Abstract

The depolymerization of natural biomass-based lignin is a definitive challenge, as it involves the integral breakdown of complex and well-constructed natural structures. A sustainable method called ‘ionoSolv pretreatment’ employs ionic liquids in biomass processing. In this study, Bronsted acidic IL (BAIL); 1-methyl-3-(3-sulfopropyl)-imidazolium chloride, [C3SO3HMIM]Cl was synthesized and commendably used to both assist the depolymerization of lignin under mild reaction conditions as well as to benefit from the commercially valuable vanillin. About 68% degree of depolymerization (DD) of lignin was achieved under optimized conditions (120 °C, 60 min), yielding ca. 43% of tetrahydrofuran (THF) soluble products. The influence of BAIL on the depolymerization was investigated using chromatographic (gas chromatography-mass spectrometry, gel permeation chromatography, and high performance liquid chromatography (HPLC) and spectroscopic techniques (Fourier transform infrared). The HPLC analysis of the depolymerized lignin detected the clear presence of 12% of vanillin was obtained from 2 wt.% of rice husk’s lignin.

Download PDF

Full Article

Rice Husk Lignin to Vanillin: IonoSolv as a Way Forward for Value-Added Biomass Depolymerization

Siti Mastura Zakaria,a,b Azila Idris,a,b Kumuthini Chandrasekaram,b,c Dazylah Darji,d and Yatimah Alias a,b,*

The depolymerization of natural biomass-based lignin is a definitive challenge, as it involves the integral breakdown of complex and well-constructed natural structures. A sustainable method called ‘ionoSolv pretreatment’ employs ionic liquids in biomass processing. In this study, Bronsted acidic IL (BAIL); 1-methyl-3-(3-sulfopropyl)-imidazolium chloride, [C3SO3HMIM]Cl was synthesized and commendably used to both assist the depolymerization of lignin under mild reaction conditions as well as to benefit from the commercially valuable vanillin. About 68% degree of depolymerization (DD) of lignin was achieved under optimized conditions (120 °C, 60 min), yielding ca. 43% of tetrahydrofuran (THF) soluble products. The influence of BAIL on the depolymerization was investigated using chromatographic (gas chromatography-mass spectrometry, gel permeation chromatography, and high performance liquid chromatography (HPLC) and spectroscopic techniques (Fourier transform infrared). The HPLC analysis of the depolymerized lignin detected the clear presence of 12% of vanillin was obtained from 2 wt.% of rice husk’s lignin.

DOI: 10.15376/biores.18.3.5385-5398

Keywords: Lignin; IonoSolv; Depolymerization; Vanillin; Chromatography

Contact information: a: Department of Chemistry, Faculty of Science, Universiti Malaya, 50603, Kuala Lumpur, Malaysia; b: University Malaya Centre for Ionic Liquids (UMCiL), Universiti Malaya, 50603 Kuala Lumpur, Malaysia; c: Research Services Division (BPP), Institute of Research Management and Services (IPPP), Universiti Malaya, 50603 Kuala Lumpur, Malaysia; d: Rubber Research Institute Malaysia, Malaysian Rubber Board, 47000 Sungai Buloh, Selangor, Malaysia;

* Corresponding author: yatimah70@um.edu.my

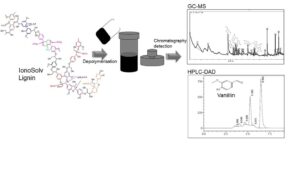

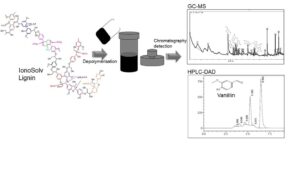

GRAPHICAL ABSTRACT

INTRODUCTION

Nearly 50% of global biomass is composed of lignocellulosic biomass (LCB), making it the most obtainable renewable organic compound on Earth (Usmani et al. 2020). Lignin is a waste byproduct material from industry sectors such as cellulosic-ethanol plants, paper, and pulp (Wang et al. 2019). It is claimed to be an undesirable component of LCB because of the complexity of cell-wall constituents, the high crystallinity of cellulose, and high degree of lignification (Giummarella et al. 2019; Ekielski and Mishra 2021). However, successful depolymerization enables the generation of phenolic products, such as propylguaiacol, vanillin, and 2,6-dimethoxy-1,4-benzoquinone, which brings economic advantages as the products can be subsequently utilized for pharmaceutical and food-based industries (Stärk et al. 2010; Varanasi et al. 2013; Blondiaux et al. 2019).

