Abstract

The sol-gel method was used to make nano-TiO2 and five Chinese herbal medicines of Sophora flavescens Alt., Hypericum perforatum L., Cnidium monnieri (L.) Cuss., Kochia scoparia (L.), and Zanthoxylum bungeanum Maxim. to prepare five kinds of nano-TiO2-Chinese herbal medicine composite anti-degradative wood. Populus tomentosa Carr was chosen as the wood sample. Indoor decay resistance test results showed that the resistance to weight gain and decay of nano-TiO2-Chinese herbal medicine composite anti-degradative wood noticeably increased compared with either Chinese herbal medicine modified wood or nano-TiO2 modified wood, reaching a strong decay resistance level. The results of the anti-loss test showed that the magnitude of loss of wood samples treated with nano-TiO2 and Chinese herbal medicine was noticeably reduced compared with that with just Chinese herbal medicine. It was found by scanning electron microscopy that the nano-TiO2 particles and the Chinese herbal medicine enter the wood cell cavity, and the wood vessels and pits were the main permeation channels. Fourier transform infrared analysis results showed that nano-TiO2 could not only enter the wood interior, and associate with wood components through physical adsorption to form hydrogen bonds, but also through the carboxyl groups in cellulose and hemicellulose, or the phenolic hydroxyl group in lignin, forming a coordinated chemical bond to fix it in the wood component.

Download PDF

Full Article

Preparation and Properties of Nano-TiO2-Chinese Herbal Medicine Composite Wood

Xiaoqi Zhao,1 Jie Wang,1 Lei Wang, Shiming Ren, Zheng Hu, and Yamei Wang *

The sol-gel method was used to make nano-TiO2 and five Chinese herbal medicines of Sophora flavescens Alt., Hypericum perforatum L., Cnidium monnieri (L.) Cuss., Kochia scoparia (L.), and Zanthoxylum bungeanum Maxim. to prepare five kinds of nano-TiO2-Chinese herbal medicine composite anti-degradative wood. Populus tomentosa Carr was chosen as the wood sample. Indoor decay resistance test results showed that the resistance to weight gain and decay of nano-TiO2-Chinese herbal medicine composite anti-degradative wood noticeably increased compared with either Chinese herbal medicine modified wood or nano-TiO2 modified wood, reaching a strong decay resistance level. The results of the anti-loss test showed that the magnitude of loss of wood samples treated with nano-TiO2 and Chinese herbal medicine was noticeably reduced compared with that with just Chinese herbal medicine. It was found by scanning electron microscopy that the nano-TiO2 particles and the Chinese herbal medicine enter the wood cell cavity, and the wood vessels and pits were the main permeation channels. Fourier transform infrared analysis results showed that nano-TiO2 could not only enter the wood interior, and associate with wood components through physical adsorption to form hydrogen bonds, but also through the carboxyl groups in cellulose and hemicellulose, or the phenolic hydroxyl group in lignin, forming a coordinated chemical bond to fix it in the wood component.

Keywords: Sol-gel method; Nano-TiO2; Chinese herbal medicines; Mechanism; Anti-loss test

Contact informational: College of Materials Science and Art Design, Inner Mongolia Key Laboratory of Sandy Shrubs Fibrosis and Energy Development and Utilization, Inner Mongolia Agricultural University, Hohhot 010018 China; 1: These two authors contributed to this work equally;

* Corresponding author: wangym80@126.com

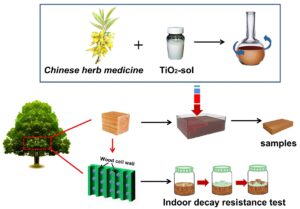

GRAPHICAL ABSTRACT

INTRODUCTION

In recent years, nanotechnology has become an active research direction in the field of wood. Combining nanotechnology with wood science will bring broad prospects for wood preservation. In the next few years, new material preparation technologies developed based on nanotechnology, such as wood modification technology, wood anti-degradative technology, wood composite preparation, etc., will greatly influence the development direction of the wood industry (Usmani et al. 2018, 2020). TiO2 is a type of inorganic antimicrobial agent with photo-catalytic activity with strong antimicrobial activity, high safety, good heat resistance, and weatherability (Kathavate and Deshpande 2020; Yang et al. 2020). TiO2 will generate -OH, O2-, H2O2, and other substances with strong oxidation property when TiO2 is exposed to light (Yang et al. 2018). These substances enter into the cell membrane and degrade the cell membrane after the metabolism is out of balance by changing the concentration of each component. The photo-catalytic and strong oxidation of TiO2 is used to act on substances in the cell and gradually promote cell death as TiO2 enters the cell (Kathavate and Deshpande 2020). Moreover, the strongly oxidizing -OH can rapidly and effectively decompose nutrients needed for the growth and survival of bacteria and play a bactericidal and bacteriostasis role (Gherardi et al. 2018). The durability of TiO2 as an antibacterial agent is better than other common antibacterial agents (Yu et al. 2020).

The sol-gel method is currently one of the most widely used methods for preparing nanometer titanium dioxide in the laboratory. The principle is that ester compounds or metal alkoxides form a uniform solution in an organic solvent after adding other components. The hydrolysis reaction and polycondensation reaction will occur in a certain temperature environment, and a sol is gradually formed. Nanometer titanium dioxide with high purity and small particle size is obtained after high-temperature calcination (Priyanka et al. 2016). Vicente Hernandez et al. (2020) treated wood samples with different TiO2 nanoparticles and evaluated the generation of free radicals and color changes after UV irradiation. The experimental results showed that the use of TiO2 whose photosensitivity was suppressed could increase the content of phenoxy groups. The color change also achieved similar results. These results indicated that the photocatalysis of TiO2 may be crucial to the performance of nanoparticles as a photoprotective treatment on the surface of wood (Hernandez et al. 2020). Iran Gomes da Rocha Segundo et al. (2018) proposed a cost-effective solution for the first time based on a low percentage of the combination of two semiconductors, TiO2 and ZnO, using two photocatalytic techniques-spray deposition and asphalt modification. The results showed that TiO2 nanoparticles and ZnO particles could make asphalt softer and have better anti-short-term aging effect, and will not cause any deterioration of asphalt before or after short-term or long-term aging (Segundo et al. 2018). Gholam Ali Shafabakhsh et al. (2020) studied the effects of nano SiO2 and nano TiO2 on the rheological behavior of asphalt. The results showed that adding different percentages of nanomaterials to asphalt could improve the asphalt’s aging resistance and resistance to rutting and fatigue damage and improve the rheology of asphalt. The results showed that the use of 1.2% nano SiO2 and 0.9% Nano TiO2 had the best performance.

