Abstract

Moso bamboo (Phyllostachys pubescens Mazei ex H. de Lebaie), one of the most commonly used species in China, is a strong and stiff material. In this paper, the manufacturing process for glued bamboo laminate (GBL) is presented. The mechanical properties of GBL (compression strength, bending, tension, and shearing) were tested. Results indicated that the mechanical properties of GBL were significantly different for different grades of GBL, but that the performance of GBL was controllable. The edge butt joint greatly influenced the tensile performance, but the butt joint had little impact on the bending performance. In addition, the good mechanical performance of GBL is sufficient for engineering members, making it a potentially useful bamboo product for engineering.

Download PDF

Full Article

Manufacture and Mechanical Properties of Glued Bamboo Laminates

Lin Ni, Xiubiao Zhang, Huanrong Liu, Zhengjun Sun, Guangnan Song, Limei Yang, and Zehui Jiang *

Moso bamboo (Phyllostachys pubescens Mazei ex H. de Lebaie), one of the most commonly used species in China, is a strong and stiff material. In this paper, the manufacturing process for glued bamboo laminate (GBL) is presented. The mechanical properties of GBL (compression strength, bending, tension, and shearing) were tested. Results indicated that the mechanical properties of GBL were significantly different for different grades of GBL, but that the performance of GBL was controllable. The edge butt joint greatly influenced the tensile performance, but the butt joint had little impact on the bending performance. In addition, the good mechanical performance of GBL is sufficient for engineering members, making it a potentially useful bamboo product for engineering.

Keywords: Glued bamboo laminate; Mechanical properties; Moso bamboo; Butt joint

Contact information: International Centre for Bamboo and Rattan, Beijing, P.R. China, 100102;

* Corresponding author: jiangzehui@icbr.ac.cn

INTRODUCTION

Bamboo is a group of woody plants that belong to the Poaceae family and Bambusoideae subfamily. Increasing interest in bamboo is due to the decline of available timber resources and increase in wood demand. Bamboo has similar environmental characteristics and comparable physical and mechanical properties with wood, and its fast growth characteristics are an important incentive. Bamboo can grow 15 to 18 cm per day and reach its full height and girth in a single growing season. Also, bamboo can be harvested in 3 to 6 years (Lee et al. 1994). In short, bamboo can be an alternative raw material to meet the demand for wood.

Among several hundred species of bamboo in China, moso bamboo is one of the most commonly used species. The total area of moso bamboo forests in China is 4,430,000 hm2, which occupies about 74% of the total bamboo forest area. Moso bamboo is a strong and stiff material with a modulus of rupture (MOR) ranging from 97.9 to 137.9 MPa and corresponding modulus of elasticity (MOE) ranging between 9000 and 20,700 MPa (Mahdavi et al. 2011).

Bamboo in its natural form is a hollow tubular structure (Liese 1987), which gives it high efficiency in resisting bending forces. However, its natural structure is also the largest impediment to its use because of the difficulty in making connections. Moreover, its hollow structure and small diameter relative to trees prevent its use in large structures.

Therefore, it is necessary to split bamboo into small elements that can be used to produce material with varying sizes and cross-sections. Various engineered bamboo products have been developed, such as bamboo oriented board (Sumardi et al. 2007), bamboo-bundle laminated veneer lumber (Chen et al. 2014), laminated bamboo lumber (Mahdavi et al. 2012), parallel strand bamboo (Huang et al. 2013), and bamboo reinforced composites (Corradi et al. 2009). Recently, laminated bamboo and bamboo scrimber have become two engineered bamboo products of particular interest (Sharma et al. 2015). Correal and Lopez (2008) manufactured Colombian glued laminated bamboo (Guadua angustifolia Kunt) and confirmed that it has similar mechanical properties to the best structural wood in Colombia. The adhesive performance and the structural behavior were also investigated to confirm its suitability for structural applications (Correal and Ramirez 2010; Correal et al. 2010). Nugroho and Ando (2000, 2001) processed moso bamboo into bamboo zephyr boards, which can be further used to produce laminated bamboo lumber, and found that laminated bamboo lumber processed in this way exhibited superior strength properties compared with commercial products. Another bamboo scrimber processing method has been used, called the cold-in and cold-out hot pressing process (Yu et al. 2014). In this way, bamboo scrimber shows not only excellent mechanical properties, but also improved behavior in resisting water absorption and swelling. Multiple studies have investigated the influence of processing factors on the physical and mechanical properties of bamboo scrimber (Zhang et al. 2012, 2014; Zhang and Yu 2015). The uniformity of density and stability of mechanical properties of bamboo scrimber were shown to improve using the one-piece veneer method (Chen et al. 2014).

