Abstract

The effects of hydrothermal pre-treatment on the color of silver birch veneer were determined. Spectrophotometric and chemical analyses of the veneer by means of extraction were conducted to determine the detailed chemical characteristics of the veneers. Results from spectrophotometric analysis revealed a significant increase in lightness (L*) and a decrease in yellowness (b*) in the veneer produced from a log soaked at 70 °C in short-term. Conversely, the effect of long-term storage resulted in a significant reduction in L* and an increase in b*. Chemical analyses of the veneer extract identified a moderate negative correlation between soluble proanthocyanidins content and treatment temperature. A higher amount of wood extractives, such as lipophilic extractives, free monosaccharides, and other organic substances, were obtained from wood material soaked at 70 °C than at 20 °C, which was most likely due to moderate chemical changes during treatment. Comparison of the results between dried veneers and wet veneers from the water extraction study revealed that the dried veneers had higher amounts of lipophilic matter and less water-soluble organic matter than the wet veneers. Other aspects of the loss of soluble proanthocyanidins in the birch veneer during plywood manufacturing are discussed.

Download PDF

Full Article

The Effect of Hydrothermal Treatment on the Color Stability and Chemical Properties of Birch Veneer Surfaces

Akio Yamamoto,* Anti Rohumaa, Eero Kontturi, Mark Hughes, and Tapani Vuorinen

The effects of hydrothermal pre-treatment on the color of silver birch veneer were determined. Spectrophotometric and chemical analyses of the veneer by means of extraction were conducted to determine the detailed chemical characteristics of the veneers. Results from spectrophotometric analysis revealed a significant increase in lightness (L*) and a decrease in yellowness (b*) in the veneer produced from a log soaked at 70 °C in short-term. Conversely, the effect of long-term storage resulted in a significant reduction in L* and an increase in b*. Chemical analyses of the veneer extract identified a moderate negative correlation between soluble proanthocyanidins content and treatment temperature. A higher amount of wood extractives, such as lipophilic extractives, free monosaccharides, and other organic substances, were obtained from wood material soaked at 70 °C than at 20 °C, which was most likely due to moderate chemical changes during treatment. Comparison of the results between dried veneers and wet veneers from the water extraction study revealed that the dried veneers had higher amounts of lipophilic matter and less water-soluble organic matter than the wet veneers. Other aspects of the loss of soluble proanthocyanidins in the birch veneer during plywood manufacturing are discussed.

Keywords: Silver birch; Plywood; Veneer; Proanthocyanidins; Soaking; Color change

Contact information: Department of Forest Products Technology, School of Chemical Technology, Aalto University, P.O. Box 16300, FI-00076 Aalto, Finland; *Corresponding author:akio.yamamoto@aalto.fi

INTRODUCTION

In industrial veneer production, it is common to soak logs at elevated temperature prior to peeling. This hydrothermal pre-treatment is carried out to soften the log and to ease the cutting during the peeling process (Mayer and Koch 2007). The chemistry of the color changes affecting silver birch (Betula pendula) during industrial veneer manufacturing, especially those resulting from the soaking and drying processes, have been the subject of intensive investigation for more than a decade (Luostarinen et al. 2002; Luostarinen and Möttönen 2004; Hiltunen et al. 2006, 2008; Rohumaa et al. 2007, 2008). In practice, soaking takes place at temperatures between 20 and 40 °C for 8 to 40 h, although occasionally a temperature of 70 °C is used; this is similar to the conditions used in the conventional drying of veneer in parquet production (Jokela and Keskitalo 1999; Luostarinen et al. 2002; Rohumaa et al. 2014). A significant difference between the soaking and drying processes, however, is the presence of water.

The surface color of veneer is generated by a combination of many factors, mostly the depletion of oxygen and the concentration of wood extractives such as tannins (Schramm 2003). During the conventional drying of birch, discoloration occurs inside the board, which is thought to be due to seasonal variations in birch extractive content and the polymerization of proanthocyanidins (condensed tannins) (Luostarinen and Luostarinen 2001). Anatomical analyses have revealed that once phenolics contained in axial and terminal parenchyma cells are exposed to air at the temperature of drying, these phenolics become darkened and form a thin layer on the surface of the cell walls (Luostarinen 2006).