The main components of wood cell walls are cellulose, hemicellulose, and lignin, which contain a large number of hydroxyl groups. The main component of cellulose is β-D-glucose, each unit of which contains three active hydroxyl groups, which is the structural basis for condensation polymerization (Fernandez-Costas et al. 2017; Valette et al. 2017; Wang et al. 2018). Therefore, the prepared TiO2 precursor sol can enter wood cells and intercellular spaces under the action of capillary tension, concentration gradient, and internal and external pressure difference (Ermeydan 2018). The wood is impregnated with inorganic nanoparticles. The hydroxyl groups on the surface of the particles are chemically bonded to the active hydroxyl groups in the wood cell wall, or they are deposited in the gap between the microfibrils in the amorphous region through physical adsorption (Antonelli et al. 2020). The hardness and density of wood cell walls can improve the physical properties of wood, such as improving mechanical properties, wear resistance, dimensional stability, bacteriostasis, flame retardancy, etc. Therefore, the durability of TiO2 as an antibacterial agent is better than other ordinary antibacterial properties (Moongraksathum and Chen 2018; Iwatsu et al. 2020; Rokicka-Konieczna et al. 2020).

Poplar is a fast-growing wood widely planted in China, but it is susceptible to rot, mildew, and moth infestation, which seriously restricts its use. The antidegradation treatment of poplar is an effective way to improve its performance and value. As people pay more attention to environmental protection, more plant-derived wood preservatives are used in wood protection, such as Chinese herbal medicine extracts, vegetable oil, and konjac powder, etc. (Ahn et al. 2010; Bae et al. 2019; Bi et al. 2019; Ahmed et al. 2020). However, due to the weathering resistance and easy loss of Chinese herbal medicine preservatives, the antifungal active ingredients in the Chinese herbal medicine extract are inactivated or lost, which affects the antiseptic effect (Tian et al. 2020). Therefore, the study uses the good weather resistance and antibacterial ability of nano-TiO2. The Chinese herbal medicine extracts and nano-TiO2 are effectively combined through the sol-gel method, so that the antibacterial properties of the two are complementary (Maness et al. 1999).

EXPERIMENTAL

Materials

Tetrabutyl titanate, ethanol, ice acetic acid, and nitric acid were purchased from Sinopharm Chemical Reagent Co., Ltd. (Hohhot, Inner Mongolia, China). Sophora flavescens, Hypericum perforatum, Cnidium monnieri, Kochia scoparia, and Zanthoxylum bungeanum were purchased from an Inner Mongolia Hohhot city pharmacy. Matrine, Forsythin, and Osthol standard were provided by Shanghai Pure Excellent Biotechnology Co., Ltd. (Shanghai, China).

Populus tomentosa Carr. (mature wood and sapwood) was produced in Hohhot (Inner Mongolia, China). The tree belongs to Salicaceae, which is widely used in urban greening. The sample size was 20 mm (R) × 20 mm (T) × 10 mm (L). The experimental strain Trametes versicolor (L.) Lloyd was selected and purchased from the Institute of Forest Ecology and Environment and Protection, Chinese Academy of Forestry (Beijing, China), and then cultivated and activated in the laboratory.

The wood samples were cleaned with an ultrasonic cleaner ((KS-300EI; Ningbo Haishu Kesheng Co., Ltd., Ningbo, China). The drying oven was used for drying wood (DHG-9245A; Shanghai Qixin Co., Ltd., Shanghai, China). A hydrothermal reaction kettle was used for compounding of Chinese herbal medicine and TiO2 sol (YZHR-250; Shanghai Yanzheng Co., Ltd., Shanghai, China). A vertical autoclave sterilizer was used for sterilization of culture medium and wood samples (SHENAN DSX-280; Shanghai Shen’an Medical Equipment Factory, Shanghai, China). The incubator with constant temperature and humidity is used to culture the strains and test the decay resistance of wood ((BSC-250; Shanghai Boxun Industry & Commerce Co., Ltd., Shanghai, China). Scanning electron microscopy (SEM) was used to observe the micromorphology of wood (FEI Quanta 200; Thermo Fisher Scientific, Waltham, MA, USA). A Fourier infrared spectroscopy analyzer was used to characterize specific tensile vibrations of chemical bonds (Dhg-9245a; Shanghai Qixin Scientific Instrument Co., Ltd., Shanghai, China). The chemical structures of Matrine, Forsythin, and Osthol were determined by nuclear magnetic resonance (NMR) (Bruker, Billerica, MA).

Test Specimens

The specimen diameter of 20 mm (R) × 20 mm (T) × 10 mm (L) was used of nature poplar wood, TiO2-sol modified wood (TSMW), Sophora flavescens-treated wood (SFTW), nano-TiO2–Sophora flavescens composite wood (NTSW), nano-TiO2–Hypericum perforatum composite wood (NTHW), nano-TiO2–Cnidium monnieri composite wood (NTCW), nano-TiO2–Kochia scoparia composite wood (NTFW), and nano-TiO2–Zanthoxylum bungeanum composite wood (NTZW).

Experimental Methods

The poplar sample was immersed in distilled water and cleaned by ultrasonic vibrations for 20 min to remove impurities and contaminants on the wood surface. Then, the wood was pretreated by drying to constant weight in an oven at 80 ℃. The purpose of pretreatment was to improve the permeability of the poplar sample. This test, which has been used to show antibacterial property and decay resistance in research related to Chinese herbal medicine, showed that white-rot fungus had a bacteriostatic effect. However, the effect was not obvious. Five low-price Chinese herbal medicines were considered: Sophora flavescens, Hypericum perforatum, Cnidium monnieri, Kochia scoparia, and Zanthoxylum bungeanum. The ratio of 1:8 Chinese herbal medicine and distilled water was used, and the specimens were soaked for 30 min; then the mixture was heated and boiled (Zhang et al. 2020). Then the TiO2 sol and the 0.6% Sophora flavescens water extract were added to the hydrothermal reactor at a ratio of 1:1.2, and the specimens were subjected to composite modification treatment by the hydrothermal method.

The five selected Chinese herbal medicines were prepared into 0.2 g/mL, 0.4 g/mL, 0.6 g/mL, 0.8 g/mL, and 1 g/mL water extract by water extraction method.

Next, nano-TiO2-Chinese herbal compound anti-degradative agents were prepared for five kinds of Chinese herbal medicine in five concentrations under the conditions of adding 10 mL of titanium source, 4 h of soaking time, pH of 1, and temperature at 90 ℃ using the sol-gel method.

Preparation of nano-TiO2-chinese herbal medicine composite preservative wood

The samples of poplar wood were placed in a drying oven at 103 ℃ to reach a constant weight, and then taken out for weighing. Five concentrations of Sophora flavescens, Hypericum perforatum, Cnidium monnieri, Kochia scoparia, and Zanthoxylum bungeanum were combined with nano-TiO2 sol and then placed in the hydrothermal reaction kettle. The samples were modified and treated with nano-TiO2 treatment materials and five kinds of Chinese herbal medicine treatment materials as the control group. Each group contained 20 samples. The processed samples were placed in the drying oven at 40 ℃ and baked to constant weight, denoted as WT. The weight gain (WPG) was calculated according to Eq. 1,

(1)

where WPG (%) is the percentage of weight gain, WC (g) is the total dry mass of the poplar sample after impregnation, and WT (g) is the total dry mass of untreated poplar samples.