In the food industry, vanillin or 4-hdroxy-3-methoxybenzaldehyde is the main substitute for vanilla to enhance taste and flavor (Zhou et al. 2022). It is widely used in the fragrance industry, as a cosmetic ingredient, and in pharmaceuticals (Fache et al. 2016; Gitaari et al. 2019). Natural vanillin is derived primarily from vanilla beans-orchid pods (1%), whereas synthetic vanillin is generated from woody LCB (15%) and petroleum-based chemicals (85%) (Fache et al. 2016). Even though petrochemical-based vanillin costs ten times less than natural-sourced vanillin, it is unfavorable because it is a non-renewable feedstock (Zevallos Torres et al. 2020). Thus, vanillin production from renewable LCB’s lignin would be suitable to alleviate health hazards, while improving environmental sustainability and economic significance (Iravani and Varma 2020; Ariyanta et al. 2023). However, due to the lack of effective modification and depolymerization approaches for further utilizing lignin waste, it is only used commercially on low-priced products such as dispersants or binding sectors (Liu et al. 2019). Therefore, the depolymerization of lignin is critical in sustainability research, especially with its potential to produce high-value-added products, such as vanillin.

IonoSolv pretreatment is a technique that utilizes ionic liquids in extracting lignin and cellulose (Tu and Hallet 2019). Brønsted acidic ionic liquids (BAILs) have the ability to donate protons because their anions have acidic protons or other acidic functional groups, which improves the deconstruction of LCB (Muhammad et al. 2014; Vafaeezah and Alinezhad 2016). The [C3SO3HMIM]Cl is chosen to depolymerize lignin in this study due to the acidic properties with the presence of –SO3H group on the cation. Thus, the employment of BAILs not only improves the quality of dissolution, separation, and depolymerization of lignin, but also works further for the generation of high-value-added aromatic products. The use of ILs to depolymerize lignin is appealing because the tunable properties of ILs allow the methods to complete at milder conditions. It has been presented as highly selective to cleave the interlinkages of lignin, increasing the generation of high-value-added products (Rawat et al. 2022).

Therefore, the main aim of this study is to detect the presence of vanillin from depolymerized rice husk lignin using the BAIL compound 1-methyl-3-(3-sulfopropyl)-imidazolium chloride, [C3SO3HMIM]Cl. The influence of [C3SO3HMIM]Cl on lignin’s depolymerization was investigated at various reaction temperatures (100, 120, and 150 °C) and times (30, 60, and 120 min). To the best of the authors’ knowledge, no similar studies have been reported on the effect of [C3SO3HMIM]Cl based-BAILs depolymerization of rice husk lignin and subsequent detection of high-value-added products, such as vanillin. The untreated lignin and depolymerized products were characterized using gel permeation chromatography (GPC), Fourier transform infrared (FTIR) spectroscopy, gas chromatography-mass spectroscopy (GC-MS), and high performance liquid chromatography (HPLC).

EXPERIMENTAL

Materials

Rice husk was received from BERNAS rice mill, Selangor, Malaysia, and the moisture content of rice husk was 10.12 ± 0.39 %. 1-methylimidazole, 1,3-propane sultone, and commercial standards, such as vanillin, eugenol, methyl 4-hydroxy-3-methoxy-benzoate, m-cresol, 2-methoxyphenol, 1,4-dimethoxybenzene, guaiacol glyceryl ether, and 3-(4-hydroxy-3-methoxyphenyl)propionic acid, were bought from Sigma Aldrich (St. Louis, MO, USA). Tetrahydrofuran, ethanol, acetone, ethyl acetate, chloroform, dichloromethane, diethyl ether, hexane, dimethyl sulfoxide, methanol, and toluene were obtained from Merck (Darmstadt, Germany). All solvents employed in the synthesis and solubility test were of analytical grade, while chromatography grade solvents were used in the extraction study without further purification. Ultrapure water (Milli-Q, UK) was used throughout the study.

