Abstract

Zeolite was investigated as a potential component in the production of medium-density fiberboard (MDF). A mixture of beech (40%), oak (30%), and pine (30%) wood chips was used for fiber production. Chips were cooked for 4 min in an Asplund defibrator with a vapor pressure of 8 bar, and a temperature of 180 °C. Chemicals were added on fibers in the blow line. The resins were added at 11 wt% based on oven-dried wood fibers. Ammonium sulphate was added at 0.72 wt% based on resins. Paraffin wax was added as 1.8 wt% based on resin. Zeolite was prepared in a separate tank for its use instead of lignocellulosic fibers in the production of 1 m³ MDF. The fibers were dried to 12% moisture. A temperature of approximately 190 °C and a pressure of approximately 32 kg.m-² were applied to the mixture for 280 s to make MDF panels (500 x 490 x 14 mm). Mechanical properties of MDF boards were significantly increased for bending (MOE) and elastic modulus (MOR), but a little negatively affected on internal bond (IB), physical properties were negatively increased thickness swelling (ThS) and water absorption (WA). Consequently, increasing zeolite minerals in MDF boards showed best results of formaldehyde emission properties of MDF.

Download PDF

Full Article

Mechanical and Formaldehyde-related Properties of Medium Density Fiberboard with Zeolite Additive

Osman Camlibel *

Zeolite was investigated as a potential component in the production of medium-density fiberboard (MDF). A mixture of beech (40%), oak (30%), and pine (30%) wood chips was used for fiber production. Chips were cooked for 4 min in an Asplund defibrator with a vapor pressure of 8 bar, and a temperature of 180 °C. Chemicals were added on fibers in the blow line. The resins were added at 11 wt% based on oven-dried wood fibers. Ammonium sulphate was added at 0.72 wt% based on resins. Paraffin wax was added as 1.8 wt% based on resin. Zeolite was prepared in a separate tank for its use instead of lignocellulosic fibers in the production of 1 m³ MDF. The fibers were dried to 12% moisture. A temperature of approximately 190 °C and a pressure of approximately 32 kg.m–² were applied to the mixture for 280 s to make MDF panels (500 x 490 x 14 mm). Mechanical properties of MDF boards were significantly increased for bending (MOE) and elastic modulus (MOR), but a little negatively affected on internal bond (IB), physical properties were negatively increased thickness swelling (ThS) and water absorption (WA). Consequently, increasing zeolite minerals in MDF boards showed best results of formaldehyde emission properties of MDF.

Keywords: MDF; Zeolite; Formaldehyde emission; Physical properties; Mechanical properties

Contact information: Interior Design Program, Kirikkale Vocational School, Kırıkkale University, Kırıkkale, Turkey; *Corresponding author: osmancamlibel@kku.edu.tr

INTRODUCTION

When preparing wood chips and lignocellulosic materials, organic and inorganic minerals and chemicals can be added in suitable proportions to produce panels. Wood-composite products containing binding zeolite materials are manufactured using synthetic adhesives, natural adhesives, plaster, magnesium cement, and Portland cement.

Lim et al. (2006) have studied the effects of different sizes and structures of zeolite when they are used in coating the surface of cellulose fibers. They investigated the effects of the different dimensions and structures of zeolite on deodorization. Boran et al. (2011) studied MDF boards produced by adding different ratios of amine compounds (urea, propylamine, methylamine, ethylamine, and cyclopentyl amine solution) in urea-formaldehyde resin (F:Ü; 1.17 mol ratios). They found that the mechanical properties of MDF boards increased, but their physical properties, i.e., thickness swelling (ThS, 24 h) and water absorption (WA, 24 h), and formaldehyde emission decreased in MDF boards. Mishra and Jain (2011) researched the structure and usage areas of zeolite. Application areas of zeolite have included domestic water and commercial water purification, softening, agriculture, industry, and nuclear waste treatment. Zahedsheijani et al. (2011) studied the potential use of nanoclay to modify fluid transfer properties of MDF production. In their works, montmorillonite (Na+MMT) nanoclay added in urea-formaldehyde resin and manufactured MDF boards. According to the test results, the air permeability of MDF boards were decreased. The mass diffusivity of board was not affected. Kalaycıoğlu et al. (2012) investigated recent developments in cement composites and wood wool. Mechanical, physical, and technological properties, as well as production, classifications and application of wood wool cement boards were considered.

Salari et al. (2012) have produced the oriented strand board (OSB) board that added nanoclays and layered silicates as adhesive reinforcement with 0%, 2%, 4%, 6%, and 8% mixing ratios with low-quality paulownia wood. They researched the chemical properties of paulownia wood, as well as the physical, mechanical, and formaldehyde gas emission properties of the resulting OSB boards. It was found that the mechanical properties of the OSB boards were increased, whereas physical properties (ThS, 24 h) and (WA, 24 h) were negatively impacted and formaldehyde emission gas decreased. İstek et al. (2013) researched combustion properties of medium-density fiberboards (MDF) coated by a mixture of water, binder, calcite, and various fire retardants coatings (borax, boric acid, zinc borate). According to the tests of combustion properties of coated MDF boards with fire retardants coatings, boric acid showed the highest inflexibility followed by borax and zinc borate, respectively. Taghiyari and Nouri (2015) investigated the influence of nano-wollastonite (5, 10, 15, and 20 g/kg dry weight basis of wood fibers) on physical and mechanical properties of MDF. According to the results, nano-wollastonite material contents of 10% and 15% were optimal.

