Abstract

Mold invasion by Trichoderma harzianum T6776 over the surface of wood-plastic composites (WPCs) made from Juniperus procera wood-branch and polypropylene with a melt-blending technique was examined using scanning electron microscopy (SEM) and electron dispersive X-ray spectroscopy (EDX). Before the addition of coupling agent, the WPC samples were made from untreated and pretreated wood-branch particles of J. procera with either cold or hot water and then mixed with polypropylene to produce panels. The surfaces of WPC samples were inoculated by a mold suspension of T. harzianum. SEM-EDX measurements of WPCs made from J. procera particles showed little or no growth of T. harzianum, irrespective of treatment with cold or hot water. The results suggest that WPCs made from the particles of J. procera wood-branch pretreated with either cold or hot water could be useable in wet conditions. In addition, using of J. procera as durable wood for manufacturing of WPCs had good effects on the prevention of the mold infestation over the surfaces of the produced panels.

Download PDF

Full Article

Study of Mold Invasion on the Surface of Wood/Polypropylene Composites Produced from Aqueous Pretreated Wood Particles, Part 2: Juniperus procera Wood-Branch

Maisa M. A. Mansour,a Ramadan A. Nasser,b,c Mohamed Z. M. Salem,b Hayssam M. Ali,d,e, * and Ashraf A. Hatamleh d

Mold invasion by Trichoderma harzianum T6776 over the surface of wood-plastic composites (WPCs) made from Juniperus procera wood-branch and polypropylene with a melt-blending technique was examined using scanning electron microscopy (SEM) and electron dispersive X-ray spectroscopy (EDX). Before the addition of coupling agent, the WPC samples were made from untreated and pretreated wood-branch particles of J. procera with either cold or hot water and then mixed with polypropylene to produce panels. The surfaces of WPC samples were inoculated by a mold suspension of T. harzianum. SEM-EDX measurements of WPCs made from J. procera particles showed little or no growth of T. harzianum, irrespective of treatment with cold or hot water. The results suggest that WPCs made from the particles of J. procera wood-branch pretreated with either cold or hot water could be useable in wet conditions. In addition, using of J. procera as durable wood for manufacturing of WPCs had good effects on the prevention of the mold infestation over the surfaces of the produced panels.

Keywords: SEM-EDX; Wood-plastic composites; Surface characterization; Juniperus procera; Trichoderma harzianum

Contact information: a: Conservation Department, Faculty of Archaeology, Cairo University, Giza 12613, Egypt; b: Forestry and Wood Technology Department, Faculty of Agriculture (EL–Shatby), Alexandria University, Egypt; c: Plant Production Department, Food and Agriculture Science College, King Saud University, Riyadh 11451, Saudi Arabia; d: Botany and Microbiology Department, College of Science, King Saud University, P.O. Box 2455, Riyadh 11451, Saudi Arabia; e: Timber Trees Research Department, Sabahia Horticulture Research Station, Horticulture Research Institute, Agriculture Research Center, Alexandria, Egypt; *Corresponding authors: hayhassan@ksu.edu.sa

INTRODUCTION

Several biodegrading agents, such as fungi, insects, and marine borers, can attack wood or wood-based products by using them either as a food source (primarily wood) or as shelter (both wood and plastic) (Morrell et al. 2010). Molds colonize the surface of wood and wood-based products, but they do not necessarily degrade the product. Wood colonization by molds involves the formation of a dense hyphal network on the surface of wood blocks with enzyme and organic acid release on the inside (de Boer et al. 2010; An et al. 2016).

Enzymes like cellulase and hemicellulases are produced by different species of Trichoderma (Shafique et al. 2009). Trichoderma species have been reported to degrade cellulose and other carbohydrates and to cause large losses to the wooden frames in museums (Garg et al. 1995; Osono and Takeda 2001). Other strains of Trichoderma species have been used for biological wound treatment against wood decay fungi on urban trees (Schubert et al. 2008). T. harzianum shows a white cottony mycelium with green conidiation over the deteriorated surfaces (Shah et al. 2012). Furthermore, T. harzianum has been found on the surface of wooden substrates and CCA-treated wood (Kim et al. 2007; Ljaljević-Grbić et al. 2013). During the storage of sapwood logs of Japanese red pine, Trichoderma species were the most frequently isolating fungi, which represented more than half of all isolates (Kim et al. 2001).

Wood-plastic composites (WPCs), which first appeared in the markets in the 1930s, are hybrid materials of wood and plastic and have been used as a substitute for wood in decking (Wolcott and Englund 1999; Clemons 2002). WPCs have many applications in our daily lives as a replacement of particleboard for indoor and outdoor uses, especially where particleboards have failed. WPCs also have several industrial purposes, such as wall paneling, automotive manufacturing, construction, the production of furniture and consumer products, and the manufacturing of kitchens and bathrooms (Youngquist 1999; Abu-Sharkh and Hamid 2004; Aref et al. 2013; Nasser and Aref 2014). Ibach (2010) reported that the same types of mold that affect solid wood can also develop within WPCs. When wetting conditions are present, the molds can be grown over the WPCs’ surfaces. In service, decking with WPCs has shown discoloration decay caused by fungi (Morris and Cooper 1998).

Several studies have focused on the biodegradation of WPCs by wood-degrading fungi including Trametes versicolor, Phanerochaete chrysosporium, Pycnoporus sanguineus, Fuscoporia ferrea, Gloeophyllum trabeum, Coniophora puteana, and Postia placenta (Morris and Cooper 1998; Naumann et al. 2012; Catto et al. 2016). WPCs can be protected against fungal growth by the addition of antifungal agents such as wood preservatives or by using natural products like essential oils (Verhey and Laks 2002; Morton et al. 2003; Simonsen et al. 2004; Xu et al. 2015).

