Abstract

This study determined some physical changes that occur on wood surfaces aged in a marine environment resulting from the removal of coatings using environmentally friendly media blasting. Scots pine (Pinus sylvestris L.) wood coated with water-borne and synthetic paints was exposed to a marine environment for 100 days. The aged paint layers were removed using five different media (sodium bicarbonate, hazelnut shell granules, corncob granules, walnut shell granules, and apricot kernel granules), varying blasting angles (45° and 90°), blasting distances (7 and 10 cm), air pressures (2 and 2.5 bar), and nozzle diameters (0.5 and 0.8 mm) using an automated blasting cabinet. The results showed that corn cob granules and sodium bicarbonate were less effective than other media for removing paint layers at the application parameters. The samples were tested for hardness, gloss, and total color change. Samples exhibited a remarkable total color change and gloss increase when the blasting distance was increased from 7 cm to 10 cm, while their hardness decreased. The highest gloss value was obtained on surfaces blasted with a nozzle diameter of 0.5 cm. Surfaces blasted with a nozzle diameter of 8 mm, however, yielded the highest total color change and hardest values.

Download PDF

Full Article

The Use of Environmentally Friendly Abrasive Blasting Media for Paint Removal from Wood Surfaces

İzham Kılınç,a Mehmet Budakçı,b,* and Mustafa Korkmaz b

This study determined some physical changes that occur on wood surfaces aged in a marine environment resulting from the removal of coatings using environmentally friendly media blasting. Scots pine (Pinus sylvestris L.) wood coated with water-borne and synthetic paints was exposed to a marine environment for 100 days. The aged paint layers were removed using five different media (sodium bicarbonate, hazelnut shell granules, corncob granules, walnut shell granules, and apricot kernel granules), varying blasting angles (45° and 90°), blasting distances (7 and 10 cm), air pressures (2 and 2.5 bar), and nozzle diameters (0.5 and 0.8 mm) using an automated blasting cabinet. The results showed that corn cob granules and sodium bicarbonate were less effective than other media for removing paint layers at the application parameters. The samples were tested for hardness, gloss, and total color change. Samples exhibited a remarkable total color change and gloss increase when the blasting distance was increased from 7 cm to 10 cm, while their hardness decreased. The highest gloss value was obtained on surfaces blasted with a nozzle diameter of 0.5 cm. Surfaces blasted with a nozzle diameter of 8 mm, however, yielded the highest total color change and hardest values.

DOI: 10.15376/biores.18.1.1185-1205

Keywords: Paint removal; Abrasive blasting media; Sea water ageing; Hardness; Gloss; Color change

Contact information: a: Department of Design, Interior Design, Vocational School of Technical Sciences, Batman University, Batman, Türkiye; b: Department of Wood Products Industrial Engineering, Faculty of Forestry, Düzce University; Düzce, Türkiye; *Corresponding author: mehmetbudakci@duzce.edu.tr

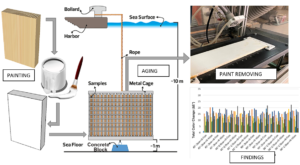

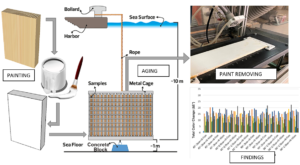

GRAPHICAL ABSTRACT

INTRODUCTION

Wood has been used for centuries in a variety of applications, both indoor and outdoor. It is a natural building material that is frequently preferred for its durability and aesthetic appeal (Cragg et al. 2001; Bilgin 2009; Uzuner 2020). Abiotic and biotic pests can cause damage to unprotected wood materials, especially in outdoor conditions (Hon and Feist 1986; Budakçı and Atar 2001; Van Acker et al. 2003; Williams 2005; Ali et al. 2007; Pánek and Reinprecht 2014). Chemical, physical, mechanical, and microscopic changes can also occur in wood materials due to outdoor conditions. It is reported that these changes are caused by the deterioration of the chemical structure of wood extractives, polysaccharides, and polyphenolics (Feist and Hon 1984; Feist 1990; Anderson et al. 1991; Budakçı 2006; Kılıç and Hafızoğlu 2007; Sivrikaya et al. 2011). Wood materials used in the construction of watercraft and marine structures are often used as food and host by marine pests. Because of this situation, the material surfaces are subjected to severe deformations, resulting in substantial economic losses (Bobat 1994; Doruk et al. 2019). Mollusc species destroy the inner parts of wood, while crustacean wood borer species destroy the surface (Maclean 1954; Eaton 1985; Doruk et al. 2019). These pests reduce both the resistance and the service life of the material used in marine conditions.

To protect the wood material from the effects of the marine environment, different preservatives, impregnations, paints, or film-forming varnishes are applied to its surfaces (Dillon et al. 2006; Çetin 2009; Özgenç et al. 2013). The pigments and ultraviolet light-absorbing additives in these preservatives stabilize the color and gloss of the wood material and reduce the deterioration caused by outdoor conditions. In addition, these preservatives often have anti-insect properties (De Meier 2001; Schaller and Rogez 2007; Gobakken and Lebow 2010; Sivrikaya et al. 2011; Forsthuber et al. 2013; Reinprecht and Pánek 2013; Pánek and Reinprecht 2014). To reduce photodegradation and provide resistance to aquatic pests, it is imperative to apply a protective layer to wood surfaces (Deka and Petrič 2008; Özgenç et al. 2013). Nevertheless, the protective layers applied to the wood surfaces lose their protective functions over time due to factors such as UV light, rain, sea salt, and mechanical rubbing (Feist 1990; Budakçı and Karamanoğlu 2014).

