Abstract

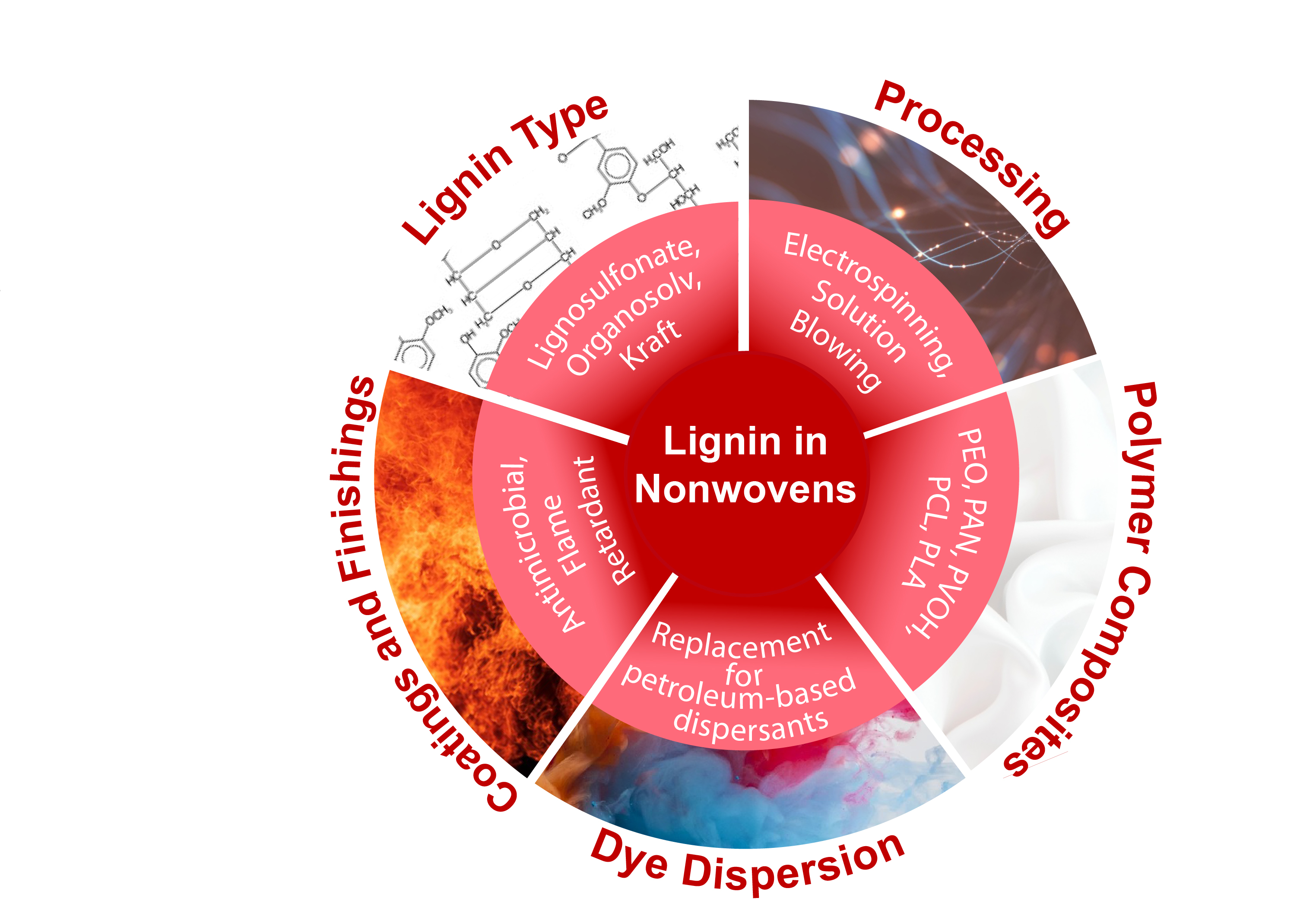

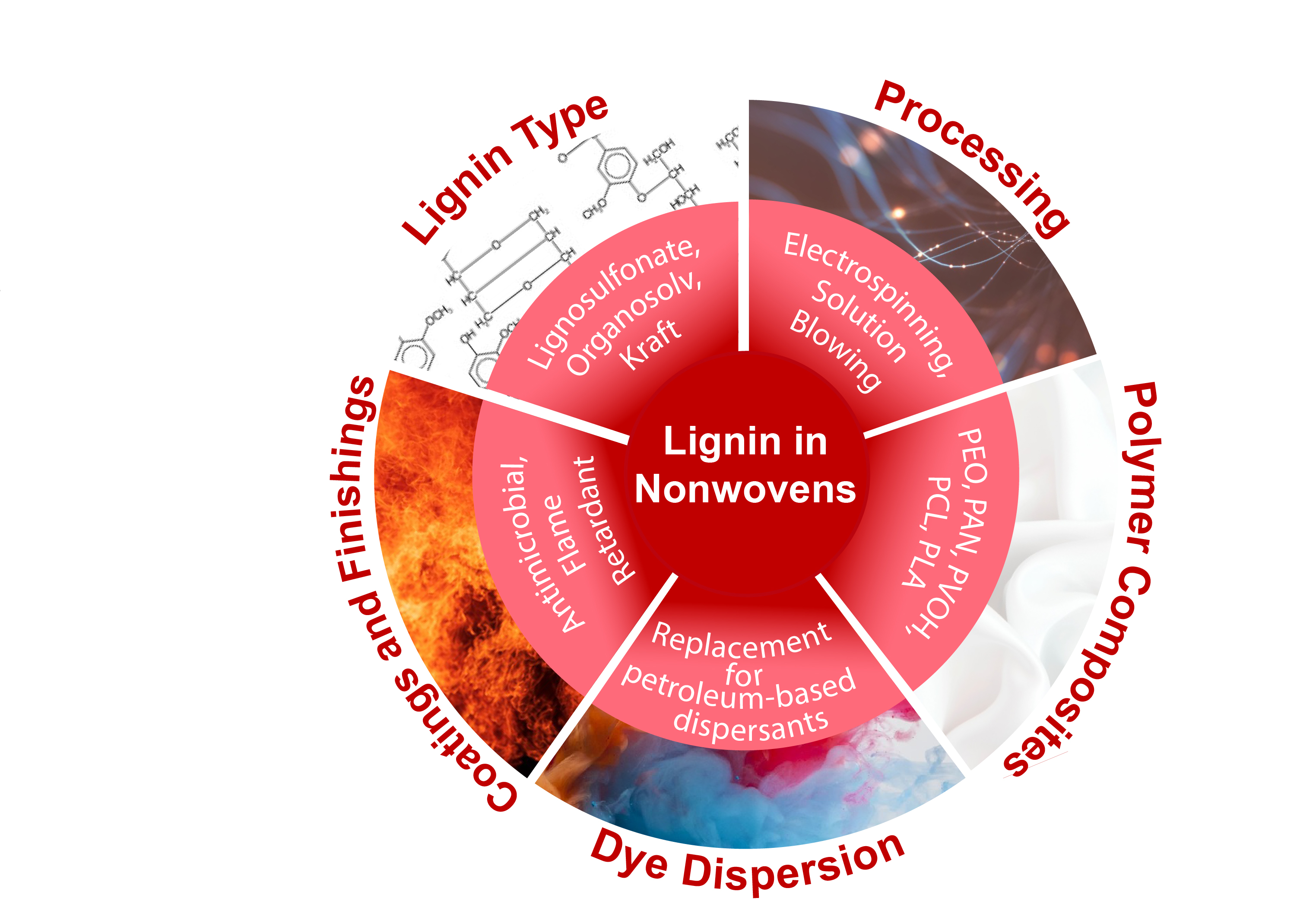

While lignin has been gaining wide research interest for a variety of applications across many industries, relatively little work has been published on its applications in nonwovens. Consequently, this article offers an overview of the underlying principles and both the present and future applications of lignin within the nonwoven industry. Due to the distinct structure of lignin, processing, fiber production, composites with polymers, dye dispersant, and fire-retardant applications are all unique opportunities for lignin application in nonwovens discussed in this review. Conventional nonwoven processing techniques, such as electrospinning, have been reported to successfully produce lignin-based nonwovens, specifically lignin/polymer composite nonwovens. This account points to pivotal polymer matrix/lignin composite compatibility issues that define various processing technologies. However, lignin use is not limited to incorporation within nonwoven fibers mats and is currently used in dye dispersion with the potential of phase out petroleum-based dye dispersants. Finally, the high phenolic content of lignin endows it with fire-retardant and antimicrobial properties, among others, that present additional opportunities for lignin in the nonwoven industry. Throughout this review, an effort is made to outline the advantages and challenges of using lignin as a green and sustainable ingredient for the production of nonwoven materials.

Download PDF

Full Article

Lignin Use in Nonwovens: A Review

J. Gavin Gaynor, Dorota B. Szlek, Soojin Kwon, Phoenix S. Tiller, Matthew S. Byington, and Dimitris S. Argyropoulos*

While lignin has been gaining wide research interest for a variety of applications across many industries, relatively little work has been published on its applications in nonwovens. Consequently, this article offers an overview of the underlying principles and both the present and future applications of lignin within the nonwoven industry. Due to the distinct structure of lignin, processing, fiber production, composites with polymers, dye dispersant, and fire-retardant applications are all unique opportunities for lignin application in nonwovens discussed in this review. Conventional nonwoven processing techniques, such as electrospinning, have been reported to successfully produce lignin-based nonwovens, specifically lignin/polymer composite nonwovens. This account points to pivotal polymer matrix/lignin composite compatibility issues that define various processing technologies. However, lignin use is not limited to incorporation within nonwoven fibers mats and is currently used in dye dispersion with the potential of phase out petroleum-based dye dispersants. Finally, the high phenolic content of lignin endows it with fire-retardant and antimicrobial properties, among others, that present additional opportunities for lignin in the nonwoven industry. Throughout this review, an effort is made to outline the advantages and challenges of using lignin as a green and sustainable ingredient for the production of nonwoven materials.

