Abstract

The separation of lignin from the black liquor generated during alkaline pulping is reviewed in this article with an emphasis on chemistry. Based on published accounts, the precipitation of lignin from spent pulping liquor by addition of acids can be understood based on dissociation equilibria of weak acid groups, which affects the solubility behavior of lignin-related chemical species. Solubility issues also govern lignin separation technologies based on ultrafiltration membranes; reduction in membrane permeability is often affected by conditions leading to decreased solubility of lignin decomposition products and the presence of colloidal matter. Advances in understanding of such phenomena have potential to enable higher-value uses of black liquor components, including biorefinery options, alternative ways to recover the chemicals used to cook pulp, and debottlenecking of kraft recovery processes.

Download PDF

Full Article

Lignin Recovery from Spent Alkaline Pulping Liquors Using Acidification, Membrane Separation, and Related Processing Steps: A Review

Martin A. Hubbe,*,a Raimo Alén,b Michael Paleologou,c Miyuru Kannangara,d and Jonas Kihlman e

The separation of lignin from the black liquor generated during alkaline pulping is reviewed in this article with an emphasis on chemistry. Based on published accounts, the precipitation of lignin from spent pulping liquor by addition of acids can be understood based on dissociation equilibria of weak acid groups, which affects the solubility behavior of lignin-related chemical species. Solubility issues also govern lignin separation technologies based on ultrafiltration membranes; reduction in membrane permeability is often affected by conditions leading to decreased solubility of lignin decomposition products and the presence of colloidal matter. Advances in understanding of such phenomena have potential to enable higher-value uses of black liquor components, including biorefinery options, alternative ways to recover the chemicals used to cook pulp, and debottlenecking of kraft recovery processes.

DOI: 10.15376/biores.14.1.Hubbe

Keywords: Black liquor; Acid precipitation; Ultrafiltration; Colloidal stability; Solubility; Debottlenecking of pulp mills; Carbon dioxide; Sulfuric acid; Lignin isolation

Contact information: a: North Carolina State University, Department of Forest Biomaterials, Campus Box 8005, Raleigh, NC, 27695-8005, USA; b: University of Jyväskylä, Department of Chemistry, POB 35, Jyväskylä 40014, Finland; c: FPInnovations, 570 St Jean Blvd, Pointe Claire, PQ H9R 3J9, Canada; d: Natl Res Council Canada, Energy Min. & Environm., 1200 Montreal Rd, Ottawa, ON K1A 0R6, Canada; e: Karlstad University, Department of Engineering and Chemical Sciences, SE651 88 Karlstad, Sweden;

* Corresponding author: hubbe@ncsu.edu

Contents

INTRODUCTION

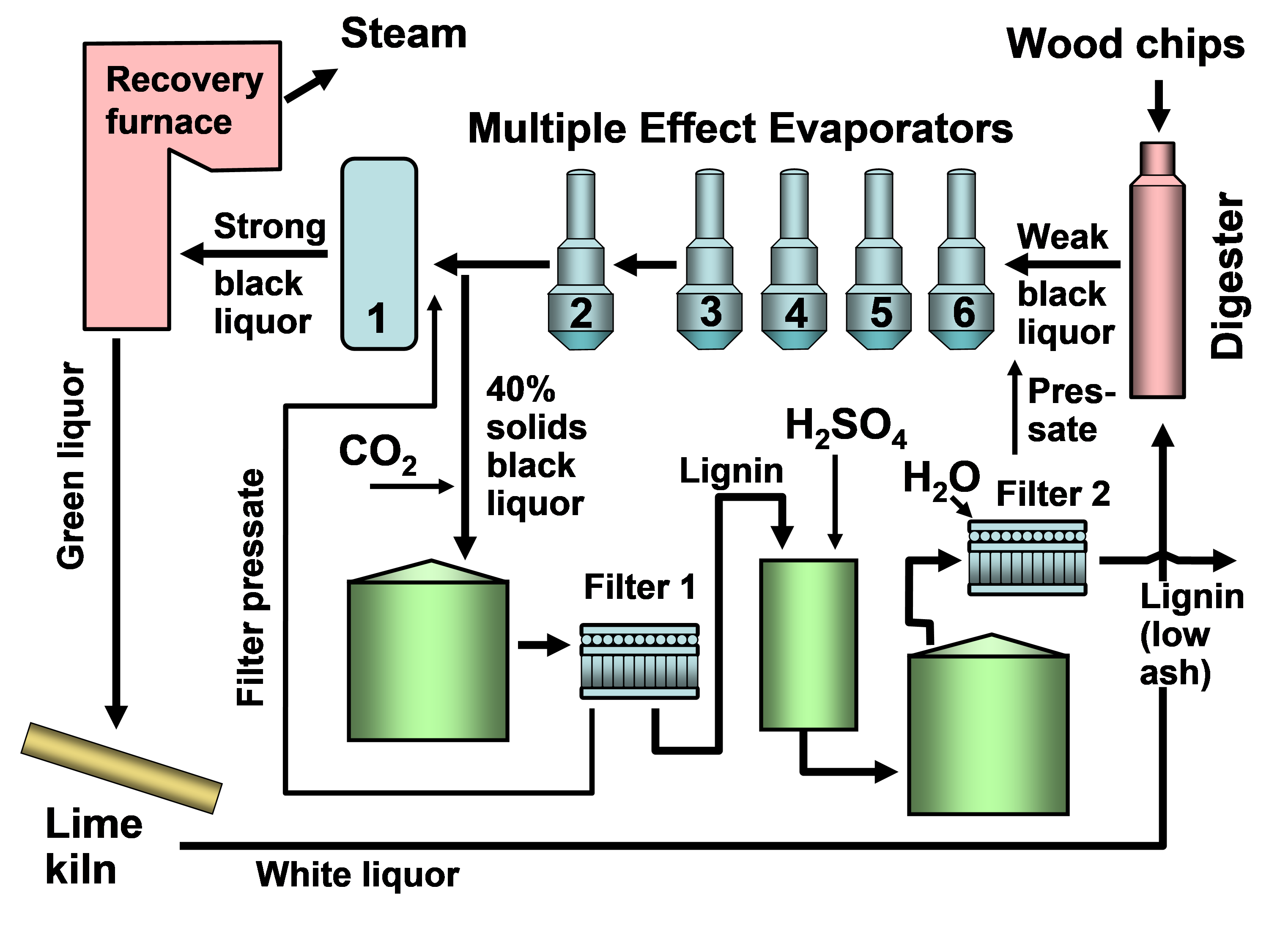

When the word “recovery” is used in the context of the pulping industry, the main focus has been on restoring the starting composition of the mixture of sodium hydroxide and sodium sulfide, which are used in the kraft process to break down and dissolve the lignin component of the wood or other cellulosic source material (Rydholm 1965; Marton 1971; Grace et al. 1989; Biermann 1996; Fardim 2011). Such pulping liberates the cellulosic fibers, whereas most of the lignin and degradation products from much of the hemicelluloses originally present in the biomass are typically incinerated in a recovery furnace, which provides steam to power the whole operation and to dry the resulting paper (Grace 1992; Adams 1997; Vakkilainen 2007; Empie 2009; Alén 2011; Bajpai 2017). The present review article considers technologies aiming to achieve a further goal – recovery of the lignin present in spent liquor from kraft pulping, i.e. “black liquor”. Emphasis is placed on chemical aspects when separation of lignin is induced by acidification, by the use of membranes, and by some other related technologies.

In general terms, lignin can be described as a three-dimensionally cross-linked polymer formed biologically from phenol-propane-type monomer units (Sjöström 1993). There can be a variety of motivations to recover lignin rather than allow all of it to be incinerated during a traditional chemical recovery process at a pulp mill. Chemical pulping accounts for about 70% of the total worldwide production of pulp, i.e. chemical, semichemical, chemimechanical, and mechanical pulps (FAOSTAT 2014). The kraft process, which uses NaOH and Na2S to break down and solubilize lignin from the cellulosic source material, accounts for about 90% of the world’s chemical pulp production. When excluding mechanical pulps, the kraft process may account for 90% of the pulp production (Sixta 2006; Alén 2011; Gellerstedt et al. 2013).