Removing the old protective layer and re-applying a new one is not only necessary from an aesthetic point of view but also from a long-term use perspective. However, it is an extremely troublesome process (Weeks and Look 1984). These defective layers can be removed from small surfaces using a variety of tools including scrapers, wire sponges, and sandpapers. However, on large-scale surfaces, such as structural members or watercraft, these tools require tremendous labor and time. It is also known that they are not effective enough to achieve the desired results on the grooved or curved surfaces (Saloni et al. 2006; Wynne et al. 2010). The inefficiency of these tools has led to the emergence of newer and more technological techniques. As a result of the developments experienced in the chemical industry since the early 1900s, paint removal chemicals have started to be developed (Riley and Fischbeck 2000). Because chemical paint removal methods, which aim to degrade the chemical structure of the protective layer on a surface, have negative effects on the environment and human health, researchers are developing environmentally and human-friendly methods (Chen et al. 2010).

In terms of affecting human health and the environment, removing paint with pressurized systems has attracted increased attention. This method involves spraying only water or micron-sized media on the surface with compressed air, either dry or mixed with water. In the early 1980s, the method began to be widely used in the paint removal process for composite materials used in aircraft (Foley and Weaver 1981; Madl et al. 2010; Zulkarnain et al. 2021). It is possible to effectively remove paint layers with different properties by modifying parameters such as media type, blasting distance, nozzle diameter, air pressure, and blasting angle using this method (Foster et al. 1995; Rudawska et al. 2016).

Sodium bicarbonate is commonly used in the paint removal industry as a medium for removing aged paint layers from wood surfaces with air pressure. Furthermore, a number of alternative media, both artificial and natural, have been evaluated for their paint removal performance (Lemaster et al. 2005). Agricultural wastes obtained from plants are particularly useful as blasting media because they are low in density and have organic structures. After these wastes are reduced in size with the help of grinders, they can be converted into efficient blasting media for pressurized systems (Hansink 2000). Surface cleaning with pressurized systems often uses media such as silica sand, mineral sand, garnet, zircon, and others, but these materials contain high levels of silica, which can be harmful to health (Hansel 2000). Furthermore, media such as silica sand, glass, spheres, and steel balls have very high hardness levels compared to agricultural waste, so using these media for cleaning wood surfaces can cause roughness and discoloration. This is because the hard media can damage the wood material, causing it to lose its original color and texture. As an alternative, using media obtained from agricultural wastes to remove old paint and varnish layers may be a safer and more reasonable option. As a result of this, studies in recent years have focused on using recyclable agricultural wastes as alternatives to sodium bicarbonate (Sharmin et al. 2012; Qi et al. 2021).

The purpose of this study was to investigate the physical effects of paint removal on painted and aged wood surfaces with different blasting media (hazelnut shell granules, corncob granules, walnut shell granules, apricot kernel granules, and sodium bicarbonate) using different blasting parameters (distance, nozzle diameter, air-pressure, and angle). Samples obtained from yellow pine (Pinus sylvestris L.) were coated with synthetic and water-based paints and aged in natural seawater for 100 days in accordance with CSN EN 927-6 (2018). Using an automated blasting cabinet designed and developed with the project support (Support No: 221O709) of the Scientific and Technological Research Council of Türkiye (TUBITAK), the aged paint layers were removed. It is by an innovative method that this machine offers dust-free cleaning in 3 different directions in the cabin without the need for an operator, and offers the possibility to adjust the cleaning distance, cleaning angle and cleaning pressure to the desired levels. For the purpose of determining the physical changes that occurred on the surfaces after the paint removal process, the hardness, gloss, and total color change of the samples were measured.

EXPERIMENTAL

Materials

Preparation of wooden materials

Scotch pine (Pinus sylvestris L.) wood that is widely used in Türkiye, especially in marine (boats, ships, piers) and outdoor conditions (roofing, garden furniture, etc.), was preferred in the research. To ensure the specimens did not have rot, knots, cracks, or density differences, attention was paid to their appearance. Flawless wood pieces were cut into samples with draft dimensions of 330 × 110 × 12 (length × width × thickness) mm from sapwood parts of the woods. These samples were subjected to technical drying at a temperature of 20 °C ± 2 °C with a relative humidity of 65% ± 3% to achieve an air-dried moisture of 12%, as per TS ISO 13061-1 (2021) standard. The conditioned samples were cut with a final dimension of 320 × 100 × 10 (length × width × thickness) mm. A sanding and calibrating machine was used to sand and calibrate the samples using 80 and 100 grit sandpapers.

Paint

A one-component synthetic and a two-component waterborne wood paint were used for coating the samples. White was chosen as the color. The samples were primed with water-borne primer paint before applying the water-borne wood paint. Painting was conducted according to the manufacturer’s instructions. A precision balance with a sensitivity of 0.01 g was used to weigh the applied paint. Samples were painted with a brush in a dust-free and controlled room-temperature environment, and then allowed to dry for 24 h. Then, surfaces of the samples were sanded equally first with 220-grit and then followed by 320-grit sandpapers. Sanding dust was removed with a soft bristle brush and compressed air. Then, a second coat of paint was applied. The painted samples were then kept in a conditioning cabinet at a temperature of 20 °C ± 2 °C with a relative humidity of 65% ± 3% until a constant weight was achieved (TS ISO 13061-1 2021). Properties of the paints and the parameters used in the application are given in Table 1. When determining the amount to be applied, the non-volatile matter content of the paints was taken into consideration (TS EN ISO 3251 2019).

Table 1. Some Physical Properties of Paints

Aging process

The samples were aged in a specially designed stainless metal cage at a depth of 10 m from the sea surface and at a height of 1 m from the ground, for 100 days off the coast of Sinop harbor (42°01’23.3″N, 35°08’46.4″E), Türkiye (Fig. 1). Upon completion of the aging process, the samples were removed from the sea and stored in the air-conditioned cabinet at 20 °C and 65% relative humidity until they reached a constant weight.