Synthesis of BAIL

1-methyl-3-(3-sulfopropyl)-imidazolium chloride, [C3SO3HMIM]Cl was synthesized in-house and prepared via a two-step process. The structure of the synthesized BAILs was confirmed with proton and carbon-13 nuclear magnetic resonance (1H and 13C NMR). The acid strength in [C3SO3HMIM]Cl was calculated with the Hammett acidity function (H0) as depicted in Fig. S1 (supplementary information).

Lignin Extraction from Rice Husk

Lignin was extracted from rice husk by ionoSolv pretreatment, as previously reported by Zakaria et al. (2020). A mixture of 150 mg of rice husk (50 μm particle size) in 10 g of [C3SO3HMIM]Cl was stirred at 100 °C for 6 h. The mixture was cooled and added gradually to the acetone/water mixture. The precipitated lignin was separated after the evaporation of acetone in the supernatant. The lignin was washed and dried under a vacuum at 60 °C.

Depolymerization of Lignin

Lignin (0.5 g) was dissolved in methanol:water (25:5 mL) along with 0.5 g of [C3SO3HMIM]Cl and treated in an autoclave reactor with Teflon coating. The mixture was stirred at room temperature for an hour to ensure a homogenous solution. The temperature of the oven was adjusted to a prespecified value and the time was recorded when the specific time was attained. For the optimization study, the temperature and reaction time was studied from 100 to 150 °C and 30 to 90 min, respectively. The autoclave was cooled once completed and the reaction mixture was centrifuged at high speed (4000 rpm) to filter out the unreacted solid lignin. The unreacted solid lignin was dried in a vacuum overnight. The supernatant was evaporated to remove methanol and water, using a rotary vacuum evaporator. The obtained recovered semisolid contained unconverted lignin and depolymerized products. To separate the high-value-added products from this mixture, tetrahydrofuran (THF) was used because of its insolubility in extracted lignin (Table S1 and Fig. S2). The measurement of solubility of the lignin and BAILs was a crucial step to select the suitable reaction medium, isolation of reaction products, and separation of BAILs for studying the recyclability. The degree of depolymerization and the yield (%) for THF soluble products were calculated using Eqs. 1 and 2,

Degree of Depolymerization (%) = [1- ((WR x Cc) / (WF x CF))] x 100 (1)

THF Soluble Products Yield (%) = (WTHF soluble products / WF) x 100 (2)

where WR is the weight of residue (g), Cc is the carbon content of the residue (%), WF is the weight of feed lignin (0.45 g), and CF is the carbon of feed lignin (49.50%).

The GC-MS analysis of THF extraction confirmed the lignin’s depolymerization and identified the presence of low molecular weight aromatic products. The measurement of the solubility of lignin and BAILs was a crucial step to select the suitable reaction medium, isolation of reaction products, and separating BAILs from the reaction (Table S1). The successful separation of vanillin from lignin’s depolymerization in [C3SO3HMIM]Cl was determined using HPLC. Control test (without [C3SO3HMIM]Cl) was run and GC-MS data shows no detection of high value-added products.

FTIR Analysis

Fourier transform infrared spectra were recorded on a Pelkin-Elmer Spectrum 400 FT-IR/FT-FIR (Waltham, MA, USA) spectrometer at room temperature. All spectra were recorded in the range of 500 to 4000 cm-1 using attenuated total reflectance (ATR) mode with 64 scans.

GPC Analysis

A GPC analysis was employed to determine the molecular weights distributions of lignin before and after depolymerization using a TOSOH HLC-8320GPC (Tokyo, Japan) with RI and UV detectors (UV-8320) and two columns (TSKgel SuperMultipore HZ-M). The measurement was carried out at 30 °C with the flow rate of THF at 1 mL/min. The lignin was acetylated before analysis to enhance the solubility in THF. Meanwhile, the depolymerized product mixture in THF was directly used in GPC. Calibration curves were obtained using polystyrene standards.

GC-MS

Chromatographic analysis was completed using a Shimadzu (Tokyo, Japan) with GC-MS QP2010 ultra, single quadrupole instrument. The NIST MS library was used for identification (capillary column: RTX 5, 29.6 m x 0.25 mm x 0.25 µm; initial column oven temperature was set at 100 ℃ and ramped to 280 ℃ at a heating rate of 10 ℃/min, and finally maintained at 280 ℃ for 20 min; carrier gas: helium with a flow rate 0.6 min/mL; injector temperature was 275 ℃, while the detector temperature was 280 ℃). Commercial standards were used to establish calibration curves.