DOI: 10.15376/biores.17.2.Gaynor

Keywords: Lignin applications; Nonwoven processes; Lignin composites; Dye dispersants; Carbonized nonwovens; Lignin coatings

Contact information: Department of Forest Biomaterials; NC State University, Campus Box 8005, Raleigh, NC 27695-8005. *Corresponding author: dsargyro@ncsu.edu

GRAPHICAL ABSTRACT

INTRODUCTION

Nonwovens: Definition and Description

Defining and segmenting nonwoven fabrics has been the topic of much discussion since the 1930s when pilot-scale production of these materials is reported to have begun. Although some consider nonwovens a part of the textile industry, others consider it a separate entity. Overall, however, it is certain that nonwovens’ technology is closely linked to the textile, pulp and paper, and fiber/polymer extrusion industries (Batra and Pourdeyhimi 2012).

The first, simplistic definition of a nonwoven was presented by the American Society for Testing and Materials (ASTM) in 1962. They defined nonwovens as “textile fabrics made of carded web or fiber web held together by adhesives” (Batra and Pourdeyhimi 2012). Today, ASTM’s definition is more evolved, yet still quite broad. Contained within their Standard Terminology Relating to Textiles (D123-19), a nonwoven fabric is defined as “a textile structure produced by bonding or interlocking of fibers, or both, accomplished by mechanical, chemical, thermal, or solvent means and combinations thereof” (ASTM 2019). Elsewhere, in the literature, Burkinshaw, states that a nonwoven is “an assembly of individual fibers or filaments that are bonded by means of friction and/or cohesion and/or adhesion” (Burkinshaw et al. 2012).

Perhaps a more detailed description is offered by the Association of the Nonwoven Fabrics Industry (INDA), who describe nonwovens as “sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally, or chemically. They are flat, porous sheets that are made directly from separate fibers or from molten plastic or plastic film. They are not made by weaving or knitting and do not require converting the fibers to yarn” (About Nonwovens).

Raw Materials

While the range of potential raw materials used in nonwoven production is generally quite extensive and can include natural, man-made, and even inorganic fibers and wood pulp, ultimately, raw material selection in nonwovens largely depends on the selected web formation type, bonding technique, and product end-use.

Natural fibers are composed of cellulosic, vegetable-based, animal, and protein fibers. Man-made fibers include regenerated/modified cellulosic fibers, polyamide, polyester, polyolefin, acrylic/modacrylic, and elastomeric fibers. Inorganic fibers are considered specialty fibers and include glass, metallic, carbon, and ceramic fibers. Finally, wood pulp is amongst the main raw materials used.

If categorized by web formation, carded staple fibers are the most used type of fibers, with polypropylene (PP) and polyethylene terephthalate (PET) being the most common. In addition, carded staple fibers can include recycled fibers, as well as bicomponent fibers used as a binder for thermal bonding. The air-laid process can use a very wide range of raw materials; from man-made fibers (PP, PET, bicomponent), recycled fibers, natural fibers (linen, flax, wool), to powders and particles and wood pulp. In wet-laid web formation, natural fibers, wood pulp, all man-made fibers, and inorganic fibers are prevalent. The spunlaid web formation technology, which includes spunbond and meltblown nonwovens, is specific in that it can only utilize thermoplastic polymers. This class of fibers are constituted of PE, PET, polyamide, and PP, with the latter being the most common polymer used in meltblown nonwovens (Karthick and Rathinamoorthy 2016).

In terms of bonding techniques, thermal bonding includes calendering and through-the-air, which is limited to thermoplastic polymers. Alternatively, chemical and hydroentangling bonding can both use a wide variety of man-made and natural fibers. Needling is web formation-dependent with regards to the raw material used; accordingly, they can only use staple air-laid and carded fibers in addition to filament spunbond fibers (Karthick and Rathinamoorthy 2016).

Industrial lignins can be obtained from paper pulp waste, fiber textile, wood hydrolysis, and lignocellulose energy operations (Chen 2015). The demand for lignin has steadily risen due to increased environmental protection coupled with the depletion of petrochemical sources. Overall, the main categories of industrial lignins include kraft, alkali, lignosulfonate, organic solvent, enzymatic hydrolysis, and steam exploded. Lastly, enzymatic hydrolysis residues of lignocellulose biomass offer more active groups due to the mild action of enzymatic hydrolysis, and thus offer more promise (Chen 2015). The abundance and unique properties of lignins present great potential for use in the nonwovens industry, a topic that has yet to be thoroughly reviewed.

The Market for Nonwovens

The nonwovens market can be compared most closely to other textile industries such as weaving, knitting, and even the paper industry. The most comparable connection between these industries is the line speeds and plant costs to produce their end products. The nonwoven industry is very comparable in speed and price point to the other industries: nonwovens can produce between 10 and 100 meters per minute compared to 1 to 2 meters/minute for weaving, 2 to 5 meters/minute for knitting, and 100 to 1000 meters/minute for the paper industry. Typical capital costs for a nonwoven plant are 10 to 100 million USD, 10 to 100 million USD for weaving, 1 to 50 million USD for knitting, and 50 to 100 million USD for the paper industry (Batra and Pourdeyhimi 2012). The nonwoven industry has the advantage of adapting techniques and knowledge from other industries. This approach helps to keep costs low, as there is little need for manufacturing innovation.

INDA represents the entire nonwoven fabric chain (INDA). As the central body for the nonwoven fabric industry, they serve as a conglomeration of companies within the industry to connect with each other and solve issues. INDA is also tasked with producing market reports, which may be accessed through resources found on their website.

According to Inkwood Research, the global nonwovens market is expected to have a compound annual growth rate of 7.43% between 2019 to 2028 and a volume compound annual growth rate of 7.54% during that same time. This would lead to a revenue of $36.5 billion by 2028. The expected growth is from rising demands in prominent markets that are difficult to replace with woven products. Markets such as incontinence care products, hygiene, and medical applications are expected to grow as the population continues to expand. The quickly rising demand for baby diapers is expected to be the main driver across all sectors. Other market sectors such as carpet, furniture, agriculture, and industrial applications are expected to grow as GDP grows globally. The furniture sector is predicted to have the highest compound annual growth rate across all sectors in both revenue and volume. Global growth for the nonwoven industry will be hampered by raw material price instability, regulations, investment cost, and substitutions. The market is projected to remain the highest in Asia, followed by Europe and North America. The production techniques are expected to remain similar between 2019 and 2028, with spunbonded as the most utilized, followed by staples, meltblown, and composites following (Inkwood Resarch).

The nonwoven filter market is also expected to experience tremendous growth. Nonwovens are ideal for filtration, as they can be engineered for excellent porosity, such that they able to capture particles passing through. The growth can be expected from every sector as an increasing population, combined with an increased concern for health, leads to a higher demand for water filtration, air filtration, pollution filtration, and industrial filtration. Increased regulation is also a driver of the industry as environmental concerns propagate across federal and local governments. Finally, improvements in technologies and capabilities have led to more efficient, less expensive filtration capabilities (North American Nonwovens Filter Market) 2018.

The Market for Lignin

Each year, 50 to 70 million tons of lignin are produced (Suhas et al. 2007; Mandlekar et al. 2018); however, 5% of annually produced lignin is used for commercial applications (Bai et al. 2019), and only 1 to 2 % of the lignin is used for value-added products (Aro and Fatehi 2017; Zhang et al. 2020d). A significant portion of the non-utilized lignin is burned to produce energy as a method of disposal and utilization (Mandlekar et al. 2018; Bai et al. 2019; Zhang et al. 2020d).

There are many kinds of lignin processes; however, the kraft and sulfite pulping processes have been used abundantly worldwide for effective lignin separation from cellulose and hemicellulose. Kraft lignin, which accounts for 85% of the world’s lignin production, is separated with sodium hydroxide and sodium sulfide (Argyropoulos 2013; Schreiber et al. 2014). Lignosulfonates are derived from the sulfite process, which treats lignin with sulfurous acid, sulfite salt, as well as magnesium, calcium, sodium, or ammonium sulfites and bisulfites (Sadeghifar and Argyropoulos 2015; Zhang et al. 2020d). As of the writing of this paper, lignosulfonates account for 90% of the total market of commercial lignin, and the worldwide production of lignosulfonates is approximately 1.8 million tons (Dallmeyer et al. 2013; Sadeghifar and Argyropoulos 2015; Aro et al. 2017).

The global lignin market has been steadily increasing. According to Global Market Insights, the lignin market size exceeded $730 million in 2019 and is estimated to experience a 5.7% compound annual growth rate between 2020 to 2026. The compound annual growth rate from 2020 to 2026 is expected to increase in the lignosulphonate segment by 5.9%, in the polymer application segment by 5.4%, and phenol downstream potential by 3.6%. These increases are due to the realization of usability in several industries (Global Market Insights 2021).