The pretreatment of wood particles (cold or hot water extraction) is primarily used to improve the quality of the produced product in terms of mechanical, physical, and thermal stability properties, where they are used to eliminate the wood extractives that cause some problems during the production of WPCs. For example, Nasser and Aref (2014) investigated the effect of aqueous extraction on the performance and properties of wood/polypropylene composites made from P. dactylifera, Juniperus procera, Conocarpus erectus, and Tamarix aphylla. They reported that pretreating the wood particles by either cold or hot water and without adding coupling agents resulted in significant improvements in the compatibility of each wood species with polypropylene. However, the effect of these pretreatments on the fungal resistance of the produced WPCs has not yet been studied.

- procera, locally known as “Arar”, is found in Hejaz and southern region of Saudi Arabia (Migahid 1978). The wood of J. procera (African pencil cedar, Cupressaceae family) is widely used for construction building, water flumes, draining boards, food containers, roofing shingles, fence posts, and transmission poles.

The mean annual increment (MAI) of J. procera was 678 ton/yr, and the extraction was 1840 tons/yr through its main outlets, also, the fuel wood extracted over the MAI was 1161 tons/yr, from Desa’a forest, Northern Ethiopia, Tigray (Teklay and Gebreslassie 2014). J. procera, which is composed of approximately 50% carbon, 6% hydrogen, and 44% oxygen, is a durable source of wood for timber and fuel and is resistant to damage by termites, fungi, and light, which makes it useful for furniture, door and window frames, flooring and floor parquet tiles, firewood, and baking end use purposes (Pohjonen and Pukkala 1992; Kinyanjui et al. 2000). The petroleum ether fraction of the dried ground aerial parts of J. procera shows the presence of the diterpenoids 4-epi-abietol, ferruginol, hinokiol, sugiol, Z-communic acid, hinokiol-1-one 3β,12-dihydroxyabieta-8,11,13-triene-1-one, and the sesquiterpene 8α-acetoxyelemol (Alqasoumi and Abdel-Kader 2012). Isocupressic acid, (+)-Z-communic acid, (+)-totarol, and sugiol isolated from the bark and leaves extracts of J. procera were observed to possess good antimicrobial activities (Muhammad et al. 1995, 1996). Bark extracts of J. procera have shown the presence of two lignans, namely β-peltatin A Me ether and deoxypodophyllotoxin (Muhammad et al. 1995). Alkanes, monoterpene alcohols or lactones were identified in the essential oil of J. procera from Saudi Arabia (Baghlaf et al. 1983).

Generally, the tree of J. procera has favorable attributes such as drought tolerance and adaptability (Chaffey 1982). The wood has distinctive qualities such as the hardness of wood and resistance to termites and fungal diseases. Because of these aspects, this work was aimed to evaluate the effects of J. procera wood-branch particle pretreatments (hot water [70 °C] and cold-water extractions) on the fungal invasion over the surface of WPCs by T. harzianum T6776. The fungal infestation and the changes in surface-elemental composition were measured using an environmental scanning electron microscope (ESEM) with dispersive X-ray spectroscopy (EDX) equipment attached to it.

EXPERIMENTAL

Materials

Wood-plastic composite samples

Branches of Juniperus procera (as softwood) were debarked, transferred into particles, ground to particle size of -20/+40 mesh (passed through 20 mesh and retained on 40 mesh) and dried (particles were dried in an oven at 100±5 °C for approximately 24 h). The particles were pretreated with two treatments; the first with water extraction (48-h soaking), and the second with hot water extraction (boiling in water for 6 h while changing water every 2 h); the particles in the control treatment did not have any pretreatments. The polymer type used was polypropylene pellets from SABIC Company, Riyadh, Saudi Arabia). The physical properties of PP are melt index (25.0 g/10 min), the density (0.954 g/cm3), vicat softening point (153°C), tensile strength at yield (36 MPa), and Shore D hardness (104R). The panels were manufactured without any coupling agent with wood/polymer ratio (50/50 g/g) in a melt-blending technique and then compression mold at temperature (180±5 °C), pressure (4.3 MPa), and time (10 min). The produced WPC panels had a target density of 1.0 g/cm3 with surface area of 300 x 300 mm and thickness of 10 mm. The WPC panels were conditioned at room temperature (65±5 °C) with a relative humidity of 20±2%. Three WPC panels per each treatment were used.

The wood/polypropylene composites (WPCs) were made from untreated J. procera branch without bark and polypropylene without maleic acid modified polypropylene “MAPP” (JP-UN-PP). J. procera wood-branch was also pretreated by cold-water extraction and polypropylene without MAPP (JP-CWS-PP). In addition, J. procera wood-branch was pretreated by hot water extraction and polypropylene without MAPP (JP-HWE-PP). Hot or cold-water extractions for the particles were used to enhance the performance and compatibility between the J. procera wood-branch and the PP (Nasser and Aref 2014; Nasser et al. 2017).

The details of the fungal inoculation of WPCs with Trichoderma harzianum in vitro, weight loss and SEM-EDX measurements of the samples after inoculation, and visual observation after 2 and 4 months of inoculation of the manufactured WPCs are shown in a previous part of the work (Nasser et al. 2017).

Statistical analysis

The significant differences in weight loss and quantitative elemental results between the un-inoculated and inoculated WPC samples made from J. procera wood-branch were analyzed using one-way analysis of variance (ANOVA) (SAS Institute software 2001) with the probability set at 0.05 (P < 0.05). The difference between means was tested by least significant difference (LSD) tests.

