Abstract

The properties of non-treated and hydrochloric acid (HCl)-treated oil palm ash (OPA)-filled natural rubber (NR) composites were investigated in terms of swelling behavior, rubber-filler interaction, ageing resistance, dynamic mechanical analysis, and thermal stability. The incorporation of OPA resulted in a lower degree of swelling in the NR composites, which was even lower after HCl treatment. Concerning the rubber-filler interaction, the HCl-treated OPA had better interfacial interaction with the NR matrix than that of non-treated OPA, resulting in higher crosslink density and improved ageing resistance. The dynamic mechanical properties of NR composites were better with the incorporation of HCl-treated OPA compared to non-treated OPA, in that they showed a higher storage modulus and lower mechanical loss factor. Thermogravimetry analysis revealed that the HCl treatment process did not affect the thermal stability of OPA-filled NR composites.

Download PDF

Full Article

The Effect of Hydrochloric Acid Treatment on Properties of Oil Palm Ash-filled Natural Rubber Composites

Zhong Xian Ooi, Hanafi Ismail,* and Azhar Abu Bakar

The properties of non-treated and hydrochloric acid (HCl)-treated oil palm ash (OPA)-filled natural rubber (NR) composites were investigated in terms of swelling behavior, rubber-filler interaction, ageing resistance, dynamic mechanical analysis, and thermal stability. The incorporation of OPA resulted in a lower degree of swelling in the NR composites, which was even lower after HCl treatment. Concerning the rubber-filler interaction, the HCl-treated OPA had better interfacial interaction with the NR matrix than that of non-treated OPA, resulting in higher crosslink density and improved ageing resistance. The dynamic mechanical properties of NR composites were better with the incorporation of HCl-treated OPA compared to non-treated OPA, in that they showed a higher storage modulus and lower mechanical loss factor. Thermogravimetry analysis revealed that the HCl treatment process did not affect the thermal stability of OPA-filled NR composites.

Keywords: Oil palm ash; Natural rubber; Treatment; Rubber-filler interaction; Dynamic mechanical properties

Contact information: Division of Polymer Engineering, School of Materials and Mineral Resources Engineering, Universiti Sains Malaysia, Engineering Campus, 14300 Nibong Tebal, Penang, Malaysia;

* Corresponding author: hanafi@eng.usm.my

INTRODUCTION

Ash, usually regarded as waste, can be obtained from the residue of combustion sources that generate steam for electrical power plants. Various kinds of ash have been obtained, e.g., coal fly ash, rice husk ash, and oil palm ash. In this study, oil palm ash (OPA) was used because Malaysia is the second largest producer of palm oil in the world, after Indonesia (Santosa 2008; Mekhilef et al. 2011). According to Teoh (2010), there has been significant growth in the production, consumption, and market share of palm oil due to its cost competitiveness. Therefore, it is expected that more oil palm trees will be planted and mature in the very near future. Along with the increasing demand for palm oil, OPA has also become highly abundant and is usually dumped in open fields, leading to severe environmental problems.

The utilisation of OPA in natural rubber composites has been studied, and the material has showed a reinforcing effect when very low OPA loading was used, as reported in a previous study (Ooi et al. 2013a). In a particulate-filled natural rubber system, the interfacial adhesion between natural rubber matrix and OPA plays an important role in enhancing the required mechanical properties. Therefore, modification of the surface properties of OPA particles is required to enhance the rubber-filler interaction as well as the dynamic mechanical properties. The ability to further improve the mechanical properties and ageing resistance of natural rubber vulcanisates is of great interest for this research.

In this work, a hydrochloric acid solution was used to treat OPA prior to compounding with natural rubber and other curing ingredients. The rubber-filler interaction between OPA and natural rubber was determined and calculated from swelling studies. Retention properties under ageing conditions and thermogravimetric analysis (TGA) were studied to evaluate the thermal stability and decomposition of natural rubber composites filled with OPA after treatment with HCl. The effect of OPA treatment with HCl on the dynamic properties of natural rubber composites was also examined.

EXPERIMENTAL

Materials

Natural rubber (grade SMR L), used as the matrix, was supplied by the Rubber Research Institute of Malaysia (RRIM).