However, previous research has not touched upon the matters of engineered materials. Although bamboo scrimber exhibits a better uniformity performance and dimensional stability to some extent, the bamboo bundle processing is not strictly repeatable. The properties of bamboo bundles and their final products are not likely controllable. In addition, the properties of bamboo vary greatly depending on the species, soil and climactic condition, silvicultural treatment, age, density, and position in the culm (Lee et al. 1994; Yu et al. 2008). When materials are manufactured using highly variable raw materials without appropriate design, the variability in properties increases remarkably. A common method to control the performance variability of products made of natural raw materials is grading of the raw materials; this can also make the best use of the raw materials.

The present research designed a repeatable processing method to control the properties of glued bamboo laminates. Dimension bamboo strips sawn from bamboo culms were graded according to their density. Then, bamboo strips of the same grade were glued vertically with butt joints homogeneously distributed to form a glued bamboo laminate, which could be used as a dimension lumber in glulam.

EXPERIMENTAL

Materials

Dimension bamboo strips

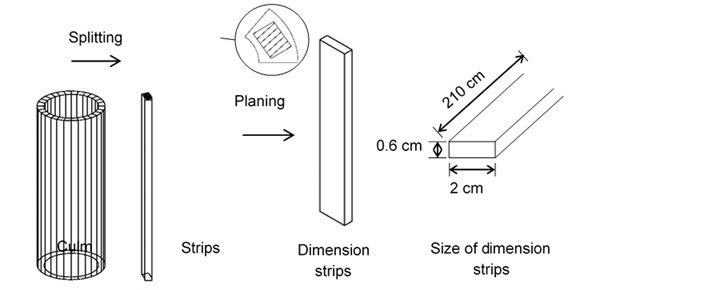

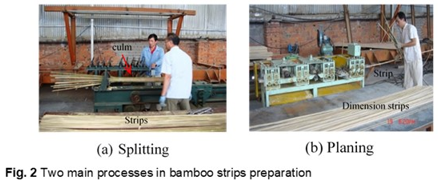

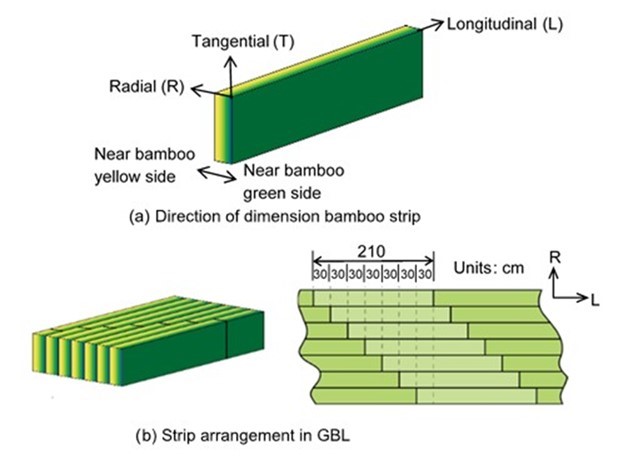

Four year-old moso bamboo culms were obtained from Xinchang County, Zhejiang Province, China. The culm diameter at breast height ranged from 100 to 120 mm, and the average thickness of culm walls was 10 to 12 mm. The moisture content of the culms was conditioned between 8% to 12% in a kiln. Then, dimension bamboo strips of 2100×20 × 6 mm (length × width × thickness) were manufactured in a series of processes, such as splitting, planning, and sawing, as shown in Fig. 1. Figure 2 shows more details of the two main processes in preparation of dimension bamboo strip.