High Performance Liquid Chromatography with Diode Array Detector (HPLC-DAD)

The detection of vanillin was performed using the HPLC-DAD device, which was equipped with a Shim-pack GIST C-18 reverse phase column (250 × 4.6 mm2), particle size (5 μm) from Shimadzu (Tokyo, Japan). The chromatographic separations were carried out with an isocratic mobile phase of 80 % THF: 20% ultrapure water at the flow rate of 1 mL/min and column temperature maintained at 40 °C. Analytes were detected at 222 nm and the overall analysis time was 15 min. The chromatogram was then compared with standard vanillin.

RESULTS AND DISCUSSION

The extracted lignin from rice husk used in this study was characterized using various techniques to understand the morphology and properties of rice husk lignin and the summary of characterization is tabulated in Table 1. As observed, the lignin used in this study has a high molecular weight (above Mw = 13,800 g mol-1) and the elemental analysis showed contents of 50% C, 5% H, 46% O, 0.33% N, and negligible sulfur. Extracted lignin has high thermal degradation temperature (301 °C) due to the properties of lignin.

Table 1. Summary of the Properties of Lignin Used in This Study

Temperature and time are important factors in depolymerizing and converting lignin into high-value-added products. The GPC and GC-MS data made it clear that time and temperature greatly influenced the depolymerization of lignin in [C3SO3HMIM]Cl. Across the whole range of examined temperatures, the molecular weight increases as temperature increases as displayed in Fig. 1(a). Temperature changes impact the depolymerization and conversion of lignin into high-value-added products. Depolymerization of lignin at lower temperatures reduces the energy required to cleave the ester linkages of lignin (Stevens and Shi 2019). The effect of reaction time on the progress of depolymerization lignin in [C3SO3HMIM]Cl is explored at 120 °C, as depicted in Fig. 1(b) for 30, 60, and 120 min. A longer reaction time increased the molecular weight, possibly due to the repolymerization of lignin under acidic conditions (Ovejero-Pérez et al. 2020). While a shorter reaction time has less effect on the depolymerization of lignin as insufficient time to break the linkages of lignin (Tolesa et al. 2017). Therefore, the reaction time of 60 min was chosen as the most suitable reaction condition for this study.

Fig. 1. The effect of reaction (a) temperature (t = 60 min) and (b) time (120 °C) on the average molecular weight of the phenolic products of lignin depolymerization in [C3SO3HMIM]Cl

The FTIR spectroscopic analysis was used to evaluate the structures before and after the depolymerization of lignin in [C3SO3HMIM]Cl, as presented in Fig. 2. At 1703 cm-1, C=O stretching was slightly displaced to a higher wavenumber with increased intensity, which is likely due to the formation of esters and carboxylic acids at 120 °C, 30 min (Fig. 2(e)) (Prado et al. 2020). The reduction in the intensity of the 1600 cm-1 band assigned to aromatic skeletal vibration, was observed at 100 and 120 °C, but the intensity increased when the temperature was increased to 150 °C. The intensity bands at 1633 and 1707 cm-1 decreased when the temperature increased demonstrating that lignin with high degree unsaturation (DU) at 150 °C had a higher content of double bonds and hence was easy to repolymerise (Long et al. 2014; Chen et al. 2018). A new band appeared at 1369 cm-1, which was likely due to the -OH stretching of phenols and aliphatic -CH stretching found exclusively in aliphatic methyl groups. Increased intensity at 1270 and 1220 cm-1, assigned to C=O stretches, primarily due to the oxidation of lignin or the formation of Hibbert ketones (Dutta et al. 2017). This suggests the depolymerization of lignin in [C3SO3HMIM]Cl generates both unconjugated and conjugated carbonyl groups (Dutta et al. 2017). At 1220 to 1020 cm-1, corresponds to stretching band of the C-O group of phenolic compounds. The intensity of the band at 1110 cm-1 assigned to the combination of syringyl and guaiacyl rings decreased as they could have been reduced after the depolymerization process. Moreover, fundamental vibration bands (1270, 1205, and 1020 cm-1) were assigned to the linkage of Ar-O of the methoxy group containing phenolic compounds (Jia et al. 2011; Biswas et al. 2021). At the lower wavenumbers (880 to 815 cm-1), the bands are assigned to para-substituted aromatic monomers.

