Abstract

Download PDF

Full Article

Optimizing Refining Conditions of Pinus massoniana Cellulose Fibers for Improving the Mechanical Properties of Ultra-Low Density Plant Fiber Composite (ULD_PFC)

Tingjie Chen,a,b Zhenzeng Wu,a Wei Wei,a Yongqun Xie,a,* Qihua Wei,a Xiaodong (Alice) Wang,b Olle Hagman,b and Olov Karlsson b

Response surface methodology was used to optimize the refining conditions of Pinus massoniana cellulose fiber and to improve the mechanical properties of ultra-low density plant fiber composite (ULD_PFC). The effects and interactions of the pulp consistency (X1), the number of passes (X2), and the beating gap (X3) on the internal bond strength of ULD_PFC were investigated. The results showed that the optimum internal bond strength (91.72 ± 2.28 kPa) was obtained under the conditions of 8.0% pulp consistency, two passes through the refiner, and a 30.0 μm beating gap. Analysis of the physical properties of the fibers and handsheets showed that the fibrillation of fibers with optimum refining conditions was improved. Also, the tear index of the optimal specimen was 13.9% and 24.5% higher than specimen-1 with a lowest beating degree of 24 oSR and specimen-6 with a highest beating degree of 73 oSR, respectively. Consequently, the optimal refining conditions of the fibers are valid for preparing ULD_PFCs.

Keywords: Refining; Physical properties; Handsheet; Internal bond strength; Optimization

Contact information: a: College of Material Engineering, Fujian Agriculture and Forestry University, 350002, Fuzhou, Fujian; b: Division of Wood Technology and Engineering, Luleå University of Technology, 93187, Forskargatan 1, Skellefteå, Sweden; *Corresponding author: fjxieyq@hotmail.com

INTRODUCTION

Ultra-low density plant fiber composite (ULD_PFC) is a foaming material with many advantages, such as low thermal conductivity and a high coefficient of sound absorption (Xie et al. 2004, 2008a, 2008b, 2011). It is derived from plant fibers that are renewable and biodegradable polymers, mainly consisting of cellulose, lignin, and hemicelluloses (Liu et al. 2008). The plant fiber composite is produced using a liquid frothing process without heating, pressing, or common adhesives. The network structure is formed by the fibers, which are adhered through water bridging and a small amount of adhesive (Xie et al. 2011). To improve the mechanical properties of ULD_PFC, it is important to expose the fiber surfaces to improve bonding between fibers, which exposes a number of hydroxyl groups that allow the polymer to form hydrogen bonds (Bhardwaj et al. 2004, 2007; Kamel et al. 2004; Mutje et al. 2006; Gulsoy 2014; Chen et al. 2016).

Refining improves the properties of fibers by friction among fibers and mechanical shear. The process mainly consists of three actions: internal fibrillation, which is caused by the breakdown of the fiber walls into separate lamellas; external fibrillation, which can increase the exposure of fibrils on the fiber surfaces; and the generation of fines from fibers (Bhardwaj et al. 2004; Hou et al. 2011; Gao et al. 2012). The physical properties of fibers are significantly affected by many factors during beating, such as the refiner speed of rotation, PFI mill revolution number, disc gap, and pulp consistency (Wei et al. 2010; Hou et al. 2011; Chen et al. 2012; Gao et al. 2012). For example, a reasonable beating time improves the properties of fibers. The improvement of fiber quality is limited by a small beating time, which results in incompletely beaten fibers. Conversely, a long beating time causes excessive shortening of fibers, decreases fiber properties, consumes more energy, and increases costs (Chen et al. 2012). Gao et al. (2012) showed that the beating degree of pulp was enhanced with an increase in the PFI mill revolution number, and a decrease in length. Additionally, pulp consistency is an important factor during beating. The friction between fibers plays an important role in the high and medium consistency refining process, which can improve the fibrillation of fibers and maintain their length. When the pulp consistency is too high, it is more likely that fibers are shortened as they pass between two discs and are subject to shear force (Wei et al. 2010; Gao et al. 2012).