Phenol formaldehyde (PF)

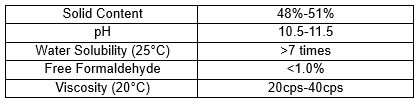

PF resin was purchased from Beijing Dynea Chemical Industry Co. Ltd. (China). The properties of PF were shown in Table 1.

Table 1. Performance index of PF

Fig. 1. Manufacturing process of bamboo strips

Methods

Preparation of bamboo strips for glued bamboo laminate

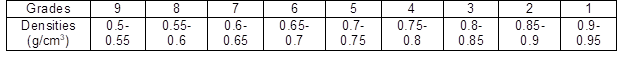

According to the dimension bamboo strips’ air-dried densities, a nine-grade density system was constructed in the range from 0.45 to 0.9 g/cm3, with intervals of 0.05 g/cm3 (Table 2). Because most of the strips were in the density range of 0.6 to 0.9 g/cm3, these dimension bamboo strips were used for glued bamboo laminate (GBL).

Table 2. Nine-Grade Density Standard for Dimension Bamboo Strips

Preparation of glued bamboo laminate

Dimension bamboo strips were glued after immersing them in PF. Strips were arranged with butt joints in the longitudinal direction and overlaid in the radial direction, and a distance between two adjacent butt joints was 300 mm. (Fig. 3). In this way, the structure and mechanical performance of GBL would be even.

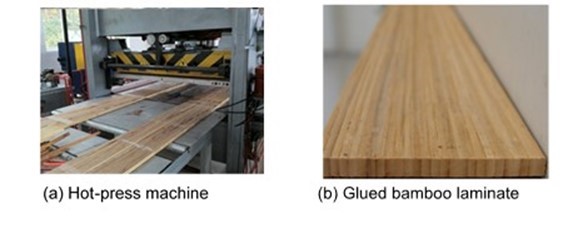

The layered-up mats were hot pressed on a pressing machine. The hot pressing pressure was 3 MPa. The hot-press time was 20 min. And the hot-press temperature was 130 °C. Figure 4 illustrates the hot-press machine and GBL products.

Fig. 3. Arrangement of dimension bamboo strips in GBL

Fig. 4. Hot-press machine and GBL

Mechanical properties of GBL

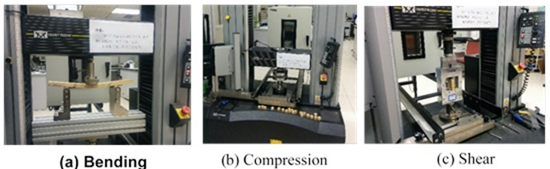

Prior to testing, all specimens were conditioned in a climate chamber with the relative humidity of 65% at 20 °C for more than three weeks. According to the standardized test method ASTM D143 (2007), static bending, compression, tension, and shear tests were conducted. The bending, compression, and shear tests were conducted on an Instron universal testing machine (Instron, series 5582; Norwood, MA). Also, an MTS universal testing machine (Eden Prairie, MN) was used for tension tests. One way variation analysis (ANOVA) with 95% confidence was made between grade and bending and tensile properties.

