Abstract

The catalytic conversion of biomass into high-value chemicals, such as furan derivatives, from 5-hydroxymethylfurfural (HMF) holds significant importance. In this study, a bifunctional catalyst prepared from phosphomolybdic acid (PMA) and chitosan was developed for the one-pot synthesis of 2,5-diformylfuran (DFF) from fructose. This approach offered the advantage of bypassing the solvent consumption and cost associated with HMF separation and purification for DFF production. The catalytic activity of the prepared catalyst primarily originated from the loaded PMA. Under optimized reaction conditions, the catalyst achieved a DFF yield of approximately 60% after a 6-h reaction at 150 °C or a 1-h reaction at 170 °C. Moreover, the catalyst exhibited good stability and reusability. These results highlight the potential of the bifunctional catalyst for efficient and cost-effective conversion of fructose into DFF, enabling practical applications in the production of valuable chemicals from bioresources.

Download PDF

Full Article

One-Pot Synthesis of 2,5-Diformylfuran from Fructose using a Bifunctional Catalyst Derived from Phosphomolybdic Acid and Chitosan

Davidraj Johnravindar,a Mian Laiq Ur Rehman,a Peixin Wang,a Reeti Kumar,a and Jun Zhao a,b,*

The catalytic conversion of biomass into high-value chemicals, such as furan derivatives, from 5-hydroxymethylfurfural (HMF) holds significant importance. In this study, a bifunctional catalyst prepared from phosphomolybdic acid (PMA) and chitosan was developed for the one-pot synthesis of 2,5-diformylfuran (DFF) from fructose. This approach offered the advantage of bypassing the solvent consumption and cost associated with HMF separation and purification for DFF production. The catalytic activity of the prepared catalyst primarily originated from the loaded PMA. Under optimized reaction conditions, the catalyst achieved a DFF yield of approximately 60% after a 6-h reaction at 150 °C or a 1-h reaction at 170 °C. Moreover, the catalyst exhibited good stability and reusability. These results highlight the potential of the bifunctional catalyst for efficient and cost-effective conversion of fructose into DFF, enabling practical applications in the production of valuable chemicals from bioresources.

DOI: 10.15376/biores.19.2.2948-2966

Keywords: Fructose; 5-Hydroxymethylfurfural; 2,5-Diformylfuran; Phosphomolybdic acid; Chitosan

Contact information: a: Department of Biology, Hong Kong Baptist University, Hong Kong SAR; b: Institute of Advanced Materials, Hong Kong Baptist University, Hong Kong SAR;

* Corresponding author: zhaojun@hkbu.edu.hk

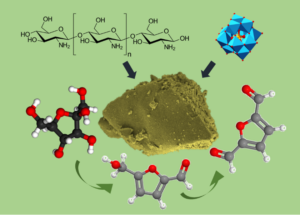

GRAPHICAL ABSTRACT

INTRODUCTION

The utilization of biomass feedstocks to produce high-value chemicals offers a promising solution to mitigate environmental pollution and high carbon emissions associated with petroleum-based industries. The conversion of biomass into value-added chemicals enables the sustainable utilization of renewable resources, reduces dependence on fossil fuels, and contributes to the development of a circular economy (Wang and Tester 2023). Among various biomass conversion reactions, the production of various furan derivatives using biomass-based 5-hydroxymethylfurfural (HMF) as a platform chemical has garnered significant attention for the valorization of biomass resources. The HMF, derived from the dehydration of fructose, possesses active chemical properties that make it an excellent precursor for the synthesis of a wide range of furan-based compounds (Rosatella et al. 2011). These derivatives find extensive applications across various industries, including plastics, pharmaceuticals, and agrochemicals.

One of the most promising derivatives of HMF is the 2,5-diformylfuran (DFF), which can be synthesized through the oxidation of HMF. The DFF serves as a key intermediate for the synthesis of a plethora of compounds, including but not limited to, polymers, fine chemicals, and even potential biofuels (Cajnko et al. 2020; Slak et al. 2022). The synthesis of DFF from HMF predominantly relies on the selective oxidation of the hydroxymethyl group of HMF and various catalysts such as VOPO4.2H2O (Carlini et al. 2005), Mn-Cs (Solanki et al. 2023), Bi2WO6/mpg–C3N4 (Cheng et al. 2021), V/Mn-1 (Zhu et al. 2021), α-MnO2 (Yu et al. 2021), MgO.MnO2.CeO2 (Nocito et al. 2018), NH4·V3O8/Fe3O4 (Lai et al. 2019), P−C−N-5-800 (Zhang et al. 2020), and NC-950 (Ren et al. 2018). These catalysts have been found to display good performance. DFF synthesis via catalytic oxidation of HMF can achieve significant yields, yet the intrinsic reactivity of HMF leads to challenging separation and purification processes. These additional steps contribute to elevated costs, rendering economically unattractive the industrial-scale production of DFF from pure HMF (Trapasso et al. 2022). Moreover, this process is environmentally detrimental due to the extensive use of organic solvents.

The direct production of DFF from ubiquitously available low-cost carbohydrates can overcome these challenges. HMF can be conveniently synthesized through the dehydration of fructose. If HMF could be transformed into downstream products in situ within the same reaction system, bypassing the need for its separation and purification, it would significantly reduce the overall production costs (Šivec et al. 2019). Therefore, this study focused on achieving the dehydration of fructose to HMF and oxidation of HMF to DFF in the same reaction system, realizing a one-pot synthesis of DFF from fructose. This approach not only simplifies the process flow but also minimizes waste generation and solvent use, further enhancing the environmental friendliness of the production method.