Anti-loss test

The purpose of anti-loss test was to investigate the leaching effect of antibacterial ingredients in compound antidegradation wood. This experiment referred to the national standard in accordance to Chinese standard GB/T 29905 (2013) and the American AWPA E11-06 (2006) standard. Six specimens from each group with concentrations of 0.2 g/mL, 0.6 g/mL, and 1 g/mL were placed in a 500-mL beaker, and 180 mL distilled water was added to make the specimens immersed below the liquid level. The distilled water was replaced every 6 h, 24 h, and 48 h, and then every 48 h for a total of 14 d. The filtrate was collected after each change and combined for content analysis. After the test, the samples were taken out and wiped clean, and put in the drying oven at 103 ℃ for drying to the constant weight, and the weight was recorded. The loss of preservative components to be measured was calculated according to the Eq. 2,

(2)

where L (%) is the component loss of preservatives to be tested, mA (mg) is the mass of preservative to be measured in the filtrate, and m (mg) is the total mass of preservative to be measured in wood sample.

All the test samples were calculated by weight changes before and after the anti-loss test, and the content of active components in the filtrate was determined by high performance liquid chromatography (HPLC, LC3010002; Fairborn Industrial Development Co. Ltd., Shanghai, China). Due to the limited experimental research on the effective ingredients of Chinese herbal medicine to inhibit wood decay fungi, only Matrine, Forsythin, and Osthol were found to be the effective antibacterial components of Sophora flavescens, Hypericum perforatum, and Kochia scoparia in Fig. 1. Therefore, the specific method for analyzing the anti-loss performance of this test was carried out as follows:

The samples treated with three Chinese herbs of Sophora flavescens, Hypericum perforatum, and Cnidium monnieri were tested for the concentration of the components in the filtrate by HPLC.

Fig. 1. Structure of the bacteriostatic components: the structure of Matrine (a); the structure of Forsythin (b); and the structure of Osthol (c)

The mobile phase of S. flavescens was acetonitrile-anhydrous ethanol-3% phosphoric acid solution (80:10:10). The mobile phase of H. perforatum was acetonitrile-water (25:75). The mobile phase of C. monnieri was acetonitrile-water (65:30). The filling agent was amino bonded silica gel and octadecylsilane bonded silica gel. The detection wavelength were 220 nm, 277 nm, and 322 nm.

The control substance of Matrine, Forsythin, and Osthole were precisely weighed and prepared. The control products were 0.05 mg/mL Matrine solution, 0.2 mg/mL Forsythin solution, and 45 μg/mL Osthole solution. In accordance with the specific methods in the Chinese pharmacopoeia, the sample solutions were prepared, and 5 μL of each control sample solution and 5 to 10 μL of each test sample solution were precisely absorbed and injected into the liquid chromatograph for determination.

Through the regression equation, the concentration was calculated according to the peak area measured by the chromatogram, and then the percentage of the effective component was calculated according to the Eq. 3,

(3)

where X (g/100 g) is the content of effective components of the filtrate, C (μg/mL) is the concentration calculated by the regression equation, V (mL) is the constant volume, m (g) is the sample quantity, n is the dilution multiple.

Indoor decay resistance test

This experiment was conducted with reference to China’s forestry industry standard LY/T 1283 (2011). The river sand sawdust medium was prepared with a screw-capped wide-mouth flask to which 75 g of washed dry river sand (20- to 30-mesh), 7.5 g of Masson pine edge sawdust (20- to 30-mesh), 4.3 g of corn flour, and 0.5 g of brown sugar were added. Three pieces of wood were put on the surface, 50 mL maltose solution was slowly added into the bottle and the bottle cap tightened, and then it was put in the steam autoclave for sterilization for 1 h. Then it was removed and put on a clean table to cool down and become inoculated.

Activation and inoculation of strains-activation of strains for testing

The 5 mm diameter potato agar medium block was inoculated into the middle part of the river sand sawdust medium under aseptic operation conditions, and it was placed in a temperature of 28 ± 2 ℃ and humidity of 75 to 85%, cultivating for 10 d in a constant temperature and humidity incubator.

Sterilization and inoculation of the sample

The modified and absolutely dry samples were wrapped with multi-layer gauze and put in a triangular flask. Then, a little distilled water was added, and it was placed in a steam sterilization pot sterilize for 30 min under the conditions of pressure of 0.01 MPa and temperature of 121 ± 2 ℃. The samples were taken out and quickly placed in the ultra-clean workbench after cooling, and the UV lamp was turned on to continue sterilization for 30 min. The sample was brought into contact with the forage wood that had been overgrown with hyphae in the culture bottle with a wide surface under aseptic operating conditions. A sample was placed on each piece of forage wood, and 3 samples were placed in each culture bottle.

Sample decay test

The sterilized samples were placed directly above the feeding wood in the culture bottle, and the culture bottle were placed in a constant temperature and humidity incubator with a temperature of 28 ± 2 ℃ and a humidity of 75 to 85% for 12 weeks after the mycelium in the sawdust culture medium was overgrown.

All light was cut off during the decay period except for the use of light during inspection. Water was added regularly and checked the temperature and humidity of the constant temperature and humidity box. The samples were removed from the culture bottle, and the surface of the samples was carefully scraped clean of mycelium and other impurities after 12 weeks. The samples were placed in the drying oven, and then dried at 40 ℃ to the constant weight. The recorded weights were accurate to 0.01 g.

The mass loss L after each sample was infected by bacteria was calculated according to the Eq. 4. There were 6 samples for each group, and the average value was taken. Finally, the mass loss was used as the evaluation index of the decay resistance of different samples, as in Eq. 4.

(4)

In Eq. 4, L (%) is the component loss of preservatives to be tested, mA (mg) is the mass of preservative to be measured in the filtrate, and m (mg) is the total mass of preservative to be measured in wood sample.

The samples treated by different methods were decayed by wood decaying fungi, as shown in Fig. 2.

Fig. 2. Decay resistance of wood samples treated by different methods. Blank (a); Chinese herbal treatment wood (b); TiO2 sol treatment wood (c); Nano-TiO2-Chinese herbal compound antidegradation wood (d)

Structural Characterization

Scanning electron microscopy (SEM) and SEM-energy dispersive X-ray (EDX)

A blade was used to cut a thin slice of 10 mm × 10 mm × 1 mm, and it was placed on a clean sample table at the same position of each sample, and the surface was sprayed gold by Ion sputtering apparatus (GVC-1000; Beijing Zhongke Instrument Co. Ltd., Beijing, China) after vacuuming, and it was placed in an electron microscope for observation, and pictures of different positions were taken at different magnifications.

