Abstract

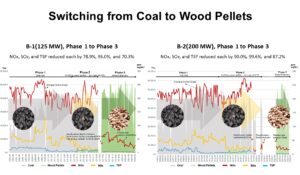

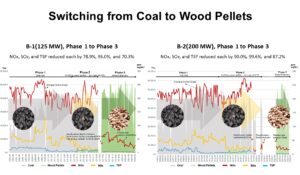

This study analyzed the particulates and gaseous emissions from 2005 to 2022 for power plants in South Korea (Utility scale: 125 MW (B-1) and 200 MW (B-2), respectively), which recently successfully converted from coal to wood pellets. The analysis showed that (1) NOx reduction was 78.9 to 90.0% (with outlet denitrification facility), (2) SOx reduction was 95.0 to 99.6% (without desulfurization facility condition), and (3) total suspended particles (TSP) reduction was 70.3 to 87.2% (with improved filtration and dust collection facility). This research confirmed the capabilities of wood pellets as a baseload power source and demonstrated their superior NOx reduction compared to coal. In the case of SOx, the desulfurization facility was discontinued at the stage of the fuel switch, so the value was affected by exogenous variable factors other than fuel. The TSP appears to be a combination of the ‘fine dust’ contained in the wood pellets and the performance of the filtration dust collector. The results suggest that fuel switching to wood pellets is a viable alternative to fossil fuels as an appropriate climate technology.

Download PDF

Full Article

Reducing Particulates and Gaseous Emissions through Fuel Switching from Coal to Wood Pellets at Power Plants in South Korea during 2005 to 2022

Seung-Rok Lee,a Sae Byul Kang,b and Gyu-Seong Han c,*

This study analyzed the particulates and gaseous emissions from 2005 to 2022 for power plants in South Korea (Utility scale: 125 MW (B-1) and 200 MW (B-2), respectively), which recently successfully converted from coal to wood pellets. The analysis showed that (1) NOx reduction was 78.9 to 90.0% (with outlet denitrification facility), (2) SOx reduction was 95.0 to 99.6% (without desulfurization facility condition), and (3) total suspended particles (TSP) reduction was 70.3 to 87.2% (with improved filtration and dust collection facility). This research confirmed the capabilities of wood pellets as a baseload power source and demonstrated their superior NOx reduction compared to coal. In the case of SOx, the desulfurization facility was discontinued at the stage of the fuel switch, so the value was affected by exogenous variable factors other than fuel. The TSP appears to be a combination of the ‘fine dust’ contained in the wood pellets and the performance of the filtration dust collector. The results suggest that fuel switching to wood pellets is a viable alternative to fossil fuels as an appropriate climate technology.

DOI: 10.15376/biores.18.4.8458-8472

Keywords: Climate crisis; Wood pellet; Forest biomass; Bioenergy; Energy transition; Fuel combustion; Fuel switching; Particles emissions; Gaseous emissions

Contact information: a: Ph.D. Student, Energy and Environment Policy Research Lab, Graduate School of Energy and Environment (KU-KIST GREEN SCHOOL), Korea University, 145 Anam-ro, Seungbuk-gu, Seoul, 02841, Republic of Korea; b: Principal Researcher, Energy Convergence System Research Department, Korea Institute of Energy Research, 152 Gajeong-ro, Yuseong-gu, Daejeon 34129, Republic of Korea; c: Professor, Department of Wood and Paper Science, College of Agriculture, Life and Environments Sciences, Chungbuk National University, 1 Chungdae-ro, Seowon-gu, Cheongju-si, Chungcheongbuk-do 28644 Republic of Korea; *Corresponding author: wood@chungbuk.ac.kr

GRAPHICAL ABSTRACT

INTRODUCTION

The international community has a broad consensus on the expansion of forest biomass energy (FBE) and the hegemony of sustainability (UN 2017; KNIFS 2021; EC 2022). The IPCC has categorized the use of forestry products for bioenergy to replace fossil fuel use as a key climate technology (IPCC 2007). The International Energy Agency (IEA) has emphasized the need to promote modernized bioenergy use systems based on sustainable forest management to create a carbon-neutral society (IEA 2018; IEA 2021). The European Union (EU) has classified bioenergy in its taxonomy as an excellent energy source for both climate change mitigation and adaptation (EC 2020). “The Seoul Forest Declaration”, adopted at the XI World Forestry Congress, included a global endorsement of the “Wood as renewable energy” agenda (KFS 2022).