The dehydration of fructose to HMF is an acid-catalyzed reaction, whereas the conversion of HMF to DFF involves an oxidation process. Currently, there are two strategies for integrating these reactions within a single reactor. The first approach employs a combination of an acidic catalyst for the dehydration process and a redox catalyst for the oxidation of HMF, requiring the initial transformation of fructose to HMF under the acidic catalyst. Subsequently, an oxidation catalyst is introduced into the reaction system along with oxygen gas or other oxidants to produce DFF. This method, while relatively straightforward in implementation, faces challenges in separating the two catalysts after the reaction, often necessitating the design of one of the catalysts to be magnetic for ease of magnetic recovery and separation (Wei et al. 2021). Moreover, the sequential addition of catalysts adds complexity to the operation, a step that is generally unavoidable to prevent the oxidative degradation of fructose and low yield of DFF if both catalysts were added at the beginning of the reaction. In contrast, the second strategy, which involves the design of a bifunctional catalyst capable of catalyzing both the dehydration of fructose and the oxidation of HMF, appears more streamlined and efficient. A single catalyst that facilitates both reactions can eliminate the issues mentioned above, eliminating the need for separate catalyst recovery steps, and simplifying the overall process. However, the design and preparation of such a bifunctional catalyst was the key. Currently, successful examples of bifunctional catalysts include FeCuPOx, PMA–MIL-101, MoOx/CS, Mo-HNC, CsMVP-HPA, etc. (Liu et al. 2014a; Zhao et al. 2017, 2018a; Zhou et al. 2018; Jia et al. 2021; Nguyen et al. 2024). Among them, heteropolyacids (HPAs) have gained considerable attention in the construction of such bifunctional catalysts due to their abundant protonic acid sites and metal oxide-like structures. To simplify the preparation of bifunctional catalysts, the authors’ idea is to immobilize phosphomolybdic acid (PMA) onto a support, thereby forming a stable structured bifunctional catalyst. In this study, the hydrogen bonding between PMA and chitosan was utilized to form a cross-linked structure, and then a highly dispersed PMA-loaded bifunctional catalyst was obtained through calcination. This catalyst was applied in the one-pot synthesis of DFF from fructose, and achieved excellent results, offering a more straightforward, efficient, and environmentally friendly approach to the synthesis of valuable chemical intermediates from biomass-derived materials.

EXPERIMENTAL

Materials

Fructose, 5-hydroxymethylfurfural (HMF), 2,5-diformylfuran (DFF), phospho-molybdic acid (PMA), ethanol, dimethylsulfoxide (DMSO), and other materials used in the work were obtained in pure form Sigma-Aldrich (Hong Kong S.A.R. China) and were used directly without any modification.

Catalyst Synthesis

Phosphomolybdic acid/chitosan (PMAC) catalysts were synthesized by a facile method. Briefly, 2.0 g of chitosan was dissolved in 100 mL of 2% acetic acid (w/v) to prepare a solution “A”. Subsequently, 0.05 g of phosphomolybdic acid was dispersed into 5 mL of H2O to form solution “B”. Afterward, solution “B” was added dropwise into solution “A” under a continuous and controlled temperature of 80 °C until entirely evaporated. The obtained solid material was collected and further dried overnight in a dry oven at 80 °C. Finally, the dried materials were calcined in a muffle furnace at 350 °C for 10 h to obtain PMAC-1. Likewise, PMAC-2, PMAC-3, and PMAC-4 were prepared through the same procedure with different loadings of PMA (PMAC-x, x = 0.1, 0.3, 0.5 g), respectively. In addition, chitosan-derived char (CN) was prepared using chitosan without PMA following the same procedure. The schematic representation of the prepared catalyst is shown in Scheme 1 below.

Scheme 1. Schematic representation of the preparation process of bifunctional catalyst derived from phosphomolybdic acid and chitosan

Catalytic Reaction

In a typical dehydration reaction, fructose (200 mg) and 30 mg of the catalyst were added to DMSO (5 mL). The mixture was then poured into a round-bottom flask equipped with a reflex condenser, which was placed in a thermostatic oil bath under controlled temperature (90 °C) and stirring (500 rpm) for the desired reaction time (0.5 to 2 h). After the reaction, samples were taken at a specified time from the reaction mixture for quantification of reaction products.

HMF oxidation to DFF

In a typical oxidation reaction of HMF to DFF, 63 mg of HMF, and 30 mg of the catalyst were added to DMSO (5 mL). The mixture was then poured into a 3-necked round bottom flask equipped with a reflex condenser and was placed in a thermostatic oil bath under a controlled temperature of 140 °C and a constant oxygen flow of 10 mL/min was maintained for a specific time. Samples were taken from the reaction mixture at the desired time (1, 2, and 6 h) for product analysis.

One pot and one-step conversion of fructose to DFF

In a one-pot and single-step conversion of fructose DFF, 63 mg of HMF, and 30 mg of the catalyst were added to DMSO (5 mL). The mixture was then poured into a 3-necked round bottom flask equipped with a reflex condenser and was placed in a thermostatic oil bath under a controlled temperature of 130 °C and a constant oxygen flow of 10 mL/min was maintained for a specific time. Samples were taken from the reaction mixture at the desired time (1, 2, and 6 h) for product analysis.

Products Analysis

After the reaction, the solids were removed via centrifugation, filtered with a 0.25 µm syringe filter, and analyzed by high-performance liquid chromatography (HPLC) equipped with a refractive index detector (RID detector Agilent Technologies, 1260 Infinity II). For the analysis of fructose, HMF, and DFF, an organic acid detection column HPX-87H Bio-Rad was used under isocratic conditions. The mobile phase was 5 mM H2SO4 aqueous solution at a flow rate of 0.6 mL/ min and the column temperature was set to 60 °C.

The fructose conversion, HMF yield, DFF yield, HMF conversion, and DFF yield from HMF were calculated using the following Eqs. 1 through 5, respectively,

where [F]0 and [HMF]0 represent the initial concentration of fructose and HMF as substrate at the beginning of the reaction, while [F]t, [HMF]t, and [DFF]t represent the remaining concentration of fructose, HMF, and DFF after the reaction time of t, respectively.

Material Characterization

The structural characterization of all prepared catalysts was completed using Field Emission Scanning Electron Microscopy coupled with Energy Dispersive X-ray analysis (FESEM/EDX, LEO 1530 Field Emission SEM (ZEISS, Germany) and transmission electron microscopy (TEM) using FEI Tecnai G2 F20 S-Twin (FEI Company, Hillsboro, OR, USA). Surface composition and different functional groups of all the catalysts were confirmed through Fourier-transform infrared spectroscopy (FTIR, Nicolet iS 5 FTIR spectrometer, Natick, MA, USA), and Raman spectra for the catalyst were recorded using a ThermoFisher DXR2x instrument (Waltham, MA, USA).