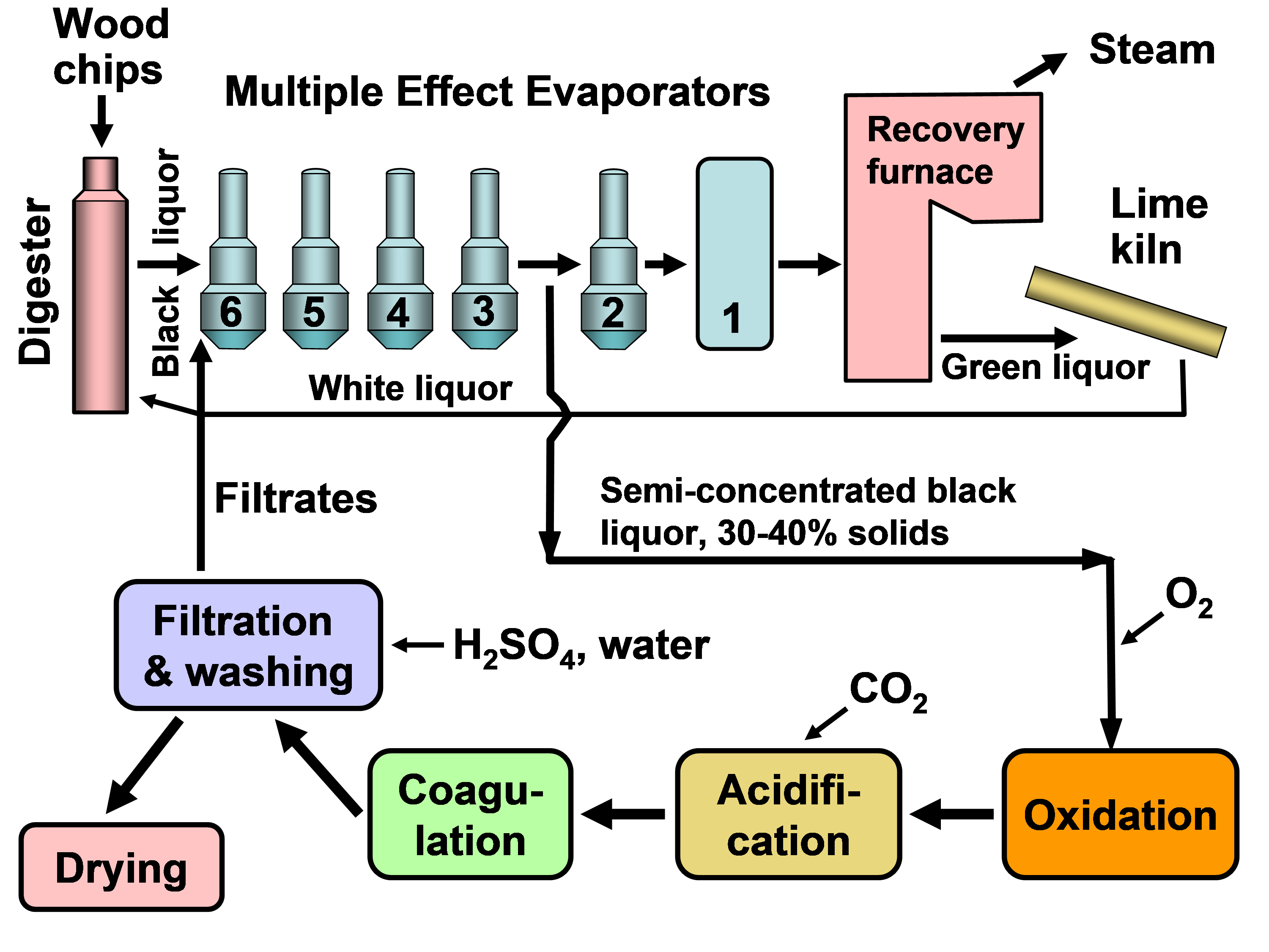

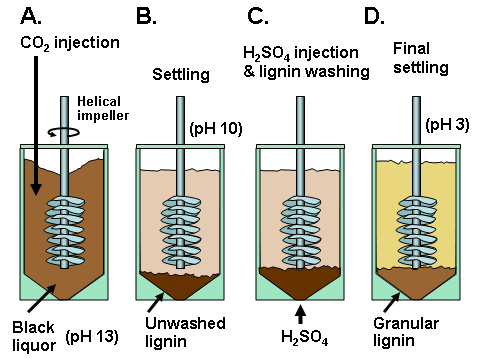

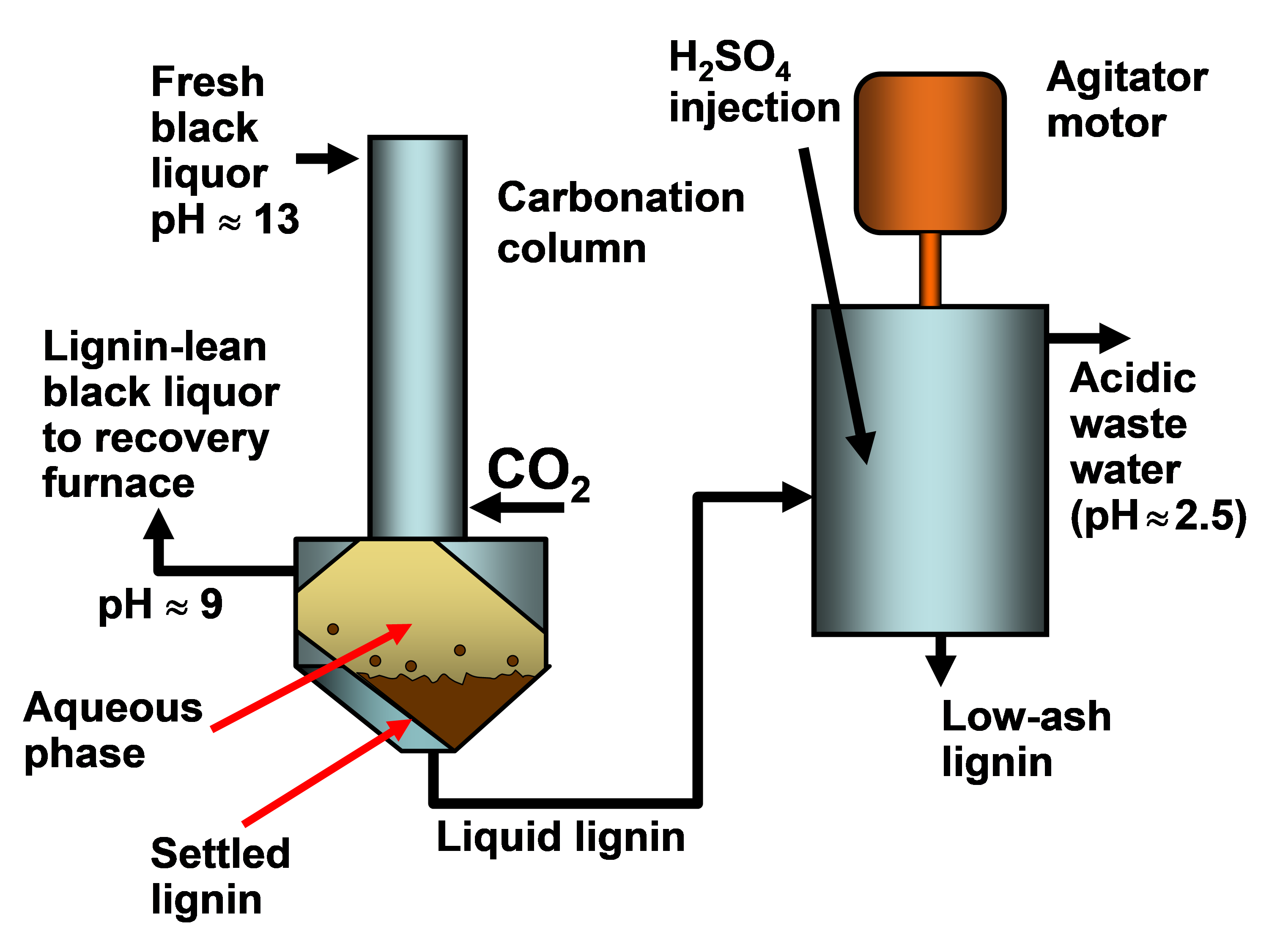

In existing pulp mills where recovery is the capacity-limiting factor, one of the strongest motivations for lignin recovery can be to “debottleneck” the process. Removal of lignin from the black liquor can allow greater pulp production at such a pulp mill in which the capacity of the recovery boiler system is limited by the calorific load or the solids load (Axelsson et al. 2006; Ohman et al. 2007b; Mesfun et al. 2014). Two systems of black liquor acidification, separation, washing, and recovery of much of the lignin have been implemented in pulp mills, and these are called LignoBoost (Wallmo et al. 2009a,b; Tomani 2010; Tomani et al. 2011; Gellerstedt et al. 2013; Zhu et al. 2014, 2016) and LignoForce (Kouisni et al. 2012, 2014, 2016). Another system that has been demonstrated at a pilot scale is the Sequential Liquid-lignin Recovery and Purification (SLRP) system (Lake and Blackburn 2011, 2016; Kihlman 2016).

Another key motivation for lignin recovery is to utilize it for such higher-value applications as carbon fiber, phenolic resins, and activated carbon (Coheen 1981; Pye 2006; Bozell et al. 2007; Kouisni et al. 2011; Gellerstedt et al. 2013; Alén 2015; Zhu and Theliander 2015; Yahya et al. 2015; Suhas et al. 2016; Teguia et al. 2017). However, probably due to the complex structure of lignin, progress in implementation of such value-added options has been slow. Lignin also can be utilized as a portable fuel (Uloth and Wearing 1989b; Tomani 2010) or as feedstock for preparation of biodiesel, which in some cases may have higher value than combustion of the material as part of a chemical recovery process in a pulp mill. Finally, there may be opportunities to rethink the entire pulping process as a biorefinery in which multiple chemical compounds, including breakdown products of polysaccharides, are fractionated, making them available as replacements for petroleum-based chemicals (Alén et al. 1989; Moshkelani et al. 2013; Alén 2015; Kumar et al. 2016; Teguia et al. 2017).

Though the main focus of this article is on the lignin present in kraft black liquor, it is important to keep in mind that the properties of lignin can be diverse, depending on its source (e.g. hardwood vs. softwood) and isolation procedures (e.g. kraft, soda, sulfite, or organosolv pulping, or enzymatic hydrolysis). These differences have been addressed elsewhere (Sarkanen and Ludwig 1971; Lora 2008; Vishtal and Kraslawski 2011; Calvo- Flores et al. 2015).

To provide a focus for this article, a hypothesis can be proposed that the separation of lignin from black liquor can be understood based on the principles of solubility (Marcus 1993; Norgren et al. 2002b; Hansen 2007) and of colloidal stability (Lindström 1979, 1980; Nyman et al. 1986; Norgren et al. 2002a; Hubbe and Rojas 2008; Fritz et al. 2017). When acidification methods are used to separate lignin, it has been shown that the variables pH, temperature, salt concentrations, the presence of coagulating ions, and the lignin type can play governing roles with respect to lignin separation. Also, the results can be highly dependent on the details of black liquor composition and pretreatments such as oxidation. Alternatively, ultrafiltration membranes (Jönsson et al. 2008; Humpert et al. 2016; Kevlich et al. 2017) and electrochemical methods can be used to separate lignin from black liquor (Jin et al. 2013; Haddad et al. 2016, 2017a). This review will consider each of these approaches, in turn.

The present article draws upon progress already achieved in earlier reviews of aspects of the topic. Humpert et al. (2016) and Kevlich et al. (2017) reviewed membrane technologies for recovery of lignin from black liquor, with emphases on the purity of the isolated lignin and process economics. Aro and Fatehi (2017) reviewed the related topic of separation of tall oil (extractives) from black liquor. In the context of the present article, one needs to be concerned about any tendency of extractives to co-precipitate with lignin when black liquor is acidified. Such co-precipitation renders the lignin less pure, which may decrease its value for certain potential applications (Norgren and Edlund 2014). Background of colloidal stability and coagulation of lignocellulosic materials also has been reviewed (Hubbe and Rojas 2008). Zhao et al. (2016) reviewed potential product opportunities based on recovered lignin as a starting material.

Lignin isolation also has the potential to serve as an initial step in alternative technologies aimed at the recovery of inorganic components from black liquor, as described in a recent review paper (Hubbe et al. 2018). Such approaches may be worth considering in situations where conventional recovery boiler operations are judged to be problematic or too expensive in relation to the production goals. For instance, when pulping grasses, such as straw and bamboo, the black liquor from pulping can be difficult to process in a conventional recovery boiler due to deposition of silica (Gilarranz et al. 1998; Mandavgane and Subramanian 2006). In such cases there is a motivation to find other ways to process the material. Removal of lignin and extractives from black liquor also can open the possibility for eutectic freeze crystallization and related technologies, which have potential to supplement the capacity of a pulp mill recovery system (Hubbe et al. 2018).

To provide background for discussions of separation of lignin by acidification, membranes, and related technologies, the next section will review some essential features of typical black liquor specimens.

BLACK LIQUOR PROPERTIES RELATIVE TO LIGNIN PRECIPITATION

Main Components and Proportions

Lignin is a major, but not the only non-water component of black liquor (Frederick 1997). According to Nagy et al. (2010), kraft pulping typically removes 85 to 93% of the lignin and 56 to 71% of the hemicelluloses present in wood, so that the breakdown products of these materials comprise the major non-water content of black liquor. Humpert et al. (2016) reported typical weak black liquor compositions of 12 to 18% solids content. Crude turpentine is recovered from the digester relief and evaporator condensates, and most of the tall oil soap is removed during the black liquor evaporation process by skimming (Alén 2011). After the recovery of the majority of extractives-based compounds, the remaining black liquor dry matter mainly contains 25 to 35% lignin, 30 to 35% aliphatic carboxylic acids, 5 to 10% other organics (i.e., extractives- and hemicelluloses-derived residues and methanol), and 30 to 40% inorganics (i.e., the residual cooking chemicals and sodium and sulfur bound to organics) (Frederick 1977; Niemelä and Alén 1999; Alén 2011, 2015, 2018; Humpert et al. 2016; Kevlich et al. 2017). The fraction of aliphatic carboxylic acids comprises “non-volatile” hydroxy carboxylic acids (with an OH group located in alpha position relative to the carboxylic acid group) (20 to 30% of the dry solids) and “volatile acids”, such as formic acid (about 5% of dry solids) and acetic acid (5 to 10% of the dry solids). The composition of black liquor is characteristically dependent on the wood species and delignification conditions. Typically, softwood black liquors contain more lignin and less aliphatic carboxylic acids (especially, acetic acid) and other organics (especially, xylan residues) than hardwood black liquors.

