley, 700487 Iaşi, Romania; b: Polyaddition and Photochemistry Department, “Petru Poni” Institute of Macromolecular Chemistry, 41A Grigore-Ghica Vodă Alley, 700487 Iaşi, Romania

* Corresponding author: cateaca@icmpp.ro; cateaca14@yahoo.com

GRAPHICAL ABSTRACT

INTRODUCTION

Polymer materials play a significant role in improving the quality of life. They are omnipresent and fulfilling almost all daily needs of society. Polymer materials comprising natural and/or synthetic components are widely employed in many applications, such as packaging, agriculture, industry, transportation, construction, as well as in different defense strategies. This widespread usage is due to their good resilience conferred by remarkable properties (mechanical strength, resistance to chemical degradation, resistance to mechanical wear, relatively low density, and low cost), and this is all despite their incomplete degradation and ability to persist for a long time under exposure to environmental conditions. It follows that implementation of proper disposal and recycling strategies are required in order to avoid harmful effects on the natural environment (water, soil, air, plants, animals, and even human beings). In this context, it is essential to consider all issues related to ensuring the effectiveness of long-term strategies for the environment, economy, and waste management.

Significant accumulation of solid waste and plastics litter, as a consequence of increased use of different polymer materials, represents a pronounced causative factor of environmental pollution in direct relation with their resistance to biodegradation. In general, global strategies for sustainable waste management are based on methods that involve waste prevention and recycling (Rudnik 2019). All these measures applied to cope with waste are aimed in fact to:

- prevent waste in the first place;

- recycle waste (the oldest known recycling method is composting);

- optimize the final disposal of waste.

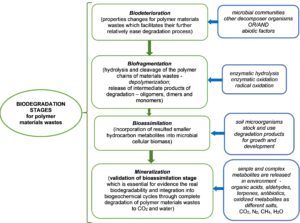

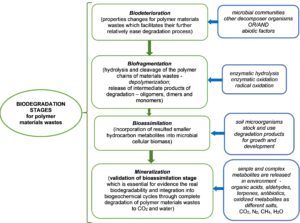

Currently, many research studies are oriented towards development of biodegradable polymer materials which can be further cleaved to their constitutive units (oligomers, dimers, and monomers) during the biodegradation process. This occurs by applying an effective and safe disposal strategy using soil or composting environments, and successfully reintroducing them into carbon cycles (Batista et al. 2010; Phetwarotai et al. 2013; Palsikowski et al. 2017; Lv et al. 2018; Salehpour et al. 2018). The resulting degradation products (Lucas et al. 2008), including carbon dioxide, water, biomass, inorganic compounds, are generally non-toxic and non-harmful to the environment. The main stages of biodegradation process are schematically represented in Fig. 1 (Shimao 2001; Lucas et al. 2008; Emadian et al. 2017; Yuan et al. 2020; Kotova et al. 2021).

Fig. 1. Schematic representation of biodegradation stages for polymer materials waste

Forestry industrial activities generate very large amounts of waste, which are currently pelletized, burned, or allowed to decay naturally, often producing environmental problems such as contamination of water and soil (including underground), as well as air pollution. Wood fibers waste represents a significant proportion of the waste stream. Wood processing sectors, namely forestry harvesting/sawmills and the pulp and paper production, produce significant amounts of wood waste, along with other activities, such as construction and demolition, wood packaging production, furniture, pallets and fencing manufacturing, roads and railway construction, housing, etc. (Cai et al. 2013).

Wood and other lignocellulosic fibers waste, from both virgin and recycled sources, represent principally a relatively inert, but organic material, which becomes more and more a priority polymer material, considering the rapid evolution of its processing strategies and end markets of this significantly redundant waste material (Coudert et al. 2013; Laleicke 2018; Berger et al. 2020; Li et al. 2020; Xing et al. 2020; Pandey 2022). Some new lignocellulosic sources can be mentioned, and these include paper mill sludge and biorefinery residues (Jaria et al. 2017; Panzella et al. 2019; Kwon et al. 2020; Du et al. 2020; Husanu et al. 2020; Moccia et al. 2022).

Wood waste (sawdust, wood chips, shavings, bark, etc.) present disposal problems for industries that generate them. Tree bark is usually disposed in landfill sites, which are often adjacent to the rivers. After the inherent degradation processes, various toxic products are leaching into the ground waters and rivers, thus raising serious environmental pollution issues. Relatively recent technologies are applied for capitalizing wood waste through compounding with plastics, mostly recycled, in order to produce a large and useful variety of wood-plastic composites (WPCs). These are commonly used for door frames, windowsills, decking and fencing, panels for interior design and compartmenting, sheets and shingles for buildings and roofing applications (Sommerhuber et al. 2015; Sommerhuber et al. 2016; Teuber et al. 2016; Keskisaari and Karki 2018; Akinyemi et al. 2019; Basalp et al. 2020; Boubekeur et al. 2020; Kaho et al. 2020; Mrówka et al. 2020). Wood and lignocellulosic fibers lead to WPC with superior properties by acting more as reinforcement than filler; thus a wise trend is to move toward the use of these fibers in applications requiring additional strength (Cai et al. 2013).

Bulky waste represents a significant and increasing waste stream in every country due to changes in habits and economic status, which results in finding affordable goods for fast replacement. This category of waste comprises, accordingly to the US Environmental Protection Agency (US EPA Terms of the Environment 2018), large items of solid waste such as household appliances, furniture, large auto parts, trees, branches, stumps, and other oversize waste whose large size precludes or complicates their handling by normal solid wastes collection, processing, or disposal methods. Manufacturing of WPCs from bulky waste at industrial scale can reduce the production cost, considering both the lower costs of employed materials and the visible reduction of the environmental effects of plastic waste (Basalp et al. 2020).

Degradation is a very complex and complicated process and depends on many factors, as represented in Fig. 2. Natural decay (biodegradation) represents an essential component of the carbon recycling system in nature. Biodegradable polymer materials of natural origin – wood fibers, plant fibers, as well as polymer plastics, per se or combined in different composite formulations – are permanently exposed to degradation processes of an environmental, chemical, or microbial nature.

The extent of the deterioration depends on the environment in which these materials are usually found in relation to their envisaged applications. Biodegradation of polymer materials waste occurs in relation with their properties (Tokiwa et al. 2009), being strongly related to both chemical and physical ones including: surface properties (area, hydrophilic, and hydrophobic behavior); molecular weight and polydispersity; thermal behavior (glass transition temperature, melting temperature); and crystalline structure and modulus of elasticity.

Fig. 2. Main factors influencing the complex degradation process of polymer materials

Most of the definitions of biodegradation process refer to the presence of microorganisms (bacteria, fungi) and their action on different polymer materials (natural, synthetic, or their combinations, per se or as waste resulting from different activities) when they cause, as preferable last stage, their conversion into carbon dioxide or methane and water, inorganic compounds, and biomass. Nevertheless, there are many situations in which the resulting products from degradation, as small pieces or powders, are not used by microorganisms as carbon and energy sources. This means that materials are degradable, but not biodegradable. It is also possible that materials cannot be subjected to composting as a recycling method, even though they are susceptible to being degraded or, moreover, biodegraded (Stevens 2002; Rudnik 2019).

Therefore, given the complexity of this assembly of correlated and interdependent phenomena which forms the in-soil degradation of polymer materials waste, and considering the variety of polymer waste that ends up intentionally or accidentally in soil, an extensive survey would be of interest. The aim of this paper was to illustrate, with examples from the most recent literature data, the main categories of polymer waste disposed in a controlled or irresponsible manner in soil, namely lignocellulose-sourced polymers, synthetic polymers, and natural fibers-polymer composites. At the same time, the degradation of each waste category is presented and discussed taking into account their specificity, but not comparing them. Simple comparison was not the goal of this work, since this type of environmental degradation occurs and evolves through a wide variety of mechanisms depending not only on the nature of waste and location (soil characteristics), but on season, vicinity, and degree of exposure, etc.

METHODS EMPLOYED FOR EVALUATION OF IN-SOIL DEGRADATION PROCESSES FOR POLYMER WASTES

Advances in the field of characterization techniques and devices have enabled scientists to use single or combined methods in order to evaluate the in-soil degradation of polymer materials. When experiments under controlled conditions (simulated media) are considered, it is very important to provide data collected before and after degradation for comparison reasons. Thus, it is possible to observe changes recorded at preset time intervals and/or monitor the evolution of certain characteristics.