Bao et al. (2016) manufactured zeolite composite filler board using a mixture of natural zeolite powder as a binder cement within wastepaper pulp. Zeolite composite filter was found to be suitable for use as a novel filter medium for the simultaneous removal of nitrogen and phosphorus in biological vent filters (organic carbon, nitrogen, ammonia, nitrogen, phosphorus) for improved wastewater treatment. Kalantarifard et al. (2016) produced modified zeolite in their research. The formaldehyde retention capacities of the modified zeolite with the natural zeolite were compared using test results. According to this test results, the formaldehyde adsorption onto the modified clinoptilolite zeolite increased about 1.6 times compared to the commercial clinoptilolite specimen.

Özdemir and Tutus (2016) studied the effects on the fire properties of particleboard after applying a coating with zeolite in combination with various fire retardants. Four different chemicals (boric acid, borax, dolomite, and melamine) were used within calcite. These compounds were added at levels of 1%, 3%, and 5% based on the oven-dry weight of calcite. According to the research results, boric acid coatings showed better thermal stability than other borax, dolomite, melamine. Taghiyari et al. (2016) produced MDF from wollastonite fibers, camel-thorn, and wood fibers. Wollastonite fibers with the further addition of camel-thorn fibers improved most of the physical and mechanical properties of MDFs. Wang et al. (2016) produced vermiculite-added MDF boards, which exhibited the effect of vermiculite on the flammability, modulus of rupture, and modulus of elasticity properties of boards. According to this research, the addition of expanded vermiculite increased the limiting oxygen index and fire retardant of MDFs and decreased modulus of rupture and modulus of elasticity properties of boards.

Akgül et al. (2017) produced agricultural-based lignocellulosic biomass (using okra stalks, tobacco stalks, hazelnut shells, walnut hulls, and pinecones) during MDF production; and they investigated the physical and mechanical properties of MDF. Funk et al. (2017) studied the use of a new type of a functional inorganic additive to reduce formaldehyde emissions from particleboards. According to this investigation, the diatomaceous earth additions insignificantly decreased bending resistance and internal bond properties of particleboards. Diatomaceous earth inorganic additive in particleboards reduced free formaldehyde releases. Özdemir and Ayaz (2017) investigated the effect on the fire resistance of MDF panels when using ammonium polyphosphate and boric acid as surface-coating materials. According to this investigation, as a consequence of calcite coating and the increase of ammonium polyphosphate and boric acid usage, the resistance to fire was increased. Dönmez Çavdar et al. (2019) examined mechanical, thermal, fire and morphological properties of thermoplastic composites filled with fire retardants (mono ammonium phosphate, ammonium zeolite, natural zeolite) and microcrystalline cellulose. According to the investigation, the use of fire retardants (mono ammonium phosphate, ammonium zeolite, natural zeolite) advanced morphological, thermal, and reaction of fire of the microcrystalline cellulose filled high-density polyethylene composites.

Da Silva et al. (2019) investigated the use of resin with zinc oxide (ZnO) nanoparticles for the purpose of produce boards added urea-formaldehyde and melamine-formaldehyde (0.5% and 1% ZnO) for the inhibition of aggressive fungi during the use of MDF in humid environments. As the usage amount of zinc oxide was increased in the MDF boards, the physical properties of performances of the boards got worse. The best result were obtained in MDF boards with 0.5% ZnO nanoparticles and melamine-formaldehyde resin. Solt et al. (2019) examined individual adhesive systems based on preferred product processes, formaldehyde emission parameters, and technological parameters suitable for particleboard production. According to the research, synthetic and renewable-based adhesives (without formaldehyde) have been evaluated in the production of wood-based products (product and process-related). Wang et al. (2019) investigated the effects of alkali and acid treatments on structure, hydrophilicity/hydrophobicity of natural zeolite. According to the studies, water vapour absorption on the alkali and acid-used zeolites was gradually reduced with increasing SiO2/Al2O3 ratio, which was consistent with the rise of hydrophobicity and fall of hydrophilicity for the specimen. This method was found to be a very effective and simple way to regulate natural zeolite.

Özdemir (2019) produced three different minerals (sepiolite, dolomite, and perlite) using five different ratios (3%, 6%, 9%, 12%, and 15%) according to the oven-dry wood fiber weight. According to investigate results, these minerals decreased both physical and mechanical properties of MDF, but a positive effect was observed on combustion resistance within all of the minerals. Dönmez Çavdar (2020) manufactured medium density fiberboard within zeolite Y zeolite, at contents of 4%, 8%, and 12%, based on dry resin amount, as filler fiberboard production with urea formaldehyde and melamine formaldehyde. According to findings in this research, zeolite contributed to both the mechanical properties and dimensional stability of the MDF boards. Besides, melamine-formaldehyde showed higher performance than urea-formaldehyde.