The average molecular weight (Mw), number weight average (Mn), polydispersity index (PDI), and retention time (RT) before and after depolymerization of lignin in [C3SO3HMIM]Cl are summarized in Table 2. The average molecular weight of untreated lignin was observed as 13818 g mol-1 and PDI is 1.29 at RT of 38.56 min. It is observed the Mw of lignin significantly decreases after depolymerization in [C3SO3HMIM]Cl. The Mw peaks appear at retention times of 42.51 to 43.98 min with different temperatures and times. At T = 100 and 150 °C for 60 min, the Mw exhibited 1278 and 163 g mol-1, corresponding to retention times at 43.78 and 43.52 min.

Fig. 2. FTIR spectra of (a) untreated lignin and depolymerized lignin in [C3SO3HMIM]Cl at different temperatures/times; (b) 100 °C / 60 min, (c) 120 °C / 60 min, (d) 150 °C / 60 min, (e) 120 °C / 30 min, and (f) 120 °C / 120 min

The Mw peaks at T = 120 °C and t = 30, 60, and 120 min exhibit retention times of 43.30, 42.51, and 43.98 min, corresponding to average molecular weights of 1385, 1362, and 12525 g mol-1, respectively. Moreover, the values of PDI after depolymerization are varied and recorded up to 1.51 at a high temperature of 150 °C for 60 min and with a longer reaction time of 120 °C for 120 min at 1.31. This might be the result of the low molecular weight monomer’s repolymerization and forming of high molecular weight fragments during the longer reaction time exposure (Cox and Ekerdt 2012; Tolesa et al. 2017). It was reported that high temperature and long reaction time caused the Mw result at T = 120 °C; 60 min, which has noticeable lower Mw (1361 g mol-1) and degree of dispersion at 1.14, indicating the depolymerization of lignin in [C3SO3HMIM]Cl being effectively degraded into low molecular weight products.

Table 2. The GPC Summary of Before and After Depolymerization of Lignin

The GC-MS analysis was carried out to detect and identify the phenolic products obtained from the depolymerized lignin in [C3SO3HMIM]Cl, and their retention time and molecular weight are listed in Table 3. It demonstrates that though the depolymerization of lignin is a very complex process, the present method of study was able to detect more than 15 different compounds with relative contents of more than 0.5%, based on peak area normalization as the use of BAILs promotes the cleavage of C-C and C-O bonds of lignin macromolecules.

Identified compounds, such as vanillin, propylguaiacyl, homovanillic acid, 2-methyl-4-propyl phenol, and ethyl vanillyl ether, originate from the guaiacyl unit of lignin (Long et al. 2015). In addition, methyl-(2-hydroxy-3-ethoxy-benzyl) ether, methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, and its derivates imply the depolymerized syringyl unit of lignin (Long et al. 2017). 2,4-Bis(1,1-dimethylethyl)phenol, and its derivatives originate from the hydroxyphenyl unit (Long et al. 2015). The results from this experiment are consistent with the depolymerization of lignin using acidic ionic liquids (Singh and Dhepe 2016; Dutta et al. 2017; Long et al. 2015).

The GC-MS results indicate that the phenolic products from [C3SO3HMIM]Cl mediated depolymerization process depended on the reaction temperature and time. At the lower reaction temperature of 100 °C (60 min), [C3SO3HMIM]Cl depolymerized the lignin and produced fewer identified phenolic products than at a temperature of 120 °C. Moreover, it was observed that at 100 and 120 °C, the depolymerization of rice husk lignin in [C3SO3HMIM]Cl efficiently cleaved the macromolecule structure of lignin into valuable identified products including vanillin monomers. At a higher temperature of 150 °C (60 min), the number of phenolic products obtained was reduced as the severe reaction conditions caused the cleaved β-O-4’ linkages to repolymerize (Ovejero-Pérez et al. 2020).