The top eight global lignin-based product manufacturers are: Borregaard LignoTech, Changzhou Shanfeng Chemical Industry Co., Ltd., Domsjo Fabriker AB, Domtar Corporation, Nippon Paper Industries Co., Ltd., MeadWestvaco Corporation, Tembec, Inc., and UPM-Kymmene Corporation (Global Market Insights 2021). The profitability of lignin in the nonwoven industry currently heavily relies on the price of petroleum (LigniMatch 2010). Technologies are under continuing development to bring down the cost of lignin incorporation, but political and environmental factors fluctuate and influence the financials. As previously stated, there are currently no reviews of lignin use pertaining to the nonwoven industry. Thus, this review will help increase lignin incorporation into industrial processes and assist in determining new directions of lignin nonwoven research.

Nonwoven Industry Applications

Production of nonwoven materials is characterized by high production rates and low costs. Nonwoven techniques are able to produce larger batches in contrast to woven processes such as yarn spinning, knitting, and weaving. Annual nonwoven production and deliveries for the Greater Europe region (Western, Central, and Eastern Europe, Turkey and Commonwealth, and the Independent States) has reached >1.6 million tonnes. Applications include single-use liquid absorbent hygiene products, representing over one-third of total production as well as durable products such as geosynthetics, filters, home furnishings, synthetic leather, automotive headliners, and floor coverings. There are various manufacturing routes for nonwovens, which essentially depend on whether the precursor web comprises a continuous filament (spunbond), or staple fiber and, in the latter case, whether it is formed either by dry (dry-laid) or wet (wet-laid) techniques; the ensuing mats can be bonded mechanically, thermally, or chemically to produce the nonwoven fabric (Burkinshaw et al. 2012). The unique properties of different lignins, a topic discussed throughout this review, endow lignins with the potential to applied across a wide range of applications.

Lignin Presence in Nonwovens

Lignin has been researched as a functional material for nonwovens and textile finishing processes for over 20 years. However, the presence of lignin in nonwoven finishings has not been fully organized and reviewed yet. This effort attempts to bridge this gap in the literature.

There are several types of lignin that have the ability to be incorporated in composites, including sulfur free lignin (Aslanzadeh 2017), but kraft lignin has shown the most potential. Kraft lignin is a readily available source of lignin that may be fractionated into materials with different functional group contents, thereby offering significant benefits for many applications (Argyropoulos 2014).

While new technologies are being explored based on enzymatic fractionation (de Avila Delucis et al. 2017; Li et al. 2017), an early differentiation of these highly heterogeneous materials (Sadeghifar and Argyropoulos 2016) is based on fractionation using acetone, creating acetone-soluble and acetone-insoluble kraft lignin fractions (Cui et al. 2014). Acetone-soluble kraft lignins are more branched and less polymeric and have smaller molecular weights than acetone-insoluble kraft lignin. Acetone-insoluble kraft lignins have a less branched structure and fewer wood native lignin bonding patterns than acetone-soluble kraft lignin fractions (Crestini et al. 2017).

Since the early acetone fractionation was proposed by Cui et al. (2014), other solvent fractionation systems have followed. The present review will mainly discuss the use of acetone as the partitioning solvent, since the associated science has been rather comprehensive, offering logical extensions for the use of other solvents. When processed, these fractions are shown to behave differently in polymeric blends, possessing differing spinnability and stability, and demonstrating unique antioxidant properties (Sadeghifar and Argyropoulos 2015). These factors, among others, will be discussed further in this review with a focus on the differences between high and low molecular weight lignin fractions as well as polymer composites.

Nonwoven process techniques are able to incorporate lignin seamlessly to create viable products for various applications. Current techniques such as electrospinning, spunbonding, melt bonding, and more, offer the ability for lignin composites of promise for future work.

Lignin composites currently include polyethylene oxide (PEO) (Dallmeyer et al. 2010; Schreiber 2012; Schreiber et al. 2014; Poursorkhabi et al. 2015; Bahi et al. 2017; Cho et al. 2020), polyacrylonitrile (PAN) (Zhao et al. 2015; Ding et al. 2016; Ogale et al. 2016; Go et al. 2018; Al Aiti et al. 2020; Nie et al. 2020; Yang et al. 2020; Zhang et al. 2020b), and polyvinyl alcohol (PVOH) (Kubo and Kadla 2003; Lai et al. 2014a; Nair et al. 2014; Ma et al. 2016; Ogale et al. 2016; Beck et al. 2017; Lu et al. 2017, 2018; Uddin et al. 2017; Aadil et al. 2018; Ko et al. 2018; Lee et al. 2018; Lee et al. 2019; Roman et al. 2019; Zhang et al. 2019; Camiré et al. 2020; Cui et al. 2021; Hou et al. 2021), which are able to be used in air filtration (Chang et al. 2017; Cui et al. 2021), water purification (Lai et al. 2014a; Bahi et al. 2017; Beck et al. 2017; Kwak et al. 2018; Zhang et al. 2019; Camiré et al. 2021; Chen et al. 2021; Hou et al. 2021), gas filtration (Amid et al. 2016; Chang and Chang 2016; Cui et al. 2021), carbonized nonwovens (Dallmeyer et al. 2010; Lai et al. 2014a; Poursorkhabi et al. 2015; Ago et al. 2016; Ding et al. 2016; Ma et al. 2016; Beck et al. 2017; Park et al. 2017; Culebras et al. 2019; Perera Jayawickramage and Ferraris 2019; Roman et al. 2019; Zhang et al. 2019; Al Aiti et al. 2020; Cho et al. 2020; Li et al. 2020; Zhang et al. 2020b), flame retardants (Cayla et al. 2016), and more. Overall, lignin has shown the ability to be incorporated into the previously enumerated applications in significant proportions, thus offering different properties with notable sustainable connotations and more.

As anticipated, amphiphilic lignosulfonates have been used rather effectively in dyestuff dispersants for over 60 years, since they possess both a hydrophobic aromatic structure and hydrophilic sulfonate groups on the side chain (Xu and Ferdosian 2017). However, additional technical lignins may be a potential resource for dye dispersants and other innovations representing viable topics for further research and potential market opportunities (Textile Chemicals). This is evident especially for polypropylene nonwovens, where coloration is currently only possible at scale through mass pigmentation with a limited number of colors (Aspland 2005). The dark color of lignin presents some challenges for dye dispersion applications, but several studies have reported the use of lignin in dye dispersion applications (Xu and Ferdosian 2017). Lignin-based dispersants have the potential to satisfy some of the market demand for biobased nonwoven processing alternatives while providing cost savings and innovations in nonwoven coloration technologies, with some limitations due to the dark color of lignin.

Kraft Lignin as a Feedstock

As discussed previously in this review, a readily available, inexpensive form of lignin is kraft lignin, which is derived from the pulp and paper process as waste after chemical (kraft) pulping is completed on woodchips. Kraft lignins are distinguished from other forms of lignin since they are rich in phenolic OH groups and high carbon content; these can provide antioxidant and fire-retardant properties respectively (Mandlekar et al. 2018; Lee et al. 2019).

Higher molecular weight lignin fractions have been seen to possess greater antioxidant activity with greater phenolic functional groups present in the fractions (Sadeghifar et al. 2017). Higher molecular weight lignin fractions also make fibers with better spinnability and better performance when fractionated with an enzymatic process with a laccase base and a 1-hydroxybenzotriazole (HBT) mediator. The lignin fractions arising from enzyme solubilization rather than acetone solubilization have different molecular weights and fewer OH groups. The kraft lignin water-insoluble portions increased molecular weight by 2.6 times, while the water-soluble kraft lignin portions decreased molecular weight by 60%. The study also demonstrated better spinnability of the laccase-HBT lignin fractions due to more linear lignin fractions with reduced interlinking, while water-soluble kraft lignin portions fractionated by the laccase-HBT complex resulted in more defects and therefore decreased mechanical performance (Li et al. 2017).

Kraft lignin with low molecular weight exhibits strong antioxidant properties, which is likely due to more exposed phenolic OH groups. When all phenolic OH groups are methylated, the fractions of kraft lignin demonstrate zero antioxidant activity, explaining the source of this behavior (Dallmeyer et al. 2014). To utilize this low molecular weight kraft lignin with stability, it is required to selectively methylate the remaining phenolic OH groups and their fractions to stabilize the kraft lignin and PE blend suitable for fiber usage. Lower molecular weight kraft lignin is optimized for blending with PE at low molecular weights, since the lignin is more easily distributed throughout the PE matrix. When mixed with PE, the kraft lignin increases the oxidation temperature by 50℃ at 5% (w/w) of kraft lignin (Dallmeyer et al. 2014). This increase in both glass transition temperature (PE blend) and oxidation temperature (fiber spinning) can be explained by π stacking, giving the structure an increased rigidity, especially for the acetone-insoluble lignin fractions. Given the high temperatures involved in melt electrospinning to create nonwovens, kraft lignin fractions’ antioxidant behavior again demonstrates an attractive and exciting raw material for manufacturing nonwovens (Dallmeyer et al. 2013, 2014; Sadeghifar and Argyropoulos 2015).

Lignin is primarily utilized as a composite material in the electrospinning method with other materials such as polyvinyl alcohol (PVOH), poly(acrylonitrile) (PAN), and poly(ethylene oxide) (PEO). Among them, PAN is a highly used material since it has high oxidative stability at high temperatures. Use of the lignin/PAN composite material at 50% lignin (w/w) led to increases in porosity of the fabric when compared to the commercial grade (74% lignin/PAN vs 42% commercial grade) (Dallmeyer et al. 2014; Alekhina et al. 2015). This is largely due to the large fiber diameter afforded by the lignin/PAN composite completed by electrospinning.