The above research investigated the use of zeolite in place of some of the lignocellulosic raw materials. There are millions of tons of the zeolite reserves in Turkey. The aim of the present study was to determine the effect of zeolite on the physical strength and mechanical resistance of the boards and formaldehyde scavenger in MDF board production. Formaldehyde scavenger is especially important to both the wood-based panel manufacturer and the wood-based panel consumer. The California Air Resources Board (CARB 2007) adopted a regulation to limit the amount of formaldehyde emitted from composite wood products. According to the CARB (2007), composite wood product formaldehyde values are determined via formaldehyde emission limits for medium-density fiberboard (MDF) ≤ 8 mm and finished goods made with these materials.

EXPERIMENTAL

Materials

Beech (Fagus orientalis Lipsky) from forests in Turkey’s Kastamonu province, oak (Quercus robur L.) from Turkey’s West Black Sea region, and pine (Pinus sylvestris L.) from Turkey’s Bolu province were supplied for the production of MDF.

Glue

Urea (U) formaldehyde (F) was produced by Kastamonu Glue Factory (Kastamonu, Turkey). Properties of the glue were as follows: solids 62 ± 1; the mole ratio of U/F for UF was 1.17; the density (at 20 °C) was 1.227 g cm–³; the viscosity (250C cps) was 20 to 35 s; the gel time (100 °C) (20% (NH4)2SO4) was 20 to 45 s; the pH was 7 to 8.5; the free formaldehyde was 0.20% max; the methylol groups were 12 to 15%; and the shelf life was 75 days.

Hardener

The ammonium sulphate was supplied from a private company in Gebze, Turkey. The catalyst used was a 20% ammonium sulphate (NH4)2SO4 solution with 20% solution properties, a density of 0.95 gcm–³, and a pH of 6.5.

Paraffin

The paraffin used was a dirty white liquid. Its solid content was 60%, and it had a pH of 9 to 10, viscosity of 13 to 23 s, and a density of 0.96 g/cm3. The liquid paraffin was supplied from Mercan Chemistry in Denizli, Turkey.

Zeolite

The natural zeolite–clinoptilolite properties were as follows: type (chemical formula: Ca, K2,Na2,Mg)4Al8Si40O96⋅24H2O), effective diameter of pore was 4 A°; the melting point was 1300 °C, and the bulk density was 0.6 to 0.8 g cm–³. The zeolite–clinoptilolite size was 275 μm. Natural zeolites were supplied by the Rota Mining Company (İzmir, Turkey).

Product parameters

In this study, hard and soft wood fibers were used. In Table 1, F designates the consumed wood fibers for boards sized 1 m3, while FA (3%), FB (6%), and FC (9%) designate the consumed zeolite for 1 m3 board. The formulation of the raw materials in the experimental MDF boards were presented in Table 1. This table shows the addition of zeolite and other chemicals to lignocellulosic biomass.

Table 1. Experimental Design of MDF

F: fiber content, L: lignocellulosic, UF: urea formaldehyde, AS: ammonium sulphate, A, B, C: zeolite

Boards Manufacturing

Firstly, the hardwood and softwood species were brought from Turkey’s Western Black Sea forests. In the production of MDF, beech, oak, and pine fibers were used as raw material. Wood fiber contained 70% hardwood and 30% softwood fibers, then chopped and stored one-by-one in silos according to the production parameters given in Table 1.

Chips used in fiber production (supplied from the MDF production line, Kastamonu Integrated Wood Inc., Kastamonu, Turkey) were cooked for 3.5 min in an Andritz defibrillator (2008 model; Andritz AG, Graz, Austria) at 190 °C with a vapor pressure of 8 bar. The fibers were dried to a moisture content of 12%. Zeolite was prepared in individual containers with the intention to use zeolite instead of lignocellulosic fibers. After that, lignocellulosic fibers were prepared as three different proportions and control boards incorporating the zeolite (3%, 6%, and 9%.) The resins and other chemicals were prepared in the glue plant. Subsequently, these chemicals, after having been prepared in the tank, were mixed with each other, and this mixture was sent to the blowline. The adhesive ratio was 11 wt% based on oven-dried wood fibers. Ammonium sulphate as a hardener was used at 0.72 wt% based on UF resins. The paraffin was added as 1.8 wt% based on each adhesive to raise the water-resistance of the MDF panels during the production. Natural zeolites were used as filler based on oven-dried adhesive up to 11 wt%. The experimental design of the study consisted of one type of adhesive UF and one type of natural zeolite.