(a) Static bending tests

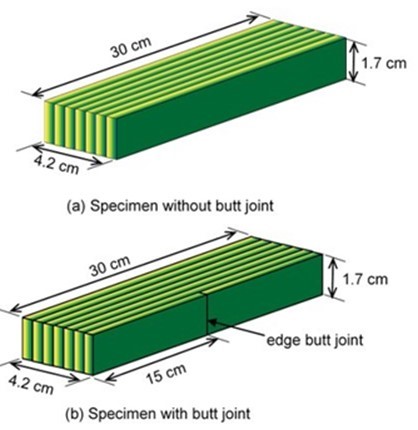

The specimens were 42 mm × 17 mm in section and 300 mm in length. The load was applied at the center of a 240-mm span with a displacement rate of 2.5 mm/min. The failure load was recorded and the modulus of rupture (MOR) calculated. In addition, the butt joint was located at the center of the span to investigate the lowest bending strength of the laminate. Samples with and without butt joints were tested to evaluate the influence of the butt joint on the bending performance (Fig. 5). Twenty specimens with butt joints and 20 specimens without joints were tested among each grade, and the test set-up can be seen in Fig. 7 (a).

Fig. 5. The size of the specimens in bending performance test

(b) Compression parallel to the grain

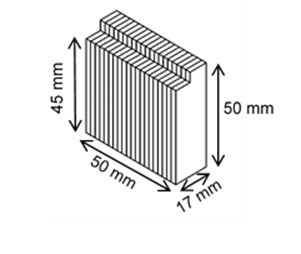

The specimens were 17 mm × 17 mm in section and 50 mm in length. A bearing plate was used to apply a continuous compression load with a displacement rate of 0.3 mm/min. The load was applied until deformation equal to 5% of the specimen thickness was reached, and the stress at that point was calculated. Ten specimens of each grade were tested. The set-up is illustrated in Fig. 7(b).

(c) Shear parallel to the grain

Dimensions of the specimen as well as the test setup are shown in Fig. 6. The load was applied continuously throughout the test at a displacement rate of 0.6 mm/min. Ultimate shear stress was calculated. Ten specimens from each grade were tested. The set-up is shown in Fig. 7 (c).

Fig. 6. Size of shear specimen

Fig. 7. Instron apparatus used in performance test

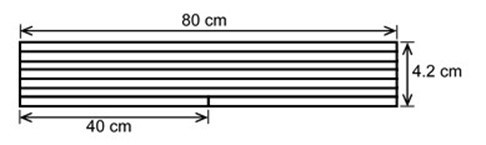

(d) Tension parallel to the grain

Fig. 8. Dimension of tensile specimen

The specimen was 17 mm × 42 mm in section and 800 mm in length, with an edge butt joint at middle of the length (Fig. 8). The test was conducted at a displacement rate of 0.9 mm/min. The butt joint in the laminate was placed at the edge of the specimens, which revealed the lowest tension performance of the laminate. Ten specimens from each grade were tested.