Kraft lignin is also an exciting field for nonwovens since it may demonstrate high fractionated yield through organic solvent extraction via the use of ethanol (Zhang et al. 2020a), 1-propanol (Zhang et al. 2020a), 1-butanol (Zhang et al. 2020 a), and acetone (Sadeghifar and Argyropoulos 2015, 2016; Crestini et al. 2017; Sadeghifar et al. 2017). The resulting fractionated kraft lignin is high in phenolic OH groups while maintaining a low molecular weight and maximizing antioxidant activity. Kraft lignin fiber material may also be successfully obtained by precipitation at high pH; such samples demonstrate exemplary purity, high molecular weight, and low sulfur content (Dallmeyer 2013). While these fibers may not have the same desirable properties as low molecular weight lignin (tensile strength, dispersity in blending composites), high molecular weight kraft lignin gives more thermal stability and resistance to cross-linking (Karaaslan et al. 2021). Furthermore, there is a possibility that lignin fractionation may be achieved via laccase-HBT enzymatic treatment (Li et al. 2017). Because this approach yields robust insoluble fractions with greater spinnability, this lignin treatment process is worthy of greater review for lignin value-added products. Overall, kraft lignin provides a cheap option for nonwoven fiber composites.

INCORPORATION OF LIGNIN IN NONWOVEN PROCESSING TECHNIQUES

Nonwovens are versatile materials, and their characteristics can be manipulated by manufacturing processes in addition to raw material qualities. There are numerous variables that impact performance from the initial web formation to finishing processes. The versatility of lignin influences different effects, depending on the selected manufacturing process. The detailed nonwoven process is elaborated in the following sections.

Web Formation

Nonwoven manufacturing processes can be divided into three steps: web formation, bonding, and finishing/converting. Depending on the web forming and bonding technologies, the basic properties of nonwoven fabrics such as fiber diameter, fiber orientation, web density, etc., can be highly unique. The web formation of nonwoven fabrics can be classified as follows: dry-laid, wet-laid, and polymer-based systems (Albrecht et al. 2004; Hutton 2016).It is commonly believed that the origins of the dry-laid technique are based in textiles, the origins of the wet-laid technique are based in papermaking, and the origins of the polymer-based technique are in the plastics and extrusion processes (Karthik and Rathinamoorthy 2016).

In the case of fiber-based raw materials, the nonwoven web is formed by dry-lay or wet-lay processes. The dry-lay web formation includes carding and air-lay processes, and the fiber raw materials are usually supplied as bale forms; thus, many other processes should be done before carding or air-lay process, such as bale opening and blending (Leifeld et al. 2004). In the carding process, roller cards disentangle the fiber tuffs and form the nonwoven web with staple fibers. Alternatively, the air-lay process takes cellulose fluff pulp or staple synthetic fibers conveyed by air to form nonwoven fabrics on a moving belt or continuous filter screen (forming wire) (Hutton 2016). During the wet lay process and in a manner analogous to the papermaking process (Pill and Afflerbach 2004; Hutton 2016), the fibers are dispersed in an aqueous slurry (stock), and the web is formed on a wire after the diluted stock is fed from the headbox and filtered on the wire. In addition to wood pulp and natural fibers, man-made fibers such as polyester, nylon, and rayon fibers can also be processed in this manner.

Polymer-type raw materials form nonwoven webs by spun-lay processes, including spunbonding and meltblown technologies (Hutton 2016). Spunbond and meltblown are the significant melt-spun processes. In both processes, the polymer is fed in the form of powder granules or pellets and melted by heat before extrusion. In the spunbond process, the extruded fibers are laid on the moving screen and form a web, but melted polymer resin directly forms the nonwoven webs in the melt-blown process; the polymer filaments are drawn by heated and high-velocity air to the collector, as shown in Fig. 1 (Hutten 2016). In the spunbond process, fibers are extruded, cooled, and laid down on the collector, in contrast to the meltbond process, where polymer filaments are cooled and collected on a moving collector screen.

Fig. 1. Comparison of melt-spun processes (Reprinted with permission from Hutten 2016).

Similar to melt blowing, solution blowing is a commonly explored technique used for industrial-scale manufacturing. The primary difference between the two is the polymer size; solution blowing tends to create nanofibers, while melt blowing creates microfibers (Kakoria and Sinha-Ray 2018). For solution blowing, a heated polymer solution is fed through a small capillary and catalyzed by a high-velocity hot gas flow. The fiber is then collected on a surface to form a nonwoven web. This process works significantly better than melt blowing for the production of biopolymer nonwovens, since solution blowing is performed at lower temperatures, decreasing the risk of denaturing the biopolymer. The biopolymer blend can be extruded instead of melted and may then be collected on a surface to form a nonwoven web (Kakoria and Sinha-Ray 2018).

Fig. 2. Schematic representation of solution blowing with a zoomed-in view of the coaxial nozzle (Reprinted with permission from Kakoria and Sinha-Ray 2018).

Another viable fiber-spinning process with polymers is electrospinning (Asmatulu and Khan 2019). Electrospinning is a nonwoven manufacturing technique that is one of the most promising potential techniques due to its current success and versatility. Electrospinning offers the capability to create a unique structure with chemical/physical properties, stability, high surface-area-to-volume ratio, and orientation control. The basic components of an electrospinning setup include a high voltage power supply that is typically DC, a spinneret, and a collector (Kakoria and Sinha-Ray 2018). The process involves electric forces to charge and eject a polymer held together by viscoelastic forces that will solidify to form a fiber or filament (Poursorkhabi et al. 2015). Electrospinning relies on electrohydrodynamic phenomena to maintain homogeneity in the polymer size and morphology (Kakoria and Sinha-Ray 2018). The size of these fibers can range from as small as tens of nanometers to several micrometers (Kakoria and Sinha-Ray 2018; Nanoscience Instruments). The fibers may be oriented, randomized, or laid out in geometric shapes (Poursorkhabi et al. 2015). This versatility offers manufacturers the ability to manipulate and thereby adapt to various needs. Table 1 lists ranges of parameters that have been employed in electrospinning.

Table 1. Electrospinning Parameters for Lignin-based Nonwovens (selected rows from Table 2 in Kakoria and Sinha-Ray 2018)

There are two main categories into which electrospinning processes may be placed: needleless electrospinning and needle-based electrospinning. Needleless electrospinning allows for large-scale production, but at the expense of morphology and quality control. Needle-based electrospinning allows for a much larger variety of materials, greater production flexibility, and increased control of the process (Nanoscience Instruments). Electrospinning has also been demonstrated as a viable process for creating high-porosity non-woven membranes, making them high-valued lithium-ion battery separator membranes. The increased porosity compared to other nonwoven fabrication methods increases battery potential by increasing electrolyte uptake. The usage of polymers can aid the performance of lithium-ion due to their good performance in conjunction with electro-spinning. The most common polymer, PAN, has shown properties such as flame resistance, ease of processing, electrochemical stability, and high oxidative stability (Zhao et al. 2015).

Electrospinning has a promising future in the nonwoven industry. The nonwoven industry is investigating methods to produce uniformly oriented fibers that do not have bending instability. Bending instability is the instability of the jet due to high charge density, which causes plastic deformation, allowing the fibers to be randomly aligned. There have been recent developments to combat bending instability by applying a low electrostatic field near the tip of the needle, lowering mass flow rate in the syringe pump, and placing an electrode plate close to the electrospinning emitter (INDA). Force spinning is another recent development that addresses material selection and efficiency. By replacing the electrostatic force with centrifugal force, the material selection can be expanded to include both conductive and non-conductive polymers (Asmatulu and Khan 2019).

Typically, lignin does not have enough viscoelastic strength to be suitable for electrospinning, so it is typically mixed with a binder such as PEO, PVOH, or PAN. These binders are typically prepared in an aqueous solution that will allow for a 50/50 mix of binder and lignin. Phenolic hydroxyl groups in lignin combine with the etheric oxygen of PEO in alkaline solutions to create a complex formation that leads to a minimal amount of binder being required. The chains of PEO become entangled, trapping lignin, while the bridging of the PEO chains creates an association-induced complex (Poursorkhabi et al. 2015). Such production processes that involve the inclusion of biopolymers are not as straightforward as with synthetic or thermoplastic polymers. At high temperatures, biopolymers can denature, leading to non-thermal techniques such as electrospinning being preferred. The solvent selection for all processes is highly dependent on factors such as molecular weight, polymer purity, charge location and amount, air temperature, and airflow. These are critical factors that determine the end product quality (Kakoria and Sinha-Ray 2018). As far as electrospinning with lignin is concerned, hardwood organosolv (Alcell) lignin has been shown to be a much better starting material for electrospinning compared to kraft lignin (Kakoria and Sinha-Ray 2018).

