Abstract

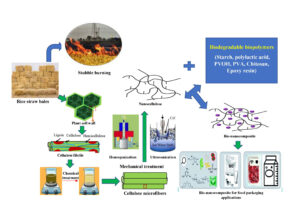

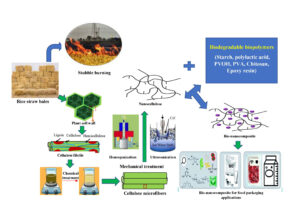

Asian countries, despite being the largest producers and yielding a significant proportion of the world’s rice, have poor disposal facilities for the harvested rice straw (stubble). Due to higher costs in their handling relative to their value, local farmers prefer the burning of stubble fields, thus creating environmental problems. Even though the government has taken initiatives, no effective solution has been discovered to handle this large agro-waste problem efficiently. In this regard, the utilization of rice straw to develop nanocellulose (NC) products is of interest. Renewability and biodegradability, along with suitable mechanical and thermal properties required for the packaging functions, are key advantages of NC. The bio-nanocomposites prepared using NC and other bio-based polymers are also being widely considered for sustainable food packaging applications due to the reinforcement provided by NC and alternative petroleum-based packaging materials. This review provides an overview of process utilization for preparing NC products using rice straw, pulping methods, and isolation to produce bio-nanocomposites for sustainable food packaging applications. The challenges and future aspects covering the utilization of rice straw for producing NC and eventually producing active packaging materials are also discussed.

Download PDF

Full Article

Rice Straw as a Source of Nanocellulose for Sustainable Food Packaging Materials: A Review

Makdud Islam,a Praveen Saini,a Rahul Das,a Shubhra Shekhar,b Akhouri Sanjay Kumar Sinha,c,* and Kamlesh Prasad a,*

Asian countries, despite being the largest producers and yielding a significant proportion of the world’s rice, have poor disposal facilities for the harvested rice straw (stubble). Due to higher costs in their handling relative to their value, local farmers prefer the burning of stubble fields, thus creating environmental problems. Even though the government has taken initiatives, no effective solution has been discovered to handle this large agro-waste problem efficiently. In this regard, the utilization of rice straw to develop nanocellulose (NC) products is of interest. Renewability and biodegradability, along with suitable mechanical and thermal properties required for the packaging functions, are key advantages of NC. The bio-nanocomposites prepared using NC and other bio-based polymers are also being widely considered for sustainable food packaging applications due to the reinforcement provided by NC and alternative petroleum-based packaging materials. This review provides an overview of process utilization for preparing NC products using rice straw, pulping methods, and isolation to produce bio-nanocomposites for sustainable food packaging applications. The challenges and future aspects covering the utilization of rice straw for producing NC and eventually producing active packaging materials are also discussed.

DOI: 10.15376/biores.18.1.Islam

Keywords: Rice straw; Nanocellulose; Bio-nanocomposite; Sustainable food packaging

Contact information: a: Department of Food Engineering and Technology, Sant Longowal Institute of Engineering and Technology, Longowal-148106, Punjab, India; b: Department of Food Process Engineering, National Institute of Technology, Raurkela – 769008, Odisha, India; c: Department of Chemical Engineering, Sant Longowal Institute of Engineering and Technology, Longowal-148106, Punjab, India; *Corresponding authors: akhouri_sanjay@yahoo.com; profkprasad@gmail.com

GRAPHICAL ABSTRACT

INTRODUCTION

Rice (Oryza sativa) is one of the world’s most significant agronomic food crops, accounting for around 20% of the worldwide population’s daily energy intake (FAOSTAT 2020). Considering the area under production, it is the world’s third-largest cereal crop, after wheat and maize. The annual rice production in 2019 was reported to be around 765 million metric tons (MMT). Among these, Asian farmers contribute 89.6% of rice production (677 MMT). The contribution of India and China during 2019 was 178 MMT (23.5%) and 211 MMT (28.0%), respectively. A total of more than 50 countries worldwide contribute to 100,000 tons of rice annually (FAOSTAT 2020). Mainly two types of residues, husk and straw, are left over after rice cultivation. Rice straw is made up of stems, leaves, and spikelets that are left over after the grain is harvested. Rice straw is produced predominantly in Asian countries due to the popularity of combine harvesters. In light of the vast scale of cultivation of rice, the byproduct, rice straw, is generated in large quantities, accounting for 23% of total agricultural crop residue in India (IARI 2012). For every ton of rice harvested, 1.40 tons of rice straw is left over in the field. Rice straw has long been utilized in several applications, including animal feed, organic fertilizer, thatching, poultry litter, mushroom production, and as a source of feedstock for bio-refinery on a small scale. However, the disposal of rice straw is a challenging task due to higher costs involved relative to its value (Abraham et al. 2016). Burning it in open fields is considered a cheap disposal method, so it has become popular among farmers. Currently, the primary proposition of rice straw, i.e., nearly three-fourths of total crop residue, equivalent to 70 to 80 million tons of rice straw, is burnt in India every year (Pandey and Sujatha 2011). Open-field burning of rice straw leads to air pollution, causing critical health hazards due to the release of various harmful substances such as volatile organic compounds (VOC), sulfur oxides (SOX), nitrogen oxides (NOX), particulate matter (PM10), and silica (Delivand et al. 2011). Silica is a significant constituent in paddy (Oryza sativa) crops, which belong to the grasses family. This silica is found in the form of nano silica in the epidermal cell of plants. It is very important as filler material in different types of paper and paperboards due to its inert nature. The silica also can be added to a pulp fiber mixture to modulate the antimicrobial and controlled vapor/gas permeability of paperboard, making it more suitable for food packaging application (Bernardos et al. 2019). Open-field burning of rice straw adds 0.05% of total greenhouse gas emissions (Bhuvaneshwari et al. 2019).

Scientists have felt compelled to find biodegradable packaging materials due to the massive accumulation of non-biodegradable packaging materials and carrying bags made of petroleum-based polymers. Synthetic plastic, which is used in various food packaging applications, is a severe global problem because it pollutes the environment and poses serious health risks to humans and other living organisms (Yang et al. 2019). Due to the low cost of plastic polymer and its versatile application, its manufacturing has witnessed a tremendous increase since the 1950s (Schmaltz et al. 2020). Food packaging materials such as plastic bottles, trays, cups, films, and sheets are derived from 40% of total plastic resources. The non-biodegradable property and poor management of these materials result in a severe ecological imbalance due to their negative effect on soil fertility, oceans, animals, and other living organisms (Jambeck et al. 2015). Out of various emerging solutions to replace synthetic plastic. Nanocellulose is an eco-friendly biomaterial that has the potential to manufacture functional food packaging material. In this regard, the abundant availability of rice straw draws attention to the possibility of rice straw-based nanocellulose materials, which can be used as reinforcement fillers for bio-nanocomposite materials (Mamat Razali et al. 2021; El-Wakil et al. 2016). These biodegradable nanocomposite materials are in massive demand by the food packaging and paper industry as an alternative source of plastic materials. Thus, the research community has sought it as a sustainable solution for both straw management and alternative synthetics polymer.

Production of nanocellulose from different types of non-wood lignocellulosic biomass (wheat straw, bagasse) and nanocomposite preparation has been described (Motaung and Mochane 2018; Mohammed et al. 2021). However, it is difficult to find any relevant review work on using rice straw-based nanocellulose containing nano silica and their use in manufacturing biodegradable packaging materials. In view of this gap, there is a need for compiling research on preparing different bio-nanocomposites from rice straw cellulose. Thus, this review article presents collected information from the currently available statistics, the composition of rice straw, and other pulping methods, including bleaching, isolation of NC, and production of nanocomposites from rice straw to develop sustainable packaging materials.

RICE STRAW AVAILABILITY

Since 6500 BC, rice has been widely cultivated in various parts of the world and more dominantly in Asian countries. China, India, Indonesia, Bangladesh, Vietnam, Thailand, Myanmar, Philippines, Brazil, and Japan are among the top 10 rice-cultivating countries in the world (FAOSTAT 2020). Rice straw, which is sometimes regarded as solid waste from rice cultivation, is generated in huge quantities worldwide. The overall biomass of the rice straw is determined by several factors, including rice variety, fertilizer management, and soil and climatic conditions (Satlewal et al. 2018). The harvesting method also determines how much rice straw is left behind in the field, as the height of crop cutting varies with harvesting methods. The paddy to straw ratio lies in the range of 0.74 to 4.3 (Zafar 2018; Kainthola et al. 2019). Total straw biomass yield ranges between 7.5 to 8 t/ha.

In contrast, the finely collected straw quantity (harvested with remaining grains) ranges between 2.7 to 8 t/ha, which corresponds to 50 to 100% of total straw biomass. Estimated data showed that an average of 5.75 t/ha of rice straw was generated during the year 2020 (Verma and Verma 2020). The maximum and minimum estimates for rice straw availability around the globe are shown in Fig. 1. The maximum annual rice straw production in Southeast Asia (SEA), the whole of Asia, and over the world is 140, 470, and 520 million t/yr, respectively.