The mechanical properties of ULD_PFC may be affected by the fiber’s original properties, the strength of the fibers (i.e., fiber length), and the extent of bonding between the fibers (Chen et al. 2016). Therefore, a suitable refining process is essential for obtaining the desired mechanical properties of ULD_PFC. To systemically examine the effects of refining on the mechanical properties of ULD_PFC, the refining conditions of pulp consistency, the number of passes through a refiner, and beating gap were considered in this study. Furthermore, a standard response surface methodology (RSM) called the Box-Behnken design (BBD) was used, and the morphology of the fibers and the mechanical properties of handsheets were analyzed.

EXPERIMENTAL

Materials and Pretreatment

Paperboard made of Pinus massoniana fibers (purchased from the Qingzhou papermaking plant, Sanming, China) was utilized as a raw material to manufacture handsheets and ULD_PFCs. The board was pretreated with water (15.0 wt.%) for 120 min and disintegrated by a beating machine (ZQS2 with 1.1 kW power, 23 L dimension, and 586r/min revolving speed) which was purchased from Northwest Institute of Light Industry Machinery Factory (Xianyang, China). Then, the pulps with 8° SR which were separated to water by filtration were used for the mechanical pulping.

Aluminum sulfate and sodium silicate, purchased from Tianjin Fuchen Chemical Reagents Factory (Tianjin, China) were used to generate the Si-Al compounds. The corresponding preparation process was described in Chen et al. (2015a). Sodium dodecylbenzene sulfonate was used as a foaming agent (Jiangsu Qingting Washing Products Co., Ltd., Changzhou, China).

Methods

Mechanical pulping and experimental design

The pulps were refined in a disc refiner (ZDP-32 with 300 mm diameter, 3000 r/min spindle speed, and 30-300 r/min feedstock screw speed), which was manufactured by the Jilin paper machinery manufacturing factory (Jilin, China). The pulping process was described in Chen et al. (2016). The refining was processed with different parameters. The pulp consistency (X1), number of passes (X2), and beating gap (X3) were chosen as the variables.

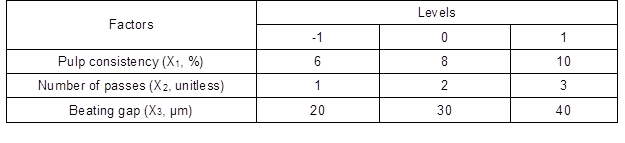

The internal bond strength (Y) was regarded as a function of the controlled variables. The RSM design of BBD was applied to study the effects of X1, X2, and X3 on Y. The software Design-Expert (Trial Version 8.0.6; Stat-Ease, Minneapolis, USA) was used to analyze data and build the models. The selected range of each variable is shown in Table 1.

Table 1. Levels of Parameter Variables Used in RSM Design for Beating

Preparation of ultra-low density plant fiber composites

Ultra-low density plant fiber composites (200 mm × 200 mm × 50 mm) were made of 55 g of dry refined Pinus massoniana pulp, with a target bulk density of 50 kg·m-3 to 90 kg·m-3. They were manufactured separately using various parameters in a demonstration line as described in Chen et al. (2015b, 2016). The additives of a Si-Al compound, polyacrylamide resin, alkyl ketene dimer (AKD, water repellent), chlorinated paraffin (fire retardant), and sodium dodecylbenzene sulfonate surfactant (10% concentration, foaming agent) were added during the different manufacturing stages and mixed with the refined pulp in all specimens at 500 mL, 20 mL, 50 mL, 46 g, and 80 mL, respectively.

Testing of beating degree and properties of refined pulp

The beating degree of the pulps was determined by the Schopper Riegler method using a beating degree tester (Z-DZY-100, Sichuan Changjiang Papermaking Equipment Co., LTD, Yibin, China). Pulp samples of 2 g were diluted in 1000 mL of distilled water. The beating degree value was calculated by Eq. 1, according to GB/T 3332 (2004),

Beating degree (°SR) = (1000 – Vwater*) / 10 (1)

where Vwater is the volume of transudatory water.