As for other parameters, the felling season affects the degree of discoloration of birch wood during the drying process. Winter felling leads to minimal discoloration of birch wood during drying (Luostarinen et al. 2002). Additionally, the characteristics of the growing site also affect the wood surface color (Luostarinen et al. 2002). To a certain extent, discoloration can be controlled by selecting the right felling season, the growth site, the storage period, and the drying method (Kreber and Byrne 1994), all of which affect the wood extractives content. Furthermore, phenolics ((+)-catechin and (+)-catechin-7-O–β-d-xylopyranoside) and saccharides (d-(+)-xylose, d-(-)-fructose, d-(+)-glucose, sucrose, maltose, and raffinose) in the xylem of silver birch can vary (Mononen et al. 2004). Brauns’ lignin, a phenolic polymer, is suspected to play an important role in the discoloration of birch wood during the drying process (Hiltunen et al. 2008). Higher concentrations of Brauns’ lignin and low-molecular weight phenols have been found on discolored birch surfaces compared to lighter colored areas (Hiltunen et al. 2008). Proanthocyanidins, which are flavonoid-based polyphenolics consisting of the flavan-3-ols(-)-epicatechin and (+)-catechin, are also considered to play a major role in the color change of birch that occurs during the drying process (Luostarinen and Möttönen 2004). The degree of discoloration also varies according to whether conventional or vacuum drying is used; in the former case, oxygen will be present, whilst in the latter, it will not (Luostarinen and Möttönen 2004).

Work done by Rohumaa et al. (2014) has shown that soaking temperature affects the colorimetric and physical properties of birch veneer surfaces, as well as its bonding performance. However, a detailed quantitative analysis of the effects of soaking on the chemical and physical changes that birch veneer surfaces undergo is lacking. This study has therefore specifically focused on colorimetric and chemical changes that occur on the veneer surface to determine in more detail how soaking affects surface color. To support this focus, water extraction was conducted on the veneer and the extracts were analyzed to determine the elutable substances from the veneer surface.

EXPERIMENTAL

Materials

Veneer preparation

Logs, approximately 130 m long, were cut from birch (Betula pendula) stems collected from a forest in Finland in autumn. The logs were heated to 20, 40, 50 or 70 °C by completely immersing them in a water tank containing ca. 1500 L of tap water heated to the appropriate temperature. Further details about the log history and the soaking conditions are reported by Yamamoto et al. (2013) in a previous study, in which the same materials were used.

After soaking, the logs were peeled on an industrial-scale rotary lathe (Model 3HV66; Raute Oyj, Lahti, Finland). Specimens (ca. 12 cm × 7 cm × 1 mm) were cut from the inner part of the birch veneer freshly produced on the lathe and randomly selected for further analysis.

Methods

Color measurement

The color of the intact veneer surface was measured immediately after peeling (short term) as well as after a 6 month of storage (long term) using a spectrophotometer (Spectrolino, Gretag-Macbeth AG, Regensdorf, Switzerland). The measurement time was initiated right after peeling of the log. To minimize measurement errors, earlywood specimens were intentionally chosen for the measurements. The area of measurement on the veneer surface was precisely marked with a permanent marker during the first measurement; thereafter, the measurements were always carried out on the same area of each veneer sample (n=10). The measurement was conducted in a laboratory room at room temperature under uniform fluorescent lighting between the measurements at 5 to 1200 minutes after the sample collection.

The CIELab space system was used to express the color scale of the veneer surface. This scale utilizes three parameters to define the color: 1) the L* scale, which represents lightness (0 = black / 100 = white); 2) the a* scale, which represents greenness and redness (-60 = green, 60 = red); and 3) the b* scale, which represents blueness and yellowness (-60 = blue, 60 = yellow). An absolute color space (which is not device-dependent) can be described by CIE XYZ coordiates. CIELab is a nonlinear transformation of CIE XYZ coordiances into the color coordinates L*, a* and b* (Hoffmann 2013). The delta values (i.e., ∆L*, ∆a* and ∆b*) indicate differences between a standard and a sample in L*, a* and b*. The total color difference, ∆E, can be calculated from these parameters as follows:

In Eq. 1, ΔEab is a single value that includes the differences between the L*, a*, and b* of the sample and the standard (Hunter 2012). ∆Eab was calculated from the mean value of the color coordinates L*, a* and b* in each set of samples. These color parameters are commonly used for the color measurement of wood surfaces (Luostarinen et al. 2002; Mononen et al. 2005; Thompson et al. 2005; Esteves and Pereira 2009; Drouin et al. 2010). To assess the effect of long-term storage on veneer surface color, the veneer specimens were stored in darkness at room temperature for six months, and then the surface color of the specimens was re-measured.

