Abstract

The particleboards with different density from specially prepared particles from black locust and willow were prepared. The standard mechanical parameters of the panels were investigated, as well as the corner wall connections with eccentric connecting fitting element or confirmat strength. The screw withdrawal resistance and hinge bearing were also measured for investigated panels. The results, compared to the strength of commercial particleboards, show that excluding panels from black locust with low density, the rest of the panels can be successfully used for furniture production purposes.

Download PDF

Full Article

INFLUENCE OF THE RAW MATERIALS AND PRODUCTION PARAMETERS ON CHOSEN STANDARD PROPERTIES FOR FURNITURE PANELS OF BIOCOMPOSITES FROM FIBROUS CHIPS

Grzegorz Kowaluk,a* Dorota Fuczek,a Piotr Beer,b and Marek Grzeskiewicz b

The particleboards with different density from specially prepared particles from black locust and willow were prepared. The standard mechanical parameters of the panels were investigated, as well as the corner wall connections with eccentric connecting fitting element or confirmat strength. The screw withdrawal resistance and hinge bearing were also measured for investigated panels. The results, compared to the strength of commercial particleboards, show that excluding panels from black locust with low density, the rest of the panels can be successfully used for furniture production purposes.

Keywords: Fibrous chip; Particleboard; Raw material; Bending; Strength; Connection; Screw

Contact information: a: Wood Technology Institute, Winiarska Str. 1, 60-654 Poznan, Poland; b: Faculty of Wood Technology, Warsaw University of Life Science, Nowoursynowska Str. 159, 02-787 Warsaw, Poland, * Corresponding author: g_kowaluk@itd.poznan.pl

INTRODUCTION

There are several reasons to produce strong and durable lightweight panels for the furniture industry: transportation, handling, and assembly costs, as well as raising raw materials and energy prices. One attempt to find alternative material with reduced weight was to produce a sandwich-construction panel from HDF panels as the face layers and specially prepared particleboard with a density profile as the core layer (Michanicki 2006). The panels’ density having 18 mm thickness can be reduced even to 240 kg/m3. The reduction of the panels’ density by use of the alternative raw materials was also investigated (Balducci et al. 2008). The raw materials evaluated were hemp, kenaf, sunflower, maize, topinambur, miscanthus, rape, poplar, and waste wood. These trials show that even with the panels’ density decrease to 400 kg/m3, there are possibilities to produce panels that meet the EN 312 requirements in terms of internal bond strength (i.e., panels made out from topinambur or poplar, with use of PMDI bonding agent). The bending strength of above mentioned panels was very low (2.4, 4.6 N/mm2), but in case of special application (i.e., furniture doors) it must not be a disqualification feature. There were successful trials to produce the panels from fibrous chips, applied in German particleboard plant (Anonym 1989). The main advantages of the panels produced from these chips were better machining parameters, as well as higher raw material’s efficiency.

According to previous research (Kowaluk 2009a,b), promising results of wood-based panels production with reduced density from alternative raw materials, such as fast-growing willow Salix viminalis and Robinia pseudoacacia have been obtained. But in such research only chosen standard mechanical parameters of the panels were tested, without information about the possibilities of fixing by furniture connectors or hinges.

The goal of the research was to investigate the properties of the particleboards produced from the fibrous chips from alternative raw materials. Apart from the standard mechanical parameters of the panels, the screw withdrawal resistance, the strength of the corner wall connections, as well as the ability of hinges to hold in the panels are described. In the range of the research was the comparison of the mechanical parameters of investigated panels to the commercial particleboards, as well as the potential application of the investigated panels from fibrous chips.

MATERIALS AND METHODS

The following materials were used in investigations:

- commercially available 3 layer 16 mm thick particleboards, with a density = 645 kg/m3 (hereinafter: i),

- 3 layer 16 mm thick particleboards with two densities (600 and 660 kg/m3) produced in laboratory conditions from industrial particles (hereinafter: ip600 and ip660),

- 3 layer 16 mm thick particleboards with two densities (600 and 660 kg/m3) produced in laboratory conditions from fibrous chips from willow Salix Viminalis L. (hereinafter: w600 and w660),

- 3 layer 16 mm thick particleboards with two densities (600 and 660 kg/m3) produced in laboratory conditions from fibrous chips from black locust Robinia Pseudoacacia L. (hereinafter: r600 and r660).

The density profiles of the investigated panels were measured with an X-ray based GreCon DA-X system. The results of the measurements are displayed on Fig. 1.

Fig. 1. The density profiles of investigated panels

The maximum variations of the produced panels average density from the assumed values were about 6%. All the samples before the tests were stored in climatic chamber under parameters 20 ºC/65% R.H.