The properties of the Pinus massoniana fibers including the fiber weight-average length and degree of fibrillation were characterized by a fiber morphology analyzer (Morfi Compact, Techpap Co., LTD, Saint Martin d’Hères, France).

Scanning electron microscopy (SEM)

The specimen surface was coated with gold, and the micromorphology was characterized by SEM (Phenom ProX, Eindhoven, Netherlands) analysis using an acceleration voltage of 15 kV.

Preparation of handsheets and testing of their properties

The refined pulps were dispersed into water using a standard pulp disintegrator (5 wt.% to 10 wt.%). The handsheets were prepared with a basis weight of 160 g·m-2. When the handsheets were prepared, they were placed at a constant temperature and humidity, according to the TAPPI T222 om-11 (2011) standard, for 24 h. The physical properties of the handsheets including the tensile index, tear index, and burst index were tested in accordance with GB/T 12914 (2008), GB/T 455 (2002), and GB/T 454 (2002), respectively. The results reported are the average of 10 replicates.

Testing of internal bond strength

The internal bond strength (IB) of each ULD_PFC was tested in accordance with GB/T 17657 (1999). The size of the specimens was 50 mm × 50 mm × 40 mm (L × W × H). The results reported are the average of five replicates.

RESULTS AND DISCUSSION

Model Fitting

The Box-Behnken design and the results of the experiments for evaluating the effectiveness of the three independent variables on the IB of ULD_PFC are presented in Table 2. The IB of the ULD_PFC against the function of the independent variables within the range under investigation is described as the following mathematical model (Eq. 2),

Y= 91.72 + 9.84X1 + 2.73X2 + 11.41X3 + 0.78X1X2 – 2.80X1X3

– 2.83X2X3 – 23.74X12 – 33.51X22 – 15.99X32 (2)

where Y is the IB of the ULD_PFC, whereas X1, X2, and X3 are the coded variables for the pulp consistency, number of passes, and beating gap, respectively.

Table 2. Box-Behnken Design and the Response Data, Internal Bond Strength

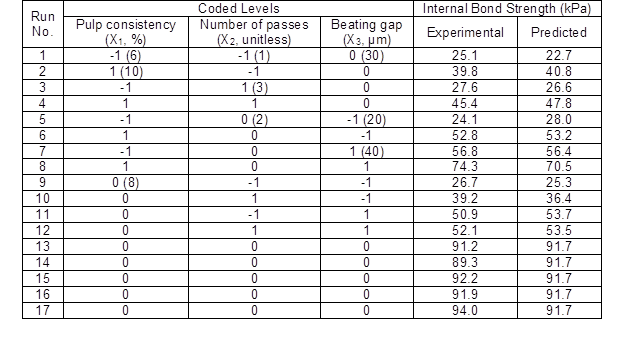

Table 3. Analysis of Variance for Regression Model for Internal Bond Strength

*Note: p < 0.01 is considered highly significant; 0.01 < p < 0.05 is considered significant; p > 0.05 is considered insignificant

As shown in Table 3, the model’s p-value was less than 0.0001, and the lack of fit value was more than 0.05, indicating that the model exhibits good fitness (Sahu et al. 2010; Brown and Brown 2012; Singh et al. 2013; Mujtaba et al. 2014). A small coefficient of determination (R2) value indicated poor relevance of the dependent variables in the model. In this study, the value of R2 was 0.9932, implying that 99.32% of the variations can be explained by the fitted model. It is in reasonable agreement with the the Radj2 (0.9844), indicating a high degree of correlation between the observed and predicted value (Tang et al. 2011). Thus, this model established that the regression model explained the true behavior of the system. The corresponding variables would be more significant with greater F-values and smaller p-values (Amini et al. 2008; Xu and He 2010).