The zeolite was added to the fibers. After that, the fibers and zeolite were mixed by hand. Homogeneous distributions between the wood fibers of the 275 μm-sized zeolites were obtained. The mat was created from the mixed fibers. The MDF boards were produced in a single layer press (Siempelkamp laboratory single hot press model; Siempelkamp, Krefeld, Germany). The special features of the hot single press were mat dimensions of 500 × 490 mm at a pressure of 32 kg cm–². The pressing parameters were 190 °C, 32 kg.m-2, and 280 s. The dimensions of the boards were 500 × 490 × 14 mm. In a study of MDF production, Xing et al. (2006) showed that wood acidity has a direct effect on the gel time and curing behavior of the UF resins. But in the present study, the amount of zeolite had no notable effect on the curing of the glue. After production of the boards, they were left to rest pre-storage for 5 days. In the raw board storage area, the panels were acclimatized. The moisture level was adjusted to 4.5%. After this process, the top and bottom surfaces of panels were sanded with 40, 80, 120-grit sandpaper. Finally, all boards were conditioned at 20 ± 2 °C and 65 ± 5% relative humidity according to ISO 554 (1976).

The manufacturing process of MDF boards is shown by the flowsheet in Fig. 1.

Fig. 1. Flowsheet describing the manufacture process of MDF boards

Test Methods

Physical testing

The standard EN 622-1 (2003) specifies the requirements for some properties that are common for all uncoated fiberboard types. Physical properties were tested according to EN 622-5 (2009), and the density of MDF sheets was tested according to EN 323 (1993). The moisture content of the boards was tested according to the EN 322 (1999). The thickness swelling (ThS, 24 h) and water absorption (WA, 24 h) properties were carried out according to the standard EN-317 (1993). Sample thickness and length of specimens were measured by using a digital micrometer and caliber with 0.01-mm gradients.

Mechanical testing

Cutting and sizing according to standards ISO 9424 (2003) and TS EN 326-1 (1999) were performed to specify the properties of MDF sheets with zeolite. These tests were: bending strength EN 310 (1993), modulus of elasticity EN 310 (1993), and internal bond EN 319 (1993).

A universal tester (Imal Mobiltemp shc 22, model IB700; San Damaso, Italy) was used to assess mechanical properties.

Formaldehyde gas analysis

Formaldehyde gas emission analysis of control MDF boards and zeolite-added MDF boards were tested according to EN 717-2 (1994), which determines the formaldehyde release at the accelerated condition from wood-based panels.

According to the gas analysis method EN 717-2 (1994), the test piece dimensions were 400 mm × 50 mm × 14 mm board thickness. The sample was placed in a 4-L cylindrical chamber with controlled temperature (60 ± 0.5 °C), relative humidity (RH ≤ 3%), airflow (60 ± 3 L h-1), and with an overpressure of 1000 to 1200 Pa. Air was continuously passed through the chamber at 1 L min-1 over the test sample. The sample’s edge was sealed with self-adhesive aluminum tape before testing.

The air with the formaldehyde emitted by the test sample was fed from the measuring chamber into wash bottles with water in which the formaldehyde was absorbed for a period of 1 h each. Afterwards, the formaldehyde content was spectrophotometrically determined by means of the acetylacetone method at a wavelength of 412 nm.

Statistical Analysis

A one-way analysis of variance (ANOVA) was performed to test for differences among different board types (F, FA, FB, and FC) using mean values of all the measured variables.

Linear regression was applied to research the relationship between physical tests, mechanical tests, formaldehyde emissions, and the content of zeolite in the tested boards (F, FA, FB, and FC). To detect differences in ANOVA, differences were investigated with the Duncan test, one of the Post-hoc tests. Results were considered statistically significant at p < 0.05.

As a result of these tests, SPSS 22 software was used to obtain Duncan results and were evaluated by statistical programs (SSPS 22 Software, IBM Corporation, Armonk, NY, USA).

RESULTS AND DISCUSSION

Appearance

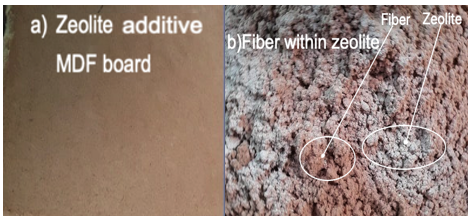

According to this study, the distribution of the inorganic zeolite mineral in the wood fibers and the MDF boards produced in a single layer press are shown in Fig. 2.

Fig. 2. Distribution of zeolite during board manufacture: (a) MDF board, (b) fiber within zeolite additive

Table 2. Density and Moisture Board Percent of the Fiberboards Made from Zeolite-added Fiberboards and Control Fiberboard

x: The average value of the samples, 95% confidence interval for the average ANOVA; a, b, c, and d values with the same letter are not significantly different (Duncan’s test)

Physical Properties

Density and moisture board percentages of the fiberboards made from zeolite-added fiber and control fiberboards are shown in Table 2.

Results of the density test

There was no significant difference between densities for zeolite-added panels F, FA, FB, and FC according to this statistical analysis result (Table 2).

The results of MDF densities remained in the range 0.65 < MDF < 0.80 g cm–³ according to the standard EN 622-5 (2009). Thus, there was no significant difference in results. The desired ratio of the lowest fiberboard density to the average fiberboard density was between 0.85 and 0.95. The efficiency of process parameters and applied hot press diagram in MDF production affected the optimum homogenous density of the fiberboard.