Fig. 1. Ageing in natural sea water

Media

Five different blasting media were used to remove the aged paint layers. Some physical properties of the blasting media are given in Table 2.

Table 2. Some Physical Properties of Blasting Media

Paint removal process

The surfaces of samples were blasted with an automated blasting cabinet designed and developed for the study (Fig. 2). Surfaces were blasted with five different media (sodium bicarbonate, hazelnut shell granules, corncob granules, walnut shell granules, and apricot kernel granules) and varying blasting angles (45° and 90°), blasting distances (7 and 10 cm), air pressures (2 and 2.5 bar), and nozzle diameters (5 and 8 mm).

Fig. 2. Automated blasting cabinet and media blasting process

Methods

Glossiness and total color change tests

Total color change and gloss values were determined using the BYK – Gardner Spektro-Guide 45/0 (Spectro-guide sphere gloss meter, model CD-6834; BYK-Gardner GmbH, Geretsried, Germany) device (Fig. 3). To measure gloss, a 60° light angle was used, and the tests followed ASTM D523 (2018) regulations. Measurements were taken from the sample surfaces in the perpendicular and parallel directions to the fibers, and their arithmetic averages were recorded as a single value.

Fig. 3. Color and gloss measurement of samples

The color values of the untreated samples were obtained and accepted as control measurements. Then, paints were applied to the surfaces. The samples were then left in the sea. After the aging process, the media was blasted onto the samples to remove the paints on their surfaces. In the next stage, the color values were again measured from treated (painted, aged, and then blasted) samples and the total change in color was analyzed. The color measurements were conducted according to the ASTM D2244-21 (2021) standard using the CIEL*a*b* color scheme. The CIEL*a*b* color scheme is shown in Fig. 4.

Fig. 4. CIEL*a*b* color scheme (Budakçı et al. 2023)

In the scheme, L* is on the black-white axis (L* = 0 is black, L* = 100 is white), a* is on the red-green axis (positive values are reddish and negative values are greenish), and b* is on the yellow-blue axis (positive values are yellowish and negative values are blueish). The total color change values, , were calculated using the Eq. 1,

(1)

where ΔE* is the total color change after media blasting. As for the other ∆ values, ∆L* represents the change in the lightness of the color (L*control – L*treated), ∆a* represents the change in the red-green color line (a*control – a*treated), ∆b* represents the change in the yellow-blue color line (b*control – b*treated). A single value was determined by averaging three measurements taken from three different regions of each sample.

Hardness test

The hardness values of the samples were determined with a Shoremeter-D hardness durometer in accordance with ASTM D2240 (2006) after paint removal. Both spring and summer wood regions were measured, and their arithmetic averages were calculated.

Fig. 5. Measurement of hardness values

Statistical analysis

The CoStat statistic software (CoHort Software, version 6.45, Berkeley, CA, USA) was used for statistical analysis. Analysis of variance (ANOVA) tests were performed to determine the effects of the paint type, media type, blasting parameters, and their interactions on some surface properties of samples. Duncan’s multiple range tests (DMRT) using the least significant difference critical value (LSD) were used to determine the significant differences between the variables.

RESULTS AND DISCUSSION

Total Color Change

The arithmetic means obtained to determine the effect of paint removal process on the total color change values of the samples differed according to the factors of paint type, media type, and blasting parameters. An ANOVA test was performed to determine statistical significance of the total color change values in terms of these factors and their interactions. The results are provided in Table 3.

Table 3. ANOVA Results of Total Color Change (ΔE*) Values

Table 4. The DMRT Comparison Results for the Paint Type, Media Type, and Blasting Parameters of the ΔE Values

The ANOVA results show that all factors and their interactions are statistically significant (P ≤ 0.05). The DMRT using the LSD critical value was conducted between all factors to see where the significant differences occurred. The results are given in Table 4.

Samples coated with water-borne paint and media blasted after aging had the highest ΔE total color change value of 14.47, according to Table 4. Contrastingly, the lowest value was determined as 1.95 in samples coated with synthetic paint and blasted with different media after aging. In terms of media type, corn cob granules (16.64) and sodium bicarbonate (16.51) produced the highest total color change values. The lowest value was obtained in samples blasted with walnut shell granules (7.78). The highest value at the level of media blasting parameters was obtained in the media-blasted samples using 90° blasting angle, 2 bar air pressure, 0.5 cm nozzle diameter, and 10 cm blasting distance. The lowest value was determined in the samples (11.25) blasted with different media using 90° blasting angle, 2.5 bar air pressure, 0.5 cm nozzle diameter, and 10 cm blasting distance.

When the paint type data were evaluated, the total color change value of the samples coated with water-borne paint and blasted with different media after aging was 20% higher than the samples coated with synthetic paint and blasted with different media after aging. The reason for this may be related to the degradation of the protective layer over time due to UV exposure, humidity, and temperature, as well as the negative effects of this condition on the components of wood. Previous studies stated that polyurethane-based protective layers turn yellow as a result of their chemical structure or natural aging (Sönmez 2005). Because the water-borne paint used in the study was originally polyurethane-based, it may have been effective in causing the higher total color change value. In a different study, the water resistance and morphological properties of polyurethane varnish were investigated, and it was reported that fine cracks formed on the surface due to the change in the structure of hydrophilic groups and therefore the samples coated with polyurethane-based paints showed high color change (Özgenç et al. 2013).