RESULTS AND DISCUSSION

Weight Loss

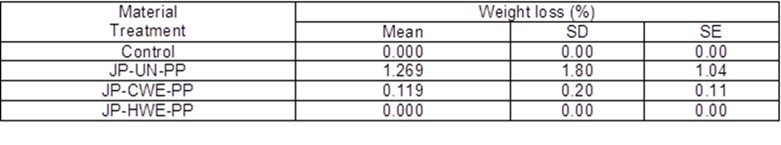

Table 1 presents the weight loss (WL) results of WPCs made from Juniperus procera wood-branch un-inoculated and inoculated with Trichoderma harzianum. As expected for T. harzianum, which is not wood decay fungi, no change in weight was observed for the WPCs made from JP-HWE-PP and a positive but small and insignificant weight change was found for the WPCs manufactured from JP-CWS-PP and JP-UN-PP, with respect to the weight of the control. WPCs made from J. procera wood-branch showed little or no growth of T. harzianum when they were untreated or treated with cold or hot water extraction.

Previous studies showed that fungi could cause WL in WPC with respect to the wood fillers only (Albertsson and Karlsson 1988; Iiyoshi et al. 1998; Fabiyi et al. 2011).

Table 1. Weight Loss (Based on Wood Fraction) of WPCs with Different Pretreatments of J. procera Wood-Branch Following Two Months of Incubation with T. harzianum

* Each value represents the average of three replicates.

SEM-EDX Analyses

Inoculated WPCs made from J. procera wood-branch

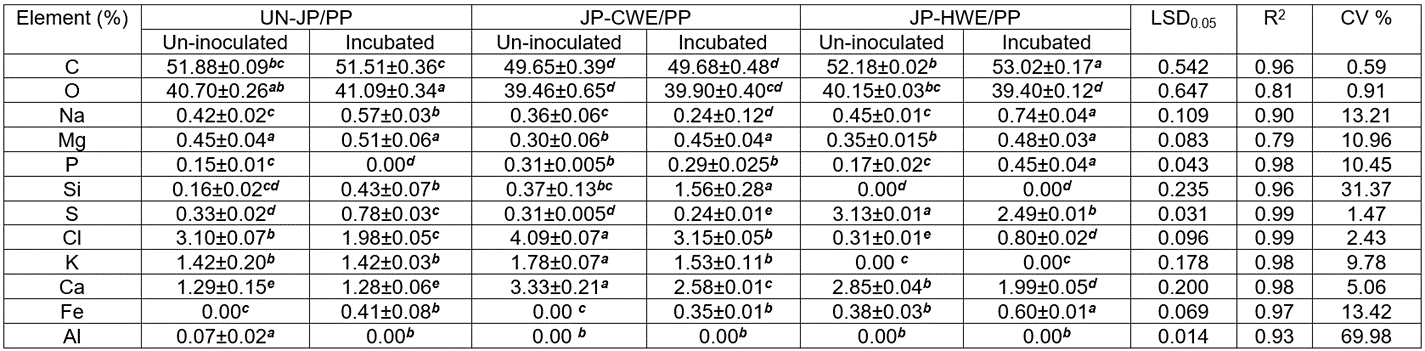

Table 2 shows the EDX analysis of WPCs made from untreated J. procera wood-branch particle and polypropylene (JP-UN-PP), inoculated and un-inoculated with T. harzianum.

No significant change was found in the C content between the control (51.88%) and the inoculated (51.51%) WPC made from JP-UN-PP. Moreover, the O content increased by an insignificant amount, from 40.70% in the control to 41.09% in the inoculated WPC. T. harzianum-inoculation of WPC made from JP-UN-PP resulted in a significant increase in Si amount from 0.16% to 0.43%, a significant increase in the S amount from 0.33% to 0.78%, and significant decreases in the elemental composition of Cl from 3.10% to 1.98% (Table 2). The small concentrations of P (0.15%) and Al (0.07%) were completely consumed as the WPC made from JP-UN-PP was inoculated with T. harzianum.

Nearly no changes were observed for C and O elements between the control and the inoculated WPC samples made from J. procera wood-branch particles and polypropylene, where the particles were pretreated by cold-water extraction (JP-CWE-PP) (Table 2).

Significantly (P<0.0001), the Si element peak increased from 0.37% to 1.56%, the Cl amount decreased from 4.09% to 3.15%, the K content from 1.78% to 1.53%, and Ca from 3.33% to 2.58%. A similar trend was found in WPCs made from J. procera wood-branch particles that were pretreated by hot water extraction with respect to the changes in elemental compositions of C, O, Na, Mg, S, and Ca.