Bonding

After the web formation, most nonwoven webs must bond to consolidate their webs. The bonding process can be classified into two groups: chemical process and physical process (Nonwoven Bonding Techniques 2016; Introduction to Nonwovens; Kittelmann et al. 2004). Chemical bonding uses binders to consolidate the nonwoven web and is usually triggered by heat treatment. Physical bonding processing includes mechanical and thermal processes. Needling and hydroentangling are the typical mechanical bonding processes. The needling process forms the nonwoven web using penetration of barbed needles. By such action the fiber can be reoriented in the vertical direction, entangled, and interlocked, and the nonwoven web can be consolidated. Hydroentangling, also called spunlacing or hydraulic needling, is the mechanical process that entangles the fiber webs by means of fine and high-speed water jets. The properties of nonwovens fabricated using hydroentanglement depend on fiber specifications, fiber webbing, surface chemistry, water jet specifications, and processing speed (Xiang et al. 2006). Multiknit stitch bonding is an additional mechanical bonding process for nonwoven fabrics (Nonwoven Bonding Techniques 2016). In multi-knit stitch bonding, both sides of the fabric are formed into a densely knitted alignment to produce a double-sided, three-dimensional nonwoven fabric. The incoming K-unit receives the intermeshing pile fibers on its surface and is able to be joined to other K-units. Other materials and compounds can also be combined in this process to produce a composite with desired properties. Thermal bonding uses heat treatments, such as thermal calendering, hot air treatment, or point bonding with embossed rollers to bond together nonwoven materials. For thermoplastics, thermal bonding is the most commonly used technique; it is used significantly in baby diapers (New Cloth Market 2021).

Finishing

The final step of nonwoven processing involves finishing treatments to complete the desired properties from the nonwovens. In many cases, nonwoven finishing shares methodology and equipment with woven or knitted textile fabrics; however, some techniques are unique to nonwovens (Stukenbrock 2004a,b; Indi et al. 2019). The finishing process can be distinguished by mechanical and chemical processes. Shrinking, compacting, creping, and calendering are examples of mechanical finishings to improve the dimensional stability or impart the soft or smooth surface. Chemical finishing includes washing to remove unwanted materials from the nonwoven, dyeing, printing, softening, coating, and other finishing to give the nonwoven functions such as water-repellent/absorbent, antistatic, and flame-resistant properties.

COMPOSITES

Modern nonwoven composites use lignin as an ingredient in a polymer blend with other polymers. Such addition may provide a more sustainable alternative to current carbon sources while maintaining target performance. Composites are a major material topic that shows promise for lignin applications in the nonwoven industry. The potential commercial applications are predominantly water treatment, battery membranes, carbon fibers, and carbonized mats. The three most common lignin composite polymers found across the literature are PEO, PAN, and PVOH. The field of lignin composites is rapidly evolving, and significant research is being performed to increase compatibility and improve the characteristics of such nonwoven composites. Additionally, research is ongoing to incorporate a wide range of lignin types into nonwoven composites, and each study presented in this section includes the type(s) of lignin used. Lignin-based carbon fibers are produced using techniques used by the nonwoven industry and are an important facet of lignin applications. For example, lignin/PEO composites have shown promise for carbon fiber production (Yu et al. 2015). Furthermore, similar materials, carbonized lignin-based nonwovens are discussed in this review. While both result in highly porous materials with high carbon content, the primary distinction between the two is the production process. Carbonized nonwovens are first produced as a nonwoven material, stabilized, and finally carbonized.

Generally, lignin composites show improved processability and fiber properties compared to lignin alone. A significant issue that arises during the electrospinning process is the formation of beaded fibers rather than smooth fibers. Beaded fibers are undesirable because the beads act as defects in the fiber structure, impacting the properties of the nonwoven. Figure 3 provides SEM images showing the difference between highly beaded fibers (a), slightly beaded fibers (b), and smooth fibers (c) (Dallmeyer et al. 2010).

Fig. 3. Comparison of highly beaded (a), slightly beaded fibers (b), and smooth (c) fiber morphologies (adapted with permission from Dallmeyer et al. 2010).

Companies building from these advances and furthering the lignin composite knowledge are Prisma Renewable Composites and EUCALIVA. Prisma Renewable Composites is focused on turning lignin into high-value composites. Currently, they are focusing on “anion-exchange membranes, carbon fiber composites, and biopolymers/plastics” (Prisma Renewable Composites). EUCALIVA is a consortium composed of companies, universities, and research institutes that specializes in the isolation and use of eucalyptus kraft lignin from black liquor. They focus on the production of nonwovens from kraft lignin blends, with a focus on stretchable electronic films and activated carbon produced from nonwoven lignin mats (Eucaliva).

Compatibility Challenges

A significant issue restricting the usage of lignin as a composite is lignin/polymer compatibility. If the lignin and polymer are not compatible, then phase separation can occur in the solution prior to the fiber formation process. As a result, several issues could arise, including the inability to form fibers, the production of fibers that are composed of only one material, and degraded properties of the produced fibers. Thus, it is important to evaluate the compatibility between the composite materials prior to attempting fiber formation.

The driving factor for lignin/polymer compatibility is the abundance of hydroxyl groups on the lignin molecule. As a result, lignin is generally compatible with polar polymers and incompatible with nonpolar polymers (Yang et al. 2019). However, the lignin source, which was discussed previously in this review, plays a major role in compatibility. The potential for different, non-hydroxyl, side groups that arise during different pulping processes in addition to different lignin structures from different plants impacts the lignin-polymer interactions and thus the compatibility of the lignin/polymer composite. Lignin has been shown to be compatible with specific polymers, including but not limited to PEO (Dallmeyer et al. 2010; Schreiber et al. 2014; Poursorkhabi et al. 2015; Bahi et al. 2017; Cho et al. 2020), PAN (Zhao et al. 2015; Ding et al. 2016; Ogale et al. 2016; Park et al. 2017; Go et al. 2018; Al Aiti et al. 2020; Nie et al. 2020; Yang et al. 2020; Zhang et al. 2020b), PVOH (Fernandes et al. 2006; Ago et al. 2016; Ma et al. 2016; Aadil et al. 2018; Kwak et al. 2018; Lee et al. 2018, 2019; Xiong et al. 2018; Perera Jayawickramage and Ferraris 2019; Roman et al. 2019; Zang et al. 2019; Camiré et al. 2020; Ko et al. 2020; Chen et al. 2021; Posoknistakul et al. 2020; Zhang et al. 2020c; Hou et al. 20210, polymethyl methacrylate (PMMA) (Kai et al. 2015), polycaprolactone (PCL) (Kai et al. 2015), polylactic acid (PLA) (Cayla et al. 2016; Culebras et al. 2019), and thermoplastic polyurethane (TPU) (Culebras et al. 2019). Most of the polymers listed are polar, which follows the trend identified by Yang et al. (2019).

One common method for determining polymer compatibility is by measuring the glass transition temperature, Tg, of the lignin/polymer composite. This method is not specific to lignin composites but can be applied to determine lignin/polymer compatibility. In this method, a single Tg value indicates that the lignin is compatible with the polymer, while two or more Tg values indicate that lignin and the polymer are not compatible. For example, Ding et al. (2020) observed a single Tg band for a lignin/PAN composite, indicating that the lignin and PAN were compatible.

Another polymer compatibility method that has been applied to lignin is the Han plot. The Han plot method focuses on rheological compatibility, looking at the first normal stress difference, as well as elastic and viscous moduli (Han et al. 1985). The Han plot method was also applied to lignin/PAN mixtures demonstrating their compatibility (Ding et al. 2016).

Pouteau et al. (2004) used image analysis of films from various polymer blends to find “good polymer candidates” and “good lignin candidates” from the perspective of compatibility. It was reported that, generally, nonpolar and highly polar polymers were only compatible with lignin that had low molecular weight. In contrast, slightly polar polymers, such as polyvinyl chloride (PVC) and polystyrene (PS), demonstrated good compatibility with lignin.

Kun and Pukánszky (2017) performed a comprehensive review on the compatibility of lignin with several classes of polymers and the effects of various modifications. For nonpolar polyolefins, complete incompatibility is anticipated; however, several sources claim to have achieved successful compatibility of lignin with polyolefins. Specifically, steam-explosion lignin and lignosulfonates were found to be compatible with various types of PE (Kun and Pukánszky 2017). In addition, organosolv lignin was found to be compatible with both PP and low-density PE. However, Kun and Pukánszky questioned the validity of these claims and still conclude that lignins and polyolefins are generally incompatible.

The second class of polymers explored by Kun and Pukánszky (2017) was aromatic polymers. Due to the presence of the aromatic ring, it is expected that lignin-aromatic polymer blends will have better compatibility than lignin-polyolefin blends. Although this should generally be the trend, it was noted that due to the large variation in lignin fractions and aromatic polymer type, it is difficult to establish a rule for lignin-aromatic polymer compatibility. Lignin was reported to have both compatibility and incompatibility with various aromatic polymers, depending on the source of lignin and any additional modifications that were performed. For example, lignin treated with maleic anhydride was found to have some compatibility with PS. while unmodified lignin was largely incompatible. In general, lignin-PS and lignin-PET blends were reported to display varying degrees of compatibility (Kun and Pukánszky 2017).

The final class of polymers examined by Kun and Pukánszky were polymers that exhibit hydrogen bonding. The strong interactions due to hydrogen bonding are expected to improve the compatibility of lignin and these polymers (Kun and Pukánszky 2017). The hydroxyl, carboxyl, and methoxy groups that are part of the lignin structure can form hydrogen bonds with a polymer, leading to compatibility (Li et al. 2021). As with the polyolefins and aromatic polymers, there isn’t a clear rule for compatibility, with various sources claiming that a certain lignin-polymer blend is compatible with other sources reporting incompatibility for the same blend (Kun and Pukánszky 2017).