As can be seen in Table 3, the F-value (112.98) and p-values (less than 0.0001) implied that the model was significant, and there was only a 0.01% chance that the result could occur due to noise. However, the F-value (7.36) and p-value (0.0618) of the lack of fit implied that it was not significant and that a 6.18% chance could occur due to noise. According to the p-values in this model, the variables X1, X3, and three quadratic terms (X12, X22, and X32) affected the IB of the ULD_PFCs significantly, whereas X2 and three interactive terms (X1X2, X2X3, and X1X3) were insignificant to the response. The results also showed that the effects of the independent variable on the IB of ULD_PFCs were as follows: beating gap (X3) > pulp consistency (X1) > number of passes (X2).

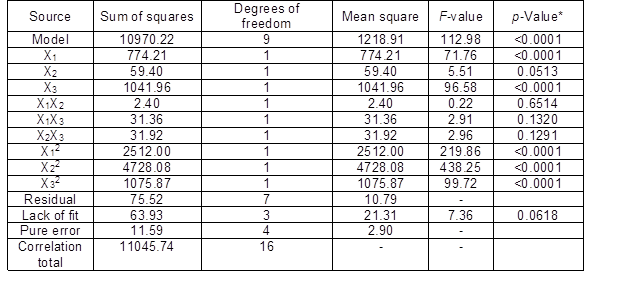

Analysis of Response Surface and Optimization

The effects of the variables on the IB of the ULD_PFC are shown in Fig. 1. A 3D representation of the response surface and the corresponding contour plot are used to illustrate the relationship between the parameters and response variable.

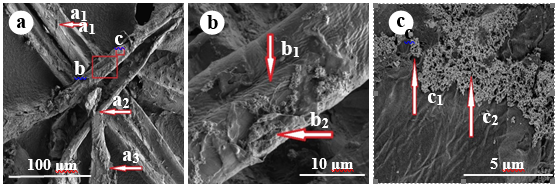

As shown in Fig. 1a, a maximal IB was obtained for two passes of refining and a pulp consistency of 8.0% to 9.0%. The IB of ULD_PFCs increased with the pulp consistency first, but then declined at a higher pulp consistency. This is because the combination among fibers and their intrinsic properties are crucial for the mechanical properties of ULD_PFCs. As an increase in the pulp consistency, the fibers are remarkably broken and fibrillated because of the function of the friction among fibers (Clark 1985; Chu and Ou 2001; Liu et al. 2008; Gao et al. 2012). As shown in Fig. 2, some of the fibers longitudinal direction exhibited splitting (Fig. 2b-b1), and some of the S1 layer of the fibers peeled away from the fiber wall (Fig. 2a-a1). Figure 2-a3 and b2 show an example of slight damage to the S2 layer. The pulp with a higher pulp consistency is difficult to pass through the discs, leading to excessive shortening due to the shear force. Figure 2a-a2 shows the fracture pattern at the end of the fiber caused by the function of shear force (Molin and Daniel 2004; Chen et al. 2012). However, the fibrillation of fibers is helpful to absorb the Si-Al compounds. During refining, the specific surface area of the fiber is enlarged. The hydroxyl groups were made accessible, and the chemical components become more easily absorbed on fibers (Fig. 2c-c1 and c2) (Bhardwaj et al. 2004; Molin and Daniel 2004; Marais and Wågberg 2012).

Figure 1b shows the combined effect of the pulp consistency and beating gap on the IB of ULD_PFCs at a constant two passes of refining. The contour plot result is elliptical, indicating significant interactive effects of the two independent variables on the IB of ULD_PFCs (Tang et al. 2011). The IB of ULD_PFCs increased with a decrease in the beating gap, especially within the range from 30.0 μm to 40.0 μm, but declined sharply when the beating gap was less than 30.0 μm. This is because fibrillation of the fibers was improved at a suitable beating gap, while their weight-average length was still maintained. When the beating gap was less than the average width of the fiber (approximately 31.1 μm), then the fiber weight-average length sharply decreased with a decrease in the beating gap. This is due to the increased probability shear force and friction force on the fibers.

