Abstract

Wet-laid forming, which can be regarded as being analogous to conventional papermaking processes but with use of chopped synthetic or staple fibers, continues to draw attention as an advantageous way to prepare advanced nonwoven textile products. This review of the literature considers scientific advances in the field, with emphasis placed on applications involving cellulosic fibers as a significant component of the product. Some primary challenges with respect to wet-laid processing concern the dispersion of the synthetic fibers in aqueous media and methods for avoiding their subsequent entanglement. Both mechanical and chemical strategies have been employed in order to achieve well-formed sheets of high uniformity and binding among the fibers to meet a variety of end-use specifications. The incorporation of cellulosic fibers has been shown to facilitate fiber dispersion and to impart certain beneficial characteristics and properties to wet-laid fabrics. The contrasting attributes of synthetic and cellulosic fibers contribute to some unique challenges during the processing of their mixtures during wet-laid forming.

Download PDF

Full Article

Wet-Laid Nonwovens Manufacture – Chemical Approaches Using Synthetic and Cellulosic Fibers

Martin A. Hubbe,a,* and Alexander A. Koukoulas b

Wet-laid forming, which can be regarded as being analogous to conventional papermaking processes but with use of chopped synthetic or staple fibers, continues to draw attention as an advantageous way to prepare advanced nonwoven textile products. This review of the literature considers scientific advances in the field, with emphasis placed on applications involving cellulosic fibers as a significant component of the product. Some primary challenges with respect to wet-laid processing concern the dispersion of the synthetic fibers in aqueous media and methods for avoiding their subsequent entanglement. Both mechanical and chemical strategies have been employed in order to achieve well-formed sheets of high uniformity and binding among the fibers to meet a variety of end-use specifications. The incorporation of cellulosic fibers has been shown to facilitate fiber dispersion and to impart certain beneficial characteristics and properties to wet-laid fabrics. The contrasting attributes of synthetic and cellulosic fibers contribute to some unique challenges during the processing of their mixtures during wet-laid forming.

Keywords: Chopped synthetic fibers; Staple fibers; Dispersion; Colloidal stability; Entanglement; Cellulosic fibers; Uniformity of formation; Product performance

Contact information: a: Department of Forest Biomaterials, North Carolina State University, Box 8005, Raleigh, NC 27695-8005 USA; b: ANL Consultants LLC, P.O. Box 2981, Savannah, GA 31408-2981 USA;

* Corresponding author: hubbe@ncsu.edu

Contents of Article

This article reviews chemical aspects of the intriguing field of wet-laid nonwoven fabric manufacture. The wet-laid process – in its various forms – makes it possible to achieve cloth-like characteristics without weaving and without use of continuous filaments or threads. It offers high production speeds, great flexibility regarding the blending of different fiber types, and opportunities to achieve uniformity in the product.

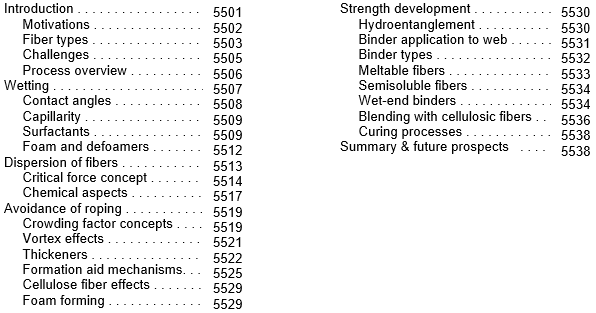

There are strong similarities between wet-laid technology and conventional papermaking. According to the Association of Nonwovens Fabrics Industry (INDA), a nonwoven product is a sheet of fibers that are bonded without weaving and without hydrogen bonding being the primary bonding mechanism (Kozak 1991). A key point of differentiation between papermaking and wet-laid nonwoven forming is that wet-laid systems employ a substantial content of fibers having lengths much greater than 3 mm, the typical length of fibers in softwood pulp (Nanko et al. 2005). Also, most nonwoven fibers are made mainly from chopped synthetic fibers or staple fibers, such as glass, polypropylene, or polyester, among others. A wide variety of cellulosic fibers are used in various wet-laid products, with particular scholarly interest having been shown for flax (Fages et al. 2012, 2013; Maity et al. 2014), cotton (Hervey et al. 1975; Farer et al. 1998), regenerated cellulose fibers (Wilke 1989; Johnson 1996; Maity et al. 2014), and wood pulp fibers (Gill et al. 1972; Schon 1977; Yang and Dean 1978a; Inagaki 1979). In wet-laid processing the fibers are initially suspended in an aqueous solution and then formed into a sheet on a moving screen, where the water is removed. To put things into perspective, it is much more common to prepare nonwoven fabric products – especially bulky nonwoven fabrics – without the use of water, using so-called “air-laid” or “dry-formed” processes; such approaches have been reviewed by others (Lichstein 1988; Turbak 1993; Russell 2007). There also have been some useful reviews of various aspects of the wet-laid nonwoven process (Fredericks 1976; Schoffmann 1980; Lichstein 1988; Turbak 1993; Williamson 1993). Table 1 lays out some typical ranges of fiber length, machine width, line speed, and basis weight for some of the most common product types.