The oil palm ash (OPA) was collected from United Oil Palm Mill, Penang, Malaysia. OPA was sieved with a 75-µm mesh screen and dried in a vacuum oven at 80 °C for 24 h to expel moisture. The main elemental composition (wt %) of OPA was analyzed by X-Ray Fluorescence (XRF) Spectrometer (model Rigaku RIX3000) as follows: C (41.5), SiO2 (34.0), CaO (7.3), Al2O3 (3.9), MgO (3.8), K2O (3.7), P2O5 (3.2), Fe2O3 (1.9) and trace elements (0.7).

Other curing ingredients, such as zinc oxide, stearic acid, N-isopropyl-N’-phenyl-p-phenylenediamine (IPPD), N-cyclohexyl-2-benzothiazole sulfenamide (CBS), and sulfur, were purchased from Bayer (M) Ltd. and used as received.

HCl-treated OPA

The HCl solution was prepared as a media treatment for the OPA particles. To study its effects on the properties of the OPA-filled NR composites, the OPA particles were mixed in 10% aqueous HCl solution and stirred for 2 h at room temperature. The soaked OPA particles were then filtered and washed thoroughly with distilled water. The filtering and washing processes were repeated several times.

After that, the HCl-treated OPA particles were dried for 24 h at 80 °C, followed by activation at 105 °C in an oven for 1 h. Finally, the dried HCl-treated OPA particles were cooled to room temperature and sieved with a 75-µm mesh screen. The HCl-treated OPA particles were kept in a desiccator prior to characterisation and the compounding process.

Preparation of OPA-filled Natural Rubber Composites

The OPA loadings used in this study were 0.5, 1, 3, 7, and 9 phr. The detailed formulation is shown in Table 1. Mixing of raw materials was performed using a conventional laboratory-sized two roll mill (model XK 160). The total mixing time was less than 20 min to avoid premature vulcanisation. The mixing sequences were kept constant for all mixtures.

The compounded rubbers were compression-molded at 150 °C according to their respective tc90 values, and molded sheets were conditioned in desiccators for 24 h prior to further testing. The HCl-treated OPA was compounded in the same manner as non-treated OPA-filled NR composites.

Table 1. Formulation of Oil Palm Ash-filled Natural Rubber Compounds

a Parts per hundred parts of rubber

b Same phr loading for non-treated and HCl-treated OPA

Measurement of Swelling, Rubber-Filler Interaction, and Crosslink Density

The swelling test was carried out according to ISO 1817. Cured specimens with dimensions of 30 mm × 5 mm × 2 mm were weighed using an electrical balance, followed by immersion in toluene for 72 h at room temperature (25 °C) in a dark environment. After the conditioning period, the swollen specimens were taken out and weighed again. The specimens were then dried in an oven at 70 °C until a constant weight was obtained. The Lorenz and Park equation (Lorenz and Park 1961) was applied to study the rubber-filler interaction. The weight of toluene uptake per gram of rubber hydrocarbon (Q) was calculated as given in Eqs. 1 and 2 below,

where the subscripts f and g refer to filled and gum NR composites, respectively. The exponent z is the ratio by weight of the filler to the rubber hydrocarbon in the composites, whereas aand b are constants. The lower the value of Qf/Qg, the higher is the extent of rubber-filler interaction.

The crosslink density was also measured by applying the Flory-Rehner equation (Flory and Rehner 1943; Pasbakhsh et al. 2010), as given in Eqs. 3 to 5 below,

where Mc is the molecular weight between crosslinks, ρp is the density of NR material (0.92 g cm-3), Vs is the molar volume of toluene (106.4 cm3/mol), Vr is the volume fraction of swollen rubber, Qm is the swelling mass of OPA-filled NR vulcanisates in toluene, χ is the interaction parameter between the rubber network and toluene (χ = 0.393), and Vc is the degree of crosslink density.

Retention Properties Under Ageing Conditions

To evaluate the retention properties of non-treated and HCl-treated OPA-filled NR composites under ageing conditions, five dumbbell-shaped specimens were placed in an oven with an air-circulating system at an operating temperature of 100 °C for 48 h, following ASTM D 573. The tensile properties of aged specimens were determined in the same manner as unaged specimens and compared. The retained percentage values of tensile properties were calculated according to Eq. 6.

Scanning Electron Microscopy

Tensile fractured surfaces of non-treated and HCl-treated OPA-filled NR vulcani-sates were scanned with a scanning electron microscope (FESEM: model Zeiss Supra 35 VP). The fractured specimens were mounted on aluminium stubs and sputter-coated with a thin layer of gold-palladium to avoid electrostatic charging and poor resolution during examination. The SEM images were used to study the mode of fracture and support the changes in ageing characteristics. Additionally, OPA was analysed in powder form with energy dispersive X-ray spectroscopy (EDX) to obtain the elemental composition of the OPA before and after treatment with HCl.