For detection and quantification, the HPLC method and column are specifically used to identify vanillin and its synthetic precursors. The quantification was calculated from the standard curve plotted using the peak area of the standard vanillin solution. The peak of vanillin from depolymerized lignin (Fig. 3(b)) was observed in comparison to standard vanillin (Fig. 3 (a)). The depolymerization of rice husk lignin in [C3SO3HMIM]Cl at 120 °C (60 min) resulted in the quantified determination of 21.16 ± 0.02 mg/mL vanillin, where 12 % of vanillin was obtained from 2 wt. % of rice husk’s lignin.

Based on the obtained products, the mechanism of lignin depolymerization in BAILs could be facilitated by the hydrolysis reaction that attacks alkyl-aryl ether linkages. As acidic ILs were employed in the depolymerization of lignin, the hypothesized mechanism in this work is similar to that proposed in the acid-catalyzed method (Li et al. 2015).

Table 3. High-Value-Added Products Obtained from Depolymerized Lignin Using [C3SO3HMIM]Cl at Different Temperatures and Reaction Times

Fig. 3. HPLC chromatogram for standard vanillin (50 mg/mL) and vanillin from depolymerized rice husk lignin in [C3SO3HMIM]Cl at 120 °C (60 min)

CONCLUSIONS

- About 68% degree of depolymerization (DD) of lignin in [C3SO3HMIM]Cl was achieved under optimized conditions (120 °C, 60 min), yielding ca. 43% of THF soluble products.

- The depolymerization and conversion of the lignin structure into high-value-added products were greatly influenced by temperature and time. Lower temperatures and shorter times resulted in a reduction of energy needed to cleave the linkages in lignin, whereas higher temperatures and longer times caused the lignin to undergo repolymerization.

- Under optimum reaction conditions, the authors succeeded in identifying the presence of vanillin, propylguaiacol, homovanillic acid, and other phenolic products from GC-MS analysis.

- The high-performance liquid chromatography (HPLC) analysis of the depolymerization of rice husk lignin in [C3SO3HMIM]Cl at 120 °C (60 min) suggested that the production of 12% of vanillin was obtained from 2 wt% of rice husk’s lignin.

ACKNOWLEDGEMENTS

This research is supported by the UM IIRG grant (IIRG003-2020FNW), Ministry of Education Malaysia Fundamental Research Grant Scheme FRGS/1/2018/STG01/ UM/01/1 grant (FP071-2018A), and Universiti Malaya Centre for Ionic Liquids (UMCiL).

REFERENCES CITED

Ariyanta, H. A., Santoso, E. B., Suryanegara, L., Arung, E. T., Kusuma, I. W., Azman Mohammad Taib, M. N., Hussin, M. H., Yanuar, Y., Batubara, I., and Fatriasari, W. (2023). “Recent progress on the development of lignin as future ingredient biobased cosmetics,” Sustainable Chemistry and Pharmacy 32, article ID 100966. DOI: 10.1016/j.scp.2022.100966

Biswas, B., Kumar, A., Krishna, B. B., and Bhaskar, T. (2021). “Effects of solid base catalysts on depolymerization of alkali lignin for the production of phenolic monomer compounds,” Renewable Energy 175, 270-280. DOI: 10.1016/j.renene.2021.04.039

Blondiaux, E., Bomon, J., Smoleń, M., Kaval, N., Lemière, F., Sergeyev, S., and Maes, B. U. (2019). “Bio-based aromatic amines from lignin-derived monomers,” ACS Sustainable Chemistry & Engineering 7(7), 6906-6916. DOI: 10.1021/acssuschemeng.8b06467

Chen, C., Jin, D., Ouyang, X., Zhao, L., Qiu, X., and Wang, F. (2018). “Effect of structural characteristics on the depolymerization of lignin into phenolic monomers,” Fuel 223, 366-372. DOI: 10.1016/j.fuel.2018.03.041

Cox, B. J., and Ekerdt, J. G. (2012). “Depolymerization of oak wood lignin under mild conditions using the acidic ionic liquid 1-H-3-methylimidazolium chloride as both solvent and catalyst,” Bioresource Technology 118, 584-588. DOI: 10.1016/j.biortech.2012.05.012