When the media type data were examined, the total color change value of the samples blasted with corn cob granules was 1% higher than the samples blasted with sodium bicarbonate, 26% higher than the samples blasted with apricot kernel granules, 39% higher than the samples blasted with hazelnut shell granules, and 114% higher than the samples blasted with walnut shell granules. The reason for the high total color change values on the sample surfaces blasted with corn cob granules (Zulfiqar et al. 2014) and sodium bicarbonate may be because alkaline soap mixtures are in the structure of the corncob and sodium bicarbonate is an alkaline salt (Hewitt et al. 2011). It is thought that these alkaline substances may interact with cellulose derivatives and pigment groups of lignin and cause changes in the original color tones of the material. Previous studies reported that acidic and alkaline substances cause discoloration in wood materials (Stachowiak et al. 2014; Arpacı and Tomak 2020). In addition, because of the low densities of these media, it was observed that the paint layers were removed relatively poorly, and paint residues remained after the paint removal process. It is thought that these residues also affect the total color change values.

Regarding the blasting parameters factor, the highest total color change value was obtained in surfaces blasted with 90° blasting angle, 2 bar air pressure, 0.5 cm nozzle diameter, and 10 cm blasting distance (16.17), and the lowest value was obtained in samples blasted with 90° blasting angle, 2.5 bar pressure, 0.5 cm nozzle diameter and 10 cm blasting distance (11.25). The literature reported that angle, pressure, and distance of blasting are highly effective on surface roughness (Lawn 1993; Bouzid and Bouaouadja 2000; Satıcı 2004). Some other studies have reported that surface roughness also affects the total color change values (Şanıvar 1978; Lamason and Gong 2007; Pelit et al. 2015; Özdemir et al. 2018). Lemaster et al. (2005) blasted uncoated wood surfaces with sodium bicarbonate and plastic-based media at angles ranging from 10° to 90° and assessed the erosion wear index of surfaces. They reported that the highest erosion wear index was obtained in media blasting at an angle of 60°.

Figure 6 presents the results of the DMRT comparison conducted at the level of interaction between the paint type, media type, and blasting parameters factors.

SYN: Synthetic paint, WB: Water-borne paint, SB: Sodium bicarbonate, HSG: Hazelnut shell granule, CG: Corncob granule, WSG: Walnut shell granule, ASG: Apricot shell granule

Fig. 6. The DMRT comparison results for the total color change values with respect to paint type, media type, and blasting parameters interaction level

At the level of interaction of all factors, the highest total color change value was obtained in samples (22.38) blasted with corncob granules after being coated with water-borne paint and aged, using a 90° blasting angle, 2.5 bar pressure, 0.8 cm nozzle diameter, and 7 cm blasting distance. The lowest value was obtained in the samples (3.49) that were blasted with walnut shell granules using 90° blasting angle, 2.5 bar pressure, 0.8 cm nozzle diameter, and 10 cm blasting distance after being coated with water-borne paint and aged.

Gloss

The arithmetic means obtained to determine the effect of the paint removal process on the gloss values of the samples differed according to the factors of paint type, media type and blasting parameters. An ANOVA test was performed to determine statistical significance of the gloss values in terms of these factors and their interactions. The results are given in Table 5. The results of ANOVA show that all factors and their interactions are statistically significant (P ≤ 0.05). The DMRT using the LSD critical value was conducted between all factors to see where the significant differences occurred. The results are given in Table 6.

Table 5. ANOVA Results of Gloss Values

Table 6. The DMRT Comparison Results for the Paint Type, Media Type, and Blasting Parameters of the Gloss Values

At the media blasting parameters factor level, the highest gloss value was obtained in the surfaces blasted with an angle of 45°, a pressure of 2 bar, a nozzle diameter of 0.8 cm and a blasting distance of 7 cm (2.26). In contrast, the lowest value (1.71) was obtained in surfaces blasted using a 90° blasting angle, 2.5 bar pressure, 0.5 cm nozzle diameter, and 7 cm blasting distance. It is thought that the decrease in gloss values in the treated samples is caused by the aging conditions as well as the physical and chemical factors that occur on the surface after the media blasting process. A previous study showed that the gloss value of Douglas fir and mahogany woods decreased after six months of exposure to weather conditions (Gorman and Feist 1989). In another study, Scots pine, eastern beech, sessile oak, and chestnut woods were subjected to natural aging. It was reported that the highest gloss change occurred in Scots pine samples (Budakçı and Karamanoğlu 2014).

When Table 6 is analyzed at the paint type level, it becomes clear that the gloss values of the surfaces after being coated with water-borne paint and aged were 20% higher than those blasted with different media after being coated with synthetic paint and aged. Compared to the control samples, the gloss value decreased up to 54% in the media-blasted surfaces after being coated with water-borne paint and up to 61% in the media-blasted samples after being coated with synthetic paint. It is thought that the decrease in the gloss value may be due to the decrease in the intensity of the light hitting the surface due to the increased surface roughness after the paint removal process, or its reflection at different angles. In addition, when the polymeric structures of the dyestuffs of the paints are examined, it is thought that aging conditions may affect the chromophore groups in the polymer chain of synthetic paint more than those of water-borne paint.

When the media type data were examined, it can be claimed that higher gloss values were obtained in samples blasted with hazelnut shell granules than those blasted with other media. The gloss value of the samples blasted with hazelnut shell granules was 20% higher than the samples blasted with sodium bicarbonate and apricot kernel granules, 11% higher than the samples blasted with walnut shell granules, and 23% higher than the samples blasted with corn cob granules. It is thought that the alkali soap and acetone ((CH3)2CO) extract (Lopez et al. 2012) in the structure of the hazelnut shell interact with the pigment groups of cellulose and lignin in the Scotch pine wood and may cause changes in the glossiness of the material.

When the blasting parameters factor was evaluated, the highest gloss value was obtained in the media-blasted samples with 45° blasting angle, 2 bar pressure, 0.8 cm nozzle diameter, and 7 cm blasting distance (2.26). The lowest gloss value was obtained in the media-blasted samples with 90° blasting angle, 2.5 bar pressure, 0.5 cm nozzle diameter, and 7 cm blasting distance (1.71). This is thought to be related to the increase in roughness on the surfaces of the samples, which is similar to the total color change. It has been reported in the literature that the increase in surface roughness value has a negative effect on gloss values (Panek et al. 2014; Kropat et al. 2020).