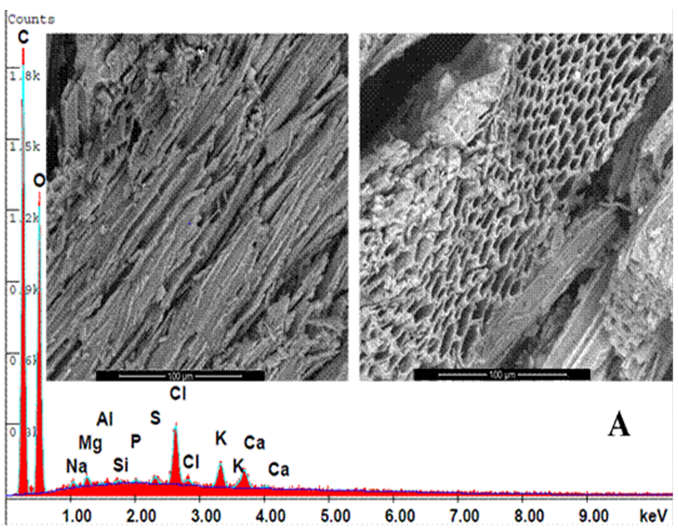

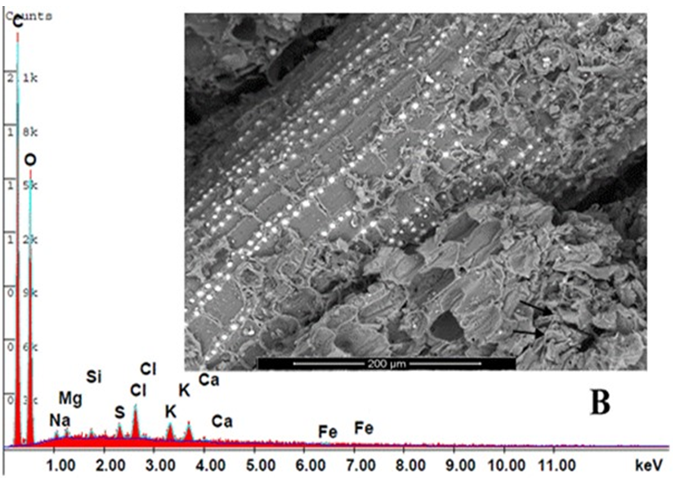

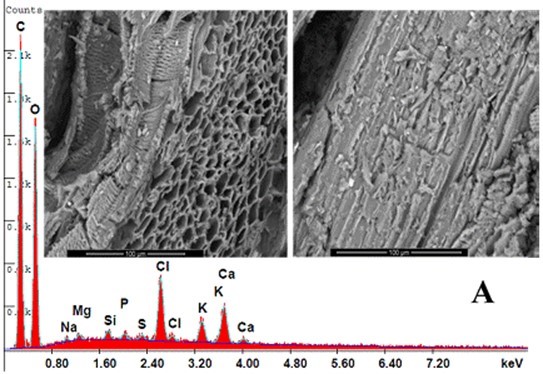

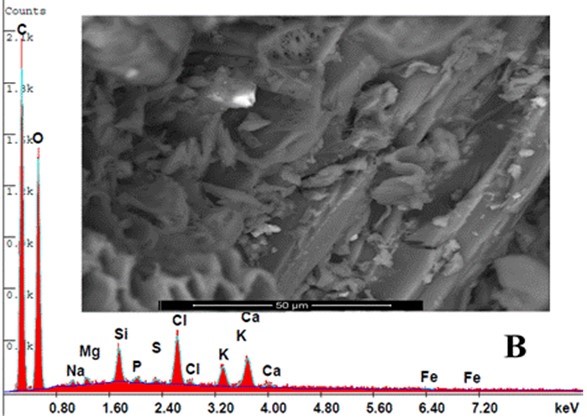

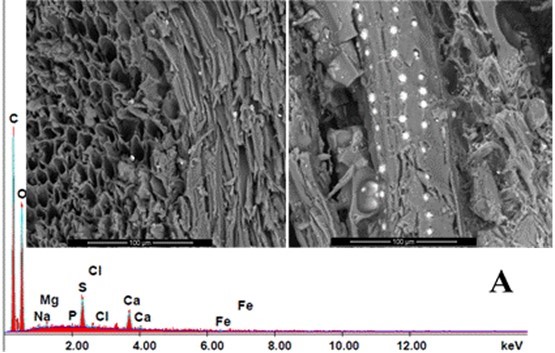

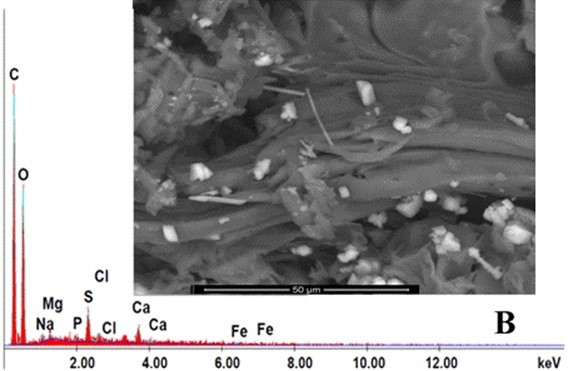

In comparison with the SEM images for the WPCs controls made from JP-UN-PP (Fig. 1), JP-CWE-PP (Fig. 2), and JP-HWE-PP (Fig. 3), nearly no fungal growth was seen over WPC surfaces of inoculated samples.

SEM-EDX results for untreated and pretreated particles of J. procera wood-branch with cold or hot water treatment used for the production of WPCs and exposed to the biodeterioration by T. harzianum showed that nearly no changes occurred. These results could be related to the extractives present in the wood, which suppressed the fungal growth. Kinyanjui et al. (2000) reported that the extracts from J. procera had potential anti-termite properties and that the compound cedrol, which is a tertiary tricyclic alcohol, was found to be in the greatest proportion in the oily layer. Phenolic compounds like 3-methylfuran, 2H-pyran-2-one, 3,4,5-trimethyl-2-cyclopenten-1-one, and 2-methylphenol were detected by GC/MS from the extracts of J. procera (Kinyanjui et al. 2000). Resin of J. procera has been reported to be active against wood colonizing fungi (white heart-rot fungus, Pyrofomes demidoffii), and the phytochemical screening revealed the presence of different chemical groups like terpenoids, alkaloids, phenolic compounds, fixed oils, saponins, and flavonoids (Bitew 2015).