During alkaline kraft pulping, the presence of hydrogen sulfide ions greatly facilitates delignification because of their strong nucleophilicity in comparison with hydroxyl ions, which are the only pulping agent present in soda pulping (Sjöström 1993; Alén 2000b; Hon and Shiraishi 2001). However, in the course of both kraft and soda pulping, lignin undergoes more or less drastic degradation reactions resulting from the liberation of phenolic hydroxyl groups – they are dissociated to sodium phenolates – with the simultaneous increase in hydrophilicity of lignin fragments. Hence, soda lignins are chemically rather similar to those from kraft pulping. Soda pulping is mostly used for non-wood or annual plants providing sulfur-free lignin.

The partial degradation and dissolution of lignin during alkaline pulping can be attributed to cleavage of certain types of chemical bonds in the lignin matrix. Nowadays all the relevant reaction mechanisms are well understood (Gierer 1970, 1980, 1982, 1985; Sjöström 1993; Hon and Shiraishi 2001). Typically in kraft pulping a significant cleavage of α- and β-aryl ether linkages between phenylpropane units (in both non-etherified and etherified phenolic units) takes place. For example, in the case of β-aryl ether linkages in non-etherified phenolic structures, the first step of the degradation reaction results, via the cleavage of the α-ether bond, in a quinone methide intermediate. In kraft pulping this intermediate readily reacts with hydrogen sulfide ions, leading to simultaneous cleavage of the β-ether bond. However, in the case of soda pulping, when only hydroxyl ions are present, this essential degradation reaction is not prominent, and instead mainly an undegradable styryl aryl ether structure is formed. In general, kraft and soda lignins have more hydroxyl groups and relatively more carbon-carbon bonds than native lignins.

The inorganic chemical content of black liquor depends on many factors, such as wood feedstock, alkali charge, sulfidity, and cooking conditions. About 60% of the sodium that is present in black liquor can be assigned to a balancing of charge of the organic acid species, which include carboxylate and phenolate salts. The average composition of the fraction of individual inorganic compounds (as % of the total compounds) in typical black liquor is 35 to 40% Na2CO3, 5 to 10% NaOH, 15 to 20% Na2S, 5 to 10% Na2SO3, 15 to 20% Na2S2O3, 10 to 15% Na2SO4, and about 10% others (Clayton et al. 1989; Niemelä and Alén 1999). Besides these major components, a large number of other inorganic components (non-process elements) are present, some of them occurring in trace amounts, and their comprehensive analysis is complicated. Additionally, Kevlich et al. (2017) reported levels of 0.2 to 0.7% silica (in the case of wood) and 1 to 30% (in case of non-wood sources of cellulosic fibers). Aspects of the inorganic components of black liquor and their recovery are considered in more detail in a companion article (Hubbe et al. 2018).

Lignin in Black Liquor

Acidic groups

Native lignin is considerably changed during the course of kraft (or other alkaline) pulping. Kraft pulping is especially effective at cleaving phenolic -aryl ether linkages within the lignin, thus liberating fragments of much reduced molecular mass (Gustafsson et al. 2008).

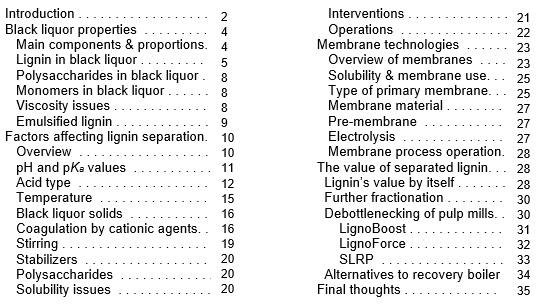

According to Sjöström (1989), the acidic groups associated with lignocellulosic materials can be arranged as shown in Table 1, where the prevalent species are shown with bold lettering. It should be noted that the R-COOH compounds would include the fatty acids and (in the case of softwood) resin acids that are part of the tall oil, but this component is ordinarily removed from black liquor in their soap form by skimming (Dong et al. 1996; McGinnis et al. 1998; Pirttinen et al. 2007; Aro and Fatehi 2017). Sjöström (1989) noted that extractives tend to be removed effectively from fibers during alkaline pulping; on the other hand, the lignin component tends to develop more acidic groups during pulping. As noted by Ragnar et al. (2000), though many of the phenolic groups in lignin have pKa values as shown in Table 1, typical lignin contains structures having pKa values in the range of about 7.4 to 11.3, depending on molecular connections to electron-donor groups or electron-withdrawing groups. In general, oxygen-containing functions adjacent to the aromatic ring tend to yield lower values of pKa. Acidity increases as the oxidation state of a para-substituted function is changed from methyl to hydroxymethyl to carboxylic acid to aldehyde.

Table 1. Acid Dissociation Constants (pKa) in Lignocellulosic Materials

Note: Data as reported by Sjöström (1989)

Molecular representations of the composition of native lignins generally show few, if any, carboxylic acid groups (Sjöström 1993; Frederick 1997), and certainly not enough of them to justify the emphasis depicted in Table 1. A reason to expect such groups to play an important role with respect to the solubility properties of kraft lignin is due to the presence of lignin-polysaccharide complexes (Lawoko et al. 2005, 2006; Gellerstedt et al. 2013; Tarasov et al. 2018). Rather than being separate, the lignin and hemicellulose components of woody materials appear to be covalently bonded together, to some degree, in their native state, and many such bonds can be expected to persist even after pulping operations. Such issues are important with respect to separation of lignin from black liquor, since the polysaccharides tend to be more water-loving, and they may contain the readily dissociated carboxylic acids, as indicated in Table 1.

Table 1 also shows that ordinary phenolic groups can be expected to play a major role with respect to the properties of lignin present in black liquor. Notably, there are no strong acid groups, such as sulfonate or sulfate, listed in the table. This is despite the fact that such groups can play important roles in materials resulting from sulfite pulping processes (Sjöström 1989; Gellerstedt et al. 2013). Evidence of the importance of such groups in sulfite pulps was uncovered by Fatehi et al. (2016). Though these authors were able to precipitate some lignin by acidification of spent sulfite liquor, the majority remained soluble, which is consistent with the presence of strong acid groups, the dissociation of which is unaffected adjustment of pH within typical ranges.

Sulfur also has been found associated with lignin from kraft pulping. Gellerstedt et al. (2013) detected about 2 to 3% sulfur content in kraft lignin that had been separated from black liquor by sequential treatment with carbon dioxide and sulfuric acid, and about half of that amount was said to be molecularly bound to lignin moieties. Helander et al. (2013) found that most covalently bound sulfur in such cases was associated with low molecular mass compounds.

Molecular mass

The quantification of lignin’s molecular mass poses challenges, and different results can be obtained depending on the type of lignin and the methods employed. Primarily due to different determination methods, there are only limited reliable data available on the molecular mass distribution of various lignins in black liquors during alkaline delignification. In practice, these data would be of great importance when considering the mass transfer aspects, but also with respect to the full-scale separation of lignin from different black liquors; for example, when predicting the lignin portion that can be separated by acid precipitation at different pHs (Pakkanen and Alén 2012; Kumar et al. 2016). As general trends, it is known that milled wood lignin preparations have weight-average molecular masses of between 15,000 and 20,000 g/mole, which is four to five times that of kraft lignin (Glasser et al. 1983) and, on the other hand, that soluble hardwood lignins typically have slightly lower molecular masses than softwood lignins (Goring 1971). Few reported determinations also suggest that the weight-average molecular mass of soluble lignin from the sulfur-free soda-AQ cook of birch is somewhat higher than that of the corresponding kraft lignin (Lehto et al. 2015). Additionally, for example, it has been found (Glasser et al. 1983) that the weight-average molecular mass of soluble lignin in wheat straw soda-AQ black liquors is significantly higher than that originated from the wheat straw kraft pulping. This finding is useful when considering the effective production of sulfur-free lignin from alkaline black liquors by membrane techniques or acid precipitation. Based on physicochemical considerations, it seems that a suitable model for soluble lignin would be a compact microgel made up of crosslinked material, which is capable of limited swelling, rather than being a hard, solvent-impermeable sphere (Goring 1971).

The molecular mass of lignin from black liquor has been studied by gel permeation chromatography. Helander et al. (2013) found that the results of such analyses depended on sample preparation. Weight-average molecular mass values ranged from 3525 g/mole (acetylated lignins dissolved in tetrahydrofuran, THF) to 2071 g/mole (non-acetylated lignins in THF) to 2005 g/mole (alkaline aqueous analysis). All of these values were decreased substantially when evaluating the material passing through an ultrafiltration membrane having a cut-off of 1 kDa. Humpert et al. (2016) reported a molecular mass range of 1100 to 6500 g/mole for lignin from black liquor from various sources. Pakkanen and Alén (2012) determined weight-average molecular mass values of 1900 to 4100 and 2200 to 2600 g/mole for softwood and birch kraft lignin, respectively, using gel permeation chromatography without any pre-fractionation. The reported maximum weight-average molecular mass of soluble lignin from the sulfur-free soda-AQ cook of birch is 3300 to 4400 g/mole (Lehto et al. 2015).

Kouisni et al. (2016) determined the weight-average mass values of several LignoForce lignins (softwood, eucalyptus, and other hardwoods) following acetobromination and elution through a GPC/UV system using BHT-stabilized THF as the mobile phase. The Mw of six softwood, four hardwood and three eucalyptus lignins from different mills ranged from 6000 to 12500 g/mole, 2635 to 6249 g/mole, and 2100 to 2700 g/mole, respectively.

Solubility properties

As will be described in more detail in later sections of this article, technologies that can be used to separate lignin from black liquor can be greatly affected by the extent to which the lignin is present in soluble or insoluble form, e.g. particles, colloids, or separate phases. From a fundamental standpoint, a solvent will be most able to dissolve a solute if there is a favorable match between four sets of parameters having to do with the hydrogen bond donation, hydrogen bond accepting, polarizability, and cohesive energy density (Marcus 1993). In practice, simplified analyses are more often applied, dealing with subsets of such parameters (Hansen 2007).