A DMRT comparison is presented in Fig. 7 at the level of interaction between paint type, media type, and blasting parameters. The untreated control samples had the highest gloss value (4.48), as shown in Fig. 7. When treated samples were examined, the highest gloss value was obtained in samples (3.39) blasted with walnut shell granules after being coated with water-borne paint and aged, using 45° blasting angle, 2 bar pressure, 0.5 cm nozzle diameter, and 10 cm blasting distance. The lowest value was obtained in the samples (1.12) that were blasted with hazelnut shell granules using 90° blasting angle, 2.5 bar pressure, 0.8 cm nozzle diameter, and 7 cm blasting distance after being coated with synthetic paint and aged.

SYN: Synthetic paint, WB: Water-borne paint, SB: Sodium bicarbonate, HSG: Hazelnut shell granule, CG: Corncob granule, WSG: Walnut shell granule, ASG: Apricot shell granule

Fig. 7. The DMRT comparison results for the gloss values with respect to paint type, media type, and blasting parameters interaction level

Hardness

The arithmetic means obtained to determine the effect of paint removal process on the hardness values of the samples differed according to the factors of paint type, media type, and blasting parameters. An ANOVA test was performed to determine statistical significance of the hardness values in terms of these factors and their interactions. The results are given in Table 7.

Table 7. ANOVA Results of Hardness Values

Table 8. The DMRT Comparison Results for the Paint Type, Media Type, and Blasting Parameters of the Hardness Values

The results of ANOVA show that all factors and their interactions were statistically significant (P ≤ 0.05). The DMRT using the LSD critical value was conducted between all factors to see where the significant differences occurred. The results are given in Table 8.

According to the results in Table 8, the highest hardness value at the paint type level was determined in the control samples without any treatment (40.68), while the lowest value was determined in the media-blasted samples after water-borne paint was applied and aged (36.09). At the media variety level, the highest hardness value was found in samples blasted with corn cob granules (38.52), while the lowest value was determined in samples blasted with apricot shell granule (35.21). At the media blasting parameters factor level, the highest hardness value (37.89) was obtained in the media-blasted samples with a blasting angle of 90°, a pressure of 2.5 bar, a nozzle diameter of 0.8 cm, and a blasting distance of 10 cm. In contrast, the lowest value (34.84) was obtained in samples blasted using 45° blasting angle, 2 bar pressure, 0.8 cm nozzle diameter, and 10 cm blasting distance. It was determined that the hardness values of the coated specimens that were media-blasted after being aged decreased compared to the untreated control specimens. This decrease is thought to be caused by the aging conditions and the physical and chemical factors that occur on the surface after the paint removal process. It is emphasized in the literature that the outdoor conditions have a decreasing effect on the hardness values of the wood material (Yalınkılıç et al. 1999; Budakçı and Atar 2001; Baysal 2008; Budakçı and Karamanoğlu 2014; Küçüktüvek et al. 2017).

When the paint type data were analyzed, the hardness value of the samples coated with synthetic paint and media-blasted after aging was 2% higher than the samples coated with water-borne paint and media-blasted after aging. Compared to the control samples, the hardness value decreased up to 11.2% in the media-blasted samples after being coated with water-borne paint and up to 9.5% in the media-blasted samples after being coated with synthetic paint.

SYN: Synthetic paint, WB: Water-borne paint, SB: Sodium bicarbonate, HSG: Hazelnut shell granule, CG: Corncob granule, WSG: Walnut shell granule, ASG: Apricot shell granule

Fig. 8. The DMRT comparison results for the hardness values with respect to paint type, media type, and the blasting parameters interaction level

When the media type data were examined, the hardness value of the samples blasted with corn cob granules was 2% higher than the samples blasted with sodium bicarbonate, 9% higher than the samples blasted with apricot kernel granules, hazelnut shell granules, and walnut shell granules. The hardness values of all coated and treated samples decreased compared to the control samples. The results of the tests suggest that the wear resistance of surfaces exposed to continuous media blasting with compressed air decreases, thus resulting in a decrease in hardness. The previous studies argued that there is a linear relationship between wear resistance and hardness value (Larsen 1983; Feist 1990; Yazıcı 2005)

When the blasting parameters factor was evaluated, the highest hardness value was obtained in the media-blasted samples with 90° blasting angle, 2.5 bar pressure, 0.5 cm nozzle diameter, and 7 cm blasting distance (37.89). The lowest hardness value was obtained in media-blasted samples with 90° blasting angle, 2 bar pressure, 0.8 cm nozzle diameter, and 10 cm blasting distance (34.94). There was a remarkable decrease in the hardness values of the media-blasted samples compared to the control samples. Figure 8 presents the results of the DMRT comparison conducted at the level of interaction between the paint type, media type, and the blasting parameters factors.

The untreated control samples had the highest hardness value (40.49), as shown in Fig. 8. When treated samples were examined, the highest hardness value was obtained in samples (40.61) blasted with sodium bicarbonate using a 90° blasting angle, 2 bar pressure, 0.8 cm nozzle diameter, and 7 cm blasting distance after being painted with synthetic paint and aged. The lowest value was obtained in the samples (32.75) that were blasted with apricot shell granules using 45° blasting angle, 2 bar pressure, 0.8 cm nozzle diameter, and 10 cm blasting distance after being coated with synthetic paint and aged.

CONCLUSIONS

- The effects of paint removal with abrasive blasting media on wood surfaces aged in sea water were investigated. For this purpose, aged paint layers were removed with the help of an automated blasting cabinet using different blasting parameters with sodium bicarbonate, which is widely preferred in the paint removal industry, and recyclable agricultural wastes.