Measurement of UV-vis reflectance spectra

Two different veneer samples (from logs soaked at 20 and 70 °C) were air-dried, and their UV-vis reflectance spectra were measured with a Lambda 15 UV-vis spectrophotometer equipped with an integrating sphere (PerkinElmer, Waltham, MA, USA). Each reflectance spectrum was the average of nine measurements (20 °C) or five measurements (70 °C). The reflectance spectra of the veneer samples were calculated using the Kubelka-Munk equation,

k/s = (1 – R∞)2/ 2R∞ (2)

where R∞ is the measured reflectance of a white optical standard (absolute reflection), k is the unit absorption coefficient, and s is the unit scattering coefficient (Pandey and Vuorinen 2008a).

Extraction of chemical compounds in veneer

A set of veneer sheets freshly produced from the soaked logs (20 and 70 °C) was stored at -20 °C in a freezer until required (Wet veneer). Another set of veneer sheets was conditioned in a controlled environment of 20 °C and 65% RH for more than two weeks (Dry veneer). Both sets of veneer were extracted using three different solvents: water, acetone-cyclohexane (9:1), and acid methanol.

For water extraction, veneer specimens (20 mm × 60 mm) were prepared from the air-dried veneer sheets using an automatic veneer sample cutter (Adhesive Evaluation Systems, Inc., Corvallis, OR, USA). Erlenmeyer flasks (250 mL) served as vessels for the water extraction. The specimens were weighed and placed in the flasks. Milli-Q water (Direct-Q 3 UV, Millipore, USA) was poured into the flask and its quantity was recorded. The necks of the flasks were sealed with Parafilm during extraction to prevent water loss. The extraction was conducted on hot plate for 24 h using a magnetic stirrer. The temperature was maintained at either 20 or 70 °C continuously. The water sample was collected and filtered for further chemical analysis using Whatman® Glass microfiber filters (Grade GF/C; 1.2 µm: Whatman plc, UK).

The gravimetric amount of extractable lipophilic matter was determined by solvent extraction. The veneer sample was milled through a Wiley mill with a 1 mm mesh screen. The milled sample was extracted with acetone and cyclohexane (9:1) in a Soxhlet apparatus for 6 h according to the SCAN test method (SCAN-CM 67:03 (2003)).

For determining the soluble proanthocyanidins in the veneer, a milled sample was extracted with acid methanol containing a 1% concentration of hydrochloric acid (v/v). This solvent is frequently used for the extraction of flavonoid pigments in plants (Harborne 1973). The extraction was carried out in the same manner as the extraction of extractable lipophilic matter (using a Soxhlet extractor for 6 h).

The amount of soluble proanthocyanidins was determined against a cyanidin chloride standard (Luostarinen and Möttönen 2004) using the acid butanol assay detailed by Hagerman (2002). The analysis was conducted in triplicate. For the selective determination of soluble proanthocyanidins, this method is generally the best assay compared to other assays, like the vanillin and the rhodanine assay (Hagerman and Butler 1989).

Chemical analysis of the water extract

For the analysis of the water extracts, six free monosaccharide species were determined according to the NREL TP-510-42623 method (Sluiter et al. 2008) using high-performance anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD) equipped with a CarboPac PA20 column (ICS-3000; Dionex Corp., Sunnyvale, CA, USA).

Total organic carbon (TOC), inorganic carbon (IC), and total carbon (TC) in the extract were also quantified using a Shimadzu TOC-5000A instrument (Shimadzu Corp., Kyoto, Japan). Soluble aromatic compounds were measured with a Shimadzu double-beam spectrophotometer (model UV-2550; Shimadzu Corp., Kyoto, Japan) using the absorbance at 280 nm and an absorptivity value of 20 L∙g-1∙cm-1 (He and Terashima 1990; Lähdetie et al. 2009).

RESULTS AND DISCUSSION

The Effect of Soaking Temperature on the Color Change of the Veneer Surface

Figure 1 shows the results obtained from the color measurements made on the veneers produced from autumn-felled birch logs. As can be seen, soaking temperature had a noticeable effect on the color coordinates of the birch veneer surface. Overall, increasing the temperature of soaking made the samples slightly darker (i.e., L* decreased) and more reddish (i.e., a* increased), except at 70 °C, at which temperature L* increased drastically and b* decreased. The increase in L* was pronounced after 1200 min. At 70 °C, the b* value decreased to a lesser extent compared to the decrease at the other temperatures. It is reasonable to assume that the color change in the veneer produced from 70 °C soaking resulted from the thermal degradation of chromophoric groups on the surfaces. A comparison of ∆Eab (color difference) values in the veneer soaked at the four different temperatures is shown in Fig. 1d. Here, ∆Eab indicated how much the color of the surface changes over time compared to the color at the beginning of the measurement. There was a clear increase in ∆Eab in all specimens and a slight negative correlation between soaking temperature and the ∆Eab values over the measurement period. This finding suggested that the amount of chromophores might affect the degree of the color change after peeling and this phenomenon may be influenced by the soaking temperature.