Fourier transform infrared (FTIR) analysis

The samples were placed in a constant temperature drying oven to be dried to absolute dryness. The samples were broken by a high-speed multifunctional crusher, sieved through a 200-mesh sieve and dried, and an appropriate amount of the dried samples were pressed with potassium bromide. The slice method was used to prepare the samples, and they were placed on the attenuated total reflectance (ATR) attachment (spectrum 100; Perkin-Elmer, Waltham, MA, USA) of the instrument sample stage for observation. The resolution was 4 cm-1, and the number of scans was 32 times.

RESULTS AND DISCUSSION

Weight Gain and Decay Resistance Analysis

Table 1 shows the variance analysis of the weight gain data (P=0.25, P=0.1, P=0.1) of nano-TiO2-Chinese herbal medicine composite antidegradative wood. Based on the F values obtained (F0.25(2, 2)=3, F0.1(2, 2)=9, F0.05(2, 4)=6.94), it can be seen that FA>F0.05(2, 2)=6.94, indicating that the influence of factor A on weight gain had a significant effect. FB>F0.05(2, 2)=6.94, indicating that the influence of factor B on weight gain also had a significant effect. FC=F0.25(2, 2)=3, indicating that factor C also had a certain effect on weight gain, but the effect was not significant. FD<F0.25(2, 2)=3, indicating that factor D had no significant effect on weight gain (A: Immersion time, B: Titanium source addition amount, C: Immersion temperature, D: pH value).

Table 2 shows the analysis of variance of the weight gain data (P=0.25, P=0.1, P=0.1) of nano-TiO2-Chinese herbal medicine composite anticorrosive wood. It was found that F0.25(2, 2)=3, F0.1(2, 2)=9, F0.05(2, 4)=6.94. It can be seen that FA>F0.25(2, 2)=3, indicating that factor A has an influence on the weight gain. FB, FC, FD<F0.25(2, 2)=3, indicating that factors B, C, D have no effect on the weight gain.

Table 3 shows the analysis of variance of the weight loss data (P=0.25, P=0.1, P=0.1) of nano-TiO2-Chinese herbal medicine composite anticorrosive wood. Because F0.25(2, 2)=3, F0.1(2, 2)=9, and F0.05(2, 4)=6.94, it can be seen from the table that FA, FB>F0.05(2, 2)=6.94, indicating that factors A and B had a significant effect on the weight loss. The comparison FC, FD<F0.25(2, 2)=3, indicates that factors C and D had no significant effect on the weight loss.

The concentration of Sophora flavescens, Hypericum perforatum, Zanthoxylum bungeanum, Cnidium monnieri, and Kochia scoparia, five kinds of Chinese medicinal water extracts, was 0.6 g/mL. The concentrations of nano-TiO2–Sophora flavescens, nano-TiO2–Hypericum perforatum, nano-TiO2–Zanthoxylum bungeanum, nano-TiO2–Cnidium monnieri, nano-TiO2– Kochia scoparia complex, and TiO2 sol were 0.2 g/mL, 0.4 g/mL, 0.6 g/mL, 0.8 g/ mL, and 1 g/mL, respectively. Chinese medicinal water extracts and different concentrations of nano-TiO2-Chinese herbal medicine were used to treated wood samples with white-rot.

Table 4 shows the weight loss after 12 weeks of bacterial decay. The weight loss of poplar wood without any treatment reached 51.0%, and the weight loss of poplar wood without treatment was greater than 45% after 12 weeks of indoor decay resistance test, and the test results were valid, as could be seen from Table 4. The weight loss values of the samples were 13.9%, 14.6%, 12.2%, 13.2%, and 15.3% after treatment with the concentration of 0.6 g/mL of S. flavescens, H. perforatum, Z. bungeanum, C. monnieri, and K. scoparia, respectively. All belonged to the II level of decay resistance, which indicated that the five-flavored Chinese herbal medicine had a certain decay resistance effect on the wood. It could also be seen that the decay resistance of the samples from strong to weak were Z. bungeanum, C. monnieri, S. flavescens, H. perforatum, and K. scoparia, and the range of weight gain was 6.67% to 7.02%. There was no noticeable difference in the drug loading of the test pieces after being treated with different Chinese herbal extracts. The weight loss of the sample treated with TiO2 sol alone was 21.6%, which belonged to the II level of decay resistance, indicating that TiO2 itself imparted certain decay resistance. The weight gain of the sample was 10.0%, which was greater than the wood test after the water extract treatment of Chinese medicine.

The weight loss of the wood samples treated with TiO2 sol and five kinds of Chinese herbal medicines was considerably lower than that of the samples treated with Chinese medicine alone and the samples treated with TiO2 sol alone, and the decay resistance level reached the I level. The results showed that the decay resistance of Chinese herbal medicines and TiO2 sol improved after compounding.

At the same time, TiO2 can act as a carrier to load more Chinese herbal medicines into the wood, and this may be a contributing reason for the enhanced decay resistance of the samples. It can be seen from the weight gain and weight loss of the wood samples after five kinds of nano-TiO2-Chinese herbal medicine composite treatment that there was no noticeable difference in the weight gain of the wood samples after the composite agent impregnation. It can be judged by the weight loss of the wood samples that the decay resistance of the composite agents from strong to weak were: nano-TiO2–Zanthoxylum bungeanum, nano-TiO2–Cnidium monnieri, nano-TiO2–Sophora flavescens, nano-TiO2–Hypericum perforatum, and nano-TiO2– Kochia scoparia. The order of decay resistance was the same as that of the five kinds of Chinese herbal medicine water extracts separately processing wood.

It can be seen from Fig. 3 that the weight loss of the wood samples after the five kinds of nano-TiO2-Chinese herbal medicine composite treatments all showed a trend of first decreasing and then increasing with the increase of the concentration of the drug solution. When the concentration of the drug solution was 0.8 g/mL, and the weight loss was the smallest, the weight loss was 2, 4, 6, 8, and 10 was 1.71%, 2.52%, 1.32%, 1.48%, and 3.01%, respectively.

Note: Set five groups of parallel tests for each concentration, repeat five times for each group of data, and take the average.

Fig. 3. The weight loss of the wood samples: 1. S ophora flavescens Alt.; 2. Nano-TiO2–Sophora flavescens; 3. Hypericum perforatum L.; 4. Nano-TiO2–Hypericum perforatum L.; 5. Zanthoxylum bungeanum Maxim.; 6. Nano-TiO2–Zanthoxylum bungeanum Maxim.; 7. Cnidium monnieri (L.) Cuss.; 8. Nano-TiO2–Cnidium monnieri (L.) Cuss.; 9. Kochia scoparia (L.); and 10 Nano-TiO2– Kochia scoparia (L.)