Results of the moisture content test

There was a significant difference between F, FA, FB, and FC according to the percentage of moisture content in the boards (Table 2). The ratio for this test was 8.3% for FA relative to F and was thus the percentage of moisture content of boards for FA. Similarly, the ratio was 18.25% for FB relative to F. Therefore, the percentage increased for FB. The ratio was 8.3% for FC relative to F. Thus, the percentage of moisture content increased for FC.

Results of the 24-h thickness swelling test

There was a significant difference between F, FA, FB, and FC with respect to the percentage change of ThS in the boards (Table 2). The ratio for this test was 6.87% for FA according to R. Therefore, the percentage of ThS decreased for FA. Similarly, the ratio was 8.84% for FB relative to F. Therefore, the percentage increased for FB. The ratio was 17.25% for FC relative to F. Therefore, the percentage of ThS increased for FC. The ThS properties of the test boards decreased as the amount of zeolite filler usage increased (Özdemir 2019).

Results of the 24-h water absorption test

There was a significant difference between F, FA, FB, and FC with respect to the percentage of WA of boards. The results are described in Table 2. The ratio for this test was 2.72% for FA relative to F. Therefore, the percentage of ThS increased for FA. Similarly, the ratio was 16.09% for FB relative to F. Therefore, the percentage increased for FB. The ratio was 17.25% for FC relative to F. Therefore, the percentage of ThS increased for FC. The ThS properties of the test boards decreased as the amount of zeolite filler increased (Özdemir 2019).

Mechanical Properties

The results of ANOVA and Duncan mean separation test for bending strength, modulus elasticity, and internal bond of the fiberboards made from zeolite-added fiber and control fiberboards are shown in Table 3.

Table 3. Mechanical Properties of the Zeolite-added Fiberboards and Control Fiberboard

x is the average value of the samples; 95% confidence interval for the average ANOVA; a, b, c, and d values with the same letter are not significantly different (Duncan’s test)

Results of the bending strength test (MOR)

There was no significant difference between F, FA, FB, and FC with respect to the percentage of bending strength test (Table 3). The ratio for this test was 1.66% for FA relative to F. Therefore, the percentage of bending strength somewhat increased for FA. Similarly, the ratio was 1.62% for FB relative to F. Therefore, the percentage of bending strength somewhat increased for FB. The ratio was 1.05% for FC relative to F. Therefore, the percentage of bending strength increased a small amount for FC. The use of zeolite as an additive adversely affected the mechanical properties. Significant decreases in bending strength values were resolved due to the increase in added zeolite. This negative effect increased with the increased use of zeolite.

The increase in the zeolite content reduced the interconnection between fibers, causing MOR and MOE resistance to be adversely affected (Özdemir 2019). Ozyhar et al. (2020) performed a study of ground calcium carbonate (GCC) filler addition on MDF production in which the data of the 550, 700, and 850 density boards showed that the MOR properties decreased as the filling amount increased.

The results of the internal bond (IB) test

There was a significant difference between (F, FA), and (FB, FC)) according to the percentage of IB test. The results are described in Table 3. The ratio for this test was 6.02% for FA relative to F. Therefore, the percentage of the internal bond decreased for FA. Similarly, the ratio was 14.24% for FB relative to FB. Therefore, the percentage of the internal bond decreased for FB. The ratio was 18.48% for FC relative to F. Therefore, the percentage of the internal bond decreased for FC. Zeolite mineral type and usage rate had a negative effect on IB values (Özdemir 2019). As the use rate of zeolite increased, the same results in the IB values continued. Ozyhar et al. (2020) investigated the effect of GCC filler addition on MDF production. According to the research, the value of the 550 and 700 density boards’ mechanical properties showed that the IB properties decreased as the mineral amount increased. Zeolites are applied in many fields as catalysts, molecular sieves, sorptive agents, ion exchange materials, etc. (Lee et al. 1995a,b). Buttersack et al (1997) investigated the pore size of any particular zeolite was unique and different from each other. According to the research, when zeolite is added to a matrix system, the polymer chains can penetrate the small pores of zeolite. The surface of the pore of zeolite is adsorbed the metal ions. It can be in the pore of zeolite. Zeolite may improve the wettability between the organic materials and inorganic materials and it can affect the mechanical properties.

Results of the MOE test

There was an insignificant difference between F, FA, FB, and FC with respect to the percentage of modulus elasticity test (Table 3). The ratio for this test was 2.09% for FA relative to F. Therefore, the percentage of modulus elasticity increased somewhat for FA. Similarly, the ratio was 1.20% for FB relative to F. Therefore, the percentage of modulus elasticity somewhat decreased for FB. The ratio was 0.30% for FC relative to F. Therefore, the percentage of modulus elasticity increased minimally for FC. Zeolite increased the contact surface between the fibers and the glue, and it also created a barrier effect. It prevented the glue from being placed in the gaps and reduced the mechanical locking of the fiber and glue (Ayrılmış et al. 2017). The intermolecular force and the sliding rubbing force between the constituents of the MDF decreased rapidly, resulting in a reduced MOR and MOE (Wang et al. 2016). As the use rate of zeolite increased, the minimal reduction result in the modulus elasticity values continued.