If these characterization methods are used on samples collected from disposal sites, the progress of degradation can be assessed. The credibility of the results is raised when the polymers have been identified with a certain amount of validity, in comparison with technical data available in literature, if any, provided either by manufacturers or by other studies. Even more, these samples can be further submitted to other degradation experiments, under controlled conditions.

Data obtained from different characterization techniques provide information on the following aspects:

- Morphological changes occurring on the surface of the material, such as the presence of cracks, fractures, pores, etc. (microscopy – light microscopy, SEM, TEM, AFM);

- Modification of thermal stability and glass transition temperature (TGA, DTG, DSC);

- Alteration of crystallinity (FTIR, XRD) and mechanical properties (mechanical tests);

- Decrease in the molecular weight and formation of oligomers and other low molecular by-products (NMR, GPC, FTIR, mass spectroscopy).

By combining characterization techniques and discussing results in an integrative manner, reliable assessments can be made and further used to reach pertinent conclusions and provide insightful prognosis. For example, wood decay can be evidenced by using both transmission electron microscopy (TEM) and ultraviolet micro-spectrophotometry measurements, these providing details on the micromorphology of wood that is affected by the brown-rot fungi, and lignin degradation, mainly produced by white-rot fungi (Schmidt et al. 2016).

Scanning electron microscopy (SEM) makes it possible to obtain high-resolution 3D images and offers information on topography, morphology, and composition of various materials. SEM images are utilized in medical and biological sciences, soil and rock analysis, forensic examination, semiconductor, and microchip fields. This is one of the most commonly exploited methods for the imaging characterization of solid objects due to its resolution of about 2.5 nm.

Atomic-force microscopy (AFM) is a non-destructive surface scanning technique that picks up data for imagining surface topography studies and affords the investigation of the functional, electrical, or mechanical properties of materials at the nanoscale. Its lateral resolution is about 30 nm due to the convolution, while the vertical resolution can be down to 0.1 nm.

Thermogravimetric analysis (TGA) measures the thermal stability and composition of materials. This technique affords the evaluation of the composition of products and supplies information about physical phenomena (phase transitions, absorption, adsorption/ desorption) or chemical phenomena (chemisorption, thermal degradation). Differential scanning calorimetry (DSC) is one of the most commonly employed thermal investigation methods, together with thermogravimetric analysis. It is a quick, sensitive, and simple method. DSC measures the enthalpy variation as a function of temperature because of the changes in the physical and chemical properties of materials during their heating. This method permits the identification of glass transition values and the finding of melting and crystallization behavior. DSC is used for various utilizations in various fields of industry.

Contact angle determination is a straightforward method used for the study of the wettability of a solid substrate by a liquid. Its value depends on the nature of solid substrate, liquid and the environment. The hydrophobicity of materials can be evaluated by using this technique.

Tensiometry is the method of determining the tensile strength and the elongation of materials. Tensile strength at break correlates to the toughness of products and it measures the maximum pressure that a sample can endure while being extended before fracture. Elongation is evaluated by utilizing tensile force and establishes the change in length from original. Tensiometry is widely employed in material science, mechanical and structural engineering for quality control and for the finding of materials’ resistance to changeable forces.

Fourier-transform infrared spectroscopy (FTIR) is a quick and easy method employed for the identification of different compounds by the detection of their functional groups that occur in the chemical structure. FTIR provides both qualitative and quantitative analysis, and it is often employed in the study of polymers or in pharmaceutical and forensic investigation.

Nuclear magnetic resonance spectroscopy (NMR) is an analytical method that affords information on the content and purity of a product along with its chemical structure. NMR can be employed to establish molecular conformation in solution and physical properties at the molecular level (solubility and diffusion, conformational and phase changes).

X-ray diffraction (XRD) analysis is one of the most appropriate methods for usual quantitative analysis in comparison with any other technique, such as FTIR or electron microscopy (SEM, TEM). XRD entails the irradiation of the materials with a beam of monochromatic X-rays. The diffracted rays are then examined based on angle of diffraction, and the intensity of the diffracted rays provides information about the crystallinity percent, crystallite shape, size, orientation, and interplanar atomic distance. This technique is a useful tool in pharmaceutical and forensic science, microelectronics, or geological analysis.

X-ray photoelectron spectroscopy (XPS) is a technique used for the investigation of material’s surface chemistry. Thus, XPS provides information about elemental composition, empirical formula, chemical and electronic state, binding energy of functional groups, and the thickness of the superior part of surfaces.

Gel permeation chromatography (GPC) affords the separation of analytes in organic solvents on the basis of their size. This technique enables the finding of dispersity value together with viscosity molecular weight (Mv) and founded on other data, number average molecular weight (Mn), the weight average molecular weight (Mw), and the size average molecular weight (Mz).

Table 1 summarizes examples of the methods employed to investigate polymer materials degradation.

Table 1. Main Methods Applied to Identify Polymer Materials Degradation

BIODEGRADATION OF LIGNOCELLULOSICS

Lignocellulosic wastes (debris) are of real significance for both forest and stream ecosystems as an unceasing source of nutrients, basic structural components, and part of any natural environment. They are basically constituted by three main polymeric components, namely cellulose, hemicellulose and lignin, their recycling being an essential part of the carbon cycle in nature. All three polymers with distinct chemical structure are degraded by a large variety of microorganisms through different enzymatic mechanisms, which act synergistically. Among these, fungi are the well-known degraders of lignocellulose substrates, but some bacteria can be also effectively involved in degradation processes. Considering the insolubility specific characteristics of such substrates, their degradation is facilitated by both fungal and bacterial pathways, which occur usually by means of extracellular mode of action. Such mechanisms rely on hydrolytic reactions that involve both enzymes called hydrolases, responsible for cellulose and hemicellulose degradation, and a specific enzymatic system involved in lignin degradation. Many soil bacteria, especially Actinomycetes sp., are well-known microorganisms that react with lignin to both depolymerize it and produce a high molecular weight metabolite named acid-precipitable polymeric lignin (APPL). Some details related to microorganisms and enzymes involved in degradation of lignocellulose-based sources (Crawford and Pometto 1988; Eriksson et al. 1990b; Uffen 1997; Pérez et al. 2002; Hammel and Cullen 2008; Horn et al. 2012; Brown and Chang 2014; Rytioja et al. 2014; Houfani et al. 2020) are presented in Scheme 1.

In general, lignocellulosic wastes are slowly degraded, at the same time offering good life support for many organisms (fungi, moss, insects, birds, small mammals). Composting can be considered a valuable way to appropriate handling and exploiting lignocellulose waste resulted from different activities (i.e. forestry and agricultural practices, timber industries, agroindustries – meat processing, for example-, yards, sewage). Composting lignocellulose waste can represent an interesting recycling strategy in order to provide useful amendments (fertilizers or organic substrates) for land applications in agriculture and silviculture with beneficial effects on the environment (Hubbe et al. 2010; Hubbe 2014). At the same time, recycling such complex waste by composting can be a real challenge for researchers, given its low decomposition rate (i.e. cellulose and hemicellulose decompose slowly, whilst lignin is resistant to decomposition). In order to optimize the composting of lignocellulosic waste, there are considered different alternatives (Reyes-Torres et al. 2018), including homogenization (waste is pre-treated by applying shredding and extraction stages), addition of co-substrates (such as inoculating microbial agents, amendments, bulking materials), and changes in processing operations (using aeration and two-stages composting processes, temperature control). All these above-mentioned can effectively reduce the duration of composting process, can ease the decomposition of recalcitrant organic compounds such as lignin and cellulose, and can provide high-quality products. Employment of wood waste for turnery and furniture construction applications are also suitable options to recycle them, alongside granulation into wood chips, conversion to charcoal or burning as fuel.

Among biodegradable materials, wood is considered to be a durable material that withstands weathering well without losing much of its structural properties (except for microbial attack). However, a number of environmental (non-biological) parameters contribute significantly to the degradation of wood, including moisture, temperature, light, atmospheric ozone content, and pollution. Another important aspect that may significantly affect the degradation rate of wood is the type of wood, i.e. softwood or hardwood. Hardwood and softwood species differ in several aspects, such as fiber dimensions, chemical composition, mainly in both lignin and cellulose contents, as well as lignin type. The hardwood presents a vessel element and lignin comprising both guaiacyl and syringyl units in the structure. Softwood does not contain vessel elements, while its lignin structure presents mostly just guaiacyl units (Fengel and Wegener 1983).