In the course of studying organosolv pulping, it was shown that native lignin from enzymatically hydrolyzed corn stalks is most soluble in liquid media having an ideal range of solvent attributes (Ye et al. 2014). Mixtures of about 15 to 35% water with THF, dioxane, or ethanol were advantageous to achieve high solubilization of lignin from enzymatically hydrolyzed cornstalks. The cited authors found that such results were consistent with a calculated Hildebrand solubility parameter of 13.7 (cal/cm3)0.5 for lignin. Earlier estimates by Goring (1971) for the Hildebrand solubility parameter of lignin were 10 to 11 (cal/cm3)0.5, and the best binary solvent systems for typical lignin were in the range 10.5 to 12.5 (cal/cm3)0.5. Yuan et al. (2009) showed that the composition of extracted lignin from eucalyptus varied depending on the character of the medium; lignin with higher content of polysaccharides and non-condensed phenol-propane units tended to be present in the extract of solvents having higher Hildebrand parameter values. Wang et al. (2010) found that eucalyptus lignin fractions of increasing molecular mass were extracted by solvents having increasing Hildebrand values and hydrogen bonding capacity. Conversely, Weerachanchai et al. (2014) found that the Hildebrand values of solutions tended to approach that of lignin with the increasing solubilization of beech wood lignin.

With respect to the polar character of lignin, two factors of great importance are the value of pH and lignin-polysaccharide complexes. Both of these topics were already discussed in connection with Table 1. Briefly stated, lignin’s solubility in water decreases with decreasing pH, which is consistent with increasing protonation of phenolic groups (especially in the pH range 12 to 9) and carboxylic acid groups (especially in the pH range 7 to 2). In addition, the multiple –OH groups (typically two per sugar monomeric unit) will contribute to polarity, rendering the lignin more soluble in water. There are no practical differences in terms of the oxygen-containing functional groups that exist in kraft, soda, and soda-AQ lignins for the same feedstock. As an example, Gellerstedt et al. (2013) have reported only some differences between spruce and birch kraft lignins; the total amount of aromatic hydroxyl groups 4.1 (spruce) and 4.3 (birch) mmol/g, total amount of aliphatic hydroxyl groups 3.1 (spruce) and 1.7 (birch) mmol/g, and total content of sulfur 1.4 to 1.6 (spruce) and 2.2 to 2.4 (birch) %. Similar to kraft lignins, soda lignins are hydrophobic even though high amounts of carboxylic acid groups in non-wood material make these lignins somewhat less hydrophobic than kraft wood lignins (Lora 2008).

Polysaccharides in Black Liquor

Sugar-related compounds may be present in black liquor as monomer units, as oligomers, or as polysaccharides. The origin of most such compounds is the hemicellulose component, which is more water-soluble, generally lower in mass, and lacks the extensively crystalline character of cellulose. Lisboa et al. (2005) studied black liquors from kraft pulping of Eucalyptus globulus and found between 2.9 and 7.3% of the black liquor solids to be comprised of polysaccharides that could be precipitated in the presence of dioxane. The average molecular mass of the xylan component (which is dominant in Eucalyptus) was about 18,000 g/mole. According to Alén et al. (1985a,b) and Niemelä et al. (1985), extensive degradation of glucomannans takes place during the heating-up period of a conventional kraft cook. The same authors observed 28 to 36% hydroxyl acids content based on the dry mass of black liquor.

Monomers in Black Liquor

The availability of extractives-related compounds in a pulp mill system is strongly dependent on the wood species used for pulping, the method and time of storing logs and chips, and the growth conditions of the trees (Alén 2011). For example, the typical content of extractives in native softwoods is less than 5% of the wood dry solids (Alén 2000a; Holmbom 2011). Of these, about 40% consists of resin acids (e.g. abietic and pimaric acids), about 10% free fatty acids (e.g. oleic, linoleic, and pinolenic acids), about 40% esters of fatty acids (e.g. fats and waxes), and about 10% others (e.g. mostly neutral substances, “nonsaponfiables”) (Frederick 1977; Back and Allen 2000). In contrast, hardwoods from temperate zones contain normally less than 4% of the wood dry solids and this fraction consists of about 20% free fatty acids, about 55% esters of fatty acids (fats), and about 25% others. During kraft pulping, the volatile turpentine components are chemically stable, but the fatty acid esters are hydrolyzed almost completely (Alén 2000b). Due to this saponification with the simultaneous neutralization of aliphatic carboxylic acids, extractives also consume cooking chemicals.

Viscosity Issues

The viscosity of black liquor has the potential to impede various processing steps, especially at high solids levels. The viscosity of softwood black liquors is mostly due to its lignin content and molecular weight (Zaman and Frinke 1995, 1996), while in the case of hardwoods the presence of xylan content enhances the effect of molecular weight (Söderhjelm et al. 1992; Söderhjelm and Sågfors 1994). As discussed by Frederick (1997), black liquor viscosity rises in an accelerated fashion with increasing solids content, but the viscosity tends to be reduced with increasing sulfidity, especially in the case of hardwoods. Black liquor viscosity tends to be reduced with increasing alkali (especially in the case of softwood liquors) up to a certain point, beyond which it rises again (U-shape curve) (Milanova and Dorris 1990). Black liquor viscosity is also influenced by the increased boiling point, which is a consequence of increasing concentration of electrolytes in black liquor as water is removed by evaporation. Also, the viscosity decreases with the passage of time of heating the black liquor at temperatures over 180 ºC without (Kiiskilä and Virkola 1987; Nikkanen 1993) or with oxygen addition (Louhelainen 2003), which is presumably due to continued molecular breakdown. This is of importance especially in the case of non-wood black liquors, which cannot be evaporated to as high a dry solids content as wood black liquors. The determination of black liquor viscosity has been carried out by many researchers (Oye et al. 1977; Söderhjelm 1988; Milanova and Dorris 1990; Söderhjelm et al. 1992; Zaman and Fricke 1994, 1995, 1996; Roberts et al. 1996; Dutka et al. 2004).

Moosavifar (2006) conducted tests to find out how softwood black liquor viscosity might be impacted by removal of some of the lignin. In general, lignin removal resulted in lower viscosity, when solids content and temperature were held constant. Accordingly, Gellerstedt et al. (2013) assumed that black liquor would have a lower viscosity after removal of some of the lignin by acidification.

Emulsified Lignin

A further issue that needs to be kept in mind when considering the separation of lignin from black liquor is that some of the content of black liquor may be present as some form of suspension, colloid, or emulsion. Evidence of the presence of fine particulate material in spent pulping liquor was shown, for example, in work by Fatehi et al. (2016), who studied neutral sulfite semichemical pulping. The present review of the literature did not find corresponding published research for kraft or soda pulp lignins. Pirttinen et al. (2007) stated that lignin particles can be stabilized in suspension due to the presence of fatty acid soaps in pulping liquor. It was noted that upon acid precipitation of such soaps, redissolution can be very difficult. When the pH was lowered to 2.5 or below, particle size analysis revealed the presence of particulate matter. Rudatin et al. (1989) found evidence of molecular-self association of lignin entities in black liquor samples that has been partly acidified. Likewise, Fritz et al. (2017) reported increasing self-association of softwood kraft lignin within alkaline solutions with increasing concentration of monovalent salt. Lake and Blackburn (2016), in their patent document refer to “dispersed lignin”, suggesting that not all of it was fully solubilized, though no quantitative information was provided. After addition of acid, the presence of solid matter becomes readily apparent; for instance Namane et al. (2015) attributed slow lignin cake dewatering after lowering the pH of black liquor to the precipitation of small particles of lignin. The black liquor was from kraft pulping of a hardwood-softwood mixture. However, this statement is contrary to other cases, in which colloidal destabilization generally has resulted in more rapid dewatering of softwood kraft lignin (Ohman and Theliander 2007; Helander et al. 2013).

FACTORS AFFECTING LIGNIN SEPARATION FROM BLACK LIQUOR

Overview

By adjustment of chemical and physical conditions, the lignin and certain other components of black liquor can be induced, either in part or almost completely, to come out of solution and precipitate. This section will consider factors that appear to influence such changes and discuss how such effects are related to the chemical composition of lignin and other components of the mixture. According to Kihlman (2016) there are three main processes by which lignin can be separated from black liquor: acidification, ultrafiltration, and electrolysis. Of these, acidification has been by far the most implemented and also the most directly affected by lignin’s solubility and phase behavior. However, as will be argued in a later section, related issues will also be important in understanding and optimizing conditions for ultrafiltration-based lignin recovery.

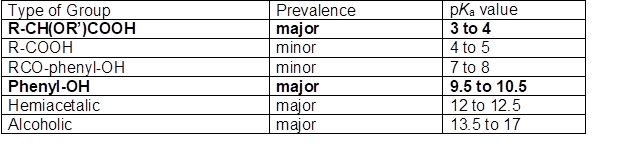

Before reviewing factors contributing to phase changes, it is worth bearing in mind a potential complicating factor, which is irreversibility. In particular, lignin cannot be readily dissolved again if it has been acidified and then dried. This aspect was shown most distinctly by Lindström (1979), who used an isolated softwood kraft lignin (Indulin ATR) in the study. Figure 1 is a replotting of his data, showing how the concentration of lignin that was in dissolved form in the filtrate was dependent on the degree of dissociation of acidic groups on the material. Fresh, never-dried lignin gave the upper line, showing a high level of solubility throughout the range of dissociation considered (related to the pH). The lower plotted line was obtained from the same kind of lignin, but after freeze-drying. Only at the highest levels of dissociation was the latter sample capable of full solubilization, or at least dispersion in sufficiently small particles to pass through a Millipore® filter membrane.

Fig. 1. Example of the irreversible nature of lignin phase behavior. Upper curve: lignin content in filtrate from fresh lignin; lower curve: lignin content in filtrate from freeze-dried lignin of the same type. Data replotted from Lindström (1979)

Norgren et al. (2001) reported related results, which can be expected to be very dependent on process conditions. Phase behaviors from soluble to precipitated states, upon changing of temperature, were observed to be irreversible. Though such phenomena have been rarely reported, any tendency of “once precipitated, never more to be soluble,” is likely to have practical implications.

Another point to make at the outset of a discussion of coagulation is the importance of the key variables pH and ionic strength. Very high levels of pH, as in the case of untreated black liquor, can be expected to immediately lead to the formation of the corresponding insoluble hydroxide species upon addition of coagulants having divalent or trivalent cations (Monhemius 1977). In addition, the best-established theories for predicting coagulation have mainly been tested under relatively low ionic strength conditions.

pH and pKa Values

In 1942 a kraft pulp mill in Charleston, SC, USA began to produce lignin as a side product by acidification of kraft lignin (Kouisni et al. 2016; Durruty et al. 2017b), and the process there has continued operation up to the present, yielding a stated 20,000 tons per year of lignin (Gellerstedt et al. 2013). Though the process details are not publicly disclosed, this example clearly shows not only that pH can have a big effect on lignin solubility, but also that the process can be run successfully at industrial scale.