Modernized forest biomass (FB) entails the use of wood pellets (WP) and wood chips (WC) in modern combustion equipment and has a wealth of applications at the international level (Lee and Han 2021; Lee et al. 2022a,b), and usage growth is evident. FB directly input into energy in the EU-27 increased from 148 Mn tons in 2009 to 194 Mn tons in 2017 (EC 2022a; Cazzaniga et al. 2022). Future Metrics estimates that WP consumption at the international level will reach 66 Mn tons by 2027 (William 2021). According to the EU Bioenergy Retrofits for Europe’s Industry Project, there are 45 factories and power plants in Europe that have switched or are planning to switch to forest-based fuels such as WP and WC (BIOFIT 2020). In line with this international trend, South Korea’s total WP demand was estimated to be 4.6 Mn tons in 2022 (KFS 2023). Based on previous studies, the maximum amount of WP that South Korea could self-source in 2050 was estimated at 3.4 Mn tons (Lee et al. 2022a). This increased use of FB is based on its cleaner combustion characteristics.

According to the European Environment Agency (EEA), SO2 and dust emissions from large combustion plants above 50 MW fell by 91% and Nitrogen Oxide (NOx) by 68% in the EU-27 region from 2004 to 2020. In the same period, the use of coal fuel has declined by 44% since 2005, while biomass has increased by 64% (EEA 2022). Considering this trend, it is worth looking specifically at the literature regarding particulates and gases, which are typical emissions. The impact of the transition from fossil fuels to FB on atmospheric CO2 concentrations cannot be determined simply by comparing CO2 emissions at the combustion point (Cowie et al, 2021). This is due to the fact that it overlooks the basic distinctions between fuel sources. From a scientific standpoint, it is vital to recognize the carbon cycle features of FB.

Compared to coal, FB produces fewer NOx emissions during combustion, and its extremely low sulfur content also contributes to the decrease of Sulfur Oxides (SOx) emissions (Hayter et al. 2004). Moreover, with increasing ratio of WP during combusting with sub-bituminous coal, a large amount of NOx-reducing NH3 is released from the volatile components of biomass, reducing the NOx concentration after combustion (Lee et al. 2014). Additionally, NOx generation during combustion was positively impacted by the WP’s reduced nitrogen content (Lee et al. 2017). Regardless of the kind of combustor, NOx is typically reduced with increased FB ratios combusting with coal, based on the findings of lab-scale research (Kim et al. 2015; Guo and Zhong 2018; Kim et al. 2019; Chae 2020). In a small-scale experimental circulating fluidized bed combustion, the use of air-staging technology allowed the combustion of WP using forest by-products to produce an atmosphere in which the fuel’s nitrogen content (Fuel-N) could be converted to N2, which was effective for denitrification in the furnace (Yoon et al. 2021). When compared to coal-fired power generation, FB combustion dramatically lowers NOx emissions in most combustion situations (Sloss 2010). Demonstration studies with biomass power plants of large scale (100 MW or more) or those that are co-fired with coal have shown a significant reduction in NOx with FB input (Jung and Yoo 2019; Ahn et al. 2019; Cahyo et al. 2020), and CFD analyses have shown the same results (Oh et al. 2014; Kang et al. 2015).

Regarding the SOx, since pure wood contains very little sulfur, the levels of SOx produced during combustion are not significant in experimental experiments involving sulfur oxides (Kim et al. 2015; Lee et al. 2017; Yoon et al. 2021). Because most of the sulfur content is concentrated in the coal during combustion, SO2 emissions increase in proportion to the amount of coal burned (Leckner and Karlsson 1993). A considerable decrease in SO2 emissions was seen in the coal and WP blending (20%) experiments (Guo et al. 2018). An increase in biomass from 10% to 20% reduced SOx by 21% to 60%. (Kim et al. 2006). Alkaline components in biomass ash can be effective in eliminating sulfur oxides (Nussbaumer 2003). Also with respect to particulates, total particulate material (TPM) measurements from 74 power plants in South Korea showed that biomass was 1.6 mg/m3, which was lower than coal at 3.3 mg/m3 and heavy oil at 3.0 mg/m3 (Park and Lee 2020).