Two different raw materials were used in these investigations to produce the fibrous chips:

- willow Salix Viminalis L., taken as about 2 m long 2 years old rods from plantation for energetic purposes (Fig. 2a),

- black locust Robinia Pseudoacacia L., taken as a 2 years old root offshoots (Fig. 2b).

Fig. 2. Raw materials for panels production: willow (a) and black locust (b)

The fibrous chips were produced on a Pallmann defibrator. The span between the hammer and milling disc was 1.2 mm. The raw material’s moisture content was about 111% for willow and 60% for black locust. The mass fraction share of produced fibrous chips and industrial particles (for comparative purposes) was as shown in Fig. 3. The fraction of 2 to 8 mm was taken for the core layer, and 0.5 to 1 mm for the face layers.

From the investigated fibrous chips, as well as from industrial particles, three-layer particleboards of the dimensions of 700x500x16 mm were produced under laboratory conditions. Important production parameters were: face layers share 32%, industrial face layers’ chips, face layers’ resination 12%, core layer resination 8%, Silekol W1-C industrial UF resin. Pressing operation parameters: press factor 10 s/mm, press plates’ temperature 210°C. The time and pressing pressure are shown in the Fig. 4. The rest of production parameters were close to industrial. All the panels were both-side sanded on the industrial sanding machine to achieve regular thickness.

Fig. 3. The mass fraction share of produced fibrous chips

All the produced panels, as well as the samples of the commercial particleboards, were tested in case of bending strength (EN 310) and internal bond strength perpendicular to the plane of the board (EN 319).

Fig. 4. The pressing schedule

The Corner Wall Connection Strength

The corner wall connection strength measuring was conducted on the samples made from all the 7 types of tested materials: i, ip600, ip660, w600, w660, r600, r660. Two different connectors were used to join the panels:

- Rastex by Hettich, two pieces, with 15 mm diameter eccentric element and 7 mm diameter connector,

- confirmat, one piece, screw-like connector with dimensions of 7 x 50 mm.

Both types of connection samples were fixed by one Rastex or one confirmat connector, respectively, and two beech/birch 8×35 mm setting dowels. The geometry of the samples of the corner wall connection with the Rastex connector is displayed in Fig. 5, and with the confirmat connector in Fig. 5. The samples of corner wall connec-tions were tested on typical testing machine Zwick Z010. The machine was equipped with rolling elements, which supports the samples during tests. The concept of loading scheme is displayed in Fig. 7a, and the view of the tested sample in Fig. 7b. The maximum force value was registered as a result of the connection strength measurement.

Fig. 5. The geometry of the corner wall connection with Rastex

Fig. 6. The geometry of the corner wall connection with confirmat

Fig. 7. Concept of measuring of corner wall connection strength (a) and sample during test (b)

Screw Withdrawal Maximum Load

The screw withdrawal maximum load of investigated materials was measured. The direction of screw axis/load was perpendicular to the panel’s face layer. The main dimensions of the screw intended for wood and wood-based materials, used in these investigations, were: thread part diameter = 4 mm and thread part length = 45 mm. The screws were driven through the panel. The test was conducted on a testing machine, where the maximum force was registered. The load speed was 10 mm/min.

Hinge Bearing

To describe the usefulness of the investigated panels to furniture doors production, the hinge bearing was investigated. The typical Hettich Intermat hinges with 35 mm cup diameter were used, with the suitable fixing screws. The hinges were mounted on the panels according to the Producer’s assembly instructions. The samples were placed in standard testing machine and loaded (unclenched) according to Fig. 8 with a load speed of 10 mm/min to destroy the connection. During the hinges bearing testing only observation of connection damage (without forces measuring) was conducted.

Fig. 8. The set-up for hinge bearing test

RESULTS AND DISCUSSION

The bending strength and modulus of elasticity of investigated panels are displayed in Fig. 9. Compare to the industrial panel i, the lowest bending strength was for panel ip600, and the difference was about 45%. The panel produced from industrial particles ip660, where the density of this panel was higher than for panel i, has the bending strength about 24% lower than panel i. The highest values of bending strength were for panels w660 and r660. Also the panel w600 had the bending strength slightly lower than panel i, which can indicate the influence of the different raw material and particles geometry on the bending strength. The highest modulus of elasticity was for panel i, and the lowest – for panels ip600 and r600. In case of modulus of elasticity the change of the density from 660 to 600 kg/m3 (9%) gives a decrease of the modulus value about 22 to 29%. In case of bending strength this drop was in the range of 20 to 30%. According the EN 312 standard, the investigated panels from fibrous chips: r660, w660 and w600 fulfilled the requirements for panels for interior equipment, including furniture (P2 type).