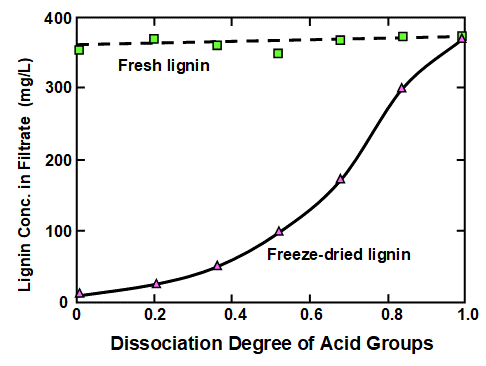

Effects of pH on lignin separation from black liquor are shown, for instance, in Fig. 2, which is a replotting of data reported by Uloth and Wearing (1989a). The black liquor in the cited work was from the kraft pulping of spruce (50%), lodgepole pine (35%), balsam fir (10%), and Douglas fir (5%), all softwoods. It is clear from the graph that the yield of precipitated lignin increased with decreasing pH. Furthermore, the results are consistent with the existence of two pH ranges in which changes in pH had large effects on lignin yield. One such range was above pH 7, and the pKa values in Table 1 suggest that those effects can be attributed to the progressive protonation of phenolic –OH groups. A second transition had a maximum slope at a pH of about 3 or 4, and Table 1 suggests that those changes can be attributed to protonation of hydroxy carboxylic acid groups, i.e. mainly products of hemicellulose breakdown in which the carboxylic acid is at a carbon adjacent to a C-OH hydroxyl group.

Fig. 2. Effect of pH, achieved by addition of strong acid to kraft black liquor, on the yield of precipitated lignin. Data are replotted from the work of Uloth and Wearing (1989a).

It is notable that commonly presented representations of lignin’s typical structure (e.g. see Sjöström 1993; Frederick 1997; Norgren and Eklund 2014) contain few or no carboxyl groups. It follows that the polysaccharide component either must be covalently bonded as lignin-polysaccharide complexes, adsorbed onto the lignin, or merely present together with the lignin material.

Tomani et al. (2012) reported that different amounts of acid are needed to neutralize the alkalinity of black liquor from pulping of different wood species. A higher content of carboxylate groups in hardwood black liquor, due to the type and amount of hemicelluloses (Wallmo 2008), can be expected to increase the consumption of acid during precipitation.

Results consistent with the general trends shown in Fig. 2 have been widely reported (Nyman et al. 1986; Wienhaus et al. 1990; Sun et al. 1999; Norgren et al. 2001; Mussatto et al. 2007; Ohman and Theliander 2007; Toledano et al. 2010a,b; Moreva et al. 2011; Velez and Thies 2013; Zhu et al. 2014; Zhu and Theliander 2015; Zhu et al. 2016), though the pH ranges and yields have exhibited large shifts when comparing different studies.

As noted by Zhu et al. (2016), protonation of acidic groups associated with lignin results in colloidal instability, leading to aggregation and precipitation. A general take-away from this diversity is that the materials within black liquor from different sources can have significant differences in colloidal behavior.

Acid Type

As described below, research involving both weak acids (mainly CO2) and strong acids has been reported as means of promoting the separation of lignin from the aqueous phase of black liquor. In both cases a key action of the acid is to protonate any phenolic functional groups, thereby rendering the some of the lignin moieties less soluble in water. But as a general rule, only the strong acids, represented most notably by sulfuric acid, are able to bring the pH low enough to protonate also the carboxylic acid functional groups associated with lignin. The type of acid used to lower the pH of black liquor can make a difference, not only in the resulting pH but also in the cost.

CO2

A key advantage of using CO2 is that it does not disturb the balance between Na and S in the recovery cycle (Wallmo 2008). Because there is abundant carbon dioxide present in the exhaust gasses in the smokestacks of alkaline pulping operations, CO2 can potentially be derived from these sources and used for at least the initial treatment of black liquor (Lake and Blackburn 2014; Kihlman 2016; Durruty et al. 2017b).

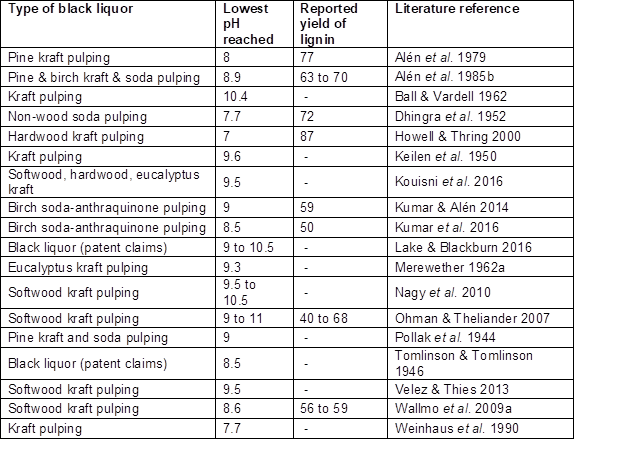

Studies have shown that CO2 can be effective for reducing the pH of black liquor to values in the approximate range of 7 to 10.5 (Tomlinson and Tomlinson 1946; Alén et al. 1979, 1985b; Weinhaus et al. 1990; Howell and Thring 2000; Ohman and Theliander 2001, 2007; Wallmo et al. 2007, 2009a,b; Nagy et al. 2010; Zhu and Theliander 2011, 2015; Velez and Thies 2013; Lake and Blackburn 2016; Kouisni et al. 2016; Kumar et al. 2016). Stocklosa et al. (2013) found that although CO2 readily reduced the pH to 9.5, the majority of softwood kraft lignin already became precipitated when the pH was lowered to a level between 10 and 11.1, which suggests that their specimen was mainly stabilized by phenolate functional groups having a pKa of about 10 or possibly higher (Table 2). The precipitation yield increases markedly at the higher carbonation pressures, especially at short carbonation times since pH is stabilized in a relatively short time at the higher pressures (Gray et al. 1953; Nikitin et al. 1963; Alén et al. 1979). Table 2 lists the final pH values achieved in various studies by addition of CO2 to black liquor.

Table 2. Summary of pH Values and Lignin Yields Achieved by Addition of CO2 to Black Liquor

Sulfuric acid

Sulfuric acid is not only relatively inexpensive, compared to other acids, but it also becomes fully dissociated in solution, regardless of the pH value, i.e. it is classed as a strong acid. Alén et al. (1979) noted that sulfuric acid treatment was able to achieve a precipitated lignin yield of 90%, which was regarded as favorable in comparison to a 77% yield that they were able to achieve with just CO2. The kraft black liquor was mainly from pine with about 8% birch content. Howell and Thring (2000) reported that generator waste acid, a byproduct from chlorine dioxide generator of kraft mill, can be used as a free source of sulfuric acid.

However, as reported by Wallmo (2008), the addition of sulfuric acid disrupts the mill’s Na and S balance in the recovery cycle. Hence, even though sulfuric acid is cheaper than carbon dioxide on a mass (or molar) basis, in reality, it can lead to significantly higher chemical costs for a lignin plant if used in black liquor acidification.

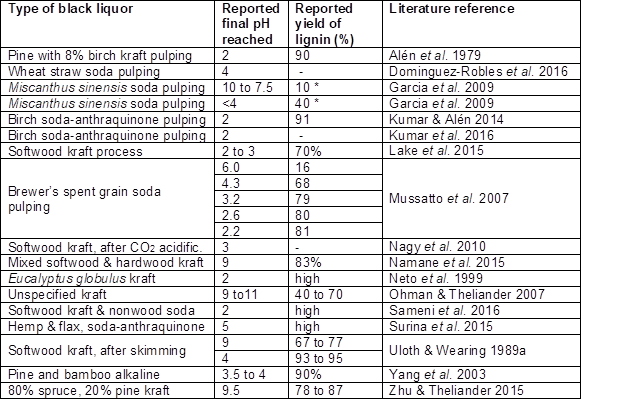

Table 3 summarizes some key findings reported by researchers who used sulfuric acid as a precipitant. Ohman and Theliander (2007) noted that the yield rose from about 40% to about 70% as the pH was decreased from 10.8 to 8.8. That range of pH was favored by the authors, since it yielded a more readily filterable lignin in comparison with higher pHs, in addition to increasing the yield. The greater filterability is consistent with colloidal destabilization due to greater protonation of acidic groups at the lowered pH values.

Table 3. Summary of pH Values and Precipitated Lignin Yields Achieved by Addition of Sulfuric Acid to Black Liquor

Notes: * = Values reported by Garcia et al. (2009) appear to be relative to the total solids content of the black liquor, rather than the lignin content. It follows that the reported numbers should be multiplied by a factor between about 2 and 2.5.

Phosphoric and hydrochloric acids

Dominguez-Robles et al. (2016) evaluated wheat straw soda pulping black liquor acidification with phosphoric acid, in comparison with parallel testing with sulfuric acid and hydrochloric acid. Target pH levels were 2 and 4. Notably, the phosphoric acid gave the highest lignin yield. The authors judged the results obtained with a final pH of 4 to be more favorable, mainly because the cost of acid was about half what was required to reach a pH of 2 and the lignin yields and properties were similar at the two pH values. Structural differences in the precipitated lignin, when using phosphoric acid to reach the lower pH, were attributed to the high concentrations of acid required. In addition it seems likely that the observed effects were attributable to higher ionic strength when phosphoric acid was used. Though hydrochloric acid can be used in lab studies, it is more expensive than sulfuric acid and also corrosive to stainless steel, which is the prevalent construction material within pulp and paper mills.

Lignin precipitation with organic acids

Namane et al. (2016) compared black liquor (from both hardwood and softwood pulping) acidification with formic, citric, and acetic acids, with sulfuric acid serving as a reference. A final pH of 4 was reached, based on the cited procedure (Namane et al. 2015). Precipitation was achieved in each case, and the resulting lignin precipitated by organic acids was low in sulfur content. Lignin precipitated with acetic and citric acids showed less weight loss during thermal decomposition compared to lignin precipitated with sulfuric or formic acids. Namane et al. (2016) make the case that organic acids (like CO2) do not disrupt the S/Na elemental balance when lignin precipitation is incorporated into a kraft recovery cycle.

Optimization of pH conditions

Sometimes, depending on what kind of acid is utilized, there are many practical constraints that can influence decisions about what final pH value or values should be targeted when acidifying black liquor. Uloth and Wearing (1989), who used a combination of sulfuric acid with chlorine dioxide (presumably to oxidize residual sulfides and hydrosulfides), noted that attempts to reach pH values lower than 7 yielded extreme evolution of gas, including CO2 and H2S. In addition, the low-pH conditions resulted in very fine particles of precipitated lignin, which were difficult to filter. Likewise, Kouisni et al. (2016) noted that at pH values below 11 there is potential to release reduced sulfur compounds, unless specific measures are undertaken to avoid that result. Marton (1971) recommended a two-stage acidification as a strategy to achieve good filterability. In the first stage the black liquor is acidified with either CO2 or sulfuric acid to a pH of about 9 to 10, and the precipitate is filtered. The precipitate is then resuspended in water and acidified with sulfuric acid to pH 2 to 3.

Gradients of progressively lower pH levels have been considered by some researchers as a means of separating the lignin into possibly useful fractions (Stoklosa et al. 2013; Kihlman 2016). For example, dos Santos et al. (2014) observed that decreasing the precipitation pH from 4 to 2 tended to increase the carboxylic acid content of the precipitated lignin. Such results are consistent with the principle that hydroxy carboxylic acid species can be expected to remain at least partly in their charged, more soluble form, until the pH is decreased below about 3.5 (Table 1). Such issues will be considered in greater detail when discussing various end-use possibilities for recovered lignin.