Scheme 1. Schematic representation of the polymeric components from lignocellulose waste and their degradation under microorganisms’ action through different enzymatic pathways

Forest residues (twigs, bark, sawdust, branches, underground) as well as other waste of vegetal origin (e.g., those resulted from annual plants processing, namely different retting approaches) are likely to be quite variable in chemical composition, texture, and moisture content. Degradation processes in an outdoor environment, including soil, are influenced by many factors such as moisture, temperature, ultraviolet radiation, soil reaction, and microorganisms.

All types of degradation have been observed when lignocellulose-based materials, per se or as components in different composite formulations, were exposed to different environmental conditions. These processes depend to a large extent on materials applications and structural chemistry particularities in relation with conferred properties, as presented in Fig. 3 (John and Thomas 2008; Beg and Pickering 2008; Methacanon et al. 2010; Suardana et al. 2011; Matuana et al. 2011; Dittenber and GangaRao 2012; Azwa et al. 2013).

Fig. 3. Inter-relations between the chemical composition in main polymer components of lignocellulose sources and their behavior under exposure to environmental conditions in relation with properties

The rhizosphere microorganisms can be used as promoters to further accelerate the biodegradation process of different polymer materials in cultivated soil and to stimulate plants’ growth and development, as well (Gerhardt et al. 2009; Janczak et al. 2018; Janczak et al. 2020; Beltrán-Sanahuja et al. 2021; Zhang et al. 2022). These microorganisms act upon complex polymer materials during degradation through releasing exo-enzymes with affinity for such substrates that are depolymerized to low molecular weight intermediate products, namely oligomers, dimers, and monomers. This process, named phytoremediation, is efficient to decontaminate both soils and wood treated using inorganic preservatives (Xing et al. 2020).

In the case of wood, fungi, mainly those belonging to Basidiomycetes species, are the major microorganisms involved in decay processes. These include both brown-rot and white-rot types, and they have significant nutrient recycling implications in forest ecosystems, being also implicated in the weathering of soils (Eriksson et al. 1990a,b). The structure and chemical composition of wood have a significant influence on its degradation by microorganisms and the resulting patterns of decay. Significant decay of wood fibers and plant fiber-based materials is promoted by microorganisms, mainly by the fungal and bacterial communities occurring in nature. In general, wood decay is classified into brown-rot, white-rot, and soft-rot types (Shimada and Takahashi 1991). White-rot fungi are able to fragment the major structural polymers of wood and other lignocellulose sources – cellulose, lignin, and hemicelluloses – and to further metabolize the fragments (Shimada and Higuchi 1991; Kirk and Cullen 1998). Brown-rot fungi selectively decompose holocellulose components (cellulose and hemicelluloses) via extensive depolymerization, leaving lignin partially intact (Goodell et al. 2008; Schilling et al. 2012; Shang et al. 2013) and release more carbon to soils in lignin residues than as atmospheric CO2. Some Actinomycetes fungi species are significantly implicated in the degradation of lignocellulose materials (Hamed 2013), having the ability to decompose lignin components, and alongside species of Eubacteria, they may exert strong antagonism toward other wood-inhabiting microorganisms (Eriksson et al. 1990b). Their mode of deterioration wood in soil may have a real significance for better knowledge the ageing of wooden cultural heritage objects buried in soil and proper conservation approaches to be implemented. Different microorganisms communities present in soil, mainly fungi and bacteria, can promote degradation through interactions such as commensalism or mutualism, and even competitive or antagonistic (Haq et al. 2014; Johnston et al. 2016; Haq et al. 2022), which influence to a large extent the deadwood environment (Tláskal et al. 2017; Christofides et al. 2019). In the soil of forest ecosystems, the proportion of brown-rotted wood residues is very significant and has an important role in their optimal functioning through high microbial activity and consequently further optimal supplying nutrients and moisture. Moreover, these residues allow survival of ecosystems even in the case of drought periods by maintaining a high moisture content in soil (Eriksson et al. 1990b). So, such decayed wood residues in the soil appear to be essential to sustain a good site quality. Considering wood waste disposal at landfill sites, the soil dynamics evaluation and determination of wood chemical composition, as well, are very important for environmental impact assessment. Such evaluation includes determination of pH value, humus, mineral elements (N, P, K), and salinity as total content of soluble salts. A previous investigation (Teacă et al. 2008) considered three wood waste landfill disposal sites, namely Bicaz (coded as P1), Tasca (coded as P2), and Borca (coded as P3), located in the Neamt County, North-Eastern Romania, in a mountain region, being surrounded by mixed coniferous and deciduous forests. The soils in these forest ecosystems are typical brown earths, with a structure of siliceous sandstones and stones. The forests are mainly composed by coniferous tree species, such as fir (Abies alba L.) and spruce (Picea abies L.), along with some deciduous tree species, namely beech (Fagus sylvatica) and birch (Betula alba). The wood waste disposed of at dumps in this landfill region are usually generated through forestry and sawmilling activities. The authors’ study evidenced that wood wastes influenced to some extent the soil chemistry on disposal area through slightly increasing the acidity (pH value as high as 7.8 to 8, while a typical brown soil has a pH value of 4.8 to 5). A decrease in humus content was noticed, with variation in the mineral elements content (P and K contents), as represented in Figs. 4 a-c.

Fig. 4. Evolution of soil dynamics from different disposal landfill sites from North-Eastern Romania: (a)- P1 Bicaz; (b)- P2 Tasca; (c)- P3 Borca (data re-drawn from Teacă et al. 2008)

Different extents of the wood biodegradation process were also evidenced for investigated wood waste dumps, the process being more intense at the bottom of these. Variation in wood waste chemical composition is represented in Fig. 5. Wood wastes extractives content decreases as a function of profile section from wood waste dumps due to the rainwater percolation. Cellulose content exhibited an opposite evolution comparatively with the lignin content, showing a significant decrease, a fact evidenced for the oldest wood waste dump.

Fig. 5. Evolution of wood wastes chemical composition from different disposal landfill sites from North-Eastern Romania (data re-drawn from Teacă et al. 2008)

BIODEGRADATION OF POLYMER PLASTICS

A Society Relying on Plastics

From the very beginning, human civilization has grown and evolved based on Earth’s bioresources. From hunter-gatherers to farming, intensive agriculture and synthetic food, through the stone, metal (bronze, iron), and industrial ages, the time span covered by each developing phase has shrunk in a relentless, accelerating manner, from tens of thousands of generations to just a few. The industrial revolution set the first stages of what is now called the modern civilization, which is characterized by both a population boom and a huge and continuously expanding variety of available products, processes, and technologies, most of them branded as synthetic/of synthesis.

The unfavorable side includes depletion of non-renewable resources, the need of hazardous substances, and an enormous environmental impact on air, water, soil, and climate, which translates into biotic impoverishment, threatened trophic chains, a lower quality of life, and a real risk to an entirely shattered biosphere in a not far away future. Such a fast pace of developments, accompanied by a plethora of benefits and financial interests, has suppressed, at least initially, the rise of associated environmental concerns. Other factors, such as the inertia of both human society and ecosystems, which tend to not react instantly but slowly and progressively, after reaching a critical point in the accumulation of detrimental inputs, have been further obscured the potential hazards given by specific activities, chemical/biological compounds, and various materials and products within their entire life cycle. As a result, environmental awareness has significantly lagged behind industrial development, with relevant improvements being made only in the last couple of decades.

For example, the first concerns regarding the environmental pollution have been reported decades after the onset of a sustained industrial development of plastics, just when the impact became difficult to neglect (Ryan 2015; Napper and Thompson 2020), while the awareness of this great societal challenge is still not well enough translated into effective strategies and policies (Lau et al. 2020; OECD 2022a,b,c).

Plastics have effectively permeated virtually all aspects of our life in just a couple of generations. In fact, the first modern plastics, based on either natural or synthetic polymers, have emerged with the discovery of vulcanized rubber and polystyrene, in 1839 (Andrady and Neal 2009), but it took about a century of expansion in structural types, technologies, and applicative horizons to have a true mass-scale production for several finite materials and achieve a clear, significant impact on everyday life. Then, the widespread societal benefits ranging from agriculture to medicine and electronics, from packaging and transportation to textile and consumer products, have put a constant pressure on demands for new, better, cheaper, and higher quantities of plastics. Versatility in terms of structure, production, functionalities and use, tailored properties, and competitive prices in comparison with most other materials, all contributed to their current globally ubiquitous distribution.