The changes in the elemental compositions of the inoculated WPCs compared with those of the control could be related to the fact that the fungal remediation processes via organic acid production can remove inorganic metals (Kartal et al. 2006). In addition, it was reported by researchers that molds like T. harzianum consumed C and N for their growth (Mansour et al. 2015a,b; Mansour and Salem 2015).

A recent study by Salem (2016) showed that C content was lower in the inoculated woods of Pinus rigida, Juglans nigra, and Fagus sylvatica with some molds (Penicillium selerotigenum, Paecilomyces variotii, and Aspergillus niger) than in controls.

Fe was observed in the inoculated WPCs but not shown in the uninoculated WPCs manufactured from untreated and pretreated particles from J. procera with cold-water extraction. Koenigs (1974) reported that elemental Fe could be involved in the deterioration of wood, which would result in the oxidative degradation of cellulose by fungi; also, elements such as Na, K, Mg, Ca, and Al in decayed wood could be related to the chemical substrates in wood (Schmidt et al. 1981; Tyler 1982).

Fig. 1. SEM-EDX graph of WPCs made from untreated J. procera wood-branch, (A) Control (uninoculated), (B) (Inoculated (fungal hyphae of T. harzianum (arrows) after 2 months)

Table 2. Elemental Analysis of WPCs made from J. procera Wood-Branch (JP) and Polypropylene (PP) as Affected by T. harzianum

* According to Fisher’s least significant difference test, means with the same letter within the same row are not significantly different at the 0.05 level of probability. Values are the mean of three replicates ± standard deviation.

Fig. 2. SEM-EDX graph of WPCs made from pretreated J. procera branch with cold-water extraction; (A) Control (uninoculated), (B) (Inoculated with T. harzianum after 2 months

Previously, researchers have focused on particle pretreatments that used high temperatures, such as 140, 155, and 170 °C, to show its effects on the mechanical, physical, and thermal properties as well as mold resistance of the manufactured wood-based composites (WPC and particleboards). This high temperature caused degradation of the main chemical components of the wood (hemicellulose) and suggested that water and mold resistance of WPC could be improved (Kim et al. 2008, 2009; Hosseinaei et al. 2011a,b, 2012). Furthermore, the removal of free sugars, starches, and lipids may explain the mold resistance of WPC manufactured with hemicellulose extraction at high temperature by hot water extraction (Hosseinaei et al. 2012).

Fig. 3. SEM-EDX graph of WPCs made from pretreated J. procera wood-branch with hot water extraction; (A) Control (uninoculated), (B) (Inoculated with T. harzianum after 2 months)

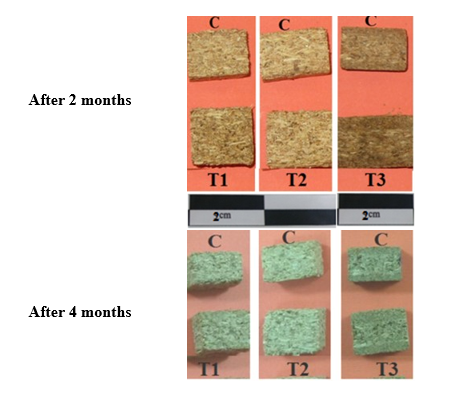

Visual Observation of the Incubated WPC Samples

The visual observations of the inoculated WPCs made with T. harzianum in comparison with the control were recorded at two months after inoculation and at four months after Petri dish storage at room temperature (Fig. 4).

It can be seen that after two and four months, the WPC samples from J. procera wood-branch inoculated by T. harzianum did not visually display any growth of T. harzianum.

As stated in the literature, the higher plants are a bioresource and produce many different secondary metabolites or natural extracts, which exhibit a broad spectrum of activities against several pathogens (EL-Hefny et al. 2017; Hussein et al. 2017; Salem et al. 2017). These nature extracts are toxic or causes inhibitory to pathogenic fungi, as well as they display the natural resistance of wood (Wagener and Davidson 1954; Cos et al. 2006, Mansour et al. 2015a,b; Salem 2016; Salem et al. 2016 a,b). From these statements, the results of the present work confirmed the natural resistance of J. procera wood, where previously, resin had shown activity against wood-colonizing fungi (Martin et al. 2002; Bitew 2015). In addition, diterpenoids and sesquiterpene constituents isolated from J. procera showed bioactivity against some plant pathogens (Muhammad et al. 1995, 1996).

C-Control; T1- JP-UN-PP; T2- JP-CWS-PP; T3- JP-HWE-PP.

Fig. 4. Visual observation of the inoculated WPCs made from J. procera wood-branch by T. harzianum after two and four months

From the above results, the fungal discoloration must be controlled in the produced WPCs panels, which can be controlled and prevented by rapid kiln drying or by treating of wood surface chemicals as was stated from the literature (Zabel and Morrell 1992; Verhey and Laks 2002; Morton et al. 2003; Simonsen et al. 2004; Xu et al. 2015). Therefore, our results observed that the using of durable wood species like J. procera in the production of WPCs had good effects on the prevention of the mold infestation over the surfaces of the produced panels.

CONCLUSIONS

- SEM-EDX images of WPCs made from the pretreated procera wood branch particles with either cold or hot water extracted WPCs showed little or no growth of T. harzianum.

- The production of WPCs from a durable wood species ( procera) had good effects on the suppression of fungal growth of T. harzianum, where the SEM-EDX measurements showed nearly no changes in elemental composition as well as fungal infestation.

- From the present results and the data related to the durability of procera wood, it is suggested to manufacture WPCs from this wood when wet conditions are expected. This way, mold growth could be suppressed.

ACKNOWLEDGMENTS

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding this Research group NO. (RG 1435-011).