Fig. 1. The effect of veneer soaking temperature on the changes to the color coordinates in birch veneer obtained from autumn-felled logs over time: a) L* scale (lightness), b) a* scale (greenness and redness), c) b* scale (blueness and yellowness), and d) ∆Eab (the color difference). For the ∆Eabcalculation, the color coordinates at 5 min were used as reference. The time in the figure indicates the time elapsed right after peeling.

Determination of the Color Stability of Veneer in Long-Term Storage

A comparison of the color coordinates and ∆Eab after the long-term storage of the veneer are shown in Fig. 2. This allowed for the influence of storage time on veneer surface color to be distinguished. The veneer samples were first produced from the logs and then stored in darkness for six months to eliminate the effects of ultraviolet irradiation. The most interesting finding was that, in contrast to the color change trends observed immediately after peeling (Fig. 1), the veneer from the log soaked at 70 °C exhibited an increase in the L* and a* values, and a reduction in the b* value.

The color of veneer produced from logs soaked at lower temperatures remained similar to the samples that were measured a day after peeling. With regard to ∆Eab, the veneer from logs soaked at 70 °C had the highest value, in contrast to the ∆Eab during the first 1200 min after peeling (Fig. 1). This observation suggested that soaking at 70 °C may result in lighter color on the veneer surface in the short-term, but that the color became darker after long-term storage. A comparison of ∆Eab values indicated that the veneer surface color was more stable in the short term (Fig. 1d) after soaking at higher temperature (70 °C); however, it became more unstable after long-term storage (Fig. 2d). It is known that some wood extractives might concentrate on the veneer surface after peeling, which may react with iron to form certain compounds, such as ferrous oxide, which makes the veneer surface darker (Schramm 2003). It is possible to hypothesize that following soaking at 70 °C, certain chromophoric compounds are thermally modified that yield a lighter color to the surface in the short-term, but may migrate to the surface and become gradually oxidized over time, which results in a larger ∆Eab after six months of aging.

Fig. 2. The effect of veneer soaking temperature on the changes to the color coordinates and ∆Eabbetween day 1 and six months later (n=8): a) L* scale (lightness), b) a* scale (greenness and redness), c) b* scale (blueness and yellowness), and d) ∆Eab (the color difference). The color cordinates at day 1 and six months were used for ∆Eab.

UV Reflectance Spectra on the Veneer Surfaces

Figure 3 shows the results obtained by reflectance spectroscopy on the birch veneer produced from logs soaked at 20 and 70 °C. The absorption spectra derived from the reflectance measurements can be utilized to approximate the amount of chromophores on the veneer’s surface (Pandey and Vuorinen 2008b). From these results, the time-dependent increase in absorbance in the 200 to 500 nm wavelength range for both veneer samples can be seen. The difference spectra can provide information on the characteristics and changes in the chromophores in the sample (Chang and Chang 2001); the absorptions at > 300 nm are indicative of conjugated structures. Thus, soaking at 20 °C resulted in an increase in the content of conjugated structures over time when compared to soaking at 70 °C. Other veneer surface analyses using Fourier transform infrared spectroscopy (FTIR) with photoacoustic detection (PAS) and attenuated total reflectance (ATR) measurement, as well as ultraviolet Raman spectrometry and confocal Raman microscopy, were also attempted to obtain additional information about the chemical composition of the veneer surface. However, the acquired data from these analyses did not yield any meaningful results (data not shown).

Fig. 3. Absorption difference spectra (∆k/s = (k/s)irradiated – (k/s)unirradiated) of veneer from the winter birch logs soaked at 20 °C and 70 °C for 48 h. Spectra obtained from UV-vis reflectance measurements.

Soluble Proanthocyanidins Content in the Veneer and the Veneer Surface Color

An acid butanol assay was employed to determine the concentrations of soluble proanthocyanidins in the milled samples. A remarkable reduction in the soluble proanthocyanidins content occurred during the soaking at 70 °C, as shown in Fig. 4. Compared to soaking at 20 °C, the soluble proanthocyanidins contents were 10.9% and 63.3% less after soaking at 50 and 70 °C, respectively. The modest positive correlation observed between the soluble proanthocyanidins content and the ∆Eab value may be attributed to the fact that higher soaking temperatures resulted in a lower soluble proanthocyanidins content, which afforded a lower ∆Eab during a shorter storage time (5 to 1200 min). This finding supported the results from previous research on the relationship between the surface color of birch wood and proanthocyanidins content (Luostarinen and Möttönen 2004).