As such, there has been a wealth of research on the fuel properties of FB, gas, particle emissions by combustion size, and market trends. However, to our knowledge, this is the first work to track data from power plants that have successfully converted fossil fuels to WP. Given that the use of FBE in Korea has recently emerged as a social interest (Han 2022), it is necessary to systematically conduct analytical studies related to this. Through this paper, the authors aim to demonstrate the role of WP as a replacement for coal by tracking long-term emissions changes based on practical examples and data of successful fuel conversion from coal to WP, providing insights to various stakeholders, and promoting social acceptance.

The structure of this paper is divided into two main parts: (1) The research framework is outlined in “Experiments,” which introduces the power plants examined in this study, the measuring techniques for particle and gas emission variables, the data organized by major time periods, and the methodology for data interpretation; (2) in the “Results and Discussion” section, there is an analysis of the changes in various indicators, such as emissions and power generation according to the timing of fuel switching for each generating unit in the B power plant from 2005 to 2022. In addition, the authors derive a relative comparison figure between the present results and the results of previous studies.

EXPERIMENTAL

Power Plants to be Analyzed

The power plant B, built in the 1970s, is divided into two units with an installed capacity of 125 MW (hereinafter ‘B-1’) and 200 MW (hereinafter ‘B-2). Currently, the B power plant uses a renovated pulverized coal-fired boiler for WP. As a fuel, both B-1 and B-2 were previously coal-only used power plants, but these utilities are now using only WP. In analyzing the data, the authors considered NOx, SOx, and TSP to be priority control elements by the Korea Environment Corporation (KEC 2022).

Collecting Emissions Data

Based on the collaboration of Power Plant B, authors gathered and referred to historical data for the examination of coal and WP consumption, power generation, environmental facilities, and emissions from 2005 to 2022 for which data were available. TSP was determined by the measured light transmission method, whereas NOx and SOx were determined by infrared absorption (IR). The authors divided combustion into three phases—coal-only (Phase 1), coal with WP (Phase 2), and WP (Phase 3)—to assess the variations in emissions. The authors also looked at how fuel type affected variations in power generation. The authors divided the data into three phases to better understand how NOx varied during combustion depending on the type of fuel input: coal combustion data (Phase 1-1), WP combustion data; immediately before passing through the denitrification facility (Phase 2-1), and WP combustion data; after passing through the denitrification facility (Phase 2-2). For this study, the excluded outliers were those that occurred when the B-1 and B-2 were not in operation. The structure of this research model is shown in Fig. 1.

Fig. 1. Research model of this study

RESULTS AND DISCUSSION

B Power Plant Highlights

The B power plant consists of two major units. Their respective fuel switching dates are June 2017 for B-1 (125 MW) and September 2020 for B-2 (200 MW). B-1 has operated Selective Non Catalytic Reduction (SNCR’) and Selective Catalytic Reduction (SCR’) since 2017 and is currently in integrated operation with improved filtration dust collectors in addition to existing electrostatic precipitators. B-2 has been operating SCR since 2017 and has updated a filtration precipitator for 2020. Both B-1 and B-2 stopped operating their desulfurization plants at the time of the fuel switch. B power plant switched to all fuel oil in 2009 to reduce sulfur oxide emissions and now only uses it in special cases (generator start-ups and shutdowns, after equipment replacement operations). Very little of the trace sulfur in WP comes from combustion, as it is absorbed into ash, but it should be noted that sulfur is contained in the anti-clinker compounds used during power generation.

B-1 (125 MW) Data

According to South Korea’s legislation system, called the “Clean Air Conservation Act” and the “Act on the Integrated Control of Pollutant-discharge Facilities”, various emission regulations are set, taking into account the location of power plants and facilities’ characteristics in South Korea (Act No. 18469 MoE 2021; Act No. 18917 MoE 2022). The legal standard for B-1 was gradually tightened from 350 ppm to 59.5 ppm for NOx between 2005 and 2022. During the same period, the legal standards for SOx were gradually tightened from 150 ppm to 10 ppm and TSP from 50 mg/Sm3 to 10 mg/Sm3. Thus, the monthly average trend of B-1 emissions is shown in Fig. 2, and all emissions were below the legal threshold during the evaluation period.

As shown in Table 1, the emission patterns per phase reduced NOx levels from Phase 1 to Phase 3 by 78.9%, and from 211.8 ppm to 44.9 ppm, respectively. The decrease in SOx was 95.0%, from 54.1 ppm to 2.7 ppm, respectively. The fuel oil type change event happened just before the Phase 2 sulfur oxide emissions calculation, so even though there were no other events in Phase 3 besides the desulfurization facility shutdown and fuel switch, the 85.4% reduction in Phase 3 compared to Phase 2 is noteworthy. When compared to Phase 1, TSP was reduced by 70.3% in Phase 3 (Table 1, Fig. 3).