RESULTS AND DISCUSSION

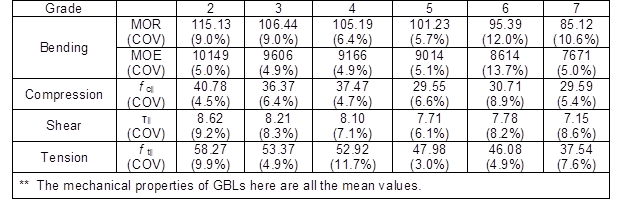

Mechanical Properties of GBLs

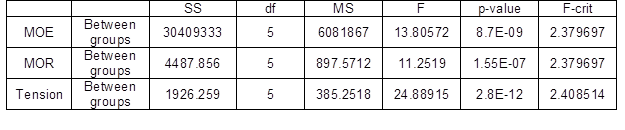

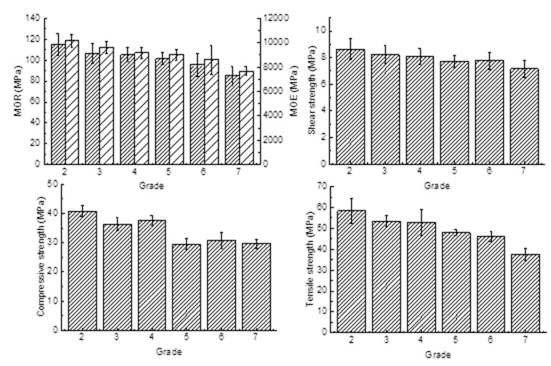

The mechanical properties of GBLs from six grades are summarized in Table 3 and Fig. 9, including bending strength, compressive strength parallel to the grain, shear strength parallel to the grain, and tensile strength parallel to the grain. The bending strength and stiffness of GBLs had a positive correlation with density. The MOR ranged from 85 to 115 MPa, depending on the density of dimension bamboo strips. Also, the corresponding MOE was distributed in the interval of 7.67 to 10.15 GPa. The compressive and shear strength parallel to the grain did not increase strictly from Grade 7 to Grade 2. The compressive strength parallel to the grain varied from 29.5 to 40.8 MPa, while the shear strength parallel to the grain was in the range of 7.1 to 8.6 MPa. The tensile strength parallel to the grain ranged from 37.5 MPa in Grade 7 to 58.2 MPa in Grade 2. The associated coefficient of variation (COV) for GBL properties was very low; the highest was only 13.7%. This result was expected because the dimension bamboo strips were graded according to their densities. The bending and tensile performances are important for GBL application in engineering. The one–way analysis of variance (1-way ANOVA) on bending and tensile properties with a 95% confidence level is shown in Table 4. The ANOVA indicated that there were significant differences in MOE, MOR, and tensile strength among six grades (p-value < 0.01; F > F-crit). The bending and tensile performance improved with increasing density of the dimension bamboo strips (Fig. 9).

Table 3. Mechanical Properties of the Laminates from Six Grades (Unit: MPa)

Note: fc∥, compressive strength parallel to the grain; τ∥, shear strength parallel to the grain; ft∥, tensile strength parallel to the grain

Table 4. ANOVA with a 95% Confidence Level Comparing MOE, MOR, and Tensile Strength of Different Grades

Note: SS, sum of squares; df, degree of freedom; MS, mean square

Fig. 9. Mechanical properties of different grades

The tensile strength of GBLs was much lower than the results (143.1 MPa) reported by Correal et al. (2014). The low tensile strength of the laminates derived from their failure mode, caused by the dimension strip arrangement in the laminate.

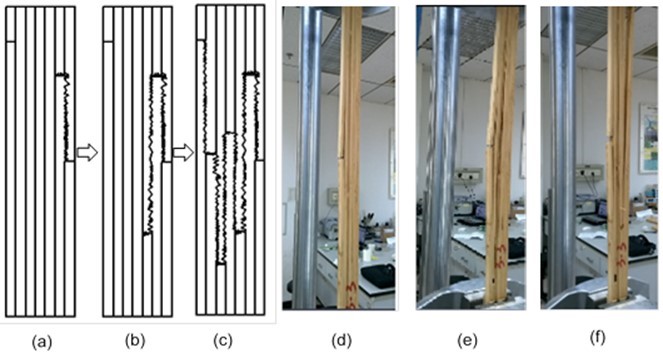

Fig. 10. Failure propagation of the tension specimen

Figure 10 shows the failure propagation of the tensile specimens. The failure began in the edge butt joints. The shear failure occurred first in the outmost part, as illustrated in (a) and (d). As the crack grew, the tensile failure occurred at a certain point and resulted in shear failure in the inner part, as shown in (b) and (e). In this way, the failure developed and the specimen was eventually destroyed, as seen in (c) and (f).