Dönmez Çavdar (2020) produced MDFs within zeolite Y and natural zeolite. Both the mechanical properties increased, and dimensional stability of the zeolite-added samples increased. According to these results, zeolites are crystalline aluminosilicate minerals that have high specific surface areas. According to the research of Özdemir (2019), as minerals (sepiolite, dolomite, and perlite) usage rate increased in MDF production, there were negative effects on physical and mechanical properties. Camlibel and Akgül (2020) used calcite inorganic minerals (3%, 6%, 9%) in place of wood fibers for MDF production. As the amount of calcite minerals was increased in medium density fiberboards, the physical properties (ThS, 24 h; WA, 24 h) of boards deteriorated. But according to the test results, the mechanical properties of MDF boards with 6% calcite additive showed better performance than the control board. Calcite usage ratios (3%, 6%) are recommended for MDF production. Thus, they explained the level of calcite inorganic minerals that can be used in MDF production. The test results of this study were consistent with similar studies using different kind inorganic minerals.

Formaldehyde Emission Gas Analysis

The EN-717-2 (2004) standard was applied for the formaldehyde gas analysis of MDF fiberboards. The results were presented in Table 4.

Table 4. Formaldehyde Gas Analysis of MDF Boards

x is the average value of the samples; 95% confidence interval for the average ANOVA; a, b, c, and d values with the same letter are not significantly different (Duncan’s test)

There was a significant difference between F, FA, FB, and FC with respect to the percentage of gas analysis (Table 4). The ratio for this test was 84.8% for FA relative to F. Therefore, the percentage of the formaldehyde gas emission decreased for FA. Similarly, the ratio was 284.3% for FB relative to F. Therefore, the percentage of the formaldehyde gas emission decreased much more for FB. The ratio was 221.2% for FC relative to F. Therefore, the highest percentage of the formaldehyde gas emission reduced in FC.

Clinoptilolite zeolite is effective for removal of formaldehyde from the air stream (Rashidi et al. 2018). Therefore, zeolite and its derivatives are used as formaldehyde scavengers. Wu et al. (2016) developed a novel zeolite thin film-coated spherical end face fiber sensor for detecting formaldehyde. Due to the physical and chemical structure of the zeolite, its formaldehyde scavenger ability has been utilized.

CONCLUSIONS

- Adding zeolite to MDF resulted in a non-significant decrease in board density and moisture content in boards containing 3%, 6%, and 9% of zeolite, as compared with boards without zeolite. A significant reduction of the modulus of rupture and a non-significant increase of the modulus of elasticity when adding 3% zeolite was observed. Also observed was a non-significant decrease of the internal bond of boards containing 3% and 6% of zeolite, compared with boards without zeolite minerals, as well as a significant internal bond reduction for panels with 9% zeolite content, as compared with the reference panels.

- A significant decrease in formaldehyde emissions by 84.8% was observed in boards with 3% zeolite, compared with boards without zeolite. A significant decrease in formaldehyde emissions by 284.3% was seen in boards with 6% zeolite compared with boards without zeolite. A significant decrease in formaldehyde emissions by 331.2% was seen in boards with 9% zeolite, as compared with boards without zeolite.

- The reason for these observations was the amount of zeolite used and its geometrical structure. As the amount of zeolite increased in the MDF, the formaldehyde emission of the board decreased. Formaldehyde gas emission decreased as the amount of zeolite increased in MDF boards. According to this study, zeolite minerals have an important formaldehyde gas scavenging ability.

- Legal arrangements were made with formaldehyde gas emission in wood-based panels. The CARB (2007) standard is related to this subject. Formaldehyde gas emission limit value was reduced in wood-based board products according to CARB (2007) standard. The formaldehyde emissions in the MDF boards were notably reduced by zeolite. Users consistently demand lower formaldehyde emissions in the MDF boards; thus MDF with zeolite is suggested as a means to lower formaldehyde emissions.

ACKNOWLEDGMENTS

I would like to thank Enüs KOÇ, the director of Kastamonu Integrated Wood Inc., and Aziz Biçer, who is Kastamonu’s research and development manager.

REFERENCES CITED

Akgül, M., Uner, B., Çamlibel, O., and Ayata, Ü. (2017). “Manufacture of medium density fiberboard (MDF) panels from agribased lignocellulosic Biomass,” Wood Research 62(4), 615-624.