Fig. 1. Production of rice straw around the world (Van Hung et al. 2020, CC BY 2.0)

COMPOSITION OF RICE STRAW

Rice straw is a tenacious part of the rice plant whose cell walls are naturally designed to meet various growth needs, including protection from extreme weather conditions, insects, and viruses. Rice straw consists of structural components such as cellulose (33 to 47%), hemicellulose (19 to 27%), lignin (5 to 27%), silica (both acid-soluble and insoluble), and other non-silica oxides. Rice straw also has other organic components including proteins (approximately 3%), pectins (2.8%), free sugars, chlorophyll, lipids, oils, and waxes (Harun and Geok 2016). Proximate analysis of rice straw, wheat straw, sugarcane bagasse, and corn stover reveals that ash percentages are 7.8 to 20.3%, 5.2 to 10.5%, 0.9 to 11.5%, and 2.65 to 10.5%, respectively. Based on these amounts, rice straw has higher ash percentage compared to other agricultural residues (Lizotte and Champlain 2015; Reza and Coronella 2015; Aristizábal et al. 2016; Shariff et al. 2016; Yao et al. 2016; Zanatta et al. 2016; Mukherjee and Halder 2017; Mensah and Awudza 2021; Zhong et al. 2021). The silica content in ash obtained from rice straw is nearby 75% (Jha and Sinha 2011). Cellulose is the most abundant polymer in rice straw. It is made up of 1,4 D-glucose units linked together by inter-and solid intra-chain hydrogen bonds to form microfibrils. The mechanical strength of the cellulose fibers depends upon the degree of polymerization and the average length of the glucose chain in the cellulose (Li and Xia 2017). It has been reported that rice straw cellulose has a slightly higher degree of polymerization (weight average molecular weight, Mw: 1820) measured by viscometry method compared to other agricultural residues such as wheat straw (Mw: 1045) and bagasse (Mw: 925) cellulose, but it is much lower than wood lignocellulosic biomass cellulose (Mw: 4000 to 5500) (Hallac and Ragauskas 2011). Moreover, rice straw contains hemicelluloses with modest molecular weights (average molecular weight 18800 to 48700) and degrees of polymerization ranging from 80 to 200 (Kausar et al. 2016). The arabinose/xylose ratio is commonly used to represent the degree of branching in hemicellulose. The lower the ratio, the higher the degree of polymerization. Rice straw has an arabinose/xylose ratio of 0.17, but bagasse has a ratio of 0.2 which indicates that rice straw has a higher degree of polymerization than bagasse (Bezerra and Ragauskas 2016). After cellulose and hemicellulose, lignin is the most abundant biopolymer in rice straw. Lignin is a heterogeneous polymer consisting of three types of monolignols (p-coumaryl, coniferyl, and sinapyl alcohols) connected by different bonds including β-O-4, 4-O-5, β-β, β-1, and β-5. The corresponding phenylpropanoid units are p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S). Among these, rice straw lignin has about 40 to 60% β-O-4 linkage ether bonds (Wang and Cheng 2009). Lignin is connected with hemicellulose via covalent bonds whereas hemicellulose and cellulose are linked with hydrogen bonds (Bezerra and Ragauskas 2016). Due to these chemical bonding and high-strength physical bonds, removing lignin in its natural state is a highly challenging task (She et al. 2012; Ghaffar and Fan 2013).

NANOCELLULOSE: DEFINITION AND CLASSIFICATION

Nanotechnology is an interdisciplinary science that combines mathematics, physics, and chemistry to create tiny particles having at least one dimension in the nanoscale range (1 to 100 nm) (Du et al. 2017). Cellulose is a biopolymer with linear homo-polysaccharide composed of D-glucopyranose units joined together by α (1–4) linkages with a repeating unit of cellobiose (Khalil et al. 2014). It can be used as a substitute for petroleum-based packaging materials (Ma and Ramakrishna 2005). Nanocellulose is composed of two regions, crystalline and amorphous, of which the crystalline region is responsible for strength and stiffness, while the amorphous region provides good flexibility to the plant cells (Fig. 2). Nanocellulose has excellent physical and mechanical qualities due to the strong hydrogen bond networking among the numerous hydroxyl groups (Dufresne 2012). They are biodegradable, light in weight, and strong, with an intrinsic density of 1.6 gm/cc and tensile strength (TS) of 10 GPa, which is roughly comparable to cast iron (Sultana et al. 2020). Nanocellulose hydroxyl groups, making them well suited for surface functionalization in various applications. Nanocellulose materials can be classified into three major categories, which are nanofibrillated cellulose (NFC), cellulose nanocrystals (CNCs), and bacterial nanocellulose (BNC) (Table 1). Due to their unique characteristics, including high mechanical strength, customizable surface chemistry, high aspect ratio, crystallinity, non-toxicity, and renewability, they are gaining attention as a green substrate for coatings, fillers in composites, and a variety of other food packaging applications (Urbina et al. 2021). All this has helped nano cellulose materials to achieve a substantial impact on commercial markets (Ferrer and Hubbe 2017).

Fig. 2. Crystalline and amorphous region of cellulose fiber

Table 1. Types of Nanocellulose Fibers (Klemm and Dorris 2011; Khalil et al. 2014; Ferrer and Hubbe 2017)

PRODUCTION OF NANOCELLULOSE FROM RICE STRAW

A significant number of publications have documented the isolation of cellulosic nanomaterials from a wide range of lignocellulosic biomass and their use in the production of value-added goods (Siqueira et al. 2010; Jonoobi et al. 2015; Oun and Rhim 2016; Xu et al. 2018; Djafari Petroudy et al. 2021). NC can be separated from different non-wood lignocellulose biomass such as cotton, kenaf, banana, bamboo, wheat straw, rice straw, bagasse, etc. However, the vast availability and economic viability of rice straws make them a potential candidate for the preparation of natural NC.

Production of nanocellulose from rice straw includes a variety of pre-treatment methods including separation of lignin and hemicellulose. Stepwise procedures for their preparation, as adopted and presented in past studies, includes: (i) separation of cellulose fiber from rice straw, (ii) pretreatment of separated cellulose fibers, and (iii) mechanical isolation of NC through an energy-efficient approach (Khalil et al. 2014), are discussed in the following sections. The production and separation of nanocellulose and nanocrystals from rice straw are shown in detail in Figs. 3 and 5, respectively.

Fig. 3. Production of NC and CNCs from rice straw

Separation of Cellulose Fiber

Separation of rice straw cellulose

The primary step of nanocellulose preparation involves the pulping treatment desired to collect cellulose and remove lignin from the rice straw biomass. Different alkaline and organosolv pulping methods are used for separating cellulosic fibers from rice straw. The detailed process conditions, characteristics of obtained pulp, and paper properties of obtained pulp are summarized in Table 2.

Table 2. Different Pulping Conditions (laboratory scale) for the Separation of Cellulose from Rice Straw

Alkaline pulping

Hugh Burgess and Charles Watt pioneered the alkaline pulping technique in the United Kingdom in 1851. The alkaline pulping method is an entirely chemical method that involves pulping different concentrations of NaOH, KOH, cooking temperatures, time, and pH values. NaOH (caustic soda) is the most frequently used chemical for rice straw pulping. The NaOH concentration, cooking temperature, and time typically range from 0.4 to 16% (w/v), 60 to 160 ℃, and 1 to 4 h, respectively (Sharma and Goswami 2017; Wu et al. 2017; Xu et al. 2018). Moreover, adding anthraquinone (AQ) as a pulping agent prevents carbohydrate breakdown during the cook (Bajpai 2018). The use of AQ (0.05 wt%) as a pulping agent during soda pulping reduces the kappa number (7.5%) and increases the tensile index (14.05%), burst index (8.84%), and viscosity (7.78%) of the pulp solution (Kaur and Lohchab 2018). Different ranges of temperature (150 to 185 °C), time (30 to 90 min), soda (10 to 20%), AQ (0 to 1%), and liquor ratio (6 to 8) were used to optimize the condition of soda-AQ pulping for rice straw. The highest pulp yield and viscosity were achieved at a low soda level, less time, and lower temperature (10%, 30 min, and 155 °C), but lower kappa number and higher brightness was obtained at 20% soda, 90 min, 185 ℃. The process condition at 20% soda, 30 min, 155 ℃, and 1.0% AQ showed the best beating degree, burst index, and tear index (Rodríguez and Jiménez 2008). However, using oxygen in soda pulping is a relatively new development. Zhang et al. (2019) used oxygen in soda pulping with an effective alkaline conventional dose of 18% (w/dry straw) and an overdose of 36% (w/dry straw). They found that overdose soda-oxygen pulping achieved a higher delignification degree (92.4%), crystallinity index (12.4%), and significantly reduced the pulp viscosity (57.2%). However, other researchers reported higher mechanical strength of the paper by using a low level of alkaline dose (2 wt%) for rice straw pulping (Polyium et al. 2019). The main disadvantage of alkaline pulping is the emission of highly alkaline liquid waste, a point of concern for the paper industry and the environment. The level of silica content in black liquor (residual fluid left after removal of rice straw pulp) is often higher in the soda process, which creates problem in the chemical recovery operation due to scaling of silica in pipelines and equipment during processing in the paper industry (Kaur et al. 2017). But, considering the case of energy consumption during fibrillation, less energy consumption was required for the xylanase-treated soda pulp (8%) as compared to the xylanase-treated neutral sulfite pulp (21%) (Hassan et al. 2018).