Table 1. Typical Fiber Length, Machine Parameters, and Basis Weights for Wet-Laid and Dry-Laid Production Methods (Russell 2007)

The global nonwovens market, which comprises both dry-formed and wet-laid production methods, represents a $37.4 billion industry (Smithers Apex 2015). Wet-laid products comprise a $534 million global industry with applications in diverse segments including wall covering, filtration, and specialties (Smithers Apex 2014). Starr (1973) noted that in the early 1970s the wet-laid sector constituted about 15% of the nonwovens market. Today, the dry-laid sector is by far the larger market, owing to strong growth in automotive, hygienic applications, disposables, and other markets. For many years production of wet-laid nonwovens has been regarded as relatively stagnant, following a climax of activity during the 1970s (Anon. 2005). The stagnation in new manufacturing capacity since about 1980 has been attributed to environmental concerns – noting the huge volumes of water that the process employs; however it appears that such concerns can be met with new materials and available water treatment technologies (Anon. 2005). Thus, continued growth in wet-laid demand seems likely in coming years, with annual growth of 5.1% projected for wet-laid nonwovens through 2019 (Smithers Apex 2015). Driving this growth is the continued expansion of traditional markets as well as the recent rapid growth in the disposable wipes market (Suominen 2015).

Organization of this Article

To lay some groundwork for a focus on chemical aspects of wet-laid nonwoven processing, this article begins with a brief overview and description of commonly used equipment and processes. Chemical aspects are then considered based generally on the usual sequence of operations. Thus, the subject of wetting is considered, with an emphasis on the use of surfactants as a means to encourage various oleophilic or oil-loving synthetic fibers to become mixed with the water medium. The next topic is dispersion, with emphasis on the use of dispersants to aid in the separation of the synthetic fibers from each other in the presence of agitation. A third class of chemicals, the thickeners, are considered next. These highly viscous hydrophilic or water-loving polymers and related chemicals are intended to repress the premature entanglement of the long fibers. And finally, a series of different approaches to achieving bonding in the wet-laid structure are considered. This is important because, unlike cellulosic fibers, the glass, polypropylene, and other types of fibers commonly used in wet-laid manufacture all lack the combination of conformability and hydrogen bonding ability that allows ordinary paper sheets to develop considerable strength during the drying process even when no bonding agent has been added.

Motivations

Fabric-like attributes; paper-like rate of production

The use of a wet-laid manufacturing strategy is generally easiest to justify in cases where the product bears some similarity to paper. Paper-like characteristics can include having the fibers oriented mainly within the plane of the sheet – though this initial orientation is sometimes later modified by hydroentanglement (White 1992). Because the forming of a paper sheet represents a kind of filtration process, wet-laid processing can provide relatively predictable or adjustable range of pore size – making the approach attractive for the preparation of various filtration media (Ahrens 1982; Bergmann 1989; Hutten 2007). Wet-laid systems allow a great deal of flexibility in the blending of different kinds of fibers, making it possible to optimize products for a wide range of applications (Ahrens 1982; Scholz 1985). In fact, even a biodegradable cover sheet for agriculture, prepared from sludge (Wang et al. 2014) can be regarded as a wet-laid nonwoven product.

The examples given in certain patents suggest that wet-laid forming is being viewed by inventors as a promising way to prepare sheets that resemble ordinary paper in many respects; the distinction that makes such products different from ordinary paper is the fact that some or all of the fibers may be non-cellulosic and considerably longer than those from hardwood or softwood trees (Clitherow et al. 1991). On the other hand, there is a strong motivation for manufacturers to incorporate cellulosic fibers due to their generally much lower cost in comparison to the synthetic alternatives (Gill et al. 1972; Williamson 1993).

The rate of production on a typical paper machine is many times greater than can be achieved in a typical woven textile line (Ahrens 1982; Williamson 1993). Williamson estimated a 1000- to 10,000-fold advantage in production rate. Some limitations or inherent drawbacks to wet-laid forming have been mentioned. For instance, wet-laid products tend not to achieve the levels of softness, conformity, or strength of ordinary cloth (Williamson 1993).