Temperature

Because various acidification technologies involve the use of pressurized chambers, the published literature includes consideration of temperatures both above and below the boiling point of water. Working at ambient pressure, Weinhaus et al. (1990), in their study of kraft black liquors, found that it was advantageous to precipitate the lignin in the temperature range of 60 to 80 ºC, but then to raise the temperature if necessary to 80 ºC for better filterability. Similar results were obtained by several researchers (Pollak et al. 1944; Keilen et al. 1950; Gray et al. 1953; Merewether 1962a; Ohman and Theliander 2007). Alén et al. (1979) observed that lignin precipitation tended to increase with increasing time as well as with increasing pressure of CO2 in pressurized systems. Velez and Thies (2016) investigated the effects of processing conditions, temperature, and pressure; three black liquors were evaluated, two from softwood and one from hardwood. An increased yield was obtained at higher acidification temperature, and the temperature also affected the molecular properties.

Tomlinson and Tomlinson (1946) claimed a process in which black liquor was acidified at a temperature of about 45 ºC, which was found to be favorable for settling. But then the temperature was raised to 90 ºC, which was favorable for separation of the viscous liquid from the water phase. Precipitation at temperatures above 76.7 ºC, using a pressurized system, was claimed by Keilen et al. (1952). The advantage of such conditions was that the precipitated lignin remained in a liquid state, facilitating separation of two liquid phases that differ in density. Velez and Thies (2013) reported that the examined liquid-lignin specimens contained about 32 to 48% water. These authors proposed that the solvating ability of the water contributes to the liquid character of the lignin phase that separates upon addition of CO2 at high temperature. This approach of operating under pressure was adopted by Lake and Blackburn (2011, 2014), whose process involved reheating the lignin to considerably higher levels. The acidification process is exothermic, which also contributes to an increase in temperature. Kihlman (2016) assumed a 10 ºC increase due to the heat of neutralization in such a process. The preferred resulting temperature has been stated as between 150 and 190 ºC (Lake and Blackburn (2011, 2014). A key advantage of such an approach is that immiscible liquid phases naturally tend to minimize their interfacial area, thus reducing any tendency for aqueous contaminants to remain entrained within or adsorbed upon particles of lignin. On the other hand, the liquid-lignin phase obtained in the SLRP process from softwood pulping has been shown to contain 32 to 48% water by mass (Velez and Thies 2013).

Black Liquor Solids

The solids level of black liquor becomes raised in stages during multi-effect evaporation in a conventional kraft recovery system, so it makes sense to consider whether a certain solids content might be most favorable for lignin recovery by acidification. Alén et al. (1979, 1985b) found that the most effective separation occurred when the black liquor had been concentrated, by partial evaporation of the water, to a solids of about 30%. At this dry solids content the separation of the tall oil soap is also effective and this soap can be removed from black liquor by skimming prior to liquor carbonation. Mesfun et al. (2014) made a similar assumption in their techno-economic modeling. A higher solids content can be regarded as an advantage because there is less volume to be acidified. On the other hand, the higher viscosity associated with higher solids can cause practical difficulties in such cases. Velez and Thies (2016) observed that black liquor with higher solids or higher inorganic content gave rise to higher amounts of ash in the isolated lignin. Moosavifar (2008) observed that lignin precipitated from black liquor of lower solids content tended to contain less sulfur.

Coagulation by Cationic Additives

Coagulation basics

As noted before, the principles governing coagulation mechanisms have been best established for low ionic strength conditions. Also, the high pH associated with black liquor, before acidification, can be expected to convert calcium and aluminum cations to the corresponding insoluble hydroxide forms. So the following discussion is not expected to be directly transferrable to some situations of primary interest to industry.

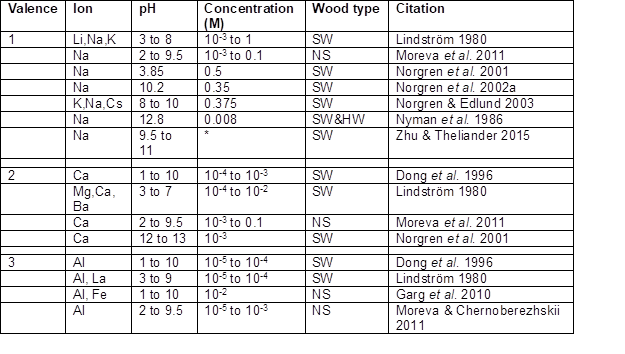

Studies have shown that addition of various cationic substances can be effective in bringing about destabilization of aqueous suspensions or solutions of lignin (Table 4). Such effects often can be attributed to reduction in the short-range repulsive forces between the negatively charged surfaces, i.e. the double-layer forces (Lindström 1979, 1980; Hiemenz and Rajagopalan 1997; Norgren and Edlund 2001, 2003; Ohman et al. 2007a; Hubbe and Rojas 2008). Addition of salt ions decreases the distance over which the repulsive forces extend between adjacent like-charged surfaces in the solution, which is the basis of the so-called DLVO theory (Derjaguin and Landau 1941; Verwey and Overbeek 1948). Another aspect is that multivalent cations, depending on their size, can form strong complexation with the negatively charged surfaces. The net result of these two effects can be a very strong dependency of coagulation on the valence of the cations, as can be expressed by the empirically-based Schulze-Hardy rule (Schulze 1882; Hardy 1899). This rule can be expressed as in Eq. 1,

![]()

where CCC is the critical coagulation concentration and z is the valence of the ion opposite in charge to the surface.

Table 4. Studies in Which Metal Cations Were Used to Coagulate Lignin

Note: * – The ionic strength was increased by either 10 or 20%. SW = softwood; HW = hardwood, NS = not specified

It is worth noting that the work of Zhu and Theliander (2015) listed in Table 4 involves much higher levels of ionic strength than most of the other reported work.

Monovalent cation effects

As shown in Table 4, precipitation of lignin from aqueous solution can be brought about by adding sufficient amounts of sodium ions or other monovalent cations. It can be seen that the concentrations of such ions as Na+, K+, and Li+ needed to bring about coagulation of various pH-near-neutral suspensions of lignin were in the range of 10-3 to 1 M. The wide range can be attributed to the very wide range of pH values considered in these studies. The value reported by Nyman et al. (1986) seems low relative to what was reported by other researchers at similarly high values of pH; however, these authors essentially purified the kraft lignin by decreasing the pH to 3 with HCl, washing, then purifying with ethanol, dioxane, and toluene treatment before redissolving it at pH 10 using NaOH. The purification steps may have removed components that otherwise would have helped to stabilize the material in solution.

The effects of monovalent salt concentration at pH values in the range 9.5 to 12.5 were studied by Norgren et al. (2002b). The greatest colloidal stability was observed at high pH and minimum ionic strength. Systems with higher pH were more likely to be able to tolerate a given level of salt without destabilization of the lignin.

While both the DLVO theory and the Schulze-Hardy rule imply that all monovalent cations ought to have equal effects, work by Norgren et al. (2003) showed that the effectiveness actually tended to follow a Hofmeister series. In general, monovalent cations having a larger radius were slightly more effective. An opposite relationship was found for the negative ions that were added in the same set of experiments. A key point to bear in mind, however, is that such effects tend to be minor in comparison to the effects of differing valences of the cations present.

Though most research related to coagulation has focused on aqueous systems, Leskinen et al. (2017) recently showed that salt addition can be used to induce precipitation of lignin, in nanoparticle form, from mixtures of THF and water.

Divalent cation effects

Dong et al. (1996) showed that addition of calcium ion markedly reduced the absolute value of zeta potential when added to lignin particle suspensions over a wide range of pH values. It is also clear from the work of Lindström (1980) and Moreva et al. (2011) that, for purposes of precipitating lignin particles from suspensions of near-neutral pH, calcium ions were at least a factor of ten more effective than monovalent ions in bringing about coagulation. Earlier work using magnesium sulfate to coagulate black liquor after its acidification to pH=2 was reported by Merewether (1962b).

Trivalent cations, including aluminum

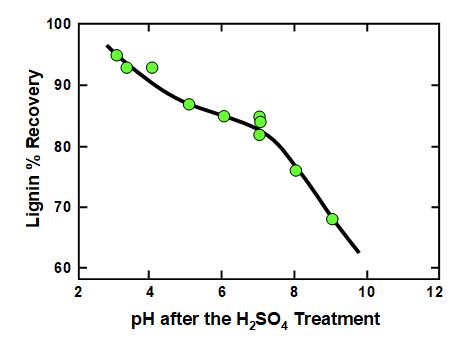

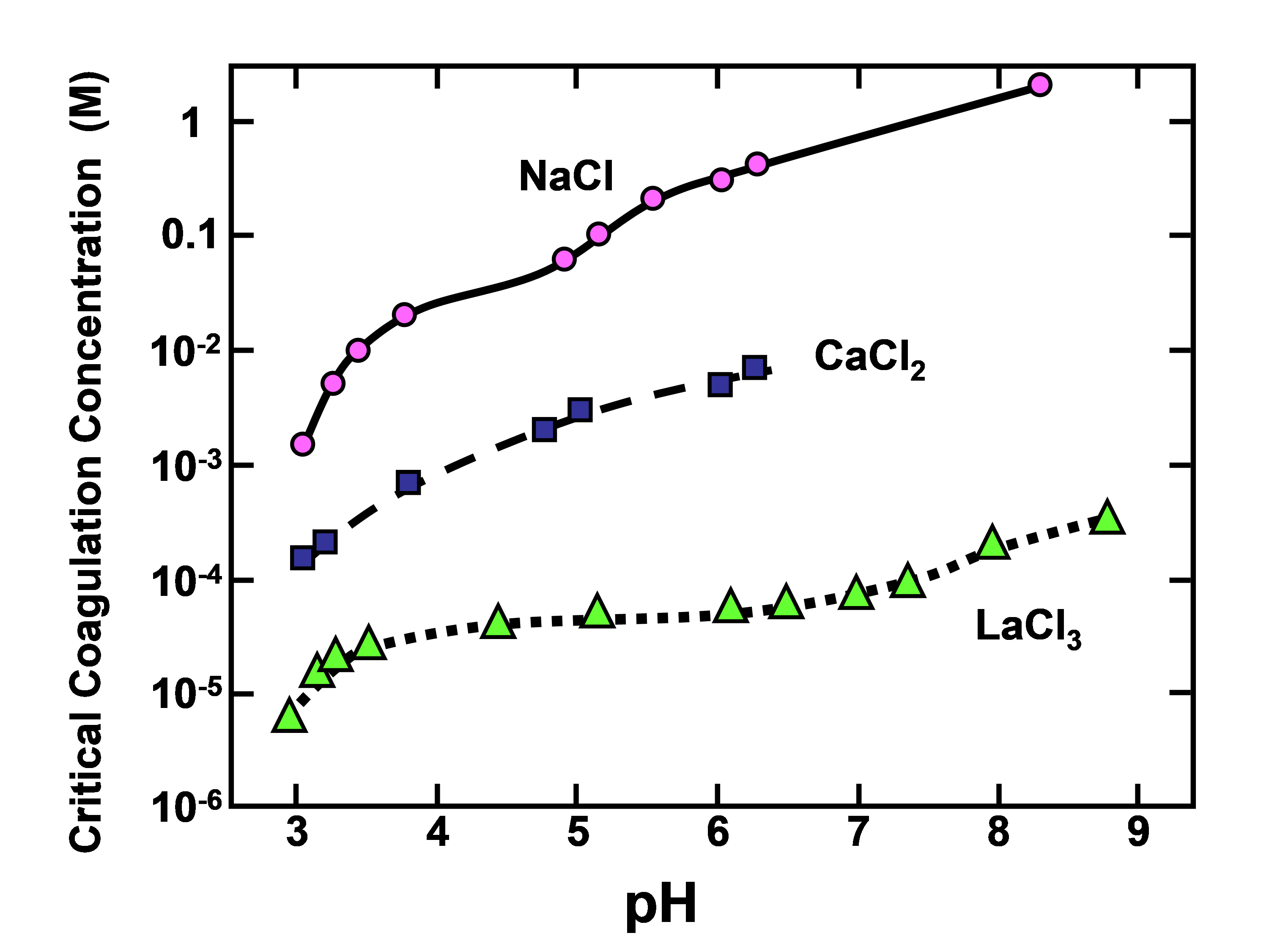

Trivalent or higher valence cations, such as those of soluble aluminum species, have been found to be highly effective for destabilization of aqueous suspensions of lignin. Figure 3 shows replotted data from Lindström (1980) for commercial softwood kraft lignin; this is an excellent example to show the much greater coagulating power of multivalent cations, as predicted by the Schulze-Hardy rule.