Organosolv pulping

Organosolv pulping is another essential chemical pulping method in which organic solvents such as ethylene glycol, methanol, ethanol, acetone, and other organic acids (formic acid, acetic acid) are used to separate hemicellulose and lignin from cellulose (Li et al. 2012). Due to their high silica content, the complexity of utilizing rice straw at the industrial level can be handled using the organosolv pulping method. The addition of catalysts (hydrochloric acid, sulphuric acid, and phosphoric acid) even boosts this pretreatment procedure and reduces the reaction temperature (Baruah et al. 2018).

A study involving the pulping of rice straw with several organic solvents (diethanolamine, ethanolamine, diethylene glycol, and ethylene glycol) showed that amine-containing solvent (diethanolamine) was more efficient in producing pulp with lower kappa index (4.42 times) and higher viscosity (1.29 times) and burst index compared to the glycol group (diethanolglycol) (Rodríguez et al. 2008). The effects of process variables of rice straw delignification in the catalyzed acetic acid medium at atmospheric pressure were carried out and found to be suitable for making an average grade of paper. The catalyst used was H2SO4 (Sinha 2008). In different research work, rice straw was treated with different formic acid concentrations and a higher degree of lignification was found with increasing formic acid concentration up to 90%. Further peroxyformic acid treatment reduced the kappa number to 17.6 and pulp yield by 17.5% due to a reduction in the lignin content of the pulp. The combined treatment induced a good TS index but lower tear and burst index (Ferdous et al. 2020).

Another study also reported similar findings for the formic acid pulping, where an increase in formic acid concentration (up to 85%) decreased the pulp yield because it increased the delignification and solubilization of hemicellulose (Sinha 2021). Pulping with 1% catalyst (H2SO4), for 180 min resulted in the best delignification, maximum holocellulose percentage (75%), and minimum kappa number (26). A mixture of acetic acid, formic acid, and water, in the ratio of 40:50:10, was cooked for 4 h to make dissolving grade pulp from rice straw and the ultimate yield of the pulp was 46.2%. It contained 100% inherent silica and with low kappa no 23.9 (Jahan et al. 2015). However, some drawbacks of organosolv treatment include its high cost when used on a large basis, highly flammable, and volatile nature of most of the solvents, necessitating pretreatment in extremely enclosed situations (Borand and Karaosmanoglu 2018).

Bleaching pretreatment

The presence of lignin in lignocellulosic biomass after pulping may obstruct the isolation of cellulose, as well as leading to poor surface wettability between the different polymer matrix and natural fibers. Lignin is the most difficult chemical component to remove from the lignocellulosic biomass (Kargarzadeh et al. 2018). In such a case, bleaching is an extra treatment that is required to remove the remaining cementing material, primarily lignin, from the pretreated rice straw (Panaitescu et al. 2013). In most paper mills across the world, chlorine dioxide (ClO2) (denoted as D) bleaching is preferred; however, other chemical sequences, such as ozone (denoted as Z), hypochlorite solutions of various strengths (H), oxygen (O), and DED (chlorine dioxide-alkali extraction- chlorine dioxide) and DEDED are mostly used. Utilization of ozone (Z) and H2O2 (P) is slightly more expensive for producing white paper on a large scale (Kaur and Lohchab 2018).

Based on the literature review, the various bleaching treatments for rice straw cellulose are summarized in Table 3. Almost all alkali-treated rice straw fibers are bleached under acidic conditions by boiling them in sodium chlorite (NaClO2) solution (Dilamian and Noroozi 2019; Sharma et al. 2017). During the bleaching process, the NaClO2 is dissolved in an acidic buffer solution and then it decomposes into chlorine dioxide (ClO2) in the presence of buffer salts. Because ClO2 can oxidize lignin that has been left in the fibers by targeting the aromatic ring of the lignin, the loss of lignin could cause the alkali-treated fiber to fibrillate even more (Zainuddin et al. 2013). Bleaching of lignocellulosic materials with chlorine and chlorine derivatives results in very toxic and dangerous pollutants (Tripathi et al. 2019). Bleaching processes involving oxygen bleaching (Kaur and Lohchab 2017), ozone bleaching (Kaur et al. 2018), and the use of peroxy acids (Polyium et al. 2019) have been introduced to decrease chlorinous waste products.

Generally, bleaching methods are mainly divided into two categories: elemental chlorine-free (ECF) and total chlorine-free (TCF). ClO2 is a common bleaching reagent used in the ECF process, and it helps to minimize halogenated residues and avoid the production of chlorinated dioxins and furans. The ECF method has been utilized to improve the pulp strength and reduce the bleaching effluent load in rice straw pulp (Kaur and Lohchab 2018). On the other hand, ozone bleaching (Z) was found to be effective in lowering the effluent load. There were decreases in recalcitrant and carcinogenic chemicals and increases in the brightness to 85% ISO, which was 3.6% higher and also provided higher strength values compared to ECF bleached pulps (Kaur and Lohchab 2018). The DED bleaching sequence of rice straw pulp showed a brightness of 82.3% ISO, and there was a decrease in ash and silica percentage with the increase in bleaching percentage (Sinha et al. 2012). However, the two-stage peroxide alkaline extraction (PE) bleaching sequence for rice straw powder increased the crystalline index by 21%, which confirmed the separation of lignin and hemicellulose from the powder (Weerakkody et al. 2021).

It has been found that an enzyme cocktail (xylanase, pectinase, a-amylase, protease, and lipase) as a bio-bleaching agent for non-wood pulp reduced the chemical usage up to 50% without compromising the brightness. Also, the process increased the TS (23.55%), burst factor (20.3%), tear factor (3.17%), and reduced the kappa number (19.5%) (Sharma et al. 2020).

Pretreatment prior to preparation of nano-fibrillated cellulose

Different pretreatments such as enzymatic and oxidation with the 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) are sometimes required to reduce the energy needed during mechanical fibrillation. These pretreatments are discussed in detail as follows.

Table 3. Different Bleaching Methods (laboratory scale) for Rice Straw Cellulose Fibers

Pretreatment with enzymes

Enzymatic hydrolysis is an environment-friendly approach that can be utilized instead of chemical pretreatments to allow fiber refinement and disintegration. This process also provides selective hydrolysis of the fibers, which results in lower degradation of cellulose chains of fibers and less formation of glucose (Karim et al. 2017). Several researchers have documented that enzymatic pretreatment decreased the energy requirement during the fibrillation of NC from different lignocellulose biomass (Djafari Petroudy et al. 2021). A cellulase enzyme complex with five subunits (endocellulases, exocellulases, cellobiases, oxidative cellulases, and cellulose phosphorylases) has been used to hydrolyze the cellulose fiber into the nanoscale. But only endocellulases and cellobiases subunits contribute to the hydrolytic degradation of β (1→4) linkages. Endocellulases stimulate the breaking of internal bonds in cellulose chains’ disorganized regions, resulting in the formation of new chain ends. The cellobiases are enzymes that hydrolyze the oligomeric exocellulase products into separate monosaccharides (Karim et al. 2017). Xylanase treated fibrillation from rice straw required less time and energy. In addition, the paper prepared from xylanase treated NC (82 MPa) showed better mechanical properties than the untreated pulp (66 MPa). Thus, the xylanase enzyme has been used to lower the size of the fibers and pre-defibrillate them, resulting in less frequent equipment blockage (Hassan and Oksman 2018). Apart from rice straw, a tailor-made enzyme treatment has been used to obtain nanocellulose from eucalyptus. A more successful and long-lasting method has been developed in which CNCs with a diameter of 24 nm were isolated from cellulose pulp employing a cellulolytic enzyme complex with intense endoglucanase-specific activity (Squinca et al. 2020). Furthermore, enzymatic pretreatment of bagasse pulp achieved isolation of nanocellulose that was 30 nm in diameter. It was created using a combination of cellulase and a low concentration of cold alkali. The enzymatic pretreatment also reduced alkali consumption and clean water (Tao et al. 2019). However, the combined effect of enzymatic (cocktail cellulite) pretreatment and organosolv pulping of miscanthus biomass showed less effect on the structure and composition of the fiber. Still, enhanced removal of the lignin and hydrolyzability of the cellulose pulp was observed, which was attributed to the applied enzymatic pretreatment (Obama et al. 2012).

Pre-treatment with TEMPO (2,2,6,6-Tetramethylpiperidine-1-oxyl radical) mediated oxidation

Besides the pulping and enzymatic pretreatment process, TEMPO-mediated oxidation has also been recommended for nanocellulose surface modification. Under mild circumstances, TEMPO transforms the primary hydroxyl groups (-OH) of C6 glucose unit of cellulose first into aldehyde product which on further oxidation results into carboxyl derivatives (COO–) (Fig. 4), thus resulting in a mixture of aldehyde and carboxylic groups.

The oxidation process can reduce the energy cost of mechanical fibrillation for the synthesis of NC from lignocellulosic biomass by reducing the inter-fibril hydrogen bonding between NC particles (Peyre et al. 2015). The oxidized carboxylated cellulose fibers prevent clogging and enable defibrillation during mechanical delamination. Thus, the process was found to reduce the number of passes required during the homogenization of cellulose fiber and lowered energy consumption (Tejado et al. 2012). This oxidation treatment is carried out using catalysts like sodium bromide (NaBr) and bleaching agents such as sodium chlorite (NaClO2), which are frequently used in alkaline conditions with a pH range of 9 to 11. NC particles were isolated from rice straw using alkaline pretreatment followed by TEMPO-mediated oxidation, and mechanical blending. It was found that TEMPO-mediated oxidation produced a yield of 36.5%. Again, the yield obtained was higher than NC produced from a three-step process (dewaxing-sodium chloride oxidation- alkali leaching) with a yield of 29.1% (Gu and Hsieh 2017). In terms of energy consumption, it was found that moderate disintegration of TOCN (TEMPO-Oxidized Cellulose Nanofiber) with 90% yield needed 1.94 kWh/kg in an aqueous medium which is very efficient for the production of rice straw NC in comparison to other processes (Isogai et al. 2018).