RESULTS AND DISCUSSION

Catalyst Characterization

The synthesis process of PMAC catalyst consists of two stages. The first stage involves the crosslinking of PMA and chitosan in a solution to form a complex. The second stage involves the drying and calcination of this complex to form a stable structure. The process in the first stage aids in the dispersion of PMA, thereby enhancing its dispersibility in the final catalyst and enabling more effective utilization of its catalytic active sites. The structural changes of PMA and chitosan mainly occurred in the second stage, where PMA underwent dehydration due to calcination, while chitosan underwent carbonization. The morphology of the catalyst, as depicted in Fig. 1a through 1f using FESEM images, revealed that the carbon material produced by chitosan after calcination exhibited an irregular block shape, with a relatively flat and clean surface. Upon combination with PMA and subsequent calcination, the surface became rough, exhibiting distinct cracks and the presence of numerous particles. There were no obvious changes in the morphologies of the PMAC catalyst before and after use. Figure 1g through 1i shows the TEM images of CN, PMAC-3, and the used PMAC-3. The CN exhibited a layered structure, PMAC-3, and the used PMAC-3 showed a similar structure, where no aggregated PMA particles were observed. This is further supported by EDS data (Fig. 1j through 1o), which showed a homogeneous distribution of Mo and P within the catalyst particles. These results demonstrated the effectiveness of the synthesis strategy involving the crosslinking of PMA and chitosan followed by calcination in controlling the dispersibility of PMA.

Figure 2a displays the XRD patterns of the catalyst. Characteristically, polymers with crystalline regions can diffract high-intensity sharp peaks, whereas the X-ray peaks for amorphous polymers are much broader. It can be seen in Fig. 2a that the carbon material derived from chitosan revealed a broad peak centered around 20 to 30° in the 2θ range, indicating the presence of an amorphous carbon structure (Kalaiselvimary and Prabhu 2019; Kong et al. 2012). The peak corresponding to chitosan at 25º exhibited reduced intensity and shifted towards 30° in the XRD spectrum of the PMAC samples, suggesting that the introduction of PMA influenced the arrangement of carbon atoms (Tong et al. 2017: Yu et al. 2014; Sadjadi et al. 2023). Moreover, the distinguished peaks at 2θ values of ~10º and ~25º were only present in PMAC samples indicating the existence of PMA (Ahmadian and Anbia 2023).

Fig. 1. FESEM images of catalysts (a) CN, (b) PMAC-1, (c) PMAC-2, (d) PMAC-3, (e) PMAC-4, (f) used PMAC-3, and TEM images of catalyst (g) CN, (h) PMAC-3, (i) used PMAC-3, and EDS of catalyst (j to o) PMSC-3

Fig. 2. (a) XRD patterns, (b) FTIR patterns, and (c) Raman spectrum of CN and PMAC catalysts

Further, Fig. 2b shows the similarities and differences in the FTIR pattern of the samples. All the samples showed three peaks at 1620, 1400, and 1060 cm-1, respectively. The absorbance peak at 1620 cm-1 corresponds to the stretching vibrations of C=O bonds, indicating the presence of carbonyl functional groups in the samples. The peak located at 1400 cm-1 was associated with the bending vibrations of the methyl or methylene groups The absorbance peak at 1060 cm-1 can be attributed to the stretching vibrations of C-O bonds, indicating the presence of oxygen-containing functional groups in the samples. These functional groups were from the chitosan-derived char (CN). In addition to these two peaks, the PMAC samples showed some unique peaks that belong to the PMA species. According to the results reported in the literature, the three absorption peaks at 960, 870, and 796 cm-1 are assigned to stretching vibrations (ν (P-O), ν (Mo-Ot), ν (Mo-Oc-Mo), ν (Mo-Oe-Mo), where Ot, Oc, and Oe refer to terminal, corner, and edge oxygen (Mishra et al. 2010; Santamaria et al. 2017). The XRD and FTIR results confirmed the composite structure of the PMAC catalysts.

The Raman spectra of CN and PMAC-3 are shown in Fig. 2c. Both curves showed Raman peaks at around 1320 and 1600 cm-1, which were attributed to the D band and G band, respectively, of the support material (Lei et al. 2022). For the PMAC-3 curve, an extra absorption peak around 1004 cm-1 was observed, which was ascribed to the stretching vibrations of (MoO) which also revealed that PMA was successfully embedded in chitosan (Baibarac et al. 2011).

Catalytic Dehydration of Fructose to HMF

The synthesized catalysts were initially screened for their catalytic activity of fructose dehydration to HMF. Herein, DMSO was used as the solvent because of its innate behavior of promoting strong acid sites, which could be effective in converting fructose to HMF (Laugel et al. 2014; Tomer and Biswas 2022). Moreover, propagation towards side reactions and humins formation in DMSO is more suppressed, making it an ideal solvent for the dehydration of fructose and stabilization of HMF (Qi et al. 2008; Mushrif et al. 2012). The conversion of fructose to HMF concerning reaction time and different PMA loadings was studied by all synthesized catalysts. Figure 3 depicts the results of fructose conversion to HMF over different catalysts. Notable HMF yields of 41.7%, 45.4%, 68.7%, and 66.7% were observed even at a short reaction time of 1 h over PMAC-1, PMAC-2, PMAC-3, and PMAC-4, respectively. Meanwhile, HMF yield was only 4.5% when CN was used as the catalyst under the same reaction conditions. Similar findings were reported by Chhabra et al. (2023), who found that increasing the PMA loadings in boron nitride (BN) resulted in an 8% increase in HMF yield, whereas using only BN as a catalyst resulted in a significantly lower yield. Likewise, Saghandali et al. (2023) obtained an increased HMF yield of 99.5% from fructose in 45 minutes in DMSO solvent by employing halloysite-supported silicotungstic acid as a catalyst. Both fructose conversion and HMF yield increased with PMA loadings in chitosan suggesting that more acidic sites were introduced to the CN due to increased PMA, which played a crucial role in the fructose dehydration reaction (Chhabra et al. 2023). Considering the slight decrease in HMF selectivity from PMAC-3 to PMAC-4, the effects were probably due to the further hydrolysis or degradation of HMF. These findings are consistent with previous research. Wang et al. (2014) reported that raising the catalyst dosage from 8 to 10 mg reduced HMF yield by 2%, and a further decrease in HMF by 7% was seen when the catalyst dose was increased to 20 mg. The high amounts of catalyst can efficiently cause the degradation and polymerization of HMF to produce byproducts and humins. Thus, optimum loading is critical for achieving efficient product yields. Based on the results, PMAC-3 seems to be the optimal catalyst for fructose to HMF transformation (Zhou et al. 2015).