- It was determined that agricultural wastes could be a good alternative to sodium bicarbonate in terms of total color change and gloss.

- As the blasting distance increased, the total color and brightness values increased, while the hardness values decreased. Additionally, as the blasting angle increased, the total color change and hardness values of the samples increased, and also the gloss values decreased.

- It was observed that the surfaces blasted with corncob granules and sodium bicarbonate had less deformation and a relatively less effective paint removal than those removed with other media. However, these media caused paint residues to remain on surfaces after paint removal.

- Compared with the control samples, the sand-blasted samples showed a decrease in gloss and hardness values.

- Although it was observed that surface cleaning was effective in removing aged paint layers, it was also observed that the surfaces may require smoothing before a potential repainting process.

- The contribution of the study to the state of the art lies in the use of agricultural wastes for industrial purposes. In addition, the automated media blasting machine designed for industrial purposes, which allows for the modification of all effective parameters in media blasting, is also notable as another important outcome of the study.

ACKNOWLEDGMENTS

This study was supported by the Turkish Scientific and Technical Research Council within the scope of TUBİTAK 1005 National – New Ideas and Products Research Support Program (Project No. 221O709). The authors would like to extend thanks to UTS Machine Technologies LC for their support in the production of the “Automated Blasting Cabinet” designed within the scope of the study. Additionally, to Dual Boya and Polisan Boya Limited Companies for their assistance in the supply of paint.

REFERENCES CITED

Acker, V. J., Stevens, M., Carey, J., Sierra-Alvarez, R., Militz, H., Le Bayon, I., Kleist, G., and Peek, R. D. (2003). “Biological durability of wood in relation to end-use,” Holz als Roh -und Werkstoff 61(1), 35-45. DOI: 10.1007/s00107-002-0351-8

Ali, T., Nasko, T., Morten, E., and Jonas, H. (2007). “Effect of accelerated weathering on surface chemistry of modified wood,” Applied Surface Science 253(12), 5355-5362. DOI: 10.1016/j.apsusc.2006.12.005

Anderson, E. L., Pawlak, Z., Owen, N. L., and Feist, W. C. (1991). “Infrared studies of wood weathering. Part I: Softwoods,” Applied Spectroscopy 45(4), 641-647. DOI: 10.1366/0003702914336930

Arpacı, Ş. S., and Tomak, E. D. (2020). “Effect of weathering tests on wood properties,” Bartın Journal of Forestry Faculty 22, 654-673.

ASTM D2240 (2006). “Standard test method for rubber property—Durometer hardness,” ASTM International, West Conshohocken, PA, USA.

ASTM D2244-21 (2021). “Standard practice for calculation of color tolerances and color differences from instrumentally measured color coordinates,” ASTM International, West Conshohocken, PA, USA.

ASTM D523-14 (2018). “Standard test method for specular gloss,” ASTM International, West Conshohocken, PA, USA.

Baysal, E. (2008). “Some physical properties of varnish coated wood preimpregnated with copper-chromated boron (CCB) after 3 months of weathering exposure in southern eagen sea region,” Wood Research 53(1), 43-54.

Bilgin, H. (2009). Wood Structure and Development Days of The Historical Process in The U.S. Wood Use, Master’s Thesis, Departmant of Natural and Applied Science, Haliç University, İstanbul, Türkiye.

Bobat, A. (1994). Use and Service Life of Preservative Treatd Wood Material in Underground Coal Mines and in Sea Water, Departmant of Natural and Applied Science, Ph.D. Thesis, Karadeniz Technical University, Trabzon, Türkiye.

Bouzid, S., and Bouaouadja, N. (2000). “Effect of impact angle on glass surfaces eroded by sand blasting,” Journal of the European Ceramic Society 20(4), 481-488. DOI: 10.1016/s0955-2219(99)00140-5

Budakçı, M. (2006). “Effect of outdoor exposure and bleaching on surface color and chemical structure of scots pine,” Progress in Organic Coatings 56(1), 46-52. DOI: 10.1016/j.porgcoat.2006.01.018

Budakçı, M., and Atar, M. (2001). “Effects of bleaching process on hardness and glossiness of pine wood (Pinus sylvestris L.) exposed to outdoor conditions,” Turkish Journal of Agriculture and Forestry 25(4), 201-207.

Budakçı, M., and Karamanoğlu, M. (2014). “Effects of weathering on some physical properties of wood,” Kastamonu University Forest Faculty Journal 14(1), 37-47.

Budakçı, M., Korkmaz M., and Karal, İ. (2023). “Antifungal effects of staining process on wood: Hardness, gloss, and color change,” Bioresources 18(1), 302-316. DOI: 10.15376/biores.18.1.302-316

Çetin, H. (2009). Physical and Chemical Analysis of Softwoods Exposed to Marine Borers, Master’s Thesis, Departmant of Natural and Applied Science, Bartin University, Bartin, Türkiye.

Chen, G. X., Kwee, T. J., Tan, K. P., Choo, Y. S., and Hong, M. H. (2010). “Laser cleaning of steel for paint removal,” Applied Physics A: Materials Science and Processing 101(2), 249-253. DOI: 10.1007/s00339-010-5811-0

Cragg, S. M., Brown, C. J., and Albuquerque, R. M., and Eaton, R. A. (2001). “Rates of emission from CCA-treated wood in the marine environment: Measurement, modelling and requirements for future research,” in: Proceedings of the 6th International Preservation Symposium; Environment and Wood Preservation, Cannes Mandelieu, France, pp. 5-6.

CSN EN 927-6 (2018). “Paints and varnishes – Coating materials and coating systems for exterior wood,” European Standards, Brussels, Belgium.