Fig. 2. B-1 emission trends (NOx, SOx, and TSP) compared to the legally permitted baseline period (2005–2022)

Table 1. Trends of B-1; Phase 1 to Phase 3 Average Value (2005–2022)

Fig. 3. B-1 Historical Data Analysis (2005-2022). Note: Phase 1 denotes generation that uses only coal. Co-firing with coal and WP is referred to as Phase 2, while generation using only WP is referred to as Phase 3. Important milestones include the switch to fuel oil in 2009, the completion of the B-1 fuel switch from coal to WP in 2017, the shutdown of the desulfurization facility in 2017, the completion of the denitrification facility (SNCR+SCR) in 2017, the retrofit of the filtration dust collector 3-4 field, and the modification of the filtration dust collector 2 field in 2020.

From 2009 to May 2022, when statistics were available, the study included the monthly average power generation, coal consumption, and WP usage of B-1. It was discovered that Phase 1’s monthly average production was 66,268 MWh and 29,895 tons of coal. 80,510 MWh, 36,053 tons of coal, and 1,603 tons of WP were used in Phase 2, while 66,543 MWh and 40,011 tons of WP were used in Phase 3 (Table 2, Fig. 4).

Table 2. From Phase 1 through Phase 3 of B-1, Monthly Average Generation and Fuel Utilization

Fig. 4. Fuel use and power generation of B-1 (monthly average)

Analysis of B-2 (200 MW) Data

Based on the South Korea’s legal standard for B-2, NOx was also gradually tightened from 350 to 34 ppm between 2005 and 2022. During the same period, the legal standards for SOx were gradually tightened from 150 ppm to 10 ppm and TSP from 50 to 5 mg/Sm3. Thus, the monthly average trend of B-2 emissions is shown in Fig. 5, and all emissions were below the legal threshold during the evaluation period.

As shown in Table 3, NOx levels decreased from Phase 1 to Phase 3 by 90.0%, and from 212.6 ppm to 21.2 ppm, respectively. The decrease in SOx was 99.6%, from 49.5 ppm to 0.2 ppm, respectively. Despite the suspension of the desulfurization facility and the change in fuel, there was a 99.2% reduction in Phase 3 compared to Phase 2. When the filtration dust collector was enhanced in Phase 3, TSP decreased by 87.2% compared to Phase 1 and by 78.6% compared to Phase 2 (Table 3, Fig. 6).

Table 3. Trends of B-2; Phase 1 to Phase 3 Average Value (2005 to 2022)

From 2009 to May 2022, when statistics were available, the study included the monthly average power generation, coal consumption, and WP usage of B-2. It was discovered that Phase 2’s monthly average production was 109,042 MWh and 50,739 tons of coal. 116,080 MWh, 50,668 tons of coal, and 2,145 tons of WP were used in Phase 2, while 100,080 MWh and 55,480 tons of WP were used in Phase 3 (Table 4, Fig. 7).

Fig. 5. B-2 emission trends (NOx, SOx, and TSP) compared to the legally permitted baseline period (2005–2022)

Fig. 6. B-2 Historical Data Analysis (2005-2022). Note. Phase 1 denotes generation that uses only coal. Co-firing with coal and WP is referred to as Phase 2, while generation using only WP is referred to as Phase 3. Important milestones include the switch to fuel oil in 2009; the completion of the denitrification facility (SCR) in 2017; the shutdown of the desulfurization facility in 2018; the completion of the B-2 fuel switch from coal to WP in 2020; and the modification of the filtration dust collector in 2020.

Table 4. From Phase 1 through Phase 3 of B-2, Monthly Average Generation and Fuel Utilization

Fig. 7. Fuel Use and Power Generation of B-2 (Monthly Average)

Comparison of NOx Emissions between B-1 and B-2

It is vital to examine historical average data for the difference in emissions between coal and WP to better understand the fuel switch. SCR and SNCR were installed in B-1, while only SCR was installed in B-2. The evaluation period was therefore split into three phases: Phase 1-1 (coal only), Phase 2-1 inlet denitrification facility (after only WP burnout but before passing through the denitrification facility), and Phase 2-2 outlet denitrification facility (after only WP burnout but after passing through the denitrification facility). According to the analysis, the NOx in Phase 2-1 for the B-1 and B-2 was reduced by 66.1% and 68.7%, respectively, compared to Phase 1-1. The reduction in Phase 2-2 compared to Phase 2-1 was 37.5% and 68.1%, respectively (Table 5).