There was no strong correlation between the panels’ internal bond and their density (Fig 10). This lack of correlation can be observed in case of panels from industrial particles (ip660 and ip600), as well as for panels from willow (w660 and w600), where the difference between density was 10% and there was no significant difference of internal bond values.

Fig. 9. The bending strength and modulus of elasticity of tested panels

Fig. 10. The internal bond of investigated panels

It is interesting that the values of the internal bond of the panels ip660 and ip600 were among the highest, compared to another tested panels, while the values of the bending strength and modulus of elasticity for these panels were low. The reason can be the differences between the mass fraction volume of the particles used for the panels’ production (Fig. 3). The chips from black locust were shorter and more shredded, but more 3D-expanded, so even if sieved on the meshes, there was still a high amount of the really smaller parts left included to the fractions with bigger particles. In addition, the sorting of the fibrous chips on the classic sieving machines with meshes is not an optimal method in case of such particles.

The Corner Wall Connection Load

The results of tests (maximum load) of the corner wall connection jointed by Rastex connector are shown in Fig. 11. The highest load was for industrial panels i, as well as for panels w660. The strong dependence between the load of the connections and the density of the panels can be recognized. According to the observations of the connections damage type, the most frequent cause of the samples’ destruction was tear-out of the outer part of the panel around of the connector fixing area by bend them (Fig. 12). Both panels with the lowest maximum load, r600 and w600, had the lowest density of the face layers (Fig. 1), and, in their case, it can be the reason of such low load of the connection (both below 150 N) fixed by Rastex connector. Similar investigations of the corner wall connections were conducted by Smardzewski (2004), but in such investigations a different loading method was used (the samples were clenched).

Fig. 11. The strength of the corner wall connection joined by Rastex

The highest average values of the maximum load of the connections with confirmat were noted for panels w660, i, ip660, and r660 (all of them more than 350 N) (Fig. 13). Except for i panel, all of the above mentioned panels had a density of about 660 kg/m3. Interestingly, even the lowest value of the maximum load of the connections with confirmat (about 259 N) was higher than the strongest connection with Rastex (210 N).

Fig. 12. The damage form of the connection with Rastex

The damage of the connections with confirmat were mostly caused by partial disruption of the nest of the confirmat, with simultaneous delamination of the core layer of the element, where the confirmat was screwed in (Fig. 14). The delamination of the panel was most commonly observed for panels r600 (Fig. 15), where the internal bond was lowest (Fig. 10).

Fig. 13. The strength of the corner wall connection joined by confirmat

Fig. 14. The damage form of the connection with confirmat

Fig. 15. The delamination of the panels r600 from connections with confirmat

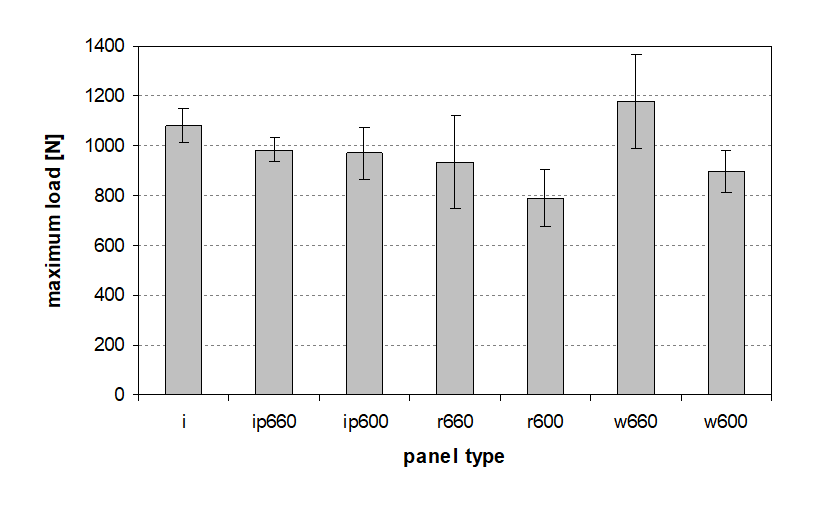

Screw Withdrawal Maximum Force

The maximum force carried out by screw driven into panel (Fig. 16) was the highest for panel w660 and the lowest for panel r600. The rest of the investigated panels had average screw withdrawal resistances in the range of 898 to 1081 N. When compared to the previous parameters of the investigated panels to screw withdrawal maximum load, there is a dependence between the screw withdrawal maximum load and internal bond (Fig. 10). Taking into account the scattering of the particular results, calculated by standard deviations, excluding w660 and r600, it can be concluded that there is no significant difference in case of screw withdrawal maximum load within the investigated panels.