The IB of ULD_PFCs increased with the number of passes, but it declined at further higher number of passes (Fig. 1c). This is due to fibers not being adequately affected the first time, it mainly breaking the fiber primary and secondary cell wall. When they were processes a second time, the probability for the fibers to suffer from the shear force and friction force increased. In this case, the breaking process caused the fibers to become swollen and softer, and the beating degree and degree of fibrillation were increased (Han et al. 2008). When the number of passes continuously increased, more fibers were shortened, which decreased the weight-average length and width.

Fig. 1. Response surface plots for the maximum IB of ULD_PFCs. (a) Effects of pulp consistency and number of passes on the IB of ULD_PFCs; (b) effects of pulp consistency and beating gap on the IB of ULD_PFCs; (c) effects of number of passes and beating gap on the IB of ULD_PFCs

Fig. 2. (a) SEM micrographs of ULD_PFC made from a refined Pinus massoniana cellulose fiber; (b and c) the surface of fiber from the frame in (a) at high magnification

Based on Eq. 2, the optimal refining conditions for ULD_PFCs are 8.10% pulp consistency, 2.06 passes through the refiner, and a 34.20 μm beating gap. Taking the practical operating condition into consideration, the modified conditions are as follows: a pulp consistency of 8.0%, 2 passes through the refiner, and a beating gap of 30.0 μm. Under these conditions, an average of 91.72 ± 2.28 kPa is obtained, which is close to the predicted values of 94.00 kPa. These results confirmed that the model adequately reflected the expected optimization and that Eq. (2) is satisfactory and accurate.

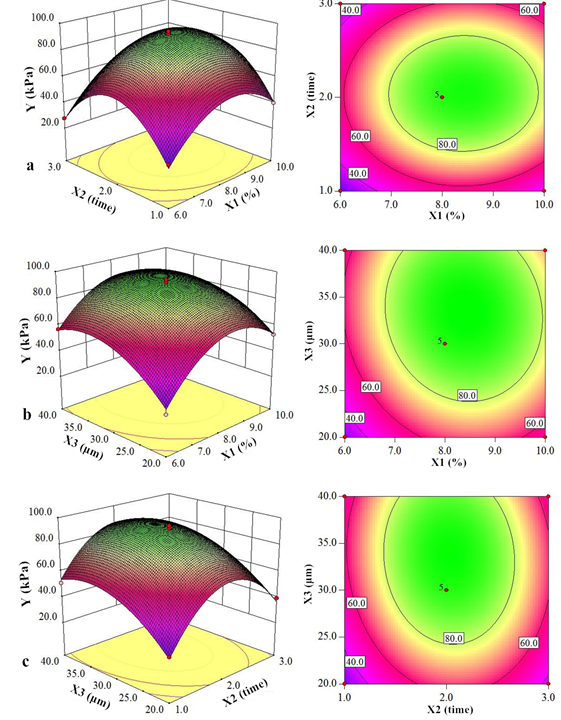

Physical Properties of Cellulose Fibers and their Handsheets

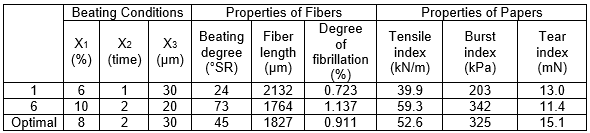

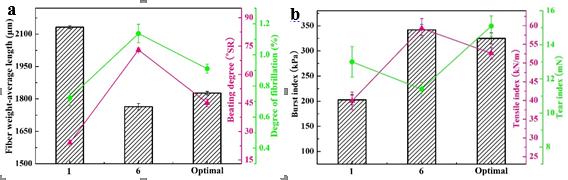

Based on the beating degree, specimen-1, specimen-6, and the optimal specimen are chosen and compared. Their beating degree, fiber weight-average length, degree of fibrillation of fibers, and the corresponding properties of paper are presented in Table 4 and Fig. 3.

Table 4. Physical Properties of Cellulose Fibers and their Handsheets

*Note: X1-Pulp consistency; X2-Number of passes; X3-Beating gap.