Fig. 3. Catalytic dehydration of fructose to HMF over CN and PMAC catalyst; Reaction conditions: 30 mg catalyst, 200 mg fructose, 5 mL DMSO, 90 °C, and 1 h

Catalytic HMF Oxidation to DFF

Heteropolyacid (HPA), such as Keggin-type phosphomolybdate acid (HPMo, H3PMo12O40), has been widely explored as a promising catalyst for oxidation reactions (Lei et al. 2021; Zhou et al. 2022; Ping et al. 2023). Such materials are mostly composed of numerous oxygen species in different coordination, including tetrahedral oxygen, bridging oxygen, and terminal oxygen.

Fig. 4. Catalytic oxidation of HMF into DFF over CN and PMAC catalysts; Reaction conditions: 30 mg catalyst, 63 mg HMF, 5 mL DMSO, 140 °C, and 4 h

The shuffling of terminal oxygen species may induce the formation of oxygen vacancies and low-coordination cations (Mo5+ or MO+6) in the lattice, which might be effective in catalyzing oxidation reactions (Xiao et al. 2013; Chang et al. 2020). Recently, Keggin-type heteropolyacid has been explored as a potential catalyst for HMF oxidation to DFF (Zhao et al. 2017; Liu et al. 2019; Wang et al. 2021). Based on this evidence, the role of PMAC in the aerobic oxidation of HMF to DFF was investigated, and the results are shown in Fig. 4. The CN showed limited catalytic activity towards HMF oxidation. After loading with PMA, the PMAC showed considerably improved catalytic activity. With PMAC-1 acting as a catalyst, a 39.4% DFF yield and a 42.2% HMF conversion were attained; moreover, both the DFF yield and HMF conversion rose with increased PMA loading onto chitosan. When PMAC-4 was used as a catalyst, the DFF yield reached a maximum of 73.4% with 80.8% HMF conversion at 140 °C in 4 h. Nevertheless, it is worth mentioning that the DFF selectivity was slightly compromised by introducing higher PMA loadings to the catalyst, and above 90%, DFF selectivity was achievable with all PMAC catalysts. The results demonstrated that high loading of PMA, as it was in PMAC-3 and PMAC-4, was necessary for the high catalytic activity.

One-pot Synthesis of DFF from Fructose

After systematic evaluation of the PMAC catalysts for subsequent fructose dehydration and HMF oxidation, the catalysts were further evaluated as bifunctional catalysts for “one-pot, one-step” direct conversion of fructose to DFF under specified reaction conditions. The experimental results are depicted in Fig. 5.

Fig. 5. Catalytic one pot and one step conversion of fructose into DFF over PMA catalyst (a) PMAC-1, (b) PMAC-2, (c) PMAC-3, and (d) PMAC-4. Reaction conditions: 30 mg catalyst, 200 mg fructose, DMSO (5 mL), O2 (10 mL/min), temperature 130 °C, and time (1 h, 2 h, and 6 h)

It was noted that with a shorter reaction time (1 h) fructose was quickly dehydrated to HMF with a maximum yield reaching 67.6% over the PMAC-3 catalyst and only 4.4% DFF yield was achievable at this stage. However, with extended reaction time (6 h) a switch to HMF oxidation was observed and an obvious DFF yield of 31.2% was achieved while HMF yield was reduced to 33.8% for PMAC-3. Similar trends were also shown for other catalysts. For example, HMF yield reduced from 50% to 30% and DFF yield increased from 4.49% to 32.2% from a reaction time of 1 h to 6 h using PMAC-4 as a catalyst. Meanwhile, the DFF yield increased faster when PMA loading was higher in the catalyst from PMAC-1 to PMAC-4, which again confirmed the PMCA’s activity in HMF oxidation to DFF. However, it seems that the PMA loading in PMAC-4 was higher than the optimized loading evidenced by the decrease in DFF selectivity in HMF oxidation and a certain degree of side reactions in the fructose dehydration stage which negatively affected the HMF yield. Therefore, PMAC-3 was selected and used in the further optimization of the reaction parameters with the expectation of higher DFF yield.

To achieve the highest DFF yield directly from fructose in a “one pot and one-step process”, the authors further screened the activity of PMAC-3 under different temperatures correlated to the reaction time (Fig. 6).

Fig. 6. Effect of reaction temperature and time on catalytic one-pot and one-step conversion of fructose into DFF over PMAC-3 catalyst (a) HMF yield, (b) DFF yield; Reaction conditions: 30 mg catalyst, 200 mg fructose, DMSO (5 mL), O2 = 10 mL/min, and time (1 h, 2 h, and 6 h)

Overall, the results indicate that the consecutive reaction from fructose to HMF and then to DFF can be effectively completed in this system, as evidenced by the decrease in HMF yield and the increase in DFF yield over time. Comparing the reaction data at different temperatures, it can be observed that higher temperatures favor the reaction. For instance, when the reaction was conducted at 110 ℃, the HMF yield decreased only about 10% from 1 h to 6 h. However, at 130 ℃, the HMF yield decreased approximately 30% over the same time, and further, this value reached 45% when the reaction temperature reached 150 ℃. The decrease in HMF yield corresponded to an increase in DFF yield. It is noteworthy that when the reaction was performed at 170 ℃, even after only 1 h, DFF became the major product with a yield of 60.4%. However, with a further increase in reaction time, the DFF yield began to decrease due to over-oxidation or decomposition of DFF. These reaction results demonstrate the effectiveness of PMAC-3 in the one-pot synthesis of DFF from fructose. It can be concluded that lower temperature and shorter reaction times favored higher HMF production and less DFF yields, in contrast, elevated reaction temperature favored oxidation of HMF and higher DFF yields. The authors’ results of this study are remarkably improved compared to previous reports (Table 1), with the activity of the PMAC-3 catalyst being comparable to or even higher than reported catalysts for one-pot fructose conversion to DFF under environmentally friendly reaction conditions.