Measurement of Dynamic Mechanical Properties

The dynamic mechanical thermal studies of OPA-filled NR composites were conducted using a dynamic mechanical analyser (Mettler Toledo: model DMA 861e). The test specimens were subjected to cyclic tensile strain with force amplitude of 1 N at a frequency of 1 Hz. The temperature ranged from -110 °C to 60 °C with a heating rate of 2 °C/min for the evaluation of the storage modulus, loss modulus, and mechanical loss factor (tan δ). In this work, the mechanical loss factor was the ratio of loss modulus to storage modulus. The glass transition temperature (Tg) was obtained from the mechanical loss factor peak.

Thermogravimetric Analysis

To evaluate the thermal stability of OPA-filled NR composites, thermograv-imetric analysis (TGA) was performed using a Perkin Elmer Pyris 6 thermogravimetric analyser. A small amount (~10 mg) of specimen, taken for the analysis, was heated from 30 °C to 600 °C at a heating rate of 10 °C/min in a nitrogen atmosphere. The weight loss was measured as a function of temperature. The TGA curve was recorded and drawn to study the thermal stability of the OPA-filled NR composites.

RESULTS AND DISCUSSION

Swelling Studies

The effect of HCl-treated OPA loading on the swelling percentage of NR composites was studied and compared with the non-treated OPA-filled NR composites, as illustrated in Table 2. It can be clearly seen that the swelling percentage decreased with the addition of either HCl-treated or non-treated OPA, particularly with higher OPA loading. This is attributed to the OPA particles, which can act as a barrier to prevent toluene from penetrating into the rubber composites. The toluene uptake can also be affected by the crosslinking types, as reported by Ismail et al. (1995). Acid also has a profound effect, causing the desulphurisation of crosslinks and leading to a dense network structure as well as a higher crosslink density, as shown in Table 2. It has been shown in previous works (Ismail and Salmiah 1999; Chukwu et al. 2011) that stearic acid and oil palm fatty acid also contribute to better crosslinking in rubber composites during vulcanisation. George and Thomas (2001) also reported less flexible chains in the network, resulting in minimum toluene uptake. Therefore, the toluene uptake for HCl-treated OPA-filled NR composites showed a lower value than the non-treated OPA-filled NR composites.

The rubber-filler interaction of OPA-filled natural rubber composites at various low loadings of non-treated and HCl-treated OPA is shown in Table 2. Recall that lower Qf/Qg values indicate a greater extent of rubber-filler interaction. For the HCl-treated OPA, it was found that Qf/Qg values were lower than non-treated OPA-filled NR composites, especially at 1 phr OPA loading, which is the optimum loading of OPA in natural rubber composites. The interfacial adhesion between OPA and NR improved with HCl pretreatment.

Table 2. Swelling Percentage and Qf/Qg of Non-treated and HCl-treated OPA-filled Natural Rubber Composites

* HOPA: HCl-treated OPA

Retention Properties Under Ageing Conditions

Tensile properties are usually used to evaluate the degradation behavior of natural rubber after thermal ageing. After thermal ageing for 2 days at 100 °C, the tensile properties and the retention percentages of non-treated and HCl-treated OPA-filled NR composites were measured and are shown in Table 3. Before thermal ageing, both OPA-filled NR composites showed higher tensile strength than that of gum NR composites. At the same filler loading, the HCl-treated OPA showed higher tensile strength than non-treated OPA-filled NR composites. This was attributed to the fact that the surface became rougher after HCl treatment and the reduction of metal elements such as Ca, Al, and Mg during the treatment process contributed to good dispersion and better interfacial adhesion between HCl-treated OPA and NR matrix. As expected, the gum NR composites underwent severe degradation after thermal ageing due to the oxidative degradation that occurs in rubber at high temperatures, as reported by Brown and Soulagnet (2001). Thus, natural rubber has poor resistance to heat and oxygen. However, with the addition of OPA, the retention properties improved over those of gum NR composites. This may suggest the existence of inorganic compounds such as silica in OPA, which can increase the thermal stability of natural rubber composites. The acid pretreatment of OPA could have helped in activating the vulcanisation system, leading to a consolidation of the network structure and thus higher crosslink density, as discussed earlier. According to Mathew and De (1983), the network structure of efficiently vulcanised rubber and higher crosslink density results in slightly greater resistance to ageing because the penetration of oxygen is restricted. In this work, the results indicated that the retention of tensile strength and elongation at break of HCl-treated OPA was very slightly higher than non-treated OPA-filled NR composites after ageing.