Fig. 3. Effects of cation valence and pH on the critical coagulation for precipitation of lignin

The reason that Lindström (1980) employed LaCl3 rather than AlCl3 in this series of tests was to simplify the chemistry; it is well known that Al has a very strong tendency to complex with OH- ions, forming a range of complex different species, depending on the pH (Exall and van Loon 2003; Bi et al. 2004).

Charge reversal has been observed by some researchers upon addition of soluble aluminum compounds to lignin suspensions (Lindström 1980; Dong et al. 1996; Garg et al. 2010; Moreva and Chernoberezhskii 2011). In related work, Rastegarfar et al. (2015) used electrocoagulation, by means of aluminum electrodes, to coagulate black liquor from soda pulping of straw. It is well known that electrocoagulation with such electrodes leads to the release of aluminum ions into the solution, thus causing the coagulation effect.

It is well known that much greater coagulating ability can be achieved if aluminum compounds are formulated so that the molar ratio of aluminum to OH is approximately 2, corresponding to a composition that is popularly known as “poly-aluminum chloride” (PAC) (Exall and van Loon 2003; Bi et al. 2004). Unsurprisingly, PAC has been shown to be very effective for precipitation of black liquor (Amriani et al. 2015; Wang et al. 2015). Wang et al. (2015) also showed the strong coagulating effect of a high-charge quaternary polymer, poly(diallyldimethylammonium chloride) (polyDADMAC) for the precipitation of lignin from black liquor.

Despite the very promising results just cited for aluminum-based compounds, there is one very serious limitation with respect to the use of such coagulants for black liquor. That is, at the high pH of typical black liquor, the Al3+ and other cationic molecular species should be instantly converted to negatively charged aluminate ions, or possibly into neutral Al(OH)3 floc if the added amounts were enough to neutralize the pH (Bottero and Fiessinger 1989). Thus, it would appear that the most sensible usage of aluminum-based coagulants would be after the pH already had been reduced to about 5 or lower by addition of CO2 and sulfuric acid. It also would be of interest to find out whether aluminum compounds in the precipitated lignin were beneficial, or at least not harmful relative to the envisioned end-use of the lignin. Suitable experiments would need to be performed.

Stirring

Stirring or agitation is mentioned in some of the publications dealing with separation of lignin by acidification of black liquor. For example, the patent disclosure by Keilen et al. (1952) recommends an agitation “not substantially in excess of 2100” Reynolds number (implying turbulent flow) as a means of favoring a small particle size of droplets of lignin during the process of acid treatment. Keilen et al. (1950) has also stated that particularly when operating at temperatures above 80 oC, the amount of agitation to which the liquor is subjected during the heating is critical (i.e., below 1500 Reynolds number). According to Wallmo (2008), increased stirring during precipitation tended to increase the rate of pH decrease, but the filtration resistance of the precipitate also increased. This was a bigger issue in the case of hardwood kraft black liquor, which may have been due to a higher content of hemicellulose.

After black liquor has been treated such as to bring about precipitation, certain publications suggest gentle agitation during the ensuing sedimentation. Presumably, such gentle agitation encourages collisions among droplets or particles of lignin, helping them to coagulate, while still allowing settling to occur. Howell and Thring (2000) recommended that agitation be “as low as possible” to allow settling for the lignin after black liquor treatment with waste acid from a chlorine dioxide generation process. Amriani et al. (2015) call for “slow stirring” at 50 revolutions per minute following a treatment with PAC. Kannangara et al. (2016) recommended to use low turbulent power mixing during coagulation to increase the filtration rate of precipitated lignin. Kouisni et al. (2016), when describing the LignoForce system, specify “gentle mixing” during the coagulation treatment.

Some other researchers have recommended agitation during the process of washing of precipitated lignin with dilute sulfuric acid solution. Thus, Gilarranz et al. (1998) recommended low agitation for a short time in order to optimize the subsequent washing with acid and water. Haddad et al. (2017a) likewise recommended agitation before a washing operation in the case of softwood kraft black liquor.

Stabilizers

As already mentioned, it is not always clear whether the lignin present in black liquor ought to be regarded as being dissolved or as being in a suspension or emulsion, depending on whether the temperature is high enough to melt it as droplets. In that context it is important to consider the likely importance of compounds capable of stabilizing such emulsions, whether those materials are already present in the black liquor, or whether they might be added later.

Some researchers have considered the effects of surfactants, i.e. molecules that have both a water-loving and an oil-loving part. For instance, Norgren and Edlund (2001) found that bile acids improved the colloidal stability of softwood kraft lignin suspensions. On the other hand, Norgren and Mackin (2009) later found that cationic surfactants could bring about an opposite effect, fast aggregation of softwood kraft lignin, leading to high yields of precipitated lignin. Another possible use of surfactant addition is to promote separation of rosin and fatty acid soaps (McGinnis et al. 1998).

The term steric stabilization means that a suspension or emulsion is stabilized by water-loving, relatively long-chain compounds on the surfaces of the dispersed entities (Tadros 1991; Hubbe and Rojas 2008). This can be due to adsorption or due to pendant chains. In such cases, the hydrophilic chains extending from the surfaces discourage close approach of the surfaces. Squeezing of the volume occupied by the extended chains is energetically unfavorable. Fritz et al. (2017) found that nonionic surfactants appeared to solubilize lignin, especially softwood kraft lignin, leading to a lower degree of self-association and lower turbidity. The relative ineffectiveness of salts to bring about coagulation of the lignin suspensions was attributed to steric stabilization by the surfactant.

Polysaccharides and Lignin Stabilization

Hemicellulose-related products, often in highly degraded and oxidized form, will be present in typical black liquor samples (Danielsson 2014). Nyman et al. (1986) proposed that typical aqueous lignin mixtures from pine kraft pulping behave as sterically stabilized colloids. Such an explanation is consistent with the observation (Durruty et al. 2017a,b) that addition of xylan to softwood black liquor can make the suspension more difficult to drain during filtration. The explanation for this is that in the filter cake the particles are more able to slide past each other, thus forming a denser layer that impedes the flow of water. The reported effect was more pronounced at higher pH (Durruty et al. 2017b), which is consistent with higher negative charges and more effective stabilization. Wallmo et al. (2009b) showed that the stabilization effect was reduced in cases where the hemicellulose content had been decreased before they applied acidification.

Solubility Issues

The phase-separation of black liquor can be understood in terms of solubility principles (Hansen 2007; Hubbe et al. 2015). The idea is that substances having similar or favorable polarity, polarizability, and hydrogen bonding capabilities are more likely to exist as a single phase. Such issues are known to become increasingly critical when dealing with high molecular mass solutes (Flory 1953). Giummarella et al. (2016) showed that the best solvents to dissolve softwood kraft lignin were generally those that are miscible with water, e.g. methanol. The best solvents for lignin also could be predicted based on the Hildebrand solubility parameters (related to cohesive energy density) and Hansen’s red numbers (Hansen 2007).

Water-immiscible solvents have been shown to affect the colloidal stability and filterability of lignin from black liquor. Whalen and Tokoli (1968) showed that addition of small amounts of hydrophobic monomers eliminated the slimy, gelatinous, and hard-to-filter component of lignin, thus promoting its filtration and settling.

In principle, the solubility of lignin in water can be manipulated by changing its charged character. As already discussed, one of the ways to accomplish this is by changing the pH. Thus, carboxylic acid functions, often associated with polysaccharide products either complexed to the lignin or adsorbed on it, will take on a negative ionic charge when the pH is near or above the corresponding pKa value, often near to 4 (see Table 1). Likewise, the phenolic groups will take on a negative charge as the pH becomes near or higher to 10, depending on the detailed chemistry. Liu and Luo (2010) showed that the stability of bamboo lignin in an aqueous medium could be improved by addition of citric acid, the adsorption of which would increase the negative charge of the surfaces.

Interventions

There are certain ways that the incoming material can be treated so as to achieve more favorable results when black liquor is acidified. The word “interventions” will be used here as a name for such treatments.

Chip pre-extraction

Extracting hemicellulose and other minor components from wood chips prior to pulping has been found to influence the composition of black liquor from brewer’s spent grains (Mussatto et al. 2007). The byproducts of hemicellulose do not have as high a heating value as cellulose, and there are higher-value potential uses if the material can be extracted before pulping (Moshkelani et al. 2013). As already mentioned, hemicellulose removal can be expected to render the lignin easier to separate from the aqueous medium (Wallmo et al. 2009b; Ziesig et al. 2014a,b). In the cited work, polysaccharides were separated from black liquor by micro- and ultrafiltration before separation of the lignin by acidification with carbon dioxide.

Black liquor oxidation

The LignoForce process, which entails acidification of black liquor with carbon dioxide, includes an oxidation step, the purpose of which is to chemically transform any of the odoriferous reduced sulfur compounds to their corresponding oxidized forms, which are not volatile; this also reduces the amount of acid (carbon dioxide) required for the acidification of black liquor to precipitate lignin because the oxidation of reduced sulfur compounds, carbohydrates, and other organics consumes alkali in black liquor (Kouisni et al. 2012, 2014, 2016). Such a step is also called for in the process developed by Lake and Blackburn (2011). Advantages, in addition to reducing odors during processing, include better filterability and reduced product odor (Kouisni et al. 2012, 2016). Recently, Ozdenkci et al. (2017) included an oxidation step in an integrated biorefinery concept that included lignin recovery. Servaes et al. (2017) evaluated an oxidation step as a pretreatment of spent pulping liquor before membrane filtration. The general principle of such treatments was previously described by Tomlinson and Tomlinson (1946), Murray and Prakash (1976), and Uloth and Wearing (1989b) in the context of reducing the emission of odoriferous reduced sulfur compounds during processing. Tomlinson and Tomlinson (1946) found that oxidation increased the fusion point of lignin, affecting its handling properties at various temperatures.