Table 5. Average Nitrogen Oxide Emissions Compare (Unit: ppm)

The emission factors at key points at this stage are as follows. For B-1, the NOx emission factors for coal only and WP only combustion are 1.222 kg/MWh and 0.218 kg/MWh, respectively. SOx is 0.217 kg/MWh and 0.001 kg/MWh, and dust is 0.016 kg/MWh and 0.012 kg/MWh, respectively. For B-2, the NOx emission factors for coal only and WP only combustion are 1.214 kg/MWh and 0.122 kg/MWh, respectively. SOx is 0.261 kg/MWh and 0.000 kg/MWh respectively, and dust is 0.010 kg/MWh and 0.003 kg/MWh, respectively.

There was a general decreasing trend in emission factors, even if there are variations depending on how well each power plant’s units’ function. This led to a strong trend of emission reduction by switching coal to WP as a renewable energy, as shown by the relative comparison between the literature analysis carried out throughout this research and the data generated from this research. However, as previously indicated in this research, CO is excluded in Table 6 as a reference, as emissions are negligible at the demonstration facility’s scale input (Jung and Yoo 2019). A separate visualization for SOx was not carried out due to the lack of a meaningful linkage with fuel characteristics, the limited sample for relative comparisons, and the existence of several exogenous factors (Fig. 8).

In this research, the authors conducted a cumulative data and literature analysis of power plants located in Korea. The results of the literature analysis confirmed the superiority of FB (especially WP) as a coal substitute and showed that low-graded FB (such as treetop, branch, bark, and damaged FB) is suitable for large-scale combustion facilities with advanced environmental facilities, given the international trend toward sustainability. This is in line with the IEA’s view that emphasizes the expansion of modern energy utilization based on forest by-products (IEA 2021) and confirms that the revitalization of FB utilization systems is a “Technology-driven climate change response strategy”.

The findings demonstrated its potential as a fossil fuel alternative and supported the critical function of denitrification as a climate technology by establishing that the change in fuel alone was sufficient to reduce NOx. WP contains very little inherent sulfur, so SOx emissions from WP combustion are almost negligible.

Fig. 8. Comparison of this research’s findings with prior data on NOx emissions (Unit: ppm). Note: The author estimates again if prior research has unclear number or graphs.

Even if there is a trace amount of sulfur in WP, it is absorbed by the ash, so there is very little SOx emitted. Therefore, when switching from coal to WP as a fuel, the desulfurization plant can be shut down. Nevertheless, if SOx is detected in the exhaust gas, it is most likely due to external factors such as fuel oil or clinker remover added to promote smooth combustion. In the case of TSP, it is likely to be a combination of the fact that WP contains much less inorganic matter than coal and the effect of the filter dust collector modification. The difference in the three emissions from Power Plant B between B-1 and B-2 is due to differences in design, plant size, and the design of environmental facilities.

B-1 produced 66,543 MWh each month (on average) after converting to WP, which is comparable to the 66,268 MWh it produced with conventional coal in Phase 1. The facility has been supplying 40,011 tons of WP instead of 29,895 tons of coal every month due to the different calorific values of WP and coal. B-2 is not comparable with B-1 due to the difference in size and type of facilities, since it is a more recent fuel transition that necessitates a time of operational stabilization. However, it can be inferred that B-1 can play a certain role as a base power generation source. It should be noted that the derived results may change depending on the evaluation period.

Through this study, it was determined that the overall trend of emission reduction caused by the use of WP was comparable to prior research (Hayter et al. 2004; Sloss 2010; Oh et al. 2014; Kang et al. 2015; Lee et al. 2017; Jung and Yoo 2019; Yang 2021). This research is significant in that it provides data to demonstrate the value of WP for efficiency and cleanliness in modern combustion facilities under appropriate combustion conditions by analyzing more than 10 years of data. This research will provide a basis for future research into bioenergy with carbon capture and storage (BECCS), socio-economic effect analysis of fuel switching, and the environmental benefit analysis of greenhouse gas reduction. In addition, from a technical perspective, this study will provide insights into the control of air pollutants that can be generated during power plant operation, as well as the advancement of environmental equipment technology and the future direction for utilities that are still using fossil fuels. At the macro level, the authors believe that this research will contribute to the spread of FBE-focused renewable energy initiatives and the shaping of the discourse on the bio-economy. It will also contribute to promoting social acceptance by providing insights to various stakeholders. Above all, the authors expect to see a discussion on climate change that is based on science and intellect.