Fig. 3. Physical properties of fibers (a), and handsheets (b), for specimen-1, specimen-6, and the optimal specimen

Table 4 and Fig. 3a show that fibers with a beating degree of 24 °SR had a longer fiber weight-average length and a smaller degree of fibrillation, as compared with a beating degree of 73 °SR. This is because the probability for fibers to be affected by the shear force and friction force increased with a high beating degree. The increase of the fibrillation increases the bonding ability and flexibility of fibers, which is beneficial to the properties of the handsheets (Gulsoy 2014). Theoretically, the tensile index and burst index of handsheets are mainly affected by the combination of fibers, while the tear index is mainly affected by the average length and strength of the fibers (Yuan 2004; Gao et al. 2012). As shown in Table 4 and Fig. 3b, specimen-1 with a low beating degree of 24 °SR and a long fiber weight-average length of 2132 μm had a lower tensile index and burst index of handsheets than specimen-6, except for the tear index. For the optimal specimen, its fibrillation was improved, and the fibers weight-average length was also maintained. The tensile index and burst index were 11.3% and 5.0% less, respectively, than specimen-6, but the tear index was increased by 24.5%. Taking these factors into consideration, the optimal refining conditions of the Pinus massoniana fibers are valid for preparing ULD_PFCs.

CONCLUSIONS

- A suitable refining process effectively improved the mechanical properties of ULD_PFCs. Taking the practical operating condition into consideration, a good internal bond strength of 91.72 ± 2.28 kPa was obtained with the conditions of 8.0% pulp consistency, 2 passes through the refiner, and a 30.0 μm beating gap.

- The physical properties of fibers and handsheets showed that the fibrillation of fibers with optimum refining conditions was improved. Specimen-1 with a lowest beating degree of 24 °SR had a lower tensile index and burst index of handsheets than specimen-6, except for the tear index. For the optimal specimen, its fibrillation was improved. Their tensile index and burst index were 11.3% and 5.0% less, respectively, than specimen-6 which had a highest beating degree of 73 °SR, but the tear index was increased by 24.5%. Consequently, the optimal refining conditions of fibers are valid for preparing ULD_PFCs.

ACKNOWLEDGEMENTS

This paper was supported by the Scientific Research Foundation of the Graduate School of Fujian Agriculture and Forestry University (1122YB020), and the Studying Abroad Scholarships of China. The authors are also grateful for the financial support of the National Science and Technology Support Program (2008BADA9B01), the National Natural Science Foundation of China (NSFC) (30781982), and the ÅForsk in Stockholm (No. 239124).

REFERENCES CITED

Amini, M., Younesi, H., Bahramifar, N., Lorestani, A. A., Ghorbani, F., Daneshi, A., and Sharifzadeh, M. (2008). “Application of response surface methodology for optimization of lead biosorption in an aqueous solution by Aspergillus niger,” Journal of Hazard Materials 154(1-3), 694-702. DOI: 10.1016/j.jhazmat.2007.10.114

Bhardwaj, N. K., Duong, T. D., and Nguyen, K. L. (2004). “Pulp charge determination by different methods: Effect of beating/refining,” Colloids and Surfaces A: Physicochemical and Engineering Aspects 236(1), 39-44. DOI: 10.1016/j.colsurfa.2004.01.024

Bhardwaj, N. K., Hoang, V., and Nguyen, K. L. (2007). “A comparative study of the effect of refining on physical and electrokinetic properties of various cellulosic fibres,” Bioresource Technology 98(8), 1647-1654. DOI: 10.1016/j.biortech.2006.05.040

Brown, J. N., and Brown, R. C. (2012). “Process optimization of an auger pyrolyzer with heat carrier using response surface methodology,” Bioresource Technology 103(1), 405-414. DOI: 10.1016/j.biortech.2011.09.117