Plasma treatment

Closely related to ordinary oxidation treatments, researchers have found favorable effects of plasma treatment of black liquor (Feng and Tian 2009). The cited authors fed hot, viscous black liquor concentrates into a nitrogen gas plasma jet prior to freeze-separation. Harmful gases such as H2S, SO2, and SO3 were eliminated.

Silica precipitation at neutral pH

Yet another material worth separating from black liquor, especially in the case of grasses such as bamboo and wheat straw, is silica. Gilarranz et al. (1998) showed that this can be achieved by selective precipitation, using a pH high enough to avoid co-precipitation of the lignin present in the mixture. However, as noted by Mandavgane and Subramanian (2006), co-precipitation of lignin together with silica can make this approach difficult. The cited authors used an undisclosed flocculant in an attempt to achieve more specific destabilization of the silica content. Given the increasing importance of non-wood biomass for alkaline pulping, more research of this type can be justified.

Operations

Factors affecting the phase separation can be supplemented by various mechanical processes, making use of specialized equipment. Such approaches will be considered in this section.

Separation of the acidified mixture by density

After acidification of the black liquor, the means of promoting separation by density include gravitational sedimentation and centrifugation. Probably for reasons of simplicity, sedimentation approaches have been most often adopted in acid precipitation processes for lignin recovery (Tomlinson and Tomlinson 1946; Howell and Thring 2000; Mandavgane and Subramanian 2006; Norgren and Mackin 2009; Garg et al. 2010; Lake and Blackburn 2014; Leskinen et al. 2017). Centrifugation, as a means of achieving faster separation of lignin from black liquor, was demonstrated by Alén et al. (1985b), Mussatto et al. (2007), Liu and Luo (2010), and Namane et al. (2015).

Filtering of solids

A critical step in the processing of precipitated lignin is its filtration to increase the solids content (dewatering or cake) and to separate it from various components of the aqueous phase. This is most often done on a filter screen device (e.g. belt filter or filter press).

Alén et al. (1979) recommended heating of precipitated black liquor to 80 ºC before filtration. The stated reason was to avoid problems with fine dispersions and colloidal mixtures. Apparently the higher temperature favored an adherent nature of the particles, leading to formation of bulky, permeable filter beds. Weinhaus et al. (1990) and Howell and Thring (2000) found better filtration if acidification was done at a higher temperature. Garg et al. (2010) observed a similar effect in the case of lignin that had been precipitated with aluminum-based coagulants or ferrous salts, then filtered at either 25 or 95 ºC.

The addition of salts has been shown to favor faster filtration in some cases (Helander et al. 2015; Durruty et al. 2017a). Such findings are consistent with the concepts of decreasing the range or strength of electrostatic repulsive forces between surfaces, thus encouraging sticking collisions between the particles and formation of bulky, permeable sediments. Accordingly, Durruty et al. (2017b) found that lower pH of the acidified material, which would be consistent with more complete neutralization of the carboxylic acid groups, favored higher rates of filtration, even in the presence of hemicellulose byproducts. Ohman and Theliander (2001, 2007) observed better filtration at higher ionic strength and lower pH.

Kouisni et al. (2014) also found that oxidation favored subsequent filterability of the lignin, which will be considered next. In particular, the treatment increased the rate of filtration sufficiently that it was feasible to use one filter press instead of two, as is the case with the LignoBoost process. In the latter process, a first filter press is used to dewater the lignin cake, the cake is then suspended in dilute sulfuric acid and finally directed to second filter press at which it is washed with dilute sulfuric acid and water.

Ohman et al. (2007b) found that pre-concentration of black liquor with an ultrafiltration membrane made subsequent filtration more difficult; the reason is not fully understood. Haddad et al. (2016) observed fouling of a membrane when using a certain electrochemical approach that resulted in decreased pH (from about 12.5 to as low as 10.5) of black liquor. Wallmo et al. (2009a) found that filtration performance could be improved by holding the mixture for a “conditioning period” before filtration.

Separation by affinity

In addition to density, the relative affinity for water is another attribute that can serve as a way to promote separation of lignin from aqueous solution. The principle of differing affinity is used, for instance, when tiny bubbles of air are used to selectively float hydrophobic particles so that they can be skimmed from the water surface as a froth (Edzwald 2010; Jamaly et al. 2015; Saththasivam et al. 2016). The present search of the literature revealed only one study, the work of Macfarlane et al. (2009), which pursued such an approach for separation of lignin from water. Rapid removal of the lignin from the water phase was promoted by increasing temperature (in the range from freezing to about 30 ºC) and increased pressure to create the bubbles (N2).

MEMBRANE TECHNOLOGIES

Membrane Filtration Overview

Although membrane-induced separation of lignin from black liquor is influenced by many of the same factors as the acid-induced separation, as described in the preceding main section, the optimized chemical conditions tend to be very different. As will be shown in this section, membrane separation methods often work well under conditions favoring solubility, or at least colloidal stability of the lignin in the mixture. Jönsson et al. (2008), Humpert et al. (2016), and Kevlich et al. (2017) have provided reviews of membrane technology as it has been studied for the recovery or fractionation of lignin from black liquor and wastewater. Niemi et al. (2011) considered membrane separation in combination with cooling crystallization as a means of isolating multiple compounds from black liquor.

Research by membrane separation of lignin in black liquor also has been used to shed light on the association of the molecules in solution (Rudatin et al. 1989). It was shown that the amount of lignin retained on an ultrafiltration membrane (molecular mass cut-off 300,000 Daltons) was a function of the pH of the solution within the range 14 > pH > 10. To account for this, the cited authors proposed that lignin moieties self-associate due to such influences as hydrogen bonding, hydrophobic character, or even association of opposite charges in specific cases. Junker (1941) may have been the first to report evidence of such self-association upon addition of monovalent ions at pH-neutral conditions.

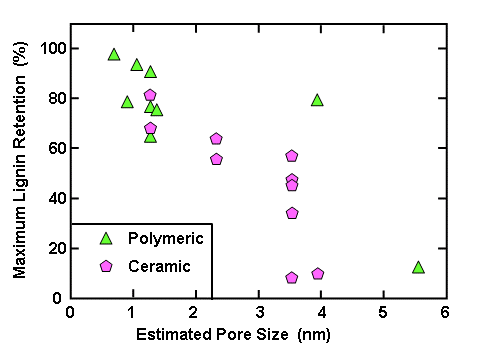

As has been shown in many studies, the class of membrane process that can be effective for retaining lignin, while allowing passage of water, salt, and monomeric compounds is called “ultrafiltration”. Such a membrane can have pore sizes suitable for retaining macromolecules in the range from one-thousand to one-million grams per mole (Zeman and Zydney 2017). Based on estimated pore diameter, available membrane filter media can be classified as follows (Khulbe et al. 2008): reverse osmosis, < 1 nm; nanofiltration, 1 to 5 nm; ultrafiltration, 2 to 100 nm, and microfiltration 100 to 2000 nm. The composition can be either polymeric (e.g. polysulfone) or ceramic. Membranes typically have a recommended pressure range to avoid excessive fouling (Peter-Varbanets et al. 2009). By applying pressure, the membranes can be used effectively to concentrate the polymer solution, while allowing passage of solution that is contains only the low-mass components of the mixture. Ultrafiltration has been applied to varying black liquors for different purposes as reported, for example, by Hill and Fricke (1984), Alén et al. (1986), Lin (1992), Sevastyanova et al. (2014), and Zhu et al. (2016).

Though membrane separation processes can be efficient and cost-effective in many cases, there are two key limitations: First, such processes get increasingly difficult to operate as the concentration of the retained material increases. For example, Humpert et al. (2016) suggested a terminal concentration of the lignin solids, after ultrafiltration, of 285 g/L. Second, the flux of permeate passing through a membrane tends to fall during continued usage due to such fouling phenomena as pore plugging and cake formation (Fane and Fell 1987; Hubbe et al. 2009; Shi et al. 2014). Indeed, membrane fouling has been reported in studies related to black liquor (Jin et al. 2013; Mattsson et al. 2015; Haddad et al. 2017a-c). Mattsson et al. (2015) used an innovative dynamic gauging test to study soft-cake fouling by precipitated softwood kraft lignin. It follows that any attempt to implement membrane separation needs to place emphasis on (a) optimizing the ultimate solids content, (b) finding appropriate uses or further processing steps for lignin-rich concentrated retentate, and (c) developing effective cleaning and rejuvenation treatments for used membranes. One possibility could be to acidify the lignin-rich retentate, thus bringing about precipitation of the lignin. Future research would be needed to determine whether or not there are important advantages of carrying out the membrane separation before such acidification.

In general, ultrafiltration appears to be well suited for separation of aqueous solutions containing intermediate levels of dissolved polymeric matter (Zeman and Zydney 2017). For the perspective of lignin recovery, this suggests two likely favorable applications. First, ultrafiltration can be used as a means to exclude lignin from the outfall of wastewater treatment plants (Hubbe et al. 2016). Second, it could be used for concentrating black liquor, possibly as an alternative to evaporation. Such a concept has been offered as a commercial process by New Logic International, Inc. (New Logic 1999). The technology also was evaluated in a 2016 study at Lund University in Sweden (Lund 2016).

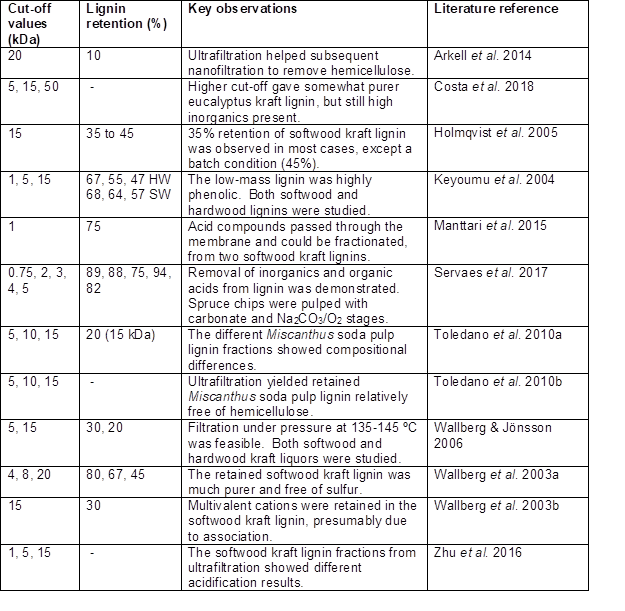

Solubility Factors Affecting Membrane Separation

It is well known that the relative solubility of lignin is affected by pH, ionic strength, temperature, and the presence of cosolvents with water. In the case of pH, two studies specified that high values of pH were employed during nanofiltration. Arkell et al. (2014) recorded a pH of 13.4, whereas the review article by Humpert et al. (2016), citing two sources, gives a pH range of 13 to 14. At such pH values, almost all phenolic groups, including the hemiacetalic phenolic groups (Table 1), will be in their charged form. Also, since the pH is very much higher than the pKa values of carboxylic acids, any of those groups also will be in their dissociated, charged form, thus contributing to the solubility. Such high solubility can be expected to facilitate permeation, as well as molecular size selection, through an ultrafiltration membrane.