The weight gain of the wood sample increased with the increase of the concentration of the chemical solution, which showed that with the concentration of the chemical solution, the absorption of the wood sample gradually increased, and thus the decay resistance increased. When the concentration of the chemical solution increased from 0.8 g/mL to 1 g/mL, the decay resistance of the wood decreased. This may be because the concentration was too large. The decay resistance decreased as the loss increased. It could be seen from the test results that the TiO2 sol promoted the absorption of the Chinese herbal medicine liquid by the wood sample and increased its decay resistance.

Analysis of Anti-loss Performance

Results for the anti-loss test of the samples treated with Sophora flavescens, Hypericum perforatum, and Cnidium monnieri by HPLC are shown in Table 5. It can be seen that the loss of wood samples after nano-TiO2 and Chinese herbal medicine composite treatment was noticeably lower than that of wood samples treated only by Chinese herbal medicine combining Table 5 and Fig. 4. The loss of nano-TiO2–Sophora flavescens composite anti-degradative wood in the treated samples was 57.1% less than that of S. flavescens treated material after the same concentration of liquid medicine (0.6 g/mL), and the loss of nano-TiO2–Hypericum perforatum composite anti-degradative wood was 56.6% less than that of H. perforatum treated material. The loss of nano-TiO2–Cnidium monnieri composite anti-degradative wood was 57.3% lower than that of Cnidium monnieri treated material. At the same time, it could be seen that the weight gain of the sample increases with the increase of the concentration of the drug solution, but the loss first decreased and then increased. When the concentration of the chemical solution was 0.6 g/mL, the loss of the three composite anti-degradative kinds of wood all reached the minimum. The losses of 0.6 g/mL Nano-TiO2–Sophora flavescens, 0.6 g/mL Nano-TiO2–Hypericum perforatum, and 0.6 g/mL Nano-TiO2–Cnidium monnieri were 13.0%, 13.5%, and 13.2%.

Note: Set five groups of parallel tests for each concentrations, repeat five times for each group of data, and take the average.

Fig. 4. Results of anti-loss performance: 1. Sophora flavescens; 2. Nano-TiO2–Sophora flavescens; 3. Hypericum perforatum L.; 4. Nano-TiO2–Hypericum perforatum L.; 5. Cnidium monnieri (L.) Cuss.; 6. Nano-TiO2–Cnidium monnieri (L.) Cuss.

It could be seen that the loss of wood samples after nano-TiO2 and Chinese herbal medicine composite treatment was noticeably lower than that of wood samples treated only with Chinese herbal medicine, combining Table 6 and Fig. 5. After the same concentration of liquid medicine (0.6 g/mL) the loss of nano-TiO2–Sophora flavescens composite anti-degradative wood in the treated samples was 51.6% less than that of Sophora flavescens-treated material, and the loss of nano-TiO2–Hypericum perforatum composite anti-degradative wood was 50.2% less than that of Hypericum perforatum treated material, the loss of nano-TiO2–Cnidium monnieri composite anti-degradative wood was 53.4% less than that of Cnidium monnieri treated material, and the loss of nano-TiO2– Kochia scoparia composite anti-degradative wood was 50.9% less than that of K. scoparia treatment. The loss of nano-TiO2–Zanthoxylum bungeanum composite anti-degradative wood was 52.8% lower than that of Z. bungeanum treatment material. At the same time, it could be seen that the weight gain of the sample increased with the increase of the concentration of the drug solution, but the loss first decreased and then increased. When the concentration of the chemical solution was 0.6 g/mL, the average leaching of the five composite anti-degradative kinds of wood all reached the minimum. The average leaching of 0.6 g/mL Nano-TiO2–Sophora flavescens, 0.6 g/mL Nano-TiO2–Hypericum perforatum, 0.6 g/mL Nano-TiO2–Zanthoxylum bungeanum, 0.6 g/mL Nano-TiO2–Cnidium monnieri, and 0.6 g/mL Nano-TiO2– Kochia scoparia were 15.96%, 16.93%, 15.31%, 15.53%, and 16.26%.

Note: Set five groups of parallel tests for each concentration, repeat five times for each group of data, and take the average.

Fig. 5. Results of anti-loss performance: 1. Sophora flavescens; 2. Nano-TiO2–Sophora flavescens; 3. Hypericum perforatum; 4. Nano-TiO2–Hypericum perforatum; 5. Zanthoxylum bungeanum; 6. Nano-TiO2–Zanthoxylum bungeanum; 7. Cnidium monnieri ; 8. Nano-TiO2–Cnidium monnieri; 9. Kochia scoparia; 10. Nano-TiO2– Kochia scoparia; 11. Blank

As can be seen in Tables 5 and 6, the loss trend of Chinese herbal medicine was consistent when detected by the two methods. The loss of the drug was noticeably reduced after adding nano-TiO2, indicating that nano-TiO2 can improve the anti-loss performance of the agent (Barbero-Lopez et al. 2021). However, it could be seen in Table 6 that the loss results in Table 5 were lower than the corresponding results. This might be due to the limited conditions when using HPLC to detect that the Chinese herbal medicines in the filtrate were effective. The concentration of bacteriostatic components could not be measured against the loss of nano-TiO2 and other components in Chinese herbal medicine, so the results obtained were less than those obtained in Table 6.

The change trend of sample loss with the concentration and weight gain of the sample might be due to the fact that the concentration of preservatives must meet a certain value when the wood was treated with preservatives, and the main components of preservatives and wood components need to be combined. When the concentration was too small, the distance between molecules exceeded the range required to produce enough interaction, and it was unable to form precipitation of insoluble substances in the wood or chemical combination with wood, so as to achieve good anti-loss effect (Brischke 2020). When the concentration was too high, too many Chinese herbal medicine particles adhere to the surface of nano-TiO2, making nano-TiO2 easy to agglomerate to form particles with a larger particle size and deposit in the cell cavity, and cannot physically adsorb or chemically react with wood components, which was easy to drain (Sadeghnejad and Shafabakhsh 2017).

EDX Analysis of Surface Composition

The energy spectrum analysis of the surface composition of nano-TiO2-Chinese herbal medicine composite anti-degradative wood sample by EDX is shown in Figs. 6 to 12. Figure 6 shows the analysis diagram of the main components of poplar wood, Fig. 7 illustrates the analysis diagram of the main components of TiO2 modified wood, and Figs. 8 through 12 are the nanometer prepared by Z. bungeanum, K. scoparia, S. flavescens, H. perforatum, and C. monnieri of TiO2-Chinese herbal medicine composite anti-degradative wood main component analysis diagram.