Ayrılmış, N., Güleç, T., Peşman, E., and Kaymakcı, A. (2017). “Potential use of cotton dust as filler in the production of thermoplastic composites,” Journal of Composite Materials 51(30), 4147-4155. DOI: 10.1177/0021998317698750

Bao, T., Chen, T., Wille, M. L., Chen, D., Yu, S., Bian, J., Qing, C., Wu, W., and Frost, R. L. (2016). “Production of zeolite composite filters using waste paper pulp as slow release carbon source and performance investigation in a biological aerated filter,” Journal of Water Process Engineering 9, 38-46. DOI: 10.1016/j.jwpe.2015.11.009

Boran, S., Usta, M., and Gümüşkaya, E. (2011). “Decreasing formaldehyde emission from medium density fiberboard panels produced by adding different amine compounds to urea formaldehyde resin,” International Journal of Adhesion and Adhesives 31(7), 674-678. DOI: 10.1016/j.ijadhadh.2011.06.011

Buttersack, C., Fornefett, I., Mahrholz, J., and Buchholz, K. (1997). “Specific adsorption from aqueous phase on apolar zeolites,” Studies in Surface Science and Catalysis, 105, 1723-1730. DOI: 10.1016/S0167-2991(97)80636-2

California Air Resources Board (2007). “Proposed airborne toxic control measure (ACTM) to reduce formaldehyde Hyde emission from composite wood productions,” (https://ww3.arb.ca.gov/toxics/compwood/retailersbrochure.pdf), Accessed 06 January 2020.

Camlibel, O., and Akgul, M. (2020). “Mechanical and physical properties of medium density fibreboard with calcite additive,” Wood Research 65(2), 231-244.

Da Silva, A. P. S., Ferreira, B. S., Favarim, H. R., Silva, M. F. F., Silva, J. V. F., Azambuja, M. A., and Campos, C. I. (2019). “Physical properties of medium density fiberboard produced with the addition of ZnO nanoparticles,” BioResources 14(1), 1618-1625. DOI: 10.15376/biores.14.1.1618-1625

Dönmez Çavdar, A. (2020). “Effect of zeolite filler in medium density fiberboards bonded with urea formaldehyde and melamine formaldehyde resins,” Journal of Building Engineering 27, Article ID 101000. DOI: 10.1016/j.jobe.2019.101000

Dönmez Çavdar, A., Boran Torun, S., Ertas, M., and Mengeloglu, F. (2019). “Ammonium zeolite and ammonium phosphate applied as fire retardants for microcrystalline cellulose filled thermoplastic composites,” Fire Safety Journal 107, 202-209. DOI: 10.1016/j.firesaf.2018.11.008

EN 310 (1993). “Wood-based panels—Determination of modulus of elasticity in bending and of bending strength,” European Committee for Standardization, Brussels, Belgium.

EN 317 (1993). “Particleboards and fiberboards—Determination of swelling in thickness after immersion in water,” European Committee for Standardization, Brussels, Belgium.

EN 319 (1993). “Particleboards and fibreboards—Determination of tensile strength perpendicular to the plane of the board,” European Committee for Standardization, Brussels, Belgium.

EN 322 (1993). “Wood-based panels—Determination of moisture content,” European Committee for Standardization, Brussels, Belgium.

EN 323 (1993). “Wood-based panels—Determination of density,” European Committee for Standardization, Brussels, Belgium.

EN 622-1 (2003). “Fibreboards—Specifications—Part 1: General requirements,” European Committee for Standardization, Brussels, Belgium.

EN 622-5 (2009). “Fibreboards—Specifications—Part 5: Requirements for dry process boards (MDF),” European Committee for Standardization, Brussels, Belgium.

EN 717-2 (1994). “Wood-based panels – Determination of formaldehyde release – Part 2: Formaldehyde release by the gas analysis method,” European Committee for Standardization, Brussels, Belgium.

Funk, M., Wimmer, R., and Adamopoulos, S. (2017). “Diatomaceous earth as an inorganic additive to reduce formaldehyde emissions from particleboards,” Wood Material Science & Engineering 12(2), 92-97. DOI: 10.1080/17480272.2015.1040066

ISO 554 (1976). “Standard atmospheres for conditioning and/or testing—Specifications,” International Organization for Standardization, Geneva, Switzerland.

ISO 9424 (2003). “Wood-based panels—Determination of dimensions of test pieces,” International Organization for Standardization, Geneva, Switzerland.

İstek, A., Aydemir, D., and Eroǧlu, H. (2013). “Combustion properties of medium-density fiberboards coated by a mixture of calcite and various fire retardants,” Turkish Journal of Agricultural and Forestry 37, 642-648. DOI: 10.3906/tar-1206-37

Kalantarifard, A., Gon, J. G., and Yang, G. S. (2016). “Formaldehyde adsorption into clinoptilolite zeolite modified with the addition of rich materials and desorption performance using microwave heating,” Terrestrial Atmospheric and Oceanic Sciences 27(6), 865-875. DOI: 10.3319/TAO.2016.05.28.01(TT)

Kalaycıoğlu, H., Yel, H., and Dönmez Çavdar, A. (2012). “Wood wool cement boards and its applications,” Kastamonu Üniversitesi Orman Fakültesi Dergisi 12(1), 122-133.

Lee, J. Y., Shim, M. J., and Kim, S. W. (1995a). Proc. IUMRS-ICA’95, Seoul, p. 711.

Lee, H, K., Shim, M.J., Lee, J.S., and Kim, S, W. (1995b). ECOM-CONF’95, China, p. 495.