The conversion process of fructose to DFF exploiting the PMAC catalyst in a DMSO environment is depicted in Fig 7. The proton generated by PMA ionization is the primary active species for fructose dehydration. Its interaction with fructose leads to the formation of isomeric intermediates (α and β-furanose), which subsequently lose a water molecule to create a carbocation that eventually yields HMF. The PMAC catalyst, which features oxidizable molybdenum (Mo) sites, then engages with HMF’s hydroxyl group to produce an intermediate (alkoxyl intermediate). These intermediates experience a β-elimination process, resulting in the formation of the carbonyl compound 2,5-diformylfuran (DFF), while simultaneously releasing molybdenum dihydride. In the final step, the molybdenum dihydride is reoxidized by molecular oxygen, which regenerates the active catalyst and releases a water molecule (Amarasekara et al. 2008; Shimizu et al. 2009; Ghezali et al. 2015; Ren et al. 2016; Chen et al. 2019, Chen et al. 2022).

Fig. 7. Proposed reaction mechanism for one pot single step fructose conversion into 2,5-diformylfuran over PMAC catalyst

Catalyst Recycling Test

Catalyst recycling is of great importance in the field of heterologous catalysis. Therefore, the reusability and stability of PMAC-3 were investigated for one-pot and one-step conversion of fructose into DFF. After each cycle, the spent catalyst was separated from the reaction mixture through centrifugation, washed sufficiently with ethanol and deionized water, and then dried in an oven at 60 °C before using in a subsequent cycle. The PMAC-3 catalyst retained its overall catalytic performance towards DFF production without any prominent loss in its catalytic performance (Fig. 8). After three times of use, there was a slight increase in HMF yield and a decrease in DFF yield by about 10%. The authors speculated that the loss of DFF could be attributed to the leaching of Mo active due to the extensive stirring in the recycling reaction causing the liberation of PMA fine particles from the catalyst (Wu et al. 2021). Secondly, the reduction in the amount of catalyst after recycling could also contribute to the decrease in DFF yield.

Fig. 8. Reusability of PMAC-3 catalyst for one-pot and one-step conversion of fructose into DFF; Reaction conditions: 30 mg catalyst, 200 mg fructose, DMSO (5 mL), O2 (10 mL/min), temperature (150 °C), and time (2 h)

Table 1. Comparison of Catalysts for One-Pot Synthesis of DFF from Fructose

The reduction in catalyst amount upon recycling mostly affects the oxidation of HMF to DFF because fructose dehydrates quickly to HMF, and a longer reaction time could be sufficient for the complete conversion of fructose. This causes the quantity of HMF to stay in the reaction products to increase, which lowers the DFF yield (Fig. 7). In general, the PMAC-3 showed its reusability and the slight decrease in the conversion of HMF to DFF could be overcome by modestly extending the reaction time.

CONCLUSIONS

- This study provides a facile method for the preparation of a bifunctional catalyst for the one-pot conversion of fructose to 2,5-diformylfuran (DFF). The method utilized phospho-molybdic acid (PMA) and chitosan as the main raw materials and employed their cross-linked structure based on hydrogen bonding as a precursor, which was then stabilized through calcination to obtain the catalyst. This method effectively enhanced the dispersion of PMA on the catalyst, thereby improving its catalytic activity.

- The catalyst exhibited excellent performance in both the conversion of fructose to 5-hydroxymethylfurfural (HMF) and the oxidation of HMF to DFF, which were inaccessible without PMA loading. However, excessively high PMA loading negatively affected the selectivity of fructose dehydration to HMF and HMF oxidation to DFF.

- In the one-pot conversion of fructose to DFF, the conversion of fructose to HMF can be rapidly completed, leading to the subsequent oxidation of HMF to DFF. Through optimization of the reaction conditions, the catalyst achieved a DFF yield of approximately 60% when reacted for 6 h at 150 °C or for 1 h at 170 °C.

- Furthermore, the catalyst demonstrated good stability and could be recycled and reused. The facile preparation method and high catalytic performance of this catalyst hold promising potential for industrial-scale applications in biomass catalytic utilization.

ACKNOWLEDGMENTS

The authors gratefully acknowledge support from National Natural Science Foundation of China (Ref. 21908184) and Hong Kong General Research Fund (Ref. 12202723).

REFERENCES CITED

Ahmadian, M., and Anbia, M.( 2023). “Keggin-type heteropolyanions immobilized on phosphorus slag derived SiO2: Synthesis, characterization, and their catalytic oxidative desulfurization activity,” Energy & Fuels 37(21), 16790-16804. DOI: 10.1021/acs.energyfuels.3c02592

Amarasekara, A.S., Williams, L.D. and Ebede, C.C. (2008). “Mechanism of the dehydration of d-fructose to 5-hydroxymethylfurfural in dimethyl sulfoxide at 150 C: an NMR study,” Carbohydrate Research 343(18), 3021-3024. DOI: 10.1016/j.carres.2008.09.008

Baibarac, M., Baltog, I., Smaranda, I., Scocioreanu, M., and Lefrant, S. (2011). “Hybrid organic–inorganic materials based on poly(o-phenylenediamine) and polyoxometallate functionalized carbon nanotubes,” Journal of Molecular Structure 985(2-3), 211-218. DOI: 10.1016/j.molstruc.2010.10.044

Cajnko, M. M., Novak, U., Grilc, M., and Likozar, B. (2020). “Enzymatic conversion reactions of 5-hydroxymethylfurfural (HMF) to bio-based 2, 5-diformylfuran (DFF) and 2, 5-furandicarboxylic acid (FDCA) with air: Mechanisms, pathways and synthesis selectivity,” Biotechnology for Biofuels 13, article 66. DOI: 10.1186/s13068-020-01705-z

Carlini, C., Patrono, P., Galletti, A.M.R., Sbrana, G. and Zima, V. (2005). “Selective oxidation of 5-hydroxymethyl-2-furaldehyde to furan-2, 5-dicarboxaldehyde by catalytic systems based on vanadyl phosphate,” Applied Catalysis A: General 289(2), 197-204. DOI: 10.1016/j.apcata.2005.05.006

Chang, X., Yang, X.-F., Qiao, Y., Wang, S., Zhang, M.-H., Xu, J., Wang, D.-H., and Bu, X.-H. (2020). “Confined heteropoly blues in defected Zr-MOF (bottle around ship) for high-efficiency oxidative desulfurization,” Small 16(14), article ID 1906432. DOI: 10.1002/smll.201906432