Proanthocyanidins have been considered to play a major role in the color change of birch wood surfaces (Luostarinen and Möttönen 2004). A higher concentration of total proanthocyanidins and catechins has been found in the darker parts of birch wood than in the lighter parts (Hiltunen et al. 2008). A correlation between the color coordinates of the birch wood surface and the concentration of proanthocyanidins has also been observed: L* had a positive correlation, whereas a* and b* had negative correlations (Luostarinen and Möttönen 2004).

Proanthocyanidins are thermolabile compounds and are easily degraded at 70 °C and higher. Makkar and Singh (1991) showed that a reduction in the proanthocyanidins content occurred in in plants when they were heated at 60 °C for 48 h. A greater reduction was observed at 90 °C for 24 h. It can therefore be assumed that the soluble proanthocyanidins might become unstable or be partially degraded during soaking, which then influences the veneer’s surface color. The reduction in soluble proanthocyanidins content may also play a role in the color stability of the veneer’s surface. Proanthocyanidins are also known to be unstable molecules that can undergo spontaneous cleavage of the interflavanic bonds under acidic conditions, which results in a change in the degree of polymerization. They are also extremely susceptible to oxidation, generally resulting in the formation of quinones that condense to form new polymers (Huang et al. 2012). This instability of the proanthocyanidins could partially explain the reason why the veneer produced from logs soaked at 70 °C in the present study became darker after long-term storage (Fig. 2).

Fig. 4. Plots of the concentrations of proanthocyanidins (n = 3) versus the ∆Eab (n = 10) measured in autumn veneer. The soaking temperature is denoted by the symbols. ∆Eab was calculated based on the color coordinates obtained at 5 and 1200 min after the peeling process.

These results could be significant in another respect. Plant phenolics, such as proanthocyanidins, are so-called secondary metabolites and are recognized to play a role in the plant’s defense against herbivorous insects and various biotic aggressors (e.g., fungi and bacteria) (Lattanzio et al. 2012). A reduction in soluble proanthocyanidins content during soaking at 70 °C may lead to impaired resistance to biological attack, which results in a deterioration in the veneer quality caused by mold or herbivorous insects.

Chemical Characteristics of Veneer Surface

Extractable lipophilic matter and water extracts from the veneer were quantified and analyzed to determine the effects of soaking temperature and drying method on the chemical characteristics of the veneer surface. The results obtained are presented in Fig. 5. It was apparent that a higher soaking temperature (70 °C) and a drier veneer resulted in a greater amount of extractable lipophilic matter when compared to the lower temperature (20 °C) and wetter veneer. The content of lipophilic substances obtained in this study were higher than the general amount of extractable lipophilic matter in birch (1.3%) mentioned in the standard method (PFI 2003). This was probably due to the additional soaking treatment. It has been found that soaking at 70 °C promotes water extraction and possible chemical degradation in wood due to a combination of hemicellulose degradation and physical changes in the wood cell wall (Yamamoto et al. 2015).

Fig. 5. Gravimetric determination of the solvent extracts from veneer samples. A combination of acetone and cyclohexane (9:1) was used as the solvent.