Chen, T. J., Niu, M., Wei, W., Liu, J. H., and Xie, Y. Q. (2015a). “Synthesis and characterization of poly-aluminum silicate sulphate (PASS) for ultra-low density fiberboard (ULDF),” RSC Advances 5(113), 93187-93193. DOI: 10.1039/C5RA13996A

Chen, T. J., Niu, M., Xie, Y. Q., Wu, Z. Z., Liu, X. Z., Cai, L. L., and Zhuang, B. R. (2015b). “Modification of ultra-low density fiberboards by an inorganic film formed by Si/Al deposition and their mechanical properties,” BioResources 10(1), 538-547. DOI: 10.15376/biores.10.1.538-547

Chen, T. J., Xie, Y. Q., Wei, Q. H., Wang, X. D., Hagman, O., Karlsson, O., Liu, J. H., and Lin, M. (2016). “Improving the mechanical properties of ultra-low density plant fiber composite (ULD_PFC) by refining treatment,” BioResources 11(4), 8558-8569. DOI: 10.15376/biores.11.4.8558-8569

Chen, Y., Wan, J., Zhang, X., Ma, Y., and Wang, Y. (2012). “Effect of beating on recycled properties of unbleached eucalyptus cellulose fiber,” Carbohydrate Polymers 87(1), 730-736. DOI: 10.1016/j.carbpol.2011.08.051

Chu, J. P., and Ou, J. Z. (2001). “Determination of cutting coefficient of fiber in the disc refiner,” Transactions of China Pulp and Paper 16(2), 134-137. DOI: 10.3321/j.issn:1000-6842.2001.02.027

Clark, J. D. A. (1985). “Some thoughts on fiber classification and length,” Tappi Journal 68(8), 119-121.

Gao, W. H., Chen, K. F., Yang, R. D., Li, J., Yang, F., Rao, G. H., and Tao, H. (2012). “Effects of beating on tobacco stalk mechanical pulp,” Cellulose Chemistry and Technology 46(3-4), 277-282.

GB/T 3332 (2004). “The determination of pulp beating degree,” Standard Press of China, Beijing, China.

GB/T 455 (2002). “The determination of tear index for paper,” Standard Press of China, Beijing, China.

GB/T 454 (2002). “The determination of burst index for paper,” Standard Press of China, Beijing, China.

GB/T 12914 (2008). “The determination of tensile strength for paper and cardboard,” Standard Press of China, Beijing, China.

GB/T 17657 (1999). “Test methods for evaluating the properties of wood-based panels and surface decorated wood-based panels,” Standard Press of China, Beijing, China.

Gulsoy, S. K. (2014). “Effects of cationic starch addition and pulp beating on strength properties of softwood kraft pulp,” Starch/Stärke 66(7-8), 655-659. DOI: 10.1002/star.201300247

Han, Y., Kwei-Nam, L., and Robert, L. (2008). “Comparative study on PFI beating response of hardwood and softwood kraft pulps,” Transactions of China Pulp and Paper 23(1), 61-63. DOI: 10.3321/j.issn:1000-6842.2008.01.014

Hou, Q., Yang, B., Liu, W., Liu, H., Hong, Y., and Zhang, R. (2011). “Co-refining of wheat straw pulp and hardwood kraft pulp,” Carbohydrate Polymers 86(1), 255-259. DOI: 10.1016/j.carbpol.2011.04.040

Kamel, S., El-Sakhawy, M., and Nada, A. M. A. (2004). “Mechanical properties of the paper sheets treated with different polymers,” Thermochimica acta 421(1), 81-85. DOI: 10.1016/j.tca.2004.03.005

Liu, D. T., Li, J., Yang, R. D., Mo, H. L., Huang, L. H., Chen, Q. F., and Chen, K. F. (2008). “Preparation and characteristics of moulded biodegradable cellulose fibers/MPU-20 composites (CFMCs) by steam injection technology,” Carbohydrate Polymers 74(2), 290-300. DOI: 10.1016/j.carbpol.2008.02.015