Flexibility in Blending of Fiber Types

A great variety of fiber types, such as glass, polyester, polyamide, and regenerated cellulose, etc., have been employed in wet-laid nonwovens (Scholz 1985). Evans and Pfeiffer (1992) described the development and use of fibrillated acrylic pulp. The high surface area and ease of dispersion in water of this material suggest that it should be regarded as a substitute for cellulosic fibers. Cellulose acetate fibrets are another example of fibrous materials that are relatively easy to disperse in water and that can provide strength advantages relative to ordinary papermaking fibers (Kozak 1991). Kevlar® fibers, based on aromatic polyamide chemistry, likewise can be prepared in a form that is highly fibrillated and easy to disperse (Merriman 1981).

Glass fibers

Chopped glass fibers are among the most studied and employed types in wet-laid applications (Chakrabarti 1979a; Stassen 1983; Fegley 1985; Whichard 1985; Brandon et al. 1988; Latimer and Schultz 1990; Jakush 1991; Brandenburg 1993; Yousfani et al. 2012). According to Chakrabarti (1979a), glass fibers often do not disperse well in water and require surfactants. Stassen (1983) recommended cleaning glass fiber surfaces with strong acid, presumably to remove hydrophobic substances that may have accumulated onto the fiber surfaces during processing, since such substances would tend to impede wetting by water. Brandon et al. (1988) describe the importance of wet-chopping to achieve the required fiber lengths. Miller (1996) describes a practical test to evaluate the quality of dispersion of glass fibers in water.

Polyolefin fibers

Polypropylene and polyethylene, i.e. polyolefins, are other polymer types that are widely used in wet-laid nonwoven manufacture (Floyd 1984; DeJong 1999; Holm and Milding 1999; Malkan 2009; Fages et al. 2012). In unmodified form such fibers are highly hydrophobic. Strategies for dispersing hydrophobic fibers in water will be dealt with in later sections (Cai et al. 2003). Considerable research has been devoted to the use of combinations of cellulosic fibers and polypropylene in wet-laid composites, allowing a range of end products, while also taking advantage of the favorable price and ease of processing of the cellulosic component (DeJong 1999; Holm and Milding 1999; Fages et al. 2012). Alternatively, as described by Butterworth et al. (1978), it is possible to prepare polyethylene fibers that resemble wood pulp in many respects, making it possible to prepare blends with ordinary papermaking stock. The use of polyethylene fibers and/or bicomponent fibers as a meltable binder in wet-laid nonwoven manufacture will be considered later.

Polyester fibers

Innovations in the development and supply of polyester staple fibers, for wet-laid applications, were summarized by Ezaki (1988). Wet-laid applications of such fibers have been described (Gregg 1974; Latimer and Schultz 1990; Robertson 1992; Shiffler 1999; Reese and Cooper 2002). Polyester fibers can be blended in different ratios with glass fibers to achieve a range of properties (Esaki et al. 1989; Latimer and Schultz 1990) for such applications as roofing mats. Polyester micro-fibers can be used for specialty applications that can benefit from small fiber size (Robertson 1992).

Aramid fibers

Nonwovens made from aromatic polyamine or aramid fibers are excellent examples of high-performance materials manufactured using wet-laid methods. These papers are derived from techniques developed in the early 1960’s, wherein staple fibers and fibrids of various polymer types were combined using a papermaking process to produce synthetic paper-like composites of improved strength and thermal resistance (Morgan 1961; Merriman 1981). In such applications the fibrids act as film-like binders made from synthetic polymers, which are placed in a shear field to enhance their surface area. The applied shear field can be generated through shear precipitation or mechanical action, such as refining (Morgan 1961). The specific surface area of fibrids generated by these methods can be as high as 60 m2/kg. Paper comprising synthetic fiber and fibrids can be calendered at elevated pressures and temperatures above the second order transition temperature of the polymer to enhance internal bonding and increase paper strength.

Paper made from aramid fibers were developed by DuPont in the early 1970s (Gross 1973). Aramid fibers, because of their high temperature resistance, are less likely to embrittle during calendaring (Gross 1973). This is especially the case with aromatic polyamide fibers of low modulus. Papers made from aramid fibers are sold under the Kevlar®, Nomax®, and Twaron brands and are used in a variety of industrial applications including personal protection wear and composite structures used in aerospace applications (DuPont 2016a,b). Other applications include electrical insulation paper, printed circuit boards, and as separators for Li-ion batteries (Teijin 2016).

Carbon fibers

Carbon fibers, which are very strong relative to their weight, can be used for specialized applications via wet-laid forming (Saylor 1981). For example, some such fabrics can be impregnated with resin and made into parts for advanced aircraft. Though it is also common to prepare pre-impregnated woven textiles for such applications, the nonwoven fabrication method can allow for higher production rates and the use stiff fiber types that are difficult to weave. Karwa et al. (2012) employed carbon nanofibers for preparation of filtration media.