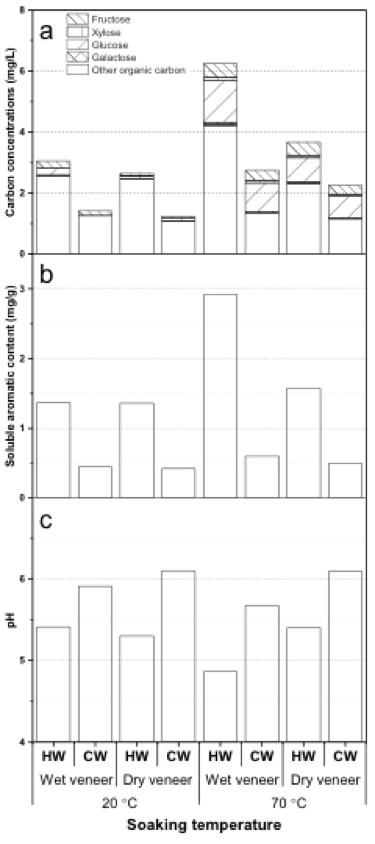

Water extraction was performed on the veneers produced from the logs soaked at either 20 or 70 °C. Chemical analyses were carried out on the water extracts, and the results were compared. The results showed that the free monosaccharides were mostly fructose and glucose, which supported the findings of previous research (Fig. 6a) (Kallio and Ahtonen 1987; Yamamoto et al. 2013). The proportion of saccharides to the total organic carbon and the total carbon concentration was higher in veneer produced from logs soaked at 70 °C rather than at 20 °C, in hot water rather than cold water, and in wet veneer rather than dry veneer. The results from the soluble aromatic content assay showed a similar trend relative to the total carbon concentration. The highest content was obtained from the wet veneers (hot water extract) produced from logs soaked at 70 °C (Fig. 6b). It is interesting to note that more extractable lipophilic matter and less water-soluble substances were obtained from the dry veneer than the wet veneer (Fig. 5 and Fig. 6a). This result may be explained by the fact that better penetration of water occurred in the wet sample and the solvent in the dry samples. These findings suggested that the drying process made the extractable lipophilic matter in the milled sample more accessible to solvent extrations.

Fig. 6. Fraction of TOC and monosaccharides (a), soluble aromatic contents (b), and pH in the water extracts (c). Extraction is described as either HW (hot water) or CW (cold water). Negligible amounts of arabinose were found in the 70 °C wet veneer (hot water). Rhamnose was not detected in samples.

Although the concentration of proanthocyanidins was inversely correlated, to some degree, with soaking temperature, the amount of soluble aromatic was higher after soaking at 70 °C (hot water) than soaking at 20 °C. This suggested that a larger amount of other chemical compounds, such as quinones and phenolic compounds (Sjöström 1993), were eluted at 70 °C. In addition, an increase in free monosaccharide concentration at the veneer surface at 70 °C (Fig. 6a) may support our earlier stated hypothesis that the deterioration in veneer quality occurred during high-temperature soaking due to an increased risk for a biological attack. Glucose and fructose are essential nutrient sources for fungal growth (Brannon 1923).

A significant reduction in the pH was found for the wet veneers produced from logs soaked at 70 °C, which had the highest total carbon concentration (Fig. 6c). This suggested that carboxylic acids were formed from birch hemicelluloses during extraction. The findings in this study mirrored those of previous studies that have determined the formation of carboxylic acids during the hydrothermal treatment of birch wood (Sundqvist et al. 2006).

CONCLUSIONS

- Elevated soaking temperatures clearly affected both the short-term and long-term color of the veneer surface. The differences in color were especially pronounced when the veneer was produced from a log soaked at 70 °C. This might be due to possible chemical changes occurring during soaking.

- High soaking temperature may induce less color change in the veneer during short-term storage after peeling; however, the extent of color change that occurred after long-term storage, which could be at least partly due to the proanthocyanidins content in veneer, was greater. Proanthocyanidins are considered to be thermolabile at temperatues 70 °C or higher.

- The results from chemical assays suggested that the veneer quality deteriorated during long-term storage when the veneer is produced from logs soaked at 70 °C. A reduction in the proanthocyanidins content and an increase in the free monosaccharides concentration in the veneer may increase its risk to biological attack by fungi and other microbes.

ACKNOWLEDGMENTS

This research was funded by the Finnish Funding Agency for Technology and Innovation (TEKES) and industrial partners (UPM-Kymmene Wood Oy, Tikkurila Oyj, Stora Enso Timber Oy and Dynea Chemicals Oy). The authors would like to thank to Sirje Liukko for her help in the UV-vis reflectance work.

REFERENCES CITED

Brannon, J. M. (1923). “Influence of glucose and fructose on growth of fungi,” Bot. Gaz. 76(3), 257-273.

Chang, S. T., and Chang, H. T. (2001). “Comparisons of the photostability of esterified wood,” Polym. Degrad. Stab. 71(2), 261-266. DOI: 10.1016/S0141-3910(00)00171-3

Drouin, M., Beauregard, R., and Duchesne, I. (2010). “Within-tree variability of wood color in paper birch in Québec,” Wood Fiber Sci. 42(1), 81-91.

Esteves, B. M., and Pereira, H. M. (2009). “Wood modification by heat treatment: A review,”BioResources 4(1), 370-404. DOI: 10.15376/biores.4.1.370-404

Hagerman, A. E. (2002). “Acid butanol assay for proanthocyanidins,” in: The Tannin Handbook, Miami University, Oxford, OH. http://www.users.muohio.edu/hagermae/Acid%20Butanol%20Assay%20for%20Proanthocyanidins.pdf(accessed Feb. 2014).