As anticipated, the tensile modulus (M100) increased with increasing OPA loading (Table 3). It is widely accepted that OPA contains a high inorganic content (Ooi et al. 2013b), which results in rigid filler particles that are embedded in a soft NR matrix. After thermal ageing, the M100 of both HCl-treated and non-treated OPA-filled NR composites shifted to higher values, and the retention percentages increased as well. This may due to scissoring of NR chain segments and polysulphidic crosslinks into shorter chains, which accounts for the hardening and embrittlement of NR composites (Ismail et al. 1997).

Table 3. Tensile Properties and Retention Percentages of Non-treated and HCl-treated OPA-filled NR Composites After Subjection to Ageing Conditions at 100 °C for 2 Days

* Retention properties (%) of tensile strength, elongation at break, and tensile modulus are shown in brackets.

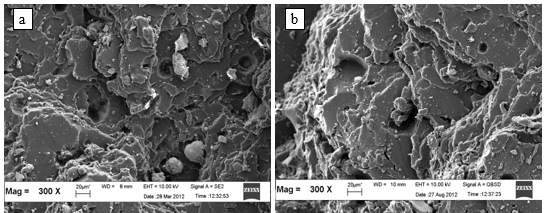

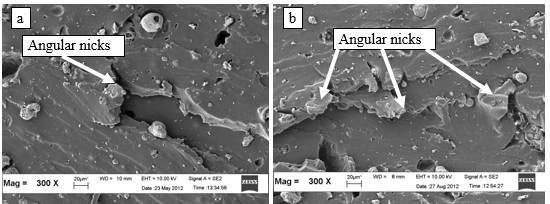

Morphological Studies

Figures 1 and 2 are micrographs of the tensile fractured surface of the non-treated and HCl-treated OPA-filled NR composites both before and after thermal ageing for 2 days. The surface shows a rough zone with high stress rupture and the occurrence of angular nicks and deeper tearing lines (Fig. 1). After thermal ageing, the tensile fractured surface showed few tearing lines and smooth zones. This reflected the low tensile strength of NR composites. However, the higher retention properties of HCl-treated OPA-filled NR composites did not cause a notable change in the fracture mode after thermal ageing. Once failure was initiated, a catastrophic tear resulted (Mathew and De 1983). Only a few angular nicks can be observed in Fig. 2.

Fig. 1. Tensile fractured surface of (a) non-treated and (b) HCl-treated OPA-filled NR composites at 7 phr loading in initial states

Fig. 2. Tensile fractured surface of (a) non-treated and (b) HCl-treated OPA-filled NR composites at 7 phr loading after being subjected to ageing conditions at 100 °C for 2 days

Dynamic Mechanical Thermal Studies

Figures 3 and 4 portray the effect of OPA with and without HCl treatment on the dynamic mechanical properties of NR composites. The OPA pretreated with HCl improved the surface characteristics because other impurities (such as Ca and Mg) had been removed during the treatment process, as determined by energy dispersive X-ray spectroscopy, shown in Fig. 3. Thus, the adhesion of OPA with the NR matrix is the factor that affects the dynamic properties of NR composites. The dynamic mechanical thermal analysis (DMA) plot of storage modulus (G’) at a frequency of 1 Hz as a function of temperature is shown in Fig. 4, and the value for maximum G’ is summarised in Table 4. The gum NR showed the lowest G’ because the rubber phase gave the material a flexible character. It can be seen that G’ changed with variations in the OPA loading and because of the effect of HCl pretreatment when in the glassy region. However, when the temperature increased, the OPA-filled NR composites lost their closely packed arrange-ment and became mobile. Therefore, the curve of G’ became flatter and did not show much variation at higher temperatures. At similar filler loadings in the glassy region, pretreatment of OPA with HCl caused a considerable increase in G’, which can be attributed to the better interfacial interaction between OPA and NR matrix due to the surface characteristics mentioned earlier. An indication of valuable information about the increasing stiffness, degree of cross-linking, and filler-matrix interaction further eluci-dated the increment of G’ for HCl-treated OPA as compared to non-treated OPA-filled NR composites. Similar phenomena were reported by Joseph et al. (2010) in a modified system of oil palm microfibril-filled NR composites.