REFERENCES CITED

Abu-Sharkh, B. F., and Hamid, H. (2004). “Degradation study of date palm fibre/ polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis,” Polym. Degrad. Stab. 85(3), 967-973. DOI: 10.1016/j.polymdegradstab.2003.10.022

Albertsson, A. C., and Karlsson, S. (1988). “The three stages in degradation of polymers – polyethylene as a model substance,” J. Appl. Polym. Sci. 35(5), 1289-1302. DOI: 10.1002/app.1988.070350515

Alqasoumi, S. I., and Abdel-Kader, M. S. (2012). “Terpenoids from Juniperus procera with hepatoprotective activity,” Pak. J. Pharm. Sci. 25(2), 315-322.

Aref, I. M., Nasser, R. A., Ali, I., Al-Mefarrej, H. A., and Al-Zahrany, S. M. (2013). “Effects of aqueous extraction on the performance and properties of polypropylene/ wood composites from Phoenix dactylifera and Acacia tortilis wood,” Reinf. Plast. Compos. 32(7), 476-489. DOI: 10.1177/0731684412454462

An, S., Hong, J. H., Song, K. Y., Lee, M., Al-Deyab, S. S., Kim, J. J., Yarin, A. L., and Yoon, S. S. (2016). “Prevention of mold invasion by eco-friendly lignin/ polycaprolactone nanofiber membranes for amelioration of public hygiene,” Cellulose 24(2), 951-965. DOI: 10.1007/s10570-016-1141-5

Baghlaf, A. O., El-Beih, S. K. A., and El-Tawil, B. A. H. (1983). “Constituents of local

plants. Part 75. Study of volatile oil of Saudi Ruta chalepensis L., Juniperus procera Hochst. ex Endle. and Euphorbia heliofscopia L.,” Herba Hung. 22, 39-42.

Bitew, D. (2015). “Assessment of the inhibitory activity of resin from Juniperus procera against the mycilium of Pyrofomes demidoffi,” J. Plant Pathol. Microb. 6, 291. DOI: 10.4172/2157-7471.1000291

Catto, A. L., Montagna, L. S., Almeida, S. H., Silveira, R. M. B., and Santana, R. M. C. (2016). “Wood plastic composites weathering: Effects of compatibilization on biodegradation in soil and fungal decay,” Int. Biodeterior. Biodegrad. 109, 11-22. DOI: 10.1016/j.ibiod.2015.12.026

Chaffey, D. R. (1982). South-West Ethiopia Forest Inventory Project, A Reconnaissance Inventory of Forests in South-West Ethiopia, Forestry and Wildlife Conservation and Development Authority, Addis Ababa, Ethiopia.

Clemons, C. (2002). “Wood-plastic composites in the United States – The interfacing of two industries,” Forest Prod. J. 52(6), 10-18.

Cos, P., Vlietinck, A. J., Berghe, D. V., and Maes, L. (2006). “Anti-infective potential of natural products: How to develop a stronger in vitro ‘proof-of-concept’,” J. Ethnopharmacol. 106(3), 290-302. DOI: 10.1016/j.jep.2006.04.003

de Boer, W., Folman, L. B., Klein Gunnewiek, P. J. A., Svensson, T., Bastviken, D., Öberg, G., del Rio, J. C., and Boddy, L. (2010). “Mechanism of antibacterial activity of the white rot fungus Hypholoma fasciculare colonizing wood,” Can. J. Microbial. 56(5), 380-388. DOI: 10.1139/w10-023

EL-Hefny, M., Ali, H. M., Ashmawy, N. A., and Salem M. Z. M. (2017). “Chemical composition and bioactivity of Salvadora persica extracts against some potato bacterial pathogens,” BioResources 12(1), 1835-1849. DOI: 10.15376/biores.12.1.1835-1849

Fabiyi, J. S., McDonald, A. G., Morrell, J. J., and Freitag, C. (2011). “Effects of wood species on durability and chemical changes of fungal decayed wood plastic composites,” Compos. Pt A – Appl. Sci. Manuf. 42(5), 501-510. DOI: 10.1016/j.compositesa.2011.01.009

Garg, K. L., Jain, K., and Mishra, A. K. (1995). “Role of fungi in the biodeterioration of wall paintings,” Sci. Total Environ. 167(1), 255-271. DOI: 10.1016/0048-9697(95)04587-Q

Hussein, H. S., Salem, M. Z. M., and Soliman, A. M. (2017). “Repellent, attractive, and insecticidal effects of essential oils from Schinus terebinthifolius fruits and Corymbia citriodora leaves on two whitefly species, Bemisia tabaci and Trialeurodes ricini,” Scientia Horticulturae 216(C),111-119. DOI: 10.1016/j.scienta.2017.01.004

Hosseinaei, O., Wang, S., Rials, T. G., Xing, C., and Zhang, Y. (2011a). “Effects of decreasing carbohydrate content on properties of wood strands,” Cellulose 18(3), 841-850. DOI: 10.1007/s10570-011-9519-x

Hosseinaei, O., Wang, S., Rials, T. G., Xing, C., Taylor, A. M., and Kelley, S. S. (2011b). “Effects of hemicellulose on physical and mechanical properties and mold susceptibility of flakeboard,” Forest Prod. J. 61(1), 31-37. DOI: 10.13073/0015-7473-61.1.31

Hosseinaei, O., Wang, S., Taylorm, A. M., and Kim, J.-W. (2012). “Effect of hemicellulose extraction on water absorption and mold susceptibility of wood-plastic composites,” Int. Biodeterior. Biodegrad. 71, 29-35. DOI: 10.1016/j.ibiod.2011.12.015

Ibach, R. (2010). “Durability of wood plastic composite lumber,” in: McGraw-Hill Yearbook of Science and Technology, McGraw-Hill, New York, NY, pp 113-116.