Hagerman, A., and Butler, L. (1989). “Choosing appropriate methods and standards for assaying tannin,” J. Chem. Ecol. 15(6), 1795-1810. DOI:10.1007/BF01012267

Harborne, J. B. (1973). “Phenolic compounds,” in: Phytochemical Methods: A Guide to Modern Techniques of Plant Analysis, Springer Netherlands, Dordrecht, Netherlands, pp. 33-88. DOI: 10.1007/978-94-009-5921-7_2

He, L. F., and Terashima, N. (1990). “Formation and structure of lignin in monocotyledons. III. Heterogeneity of sugarcane (Saccharum officinarum L.) lignin with respect to the composition of structural units in different morphological regions,” J. Wood Chem. Technol. 10(4), 435-459. DOI: 10.1080/02773819008050251

Hiltunen, E., Alvila, L., and Pakkanen, T. T. (2006). “Characterization of Brauns’ lignin from fresh and vacuum-dried birch (Betula pendula) wood,” Wood Sci. Technol. 40(7), 575-584. DOI: 10.1007/s00226-006-0072-y

Hiltunen, E., Mononen, K., Alvila, L., and Pakkanen, T. T. (2008). “Discolouration of birch wood: Analysis of extractives from discoloured surface of vacuum-dried European white birch (Betula pubescens) board,” Wood Sci. Technol. 42(2), 103-115. DOI: 10.1007/s00226-007-0143-8

Hoffmann, G. (2013). CIE Lab Color Space, Gernot Hoffmann, Emden, Germany. http://docs-hoffmann.de/cielab03022003.pdf (accessed Feb. 2014).

Huang, Y., Cheynier, V., and Terrier, N. (2012). “Shedding light on the black boxes of the proanthocyanidin pathway with grapevine,” in: Recent Advances in Polyphenol Research. Volume 3, V. Cheynier, P. Sarni-Manchado, and S. Quideau. (eds.), Wiley-Blackwell, Oxford, England, pp. 161-190.

Hunter (2012). “Measuring Color with Hunter L, a, b vs. CIE 1976 L*, a*, b*,” Application Note AN 1005.00. Hunter Associates Laboratory Inc., Reston, VA. http://www.hunterlab.com/an-1005b.pdf(Accessed Feb. 2014).

Jokela, P., and Keskitalo, P. (1999). “Plywood mill water system closure by dissolved air flotation treatment,” Water Sci. Technol. 40(11-12), 33-41. DOI: 10.1016/S0273-1223(99)00698-8

Kallio, H., and Ahtonen, S. (1987). “Seasonal-variations of the sugars in birch sap,” Food Chem.25(4), 293-304. DOI: 10.1016/0308-8146(87)90016-1

Kreber, B., and Byrne, A. (1994). “Discolorations of hem-fir wood – A review of the mechanisms,”For. Prod. J. 44(5), 35-42.

Lähdetie, A., Liitiä, T., Tamminen, T., Pere, J., and Jääskeläinen, A. (2009). “Activation of thermomechanical pulp by laccases as studied by UV-Vis, UV resonance Raman and FTIR spectroscopy 10(th) EWLP, Stockholm, Sweden, August 25-28, 2008,” Holzforschung. 63(6), 745-750.

Lattanzio, V., Cardinali, A., and Linsalata, V. (2012). “Plant phenolics: A biochemical and physiological perspective,” in: Recent Advances in Polyphenol Research. Volume 3, V. Cheynier, P. Sarni-Manchado and S. Quideau. (eds.), Wiley-Blackwell, Oxford, England, pp. 1-39.

Luostarinen, K. (2006). “Relationship of selected cell characteristics and colour of silver birch wood after two different drying process,” Wood Mater. Sci. Eng. 1(1), 21-28. DOI: 10.1080/17480270600664850

Luostarinen, K., and Luostarinen, J. (2001). “Discolouration and deformations of birch parquet boards during conventional drying,” Wood Sci. Technol. 35(6), 517-528. DOI: 10.1007/s002260100109

Luostarinen, K., and Möttönen, V. (2004). “Effects of log storage and drying on birch (Betula pendula) wood proanthocyanidin concentration and discoloration,” J. Wood Sci. 50(2), 151-156. DOI: 10.1007/s10086-003-0547-5

Luostarinen, K., Mottonen, V., Asikainen, A., and Luostarinen, J. (2002). “Birch (Betula pendula) wood discolouration during drying. Effect of environmental factors and wood location in the trunk,”Holzforschung. 56(4), 348-354. DOI: 10.1515/HF.2002.055

Makkar, H. P. S., and Singh, B. (1991). “Effect of drying conditions on tannin, fibre and lignin levels in mature oak (Quercus incana) leaves,” J. Sci. Food Agric. 54(3), 323-328. DOI: 10.1002/jsfa.2740540302