The variation of tan δ of the non-treated and HCl-treated OPA-filled NR composites as a function of temperature is shown in Fig. 5. It can be seen that the tan δ of all rubber composites showed a maximum peak within the range -70 °C to -80 °C. Among rubber composites, the gum NR composites showed the highest tan δmax value. This phenomenon indicated greater dynamic mechanical losses for gum NR composites. As reported by Kumnuantip and Sombatsompop (2003), higher tan δmax values resulted in greater mechanical losses. Geethamma et al. (2005) reported that the incorporation of reinforcing filler decreased the damping of rubber composites. Thus, the DMA results indicated that OPA is a reinforcing filler that reduces the tan δmax value. At similar filler loadings, the HCl-treated OPA-filled NR composites showed slightly lower tan δmax values than the non-treated OPA-filled NR composites. This suggests that the interfacial adhesion between OPA and the NR matrix improved as a result of HCl treatment, which is in agreement with the rubber-filler interaction discussed earlier.

It is well known that the peak of the tan δ curve corresponds to the Tg value of rubber composites during dynamic stressing, where the transition occurs from the glassy region to the rubbery region. According to Lopez-Manchado et al. (2004), the shift of Tg to a higher temperature was due to stronger interaction between the filler and rubber. Surprisingly, the incorporation of non-treated OPA did not cause a significant increase in the Tg of rubber composites. However, the shift of Tg to a higher temperature was evidence for the case that HCl treatment caused a stronger interaction between the natural rubber matrix and the treated OPA. Overall, the HCl-treated OPA-filled NR composites showed a good elastomeric compound where the elastic materials usually have high G’, low tan δmax value, and high Tg value.

Fig. 3. Elemental composition of oil palm ash as detected by energy dispersive X-ray spectroscopy: (a) non-treated OPA, (b) OPA after treatment by HCl

Fig. 4. Storage modulus as a function of temperature for NR composites

Fig. 5. Tan δ as a function of temperature for NR composites

Table 4. Tan δmax Value and Dynamic Tg of Various Filler-filled NR Vulcanisates

Thermogravimetric Analysis

Figure 6 shows the TGA curve and DTG curve of the gum NR composite and OPA-filled NR composites with and without HCl treatment. The detailed variations of 5% weight loss (T-5%), 10% weight loss (T-50%), 50% weight loss (T-90%), temperature at maximum weight loss rate (TmaxI), and char residue (%) are summarised in Table 5. As anticipated, the thermal stability was enhanced with the incorporation of OPA and slightly improved by increasing the OPA loading. This observation was evident when the gum NR composites were compared to the OPA-filled NR composites. OPA contained various inorganics with a high melting point, and thus the incorporation of OPA enhanced the thermal stability of NR composites, leading to more char residue at the end of the experiment. With HCl treatment, no significant thermal stability change was observed compared to non-treated OPA-filled NR composites. During the HCl treatment process, the reduction of certain metal elements (Ca, Mg) occurred. However, the total inorganic content that was incorporated into the NR composites remained the same. Hence, the thermal stability of the OPA-filled NR composites did not decrease, even after HCl treatment.

Fig. 6. Thermogravimetric analysis curve (a) TGA curve, (b) DTG curve of gum NR composite and OPA-filled NR composites with and without HCl treatment

Table 5. Thermal Stability Data for Gum NR Composite and OPA-filled NR Composites With and Without HCl Treatment

T-5% = temperature at 5% weight loss

T-10% = temperature at 10% weight loss

T-50% = temperature at 50% weight loss

Tmax I = temperature at maximum weight loss rate

CONCLUSIONS

- The degree of swelling decreased with oil palm ash (OPA) content and was further reduced with HCl treatment of the OPA. An improvement in crosslink density and better rubber-filler interaction was observed for HCl-treated OPA compared to non-treated OPA-filled natural rubber (NR) composites.

- Due to better rubber-filler interaction, the properties of the system (such as load bearing capacity, ageing resistance, and dynamic mechanical properties) improved significantly after HCl treatment, which was evidenced by a higher storage modulus and lower mechanical loss factor.

- Thermogravimetric analysis showed that the thermal stability of OPA-filled NR composites was maintained even after HCl treatment.