Figure 6 shows that the composition of poplar wood was mainly composed of two elements, C and O. The weight percentage (wt%) was 53.5% and 45.8%, and the atomic number percentages (At%) were 60.7% and 39.0%. The remaining elements Ca, P, K, Al, etc., were trace elements present in wood, and the sum of weight percentage was 0.64 wt%, and the sum of atomic number percentage was 0.27 at%. The higher carbon content indicates that the wood mainly consists of lignin, cellulose, and hemicellulose.

Fig. 6. The poplar wood

Fig. 7. TiO2 sol modified wood

Figure 7 shows that the TiO2 sol modified wood sample mainly contained three elements: C, O, and Ti, and the weight percentages were 52.1 wt%, 46.4 wt%, and 0.71 wt%, respectively. The atomic percentages were 59.6 At%, 39.8 At%, and 0.2 At%, respectively. Among them, C came from wood, Ti came from TiO2 grains, and O came from wood and TiO2 grains. The remaining elements Ca, P, K, Si, etc., were trace elements present in wood, and the sum of weight percentage was 0.83 wt%, and the sum of atomic percentage was 0.31 At%. The results of EDX showed that TiO2 grains successfully entered the wood body.

Figures 8 to 12 show that the main components of the preservative wood samples of nano-TiO2 compounded with Z. bungeanum, K. scoparia, S. flavescens, H. perforatum and C. monnieri were C, O, and Ti, of which C and O were mainly from Chinese herbal medicine and wood, and the weight percentage of C element wt% and atomic number percentage At% were the highest. Among them, the abundant carbon compounds were contained in Chinese herbal medicine.

Fig. 8. Nano TiO2–Zanthoxylum bungeanum composite anti-degradative wood

Fig. 9. Nano TiO2– Kochia scoparia composite anti-degradative wood

Fig. 10. Nano TiO2–Sophora flavescens composite anti-degradative wood

Fig. 11. Nano TiO2 –Hypericum perforatum composite anti- degradative wood

Fig. 12. Nano TiO2–Cnidium monnieri composite anti- degradative wood

From the results of EDX, it can be seen that the main components of poplar wood were C, O, Ca, and the main components of wood treated with TiO2 are C, O, Ca, Ti. It can be seen that there were TiO2 crystal grains on the surface of the modified wood, and Chinese herbal medicine and nano-TiO2 chemically combined. Moreover, nano-TiO2 can act as a carrier to transport more Chinese herbal medicine into wood.

SEM Analysis of Surface Morphology

The SEM diagram is shown in Fig. 13, which shows the surface morphology of the original wood and the wood after anti-degradative treatment. Figure 13 (a, b) shows the original pictures of untreated wood. The orderly arrangement of conduits and pore structures on the surface of the untreated wood through SEM can be clearly observed. Figure 13 (c, d) shows the wood after antiseptic treatment with Chinese herbal medicine. It can be seen from the figure that the morphology of the wood changed after the Chinese herbal medicine was impregnated. In addition, the Chinese herbal medicine was evenly distributed in wood vessels and fiber-tracheids.

It could be seen from Fig. 13 (d) that there were trace deposits in the wood, and the wood had a small amount of Chinese herbal medicine after treatment that will enter its interior which are consistent with the results of EDX.

Figure 13 (e, f) shows the morphology of wood after TiO2 sol treatment. It could be seen from Fig. 13 (e) that there were obvious particles in the lumen. It could be seen that TiO2 particles entered the wood through the pipes and pits between the pipes after TiO2 sol treatment combined with EDX analysis. Figure 13 (g, h) shows the topography of wood after nano-TiO2-Chinese herbal medicine composite treatment. It could be seen from the figure that the tracheids and pores inside the wood were filled with a large amount of TiO2 particles and a small amount of Chinese herbal medicine deposits. According to the enlarged image Fig. 13 (h), there were a large number of particles in the pores of the wood, which indicated that the TiO2 particles could enter the pores inside the wood. Comparing Fig. 13 (h and f), the internal filling of wood after nano-TiO2-Chinese herbal medicine composite treatment was noticeably greater than that of wood only after TiO2 sol treatment. It showed that TiO2 particles entered the wood and also served as a carrier with loading more Chinese herbal medicines.

From Fig. 13(e, g), it can be seen that the TiO2 particles were attached to the vessel cell wall in a granular form, which made the inner wall of the vessel appear uneven compared to untreated wood, and it could be seen that the TiO2 particles were agglomerated after entering the wood from Fig. 13 (h). The above analysis showed that the TiO2 particles were mainly distributed in the lumens and pits of the wood. It could be inferred that the vessels and pits of the wood were the main channels through which nano-TiO2 penetrates the wood. At the same time, the TiO2 provided a suitable high-surface-area support that allowed the herbal extract compounds to fixed to be effective against microbial species. Nano-TiO2 would serve as a carrier to allow more Chinese herbal medicines to enter the wood to produce a synergistic bactericidal effect. After the wood was impregnated with the preservative solution, it will not significantly change the color, because the concentration of the preservative solution is very low, and the color itself is also very natural, so there is no obvious change in the color, gloss, etc. of the wood (Wu et al. 2020). At present, the combination of TiO2 particles and Chinese herbal medicine and wood had not yet been explained, and further research was needed.

Fig. 13. SEM images of poplar wood and composite materials prepared by different methods: Untreated wood (a, b); Chinese herbal medicine treatment wood (c, d); TiO2 sol treatment wood (e, f); Nano-TiO2-Chinese herbal medicine compound treatment wood (g, h)

FTIR Analysis

The infrared spectra of poplar material, TiO2 sol treatment material, Chinese herbal medicine treatment material, and nano-TiO2-Chinese herbal medicine composite treatment material are shown in Fig. 14 (a to d), respectively. It can be seen from Fig. 14 that the characteristic hydroxyl peaks at 3200 to 3500 cm-1 of the poplar spectra b, c, and d after three different conditions were weakened to different degrees than the poplar spectra a, and the intensity became lower. Among them, the spectrum c of the TiO2 sol treatment material showed the largest change, the spectrum b of the Chinese herbal medicine treatment material was extremely small, and the change of the spectrum d of the nano-TiO2-Chinese herbal medicine composite treatment material was between b and c. It showed that a large number of hydroxyl groups on poplar cellulose and TiO2 particles were chemically combined and deposited in the wood after treatment. It would not be noticeably weakened with only physical adsorption while the Chinese herbal medicine and wood were only weakly combined. The weakening degree of c was less than that of d, indicating that the TiO2 sol had acted as a carrier and successfully loaded Chinese herbal medicine into the wood. Compared with poplar wood material, in the TiO2 sol-treated material and the nano-TiO2-Chinese herbal medicine composite treatment material, the absorption band of the characteristic peak of 1700 to 1725 cm-1 disappeared. The characteristic peak was the C=O stretching vibration peak, which mainly came from the acetyl group in wood hemicellulose and the ester group in lignin. The disappearance of this peak indicated that the hemicellulose and lignin of the wood were hydrolyzed under acidic conditions. They formed a coordination chemical bond with Ti4+ on the surface of the TiO2 particles to combine with the wood components. The peak value of Chinese herbal medicine treatment material here was the same as that of poplar wood material. This showed that TiO2 particles were successfully introduced into the wood and formed a chemical bond with the components in the wood. Compared with poplar wood, the characteristic peak of 500 to 800 cm-1 in TiO2 sol-treated material and nano-TiO2-Chinese herbal medicine composite treatment material was clearly enhanced. This characteristic peak was the stretching vibration peak of Ti-O-Ti in TiO2, which indicated that TiO2 particles enter up the wood interior.