CONCLUSIONS

- During the evaluation period set by this research (2005 to 2022), the effect of switching fuels on NOx reduction ranged from 78.9% to 90.0% (Coal only, 211.8 to 212.6 ppm, changed to WP only, 21.2 to 44.9 ppm).

- The authors also examined the WP with and without denitrification to examine the effect of NOx reduction data, and the authors discovered that the WP reduced NOx by 66.2 to 68.6% when compared to the usage of coal alone (Coal 211.8~212.6 ppm → WP 66.5 to 71.8 ppm). With the aid of denitrification technology, further reduction effects of 37.5 to 68.1% (WP 66.5 to 71.8 ppm, NOx inlet → WP 21.2 to 44.9 ppm, NOx outlet) were achieved.

- During the same period, 95.0 to 99.6% less SOx was released (Coal 49.5 to 54.1 ppm, WP 0.2 to 2.7 ppm). In the case of TSP, the reduction was 70.3 to 87.2% (Coal 11.7 to 11.8 mg/Sm3 → WP 1.5 to 3.5 mg/Sm3).

- The authors observed that B-1 had 66,268 MWh/month when using solely coal, but that number grew by 275 MWh to 66,543 MWh/month upon converting to WP by examining the monthly average generation and monthly average fuel use. Judging by the power generation volume, WP is the realistic alternative fuel of coal.

- Based on the B Power Plant case, switched fuel from coal to WP has a positive effect, and it was demonstrated more clearly by this study: (1) Total NOx reduction was 78.9 to 90.0% (with outlet denitrification facility), (2) Total SOx reduction was 95.0 to 99.6% (without desulfurization facility condition), and (3) Total suspended particles (TSP) reduction was 70.3 to 87.2% (with improved filtration and dust collection facility).

ACKNOWLEDGEMENTS

This research was carried out with the support of the R&D Program for Forest Science Technology (Project No. 2021353D10-2123-AC03) provided by the Korea Forest Service (Korea Forestry Promotion Institute) and supported by funding for the academic research program of Chungbuk National University in 2023.

REFERENCES CITED

Act on the Integrated Control of Pollutant-discharging Facilities, Act No. 18917, Jun. 10, (2022), Ministry of Environment, Sejong, Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=242971&ancYd=20220610&ancNo=18917&efYd=20220610&nwJoYnInfo=Y&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (Accessed 26 Oct 2022).

Ahn, S. K., Lee, J. S., Park, J. S., and Jeong, S. M. (2019). “Combustion and emission characteristics of wood pellet co-firing in 550MW CFB boiler,” in: KOSCO 58th Symposium, Samcheok, Gangwon State, South Korea, pp. 147-148.

Bioenergy Retrofits for European’s Industry (BIOFIT) (2020). “BIOFIT Industry Map, Munich,” (https://www.biofit-h2020.eu/biofit-industry-map/), Accessed 9 August 2022.

Cahyo, N., Alif, H. H., Saksono, H. D., and Paryanto, P. (2020). “Performance and emission characteristic of co-firing of wood pellets with sub-bituminous coal in a 330 MWe pulverized coal boiler,” in: 2020 International Conference on Technology and Policy in Energy and Electric Power (ICT-PEP), pp. 44-47. IEEE. DOI: 10.1109/ICT-PEP50916.2020.9249930.

Cazzaniga, N., Jasinevičius, G., and Mubareka, S. (2022). “Sankey diagrams of woody biomass flows in the EU – 2021 release (European Commission), JRC127989,” (https://publications.jrc.ec.europa.eu/repository/handle/JRC127989), Accessed 1 October 2022.

Chae, T. (2020). “NOx reduction by co-firing and reburning of biomass,” in: 1MWth Coal Combustion. DOI: 10.15231/jksc.2020.25.3.048.

Clean Air Conservation Act, Act No. 18469, Sept. 24, (2021), Ministry of Environment, Sejong, Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=235591&ancYd=20210924&ancNo=18469&efYd=20220325&nwJoYnInfo=Y&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (Accessed 26 Oct 2022).