Iiyoshi, Y., Tsutsumi, Y., and Nishida, T. (1998). “Polyethylene degradation by lignin degrading fungi and manganese peroxidase,” J. Wood Sci. 44(3), 222-229. DOI: 10.1007/BF00521967

Kartal, S. N., Katsumata, N., and Imamura, Y. (2006). “Removal of copper, chromium, and arsenic from CCA-treated wood by organic acids released by mold and staining fungi,” Forest Prod. J. 56(9), 33-37.

Kim, J.-W., Harper, D. P., and Taylor, A. M. (2009). “Effect of extractives on water sorption and durability of wood-plastic composites,” Wood Fiber Sci. 41(3), 279-290.

Kim, J.-W., Harper, D. P., and Taylor, A. M. (2008). “Effect of wood species on water sorption and durability of wood-plastic composites,” Wood Fiber Sci. 40(4), 519-531.

Kim, J.-J., Kang, S.-M., Choi, Y.-S., and Kim, G.-H. (2007). “Microfungi potentially disfiguring CCA-treated wood,” Int. Biodeterior. Biodegrad. 60(3), 197-201. DOI: 10.1016/j.ibiod.2007.05.002

Kim, J.-J., Ra, J.-B., Son, D.-S., and Kim, G.-H. (2001). “Fungi colonizing sapwood of Japanese red pine logs in storage,” Mycobiology 29(4), 205-209.

Kinyanjui, T., Gitu, P. M., and Kamau, G. N. (2000). “Potential antitermite compounds from Juniperus procera extracts,” Chemosphere 41(7), 1071-1074. DOI: 10.1016/S0045-6535(99)00460-9

Koenigs, J. W. (1974). “Hydrogen peroxide and iron: A proposed system for decomposition of wood by brown-rot basidiomycetes,” Wood Fiber 6(1), 66-79.

Ljaljević-Grbić, M., Stupar, M., Vukojević, J., Maričić, I., and Bungur, N. (2013). “Molds in museum environments: Biodeterioration of art photographs and wooden sculptures,” Arch. Biol. Sci. Belgr. 65(3), 955-962. DOI: 10.2298/ABS1303955G.

Mansour, M. M. A., and Salem, M. Z. M. (2015). “Evaluation of wood treated with some natural extracts and Paraloid B-72 against the fungus Trichoderma harzianum: Wood elemental composition,” Int. Biodeterior. Biodegr. 100, 62-69. DOI: 10.1016/j.ibiod.2015.02.009

Mansour, M. M. A., Salem, M. Z. M., Khamis, M. H., and Ali, H. M. (2015a). “Natural durability of Citharexylum spinosum and Morus alba woods against three mold fungi,” BioResources 10(3), 5330-5344. DOI: 10.15376/biores.10.3.5330-5344

Mansour, M. M. A., Abdel-Meged, A., Nasser, R. A., and Salem, M. Z. M. (2015b). “Comparative evaluation of some woody trees methanolic extracts and Paraloid B-72 against phytopathogenic mold fungi Alternaria tenuissima and Fusarium culmorum,” BioResources 10(2), 2570-2584. DOI: 10.15376/biores.10.2.2570-2584

Martin, D. M., Tholl, D., Gershenzon, J., and Bohlmann, J. (2002). “Methyl jasmonate induces traumatic resin ducts, terpenoid resin biosynthesis, and terpenoid accumulation in developing xylem of Norway spruce stems,” Plant Physiol. 129(3), 1003-1018.

Migahid, A. M. (1978). “Flora of Saudi Arabia,” Riyadh University, Riyadh, Saudi Arabia, 2nd edition, 1978.

Morris, P. I., and Cooper, P. (1998). “Recycled plastic/wood composite lumber attacked by fungi,” Forest Prod. J. 48(1), 86-88.

Morrell, J. J., Stark, N. M., Pendleton, D. E., and McDonald, A. G. (2010). “Durability of wood-plastic composites,” in: Tenth International Conference on Wood and Biofiber Plastic Composites and Cellulose Nanocomposites Symposium, May 11-13, Madison, WI.

Morton, J., Quarmley, J., and Rossi, L. (2003). “Current and emerging applications for natural and woodfiber composites,” in: Proceedings 7th International Conference on Wood Fiber-Plastic Composites, Forest Products Society, Madison, WI.

Muhammad, I., Mossa, J. S., Al-Yahya, M. A., Ramadan, A. F., and El-Feraly, F. S. (1995). “Further antibacterial diterpenes from the bark and leaves of Juniperus procera Hochst. ex Endl.,” Phytother. Res. 9(8), 584-588. DOI: 10.1002/ptr.2650090810

Muhammad, I., Mossa, J. S., and El-Feraly, F. S. (1996). “Additional antibacterial diterpenes from the bark of Juniperus procera,” Phytother. Res. 10(7), 604-607. DOI: 10.1002/(SICI)1099-1573(199611)10:7<604::AID-PTR922>3.0.CO;2-C

Nasser, R. A., and Aref, I. M. (2014). “The performance and properties of wood/ polypropylene panels as affected by wood aqueous extraction,” Forest Prod. J. 64(5/6), 192-198. DOI: 10.13073/FPJ-D-12-00045

Nasser, R. A., Mansour, M. M. A., Salem, M. Z. M., Ali, H. M., and Aref, I. M. (2017). “Study the mold invasion on the surface of wood/polypropylene composites produced from aqueous pretreated wood particles, Part 1: Date palm midrib,” BioResources 12(2), 4078-4092. DOI: 10.15376/biores.12.2.4078-4092

Naumann, A., Stephan, I., and Noll, M. (2012). “Material resistance of weathered wood-plastic composites against fungal decay,” Int. Biodeterior. Biodegrad. 75, 28-35. DOI: 10.1016/j.ibiod.2012.08.004.