Deka, M., and Petrič, M. (2008). “Photo-degradation of water borne acrylic coated modified and non-modified wood during artificial light exposure,” BioResources 3(2), 346-362.

Dillon, J., Division, S., Division, H. C., and Rosa, S. (2006). Creosote-Treated Wood in Aquatic Environments: Technical Review and Use Recommendations (Report No. 10702), Duke University, Durham, NC, USA.

Doruk, Ş., Perçin, O., and Yörür, H. (2019). “Bending strength of ımpregnated laminated wood material placed on sea and beach,” Bartin Forest Faculty Journal 21(3), 771-776. DOI: 10.24011/barofd.599302

Eaton, R. A. (1985). “Preservation of marine timbers,” in: Preservation of timber in the Tropics, W. P. K. Findley (Ed.), Adam and Charles Black, London, UK, pp. 157-191. DOI: 10.1007/978-94-017-2752-5_8

Feist, W. C. (1990). “Outdoor wood weathering and protection, archaeological wood, properties, chemistry and preservation,” in: Advances in Chemistry, Series No. 225, R. Rowell (ed.), American Chemical Society, Washington, D.C., USA, pp. 263-298. DOI: 10.1021/ba-1990-0225

Feist, W. C., and Hon, D. N. S. (1984). “Chemistry of weathering and protection,” in: The Chemistry of Solid Wood, American Chemical Society, Washington D.C., USA, pp. 401-451. DOI: 10.1021/ba-1984-0207.ch011

Foley, K. M., and Weaver, T. (1981). “An update on soft grit blast cleaning with corncob grit,” in: Abrasive Engineering Annual Conference, Dearborn, MI, USA, pp. 107-116.

Forsthuber, B., Schaller, C., and Grüll, G. (2013). “Evaluation of the photo stabilising efficiency of clear coatings comprising organic UV absorbers and mineral UV screeners on wood surfaces,” Wood Science and Technology 47, 281-297. DOI: 10.1007/s00226-012-0487-6

Foster, T., Malavallon., O, and Visaisouk., S. (1995). Environmentally Safe and Effective Processes for Paint Removal (Report No. 201), U.S. North Atlantıc Treaty Organization Science and Technology Organization, Washington, D.C., USA.

Gobakken, L. R., and Lebow, P. K. (2010). “Modelling mould growth on coated modified and unmodified wood substrates exposed outdoors,” Wood Science and Technology 44(2), 315-333. DOI: 10.1007/s00226-009-0283-0

Gorman, T. M., and Feist, W. C. (1989). Chronicle of 65 Years of Wood Finishing Research at the Forest Products Laboratory (Report No. FPL-GTR-60), U.S. Department of Agriculture Forest Products Laboratory, Madison, WI, USA.

Hansink, J. D. (2000). “Introduction to abrasives for protective coating removal operations,” Journal of Protective Coatings and Linings 17(4), 66-73.

Hewitt, J., Uniacke, M., Hansi, N. K., McCarthy, K., and Venkat-Raman, G. (2011). “Sodium bicarbonate supplements for treating acute kidney injury,” Cochrane Database of Systematic Reviews 2011(7), article no. CD009204. DOI: 10.1002/14651858.cd009204

Hon, D. N. S., and Feist, W. C. (1986). “Weathering characteristics of hardwood surfaces,” Wood Science and Technology 20(2), 169-183. DOI: 10.1007/BF00351028

Kılıç, A., and Hafızoğlu, H. (2009). “Influences of weatherıng on chemıcal structure of wood and protectıon treatments,” Suleyman Demirel University Journal of Forestry Faculty 8(2), 175–183.

Kropat, M., Hubbe, M. A., and Laleicke, F. (2020). “Natural, accelerated and simulated weathering of wood: A Review,” BioResources 15(4), 9998-10062. DOI: 10.15376/biores.15.4.Kropat

Kucuktuvek, M., Baysal, E., Turkoglu, T., Peker, H., Gunduz, A., and Toker, H. (2017). “Surface characteristics of scots pine wood heated at high temperatures after weathering,” Wood Research 62(6), 905-917.

Lamason, C., and Gong, M. (2007). “Optimization of pressing parameters for mechanically surface-densified aspen,” Forest Products Journal 57(10), 64-68.

Larsen, B.J. (1983). “Resistance of cemented carbides to sliding abrasion: Role of binder metal,” in: Science of Hard Materials, R. K. Viswanadham, D. J. Rowcliffe, and J. Gurland (Eds.), Springer, Boston, MA, USA, pp. 797-813. DOI: 10.1007/978-1-4684-4319-6_43

Lawn, B. (1993). Fracture of Brittle Solids, 2nd Edition, Cambridge University Press, Cambridge, United Kingdom.

Lemaster, R. L., Shih, A. J., and Yu, Z. (2005). “Blasting and erosion wear of wood using sodium bicarbonate and plastic media,” Forest Products Journal 55(5), 59-64.

Lopez, L. P. C., Martins, J., Esteves, B., and Lemos, L. T. D. E. (2012). “New products from hazelnut shell,” in: ECOWOOD 2012-5th International Conference on Environmentally-Compatible Forest Products, Porto, Portugal, 83-90.

Maclean, J. D. (1954). Results of Experıments on the Effectiveness of Various Preservatives in Procting Wood Against Marine-Borer Attack (Report No. D1773), U.S. Department of Agriculture Forest Products Laboratory, Madison, WI, USA.

Madl, A.K., Carosino, C., and Pinkerton, K. (2010). “Particle toxicities,” in: Comprehensive Toxicology, C. A. McQuenn (ed.), Elsevier, Amsterdam, Netherlands, pp. 421-453.

Özdemir, F., Ramazanoğlu, D., and Tutuş, A. (2018). “Investigation of the effect of aging time, sanding and cross section on the surface quality of fir wood,” Bartın Journal of Forestry Faculty 20(2), 194-204.