Cowie, A. L., Berndes, G., Bentsen, N. S., Brandão, M., Cherubini, F., Egnell, G., George, B., Gustavsson, L., Hanewinkel, M., Harris, Z. M., Johnsson, F., Junginger, M., Kline, K. L., Koponen, K., Koppejan, J., Kraxner, F., Lamers, P., Majer, S., Marland, E., Nabuurs, G. J., Pelkmans, L., Sathre, R., Schaub, M., Smith, C. T., Sominakallio, S., Hilst, F. V. D., Woods, J., and Ximenes, F. A. (2021). “Applying a science‐based systems perspective to dispel misconceptions about climate effects of forest bioenergy,” GCB Bioenergy 13(8), 1210-1231.

European Commission (EC). (2020). Sustainable Finance: TEG Final Report on the EU Taxonomy; Supporting Policy with Scientific evidence, European Commission. (https://knowledge4policy.ec.europa.eu/publication/sustainable-finance-teg-final-report-eu-taxonomy_en), Accessed on 5 September 2022.

European Commission (EC). (2022). “Biomass,” European Commission. (https://energy.ec.europa.eu/topics/renewable-energy/bioenergy/biomass_en), Accessed 4 September, 2022.

European Commission (EC). (2022a). “Data-Modelling platform of resource economics (Biomass flows),” European Commission. (https://datam.jrc.ec.europa.eu/datam/mashup/BIOMASS_FLOWS/), Accessed on 7 September 2022.

European Environment Agency (EEA). (2022). “Emissions and energy use in large combustion plants in Europe, Copenhagen,” (https://www.eea.europa.eu/ims/emissions-and-energy-use-in), Accessed on 10 June 2022.

Guo, F., and Zhong, Z. (2018). “Co-combustion of anthracite coal and wood pellets: Thermodynamic analysis, combustion efficiency, pollutant emissions and ash slagging,” Environ. Pollut. 239, 21-29. DOI: 10.1016/j.envpol.2018.04.004

Han, G. S. (2022). “Forest biomass energy utilization and ESG innovation,” Energy Economic, Seoul, (https://www.ekn.kr/web/view.php?key=20220523010003698), Accessed 25 May 2022.

Hayter, S., Tanner, S., Corner, K., and Demeter, C. (2004). “Biomass cofiring in coal-fired boilers,” Federal Energy Management Program, 5. United States. (https://www.osti.gov/servlets/purl/15007847), Accessed on 19 July 2022.

IEA. (2018). “Is energy from woody biomass positive for the climate?”, (https://www.ieabioenergy.com/iea-publications/faq/woodybiomass/#), Accessed 17 September 2022.

IEA. (2021). “Net zero by 2050,” (https://www.iea.org/reports/net-zero-by-2050), Accessed 10 September 2022.

IPCC. (2007). “Fourth assessment report,” Switzerland, (https://www.ipcc.ch/assessment-report/ar4/), Accessed 10 September 2022.

Jung, K. S., and Yoo, H. (2019). “The effect of supply patterns of overfire air on generation of NOx and CO in a wood pellet fired boiler,” Plant J. 15(3), 35-41, URL: https://koreascience.kr/article/JAKO201924063316803.pdf

Kang, K., Oh, J., Yang, J., Yang, W., and Ryu, C. (2015). “Biomass co-firing with fuel staging for NOx emission reduction in coal-fired boiler,” in: KOSCO 50th Symposium, Suncheon, Jeollanam-do, South Korea, pp. 123-126.

Kim, D. W., Park, K. I., Lee, J. M., and Bae, Y. C. (2019). “Characteristics of co-combustion of wood pellet with sub-bituminus coal in a pilot CFB combustor,” KHINES 30(5), 436-447. DOI: 10.7316/KHNES.2019.30.5.436

Kim, J. H., Yang, S. Y., Kim, G. B., and Jeon, C. H. (2015). “The co-combustion characteristics of coal and wood pellet in a 25W lab-scale circulating fluidized bed reactor,” Trans. Korean Soc. Mech. Eng. 39(8), 683-691. DOI: 10.3795/KSME-B.2015.39.8.683

Kim, S. C., Lee, H. D., and Kim, J. G. (2006). “Combustion characteristics of coal and wood biomass co-firing on the pulverized coal combustion furnace,” Proceedings of the KOSCO, 293-298.

Korea Environment Corporation (KEC). (2022). “Tele-Monitoring System Open Data,” Incheon, (https://cleansys.or.kr/introBn.do.), Accessed 5 May 2022.