Several factors can explain the reported differences in lignin-polymer compatibility. Primarily, the importance of technical lignin fraction cannot be understated, as a wide range of lignin structures are observed depending on how the lignin was produced. In addition, different methods have been used to determine compatibility, which may lead to variations in what different researchers and research groups defined as a compatible blend. Thus, for lignin applications to nonwovens, it is difficult to formulate general compatibility rules due to the wide variation in lignin structure based on the lignin production process. As a result, it appears that the best method to determine compatibility is to perform lignin nonwoven processing techniques, such as electrospinning, at a bench-scale prior to scaling efforts. Due to the demonstrated heterogeneity of lignin, as the amount of lignin significantly increases within a composite, the probability for the occurrence of sufficiently different lignin structures also increases, and this could result in incompatibility issues. While the general compatibility trends discussed above will likely still hold, a few incompatible lignin fractions could severely impact a large-scale fiber production process. In processes that use spinnerets, the interruption of a single spinneret could necessitate halting the entire process to clear blockages and resume production.

As the demand for lignin increases, the availability of technical lignins will need to be considered to ensure an adequate supply is available. Consider the case of organosolv lignin: If a successful large-scale fiber production process is developed using a polymer that is only compatible with organosolv lignin, then the availability of organosolv lignin will play a major role in the ability to mass-produce the fiber. In contrast, if the compatible lignin is kraft lignin, then there will be much less concern about the lignin supply due to the abundance of kraft mills.

Lignin/PEO Nonwovens

A common lignin composite that shows promise for industrial applications is the combination of lignin and PEO. Lignin/PEO composites have shown potential applications in water filtration, carbonized nonwoven production, and air filtration. Nonwovens have been found to be rather efficient, since they are able to easily contain adsorbents and offer good efficiency when fabricated using electrospun, meltblown, and spunbond structures. The three primary design adjectives are immobilizing the adsorbents, controlling medium packing density, and improving the filtration capacity as a final composite structure (Amid et al. 2016). Dimethylformamide (DMF) was identified as a desirable solvent for lignin/PEO electrospinning (Schreiber 2012; Schreiber et al. 2014). In addition to DMF, water solutions with some added sodium hydroxide were also reported to result in successful electrospinning attempts (Poursorkhabi et al. 2015).

There is evidence that due to the nanoscale size of lignin/PEO nonwoven fibers produced via electrospinning, their filtration efficiency is improved, at similar pressure drop regimes, when compared to larger fibers (Graham et al. 2002; Chang and Chang 2016). This provides further evidence that lignin/PEO nonwovens have the potential to be used in filtration applications (Ding et al. 2016). It is also to be noted that filtration is not just limited to solids and liquids. In this respect lignin nonwovens have also been shown to be suitable for the filtration of gases to control odors and/or irritant vapors (Amid et al. 2016).

The state of entanglement determines the performance of PEO. The quantity of lignin heavily impacts the flocculation, as an increase in lignin correlates to a reduced flocculation (The North American Filter Market 2018). The key factors impacting lignin/PEO composites are lignin to PEO ratio, total polymer concentration, technical lignin source, and PEO molecular weight. Reported lignin to PEO ratios were between 85:15 and 99:1, with the most focus on 95:5 and 99:1 (Cho et al. 2020). The total polymer concentration investigated varied widely, from 5 to 50%, with most papers reporting successful electrospinning at concentrations between 20 and 40% in DMF (Schreiber 2012; Schreiber et al. 2014; Cho et al. 2020). However, aqueous electrospinning was reported to be successful between concentrations of 5 and 11%, which is significantly different from the efforts that used DMF (Poursorkhabi et al. 2015). The lignin type, pulping process, and plant were all shown to have significant impact on the electrospinning conditions required to produce smooth fibers. Dallmeyer et al. (2010) investigated the impact of pulping processes and found that softwood kraft lignin/PEO could be successfully electrospun at a 95:5 ratio with 30 wt% total polymer. In contrast, they determined that organosolv/PEO, hardwood kraft/PEO, and lignosulfonate/PEO composites required approximately 40 wt% total polymers, which is a significant difference (Dallmeyer et al. 2010). PEO molecular weight impacts the ability to be electrospun with low molecular weights, resulting in spraying rather than electrospinning, while high molecular weights were successful (Poursorkhabi et al. 2015).

The four key factors mentioned above may be manipulated to adjust the lignin/PEO membrane characteristics to meet a specific application. Carbonized nonwoven applications will have significantly different desired properties when compared to water filtration applications (Bahi et al. 2017; Cho et al. 2020). This versatility is an attractive component to lignin/PEO polymer blends. Some specific potential applications of lignin/PEO composites are discussed below.

Lignin/PEO – Water Filtration

For water purification purposes, zeolites were introduced to the lignin/PEO composite (Bahi et al. 2017), The addition of zeolites resulted in the surfaces of the composite fibers becoming coarser, which can be beneficial for trapping contaminants such as microorganisms or microplastics. In addition to the change in surface morphology, the properties of the electrospinning solutions and the fibers that are produced are significantly altered by the addition of zeolite (Bahi et al. 2017). In the cited work, a 25 to 30 wt% (total polymer) in DMF with a lignin to PEO ratio of 99:1 was used. Based on several experiments, the optimal zeolite concentration was determined to be 1%. The major concern for this composite membrane is durability, which was addressed through a post-spinning heat treatment process, resulting in a much stronger membrane. Retention of PS particles was used to measure membrane retention (Bahi et al. 2017). The lignin/PEO/zeolite composite achieved a retention percentage of 95% for particles larger than 1 micrometer, but particles smaller than 1 micrometer were not significantly removed. The 95% retention is important because a significant number of microorganisms and most microplastic particles are larger than 1 micrometer, indicating the potential for a lignin/PEO/zeolite membrane in water filtration (Bahi et al. 2017). The packing density of adsorbents in filter material depends on a number of conditions such as the presence of water – if water is present in hydrophilic housings; this leads to a substantial increase in back-swelling due to swelling in the fibers (Amid et al. 2016).

Lignin/PEO – Air Filtration

Air filtration testing has demonstrated that lignin membranes alone may not be sufficient for air filtration due to high penetration values. In addition, the lignin membranes showed cracking that was visible to the naked eye, providing pathways through the membrane. In contrast to the other lignin/PEO composites reported in several papers above (Dallmeyer et al. 2010; Poursorkhabi et al. 2015; Schreiber 2020; Schreiber et al. 2014; Bahi et al. 2017; Cho et al. 2020), where the lignin and PEO were electrospun together, this approach focused on electrospinning a lignosulfonate-based filter and then attaching PEO filters to either side. The composite filter was inserted into a surgical mask, and the resulting combination achieved a filtration efficiency equivalent to an N95 mask. However, the combination of so many layers resulted in an unacceptable pressure drop across the mask (Chang and Chang 2016). As a result, there is the potential for air filtration applications, but significant future work is needed to address the excessive pressure drop and reduce the number of layers.

Lignin/PEO – Carbonized Nonwovens

Significant research has gone into the preparation of carbonized nonwovens from several types of lignin (kraft, organosolv, Alcell, pyrolytic, etc.), but there is difficulty in achieving sufficient carbon content. In the carbonized nonwoven production process, the electrospun mats are first thermally stabilized and then carbonized. As discussed previously, the addition of PEO improves the ability of lignin to be electrospun. However, increasing the content of PEO has a negative effect on the quality of the carbonized nonwoven (Dallmeyer et al. 2010). As a result, the maximum PEO concentration reported for carbonized nonwoven-specific applications was 5% (Dallmeyer et al. 2010; Cho et al. 2020).

Lignin/PAN Nonwovens

A second common lignin nonwoven composite that shows promise is lignin with PAN. This has shown potential applications for battery separation membranes and in the production carbonized nonwovens. Similar to lignin/PEO composites, the main solvent identified for lignin/PAN electrospinning was DMF. In addition to DMF, dimethyl sulfoxide (DMSO) was also used for lignin/PAN electrospinning, and the ionic liquid, 1-ethyl-3-methylimidazolium chloride ([EMIM]Cl) was used for lignin/PAN dry-jet wet spinning (Al Aiti et al. 2020; Zhang et al. 2020b).

The primary factors affecting lignin/PAN composites were identified to be the lignin to PAN ratio and total polymer concentration. Unlike the lignin/PEO composites, which had similar desired properties for the end products, the desired characteristics of lignin/PAN composites are highly dependent on the end-use, resulting in a wider array of successful processing conditions. Carbonized nonwoven applications focus on carbon content and mechanical properties such as tensile strength, while battery applications focus on electrolyte uptake and porosity. In general, the total polymer solution concentration ranged from 10 to 25 wt%, while the ratios of lignin to PAN varied from 0:100 to 70:30. The most common successful electrospinning ratios were identified to be between 30:70 and 50:50 for DMF and below 30:70 for DMSO. In these ranges, the lignin/PAN fibers were found to be uniform, smooth, and bead-free (Zhao et al. 2015; Amid et al. 2016; Ding et al. 2016; Zhang et al. 2020b).