Fig. 4. TEMPO-mediated oxidation of cellulose primary hydroxyl group to carboxyl groups

Fig. 5. Full schematic diagram for the production of NC and CNCs

Mechanical isolation of NC through energy-efficient approaches

Cellulose fibers have been mechanically treated to isolate NC through a variety of mechanical processes, the most common of which are ultrafine grinders or micro grinders, high-pressure homogenization (HPHs), high-pressure microfluidization (HPMs), high-intensity ultrasonication (HIUs) (Sharma and Goswami 2019; Djafari Petroudy et al. 2021). However, the major drawbacks of these processes are the high energy input required. As a result, they are frequently combined with some initial pretreatments to reduce energy consumption. The selection of the best mechanical technique depends on factors such as input materials’ type, morphological and chemical characterization, and the final applications of the manufactured NC (Djafari Petroudy et al. 2021). The effects of different mechanical isolation processes for rice straw NC have been summarized in Table 4.

Table 4. Different Mechanical Isolation Processes for Rice Straw NC

Microgrinding

Microgrinding is one of the most popular mechanical isolation processes for NC from rice straw pulp. In this isolation process, dilute cellulose fiber suspension (typically 1 to 2.5 wt%) is fed via a gap into the ultrafine grinder, which has a static upper stone and a spinning lower stone. The surfaces of these stones, which are constructed of coarse silicon carbide (SiC), are fitted with bars and grooves, against which cellulose fibers are subjected to repetitive cyclic pressures. To prevent the grinder from blocking, the rotor speed is increased to 1440 to 1500 rpm immediately after feeding (Jonoobi et al. 2015). Fibrillation in a grinder occurs when shear pressures break down hydrogen bonds and cell wall structure, separating pulp into nanoscale fibers. The specific energy requirement and the processing parameter of the grinder are crucial factors that need to be considered. The particular energy requirement to downsize the paper sludge changes with the variation of rotor speed, ranging from 3200 to 1440 rpm. The energy consumption was 1.3 kWh/ kg for lower speeds, compared to 3.1 kWh/ kg for high-speed rotation (Jonoobi and Oksman 2012). Ultrafine grinder combined with HPHs has been introduced to isolate rice straw NC, and the result showed that higher nanofiber production took place in the ultrafine grinding phase compared to only HPHs (Hassan et al. 2012). The separation of rice straw NC was done using a high-pressure grinder, and it was found that the crystallinity of the NC was less compared to the rice straw CNCs, but thermal stability was higher for the NC compared to the CNCs (Zhao et al. 2019). It was investigated and reported that ultrafine grinding increased the degree of crystallinity by 10.26% for rice straw NC with minimal damage to nanocellulose (Abe and Yano 2009).

High-pressure homogenization (HPH)

Nowadays, HPHs are widely utilized in the lab, pilot, and industrial scales to produce NC with various grades. The production of NC usually consists of a mechanical refining and homogenizing process. The disk refiner and Hollander beater are commonly used for the refining sub-process. HPH process involves forcing the cellulose slurry (0.5 to 1 wt%) into a small nozzle of the vessel at high pressure in the range of 50 to 2000 bar. The homogenization gap width ranges between 5 and 20 µm, depending on the viscosity of the suspension and the applied pressure (Kargarzadeh et al. 2017). Nano-sizing of fibers can be gained by the sudden pressure drop, high shear rate, turbulent flow, and impact forces on the fluid (Frone et al. 2011). Because of its great efficiency, simplicity, and lack of requirement for organic solvents, HPHs can be regarded as an efficient approach for refining cellulosic fibers. Insufficient disintegration of cellulose fibers, clogging of the homogenizer, high energy consumption, and crystalline structure disruption are some challenges for the HPHs process. Accordingly, various strategies, such as mechanical, enzymatic, and chemical pretreatments, have been proposed to overcome the challenges. Some researchers have used HPHs combined with an ultrafine grinder (Hassan et al. 2012) and ultrasonication (Sharma et al. 2019) to isolate NC from rice straw. The two stages HPHs have been used consisting of 40 and 400 MPa, which followed the micro-grinding operation and resulted in the production of nanofibers with diameter in the range of 3.5 to 60 nm. This also improved the TS of the paper (produced with obtained nanofibers) by 29.57% (Hassan et al. 2012). Another researcher has reported a dramatic change in crystallinity index (92.08%) and decomposition temperature (437 ℃) of rice straw NC when applying HPHs (150 MPa) with the ultrasonication process (Sharma et al. 2019).

High-intensity ultrasonication (HIU)

In the direction of developing efficient and environment-friendly ways to synthesize nanocellulose, high-intensity ultrasonication is an innovative approach that uses oscillating power to isolate NC using ultrasound’s hydrodynamic forces. During the HIUS process, high intense waves create cavitation bubbles, and its collapse causes a high impactful mechanical oscillation that disintegrates the cellulose fibers in the nanoscale (Chen et al. 2013). Large numbers of documents have been published for the isolation of NC fibers from rice straw by using the HIUs process. The effect of several process parameters such as temperature, time, liquid-solid ratio (LSR), power, size, and position of the ultrasonication probe tip on the degree of fibrillation of cellulose fibers have been evaluated. It was found that higher power and temperature produced more fibrillation effect but an increase in the initial length of fibers decreased the fibrillation effect (Wang and Cheng 2009). On the other hand, concentration and a longer distance between the probe and the beaker were not favorable for fibrillation. When only HIUs for fibrillation of NC were applied, the power of 400 W and sonication time from 25 to 30 min were found sufficient to get the cellulose fibers in the nanoscale (Xu et al. 2018). Furthermore, it was discovered that combining HPHs and HIUs increased nanofiber fibrillation (6 to 20 nm) and homogeneity of rice straw (Dilamian and Noroozi 2019). HIUs in combination with reflex heating have been used as a green alternative for separating micro or nanofibers for industrial application. A significant reduction in processing time was reported compared to alkaline processing (1.5 h vs. 6 h) (Freitas et al. 2022). However, it was found that less fibrillation and homogeneity was obtained when using HIUs alone, compared with the combined effect of HPHs and HIUs. The higher degree of lignin separation (72.8% to 84.7%) and increased degradation temperature (to more than 230 °C) of rice straw fibers were obtained by the ultrasonic treatment with 500 W power at 20 kHz for 30 min (Cuong et al. Chung 2021).

SURFACE MODIFICATION OF NANOCELLULOSE FIBERS

Surface modification of NC is a vital aspect of improving compatibility and uniform dispersion inside the polymer matrix. Nanocellulose has a considerable number of hydroxyl groups on the molecular level, which makes it more hydrophilic in nature. Due to the hydrophilic nature of nanocellulose, it might not be easy to disperse in hydrophobic matrices (Rol et al. 2019). Nanocellulose’s incompatibility with non-polar matrices causes interfacial disruption, which leads to aggregation and phase separation.

A homogeneous dispersion of nanocellulose is essential in order to obtain products with superior mechanical characteristics. As a result, additional post-production steps are required to alter the surface features of nanocellulose. The physical and/or chemical methods such as i.e., esterification, chemical grafting, silylation, oxidation, and TEMPO oxidation techniques are in use to widen the application of nanocellulose in industrial domains (Kargarzadeh et al. 2017; Dhali et al. 2021).

ENVIRONMENT-FRIENDLY CELLULOSE NANOBIOCOMPOSITE

NC from rice straw has a large potential to produce eco-friendly cellulose nanocomposites with the addition of different bio-based polymers. Biopolymers, bio-based polymers, and other bio-compatible polymers such as chitosan, polylactic acid (PLA), poly(vinyl alcohol) (PVOH), and starch have been extensively used to manufacture cellulose composites without needing fossil fuels. As biopolymers have weak mechanical properties compared to petroleum-based polymers, their uses have been limited to packaging applications.

However, researchers are working to reinforce nanoparticles and boost mechanical and thermal versatility without sacrificing the environmental benefits of biopolymers (Azeredo et al. 2010).

Enhancement in Mechanical and Thermal Characteristics

NC products are among the most important reinforcing materials due to their intrinsic biocompatibility, renewability, biodegradability, and universality. The value addition of NC can be achieved without disrupting their molecular backbone architectures, allowing uniform dispersion and robust matrix interaction in polymeric composites. NC particles have high stiffness and a high aspect ratio (diameter/length), which promote efficient load-bearing transfer from the matrix to the nanocomposite materials (Eichhorn et al. 2010).

Due to all these factors, NC products are a good eco-friendly reinforcement material for converting weak biopolymers to strong engineering biocomposites in addition to high mechanical properties. The different rice straw cellulose-based nanocomposites (chitosan, PVOH, PLA, starch) for packaging application are summarized in Table 5.