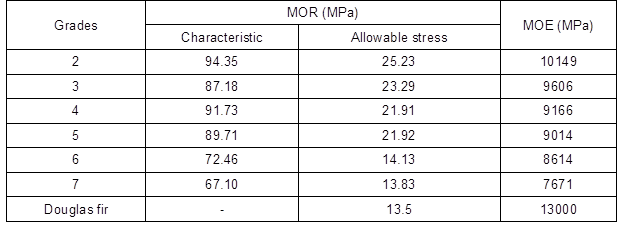

The MOE and MOR of GBL compares well with previous research on laminated bamboo products (Yu et al. 2008; Mahdavi et al. 2011). To compare with dimension lumber of commercial species, it is necessary to convert the average values to allowable values. In addition, the edge joint in GBL greatly influenced the tensile performance, so it is necessary to evaluate its impact on bending performance.

Comparison to Douglas Fir

The allowable stress of GBLs was computed, using the method established in ISO 22157 (2004) and ISO 22156 (2004), with the following equations,

Rck = R0.5 [1 – (2.7 s/m) / N0.5 ] (1)

sall = Rck x G x D/S (2)

where Rck is the characteristic value; R0.05 is the 5th percentile value (i.e., Mean – 2 × standard deviations); m is the mean of all values from the test data; s is the standard deviation; N is the number of tests (at least 10); σall is the allowable bending stress; G is the modification factor for differences between laboratory and practice conditions, with a default value of 0.5; D is the modification factor for duration of load (1.0 for permanent loads); and S is the safety factor, with a default value of 2.25.

Using Eq. 1, the characteristic values for bending stress of all grades were calculated and then substituted into Eq. 2 to obtain the allowable bending stress, as presented in Table 5. Also, these were compared to an allowable value for bending stress for 2 × 6 in. selected structural Douglas fir, i.e., 13.5 MPa (FPL 2010). The corresponding Douglas fir MOE was 13000 MPa, as presented in Table 5. The lowest MOR from Grade 7 was 13.83 MPa, which was approximately equal to the MOR of Douglas fir. Also, the highest MOE from Grade 2 was lower than that of Douglas fir.

Table 5. Characteristic Value and Allowable Stress Value of GBLs and Douglas Fir

Influence of Butt Joints on the Bending Performance

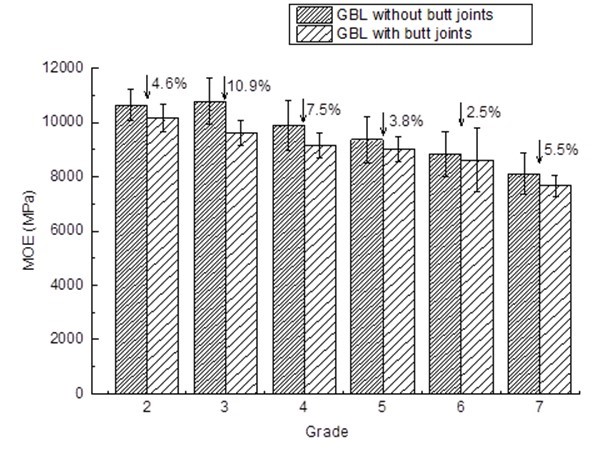

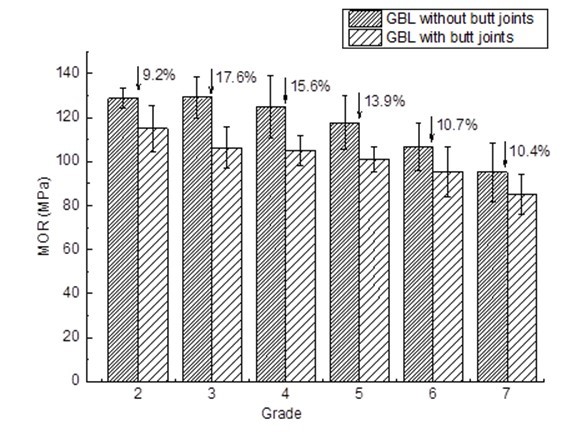

Butt joints in current research influenced the bending performance, similar to knots in dimension lumber. As Figs. 11 and 12 show, the bending MOR and MOE of the laminates was expected to be the lowest because of the edge butt joints in specimens. The MOE and MOR of laminates with butt joints at the center of the span decreased compared with those without butt joints.