Fig. 16. Screw withdrawal maximum load

Hinge Bearing

The research directed to characterize the investigated panels according to hinges fixing show, that there is no special limitations in such utilization of these panels. All tested samples with fixed hinge were damaged by mechanical destruction of the hinge, caused by too wide unclench of such furniture fitting. As is shown on Fig. 17, the part of the narrow surface of the panel, where the can was fixed, was damaged. This damage was preceded by the above-mentioned hinge destruction. It should be pointed out that no hinge can or fence (rail) tear-out was observed. The conclusion can be drawn, that there is no special limitations in case of hinges used to connect the furniture elements produced from panels from fibrous chips.

Comparison of Mechanical Parameters of Panels from Fibrous Chips to the Requirements for Particleboards for Furniture Production

An interesting comparison, on the end-user’s point of view, can be the list of the chosen mechanical parameters of the investigated particleboards produced from fibrous chips to the requirements of the standard EN 312:2005 (Table 1). According to the above mentioned comparison, only in case of the investigated panel r600 with the lowest mechanical parameters, the problems with matching the rest of the panels can occur. The rest of the investigated panels (r660, w600, and w660) are close to the requirements of above mentioned standard. What’s more, the mechanical parameters of the panel w660, especially bending strength and internal bond, were among the highest.

Fig. 17. Example of testing of hinge bearing connection

Table 1. Important Mechanical Resistance Parameters Values of Investigated Panels from Fibrous Chips

Potential Application of the Investigated Panels from Fibrous Chips

According to the information about the mechanical parameters of the panels produced from fibrous chips, including the strength of the corner wall connections and screw withdrawal, taking into account the ability to keep hinges intact, there were no special limitations in potential utilization of these panels. There was one exception: panel r600 did not meet the requirements. Also there were no special requirements in case of furniture fittings or connectors. It was notable that panels w600, which had density lower than typical density of commercial 16-mm thick panel, can be successfully used for those furniture elements, where the weight of the element is essential. Connected with use the typical hinges, the panels with lower density can be used as the furniture doors. The panel density reduction is favorable in terms of furniture weight, as well as to the durability of hinges and other connectors.

CONCLUSIONS

On the basis of above mentioned results, as well as taking into account the information from literature, it is possible to formulate the following conclusions and remarks:

1. There are favourable prospects to produce panels from fibrous chips obtained from alternative lignocellulose raw materials such as willow and black locust.

2. The chosen standard mechanical parameters of the panels produced with the density as for commercial panels from fibrous chips were not significantly different from the parameters of the commercial industrial particleboards.

3. The mechanical parameters of the panel produced from willow fibrous chips with lower density met the requirements of the standard for panels for furniture production.

4. The panels from fibrous chips exhibited the proper ability to be fitted with typical cup hinges.

5. There are no special mechanical limitations to utilize the panels from willow fibrous chips, even with lower density, as a base material for furniture production.

ACKNOWLEDGEMENT

This study has been carried out with the financial support of the Ministry of Science and Higher Education in Poland, in years 2007 – 2010, project number N 309 1068 33.

REFERENCES CITED

Anonym. (1989). “Messerlose Faserspanaufbereitung,” HK 11/89.

Balducci, F., Harper, Ch., Meinlschmidt, P., Dix, B., and Sanasi, A. (2008). “Development of innovative particleboard panels,” Drvna Industrija 59(3), 131-136.

Barboutis, J. A., and Philippou, J. L. (2007). “Evergreen Mediterranean hardwoods as particleboard raw material,” Building and Environment 42, 1183-1187.

Kowaluk, G. (2009a). “Influence of the density on the mechanical properties of the particleboards produced from fibrous chips,” Ann. WULS-SGGW, For. and Wood Technol. 68, 397-400.

Kowaluk, G. (2009b). “Influence of the method of milling on the geometry of fibrous chips and bending strength of produced particleboards,” Proc. 3rd Int. Sc. Conf. Woodworking Techniques; Zalesina, Croatia; 02.-05.09.2009: 323-331.

Michanicki, A. (2006). “Development of a new light wood-based panel,” Proc. 5th European Wood-based Panel Symposium, 4-6 October 2006, Hannover, Germany

EN 310:1994 Wood-based panels. Determination of modulus of elasticity in bending and of bending strength.

EN 312:2005 Particleboards. Specifications.

EN 319:1999 Particleboards and fibreboards. Determination of tensile strength perpendicular to the plane of the board.

Smardzewski, J. (2004). “Strength-rigidity models of furniture construction,” http://www.up.poznan.pl/wtd/att/km/BADANIA/GRANT_3P06L00222.pdf /access 07/06/2010.

Article submitted: March 20, 2011; Peer review completed: April 22, 2011; Revised version accepted: June 20, 2011; Published: June 23, 2011.