Table 5. Rice Straw Nanocellulose-based Composite Films (solvent casting, melt mixing, in-situ polymerization, and electrospinning)

Chitosan-NC nanocomposite

Chitosan is the next most widely available biopolymer after cellulosic materials. It can be synthesized by deacetylation of chitin. Some inherent properties, including non-toxicity, biodegradability, and biocompatibility, make it worthy for consideration as a biocomposite material. The effect of the ratio of rice straw NC to nano-chitosan concentrations has been optimized for coating on the paper sheet of 125 g/m2. It was recommended that 0.5 wt% cellulose with 1.5 wt% nano-chitosan provided the best tearing strength and 1.0 wt% nanocellulose with 1.0 wt% nano-chitosan showed the best bursting index (Cuong et al. 2021). Chitosan reinforcement with 25 wt% rice straw NC showed higher yield strength (23.6%) and Young’s modulus (8.3% more) compared to a synthetic plastic bag. There was also a significant improvement in the mechanical strength of a chitosan/NC-based nanocomposite due to forming a three-dimensional network of hydrogen bonds between rice straw nanofibers and chitosan. However, the breaking length of chitosan/NC nanocomposite and a plastic bag was almost equal (Elhussieny et al. 2020). A similar finding was observed for a chitosan-rice straw CNC-based biocomposite that showed best TS at 5 wt% CNC loading, while the elongation at breakpoint decreased from 32.5% to 12.5% as the addition of CNC raised from 0 to 20 wt%. Because efficient stress transfer was limited by the creation of penetration on networks and interaction between fillers and matrices, only a modest amount of CNC could be used to strengthen chitosan (Xu et al. 2018). However, another research reported that CNC used at more than 4 to 5wt% with chitosan resulted in a decrease of the TS. This finding may be reasoned as being due to agglomeration of CNC and poor dispersion between -COO and NH3+ moieties with neutralized charge and hence reduction of the reinforcing effect (Espinosa-Andrews et al. 2013). Still, the addition of adipic acid cross-linking agent can enhance the TS, modulus of elasticity, and thermal degradation temperature of the nanocomposite (Gan et al. 2020).

PVOH- NC nanocomposite

PVOH is a recyclable synthetic polymer whose unique characteristics include thermoplastic nature, water-solubility, semi-crystallinity, nontoxicity, transparency, and biocompatibility. It can be synthesized from polyvinyl acetate after full or partial deacetylation under aerobic or anaerobic condition (Liu et al. 2013). As the PVOH is hydrophilic, it has limited application in composite films. However, adding reinforcement fillers such NC to the PVOH can improve its water resistance capacity and enhance its mechanical and thermal properties (Solikhin et al. 2018). A different research group (Alcántara et al. 2020) investigated the effect of rice straw NC as a reinforcing filler in the PVOH matrix. The reinforcing of rice straw NC (5 wt%) on the PVOH matrix increased the Young’s modulus and ultimate TS to the extent of 3.5 and 2 times, respectively, whereas elongation in the sample till the breaking point decreased from 136.5 to 1.76%. Glass transition temperature and melting temperature of nanocomposite also increased compared to pure PVOH. Another group (Perumal et al. 2018a) used montmorillonite with PVOH and CNC from rice straw to enhance nanocomposite packaging material’s properties. The addition of up to 6 wt% CNC improved the mechanical strength and thermal stability, but adding more montmorillonite and CNC reduced the transparency of the biocomposite films due to functional moieties and physical property of clay particles. Alternatively, adding rice straw NC loading in the range of 1 to 60 wt% showed maximum TS and Young’s modulus at a maximum NC loading of 60 wt% (Liu et al. 2013). However, the nanocomposite films presented moderate transparency and sound absorption of ultraviolet rays. Other researchers (Nuradibah et al. 2018) investigated the effect of adipic acid (AA) on PVOH/CNC nanocomposite and found that TS and modulus of elasticity of PVOH/CNC/AA composite film increased by 25% and 30 %, respectively. The adipic acid worked as a cross-linker among the hydroxyl group (OH) present in PVOH and elevated the mechanical property of nanocomposite Incorporation of NC (3 wt%) from rice straw with PVOH showed improvement of TS by 34 % compared to cellulose microfibers (CMFs)/PVOH nanocomposite. The reason for this is a uniform distribution of NC throughout the PVOH matrix, whereas CMFs could not evenly distribute. The composite films from rice straw NC/PVOH exhibited higher thermal stability and water absorption capacity, but the PVOH biocomposite’s transmittance was reduced (Wang et al. 2018).

Starch-NC nanocomposites

Starch is a commonly used biopolymer in food containers and packaging applications due to its large availability, biodegradability, biocompatibility, and ease of chemical modification (Clerici 2012). Starch has some disadvantages over synthetic polymers, such as high-water sensitivity, brittleness, lower mechanical properties, and poor barrier qualities (Nasri-Nasrabadi et al. 2014). NC from non-wood lignocellulosic biomass could be used as a reinforcement filler to overcome the limitation of starch and improve mechanical and thermal properties. NC (50 wt% loading) from wheat straw with starch showed higher Young’s modulus values of 586 MPa, which represent good stiffness, but elongation and puncture decrease with the addition of NC (do Lago et al. 2021). Again, rice straw NC (15% loading) and starch-based nanocomposite resulted in 4.4 and 1.61 times increases in Young’s modulus and yield strength, respectively. However, the transparency of the cellulose composite decreased with the increase of NC loading due to the light scattering of nanofibers, but the glass transition temperature was shifted to a higher range (Nasri-Nasrabadi et al. 2014). A similar finding was observed for the rice straw CNC with starch biocomposite, where the TS and Young’s modulus of the starch composite increased by 2.6 and 2.7 times, respectively. However, the addition of CNC in starch reduced the thermal stability of composite films (Agustin et al. 2014).

Polylactic acid (PLA) nanocellulose nanocomposites

Polylactic acid (PLA) is a sustainable thermoplastic polymer manufactured from agricultural ingredients such as corn starch and fermented with lactic acid. PLA has many beneficial qualities, but the major problems with PLA products are the weak toughness and relatively low thermal stability (Oliver-Ortega et al. 2017). Extensive research is underway to overcome PLA’s limitations by introducing reinforcing fillers such as NC and CNC from lignocellulose biomass. In a study, NC was isolated from non-wood pulp source such as kenaf pulp and reinforced with PLA to prepare PLA-NC bio-nanocomposite by twin-screw extrusion (Jonoobi et al. 2010). A significant increase in the tensile modulus and strength from 2.9 to 3.6 GPa and 58 to 71 MPa, respectively, with the addition of 5 wt% NC was observed along with increased thermal stability of the composite. PLA with milled rice straw powder at the different ratios above composite showed a decrement in TS and elongation at break as the rice strew fibers increased from 5 to 25 wt% whereas the Young’s modulus value was increased (Mat Zubir et al. 2016). Alternatively, another biocomposites was made using benzylated rice straw, PLA, and nano clay. The composite showed a higher TS (70.4%) and Young’s modulus (56.0%) (Chaboki et al. 2019). At the same time, further research for the incorporation of rice straw nanocellulose in PLA is needed to explore the reinforcing properties.

Barrier Properties

Petroleum-based non-biodegradable polymers are commonly used in packaging applications due to their excellent gas and water barrier qualities and low cost. But society is demanding eco-friendly and sustainable biomaterials for food packaging applications to replace the conventional non-biodegradable polymers and thus tackle environmental challenges such as resource scarcity (Khalil et al. 2020). However, biopolymers’ barrier and optical properties are not as good as petroleum-based polymers such as polypropylene, polyethylene, and PET. The permeability of low molecular weight gases through biopolymers can be reduced by increasing the crystallinity of the biopolymers (Syverud and Stenius 2009). The crystallinity of the biocomposite often can be increased by adding nanomaterials (such as nanocrystals) without affecting their inherent properties such as transparency and biodegradability. The water resistance of starch/CNC nanocomposite was improved with the increasing of rice straw CNC loading up to 15 wt%. This decrease may be due to the formation of hydrogen bonds between the CNC and hydroxyl functional group of the starch matrix (Agustin et al. 2014). Similarly, NC (10 wt%) reinforced thermoplastic starch showed a decrease in permeability coefficient (P×108) by 47.3% (Nasri-Nasrabadi et al. 2014). Addition of 5 wt% rice straw CNC with carboxymethyl cellulose reduced the water vapor permeably by 26.3% (Oun and Rhim 2016). However, when alginate cross-linker was incorporated with rice straw and bagasse nanocellulose, the results showed that nanocomposite with rice straw NC loading (< 20wt%) had a lower water absorption in comparison to bagasse nanofibers due to presence of more silica nanoparticles within rice straw nanofibers (Hassan et al. 2015).

Antimicrobial Properties

Nanocellulose biocomposite films are gaining popularity among researchers and companies because of their eco-friendly properties and potential to carry antibacterial and antioxidant compounds, improving food shelf life, quality, and enhanced security (Freire et al. 2011). Nanocomposites have enormous potential for developing low-cost, compact films for food packaging applications. It was found that the highest inhibition against C. gloeosporioides in the PVOH/CS and rice straw nanocomposite-based films is because chitosan is cationic, which drives its antifungal activity. The antibacterial activity of PVOH/CS and PVOH/CS/CNC was apparent against gram-negative and gram-positive bacteria, but the addition of CNC did not show a significant change in the antibacterial activity of films (Perumal et al. 2018b). In another study, antimicrobial paper with chitosan and rice straw nanocellulose was prepared, and the paper showed antibacterial properties against E. coli, suggesting high potential for use in food packaging applications (Cuong et al. 2021). Moreover, the inherent silica present in the resultant pulp after organosolv pulping process improved antimicrobial and controlled vapor/gas permeability in nanocomposite materials (Bernardos et al. 2019).