Regarding production, the continual rise in yearly amounts has been remarkable, from about 2 million tons in 1950-1952 to 20 million tons in 1966, 202 million tons in 1999, and 460 million tons in 2019, including fibers and additives (Geyer et al. 2017; OECD 2022c). This means a total amount of about 8.3 billion tons in 2015 and over the mark of 10 billion tons in 2019. The greatest volumes are used in packaging (31%), construction (17%), transportation (12%), consumer products (10%), and textiles (10%). Despite the huge variety of commercially available polymers, only a few ones, all obtained from non-renewable petrochemicals, are responsible for two-thirds of these shares: polypropylene (PP, 16%), low-density and high-density polyethylene (LDPE and HDPE, 12% each), polyvinylchloride (PVC, 11%), polyethylene terephthalate (PET, 5%), polystyrene (PS, 5%), and polyurethane resins (PU, 4%) (OECD 2022c).

A relatively recent and noteworthy minority is represented by bio-plastics, which have been produced at a level of 2.4 million tons in 2021, which is expected to grow to about 7.6 million tons by 2026, or just over 2% of the total (EUPB 2021). This group includes starch and cellulose derivatives, polyhydroxyalkanoates (PHA), polylactic acid (PLA), polybutylene succinate (PBS), polybutylene adipate terephthalate (PBAT) as biodegradable polymers (naturally or by design), and respectively bio-polyamide, bio-PE, and bio-PET, as non-biodegradable ones. Some of these polymers are usually considered bio-plastics (i.e. PBAT) despite the fact that are only partially derived from bioresources (Kumar et al. 2020; EUPB 2021), which may be confusing at times.

The main issue related to plastics consists of their life cycle management. It was estimated (Geyer et al. 2017) that about 60% (~ 4.9 billion tons) from all plastics produced until 2015 were left over in the environment as solid waste. Another tentative assessment (OECD 2022c) indicated for 2019 a yearly plastic waste outcome of 353 million tons, from which 174 million tons were discarded into sanitary landfills and 22 million tons runaway in the environment. These high volumes of leaked polymeric wastes tend to accumulate, since the main amounts of polymers are designed for single use or limited time usage (days to years), while their natural degradation could last centuries or millennia in optimum conditions (Chamas et al. 2020). They also disperse either by abrasion during use, or by erosion and fragmentation of wastes in smaller chunks, microsized and nanosized plastic, which could be furthermore carried out by wind, rain, surface and ground waters, animals (FAO 2021). Thus, the ubiquity of plastics has become a trademark feature of both our current society and environment, with notorious negative impacts on human health, ecosystems, and climate.

Plastics and Soil – A Complex Mixture of Concerns

Soil represents a complex organic–inorganic/biotic–abiotic environment, characterized by high spatial and temporal variability and continuous interactions with atmosphere, hydrosphere, and human activities (Strawn et al. 2020; Tate 2020; FAO 2021; Li et al. 2022). The complexity of soil ecosystems, together with a far higher difficulty in visualizing, identifying, and analyzing the plastic residues mixed within, are likely accountable for the minor scientific interest in comparison with the aquatic ones (de Souza Machado et al. 2018; Scalenghe 2018).

Reckless dumping of plastic waste in nature (picnic sites, woods, excavations and accidental landslides, illegal disposal by burying) from where they can no longer be collected and correctly disposed of is a source of constant concern. Partially degraded plastic waste can be easily displaced and transported by heavy rains and floods, and further carried away by wind. Plastic particles of micrometer dimensions end up at different sites (on land or in water) where they continue to undergo further degradation; when they reach the nanometric scale, these waste particles can enter various biologic cycles: they can pass through the cell wall barrier of microorganisms and can be absorbed by plant roots from soil, can access the animal’s metabolism when they accidentally drink from fresh waters, etc. In dry state, these particles of both micro- and nanometric dimensions can be easily wind driven and further embedded in different types of clouds as solid impurities. And thus, these waste particles end up traveling around the globe as proven by most recent studies on snow in Antarctica (Aves et al. 2022).

Recent reports (Horton et al. 2017; Lebreton et al. 2017) indicate that oceans contamination with plastics and microplastics could be only the tip of the iceberg. Thus, a terrestrial pollution of up to 23-fold larger is supposed. Soil also accounts for the initial degradation and downsizing of much of the plastic amounts found in oceans later on. From these perspectives, soils could be viewed as huge transient containers for slow and uneven composting of polymeric species with the price of dramatic and potentially irreversible ecological transformations.

Apart from plastics, land is simultaneous overwhelmed and degraded by various forms of pollution, intensive and heavy mechanized agriculture, climate changes, conducting in the end to significant treats for food production, trophic chains, biodiversity, and health (Saha et al. 2017). Moreover, the coexisting pollutants may act on both soil components and plastic particles, subsequently changing the degradation patterns. The relatively common occurrence of several polymeric species and plastic additives in the same soil horizon adds further complications and secondary processes. Cross-contamination not only increases the potential hazards, but also adds supplementary interferences on the assessment of the fate of each individual component.

Soil and Plastic Biodegradation

Polymers are traditionally classified as biodegradable or non-biodegradable, independent of their natural, synthetic, fossil, partial or full biomass-derived source, where biodegradation is mainly brought about by microbial enzymes (Ahmed et al. 2018). However, biodegradability is generally achieved in optimum, simplified laboratory conditions, which are not completely reproducible in complex natural soil ecosystems (Wierckx et al. 2018; Haider et al. 2019).

Several difficulties arising from multiple independent variables tend to make in-soil biodegradation of plastics a tough theme of research. Wide variability of soil and plastics features is frequently coupled with random effects of external factors, difficult implementation of investigative techniques, as well as non-uniform and incomplete reports (He et al. 2018).

Moisture content is an important factor for polymer biodegradation by favoring enzymatic reactions and microbial colonization. Permeability, water retention, and water movement are determined by three physical features that are soil-specific: micro and macroporous structural architecture obtained due to different arrangements of particles having various sizes and shapes, flora, and fauna; very high specific surface area generating strong interactions between water and ions; and high density of electric charges, which inhibits the irreversible aggregation of particles (Iwata et al. 1995). Still, soil moisture content depends for example on local climate, day/night and seasonal alternation, drought/wet weather events, plant cover, structural changes driven by heavy machinery, depth. Moister and warmer soils obviously favor the development of a more diverse and consistent microbiota, but are also beneficial for abiotic degradation, making the biotic one even more difficult to quantify. On the other hand, the presence of polymers alters soil porosity and microbial respiration, influencing the moisture content and microbiota (Liwarska-Bizukojc 2021; Sajjad et al. 2022). But soil porosity is also modified by earthworms, which are in addition good 3D-dispersing agents for plastic fragments (Rillig et al. 2017).

The mineral/organic composition has a direct influence on soil biota and pH value. A given pH favors specific microorganisms and enzymes, influencing the decomposition of a corresponding polymer, but the resulting degradation of by-products may change in turn the acido-basic equilibrium. The presence of other pollutants and additives may impact biodegradation by affecting the surface properties of polymers, as well as the soil texture, moisture content, pH, and biota (Maddela et al. 2022; Sajjad et al. 2022). Plastics themselves frequently contain various amounts and types of substances added to improve the resilience and practical performances of native polymer chains, which could significantly alter the biological degradative response (Allen and Edge 2020; Brdlik et al. 2022; Hahladakis et al. 2018; Hermabessiere et al. 2022; Sridharan et al. 2022). The shape of plastic debris could be a relevant factor as well (Lehmann et al. 2021).

Polymer biodegradation is essentially an enzymatic degradation that begins on accessible surfaces and continues by “peeling/mining” – like attacks on the successive newly formed horizons within the initial plastic part. These enzymes result as products or by-products of various metabolic pathways accomplished by a large variety of soil biological ecosystems. Some are produced by worms and insect larvae (Rillig et al. 2017; Zhang et al. 2022a), but most of them are extracellular enzymes (hydrolases, oxidoreductases) of microbial origin (bacteria, fungi). These are commonly produced to decompose the organic matter in readily available nutrients and energy sources such as assimilable organic carbon, nitrogen, and phosphorus molecules (Arnosti et al. 2014; Jian et al. 2016; Enyoh et al. 2022; Ndabankulu et al. 2022). Since the vast communities of soil microbes are very competitive grounds, enzyme synthesis is economically driven to reflect the dynamics of nutrient abundance and demand (Allison and Vitousek 2005).