Dutta, T., Isern, N. G., Sun, J., Wang, E., Hull, S., Cort, J. R., Simmons, B. A., and Singh, S. (2017). “Survey of lignin-structure changes and depolymerization during ionic liquid pretreatment,” ACS Sustainable Chemistry and Engineering 5(11), 10116-10127. DOI: 10.1021/acssuschemeng.7b02123

Ekielski, A., and Mishra, P. K. (2021). “Lignin for bioeconomy: The present and future role of technical lignin,” International Journal of Molecular Sciences 22(1), 1-24. DOI: 10.3390/ijms22010063

Fache, M., Boutevin, B., and Caillol, S. (2016). “Vanillin production from lignin and its use as a renewable chemical,” ACS Sustainable Chemistry and Engineering 4(1), 35–46. DOI: 10.1021/acssuschemeng.5b0134

Gitaari, N., Benard, K., Gichuki, J., and Kareru, P. (2019). “Synthesis of vanillin from lignin,” Chemical Science International Journal 27(1), 1-5. DOI: 10.9734/CSJI/2019/v27i130104

Giummarella, N., Pu, Y., Ragauskas, A. J., and Lawoko, M. (2019). “A critical review on the analysis of lignin carbohydrate bonds,” Green Chemistry 21(7), 1573-1595. DOI: 10.1039/c8gc03606c

Iravani, S., and Varma, R. S. (2020). “Greener synthesis of lignin nanoparticles and their applications,” Green Chemistry 22(3), 612–636. DOI: 10.1039/c9gc02835h

Jia, S., Cox, B. J., Guo, X., Zhang, Z. C., and Ekerdt, J. G. (2011). “Hydrolytic cleavage of β-O-4 ether bonds of lignin model compounds in an ionic liquid with metal chlorides,” Industrial and Engineering Chemistry Research 50(2), 849-855. DOI: 10.1021/ie101884h

Li, C., Zhao, X., Wang, A., Huber, G. W., and Zhang, T. (2015). “Catalytic transformation of lignin for the production of chemicals and fuels,” Chemical Reviews, 115(21), 11559-11624. DOI:10.1021/acs.chemrev.5b00155

Liu, Y., Nie, Y., Lu, X., Zhang, X., He, H., Pan, F., Zhou, L., Liu, X., Ji, X., and Zhang, S. (2019). “Cascade utilization of lignocellulosic biomass to high-value products,” Green Chemistry 21(13), 3499-3535. DOI: 10.1039/c9gc00473d

Long, J., Lou, W., Wang, L., Yin, B., and Li, X. (2015). “[C4H8SO3Hmim]HSO4 as an efficient catalyst for direct liquefaction of bagasse lignin: Decomposition properties of the inner structural units,” Chemical Engineering Science 122, 24-33. DOI: 10.1016/j.ces.2014.09.026

Long, J., Zhang, Q., Wang, T., Zhang, X., Xu, Y., and Ma, L. (2014). “An efficient and economical process for lignin depolymerization in biomass-derived solvent tetrahydrofuran,” Bioresource Technology 154, 10-17. DOI: 10.1016/j.biortech.2013.12.020

Muhammad, N., Man, Z., Elsheikh, Y. A., Bustam, M. A., and Mutalib, M. I. A. (2014). “Synthesis and thermophysical properties of imidazolium-based bronsted acidic ionic liquids,” Journal of Chemical and Engineering Data 59(3), 579-584. DOI: 10.1021/je400243j

Ovejero-Pérez, A., Rigual, V., Domínguez, J. C., Alonso, M. V., Oliet, M., and Rodriguez, F. (2020). “Acidic depolymerization vs ionic liquid solubilization in lignin extraction from eucalyptus wood using the protic ionic liquid 1-methylimidazolium chloride,” International Journal of Biological Macromolecules 157, 461-469. DOI: 10.1016/j.ijbiomac.2020.04.194

Prado, R., Erdocia, X., De Gregorio, G. F., Labidi, J., and Welton, T. (2020). “Willow lignin oxidation and depolymerization under low cost ionic liquid,” ACS Sustainable Chemistry and Engineering 4(10), 5277-5288. DOI:10.1021/acssuschemeng.6b00642

Rawat, S., Kumar, A., and Bhaskar, T. (2022). “Ionic liquids for separation of lignin and transformation into value-added chemicals,” Current Opinion in Green and Sustainable Chemistry 34, article 100582. DOI: 10.1016/j.cogsc.2021.100582