Mayer, I., and Koch, G. (2007). “Element content and pH value in American black cherry (Prunus serotina) with regard to colour changes during heartwood formation and hot water treatment,” Wood Sci. Technol. 41(6), 537-547. DOI: 10.1007/s00226-007-0144-7

Mononen, K., Alvila, L., and Pakkanen, T. (2004). “Effect of growth site type, felling season, storage time and kiln drying on contents and distributions of phenolic extractives and low molar mass carbohydrates in secondary xylem of silver birch Betula pendula,” Holzforschung 58, 53-65. DOI:10.1515/HF.2004.008

Mononen, K., Jaaskelainen, A., Alvila, L., Pakkanen, T., and Vuorinen, T. (2005). “Chemical changes in silver birch (Betula pendula Roth) wood caused by hydrogen peroxide bleaching and monitored by color measurement (CIE Lab) and UV-Vis, FTIR and UVRR spectroscopy,” Holzforschung 59(4), 381-388. DOI: 10.1515/HF.2005.063

Pandey, K. K., and Vuorinen, T. (2008a). “UV resonance Raman spectroscopic study of photodegradation of hardwood and softwood lignins by UV laser,” Holzforschung 62(2), 183-188. DOI: 10.1515/HF.2008.046

Pandey, K. K., and Vuorinen, T. (2008b). “Comparative study of photodegradation of wood by a UV laser and a xenon light source,” Polym. Degrad. Stab. 93(12), 2138-2146. DOI: 10.1016/j.polymdegradstab.2008.08.013

PFI (2003). “Content of extractable lipophilic matter (Wood chips for pulp production and pulp) SCAN-CM 67:03,” Scandinavian Pulp, Paper and Board Testing Committee, Stockholm, Sweden.

Rohumaa, A., Antikainen, T., Hughes, M., and Ohlmeyer, M. (2007). “Process factors influencing birch (Betula pendula Roth) veneer surface properties and bond strength development in veneer-based products,” Third International Symposium on Veneer Processing and Products, Nanjing, China, pp. 131-139.

Rohumaa, A., Hughes, M., and Ohlmeyer, M. (2008). “Factors influencing the properties of veneer-based products,” International Panel Products Symposium, Bangor, UK, pp. 57-65.

Rohumaa, A., Hunt, C. G., Frihart, C. R., Saranpää, P., Ohlmeyer, M., and Hughes, M. (2014). “The influence of felling season and log-soaking temperature on the wetting and phenol formaldehyde adhesive bonding characteristics of birch veneer,” Holzforschung 68(8), 965-970. DOI: 10.1515/hf-2013-0166

Schramm, A. (2003). A Complete Guide to Hardwood Plywood and Face Veneer, Purdue University Press, West Lafayette, IN.

Sjöström, E. (1993). Wood Chemistry: Fundamentals and Applications, Second Ed., Academic Press, New York, NY.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., and Templeton, D. (2008). “Determination of sugars, byproducts, and degradation products in liquid fraction process samples, laboratory analytical procedure (LAP),” Technical Report NREL/TP-510-42623, National Renewable Energy Laboratory (NREL), U.S. Dept. of Energy, Golden, CO ( http://www.nrel.gov/biomass/pdfs/42623.pdf ).

Sundqvist, B., Karlsson, O., and Westermark, U. (2006). “Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness,” Wood Sci. Technol. 40(7), 549-561. DOI: 10.1007/s00226-006-0071-z

Thompson, D. W., Kozak, R. A., and Evans, P. D. (2005). “Thermal modification of color in red alder veneer. I. Effects of temperature, heating time, and wood type,” Wood Fiber Sci. 37(4), 653-661.

Yamamoto, A., Rohumaa, A., Kontturi, E., Hughes, M., Saranpää, P., Andberg, M., and Vuorinen, T. (2013). “Colorimetric behavior and seasonal characteristic of xylem sap obtained by mechanical compression from silver birch (Betula pendula),” ACS Sust. Chem. Eng. 1(9), 1075-1082. DOI: 10.1021/sc400090a

Yamamoto, A., Rohumaa, A., Kontturi, E., Hughes, M., and Vuorinen, T. (2015). “Chemical characteristics of squeezable sap of hydrothermally treated silver birch logs (Betula pendula): Effect of treatment time and the quality of the soaking water in pilot scale experiment,” Wood Sci. Technol.49(2), 289-302. DOI: 10.1007/s00226-014-0693-5

Article submitted: April 27, 2015; Peer review completed: July 20, 2015; Revised version received and accepted: August 10, 2015; Published: August 17, 2015.

DOI: 10.15376/biores.10.4.6610-6623