Scarce, growth-limiting nutrients could trigger changes in the amount and types of enzymes in an attempt to acquire them from any available soil substrates, including anthropogenic materials. Plastics, as complex, difficult and recalcitrant sources of essential molecules, exert a selective pressure on these substrate-dependent heterotrophic microbial communities, reducing the microbiome diversity, enriching the adjacent microbiota in microbial taxa able to degrade them, and hence shaping a new surrounding habitat, the so-called “plastisphere microbial community” (MacLean et al. 2021; Yi et al. 2021; Zhang et al. 2021). In general, polymers’ biodegradation in soil is therefore not the attribute of a sole microorganism, but is rather performed within a competitive, sequential, and auto-tunable embodiment driven in variable proportions by several taxa from within microbial consortia (Dey and Tribedi 2018).

Abiotic weathering processes on plastic fragments dynamically change their surface characteristics in terms of rugosity, porosity, and hydrophobicity, thus enhancing the microbial colonization, exoenzyme adsorption, and biofilm formation (Siakeng et al. 2020; Anunciado et al. 2021). The initial biodeterioration is followed by successive processes of fragmentation and depolymerization into micro/nano-plastics, oligomers, and monomers under the interplay among the microbial enzymatic equipment, soil geochemistry, and physical factors (Ali et al. 2021). The resulting low-molecular weight compounds are ingested and assimilated through cell-specific metabolic pathways until complete mineralization (Zhang et al. 2022b).

It is obvious that exoenzymes will be increasingly less successful in plastic degradation as far the polymer debris are from the common range of natural organic substrates used by soil microbiota, so the elemental composition and type of molecular units, the way of bonding between them, and spatial architectures of resulting chains are key factors for decaying.

Naturally abundant polymers such as cellulose, lignin, and their derivatives are among the most biodegradable ones due to their easily recognition by a microbiota already adapted to use them as substrates by producing highly specific enzymes such as β-glucosidases, respective phenoloxidases. However, higher crystallinity and polymerization degree, as well as chemical modifications, delay the cellulose mineralization (Erdal and Hakkarainen 2022), while impregnations with antimicrobial nanoparticles were effective for silver, but not in the case of copper oxides (Milošević et al. 2017; Tomšič et al. 2022). Lignins degrade more slowly than glycosidic bonded cellulosic materials due to the presence of multiple phenolic moieties linked by random C-C and C-O bonds and its rigid, three-dimensional structure (Donnelly et al. 1990; Thevenot et al. 2010; Hall et al. 2020).

The ester bonds are vulnerable to cleavage under the action of soil hydrolases, especially lipases, esterases and cutinases, which make polyesters susceptible to enzymatic hydrolysis (Satti and Shah 2020). However, biodegradation typically requires higher incubation times and microbial functional diversities, due to the lower enzyme specificities and subtle requirements of metabolic adaptations, even in the case of natural, microbial-synthesized polyhydroxyalkanoates PHAs (Dey and Tribedi 2018). Soil microbiota correspondingly adjusts itself to the modified environment by changes in composition and functionalities (Tanunchai et al. 2021). Overall, biodegradability is improved by decreasing polymer crystallinity, rigidity, molecular weight, aromatic content, side groups or chains; as an outcome, rate is higher for polycaprolactone (PCL) than PHA like polyhydroxybutyrate (PHB). There are slower degradation rates for polylactic acid PLA and polybutylene succinate PBS, and also the rate is sluggish in the case of polyethylene terephthalate PET (Al Hosni et al. 2019; Larrañaga and Lizundia 2019; Qi et al. 2022). Polyester biodegradation could be improved by copolymerization, as is the case of polybutylene adipate terephthalate PBAT, insertion of natural polyols, adipate and succinate diols in polyurethanes, or by mixing with additives or other biodegradable polymers like modified celluloses and PLA in blends or composites (Brdlik et al. 2022; Erdal and Hakkarainen 2022; Schöpfer et al. 2022).

Polyolefins are the most decay-resistant plastics in pristine soil conditions due to the extreme levels of hydrophobicity and highly stable C-C bonds established within the entire polymer backbone. Higher crystallinity and density of high-density polyethylene HDPE, the aliphatic side groups in polypropylene PP, and especially the aromatic one in polystyrene PS increase their resilience (Zhang et al. 2022b). These polymers require an extended time of onset for preliminary surface deterioration, when both abiotic factors and oxidative enzymes succeed in the randomly oxidation of a critical quantity of exposed carbons to carbonyls and carboxylic acids (Zhang et al. 2022c). Bio-fragmentation starts later under the action of various enzymes (oxidases, peroxidases, and hydrolases) secreted by those microorganisms that are able to remain attached to the polymer’s surface. The adjacent microbial functional diversity from soil makes up the selection base of a specific plastisphere, but its formation is strongly inhibited by the difficult adaptation into the use of such substrates and long waiting times until a limited amount of nutrients became useful for living and growth. In practice, the respective soil should be extremely low or depleted of specific nutrients such as carbon sources to force the existing microbiota to adapt to using polyolefin debris as substrate. Thus, despite the isolation of several degrading microorganisms, for example more than 20 genera of PE-degrading bacteria (Ghatge et al. 2020), the demise of soil-discarded polyolefins, from fragmentation to the final mineralization, and associated molecular mechanisms are still controversial (Zhang et al. 2022c).

Soil microbiota is quasi-dominated by bacteria, fungi, and their strong antagonism finely tuned by environmental variables (Bahram et al. 2018). Just a very small part from this universe was uncharted until now due to the plethora of dynamically and elusive changing individual components, and inherent difficulties in investigations. Moreover, an isolated microorganism may behave more or less dissimilar than a same one incorporated into the soil microbiota. So, despite the evolving analysis techniques, as well as the huge amount of already known microorganisms and enzymes involved in the biodegradation of natural and synthetic polymers, a lot of uncertainties remain to be clarified (Mohanan et al. 2020; Ru et al. 2020; Ghatge et al. 2020; Gambarini et al. 2021; Lear et al. 2021; Zrimec et al. 2021; MacLean et al. 2021; Chattopadhyay 2022; Ekanayaka et al. 2022; Enyoh et al. 2022; Qi et al. 2022; Schöpfer et al. 2022; Zhang et al. 2022b; Zhang et al. 2022c). Some recent biodegradation investigations are summarized within Tables 2 to 4.

BIODEGRADATION OF NATURAL FIBERS-POLYMER COMPOSITES

The nature of the components and the interaction between them, as well as the environmental conditions (soil temperature, humidity and pH, biological attack, and nutrient supply) to which the material is exposed, influence the rate of biodegradation of composites. The material-environment interface and the surface properties exposed to biological contact are of significant importance. Biodegradation is favored by a rough interface, characterized by a large number of polar hydrophilic functional groups, and less by a smooth, hydrophobic, and inert one (Muniyasamy and John 2017; Brebu 2020). Natural fillers, such as wood flour and fibers, favor the in-depth penetration of water due to their intrinsic porosity, increase the adhesion of microorganisms to the composite material, and favor biofouling because they are hydrophilic and generally biodegradable (Shah et al. 2008). In fiber-reinforced composites, the polymer matrix protects the fibers from environmental damaging factors and transfers the external loads to the fibers that absorb the mechanical stress applied to the matrix (Gholampour and Ozbakkaloglu 2020). The interface between matrix and filler is the weak zone of composites because it allows the access of the biological (fungi) or chemical (moisture/oxygen) agents into the rather inert polymer matrix. Diffusivity of destroying compounds through the material is favored by the amorphous domains that are more biodegradable than the crystalline ones (Ruka et al. 2015).

Environmental degradation of plastic materials is determined based on various standard methods and testing practices (Krzan et al. 2006), but the most important of them consists of monitoring the evolution of CO2 and CH4 when polymeric materials are maintained under microbial conditions. Respirometric test methods have been standardized both for aerobic biodegradation in soil burial or in compost (Müller 2006) and for anaerobic biodegradation under sewage sludge (O’Malley 2006) or anaerobic digestion (Gartiser et al. 1998). Biodegradation of polymer composites through the action of microorganisms is a complex process controlled by a large number of natural variables, such as temperature, pH, moisture, oxygen, and biodiversity of soil characterized by huge amounts of bacteria and fungi unique species (Briassoulis and Innocenti 2017; Emadian 2017; Rudnik 2019; Agarwal 2020).