Singh, S. K., and Dhepe, P. L. (2016). “Ionic liquids catalyzed lignin liquefaction: mechanistic studies using TPO-MS, FT-IR, Raman and 1D, 2D-HSQC/NOSEY NMR,” Green Chemistry 18, 4098-4108. DOI: 10.1039/c6gc00771f

Stärk, K., Taccardi, N., Bösmann, A., and Wasserscheid, P. (2010). “Oxidative depolymerization of lignin in ionic liquids,” ChemSusChem 3(6), 719-723. DOI: 10.1002/cssc.200900242

Stevens, J. C., and Shi, J. (2019). “Biocatalysis in ionic liquids for lignin valorization: Opportunities and recent developments,” Biotechnology Advances 37(8), article 107418. 10.1016/j.biotechadv.2019.107418

Tolesa, L. D., Gupta, B. S., and Lee, M. (2017). “The chemistry of ammonium-based ionic liquids in depolymerization process of lignin,” Journal of Molecular Liquids 248, 227-234. DOI: 10.1016/j.molliq.2017.10.054

Tu, W. C., and Hallett, J. P. (2019). “Recent advances in the pretreatment of lignocellulosic biomass,” Current Opinion in Green and Sustainable Chemistry 20, 11-17. DOI: 10.1016/j.cogsc.2019.07.004

Usmani, Z., Sharma, M., Gupta, P., Karpichev, Y., Gathergood, N., Bhat, R., and Gupta, V. K. (2020). “Ionic liquid based pretreatment of lignocellulosic biomass for enhanced bioconversion,” Bioresource Technology 304, article ID 123003. DOI: 10.1016/j.biortech.2020.123003

Vafaeezadeh, M., and Alinezhad, H. (2016). “Brønsted acidic ionic liquids: Green catalysts for essential organic reactions,” Journal of Molecular Liquids 218, 95-105. DOI: 10.1016/j.molliq.2016.02.017

Varanasi, P., Singh, P., Auer, M., Adams, P. D., Simmons, B. A., and Singh, S. (2013). “Survey of renewable chemicals produced from lignocellulosic biomass during ionic liquid pretreatment,” Biotechnology for Biofuels 6(1), 1-9. DOI: 10.1186/1754-6834-6-14

Wang, H., Pu, Y., Ragauskas, A., and Yang, B. (2019). “From lignin to valuable products – Strategies, challenges, and prospects,” Bioresource Technology 271, 449-461. DOI: 10.1016/j.biortech.2018.09.072

Zakaria, S. M., Idris, A., Chandrasekaram, K., and Alias, Y. (2020). “Efficiency of bronsted acidic ionic liquids in the dissolution and depolymerization of lignin from rice husk into high value-added products,” Industrial Crops and Products 157, article ID 112885. DOI: 10.1016/j.indcrop.2020.112885

Zevallos Torres, L. A., Lorenci Woiciechowski, A., de Andrade Tanobe, V. O., Karp, S. G., Guimarães Lorenci, L. C., Faulds, C., and Soccol, C. R. (2020). “Lignin as a potential source of high-added value compounds: A review,” Journal of Cleaner Production 263, article ID 121499. DOI: 10.1016/j.jclepro.2020.121499

Zhou, N., Thilakarathna, W. P. D. W., He, Q. S., and Rupasinghe, H. P. V. (2022). “A review: Depolymerization of lignin to generate high-value bio-products: Opportunities, challenges, and prospects,” Frontiers in Energy Research 9, article ID 758744. DOI: 10.3389/fenrg.2021.758744

Article submitted: May 11, 2023; Peer review completed: June 10, 2023; Revised version received and accepted: June 22, 2023; Published: June 27, 2023.

DOI: 10.15376/biores.18.3.5385-5398

APPENDIX

CHNS (%) Theoretically: C, 34.93; H, 5.44; N, 11.64; O, 19.94; S, 13.32. CHNS (%) (Found): C, 34.9212; H, 5.3391; N, 11.5592; O, 19.9124; S, 13.2992. H0: 1.49.

Fig. S1. Characterization of [C3SO3HMIM]Cl

Table S1. Solubility Test of Lignin and BAILs

Fig. S2. Extraction of THF soluble products after depolymerization