APPLICATION OF NANOCOMPOSITE AS A SUSTAINABLE FOOD PACKAGING

Sustainable packaging may be defined as the packaging film made from recyclable materials with good ecological impact, better economy, and minimum environmental degradation (Yam and Lee 2012). As per the definition of sustainable packaging alliance, the four basic principles of sustainable packaging can be described by the adjectives effective, efficient, cyclic, and clean. The first principle of sustainable packaging is to maximize functionality, minimize waste generation, and cost-effectiveness. The second principle states that the packaging system should be designed to maximize efficiency. Again, packaging materials should be recyclable, reusable, and biodegradable (third principle). And finally, according to the fourth principle, packaging components should not pose any risk to humans and the ecosystem (Lewis et al. 2010). Cellulose nanocomposite reinforced with NC has been regarded as a remarkable engineering material due to its high mechanical, thermal, barrier property, and biodegradability (Khalil et al. 2014). Rice straw cellulose nanofibers are inexpensive and globally abundant. The packaging sector could be one of the domains where rice straw NC can be used as sustainable and green packaging materials. Researchers consider using NC as reinforcing elements in various bio-based polymeric composites. In such applications, the NC can enhance mechanical and functional properties such as heat stability, gas barrier properties, crystallinity, transparency, and specific surface area (Freire et al. 2011; Li and Kong 2014). Because of their versatile characteristics, bio nanocomposites have a wide range of applications inducing packaging, paper and coating, electronic and membrane preparation, etc.

Food and Beverage

NC and cellulose bionanocomposite have been used as active packaging for many foods, including fresh foods, frozen or liquid foods, and dry food products (Youssef and El-Sayed 2018). As a primary function, food packaging is used to protect the food item from the external environment (including light, air, and water) and preserve the quality to reduce food wastage (Garavand et al. 2017). Cellophane (cellulose in the film) is the most used food packaging material. Therefore, cellulose-based biocomposites have all the qualities to meet the requirement of functional packaging. The cellulose-based film comprises various cellulose derivatives such as carboxy, methylcellulose, ethyl cellulose, hydroxyl propyl cellulose, hydroxyl propyl cellulose, hydroxyl ethyl cellulose, and cellulose acetate. Carboxymethyl cellulose-based nanocomposites incorporated with rice straw nanocrystals have good gas and moisture barrier properties and can be used as food packaging films, nano-papers, and coating films (Oun and Rhim 2016). The use of rice straw-based montmorillonite-PVOH bio-nanocomposite packaging film enhanced the self-life of post-harvest mango fruits up to 19 ± 2 days with all good quality parameters, reduced mass loss, increased CO2, and decreased O2 levels (Perumal et al. 2018a). Biodegradable food packaging was produced from rice straw nanocellulose and chitosan, which had favorable characteristics including high strength, and higher Young’s modulus than Egyptian synthetic plastic bags (Elhussieny et al. 2020). This could be an alternative to plastic bags and potentially tackle the rice straw stubble burning issue.

Paper Industry

The paper industry uses cellulose and nanocellulose in vast quantities. Nanocellulose has been in use for the papermaking process in several phases (refining, forming, pressing, and drying). In the formulation of specialised papers (paper with special function), such as waterproof paper, cling paper, oil-absorbing paper, wrapping paper, insulating paper, and antibacterial paper, NC may play a significant role (Li et al. 2021). It can be used with various aims, such as a strengthening agent, a component of the retention system, a good printing quality aid a coating binder, and a barrier agent for controlling water vapor and oxygen transfer (Jele et al. 2021). Many studies have demonstrated their additional benefits as a bio nano-filler in papermaking (Barbash and Yashchenko 2020). The use of non-wood cellulose nano-fibres as a reinforcement to improve the quality of paper and paper boards has been investigated. Hydroxypropyl cellulose has been used with rice straw cellulose nanocrystals as a coating material for bagasse paper sheets. Coating of paper sheets increased the TS, water vapour permeability significantly and reduced the porosity of the paper sheets (El-Wakil et al. 2016). Another work reported the use of rice straw NC with chitosan as a biocomposite for coating the paper sheet and observed higher mechanical, barrier, antimicrobial properties and can enhance the self-life of liquid and solid food products (Cuong et al. 2021). Nordeng et al. (2018) patented a novel technology to produce thermoset such as epoxies and polyurethanes consisting of nano-cellulose with special property. That can be used as a coating material to improve the barrier property of paper. Another patented novel technology provides composites or coatings for the paper industry which contain polypeptides (e.g., casein polypeptides) attached to polysaccharides (cellulose) and other molecules (Catchmark et al. 2011). The practice of rice straw-based nanocellulose and nanocellulose containing composite in commercial level is not well established in India and around the world. In addition, a business called Bio-Lutions from Hamburg, Germany, operating in Ramanagara, Bangalore, introduced a brand-new substance called “Plantio” to replace the roles of paper and plastic. Basically, “Plantio” is made up of waste crop residue such as rice straw and they are producing completely fiber-based packaging and microwaveable tableware (Sain 2020). Production of rice straw-based nanocellulose is still an unexplored area of research, despite rice straw being availability in huge quantity at nearly zero cost. Rice straw contains a good percentage of cellulose and hemicellulose, making it potential resource of nano-cellulose production in future. Again, several research works have been carried out in recent past for innovative utilization of nano cellulose in different types of paper and packaging products. So, there is an urgent need for finding a suitable economical process for production of nano cellulose from rice straw and its application in different innovative products including packaging and other composite materials. As a result, it can be stated that nanocelluloses and their composites have the potential to be employed as environment-friendly alternatives to synthetic reinforcing molecules that are currently in use in paper industries.

CONCLUSION AND FUTURE SCOPE

A large group of researchers have shown interest in eco-friendly and renewable packaging materials due to their sustainability and environment-friendly nature compared to petroleum-based packaging materials. Nanocellulose, due to its versatile qualities, has become widely used for producing high-performance biomaterials from non-wood lignocellulose biomass like rice straw. Rice straw is not only readily available and cost-effective but also has excellent potential for the production of different value-added functional biodegradable nanomaterials. This review highlights the availability, composition, and preparation of NC from rice straw and its application as reinforcing filler in different biopolymer to prepare various biocomposite materials. Application of nanocellulose in the field of food packaging, paper industry, and high-strength composite materials is also included in this study. But the production of cellulose from rice straw on a large scale is limited, mainly due to its high silica content, which creates problems during the recovery of residual pulping chemicals and byproducts formed during different pulping processes from black liquor. The nano-silica particles remaining with cellulosic fibers during organosolv pulping process have the advantage of simplifying chemical recovery from filtrate, i.e., black liquor. Due to the inherent silica left in the pulp with organosolv pulping method, important value-addition properties including antimicrobial and controlled vapor/gas permeability have been observed in the resultant nanocomposite materials, but there is a need for further exploration. Moisture and oxygen permeability in PVOH/CS biodegradable films for food packages were significantly reduced due to incorporation of in-situ SiO2 and provided highly extended perseveration time (Yu et al. 2018). Until now, no such patented literature has been published for the preparation of rice straw-based nanocellulose and its nanocomposites. Research for developing industrial-scale pulping of rice straw and producing different functional composites using rice straw-derived nano cellulose fibers for manufacturing sustainable packaging material is eagerly awaited and needed at present.

ACKNOWLEDGMENTS

The authors acknowledge the Director, Sant Longowal Institute of Engineering and Technology, for supporting this work as part of the literature review of a PhD research project. Special thanks to senior laboratory technician Mr. Ramnik Agrawal from the Paper Technology Lab, Chemical Engineering Department for assisting time to time in the process of making this manuscript.

Authors Contributions

Makdud Islam: Writing-original draft; Conceptualization; Editing; Praveen Saini: Writing review & editing; Rahul Das and Shubhra Shekhar: Editing; A.S.K Sinha: Writing-review & editing; Conceptualization; Kamlesh Prasad: Writing- review & editing; Conceptualization

Declarations

Consent for publication: All authors consent to the publication of this review.