From the above analysis, it could be seen that after TSMW and nano-TiO2-Chinese herbal medicine composite-treated wood, nano-TiO2 particles entered the wood, some of which were combined with wood components through hydrogen bonding through physical adsorption, and the other was chemically combined with wood cell walls. The carboxyl groups of the cellulose and hemicellulose in the lignin chemically associated with the phenolic hydroxyl groups in the lignin and were fixed in the wood. The above conclusions were consistent with the conclusions of the wood indoor decay resistance test and anti-loss test.

Fig. 14. FTIR spectra of poplar wood and composites fabricated by different methods

CONCLUSIONS

1. The anti-degradative test results of the wood treated with nano-TiO2 and Chinese herbal medicine composite showed that the wood treated with the Chinese herbal medicine and nano-TiO2 composite had noticeably enhanced the anti-degradative effect in comparison to the wood treated with either the Chinese herbal medicine itself or the TiO2 sol alone. The combined treatment provided strong resistance relative to the original level of decay, indicating the successful combination of Chinese herbal medicine and nano-TiO2 through the sol-gel method, so that the antibacterial properties of the two complement each other. In addition to anti-fungal effects, Chinese herbal medicines can also prevent termites. After termites eat Chinese herbal medicine, the Chinese herbal medicine can inhibit the symbiotic bacteria in the termite body and achieve the purpose of killing termites. Therefore, Chinese herbal medicine is also an agent for killing termites.

2. The anti-degradative effect of nano-TiO2–Zanthoxylum bungeanum treatment material was the best, and the anti-degradative effect of nano-TiO2–Kochia scoparia was relatively poor. The treated materials after nano-TiO2 combined with Chinese herbal medicines, such as Cnidium monnieri, Sophora flavescens, and Hypericum perforatum, also showed different anti-degradative effects, and the weight loss rate of the treated specimens gradually increased with the increase of the concentration of the agent reduced.

3. The test results of anti-loss resistance showed that the anti-loss resistance of the Chinese herbal medicine and nano-TiO2 composite post-treatment material was noticeably higher than that of the Chinese herbal medicine itself. This might be caused by the adhesion of the nanomaterial itself, and the loss of preservatives increased with the concentration of the compound agent. The increase of TiO2 showed a trend of first decreasing and then increasing, indicating that the composite of nano-TiO2 and Chinese herbal medicines could help increase the fixation between Chinese herbal medicines and wood.

ACKNOWLEDGEMENTS

This study was financially supported by the Natural Science Foundation of Inner Mongolia (2018MS03048) and the Science and Technology Innovation Guidance Project of Inner Mongolia. The authors would also like to thank the National Key Research and Development Program of China (2016YFD0600904).

REFERENCES CITED

Ahmed, S., Fatima, R., and Hassan, B. (2020). “Evaluation of different plant derived oils as wood preservatives against subterranean termite Odontotermes obesus,” Maderas. Ciencia y Tecnologia 22(1), 109-120. DOI: 10.4067/S0718-221X2020005000110

Ahn, S. H., Oh, S. C., Choi, I. G., Han, G. S., Jeong, H. S., Kim, K. W., Yoon, Y. H., and Yang, I. (2010). “Environmentally friendly wood preservatives formulated with enzymatic-hydrolyzed okara, copper and/or boron salts,” Journal of Hazardous Materials 178(1-3), 604-611. DOI: 10.1016/j.jhazmat.2010.01.128

Antonelli, F., Bartolini, M., Plissonnier, M. L., Esposito, A., Galotta, G., Ricci, S., Davidde Petriaggi, B., Pedone, C., Di Giovanni, A., Piazza, S., et al. (2020). “Essential oils as alternative biocides for the preservation of waterlogged archaeological wood,” Microorganisms 8(12), Article Number 2015. DOI: 10.3390/microorganisms8122015

AWPA E11-06 (2006). “Standard method for evaluating the loss performance of wood preservatives,” American Wood Protection Association, Washington D.C., USA.

Bae, W. Y., Kim, H. Y., Choi, K. S., Chang, K. H., Hong, Y. H., Eun, J., Lee, N. K., and Paik, H. D. (2019). “Investigation of Brassica juncea, Forsythia suspensa, and Inula britannica: Phytochemical properties, antiviral effects, and safety,” BMC Complementary and Alternative Medicine 19(1), Article Number 253. DOI: 10.1186/s12906-019-2670-x

Barbero-Lopez, A., Akkanen, J., Lappalainen, R., Peraniemi, S., and Haapala, A. (2021). “Bio-based wood preservatives: Their efficiency, leaching and ecotoxicity compared to a commercial wood preservative,” Science of The Total Environment 753, Article ID 142011. DOI: 10.1016/j.scitotenv.2020.142013

Bi, Z. J., Yang, F. X., Lei, Y. F., Morrell, J. J., and Yan, L. (2019). “Identification of antifungal compounds in konjac flying powder and assessment against wood decay fungi,” Industrial Crops and Products 140, Article ID 111650. DOI: 10.1016/j.indcrop.2019.111650

Brischke, C. (2020). “Wood protection and preservation,” Forests 11(5), Article Number 549. DOI: 10.3390/f11050549

Ermeydan, M. A. (2018). “Modification of spruce wood by UV-crosslinked PEG hydrogels inside wood cell walls,” Reactive and Functional Polymers 131, 100-106. DOI: 10.1016/j.reactfunctpolym.2018.07.013

Fernandez-Costas, C., Palanti, S., Charpentier, J. P., Sanroman, M. A., and Moldes, D. (2017). “A sustainable treatment for wood preservation: Enzymatic grafting of wood extractives,” ACS Sustainable Chemistry & Engineering 5(9), 7557-7567. DOI: 10.1021/acssuschemeng.7b00714

GB/T 29905 (2013). “Laboratory method of determining the leach-ability of wood preservatives,” Standardization Administration of China, Beijing, China.