Osono, T., and Takeda, H. (2001). “Organic chemical and nutrient dynamics in decomposing beech leaf litter in relation to fungal ingrowth and succession during 3-year decomposition processes in a cool temperate deciduous forest in Japan,” Ecol. Res. 16(4), 649-670. DOI: 10.1046/j.1440-1703.2001.00426.x

Pohjonen, Y., and Pukkala, T. (1992). “Juniperus procera Hocht. ex. Endl. in Ethiopian forestry,” Forest Ecol. Manag. 49(s1-2), 75-85. DOI: 10.1016/0378-1127(92)90161-2

Salem, M. Z. M., EL-Hefny, M., Nasser, R. A., Ali, H. M., El-Shanhorey, N. A., and Elansary, H. O. (2017). “Medicinal and biological values of Callistemon viminalis extracts: History, current situation and prospects,” Asian Pac. J. Trop. Med. 10(3), 229-237. DOI: 10.1016/j.apjtm.2017.03.015

Salem, M. Z. M. (2016). “EDX measurements and SEM examination of surface of some imported woods inoculated by three mold fungi,” Measurements 86, 301-309. DOI: 10.1016/j.measurement.2016.03.008

Salem, M. Z. M., Zidan, Y. E., Mansour, M. M.A., El Hadidi, N. M. N., and Abo Elgat, W. A. A. (2016a). “Antifungal activities of two essential oils used in the treatment of three commercial woods deteriorated by five common mold fungi,” Int. Biodeterior. Biodegrad. 106, 88-96. DOI: 10.1016/j.ibiod.2015.10.010

Salem, M. Z. M., Zidan, Y. E., Mansour, M. M.A., El Hadidi, N. M. N., and Abo Elgat, W. A. A. (2016b). “Evaluation of usage three natural extracts applied to three commercial wood species against five common molds,” Int. Biodeterior. Biodegrad. 110, 206-226. DOI: 10.1016/j.ibiod.2016.03.028

SAS Institute (2001). “SAS/Stat User’s Guide,” Version 9, SAS Institute Inc., Cary, NC.

Schmidt, C. J., Whitten, B. K., and Nicholas, D. D. (1981). “A proposed role for oxalic acid in non-enzymatic wood decay by brown-rot fungi,” Proc. Am. Wood Preser. Assoc. 77, 157-164.

Schubert, M., Fink, S., and Schwarze, F. W. M. R. (2008). “Evaluation of Trichoderma spp. as a biocontrol agent against wood decay fungi in urban trees,” Biological Control, 45(1), 111-123. DOI: 10.1016/j.biocontrol.2008.01.001

Shafique, S., Bajwa, R., and Shafique, S. (2009). “Cellulase biosynthesis by selected Trichoderma species,” Pak. J. Bot. 41(2), 907-916.

Shah, S., Nasreen, S., and Sheikh, P. A. (2012). “Cultural and morphological characterization of Trichoderma spp. associated with green mold disease of Pleurotus spp. in Kashmirm,” Res. J. Microbiol. 7(2), 139-144. DOI: 10.3923/jm.2012.139.144.

Simonsen, J., Freitag, C. M., Silva, A., and Morrell, J. J. (2004). “Wood/plastic ratio: Effect on performance of borate biocides against a brown rot fungus,” Holzforschung 58(2), 205-208. DOI: 10.1515/HF.2004.031.

Teklay, G., and Gebreslassie, H. (2014). “Current status and future prospect of Olea europaea and Juniperu procera on Desa’a Afro Alpine forest, North Ethiopia,” Journal of Natural Sciences Research 4(18), 62-65.

Tyler, G. (1982). “Metal accumulation by wood-decaying fungi,” Chemosphere 11(11), 1141-1146. DOI: 10.1016/0045-6535(82)90124-2

Youngquist, J. A. (1999). Wood-based composites and panel products,” Wood Handbook – Wood as an Engineering Material, General Technical Report FPL-GTR-113, USDA, Forest Service, Forest Products Laboratory, Madison, WI, p. 31.

Verhey, S., and Laks, P. (2002). “Wood particle size affects the decay resistance of woodfiber/thermoplastic composites,” Forest Prod. J. 52, 78-81.

Wagener, W. W., and Davidson, R. W. (1954). “Heart rots in living trees,” Bot. Rev. 20(2), 61-134.

Wolcott, M. P., and Englund, K. (1999). “A technology review of wood-plastic composites,” in: 33rd International Particleboard/Composite Materials Symposium Proceedings, 13-15 April, Washington State University, Pullman, WA, pp. 103-111.

Xu, K., Feng, J., Zhong, T., Zheng, Z., and Chen, T. (2015). “Effects of volatile chemical components of wood species on mould growth susceptibility and termite attack resistance of wood plastic composites,” Int. Biodeterior. Biodegrad. 100, 06-115. DOI: 10.1016/j.ibiod.2015.02.002

Zabel, R.A., and Morrell, J. J. (1992). Wood Microbiology: Decay and Its Prevention, Academic Press, Cambridge, MA.

Article submitted: February 8, 2017; Peer review completed: April 6, 2017; Revised version received and accepted: April 18, 2017; Published: April 25, 2017.

DOI: 10.15376/biores.12.2.4187-4201