Lignin/PAN – Carbonized Nonwovens

Traditionally, carbon fiber processing begins with precursor production/isolation, then continues with fiber spinning, stabilization, carbonization, and finally, on occasions, fiber graphitization (de Avila Delucis et al. 2017). However, despite their excellent strength and performance characteristics, PAN carbon fibers are expensive and known to generate toxic byproducts, such as hydrogen cyanide (HCN). On the other hand, lignin is widely available, inexpensive, sustainable, and renewable material, and as such in theory it fulfills many of the requirements for ideal carbonized nonwoven production (de Avila Delucis et al. 2017). However, on their own, lignins lack the necessary carbon yields and associated mechanical strengths that pure PAN precursors offer (Sagues et al. 2019). For this reason, lignin/PAN polymer blends have been explored prior to carbonization (de Avila Delucis et al. 2017). Much of the lignin/PAN research has focused on carbonized nonwoven production (Ogale et al. 2016). For such lignin/PAN combinations, the lignin content was found to significantly impact both thermostabilization and carbonization (Zhang et al. 2020b), with documented associated efforts on the morphology of the fiber and the mechanical properties. Carbonization temperatures between 1000 and 1400 °C were found to be sufficient for lignin/PAN carbonization, with 1000 °C being the most commonly reported temperature (Ding et al. 2016; Park et al. 2017). The resulting carbonized nonwoven lignin/PAN mats have shown good elongation and strain at the breaking point with promise for carbonized nonwoven applications (Ding et al. 2016; Al Aiti et al. 2020).

To further explore this important area, lignin modification reactions have also been explored. One report discussed butyrated organosolv lignin (Ding et al. 2016), while another discussed a grafting approach of kraft lignin onto PAN (lignin-g-PAN) (Park et al. 2017). Both aimed to improve the compatibility of the two polymers prior to carbonization. The butyrated organosolv lignin was found to produce smooth fibers at lignin to PAN ratios below 60:40, with beads forming as the lignin content surpassed 60% of the total polymer weight (Ding et al. 2016). The addition of kraft lignin-g-PAN was shown to improve the tensile strength performance relative to lignin/PAN carbonized nonwovens. Surprisingly, it offered a higher tensile strength than neat PAN carbonized nonwovens, which is a key property for the utilization of carbonized nonwovens (Park et al. 2017).

Additional lignin modification efforts have been carried out by introducing propargyl groups on the phenolic groups of the lignin, which, upon subsequent thermal treatment (fiber formation and stabilization), have been shown to cyclize creating cyclic moieties similar to PAN cyclization chemistry that occurs during carbon fiber thermal regimes (Sen et al. 2013; Sadeghifar et al. 2016).

Lignin/PAN – Electrical applications

Lignin/PAN composites were found to work well as supercapacitors, batteries, and fuel cells (Nie et al. 2020). They are also ideal potential candidates as absorbers, filters, and electronic applications, where PAN-based carbon fibers and carbon fiber mats are already being used due to their high surface area (Go et al. 2018).

Zhao et al. (2015) investigated the potential for lignin/PAN membranes as replacements for commercial polypropylene (PP) battery separators. It was determined that an increase in lignin content led to an increase in membrane porosity, which is advantageous for electrolyte uptake, a key factor in battery separation membranes. The lignin/PAN showed better thermal and electrochemical stability, as well as faster electrolyte uptake when compared to commercial PP membranes. The lignin to PAN ratio of 3:7 was found to be the optimum ratio offering lignin/PAN membranes with superior C-rate and cycling performances. C-rate performance is a measure of discharge capacity relative to the discharge current density. For C-rate testing, desirable qualities include higher discharge capacities and lower capacity fading. Cycling performance is the ability for the electrochemical cell to retain its discharge capacity, with higher retention values corresponding to better cycling performance. Overall, the authors concluded that lignin/PAN membranes have the potential to replace the PP separators due to low costs and simple production methods (Zhao et al. 2015).

Electrodes are another lignin/PAN application in batteries, where they are used in carbonized PAN nonwoven composites produced via electrospinning. Carbonized nonwoven mats possess superior mechanical properties, as well as structural stability. Additionally, electrospun carbon fibers and carbonized nonwovens offer a large surface-to-volume ratio, 3D conductivity network, fast ion kinetics, and are simple to prepare. All of these are favorable qualities in electrode applications (Li et al. 2020).

In the past, carbon nanotubes, graphene, and 3D mesoporous carbon have all been used as supercapacitor flexible electrode materials. In one study, where a lignin/PAN-based carbonized nonwoven with hollow fibers was used as an electrode material, it was found that the composite exhibited excellent electrochemical properties (Yang et al. 2020). To produce the hollow nonwoven mats, coaxial electrospinning was used, followed by carbonization. The hydroxyl groups in lignin macromolecules and the low cost of lignin, as opposed to the PAN component, proved beneficial for a more sustainable mesoporous carbon synthesis. The heteroatoms in lignin were actually seen to be used to enhance the electrochemical performance of electrode material, and lignin‐based carbonized nonwovens can help reduce the cost of electrodes while maintaining their flexibility (Yang et al. 2020).

Lignin/PAN – Challenges

While the primary challenge in pure lignin-based carbonized nonwovens is mechanical performance (Dallmeyer et al. 2014), additional complications arise from the use of lignin such as the extensive pre-processing required, including its isolation and purification from the various waste streams, as well as the inherent inconsistency in feedstock quality and the heterogeneity of properties across batches (Argyropoulos 2014; Nie et al. 2020). In general, work with kraft lignin indicates it is incompatible for use as a carbonized nonwoven precursors, since it is of rather low molecular weight and of a high phenolic content, resulting in excessive reactivity yet good antioxidant activity (de Avila Delucis et al. 2017). During the actual stabilization and carbonization steps in nonwoven processing, the use of lignin adds another level of complexity. It has been shown that during, even minor thermal treatments of completely non-derivatized lignin, extensive crosslinking occurs and its Tg dramatically increases, causing it to become a thermoset (Cui et al. 2013). If this happens too quickly, fiber quality is severely affected. Above 1500 °C, the tensile strength decreases, even though the modulus continues to increase. This can lead to structural fiber defects as a result of a high carbonization rate and a considerable loss of heteroatoms (de Avila Delucis et al. 2017).

In general, while a lot of progress has been made and the demand is continuously expanding, many improvements are still required with regards to the use of lignin in carbonized nonwovens. Processing optimization is a much-needed improvement that is still missing, beginning with lignin extraction, isolation, purification, fiber processing and finally, if solvents are to be used, with potentially costly solvent recovery operations. With regards to equipment, low-cost industrial scale electrospinning technologies are still unavailable (Nie et al. 2020). Lastly, homogeneity of properties across feedstock used and improved mechanical strengths are keys to bringing lignin carbonized nonwovens to scale (Argyropoulos 2014; de Avila Delucis et al. 2017).

Lignin/PVOH Nonwovens

Lignin/PVOH composites have shown potential for industrial applications in three major categories, namely; electrical, water purification, and antimicrobial. Most of the lignin/PVOH literature examined showed that an extra stabilization step is required for the creation of lignin/PVOH membranes, which are distinct from the lignin/PEO and lignin/PAN composites previously discussed. This is because if such composite membranes are not treated, they otherwise dissolve in water (Lee et al. 2019; Camiré et al. 2020). For carbonized nonwoven-based applications, this is not an issue since the thermostabilization and carbonization processes dramatically alter the structure of the polymers, eliminating water dissolution issues. However, for non-carbonized nonwoven-based applications, several methods have been examined to limit solubility in water. Thermostabilization alone is not enough to stabilize the lignin/PVOH composite. As a result, other methods were explored including acid treatment, photo-crosslinking, and steam treatment. The most successful stabilization methods were found to be (1) heat treatment followed by acid treatment with a citrate buffer and (2) a three-step process of steam, visible light, and heat treatments (Aadil et al. 2018; Lee et al. 2019).

Despite reports that lignin and PVOH intermolecularly interact, the lignin and PVOH are immiscible in bulk. Furthermore, the PVOH and lignin have different solubility parameters, which ultimately affect their compatibility (Zhao et al. 2018). Therefore, some treatment is necessary to overcome the immiscibility of lignin and PVOH. For example, Nair et al. (2014) applied high-shear homogenization to produce nanolignin. The nanolignin was blended with PVOH and exhibited improved thermal stability of the lignin/PVOH blending with a well-dispersed structure.

Similar to the lignin/PEO and lignin/PAN nonwoven composites, the key factors in lignin/PVOH electrospinning are both the lignin to PVOH ratio and total polymer content in the solvent. For lignin/PVOH, the ratio ranged from 0:100 to 90:10, and the total polymer content ranged from 5 to 25 wt%. The solvents examined included water (Lai et al. 2014a; Ago et al. 2016; Ma et al. 2016; Uddin et al. 2017; Lee et al. 2018; Lee et al. 2019; Perera Jayawickramage et al. 2019; Zhang et al. 2019), DMSO (Kwak et al. 2018; Roman et al. 2019; Hou et al. 2021), DMF (Beck et al. 2017), and a methanol-water mixture (Aadil et al. 2018), with water being the most common. Successful electrospinning conditions were reported with lignin to PVOH ratios below 50:50 and polymer concentrations near 10 wt%. Similar trends were observed for the lignin/PVOH system as the previously discussed systems. Increasing lignin content consistently reduced the viscosity of the electrospinning solution, consequently leading to a decrease in fiber diameter. Increasing lignin content was also found to increase porosity and specific surface area, which is highly advantageous for various applications (Beck et al. 2017; Zhang et al. 2019).