Lim, H. M., Jung, J. S., Kim, B. Y., and Lee, S. H. (2006). “Application of zeolites on cellulose fiber,” Key Engineering Materials 317-318, 777-780. DOI: 10.4028/www.scientific.net/KEM.317-318.777

Mishra, M., and Jain, S. K. (2011). “Properties and applications of zeolites: A review,” Proceedings of the National Academy of Sciences, India – Section B: Biological Sciences 81, 250-259.

Özdemir, F. (2019). “Effect of mineral materials content as filler in medium density fiberboard,” BioResources 14(1), 2277-2286. DOI: 10.15376/biores.14.1.2277-2286

Özdemir, F., and Ayaz, A. (2017). “Investigation of the effect on combustion resistance of ammonium polyphosphate and boric acid chemicals added to surface coating,” Kastamonu Üniversitesi Orman Fakültesi Dergisi 17(2), 290-297. DOI: 10.17475/kastorman.310967

Özdemir, F., and Tutus, A. (2016). “Effects of coating with calcite together with various fire retardants on the fire properties of particleboard,” BioResources 11(3), 6407-6415. DOI: 10.15376/biores.11.3.6407-6415

Ozyhar, T., Depnering, T., Ridgway, C., Welker, M., Schoelkopf, J., Mayer, I., and Thoemen, H. (2020). “Utilization of inorganic mineral filler material as partial replacement for wood fiber in medium density fiberboard (MDF) and its effect on material properties,” European Journal of Wood and Wood Products 78, 75-84. DOI: 10.1007/s00107-019-01480-1

Rashidi, R., Yousefinejad, S., and Mokarami, H. (2018). “Catalytic ozonation process using CuO/clinoptilolite zeolite for the removal of formaldehyde from the air stream,” International Journal of Environmental Science and Technology 16, 6629-6636.

Salari, A., Tabarsa, T., Khazaeian, A., and Saraeian, A. (2012). “Effect of nanoclay on some applied properties of oriented strand board (OSB) made from underutilized low quality paulownia (Paulownia fortunei) wood,” Journal of Wood Science 58(6), 513-524. DOI: 10.1007/s10086-012-1278-2

Solt, P., Konnerth, J., Gindl-Altmutter, W., Kantner, W., Moser, J., Mitter, R., and Van Herwijnen, H. W. G. (2019). “Technological performance of formaldehyde-free adhesive alternatives for particleboard industry,” International Journal of Adhesion and Adhesives 94, 99-131. DOI: 10.1016/j.ijadhadh.2019.04.007

Taghiyari, H. R., and Nouri, P. (2015). “Effects of nano-wollastonite on physical and mechanical properties of medium-density fiberboard,” Maderas. Ciencia y Tecnología 17(4), 833-842. DOI: 10.4067/S0718-221X2015005000072

Taghiyari, H. R., Mohammad-Panah, B., and Morrell, J. J. (2016). “Effects of wollastonite on the properties of medium-density fiberboard (MDF) made from wood fibers and camel-thorn,” Maderas. Ciencia y Tecnología 18(1), 157-166. DOI: 10.4067/S0718-221X2016005000016

TS EN 326-1 (1999). “Wood-based panels—Sampling, cutting and inspection—Part 1: Sampling test pieces and expression of test results,” Turkish Standards Institution, Ankara, Turkey.

Wang, C., Leng, S., Guo, H., Cao, L., and Huang, J. (2019). “Acid and alkali treatments for regulation of hydrophilicity/hydrophobicity of natural zeolite,” Applied Surface Science 478, 319-326. DOI: 10.1016/j.apsusc.2019.01.263

Wang, J., Wang, F., Gao, Z., Zheng, M., and Sun, J. (2016). “Flame retardant medium-density fiberboard with expanded vermiculite,” Bioresources 11(3), 6940-6947. DOI: 10.15376/biores.11.3. 6940-6947

Wu, B., Zhao, C., and Kang, J. (2016). Formaldehyde sensor based on zeolite thin film-coated spherical end-face fiber, 15th International Conference on Optical Communications and Networks (ICOCN). Sep. 24-27, 2016 in Hangzhou, China. DOI: 10.1109/ICOCN37935.2016.

Xing, C., Zhang, S. Y., Deng, J., Riedl, B., and Cloutier, A. (2006). “Medium-density fiberboard performance as affected by wood fiber acidity, bulk density, and size distribution,” Wood Science and Technology 40, 637-646. DOI: 10.1007/s00226-006-0076-7

Zahedsheijani, R., Gholamiyan, H., Tarmian, A., and Yousefi, H. (2011). “Mass transfer in medium density fiberboard (MDF) modified by Na+ montmorillonite (Na+Mmt) nanoclay,” Maderas. Ciencia y Tecnología 13(2), 163-172. DOI: 10.4067/S0718-221X2011000200004

Article submitted: May 19, 2020; Peer review completed: July 19, 2020; Revised version received: August 8, 2020; Updated revised version received and accepted: August 26, 2020; Published: September 1, 2020.

DOI: 10.15376/biores.15.4.7918-7932