Table 2. In-Soil Biodegradability Investigations for Different Synthetic Plastics

Table 3. In-soil Biodegradability Investigations for Different Natural Plastics

Table 4. In-soil biodegradability Investigations for Different Blend/Composite Plastics

Several conventional plastics, modified with additives to enhance their biodegradability, and natural fiber composites were tested under standardized laboratory-scale in three environments (soil incubation, composting, and anaerobic digestion) (Gómez and Michel 2013). The biodegradability of polymers such as PE and PP was not improved by adding natural additives. At the same time, co-polyester-based composites, or corn-based plastics with coconut coir materials presented some surface changes, but polyhydroxyalkanoate-based plastics underwent important biodegradation. During anaerobic digestion for 50 days, 20 to 25% of the bio-based materials but less than 2% of the additive containing plastics were converted to biogas (CH4+CO2). After 115 days of composting, 0.6% of an additive modified PP, 50% of a starch-based material, and 12% of a soy wax permeated paper pulp was converted to CO2. This study considered only the natural materials used as additives or components in blends, with no interest in the natural materials used as fillers or fibers in composites (Pires et al. 2022).

The biodegradability in soil burial of flax fiber reinforced PLA composites was influenced by the presence of amphiphilic additives used as accelerators for biodegradation (Kumar et al. 2010). The composites showed accelerated biodegradation with 20 to 25% loss in weight after 50 to 60 days in the presence of mandelic acid, and only 5 to 10% loss in weight even after 80 to 90 days in the presence of dicumyl peroxide.

The interface of composites based on PP as matrix and natural fibers (kenaf, coconut and wood) as fillers is stabilized by montmorillonite nanoclay, even though that mineral is hydrophilic (Islam et al. 2017). The results showed that biodegradability of these composites was decreased by limiting the access of moisture inside the material in early stages of soil burial, and by increasing water absorption in higher amounts at later stages of biodegradation.

A soil burial experiment on biodegradable composites prepared from poly(butylene succinate) (PBS) and sugarcane rind fiber (SRF) lasted for 100 days under natural soil conditions (Huang et al. 2018). The maximum weight loss, the degree of erosion, crystallization temperature, and degree of crystallinity of SRF/PBS composites were higher than those of pure PBS, and they reached a maximum value when the SRF content was 5 wt%. Another study looked at changing the mechanical properties of starch-based composites reinforced with various lignocellulosic fibers (i.e., flax, date palm, banana, and bagasse) during soil-burial composting, and the influence of the filler type on the process of biodegradation of the corresponding biopolymer (Ibrahim et al. 2018). The tensile strength and modulus of elasticity for all composites decreased significantly during the first week (more than 50%), then further gradual deterioration took place until the end of composting.

The effect of the incorporation of cellulose nanofibers (CNF) on the biodegradation of poly(vinyl alcohol) (PVA) in the compost was investigated (Salehpour et al. 2018). It was observed that the PVA/nanocellulose had lower biodegradation rates than the neat PVA. This can be attributed to the difficult access of water molecules to the polymer matrix. Consequently, it contributed to the reduced microbial growth and activity and to the good interfacial bonding between CNF and PVA that makes it very difficult to break the strong bonds of the film. Another remarkable observation during the thermal analysis was the increase in the biopolymer crystallinity over the composting time. This can be explained by the evidence that microbes easily degrade the random amorphous component of the polymer, rather than the crystalline segments.

Plant-based natural jute fiber reinforced polypropylene (PP) matrix composites (20 wt% fiber) and animal based natural B. mori silk fiber reinforced polypropylene (PP) matrix composites (20 wt% fiber) were subjected to degradation in soil up to twelve weeks (Shubhra et al. 2010). It was found that jute fiber/PP composite lost more of its strength than silk fiber/PP composite, for the same interval of composting. While the mechanical properties of silk/PP composites are superior to those of jute/PP composites, the jute/PP composites are more degradable than silk/PP composites; i.e., silk/PP composites retain their strength for a longer period than jute/PP composites.

Water uptake and soil degradation tests of the coir and abaca fiber-reinforced linear low-density polyethylene (LLDPE) composites (30 wt% fiber) were performed in soil, at ambient conditions, for up to 60 days (Zaman et al. 2011). Simultaneously, 3% starch treated coir fiber/LLDPE composite (SC), and 5% starch treated abaca fiber/LLDPE composite (SA) samples (about 60 mm in length) were subjected to biodegradation under the same conditions. It was found that for the composite samples, both tensile strength (TS) and tensile modulus (TM) decreased slowly with time. After 120 days of soil degradation, SC and SA composite samples lost almost 21% and 29% of TS and 13% and 19% of TM respectively, but the untreated coir and abaca composite samples lost almost 33% and 38% of TS and 26% and 21% of TM, respectively. During soil degradation tests (soil contains only 3% water), water penetrates from the cutting edges of the composites and degradation of cellulose occurred in the composites and as a result, the mechanical properties of the composites decreased significantly.

Soil degradation testing of short jute fiber/PP and short E-glass fiber/PP-based composites (20% fiber by weight) revealed that the jute/PP composites significantly lost much of their mechanical properties (Khan et al. 2012). On the contrary, the E-glass/PP composites retained a major portion of their original integrity after the degradation test. During soil degradation tests, water penetrates from the cutting edges of the composites in jute-based samples and degradation of cellulose occurred in jute; as a result, the mechanical properties of the composites decreased significantly. But E-glass based composites are strongly hydrophobic and repel water, thus they retained much of their integrity during in- soil testing.

The weight loss of untreated and treated elephant grass fiber/PLA composites with varying fiber loading after composting for 90 days in comparison with plain PLA was found to linearly increase with number of days of soil burial (Gunti et al. 2018). The higher weight loss of untreated fiber reinforced PLA composites as compared to surface modified composites may be attributed to the poor fiber matrix adhesion, leading to an accelerated degradation. The alkali treatment has led to an increase in the hydrophobic nature of fibers and, hence, less moisture absorption by the composite from the soil, leading to a reduction in the degradation rate for the composite with surface modified fibers.

The biodegradation of a composite made of a poly(hydroxybutyrate-co-hydroxyvalerate) matrix reinforced with curaua fibers (with and without alkaline treatment) in simulated soil, according to the ASTM G160-03 method, was found to be mainly caused by erosion of the surface layer resulting from microorganisms’ activity (Beltrami et al. 2014). Thermogravimetric analysis revealed reduced thermal stability of the samples, and results of differential scanning calorimetry showed that the degree of crystallinity increased and then decreased progressively throughout the degradation period, indicating that enzymatic degradation primarily occurs in the amorphous phase of the material and thereafter in the crystalline phase. For curaua composite fibers, reductions in tensile strength and elastic modulus are more significant, indicating that the presence of fibers promotes biodegradation of the composite.

Another study investigated the influence of flax fiber reinforcements on the decaying process of poly(lactic acid) (PLA) in flax – PLA composites under composting conditions (Bayerl et al. 2014). The experimental results indicated that the fibers enhanced the biodegradation by enlarging the potential surface, thus contributing to the decaying process. At the same time, the fibers acted as channels and distributed water and microorganisms inside the composite. The decaying process is attributed to fiber decomposition and hydrolysis of PLA, which led to increased degradation rates for composites with high fiber weight content. The degradation (weight loss) increased with both fiber content and time in the compost. Neat PLA samples, having no fibers, underwent only marginal degradation on the outside surfaces, even over eight weeks. The presence of fibers and the architecture of fiber structure in a PLA composite can intensely affect the degradation behavior of the composite.

Taking into consideration the conclusions provided by literature reports, it can be stated that natural fiber-polymer composites are a source of plastic residues. Even the presence of natural fibers favors and accelerates their in-soil degradation. Although the mechanisms of degradation are different, the decomposition of polymeric materials and natural fibers-polymer composites in soil became increasingly dangerous for ecosystems upon their accumulation. Plastic particles of micrometer dimensions can be transported (rains, floods, airflow) to different sites (on land or in water), where they continue to accumulate and undergo further degradation.

MICROPLASTICS AND SOIL BIOREMEDIATION

Another related issue has risen in the last decades, namely soil contamination with microplastics. Typically, they are defined as plastic fragments (fibers, particles) no larger than 5 mm in diameter (Guo et al. 2020) and are products of partial degradation of plastics under environmental conditions (enzyme-mediated reactions, weathering, catalytic hydrolysis). Huge amounts of plastic waste are to be found in landfills (approx. 79% of global plastic waste (Horton et al. 2017; Ng et al. 2018), from where they further migrate into the groundwater and water streams, and air. Furthermore, their presence in soil and water makes them readily available for plants and animals, thus increasing their toxic effects (Huerta Lwanga et al. 2017; Panebianco et al. 2019; Grasserová et al. 2020).