Marais, A., and Wågberg, L. (2012). “The use of polymeric amines to enhance the mechanical properties of lignocellulosic fibrous networks,” Cellulose 19(4), 1437-1447. DOI: 10.1007/s10570-012-9712-6

Molin, U., and Daniel, G. (2004). “Effects of refining on the fibre structure of kraft pulps as revealed by FE-SEM and TEM: Influence of alkaline degradation,” Holzforschung 58(3), 226-232. DOI: 10.1515/HF.2004.035

Mujtaba, A., Ali, M., and Kohli, K. (2014). “Statistical optimization and characterization of pH-independent extended-release drug delivery of cefpodoxime proxetil using Box-Behnken design,” Chemical Engineering Research and Design 92(1), 156-165. DOI: 10.1016/j.cherd.2013.05.032

Mutjé, P., Pelach, M. A., García, J. C., Presta, S., Vilaseca, F., and Jimenez, L. (2006). “Comparison of cationic demand between olive wood organosolv pulp and eucaliptus kraft pulp,” Process Biochemistry 41(7), 1602-1607. DOI: 10.1016/j.procbio.2006.03.006

Sahu, J. N., Acharya, J., and Meikap, B. C. (2010). “Optimization of production conditions for activated carbons from Tamarind wood by zinc chloride using response surface methodology,” Bioresource Technology 101(6), 1974-1982. DOI: 10.1016/j.biortech.2009.10.031

Singh, P., Shera, S. S., Banik, J., and Banik, R. M. (2013). “Optimization of cultural conditions using response surface methodology versus artificial neural network and modeling of L-glutaminase production by Bacillus cereus MTCC 1305,” Bioresource Technology 137, 261-269. DOI: 10.1016/j.biortech.2013.03.086

Tang, L. R., Huang, B., Ou, W., Chen, X. R., and Chen, Y. D. (2011). “Manufacture of cellulose nanocrystals by cation exchange resin-catalyzed hydrolysis of cellulose,” Bioresource Technology 102(23), 10973-10977. DOI: 10.1016/j.biortech.2011.09.070

TAPPI T222 om-11 (2011). “Acid-insoluble lignin in wood and pulp,” TAPPI Press, Atlanta, GA, USA.

Wei, Y. J., Zhu, X. L., Liu, H. B., Li, J. G., and Tao, J. S. (2010). “Study on the difference of fiber morphology of eucalyptus pulp refined at different consistencies,” Paper Science and Technology 29(4), 8-11. DOI: 10.3969/j.issn.1671-4571.2010.04.003

Xie, Y. Q., Chen, Y., and Zhang, B. G. (2004). “Study on a foamed material from plant fibers,” China Wood Industry 18(2), 30-32. DOI: 10.3969/j.issn.1001-8654.2004.02.009

Xie, Y. Q., Tong, Q. J., and Chen, Y. (2008a). “Construction mechanism of reticular structure of plant fiber,” Journal of Korea Furniture Society 19(2), 106-110.

Xie, Y. Q., Chen, Y., Wei, Q. H., and Zhang, D. Z. (2008b). “Study on forming a truss-like reticular structure made from nature fiber under the effect of liquid frothing,” Journal of Fujian College of Forestry 28(3), 203-207. DOI: 10.3969/j.issn.1001-389X.2008.03.003

Xie, Y. Q., Tong, Q. J., and Chen, Y. (2011). “Manufacture and properties of a novel ultra-low density fiberboard,” BioResources 6(4), 4055-4066. DOI: 10.15376/biores.6.4. 4055-4066

Xu, X. H., and He, M. Z. (2010). Experimental Design and the Application of Design-Expert and SPSS, Science, Beijing, China.

Yuan, S. J. (2004). “The structure, properties, and influencing factors of paper,” Hubei Zaozhi (1), 8-10. DOI: 10.3969/j.issn.1006-9631.2004.01.003

Article submitted: September 4, 2016; Peer review completed: October 22, 2106; Revised version received and accepted: October 26, 2016; Published: November 2, 2016.

DOI: 10.15376/biores.12.1.8-18