Conflict of interest

Authors declare no conflict of interest

LIST OF ABBREVIATIONS

Abbreviation Description

NC – Cellulose nanofibers

CNCs – Cellulose nanocrystals

BNC – Bacterial nanocellulose

AQ – Anthraquinone

PLA – Poly Lactic Acid

PVOH – Polyvinyl Alcohol

NaOH – Sodium hydroxide

NaClO2 – Sodium chlorite

KOH – Potassium hydroxide

TEMPO – 2,2,6,6-Tetramethylpiperidine-1-oxyl radical

CIO2 – Chlorine dioxide

AA – Adipic acid

TS – Tensile strength

MMT – Million metric ton

t/ha – Ton/hectare

% – Percentage

℃ – Degree Celsius

kW – Kilowatt

min – Minutes

REFERENCES CITED

Abe, K., and Yano, H. (2009). “Comparison of the characteristics of cellulose microfibril aggregates of wood, rice straw and potato tuber,” Cellulose 16(6), 1017-1023. DOI: 10.1007/s10570-009-9334-9

Abraham, A., Mathew, A. K., Sindhu, R., Pandey, A., and Binod, P. (2016). “Potential of rice straw for bio-refining: An overview,” Bioresource Technology, 215, 29-36. DOI: 10.1016/j.biortech.2016.04.011

Agustin, M. B., Ahmmad, B., Alonzo, S. M. M., and Patriana, F. M. (2014). “Bioplastic based on starch and cellulose nanocrystals from rice straw,” Journal of Reinforced Plastics and Composites 33(24), 2205-2213. DOI: 10.1177%2F0731684414558325

Alcántara, J. C., González, I., Pareta M. M., and Vilaseca, F. (2020). “Biocomposites from rice straw nanofibers: Morphology, thermal and mechanical properties,” Materials 13(9), Article No. 2138. DOI: 10.3390/ma13092138

Aristizábal, M, V., García-Velásquez, C. A., and Cardona, C. A. (2016). “Integrated production of different types of bioenergy from oil palm through biorefinery concept,” Waste and Biomass Valorization 7(4), 737-745. DOI: 10.1007/s12649-016-9564-7

Azeredo, H. M. C., Mattoso, L. H. C., Avena-Bustillos, R. J., Filho, G. C., Munford, M. L., Wood, D., and McHugh, T. H. (2010). “Nanocellulose reinforced chitosan composite films as affected by nanofiller loading and plasticizer content,” Journal of Food Science 75(1), N1-N7. DOI: 10.1111/j.1750-3841.2009.01386.x

Bajpai, P. (2018). Biermann’s Handbook of Pulp and Paper: Volume 1: Raw Material and Pulp Making, Elsevier, 128142413.

Barbash, V. A., and Yashchenko, O. V. (2020). “Preparation and application of nanocellulose from non-wood plants to improve the quality of paper and cardboard,” Applied Nanoscience 10(8), 2705-2716.

Baruah, J., Nath, B. K., Sharma, R., Kumar, S., Deka, R. C., Baruah, D. C., and Kalita, E. (2018). “Recent trends in the pretreatment of lignocellulosic biomass for value-added products,” Frontiers in Energy Research 6, Article No. 141. DOI: 10.3389/fenrg.2018.00141

Bernardos, A., Piacenza, E., Sancenón, F., Hamidi, M., Maleki, A., Turner, R. J., and Martínez-Máñez, R. (2019). “Mesoporous silica-based materials with bactericidal properties,” Small 15(24), Article No. 1900669. DOI: 10.1002/smll.201900669

Bezerra, T. L., and Ragauskas, A. J. (2016). “A review of sugarcane bagasse for second-generation bioethanol and biopower production,” Biofuels, Bioproducts and Biorefining 10(5), 634-647. DOI: 10.1002/bbb.1662

Bhuvaneshwari, S., Hettiarachchi, H., and Meegoda, J. N. (2019). “Crop residue burning in India: Policy challenges and potential solutions,” International Journal of Environmental Research and Public Health 16(5), Article No. 832. DOI: 10.3390/ijerph16050832

Borand, M. N., and Karaosmanoglu, F. (2018). “Effects of organosolv pretreatment conditions for lignocellulosic biomass in biorefinery applications: A review,” Journal of Renewable and Sustainable Energy 10(3), Article No. 33104. DOI: 10.1063/1.5025876

Catchmark, J. M., Mears, D. M., and Siggins, J. (2011). “Composites containing polypeptides attached to polysaccharides and molecules,” WO 2011047047A2,

Chaboki, G., M., Mohammadi-Rovshandeh, J., and Hemmati, F. (2019). “Poly (lactic acid)/thermoplasticized rice straw biocomposites: Effects of benzylated lignocellulosic filler and nanoclay,” Iranian Polymer Journal 28(9), 777-788. DOI: 10.1007/s13726-019-00743-

Chen, P., Yu, H., Liu, Y., Chen, W., Wang, X., and Ouyang, M. (2013). “Concentration effects on the isolation and dynamic rheological behavior of cellulose nanofibers via ultrasonic processing,” Cellulose 20(1), 149-157. DOI: 10.1007/s10570-012-9829-7

Clerici, M. (2012). “Physical and/or chemical modifications of starch by thermoplastic extrusion,” Thermoplastic Elastomers 3, 39-56.

Cuong, T. D., Linh, N. V., and Chung, N. H. (2021). “Study on antibacterial papermaking for food packaging using rice straw nanocellulose and nanochitosan,” IOP Conf. Series: Earth and Environmental Science 987, 1755-1315. DOI: 10.1088/1755-1315/947/1/012023

Delivand, M. K., Barz, M., and Gheewala, S. H. (2011). “Logistics cost analysis of rice straw for biomass power generation in Thailand,” Energy 36(3), 1435-1441. DOI: 10.1016/j.energy.2011.01.026

Delmas, M., Hoang, Q. L., Bigot,Y. L., and Avignon, G. (2003). “A new non-wood pulping process for high silicon content raw materials. application to rice straw,” Appita Journal 56(2), 102-106.

Dhali, K., Ghasemlou, M., Daver, F., Cass, P., and Adhikari, B. (2021). “A review of nanocellulose as a new material towards environmental sustainability,” Science of the Total Environment 775, Article No. 145871. DOI: 10.1016/j.scitotenv.2021.145871

Dilamian, M., and Noroozi, B. (2019). “A combined homogenization-high intensity ultrasonication process for individualizaion of cellulose micro-nano fibers from rice straw,” Cellulose 26(10), 5831-5849. DOI: 10.1007/s10570-019-02469-y

Dinh Vu, N., Thi Tran, H., Bui, N. D., Duc Vu, C., and Viet Nguyen, H. (2017). “Lignin and cellulose extraction from Vietnam’s rice straw using ultrasound-assisted alkaline treatment method,” International Journal of Polymer Science 2017.

Djafari Petroudy, S. R., Chabot, B., Loranger, E., Naebe, M., Shojaeiarani, J., Gharehkhani S., Ahvazi, B., Hu, J., and Thomas, S. (2021). “Recent advances in cellulose nanofibers preparation through energy-efficient approaches: A review,” Energies 14(20), Article No. 6792. DOI: 10.3390/en14206792

do Lago, R. C., de Oliveira, A. L. M., dos Santos, A. d. A., Zitha, E. Z. M., Carvalho E. E. N., Tonoli, G. H. D., and de Barros Vilas Boas, E. V. (2021). “Addition of wheat straw nanofibrils to improve the mechanical and barrier properties of cassava starch–based bionanocomposites,” Industrial Crops and Products 170, Article No. 113816. DOI: 10.1016/j.indcrop.2021.113816

Du, X., Zhang, Z., Liu, W., and Deng, Y. (2017). “Nanocellulose-based conductive materials and their emerging applications in energy devices – A review,” Nano Energy 35, 299-320. DOI: 10.1016/j.nanoen.2017.04.001

Dufresne, A. (2012). “Nanocellulose: Potential reinforcement in composites,” Natural Polymers 2, Article No. 44743.

Eichhorn, S. J., Dufresne, A., Aranguren, M., Marcovich, N. E., Capadona, J. R., Rowan, S. J., Weder, C., Thielemans, W., Roman, M., and Renneckar, S. (2010). “Current international research into cellulose nanofibres and nanocomposites,” Journal of Materials Science 45(1), Jan-33. DOI: 10.1016/j.asej.2020.01.008

El-Wakil, N. A., Kassem, N. F., and Hassan, M. L. (2016). “Hydroxypropyl cellulose/rice straw oxidized cellulose nanocrystals nanocomposites and their use in paper coating,” Industrial Crops and Products 93, 186-192.

Elhussieny, A., Faisal, M., D’Angelo, G., Aboulkhair, N. T., Everitt, N. M., and Fahim, I. S. (2020). “Valorisation of shrimp and rice straw waste into food packaging applications,” Ain Shams Engineering Journal 11(4), 1219-1226. DOI: 10.1016/j.asej.2020.01.008

Espinosa-Andrews, H., Enríquez-Ramírez, K. E., García-Márquez, E., Ramírez-Santiago, C., Lobato-Calleros, C., and Vernon-Carter, J. (2013). “Interrelationship between the zeta potential and viscoelastic properties in coacervates complexes,” Carbohydrate Polymers 95(1), 161-166.

FAOSTAT (2020). “Faostat Database,” Food and Agricultural Organization Rome, Italy.

Ferdous, T., Jahan, M. S., Quaiyyum, M. A., and Uddin, M. N. (2020). “Formic acid pulping of crops residues available in Bangladesh,” Biomass Conversion and Biorefinery 10(2), 289-297.

Ferrer, A., Pal, L., and Hubbe, M. A. (2017). “Nanocellulose in packaging: Advances in barrier layer technologies,” Industrial Crops and Products 95, 574-582. DOI: 10.1016/j.indcrop.2016.11.012

Freire, M. G., Teles, A. R. R., Ferreira, R. A. S., Carlos, L. D., Lopes-da-Silva, J. A., and Coutinho, J. A. P. (2011). “Electrospun nanosized cellulose fibers using ionic liquids at room temperature,” Green Chemistry 13(11), 3173-80. DOI: 10.1039/C1GC15930E

Freitas, P. A. V., González-Martínez, C., and Chiralt, A. (2022). “Applying ultrasound-assisted processing to obtain cellulose fibres from rice straw to be used as reinforcing agents,” Innovative Food Science & Emerging Technologies 76, Article No. 102932.