While the preceding lignin/PVOH discussion focused on electrospinning of lignin/PVOH composites, lignin/PVOH fibers were also reported to be created using a gel spinning process (Lu et al. 2017, 2018). The gel spinning was performed with varying ratios of methanol and acetone as the solvent. The addition of acetone to an excess of methanol was found to improve the fiber properties by inhibiting the diffusion of lignin from PVOH into the coagulation bath. Increasing lignin content was reported to increase the melting temperature and thus the fiber drawing temperature of the lignin/PVOH fibers. The best performing fibers were obtained from a 5:95 lignin to PVOH weight ratio using a 15:85 methanol to acetone volume ratio. These lignin/PVOH fibers were found to have superior mechanical properties when compared to commercially available PVOH fibers. Increasing the lignin to PVOH ratio to 50:50 resulted in a deterioration of the mechanical properties compared to the 5:95 fibers. However, the 50:50 fiber mechanical properties were still comparable to the commercial PVOH fibers, demonstrating the ability of lignin to replace some of the carbon sources for fibers (Lu et al. 2017).

Lignin/PVOH – Water purification membranes

Much of the research related to lignin/PVOH composite membranes has been carried out for water treatment and purification purposes. Camiré et al. (2020) reported that the optimal alkali lignin:PVOH ratio was 50:50 at a total polymer concentration of 15 wt% in water. A rather detailed table of electrospinning parameters was also provided by the authors. The produced alkali lignin/PVOH composite membrane was found to remove 70% of the fluoxetine (the representative pharmaceutical contaminant) from the solution (Camiré et al. 2020). For the same kraft lignin/PVOH composite membrane system, Hou et al. (2021) reported the optimal ratio was 60:40 with a total polymer concentration of 25 wt% in DMSO. In addition to the reported optimal ratio, this system contained a cobalt/iron bi-metal-organic-framework (bi-MOF) incorporated into the kraft lignin/PVOH membrane using in-situ solvothermal methods. Finally, peroxymonosulfate (PMS) was added to the system to increase the activity of the membrane. In the dark, the kraft lignin/PVOH/bi-MOF membrane with PMS degraded 60% of the perfluorooctanoic acid, the representative contaminant. The degradation value increased to 90% under solar irradiation and 100% under UV irradiation. The membrane was found to retain a 77% removal percentage after four adsorption/desorption cycles, indicating sufficient stability (Hou et al. 2021). In other efforts, Chen et al. (2021) reported an alkali lignin/PVOH composite intended for purification, pervaporation, and desalination of seawater. In this effort, thin-film composites were synthesized by casting alkali lignin/PVOH solutions (70 to 90 wt% of lignin content with the remaining being PVOH) supported and fabricated onto a polyester/PAN substrate. These composite membranes performed well with respect to pervaporation desalination of high salinity water, offering drinkable water.

Alternatively, carbonized nonwoven water purification systems utilize the adsorption characteristics of the nonwoven mat. In one such effort, Beck et al. (2017) compared alkali lignin/PVOH carbonized nonwoven membranes against PAN carbon fiber membranes and activated carbon for the adsorption of methylene blue (representative of a large molecule), iodine (representative of a small molecule), and tannic acid (representative of a major water contaminant). In all cases, the alkali lignin/PVOH carbonized nonwoven membranes exhibited significantly higher adsorption when compared to their PAN carbon fiber membrane counterparts. One unique aspect of this study was a sample economic impact calculation, which concluded that in a hypothetical water purification process the operating costs of the alkali lignin/PVOH carbonized nonwoven membrane would be approximately $340,000 cheaper than using activated carbon. This cost reduction was attributed to the increased adsorption capacity and faster binding of the adsorbent (Beck et al. 2017). This was further confirmed by another study, using a cationic dye; the study showed similar adsorption performance data with such carbonized nonwoven membranes. This effort also pointed to other important improvements for carbonized alkali lignin/PVOH characteristics such as better flexibility and stability during various adsorption/desorption cycles (Zhang et al. 2019). Finally, Kwak et al. (2018) examined wet-spun alkali lignin/PVOH blended fibers and demonstrated that the blended fibers had better stability, water-resistance, heavy metal absorption and regeneration abilities, especially through glutaraldehyde-induced crosslinking.

Lignin/PVOH – Electrical applications

In addition to the previously discussed battery membrane applications, lignin/PVOH composite membranes have been compared against commercially available PP membranes. It is important to note at this point that the most important factors for battery membrane applications are electrolyte uptake as well as thermal and chemical stability. Specifically, Uddin et al. (2017) compared the electrolyte uptake using common electrolytes for graphite, silicon, and lithium titanium oxide anodes and found that the alkali lignin/PVOH membranes showed faster electrolyte uptake profiles for all three electrolytes. In addition, the percent uptake of the alkali lignin/PVOH membranes was significantly higher than that of the PP membranes. These are desirable properties, as they allow the assembly time of the batteries to be reduced. Alkali lignin/PVOH membranes also showed better thermal stability (measured by shrinkage under thermal stress), shrinking only 15% versus 45% for the PP membranes. Finally, chemical performance and stability studies showed that for a single charge/discharge cycle, the PP and alkali lignin/PVOH membranes performed nearly identically. However, the alkali lignin/PVOH membrane showed a significantly better C-rate performance and resisted electrochemical side reactions. According to the authors in this field, future work needs to be focused on decreasing the membrane thickness since the functional alkali lignin/PVOH membranes needed to be significantly thicker than the industry standard (Uddin et al. 2017). Overall, however, the creation of lignin/PVOH composites as potential battery separation membranes appears promising.

Various publications have also described potential breakthroughs in using lignin/PVOH composites as carbonized nonwoven-based electrodes for supercapacitor applications (Lai et al. 2014a; Ago et al. 2016; Roman et al. 2019; Zhang et al. 2020c). In a manner similar to all other carbonized nonwoven applications, the lignin/PVOH mat needs to be thermally stabilized and carbonized to produce the carbonized nonwoven membrane. Ago et al. (2016) produced alkali lignin/PVOH carbonized nonwovens for use as conductive electrodes in supercapacitors. The performance of the examined electrode was notable despite the fact that only one a single sample range ratio (75/25 alkali lignin/PVOH) was examined. Lai et al. (2014) compared the alkali lignin/PVOH carbonized nonwovens against PVOH carbon nanofiber mats and concluded that the composite nonwoven mats had the potential to act as sustainable electrode materials in supercapacitors. They found that the optimal alkali lignin to PVOH ratio for this application was 70:30. The composite carbonized nonwovens were determined to lose only ten percent of their capacity over 6,000 charges/discharge cycles and performed well under high current situations (Lai et al. 2014a). Perera Jayawickramage and Ferraris (2019) also produced carbonized nonwovens with alkali lignin and PVOH. They used electrospinning followed by carbonization and activation of the fibers for supercapacitor electrodes. The resulting carbonized nonwovens showed a four-fold improvement compared to the neat ionic liquid coin cell supercapacitors with the blending ratio of 80:20, which is similar to the study done by Lai et al. (2014). Thus, there is a potential application for lignin/PVOH supercapacitor electrode applications.

It was reported that for a 70:30 ratio of alkali lignin to PVOH and a 1:1 ratio of alkali lignin/PVOH carbonized nonwoven to manganese (IV) oxide (MnO2), the application of alkali lignin/PVOH composites as supercapacitor electrodes can be improved (Ma et al. 2016). The MnO2 nanowhiskers were grown onto the alkali lignin/PVOH carbonized nonwoven mat using redox reactions. The 1:1 ratio displayed “excellent” supercapacitor behavior and performed better than 2:1 and 1:2 ratios as well as electrodes without MnO2. The electrode without MnO2 showed the best cycling stability (approximately 1% capacitance loss over 10,000 charges/discharge cycles), whereas the 1:1 ratio electrode demonstrated an 8% capacitance loss over the 10,000 cycles. Even with a larger loss in capacitance, it was concluded the 1:1 ratio was still the best due to its superior electrochemical properties (Ma et al. 2016).

Lignin/PVOH – Antimicrobial applications

Lignin has been shown to have antimicrobial properties, which carry through the electrospinning process. As a result, there is the potential to create nonwoven materials with antimicrobial characteristics (Aadil et al. 2018; Lee et al. 2018, 2019). The specifics of the lignin antimicrobial properties are further explained in the section of this review covering coatings and finishings. Various literature accounts describe that alkali lignin/PVOH composites were effective against Gram-positive bacteria Staphylococcus aureus, but ineffective against Gram-positive bacteria Escherichia coli (Lee et al. 2019). However, Aadil et al. (2018) found that incorporation of silver nanoparticles into acetone-extracted lignin/PVOH composites allowed the composite to be effective against E. coli. Overall, lignin/PVOH composite nonwovens have been proposed for potential applications in antimicrobial fabrics and biomedical applications such as wound dressings (Aadil et al. 2018; Lee et al. 2019). In other efforts, Lee et al. (2018) have discussed lignin/PVOH composites with antimicrobial properties. Their work involved the dispersion of thin multi-walled carbon nanotubes into the lignin/PVOH aqueous solution followed by electrospinning suspension into a fiber. These lignin/carbon nanotubes/PVOH fibers showed improved antimicrobial and mechanical properties, which are desirable appropriate characteristics for wound dressing purposes (Lee et al. 2018).

Lignin/PVOH – Other applications

Another application of lignin/PVOH electrospun nonwovens is air filtration (Cui et al. 2021). The cited authors prepared the air filter membrane by electrospinning PVOH with lignosulfonate on a nonwoven fabric. The hydrogen bonding capacity of the lignosulfonate offered a transparent filter with improved filtration efficiency, allowing the creation of PM2.5 filters. Such efforts demonstrate that lignin/PVOH composites offer high-performance filtration media with transparency, biodegradability, and excellent mechanical properties for personal use.