Microplastics’ migration in soil depends on the soil residual water, biota, pores, aggregation, and dynamics of agricultural practices. The presence of vegetation and animals can create passageways to other components of the ecosystem. On the other hand, microplastics’ properties can also influence their migration. In example, microfibers can interact with soil aggregates and block the movements (de Souza Machado et al. 2018).

Recent studies confirmed the completion of the cycle soil-water-air-soil for microplastics: first evidences of microplastics (mostly PET fibers that travelled approx. 6000 km) in Antarctic snow have been reported based on samples collected from 19 sites in Ross Island (Aves et al. 2022). Previously, microplastics were also found in an Antarctic inland fresh water source from a protected area (González-Pleiter et al. 2020).

The presence of microplastics in soil alters its structure and properties (e.g., soil saturated hydraulic conductivity), function, and biologic diversity, finally resulting in changes, with unexpected ecologic impact. Various approaches of bioremediation must be considered, taking into account that some of them (i.e., ex situ methods) can contribute to further contamination of adjacent areas due to mobilization of the contaminant particles by flushing or airflow drive. Therefore, in situ remediation should be the prevalent choice (Sales da Silva et al. 2020). This comprises two groups of methods: (1) intrinsic bioremediation, and (2) projected bioremediation (a collection of techniques applied selectively according to local needs and requirements: use of permeable reactive barriers; bioslurping; bioventing; biosparging; phyto-, fungal, and bacterial remediation; bioaugmentation; biostimulation) (Zeneli et al. 2019; Quintella et al. 2019; Cristaldi et al. 2020; Raffa and Chiampo 2021; Medaura et al. 2021; Geng et al. 2022). The selection of a certain bioremediation approach is made in close correlation with the soil characteristics, level of contamination, concentration of pollutant(s), biota availability, etc. (Valizadeh et al. 2021; Karimi et al. 2022; Yuan et al. 2022). In a holistic approach, in-soil degradation of waste and bioremediation of soil are complex, interrelated processes, and both of them have significant environmental impact.

CONCLUSIONS AND FUTURE TRENDS

Polymers and natural fibers-polymer materials are a significant part of municipal solid waste, which is largely disposed in landfills. Therefore, their degradation in soil and under environmental conditions must be considered in relation with the environmental impact of these processes.

This paper systematically presented a review of the most relevant aspects, namely: the degradation of plastics (made of natural and/or synthetic polymers) and natural fibers waste, and waste of natural fiber-polymer composites; the most common methods of characterization for the polymers and natural fiber-reinforced polymer composites submitted to composting; and the role of factors that contribute to the waste biodegradation. At the same time, this survey considered some of the most recent literature reports on waste composting (materials and experimental protocols), highlighting some new concepts and trends, such as soil bioremediation by ex situ and in situ methods.

The transfer of the composting tests from laboratory scale to field experiments has encountered a series of difficulties (incomplete analysis of factors, inappropriate design, poor control, and inaccurate results). Consequently, only a small part of reported data can be successfully applied in practice.

Microplastics accumulated in soil are by-products of biodegradation of polymers and polymer materials waste, and they represent a serious problem. The phenomenon can be considered as a secondary pollution of soil and, subsequently, water and atmosphere, as evidenced by analyzing the recent snow layers in Antarctic areas. Bioremediation of contaminated soils is an approach with a positive environmental impact, as it allows soil recovery and restoration of ecosystems, thus contributing to the preservation of biodiversity and limiting the human health risk.

REFERENCES CITED

Agarwal, S. (2020). “Biodegradable polymers: Present opportunities and challenges in providing a microplastic-free environment,” Macromol. Chem. Phys. 221, article no. 2000017. DOI: 10.1002/macp.202000017

Ahmed, T., Shahid, M., Azeem, F., Rasul, I., Shah, A. A., Noman, M., Hameed, A., Manzoor, N., Manzoor, I., and Muhammad, S. (2018). “Biodegradation of plastics: current scenario and future prospects for environmental safety,” Environ. Sci. Pol. Res. 25, 7287-7298. DOI: 10.1007/s11356-018-1234-9

Akinyemi, B. A., Okonkwo, C. E., Alhassan, E. A., and Ajiboye, M. (2019). “Durability and strength properties of particle boards from polystyrene–wood wastes,” J. Mater. Cycles Waste Manag. 21(6), 1541-1549. DOI: 10.1007/s10163-019-00905-6

Al Hosni, A. S., Pittman, J. K., and Robson G. D. (2019). “Microbial degradation of four biodegradable polymers in soil and compost demonstrating polycaprolactone as an ideal compostable plastic,” Waste Manage. 97, 105-114.

Ali, S. S., Elsamahy, T., Al-Tohamy, R., Zhu, D., Mahmoud, Y., Koutra, E., Metwally, M. A., Kornaros, M., and Sun, J. (2021). “Plastic wastes biodegradation: Mechanisms, challenges and future prospects,” Sci. Total Environ. 780, article no. 146590.

Allen, N. S., and Edge, M. (2020). “Perspectives on additives for polymers. 1. Aspects of stabilization,” J. Vinyl Addit. Technol. 27 (1), 1-23.

Allison, S. D., and Vitousek, P. M. (2005). “Responses of extracellular enzymes to simple and complex nutrient inputs”, Soil Biol. Biochem. 37(5), 937-944.

Altaee, N., El-Hiti, G. A., Fahdil, A., Sudesh, K., and Yousif, E. (2016). “Biodegradation of different formulations of polyhydroxybutyrate films in soil,” SpringerPlus 5, 762. DOI: 10.1186/s40064-016-2480-2

Amir, M., Bano, N., Baker, A., Zia, Q., Banawas, S., Zaheer, M. R, Shariq, M., Nawaz, Md. S. M. F., Khan, Z. R., Azad, A. A., Gupta, A., Iqbal, D., and Rooh (2022). “Isolation and optimization of extracellular PHB depolymerase producer Aeromonascaviae Kuk1-(34) for sustainable solid waste management of biodegradable polymers,” PLoS ONE 17(4), article no. e0264207. DOI: 10.1371/journal.pone.0264207

Andrady, A. L., and Neal, M. A. (2009). “Applications and societal benefits of plastics,” Philos. Trans. R. Soc. Lond. B Biol. Sci. 364(1526), 1977-1984. DOI: 10.1098/rstb.2008.0304

Anunciado, M. B., Hayes, D. G., Astner, A. F., Wadsworth, L. C., Cowan-Banker, C. D., Gonzalez, J. E. L., and DeBruyn, J. M. (2021). “Effect of environmental weathering on biodegradation of biodegradable plastic mulch films under ambient soil and composting conditions,” J. Polym. Environ. 29, 2916-2931.

Ariole, C. N., and George-West, O. (2020). “Bioplastic degradation potential of microorganisms isolated from the soil,” Am. J. Chem. Biochem. Eng. 4(1), 1-7. DOI: 10.11648/j.ajcbe.20200401.11

Arnosti, C., Bell, C., Moorhead, D. L., Sinsabaugh, R. L., Steen, A. D., Stromberger, M., Wallenstein, M., and Weintraub, M. N. (2014). “Extracellular enzymes in terrestrial, freshwater, and marine environments: perspectives on system variability and common research needs,” Biogeochemistry 117, 5-21.

Aves, A. R., Revell, L. E., Gaw, S., Ruffell, H., Schuddeboom, A., Wotherspoon, N. E., LaRue, M., and McDonald, A. J. (2022). “First evidence of microplastics in Antarctic snow,” The Cryosphere 16, 2127-2145. DOI: 10.5194/tc-16-2127-2022

Azwa, Z. N., Yousif, B. F., Manalo, A. C., and Karunasena, W. (2013). “A review on the degradability of polymeric composites based on natural fibers,” Mater. Des. 47, 424-442. DOI: 10.1016/j.matdes.2012.11.025

Bahram, M., Hildebrand, F., Forslund, S. K., Anderson, J. L., Soudzilovskaia, N. A., Bodegom, P. M., Bengtsson-Palme, J., Anslan, S., Coelho, L. P., Harend, H., Huerta-Cepas, J., Medema, M. H., Maltz, M. R., Mundra, S., Olsson, P. A., Pent, M., Põlme, S., Sunagawa, S., Ryberg, M., Tedersoo, L., and Bork, P. (2018). “Structure and function of the global topsoil microbiome,” Nature 560 (7717), 233-237.