Chen, B., Li, X., Rui, P., Ye, Y., Ye, T., Zhou, R., Li, D., Carter, J.H. and Hutchings, G.J. (2022). “The reaction pathways of 5-hydroxymethylfurfural conversion in a continuous flow reactor using copper catalysts,” Catalysis Science & Technology 12(9), 3016-3027. DOI: 10.1039/D1CY02197D

Chen, R., Xin, J., Yan, D., Dong, H., Lu, X. and Zhang, S. (2019). “Highly efficient oxidation of 5‐hydroxymethylfurfural to 2, 5‐furandicarboxylic acid with heteropoly acids and ionic liquids,” ChemSusChem 12(12), 2715-2724. DOI: 10.1002/cssc.201900651

Cheng, L., Huang, D., Zhang, Y. and Wu, Y. (2021). “Photocatalytic selective oxidation of HMF to DFF over Bi2WO6/mpg–C3N4 composite under visible light,” Applied Organometallic Chemistry 35(11). 6404. DOI: 10.1002/aoc.6404

Chhabra, T., Bisht, B., Kumar, S. and Krishnan, V. (2023). “Nanoarchitectonics of Boron‐Nitride‐Supported Phosphomolybdic Acid as a Heterogeneous Catalyst for Conversion of Fructose to 5‐Hydroxymethylfurfural,” ChemistrySelect 8(29), 202302365. DOI: 10.1002/slct.202302365

Fang, R., Luque, R., and Li, Y. (2017). “Efficient one-pot fructose to DFF conversion using sulfonated magnetically separable MOF-derived Fe3O4 (111) catalysts,” Green Chemistry 19(3), 647-655. DOI: 10.1039/C6GC02018F

Ghezali, W., Vigier, K.D.O., Kessas, R. and Jérôme, F. (2015). “A choline chloride/DMSO solvent for the direct synthesis of diformylfuran from carbohydrates in the presence of heteropolyacids,” Green Chemistry, 17(8), 4459-4464. DOI: 10.1039/C5GC01336D

Hu, W., She, J., Fu, Z., Yang, B., Zhang, H., and Jiang, D. (2021). “Highly efficient and tunable visible-light-catalytic synthesis of 2,5-diformylfuran using HBr and molecular oxygen,” RSC Advances 11(38), 23365-23373. DOI: 10.1039/D1RA00865J

Jia, W., Zhang, J., Zuo, M., Yu, X., Liu, H., Li, Z., Sun, Y., Yang, S., Tang, X., and Zeng, X. (2021). “Boosting the acid sites and lattice oxygen activity of the Fe–Cu catalyst for one-pot producing 2, 5-diformylfuran from fructose,” ACS Sustainable Chemistry & Engineering 10(1), 421-430. DOI: 10.1021/acssuschemeng.1c06644

Kalaiselvimary, J., and Ramesh Prabhu, M. (2019). “Fabrications and investigation of physicochemical and electrochemical properties of heteropoly acid-doped sulfonated chitosan-based polymer electrolyte membranes for fuel cell applications,” Polymer Bulletin 76, 1401-1422. DOI: 10.1007/s00289-018-2445-4

Kong, A., Wang, P., Zhang, H., Yang, F., Huang, S., and Shan, Y. (2012). “One-pot fabrication of magnetically recoverable acid nanocatalyst, heteropolyacids/chitosan/ Fe3O4, and its catalytic performance,” Applied Catalysis A: General 417, 183-189. DOI: 10.1016/j.apcata.2011.12.040.

Lai, J., Zhou, S., Cheng, F., Guo, D., Liu, X., Xu, Q. and Yin, D. (2020). “Efficient and selective oxidation of 5-Hydroxymethylfurfural into 2, 5-Diformylfuran catalyzed by magnetic vanadium-based catalysts with air as oxidant,” Catalysis Letters 150, 1301-1308. DOI: 10.1007/s10562-019-03041-w

Laugel, C., Estrine, B., Le Bras, J., Hoffmann, N., Marinkovic, S., and Muzart, J. (2014). “NaBr/DMSO-induced synthesis of 2,5-diformylfuran from fructose or 5-(hydroxy-methyl)furfural,” ChemCatChem 6(5), 1195-1198. DOI: 10.1002/cctc.201400023

Lei, M., Gao, Q., Zhou, K., Gogoi, P., Liu, J., Wang, J., Song, H., Wang, S., and Liu, X. (2021). “Catalytic degradation and mineralization mechanism of 4-chlorophenol oxidized by phosphomolybdic acid/H2O2,” Separation and Purification Technology 257, article ID 117933. DOI: 10.1016/j.seppur.2020.117933

Lei, Z., Li, X., Liu, Y., Wu, J., Wang, Y., Luo, Y., Chen, Q., Wei, M., Zeng, L., and Qian, Q. (2022). “Two-dimensional MoSe2/chitosan-derived nitrogen-doped carbon composite enabling stable sodium/potassium storage,” Journal of Physics and Chemistry of Solids 163, article ID 110573. DOI: 10.1016/j.jpcs.2022.110573

Liu, R., Chen, J., Chen, L., Guo, Y., and Zhong, J. (2014a). “One-step approach to 2, 5‐diformylfuran from fructose by using a bifunctional and recyclable acidic polyoxometalate catalyst,” ChemPlusChem 79(10), 1448-1454. DOI: 10.1002/cplu.201402147

Liu, S., Fu, X., Dai, J., Liu, Z., Zhu, L., and Hu, C. (2019). “One-pot synthesis of 2,5-diformylfuran from fructose by bifunctional polyaniline-supported heteropolyacid hybrid catalysts,” Catalysts 9(4), article 445. DOI: 10.3390/catal9050445

Liu, Y., Zhu, L., Tang, J., Liu, M., Cheng, R., and Hu, C. (2014b). “One-pot, one-step synthesis of 2,5-diformylfuran from carbohydrates over mo-containing Keggin heteropolyacids,” ChemSusChem 7(12), 3541-3547. DOI: 10.1002/cssc.201402468

Lv, G., Chen, C., Lu, B., Li, J., Yang, Y., Chen, C., Deng, T., Zhu, Y., and Hou, X. (2016). “Vanadium-oxo immobilized onto Schiff base modified graphene oxide for efficient catalytic oxidation of 5-hydroxymethylfurfural and furfural into maleic anhydride,” RSC Advances 6(103), 101277-101282. DOI: 10.1039/C6RA21795H