Fig. 11. Comparison of MOE between laminates with and without butt joints

Fig. 12. Comparison of MOR between laminates with and without butt joints

The bending strength of the laminates without edge butt joints was distributed in the range from 95 to 126 MPa, with the corresponding MOE in the interval of 8115 to 10635 MPa. In contrast, the MOR and MOE of the laminates with edge butt joints were respectively located in the range of 85 to 115 MPa and 7671 to 10149 MPa. The MOR from Grade 2 to Grade 7 respectively decreased by 9.2%, 17.6%, 15.6%, 13.9%, 10.7%, and 10.4%, while the corresponding decrease in MOE was 4.6%, 10.9%, 7.5%, 3.8%, 2.5%, and 5.4%. The MOR dropped by a greater amount than MOE, but both reductions were acceptable. Also, a butt joint located inside would cause less reduction. The fabrication method in this study was therefore feasible.

CONCLUSIONS

- The grading method had a significant effect on bending and tensile strength between different grades. This method was important for controlling the variability of the glued bamboo laminates and making the best use of the dimension bamboo strips.

- The edge butt joints in the glued bamboo laminates decreased the bending and tensile strength. There was less of a decline in bending strength compared with tensile strength.

- The low tensile strength in the current study was due to the butt join layer-up manner of GBL. The gradual crack propagation from edge to inner also decreased tensile strength.

- In future applications, the edge butt joint should be placed in the interior of the final products because of their great influence on the tensile properties of GBL.

ACKNOWLEDGMENTS

The authors are grateful for the support of the 12th Five Years Key Technology R&D Program of China (2012BAD23B01) and the Special Fund of the International Center for Bamboo and Rattan (1632015001).

REFERENCES CITED

ASTM D143 (2007). “Standard method of testing small clear specimens of timber,” ASTM International, West Conshohocken, PA.

Chen, F., Jiang, Z., Deng, J., Wang, G., Zhang, D., Zhao, Q., Cai, L., and Shi, S. Q. (2014). “Evaluation of the uniformity of density and mechanical properties of bamboo-bundle laminated veneer lumber (BLVL),” BioResources 9(1), 554-565. DOI: 10.15376/biores.9.1.554-565

Corradi, S., Isidori, T., Corradi, M., Soleri, F., and Olivari, L. (2009). “Composite boat hulls with bamboo natural fibres,” International Journal of Materials and Product Technology 36(1-4), 73-89.

Correal, J. F., and Lopez, L. F. (2008). “Mechanical properties of Colombian glued laminated bamboo,” in: Modern Bamboo Structures, Paudel, S. K., Xiao, Y., and Inoue, M. (eds.), Taylor & Francis, London, UK, pp. 121-127. DOI: 10.1201/9780203888926.pt3

Correal, J. F., and Ramirez, F. (2010). “Adhesive bond performance in glue line shear and bending for glued laminated guadua bamboo,” Journal of Tropical Forest Science 22(4), 433-439.

Correal, J. F., Ramirez, F., Gonzalez, S., and Camacho, J. (2010). “Structural behavior of glued laminated guadua bamboo as a construction material,” Proceedings of the 11th World Conference on Timber Engineering, 20-24 June, Riva del Garda, Italy.

Correal, J. F., Echeverry, J. S., Ramírez, F., and Yamín, L. E. (2014). “Experimental evaluation of physical and mechanical properties of glued laminated Guadua angustifolia Kunth,” Construction and Building Materials 73, 105-112. DOI: 10.1016/j.conbuildmat.2014.09.056

Forest Products Laboratory (FPL) (2010). “Wood handbook—Wood as an engineering material,” General Technical Report FPL-GTR-190, Forest Products Laboratory, Forest Service, U.S. Department of Agriculture, Madison, WI.