Frone, A. N., Panaitescu, D. M., and Donescu, D. (2011). “Some aspects concerning the isolation of cellulose micro-and nano-fibers,” UPB Bulletin Scientific, Series B: Chemistry and Materials Science 73(2), 133-152.

Gan, P., Sam, S., Abdullah, M. F. b., and Omar, M. F. (2020). “Thermal properties of nanocellulose‐reinforced composites: A Review,” Journal of Applied Polymer Science 137(11), Article No. 48544.

Garavand, F., Rouhi, M., Razavi, S. H., Cacciotti, I., and Mohammadi, R. (2017). “Improving the integrity of natural biopolymer films used in food packaging by crosslinking approach: A Review,” International Journal of Biological Macromolecules 104, 687-707. DOI: 10.1016/j.ijbiomac.2017.06.093.

Ghaffar, S. H., and Fan, M. (2013). “Structural analysis for lignin characteristics in biomass straw,” Biomass and Bioenergy 57, 264-279.

Gu, J., and Hsieh, Y.-L. (2017). “Alkaline cellulose nanofibrils from streamlined alkali treated rice straw,” ACS Sustainable Chemistry & Engineering 5(2), 1730-37. DOI: 10.1021/acssuschemeng.6b02495.

Hallac, B. B., and Ragauskas, A. J. (2011). “Analyzing cellulose degree of polymerization and its relevancy to cellulosic ethanol,” Biofuels, Bioproducts and Biorefining 5(2), 215-225. DOI: 10.1002/bbb.269.

Harun, S., and Geok, S. K. (2016). “Effect of sodium hydroxide pretreatment on rice straw composition,” Indian J. Sci. Technol. 9(21). DOI: 10.17485/ijst/2016/v9i21/95245, June 2016.

Hassan, M., Berglund, L., Hassan, E., Abou-Zeid, R., and Oksman, K. (2018). “Effect of xylanase pretreatment of rice straw unbleached soda and neutral sulfite pulps on isolation of nanofibers and their properties,” Cellulose 25(5), 2939-2953. DOI: 10.1007/s10570-018-1779-2

Hassan, M., Kassem, N., and El-Sakhawy, M. (2015). “Effect of bagasse and rice straw cellulose nanofibers on physico–mechanical properties of alginate nanocomposites films,” Egyptian Journal of Chemistry 58, 299.

Hassan, M. L., Mathew A. P., Hassan, E. A., El-Wakil, N. A., and Oksman, K. (2012). “Nanofibers from bagasse and rice straw: process optimization and properties,” Wood Science and Technology 46(1), 193-205. DOI: 10.1007/s00226-010-0373-z.

Hassan, M. L., Fadel, S. M., El‐Wakil, N. A., and Oksman, K. (2012). “Chitosan/rice straw nanofibers nanocomposites: Preparation, mechanical, and dynamic thermomechanical properties,” Journal of Applied Polymer Science 125(S2), E216-E222.

IARI (2012). “Crop residues management with conservation agriculture: Potential, constraints and policy needs,” (Indian Agriculture Research Institute, New Delhi).

Isogai, A., Hänninen, T., Fujisawa, S., and Saito, T. (2018). “Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions,” Progress in Polymer Science 86, 122-148. DOI: 10.1016/j.progpolymsci.2018.07.007.

Jahan, M. S., Lee, Z. Z., and Jin, Y. (2006). “Organic acid pulping of rice straw. I: Cooking,” Turkish Journal of Agriculture and Forestry 30(3), 231-239.

Jahan, M. S., Rahman, M. M., Sutradhar, S., and Quaiyyum, M. A. (2015). “Fractionation of rice straw for producing dissolving pulp in biorefinery concept,” Nordic Pulp & Paper Research Journal 30(4), 562-567. DOI: 10.3183/npprj-2015-30-04-p562-567.

Jambeck, J. R., Geyer, R., Wilcox, C., Siegler, T. R., Perryman, M., Andrady, A., Narayan, R., and Law, K. L. (2015). “Plastic waste inputs from land into the ocean,” Science 347(6223), 768-771. DOI: 10.1126/science.1260352.

Jele, T. B., Lekha, P., and Sithole, B. (2021). “Role of cellulose nanofibrils in improving the strength properties of paper: A review,” Cellulose 55-81. DOI: 10.1007/s10570-021-04294-8.

Jha, P., and Sinha, A. S. K. (2011). “Application of rice-straw as raw material for production of handmade paper,” IPPTA 23(2), 145-148.

Jonoobi, M., Oladi, R., Davoudpour, Y., Oksman, K., Dufresne, A., Hamzeh, Y., and Davoodi, R. (2015). “Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review,” Cellulose, 22(2), 935-969.

Jonoobi, M., Mathew, A. P., and Oksman, K. (2012). “Producing low-cost cellulose nanofiber from sludge as new source of raw materials,” Industrial Crops and Products 40, 232-238. DOI: 10.1016/j.indcrop.2012.03.018.

Jonoobi, M., Harun, J., Mathew, A. P., and Oksman, K. (2010). “Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion,” Composites Science and Technology 70(12), 1742-1747. DOI: 10.1016/j.compscitech.2010.07.005.

Jonoobi, M., Oladi, R., Davoudpour, Y., Oksman. K., Dufresne, A., Hamzeh, Y., and Davoodi, R. (2015). “Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review,” Cellulose 22(2), 935-969. DOI: 10.1007/s10570-015-0551-0.

Kainthola, J., Kalamdhad, A. S., and Goud, V. V. (2019). “A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques,” Process Biochemistry 84, 81-90. DOI: 10.1016/j.procbio.2019.05.023.

Kargarzadeh, H., Mariano, M., Gopakumar, D., Ahmad, I., Thomas, S., Dufresne, A., Huang, J., and Lin, N. (2018). “Advances in cellulose nanomaterials,” Cellulose 25(4), 2151-2189. DOI: 10.1007/s10570-018-1723-5.

Kargarzadeh, H., Ioelovich, M., Ahmad, I., Thomas, S., and Dufresne, A. (2017). “Methods for extraction of nanocellulose from various sources,” Handbook of Nanocellulose and Cellulose Nanocomposites 1.

Karim, M. S., Seal, H. P., Rouf, M. A., Rahman, M. I., Talukder, M. H. R., and Karmaker, P. G. (2010). “Acetic acid pulp from jute stick, rice-straw and bagasse,” J. Agrofor. Environ. 3(2), 171-174.

Karim, Z., Afrin, S., Husain, Q., and Danish, R. (2017). “Necessity of enzymatic hydrolysis for production and functionalization of nanocelluloses,” Critical Reviews in Biotechnology 37(3), 355-370. DOI: 10.3109/07388551.2016.1163322.

Kaur, D., Bhardwaj, N. K., and Lohchab, R. K. (2018). “Reduction in chlorophenolic compounds during bleaching of rice straw pulp by replacing elemental chlorine with chlorine dioxide,” International Journal of Environmental Science and Technology 15(5), 1113-1122. DOI: 10.1007/s13762-017-1448-2.

Kaur, D., Bhardwaj, N. K., and Lohchab, R. K. (2018). “A study on pulping of rice straw and impact of incorporation of chlorine dioxide during bleaching on pulp properties and effluents characteristics,” Journal of Cleaner Production 170, 174-182. DOI: 10.1016/j.jclepro.2017.09.111.

Kaur, D., Bhardwaj, N. K., and Lohchab, R. K. (2017). “Prospects of rice straw as a raw material for paper making,” Waste Management 60, 127-139. DOI: 10.1016/j.wasman.2016.08.001.

Kausar, A., Rafique, I., and Muhammad, B. (2016). “Review of applications of polymer/carbon nanotubes and epoxy/CNT composites,” Polymer-Plastics Technology and Engineering 55(11), 1167-1191. DOI: 10.1080/03602559.2016.1163588.

Khalil, H. P. S. A., Davoudpour Y., Islam, M. N., Mustapha, A. , Sudesh, K.,Dungani, R., and Jawaid, M. (2014). “Production and modification of nanofibrillated cellulose using various mechanical processes: A Review,” Carbohydrate Polymers 99, 649-665. DOI: 10.1016/j.carbpol.2013.08.069.

Khalil, H. P. S. A., Jummaat, F., Yahya, E. B., Olaiya, N. G., Adnan, A. S., Abdat, M., Nam, N., Halim, A. S., Kumar, U. S. U., and Bairwan, R. (2020). “A review on micro-to nanocellulose biopolymer scaffold forming for tissue engineering applications,” Polymers 12(9), Article No. 2043.

Klemm, D., Kramer, F., Moritz. S., Lindström, T., Ankerfors, M., Gray, D., and Dorris, A. (2011). “Nanocelluloses: A new family of nature-based materials,” Angewandte Chemie International Edition 50(24), 5438-5466. DOI: 10.1002/anie.201001273.

Lam, H. Q., Yves Le Bigot, and Delmas, M. (2001). “Formic acid pulping of rice straw,” Industrial Crops and Products 14(1), 65-71. DOI: 10.1016/S0926-6690(00)00089-3.

Lewis, H., Verghese, K., and Fitzpatrick, L. (2010). “Evaluating the sustainability impacts of packaging: The plastic carry bag dilemma,” Packaging Technology and Science: An International Journal 23(3), 145-160. DOI: 10.1002/pts.886.