Mishra, R. K., Mondal, S., Datt, M., and Banthia, A. K. (2010). “Development and characterization of chitosan and phosphomolybdic acid (PMA) based composites,” International Journal of Plastics Technology 14(1), 80-92. DOI: 10.1007/s12588-009-0018-y

Mushrif, S. H., Caratzoulas, S., and Vlachos, D. G. (2012). “Understanding solvent effects in the selective conversion of fructose to 5-hydroxymethyl-furfural: A molecular dynamics investigation,” Physical Chemistry Chemical Physics 14(8), 2637-2644. DOI: 10.1039/C2CP22694D

Nguyen, L. T., Doan, V. T. C., Nguyen, T. H., Phan, H. B., Van Pham, V., Van Dang, C., and Tran, P. H. (2024). “One-pot aerobic conversion of fructose to 2, 5-diformylfuran using silver-decorated carbon materials,” Renewable Energy 221, article ID 119850. DOI: 10.1016/j.renene.2023.119850

Nocito, F., Ventura, M., Aresta, M. and Dibenedetto, A. (2018). “Selective oxidation of 5-(hydroxymethyl) furfural to DFF using water as solvent and oxygen as oxidant with earth-crust-abundant mixed oxides,” ACS omega 3(12), 18724-18729. DOI: 10.1021/acsomega.8b02839

Ping, Y., Zong, M.-Y., Zhao, Z., Wang, C.-J., and Wang, D.-H. (2023). “Introducing VO2+ group in phosphomolybdic acid and supporting on MOF-808 for efficient oxidative desulfurization,” ACS Omega 8(40), 37421-37430. DOI: 10.1021/acsomega.3c05458

Qi, X., Watanabe, M., Aida, T. M., and Smith, R. L., Jr. (2008). “Selective conversion of d-fructose to 5-hydroxymethylfurfural by ion-exchange resin in acetone/dimethyl sulfoxide solvent mixtures,” Industrial & Engineering Chemistry Research 47(23), 9234-9239. DOI: 10.1021/ie801016s

Ren, L.K., Yang, H.Q. and Hu, C.W. (2016). “Theoretical study of the catalytic oxidation mechanism of 5-hydroxymethylfurfural to 2, 5-diformylfuran by PMo-containing Keggin heteropolyacid,” Catalysis Science & Technology 6(11), 3776-3787. DOI: 10.1039/C5CY01895A

Ren, Y., Yuan, Z., Lv, K., Sun, J., Zhang, Z. and Chi, Q. (2018). “Selective and metal-free oxidation of biomass-derived 5-hydroxymethylfurfural to 2, 5-diformylfuran over nitrogen-doped carbon materials,” Green chemistry 20(21), 4946-4956. DOI: 10.1039/C8GC02286K

Rosatella, A. A., Simeonov, S. P., Frade, R. F. M., and Afonso, C. A. M. (2011). “5-Hydroxymethylfurfural (HMF) as a building block platform: Biological properties, synthesis and synthetic applications,” Green Chemistry 13(4), 754-793. DOI: 10.1039/C0GC00401D

Sadjadi, S., Abedian-Dehaghani, N., Heydari, A., and Heravi, M. M. (2023). “Chitosan bead containing metal–organic framework encapsulated heteropolyacid as an efficient catalyst for cascade condensation reaction,” Scientific Reports 13(1), article 2797. DOI: 10.1038/s41598-023-29548-2

Saghandali, F., Kazemeini, M. and Sadjadi, S. (2024). “Halloysite-supported silicotungstic acid as an efficient catalyst for dehydration of fructose to 5-hydroxymethylfurfural,” Journal of Physics and Chemistry of Solids 184, 111697. DOI: 10.1016/j.jpcs.2023.111697

Santamaria, M., Pecoraro, C. M., Di Franco, F., and Di Quarto, F. (2017). “Phosphomolybdic acid and mixed phosphotungstic/phosphomolybdic acid chitosan membranes as polymer electrolyte for H2/O2 fuel cells,” International Journal of Hydrogen Energy 42(9), 6211-6219. DOI: 10.1016/j.ijhydene.2017.02.069

Shimizu, K.I., Uozumi, R. and Satsuma, A. (2009). “Enhanced production of hydroxymethylfurfural from fructose with solid acid catalysts by simple water removal methods”. Catalysis Communications 10(14), 1849-1853. DOI: 10.1016/j.catcom.2009.06.012

Šivec, R., Grilc, M., Huš, M. and Likozar, B. (2019). “Multiscale modeling of (hemi) cellulose hydrolysis and cascade hydrotreatment of 5-hydroxymethylfurfural, furfural, and levulinic acid,” Industrial & Engineering Chemistry Research 58(35), 16018-16032.DOI: 10.1021/acs.iecr.9b00898

Slak, J., Pomeroy, B., Kostyniuk, A., Grilc, M. and Likozar, B. ( 2022). “A review of bio-refining process intensification in catalytic conversion reactions, separations and purifications of hydroxymethylfurfural (HMF) and furfural,” Chemical Engineering Journal 429, 132325. DOI: 10.1016/j.cej.2021.132325

Solanki, B.S., Roh, H.S. and Rode, C.V. (2023). “Selective oxidation of 5-HMF to DFF over alkali promoted Mn nanocomposite,” Applied Catalysis A: General 659, 119180. DOI: 10.1016/j.apcata.2023.119180

Tomer, R., and Biswas, P. (2022). “Dehydration of glucose over sulfate impregnated ZnO (hexagonal-monoclinic) catalyst in dimethyl sulfoxide (DMSO) medium: Production, separation, and purification of 5-hydroxymethylfurfural (5-HMF) with high purity,” Catalysis Today 404, 219-228. DOI: 10.1016/j.cattod.2022.02.009

Tong, T., Li, Y., Hou, R., Wang, X. and Wang, S. (2017). “Decoration of chitosan microspheres with Brønsted heteropolyacids and Lewis ion Ti: Trifunctional catalysts for esterification to biodiesel,” RSC Advances 7(67), 42422-42429. DOI: 10.1039/C7RA07479D

Trapasso, G., Mazzi, G., Chícharo, B., Annatelli, M., Dalla Torre, D., and Aricò, F. (2022). “Multigram synthesis of pure HMF and BHMF,” Organic Process Research & Development 26(10), 2830-2838. DOI: 10.1021/acs.oprd.2c00196