Korea Forest Service (KFS), (2022), “The Seoul Forest Declaration,” Daejeon, (https://www.forest.go.kr/kfsweb/cop/bbs/selectBoardArticle.do?bbsId=BBSMSTR_1036&mn=NKFS_04_02_01&nttId=3170456), Accessed on 26 September 2022.

Korea Forest Service (KFS). (2023). “Wood pellet production by annual,” (https://forestoutlook.kr/info), Accessed on 14 Feb 2023.

Korea National Institute of Forest Science (KNIFS). (2021). “Current status and implications of carbon-neutral, long-term low-carbon development strategies and nature-based solutions,” International Forest Policy Topics 102, 22-24, Seoul.

Leckner, B., and Karlsson, M. (1993). “Gaseous emissions from circulating fluidized bed combustion of wood,” Biomass Bioenergy 4(5), 379-389. DOI: 10.1016/0961-9534(93)90055-9

Lee, S., Sung, Y., Choi, M., Moon, C., Choi, G., and Kim, D. (2014). “Combustion characteristics of biomass blends on a 15KW pulverized coal furnaces,” in: KOSCO 49th Symposium, Jeju Island, South Korea, pp. 41-44.

Lee, S. R., and Han, G. S. (2021). “UK case research for sustainable forest biomass policy development of South Korea,” New. Renew. Energy 17(1), 50-60. DOI: 10.7849/ksnre.2021.2029

Lee, S. R., Hee, H., Chang, Y. S., Jeong, H. S., Lee, S. M., and Han, G. S. (2022a). “Mid- and long-term forecast of forest biomass energy in South Korea, and analysis of the alternative effects of fossil fuel,” New. Renew. Energy 18(3), 1-9. DOI: 10.7849/ksnre.2022.0021

Lee, S. R., Park, S. H., Koh, M. H., and Han, G. S. (2022b). “S. Korea’s approach strategy through policy analysis of major countries to promote the use of forest biomass as renewable energy,” New. Renew. Energy 18(3), 10-22. DOI: 10.7849/ksnre.2022.0020

Lee, Y., Kim, J., Kim, D., and Lee, Y. (2017). “Experimental research of co-firing and emission characteristics fueled by sewage sludge and wood pellet in bubbling fluidized bed,” Clean Technol. 23(1), 80-89. DOI: 10.7464/ksct.2017.23.1.080.

Nussbaumer, T. (2003). “Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction,” Energy Fuels 17(6), 1510-1521.

Oh, J. H., Yang, J. H., Kang, K. S., and Ryu, C. (2014). “Numerical studies on co-combustion of biomass in a 500 MWe coal-fired power plant,” in: KOSCO 48th Symposium, Hoengseong, Gangwon State, South Korea, pp. 9-12.

Park, S., and Lee, G. (2020). “Emission characteristics of fine particles from thermal power plants,” KEPCO J. Electr. Power Energy 6(4), 455-460. DOI: 10.18770/KEPCO.2020.06.04.455

Sloss, L. (2010). “Emissions from cofiring coal, biomass and sewage sludge,” London, IEA Clean Coal Centre. DOI: 10.13140/RG.2.2.11700.40328

United Nations (UN). (2017). United Nations Strategic Plan for Forests 2030, New York, (https://www.un.org/esa/forests/documents/un-strategic -plan-for-forests-2030/index.html), Accessed on 3 September 2022.

William, S. (2021). “2021 global wood pellet markets outlook,” Canadian Biomass, (https://www.canadianbiomassmagazine.ca/ 2021-global-wood-pellet-markets-outlook/), Accessed 20 September 2022.

Yang, W. (2021). “Research on changes in power generation efficiency and reduction of NOx emissions due to co-firing of biomass in pulverized coal-fired power plants,” in: Chungbuk National University Symposium, Cheongju, Chungcheongbuk-do, South Korea, pp.1-40.

Yoon, S. H., Beak, G. U., Moon, J. H., Jo, S. H., Park, S. J., Kim, J. Y., and Mun, T. Y. (2021). “Air-staging effect for NOx reduction in circulating fluidized bed combustion of domestic unused biomass,” Korean Chem. Eng. Res. 59(1), 127-137. DOI: 10.9713/kcer.2021.59.1.127

Article submitted: August 15, 2023; Peer review completed: October 14, 2023; Revised version received and accepted: October 19, 2023; Published: October 26, 2023.

DOI: 10.15376/biores.18.4.8458-8472