Özgenç, Ö., Yıldız, Ü. C., and Yıldız, S. (2013). “The wood surface protection with some new generation wood preservatives and coating processings against weathering conditions,” Artvin Coruh University Journal of Forestry Faculty 14(2), 203-215. DOI: 10.17474/acuofd.83528

Pánek, M., and Reinprecht, L. (2014). “Colour stability and surface defects of naturally aged wood treated with transparent paints for exterior constructions,” Wood Research 59(3), 421-430.

Pelit, H., Budakçı, M., Sönmez, A., and Burdurlu, E. (2015). “Surface roughness and brightness of scots pine (Pinus sylvestris) applied with water-based varnish after densification and heat treatment,” Journal of Wood Science 61(6), 586-594. DOI: 10.1007/s10086-015-1506-7

Qi, C., Weinell, C. E., Dam-Johansen, K., and Wu, H. (2021). “A review of blasting waste generation and management in the ship repair industry,” Journal of Environmental Management 300, article ID 113714 DOI: 10.1016/j.jenvman.2021.113714

Riley, D. M., and Fischbeck, P. S. (2000). History of Methylene Chlorıde in Consumer Products: Tracıng Scıentıfıc Knowledge Regulatıons and Perceptıons, Chemical Rubber Company Press, Cleveland, OH, USA.

Rudawska, A., Danczak, I., Müller, M., and Valasek, P. (2016). “The effect of sandblasting on surface properties for adhesion,” International Journal of Adhesion and Adhesives 70, 176-190. DOI: 10.1016/j.ijadhadh.2016.06.010

Satıcı, M. E. (2004). Study About Blasting and Shot Peenıng Processes and Parameters Affectıng on them, Master’s Thesis Departmant of Natural and Applied Science İstanbul Technical University, Istanbul, Turkey.

Schaller, C., and Rogez, D. (2007). “New approaches in wood coating stabilization,” 4(4), 401-409. DOI: 10.1007/s11998-007-9049-5

Sharmin, E., Sharif, A., and Fahmina, Z. (2012). “Renewable resources in corrosion resistance,” Corrosion Resistance 20, 449-465. DOI: 10.5772/31995

Sivrikaya, H., Hafizoglu, H., Yasav, A., and Aydemir, D. (2011). “Natural weathering of oak (Quercus petrae) and chestnut (Castanea sativa) coated with various finishes,” Color Research and Application 36(1), 72-78. DOI: 10.1002/col.20581

Sönmez, A. (2005). Finishing on Woodworking I, Preparation and Coloring, Gazi University Cem Web Offset, Ankara, Turkey.

Stachowiak-Wencek, A., Zborowska, M., Waliszewska, B., and Pradzynski, W. (2014). “Color changes of pine wood under the influence of xenon light irradiation after treatment with acid and alkaline buffers,” Annals of Warsaw University of Life Sciences, Forest and Wood Technology 86, 210-214.

Şanıvar, N. (1978). Finishing on Woodworking, National Education Printery, İstanbul, Turkey.

TS EN ISO 2813 (2014). “Paints and varnishes – Determination of specular gloss of non-metallic paint film at 20° , 60° and 85°,” Turkish Standards Institution, Ankara, Türkiye.

TS EN ISO 3251 (2019). “Paints, varnishes and plastics – Determination of non-volatile- matter contenz,” Turkish Standards Institution, Ankara, Türkiye.

TS ISO 13061-1 (2021). “Physical and mechanical properties of wood – Test methods for small clear wood specimens – Part 1: Determination of moisture content for physical and mechanical tests,” Turkish Standards Institution, Ankara, Türkiye.

Uzuner, M. (2020). Evaluatıon of Wood Materıals in Furnıture Desıgn: The Example of Bursa Inegol Furnıture Companıes, Master’s Thesis, University of Işık, İstanbul, Türkiye.

Weeks, K. D., and Look, W. D. (1982). Exterior Paint Problems on Historic Woodwork, U.S. Department of the Interior, Technical Preservation Services, Washington, D.C., USA, pp. 1-11.

Williams, R. S. (2005). “Weathering of wood,” in: Handbook of Wood Chemistry and Wood Composites, CRC Press, Boca Raton, FL, USA, pp. 139-185.

Wynne, J. H., Watson, K.E., Yesinowski, J.P., Young, C.N., Clayton, C.R., Nesteruk, N., Kelley, J., and Braswell, T. (2010). Interim Report on Scientific Basis for Paint Stripping: Mechanism of Methylene Chloride Based Paint Removers (Report No. ADA539879), Naval Research Laboratory, Washıngton, D.C., USA.

Yalınkiliç, M. K. (1999). “Weathering durability of CCB-impregnated wood for clear varnish coatings,” Journal of Wood Science 45(6), 502-514. DOI: 10.1007/bf00538961

Yazıcı, H. (2005). “The effects of weathering on wood strength,” Bartın Journal of Forestry Faculty 7, 72-79.

Zulfiqar, A., Maqsood, H., and Arshad, M. (2014). “Saccharification of corn cobs an agro-industrial waste by sulphuric acid for the production of monomeric sugars,” International Journal of Biosciences 5(3), 204-213.

Zulkarnain, I., Kassim, N. A. M., Syakir, M. I., Rahman, A. A., Yusuff, M. S., Yusop, R. M., and Keat, N. O. (2021). “Sustainability-based characteristics of abrasives in blasting industry,” Sustainability 13(15), 1-13. DOI: 10.3390/su13158130

Article submitted: October 19, 2022; Peer review completed: November 29, 2022; Revised version received and accepted: December 14, 2022; Published: December 19, 2022.

DOI: 10.15376/biores.18.1.1185-1205