ACKNOWLEDGEMENTS

This work was financially supported by the Ministry of Science, Technology and Innovation (MOSTI) Science Fund (Project No. 305/PBAHAN/6013380) and MyPhD (Z. X. Ooi).

REFERENCES

Brown, R. P., and Soulagnet, G. (2001). “Microhardness profiles on aged rubber compounds,” Polymer Testing 20(3), 295-303.

Chukwu, M. N., Madufor, I. C., Ayo, M. D., and Ekebafe, L. O. (2011). “Effect of stearic acid level on the physical properties of natural rubber vulcanisate,” The Pacific Journal of Science and Technology 12(1), 344-350.

Flory, P. J., and Rehner, J. (1943). “Statistical mechanics of cross-linked polymer networks II. Swelling,” Journal of Chemical Physics 11(11), 521-526.

Geethamma, V. G., Kalaprasad, G., Groenincks, G., and Thomas, S. (2005). “Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites,” Composites: Part A36(11), 1499-1506.

George, S. C., and Thomas, S. (2001). “Transport phenomena through polymeric system,” Progress in Polymer Science 26(6), 985-1017.

Ismail, H., Freakley, P. K., Sutherland, I., and Sheng, E. (1995). “Effects of multifunctional additive on mechanical properties of silica filled natural rubber compound,” European Polymer Journal 31(11), 1109-1117.

Ismail, H., Ishiaku, U. S., Azhar, A. A., and Mohd Ishak, Z. A. (1997). “A comparative study of the effect of thermo-oxidative aging on the physical properties of rice husk ash and commercial fillers in epoxidized natural rubber compounds,” Journal of Elastomers and Plastics 29(4), 270-289.

Ismail, H., and Salmiah, I. (1999). “Palm oil fatty acid as an activator in carbon black filled natural rubber compounds: Effect of epoxidation,” International Journal of Polymeric Materials and Polymeric Biomaterials 43(1-2), 115-125.

Joseph, S., Appukuttan, S. P., Kenny, J. M., Puglia, D., Thomas, S., and Joseph, K. (2010). “Dynamic mechanical properties of oil palm microfibril-reinforced natural rubber composites,” Journal of Applied Polymer Science 117(3), 1298-1308.

Kumnuantip, C., and Sombatsompop, N. (2003). “Dynamic mechanical properties and swelling behavior of NR/reclaimed rubber blends,” Materials Letters 57(21), 3167-3174.

Lopez-Manchado, M. A., Herrero, B., and Arroyo, M. (2004). “Organoclay-natural rubber nanocomposites synthesized by mechanical and solution,” Polymer International 53(11), 1766-1772.

Lorenz, O., and Parks, C. R. (1961). “The crosslink efficiency of some vulcanizing agents in natural rubber,” Journal of Polymer Science 50(154), 299-312.

Mathew, N. M., and De, S. K. (1983). “Thermo-oxidative ageing and its effect on the network structure and fracture mode of natural rubber vulcanizates,” Polymer 24(8), 1042-1054.

Mekhilef, S., Siga, S., and Saidur, R. (2011). “A review on palm oil biodiesel as a source of renewable fuel,” Renewable and Sustainable Energy Reviews 15(4), 1937-1949.

Ooi, Z. X., Ismail, H., and Abu Bakar, A. (2013a). “Synergistic effect of oil palm ash filled natural rubber compound at low filler loading,” Polymer Testing 32(1), 38-44.

Ooi, Z. X., Ismail, H., and Abu Bakar, A. (2013b). “Characterization of oil palm ash (OPA) and thermal properties of OPA filled natural rubber compounds,” Journal of Elastomers and Plastics DOI: 10.1177/0095244313489901.

Pasbakhsh, P., Ismail, H., Ahmad Fauzi, M. N., and Abu Bakar, A. (2010). “EPDM/modified halloysite nanocomposites,” Applied Clay Science 48(3), 405-413.

Santosa, S. J. (2008). “Palm oil boom in Indonesia: From plantation to downstream products and biodiesel,” CLEAN–Soil, Air, Water 36(5-6), 453-465.

Teoh, C. H. (2010). “Key sustainability issues in the palm oil sector,” Discussion Paper for Multi-Stakeholders Consultations, World Bank Group.

Article submitted: May 1, 2013; Peer review completed: August 14, 2013; Revised version received and accepted: August 18, 2013; Published: August 20, 2013.