Gherardi, F., Goidanich, S., Dal Santo, V., and Toniolo, L. (2018). “Layered nano-TiO2 based treatments for the maintenance of natural stones in historical architecture,” Angewandte Chemie-Int. Ed. 57(25), 7360-7363. DOI: 10.1002/anie.201712752

Hernandez, V., Morales, C., Sagredo, N., Perez-Gonzalez, G., Romero, R., and Contreras, D. (2020). “Radical species production and color change behavior of wood surfaces treated with suppressed photoactivity and photoactive TiO2 nanoparticles,” Coatings 10(11), Article Number 1033. DOI: 10.3390/coatings10111033

Iwatsu, M., Kanetaka, H., Mokudai, T., Ogawa, T., Kawashita, M., and Sasaki, K. (2020). “Visible light-induced photocatalytic and antibacterial activity of N-doped TiO2,” Journal of Biomedical Materials Research Part B-Applied Biomaterials 108(2), 451-459. DOI: 10.1002/jbm.b.34401

Kathavate, V. S., and Deshpande, P. P. (2020). “Role of nano TiO2 and nano ZnO particles on enhancing the electrochemical and mechanical properties of electrochemically deposited phosphate coatings,” Surface & Coatings Technology 394, Article ID 125902. DOI: 10.1016/j.surfcoat.2020.125902

LY/T 1283 (2011). “Laboratory test method for wood preservatives’ toxicity to rotten bacteria,” Forestry Industry Standard of China, Beijing, China.

Maness, P. C., Smolinski, S., Blake, D. M., Huang, Z., Wolfrum, E. J., and Jacoby, W. A. (1999). “Bactericidal activity of photocatalytic TiO2 reaction: Toward an understanding of its killing mechanism,” Applied and Environmental Microbiology 65(9), 4094-4098. DOI: 10.1128/aem.65.9.4094-4098.1999

Moongraksathum, B., and Chen, Y.-W. (2018). “Anatase TiO2 co-doped with silver and ceria for antibacterial application,” Catalysis Today 310, 68-74. DOI: 10.1016/j.cattod.2017.05.087

Priyanka, K. P., Sukirtha, T. H., Balakrishna, K. M., and Varghese, T. (2016). “Microbicidal activity of TiO2 nanoparticles synthesised by sol-gel method,” IET Nanobiotechnology 10(2), 81-86. DOI: 10.1049/iet-nbt.2015.0038

Rokicka-Konieczna, P., Wanag, A., Sienkiewicz, A., Kusiak-Nejman, E., and Morawski, A. W. (2020). “Antibacterial effect of TiO2 nanoparticles modified with APTES,” Catalysis Communications 134, Article ID 105862. DOI: 10.1016/j.catcom.2019.105862

Sadeghnejad, M., and Shafabakhsh, G. (2017). “Use of nano SiO2 and nano TiO2 to improve the mechanical behaviour of stone mastic asphalt mixtures,” Construction and Building Materials 157, 965-974. DOI: 10.1016/j.conbuildmat.2017.09.163

Segundo, I. C. D., Dias, E. A. L., Fernandes, F. D. P., de Freitas, E. F., Costa, M. F., and Carneiro, J. O. (2018). “Photocatalytic asphalt pavement: The physicochemical and rheological impact of TiO2 nano/microparticles and ZnO microparticles onto the bitumen,” Road Materials and Pavement Design 20(6), 1452-1467.

Shafabakhsh, G. A., Sadeghnejad, M., Ahoor, B., and Taheri, E. (2020). “Laboratory experiment on the effect of nano SiO2 and TiO2 on short and long-term aging behavior of bitumen,” Construction and Building Materials 237, Article ID 117640.

Tian, X. H., Wang, P. L., Li, T., Huang, X. M., and Lei, H. M. (2020). “Self-assembled natural phytochemicals for synergistically antibacterial application from the enlightenment of traditional Chinese medicine combination,” Acta Pharmaceutica Sinica B 10(9), 1784-1795. DOI: 10.1016/j.apsb.2019.12.014

Usmani, S. M., Stephan, I., Hubert, T., and Kemnitz, E. (2018). “Nano metal fluorides for wood protection against fungi,” ACS Applied Nano Materials 1(4), 1444-1449. DOI: 10.1021/acsanm.8b00144

Usmani, S. M., Plarre, R., Hubert, T., and Kemnitz, E. (2020). “Termite resistance of pine wood treated with nano metal fluorides,” European Journal of Wood and Wood Products 78(3), 493-499. DOI: 10.1007/s00107-020-01522-z

Valette, N., Perrot, T., Sormani, R., Gelhaye, E., and Morel-Rouhier, M. (2017). “Antifungal activities of wood extractives,” Fungal Biology Reviews 31(3), 113-123. DOI: 10.1016/j.fbr.2017.01.002

Wang, Y. M., Zhang, Z. X., Fan, H. Q., and Wang, J. (2018). “Wood carbonization as a protective treatment on resistance to wood destroying fungi,” International Biodeterioration & Biodegradation 129, 42-49. DOI: 10.1016/j.ibiod.2018.01.003

Wu, Y., Zhou, J. C., Huang, Q. T., Yang, F., Wang, Y. J., Liang, X. M., and Li, J. Z. (2020). “Study on the colorimetry properties of transparent wood prepared from six wood species,” ACS Omega 5(4), 1782-1788. DOI: 10.1021/acsomega.9b02498

Yang, J. M., Wu, H. J., Wang, M. R., and Liang, Y. Y. (2018). “Prediction and optimization of radiative thermal properties of nano TiO2 assembled fibrous insulations,” International Journal of Heat and Mass Transfer 117, 729-739. DOI: 10.1016/j.ijheatmasstransfer.2017.09.069

Yang, L. L., Yang, H., Hao, W. T., Li, Y. C., Li, Q. Y., and Sun, T. (2020). “Fabrication, characterization and antibacterial mechanism of in-situ modification nano-CaCO3/TiO2/CS coatings,” International Journal of Food Science + Technology Online, Article ID 14897. DOI: 10.1111/ijfs.14897

Yu, S. Q., Han, B., Lou, Y. C., Liu, Z., Qian, G. D., and Wang, Z. Y. (2020). “Rational design and fabrication of TiO2 nano heterostructure with multi-junctions for efficient photocatalysis,” International Journal of Hydrogen Energy 45(53), 28640-28650. DOI: 10.1016/j.ijhydene.2020.07.184

Zhang, S., Guo, Y., Zhao, Q. H., Li, Y. R., Wu, X. J., and Huo, S. Y. (2020). “Study on the bacteriostatic action of Chinese herbal medicine on avian Trichosporon,” Poultry Sci 99 (9), 4530-4538. DOI: 10.1016/j.psj.2020.06.011

Article submitted: December 24, 2020; Peer-review completed: April 10, 2021; Revised version received and accepted: April 29, 2021; Published: May 2, 2021.

DOI: 10.15376/biores.16.2.4252-4274