Basalp, D., Tihminlioglu, F., Sofuoglu, S. C., Inal, F., and Sofuoglu, A. (2020). “Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites,” Waste Biomass Valorization 11(10), 5419-5430. DOI: 10.1007/s12649-020-00986-7

Batista, K. C., Silva, D. A. K., Coelho, L. A. F., Pezzin, S. H., and Pezzin, A. P. T. (2010). “Soil biodegradation of PHBV/peach palm particles biocomposites,” J. Polym. Environ. 18(3), 346-354. DOI: 10.1007/s10924-010-0238-4

Bayerl, T., Geith, M., Somashekar, A. A., and Bhattacharyya, D. (2014). “Influence of fibre architecture on the biodegradability of FLAX/PLA composites,” Int. Biodeter. Biodegr. 96(1), 18-25. DOI: 10.1016/j.ibiod.2014.08.005

Beg, M. D. H., and Pickering, K. L. (2008). “Accelerated weathering of unbleached and bleached kraft wood fibre reinforced polypropylene composites,” Polym. Degrad. Stabil. 93(10), 1939-1946. DOI: 10.1016/j.polymdegradstab.2008.06.012

Beltrami, L. V., Bandeira, J. A., Scienza, L. C., and Zattera, A. J. (2014). “Biodegradable composites: Morphological, chemical, thermal, and mechanical properties of composites of poly(hydroxybutyrate-co-hydroxy valerate) with curaua fibers after exposure to simulated soil,” J. Appl. Polym. Sci. 131, article no. 40712. DOI: 10.1002/app.40712

Beltrán-Sanahuja, A., Benito-Kaesbach, A., Sánchez-García, N., and Sanz-Lázaro, C. (2021). “Degradation of conventional and biobased plastics in soil under contrasting environmental conditions,” Sci. Total Environ. 787, article no. 147678. DOI: 10.1016/j.scitotenv.2021.147678

Berger, F., Gauvin, F., and Brouwers, H. J. H. (2020). “The recycling potential of wood waste into wood-wool/cement composite,” Constr. Build. Mater. 260, article no. 119786. DOI: 10.1016/j.conbuildmat.2020.119786

Bjordal, C. G., and Elam, J. (2021). “Bacterial degradation of nine wooden foundation piles from Gothenburg historic city center and correlation to wood quality, environment, and time in service,” Int. Biodeter. Biodegr. 164, article no. 105288. DOI: 10.1016/j.ibiod.2021.105288

Boubekeur, B., Belhaneche-Bensemra, N., and Massardier, V. (2020). “Low density polyethylene/poly(lactic acid) blends reinforced by waste wood flour,” J. Vinyl Addit. Technol. 26(4), 443-451. DOI: 10.1002/vnl.21759

Brebu, M. (2020). “Environmental degradation of plastic composites with natural fillers – A review,” Polymers 12, article no. 166. DOI: 10.3390/polym12010166

Breister, A. M., Imam, M. A., Zhou, Z., Ahsan, Md A., Noveron, J. C., Anantharaman, K., and Prabhakar, P. (2020). “Soil microbiomes mediate degradation of vinyl ester-based polymer composites,” Commun. Mater. 1(101), 1-15. DOI: 10.1038/s43246-020-00102-1

Brdlik, P., Boruvka, M., Behalek, L., and Lenfeld P. (2022). “The influence of additives and environment on biodegradation of PHBV biocomposites,” Polymers 14, 83.

Briassoulis, D., and Innocenti, F. D. (2017). “Standards for soil biodegradable plastics,” in: Soil Degradable Bioplastics for a Sustainable Modern Agriculture, M. Malinconico (ed.), Springer, Cham, Switzerland, pp. 139-168. DOI: 10.1007/978-3-662-54130-2_6

Brown, M. E., and Chang, M. C. (2014). “Exploring bacterial lignin degradation,” Curr. Opin. Chem. Biol. 19, 1-7. DOI:10.1016/j.cbpa.2013.11.015

Cai, Z., Rudie, A., Stark, N., Sabo, R., and Ralph, S. (2013). “New products and product categories in the global forest sector,” in: The Global Forest Sector: Changes, Practices, and Prospects, E. Hansen, R. Panwar, and R. Vlosky (eds.), CRC Press, Boca Raton, pp. 129-149.

Catto, A. L., Montagna, L. S., Almeida, S. H., Silveira, R. M. B., and Santana, R. M. C. (2016). “Wood plastic composites weathering: Effects of compatibilization on biodegradation in soil and fungal decay,” Int. Biodeterior. Biodegradation 109, 11-22. DOI: 10.1016/j.ibiod.2015.12.026

Chamas, A., Moon, H., Zheng, J., Qiu, Y., Tabassum, T., Jang, J. H., Abu-Omar, M., Scott, S. L., and Suh S. (2020). “Degradation rates of plastics in the environment,” ACS Sustain. Chem. Eng. 8, 3494-3511. DOI: 10.1021/acssuschemeng.9b06635

Chattopadhyay, I. (2022). “Role of microbiome and biofilm in environmental plastic degradation,” Biocatal. Agricultural Biotechnol. 39, article no. 102263.

Chinaglia, S., Tosin, M., and Degli-Innocenti, F. (2018). “Biodegradation rate of biodegradable plastics at molecular level,” Polym. Degrad. Stab. 147, 237-244. DOI: 10.1016/j.polymdegradstab.2017.12.011

Christofides, S. R., Hiscox, J., Savoury, M., Boddy, L., and Weightman, A. J. (2019). “Fungal control of early-stage bacterial community development in decomposing wood,” Fungal Ecol. 42, article no. 100868. DOI: 10.1016/j.funeco.2019.100868

Coudert, L., Blais, J.-F., Mercier, G., Cooper, P., Gastonguay, L., Morris, P., Janin, A., and Reynier, N. (2013). “Pilot-scale investigation of the robustness and efficiency of a copper-based treated wood wastes recycling process,” J. Hazard Mater. 261(10), 277-285. DOI: 10.1016/j.jhazmat.2013.07.035

Crawford, D. L., and Pometto, A. L. (1988). “Acid-precipitable polymeric lignin: Production and analysis,” in: Biomass Part B: Lignin, Pectin, and Chitin, W. A. Wood and S. T. Kellogg (eds.), Methods in Enzymology (book series), Academic Press, 161, 35-47. DOI:10.1016/0076-6879(88)61007-x

Cristaldi, A., Oliveri Conti, G., Cosentino, S. L., Mauromicale, G., Copat, C., Grasso, A., Zuccarello, P., Fiore, M., Restuccia, C., and Ferrante, M. (2020). “Phytoremediation potential of Arundo donax (Giant Reed) in contaminated soil by heavy metals,” Environ. Res. 185, article no. e109427. DOI: 10.1016/j.envres.2020.109427

Das, M. P., and Kumar, S. (2015). “An approach to low-density polyethylene biodegradation by Bacillus amyloliquefaciens,” 3 Biotech. 5, 81-86. DOI: 10.1007/s13205-014-0205-1

Delacuvellerie, A., Cyriaque, V., Gobert, S., Benali, S., and Wattiez, R. (2019). “The plastisphere in marine ecosystem hosts potential specific microbial degraders including Alcanivorax borkumensis as a key player for the low-density polyethylene degradation,” J. Hazard. Mater. 380, article no. e120899. DOI: 10.1016/j.jhazmat.2019.120899

Dey, S., and Tribedi P. (2018). “Microbial functional diversity plays an important role

in the degradation of polyhydroxybutyrate (PHB) in soil,” 3 Biotech 8, 171.

Dhaka, V., Singh, S., Ramamurthy, P.C., Samuel, J., Swamy Sunil Kumar Naik, T., Khasnabis, S., Prasad, R., and Singh, J. (2022). “Biological degradation of polyethylene terephthalate by rhizobacteria,” Environ. Sci. Pollut. Res. Int. 1-10. DOI: 10.1007/s11356-022-20324-9

Dittenber, D. B., and GangaRao, H. V. S. (2012). “Critical review of recent publications on use of natural composites in infrastructure,” Compos. A: Appl. Sci. Manuf. 43(8), 1419-1429. DOI: 10.1016/j.compositesa.2011.11.019

Donnelly, P. K. Entry, J. A., Crawford, D. L., and Cromack Jr, K. (1990). “Cellulose and lignin degradation in forest soils: Response to moisture, temperature, and acidity,” Microb. Ecol. 20(1), 289-295.

Du, H., Parit, M., Wu, M., Che, X., Wang, Y., Zhang, M., Wang, R., Zhang, X., Jiang, Z., and Li, B. (2020). “Sustainable valorization of paper mill sludge into cellulose nanofibrils and cellulose nanopaper,” J. Hazard. Mater. 400, article no. 123106. DOI: 10.1016/j.jhazmat.2020.123106