Wang, H., Kong, Q., Wang, Y., Deng, T., Chen, C., Hou, X. and Zhu, Y. (2014). “Graphene oxide catalyzed dehydration of fructose into 5‐hydroxymethylfurfural with isopropanol as cosolvent,” ChemCatChem 6(3), 728-732. DOI: 10.1002/cctc.201301067

Wang, K., and Tester, J. W. (2023). “Sustainable management of unavoidable biomass wastes,” Green Energy and Resources 1(1), article ID 100005. DOI: 10.1016/j.gerr.2023.100005

Wang, Q., Li, Y., Guan, H., Yu, H., and Wang, X. (2021). “Hydroxyapatite-supported polyoxometalates for the highly selective aerobic oxidation of 5-hydroxymethyl-furfural or glucose to 2,5-diformylfuran under atmospheric pressure,” ChemPlusChem 86(7), 997-1005. DOI: 10.1002/cplu.202100199

Wei, W., Lyu, G., Jiang, W., Chen, Z., and Wu, S. (2021). “High-efficiency synthesis of 5-hydroxymethylfurfural and 2, 5-diformylfuran from fructose over magnetic separable catalysts,” Journal of Colloid and Interface Science 602, 146-158. DOI: 10.1016/j.jcis.2021.05.161

Wu, J., Yan, S., Wang, C., Lay, C.-H., Wang, X., Wang, X., and Huo, M. (2021). “Fabrication of ordered mesoporous POMs/SiO2–NH2 nanofibers for production of DFF from 5-HMF for cellulose wastewater resource recovery,” Chemosphere 277, article ID 130316. DOI: 10.1016/j.chemosphere.2021.130316

Xiao, P., Dumur, F., Tehfe, M.-A., Graff, B., Fouassier, J. P., Gigmes, D., and Lalevée, J. (2013). “Keggin-type polyoxometalate ([pmo12o40]3−) in radical initiating systems: Application to radical and cationic photopolymerization reactions,” Macromolecular Chemistry and Physics 214(15), 1749-1755. DOI: 10.1002/macp.201300282

Yu, L., Chen, H., Wen, Z., Jin, M., Ma, Z., Ma, X., Sang, Y., Chen, M. and Li, Y. (2021). “Highly selective oxidation of 5-hydroxymethylfurfural to 2, 5-diformylfuran over an α-MnO2 catalyst,” Catalysis Today 367, 9-15. DOI: 10.1016/j.cattod.2020.10.037

Yu, X., Lu, Z., Wu, D., Yu, P., He, M., Chen, T., Shi, W., Huo, P., Yan, Y., and Feng, Y. (2014). “Heteropolyacid–chitosan/TiO2 composites for the degradation of tetracycline hydrochloride solution,” Reaction Kinetics, Mechanisms and Catalysis 111, 347-360. DOI: 10.1007/s11144-013-0631-9

Zhang, H., Clark, J.H., Geng, T., Zhang, H. and Cao, F. (2021). “A Carbon Catalyst Co‐Doped with P and N for Efficient and Selective Oxidation of 5‐Hydroxymethylfurfural into 2, 5‐Diformylfuran,” ChemSusChem 14(1), 456-466. DOI: 10.1002/cssc.202001525

Zhao, J., Anjali, J., Yan, Y., and Lee, J.-M. (2017). “Cr-MIL-101-encapsulated Keggin phosphomolybdic acid as a catalyst for the one-pot synthesis of 2,5-diformylfuran from fructose,” ChemCatChem 9(7), 1187-1191. DOI: 10.1002/cctc.201601546

Zhao, J., Jayakumar, A., and Lee, J.-M. (2018b). “Bifunctional sulfonated MoO3–ZrO2 binary oxide catalysts for the one-step synthesis of 2,5-diformylfuran from fructose,” ACS Sustainable Chemistry & Engineering 6(3), 2976-2982. DOI: 10.1021/acssuschemeng.7b02671

Zhao, J., Jayakumar, A., Hu, Z.-T., Yan, Y., Yang, Y., and Lee, J.-M. (2018a). “MoO3-containing protonated nitrogen doped carbon as a bifunctional catalyst for one-step synthesis of 2, 5-diformylfuran from fructose,” ACS Sustainable Chemistry & Engineering 6(1), 284-291. DOI: 10.1021/acssuschemeng.7b02408

Zhao, J., Yan, Y., Hu, Z.-T., Jose, V., Chen, X., and Lee, J.-M. (2020). “Bifunctional carbon nanoplatelets as metal-free catalysts for direct conversion of fructose to 2,5-diformylfuran,” Catalysis Science & Technology 10(13), 4179-4183. DOI: 10.1039/D0CY00489H

Zhou, C., Zhao, J., Sun, H., Song, Y., Wan, X., Lin, H., and Yang, Y. (2018). “One-step approach to 2, 5-diformylfuran from fructose over molybdenum oxides supported on carbon spheres,” ACS Sustainable Chemistry & Engineering 7(1), 315-323. DOI: 10.1021/acssuschemeng.8b03470

Zhou, L., He, Y., Ma, Z., Liang, R., Wu, T., and Wu, Y. (2015). “One-step degradation of cellulose to 5-hydroxymethylfurfural in ionic liquid under mild conditions,” Carbohydrate Polymers 117, 694-700. DOI: 10.1016/j.carbpol.2014.10.062

Zhou, S., He, J., Wu, P., He, L., Tao, D., Lu, L., Yu, Z., Zhu, L., Chao, Y., and Zhu, W. (2022). “Metal-organic framework encapsulated high-loaded phosphomolybdic acid: A highly stable catalyst for oxidative desulfurization of 4,6-dimethyldibenzo-thiophene,” Fuel 309, article ID 122143. DOI: 10.1016/j.fuel.2021.122143

Zhu, J., Cheng, F., Wang, F., Wen, S. and Liu, X. (2022). “Selective Oxidation of 5-Hydroxymethylfurfural to 2, 5-Diformylfuran Over a Vanadium Manganese Oxide Catalyst,” Catalysis Letters,1-8. DOI: 10.1007/s10562-021-03817-z

Article submitted: February 3, 2024; Peer review completed: March 2, 2024; Revised version received and accepted: March 13, 2024; Published: March 22, 2024.

DOI: 10.15376/biores.19.2.2948-2966