Huang, D. S., Zhou, A. P., and Bian, Y. L. (2013). “Experimental and analytical study on the nonlinear bending of parallel strand bamboo beams,” Construction and Building Materials 44, 585-592. DOI: 10.1016/j.conbuildmat.2013.03.050

ISO 22156 (2004). “Bamboo—Structural design,” International Organization for Standardization, Geneva, Switzerland.

ISO 22157-1 (2004). “Bamboo—Determination of physical and mechanical properties. Part I: Requirements,” International Organization for Standardization, Geneva, Switzerland.

ISO 22157-2 (2004). “Bamboo—Determination of physical and mechanical properties. Part II: Laboratory manual,” International Organization for Standardization, Geneva, Switzerland.

Lee, A. W. C., Bai, X., and Peralta, P. N. (1994). “Selected physical and mechanical properties of giant timber bamboo grown in South Carolina,” Forest Products Journal 44(9), 40-46.

Liese, W. (1987). “Research on bamboo,” Wood Science and Technology 21(3), 189-209.

Mahdavi, M., Clouston, P. L., and Arwade, S. R. (2011). “Development of laminated bamboo lumber: Review of processing, performance, and economical considerations,” Journal of Materials in Civil Engineering 23(7), 1036-1042. DOI: 10.1061/(ASCE)MT.1943-5533.0000253

Mahdavi, M., Clouston, P. L., and Arwade, S. R. (2012). “A low-technology approach toward fabrication of laminated bamboo lumber,” Construction and Building Materials 29, 257-262. DOI: 10.1016/j.conbuildmat.2011.10.046

Nugroho, N., and Ando, N. (2000). “Development of structural composite products made from bamboo I: Fundamental properties of bamboo zephyr board,” Journal of Wood Science 46(1), 68-74. DOI: 10.1007/BF00779556

Nugroho, N., and Ando, N. (2001). “Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber,” Journal of Wood Science 47(3), 237-242. DOI: 10.1007/BF01171228

Sharma, B., Ramage, M., Bock, M., Gatoo, A., and Mulligan, H. (2015). “Engineered bamboo: State of the art,” Proceedings of the ICE – Construction Materials 168, 57-67.

Sumardi, I., Ono, K., and Suzuki, S. (2007). “Effect of board density and layer structure on the mechanical properties of bamboo oriented strandboard,” Journal of Wood Science 53(6), 510-515. DOI: 10.1007/s10086-007-0893-9

Yu, H. Q., Jiang, Z. H., Hse, C. Y., and Shupe, T. F. (2008). “Selected physical and mechanical properties of moso bamboo (Phyllostachys pubescens),” Journal of Tropical Forest Science 20(4), 258-263.

Yu, Y., Zhu, R., Wu, B., Hu, Y., and Yu, W. (2014). “Fabrication, material properties, and application of bamboo scrimber,” Wood Science and Technology 49(1), 83-98. DOI: 10.1007/s00226-014-0683-7

Zhang, Y., and Yu, W. (2015) “Changes in surface properties of heat-treated Phyllostachys pubescens bamboo,” BioResources 10(4), 6809-6818. DOI: 10.15376/biores.10.4.6809-6818

Zhang, Y. M., Yu, Y. L., and Yu, W. J. (2012). “Effect of thermal treatment on the physical and mechanical properties of Phyllostachys pubescens bamboo,” European Journal of Wood and Wood Products 71(1), 61-67. DOI: 10.1007/s00107-012-0643-6

Zhang, D., Wang, G., and Ren, W. (2014). “Effect of different veneer-joint forms and allocations on mechanical properties of bamboo-bundle laminated veneer lumber,” BioResources 9(2), 2689-2695. DOI: 10.15376/biores.9.2.2689-2695

Article submitted: December 9, 2015; Peer review completed: January 31, 2016; Revised version received and accepted: February 18, 2016; Published: April 4, 2016.

DOI: 10.15376/biores.11.2.4459-4471