Regenerated cellulose fibers

Wide ranges of fiber length, denier, and morphology of cellulosic fibers can be provided by various processes of cellulose regeneration, followed by chopping. Viscose, a process that regenerates cellulose from sulfuric acid solution to produce RayonÒ fibers, is widely used for nonwovens (Gregg 1974; Woodings 1979; Floyd 1984; Wilke 1989; Hutten 1995; Maity et al. 2014). Wilke (1989) describes an innovative RayonÒ fiber having a tri-lobal cross-section, which can offer some performance advantages in absorbent products. The related lyocell fibers, which are regenerated from an n-methylmorpholine oxide (NMMO) solution, are also used in wet-laid nonwovens (Johnson 1996). Such products can offer high strength for such products as tea bags, wipes, and electrical papers. Riedel et al. (1996) describe the preparation of lyocell microfibers, which are said to have improved handling and can serve as a bonding agent in blends of other fibers wet-laid nonwoven products.

Flax and hemp

Among the non-wood plant-based fibers, flax has received much attention (DeJong 1999; Kohler and Nebel 2006; Fages et al. 2012, 2013; Maity et al. 2014). Use of hemp fibers has been described by Hutten (1995) and DeJong (1999). In each case the bast fibers are long and strong enough to meet the requirements of demanding end-use performance, and the cellulosic nature is helpful for achieving good fiber dispersion in water. DeJong used a chemimechanical pulping process and advocated using bast fibers from flax or hemp as a replacement for polypropylene or polyethylene fibers on some nonwoven products. Hervey et al. (1975) patented a process of partially acetylating flax fibers as a means to further improve their dispersibility in water.

Cotton

Cotton fiber usage in wet-laid applications requires careful consideration on account of its relatively high fiber length. Ordinary, unchopped cotton fibers have lengths of 22 to 36 mm, whereas cotton linters are about 12 to 15 mm long (Balaji 2015). Farer et al. (1998) described the blending of cotton fibers of different length to achieve suitable dispersion for wet-laid forming. Achieving good dispersion of very long fibers (>18 mm) remains a challenge for typical cotton fibers (Hervey et al. 1975; Farer et al. 1998). Gilmore et al. (1996) found that hydroentanglement technology (to be described later) was very well suited to the bonding of nonwoven sheets comprised of cotton fibers.

Wood pulp

Cellulosic fibers can play some important roles both during the production and usage of wet-laid nonwoven products. During the initial dispersion and forming of mats composed mainly of long synthetic fibers, the addition of wood pulp fibers, which are much shorter, in principle can decrease the tendency for fiber entanglement (Kerekes and Schell 1992, 1995). The substitution of a portion of the fibers with wood pulp fibers can be expected to decrease the entanglement tendency due to crowding among the fibers in suspension. In addition, if cellulosic material becomes adsorbed or draped over the surfaces of the hydrophobic fibers, then the more hydrophilic character of the cellulosic matter can be expected to help compatibilize fibers such as polypropylene with the aqueous medium. From a product standpoint, the cellulosic fibers can contribute to absorbency, a softer feel, bonding, and opacity, among other attributes.

Challenges

A variety of technical, economic, and environmental challenges need to be overcome in order to achieve commercially viable production of wet-laid nonwoven fabrics. In the face of environmental regulations, coupled with the large flows of water within a typical wet-laid process, some people have wondered whether wet-laid nonwoven production would become a thing of the past (Anon. 2005). Relative to conventional paper forming, which typically involves fibers solids levels of about 0.3% to 1.0% just before preparation of the sheet, formation of a nonwoven sheet often requires dilution levels that are 10× greater. As will be described later, excessive crowding of the fibers can be expected to yield clumping (i.e. flocs) and knot formation among the long fibers in the suspension. Due to the high aspect ratios of the chopped synthetic fibers that are typically used in nonwoven manufacture, there is a high potential for unintended entanglement of fibers into “ropes,” which then can become incorporated into the product as blemishes (Ramasubramanian et al. 2008). Measures to decrease the tendency of fibers to prematurely become entangled, such as high levels of dilution, as well as the use of surfactants, dispersants, and thickeners (see later sections), can all be regarded as potential sources of pollution when water is discharged from the production facility. Careful planning, testing, and implementation of water treatment systems will be needed to mitigate such problems.

The capital equipment needed for wet-laid processing can serve as a contributing barrier to entry into the manufacture of wet-laid nonwoven fabrics. It is worth noting that ordinary papermaking equipment is often ill-suited for the manufacture of products that have fibers longer than about 3 mm. For one thing, the slotted screens used in a typical paper mill for removal of large debris from the process can be expected to become clogged rapidly if longer fibers are present. To minimize such problems, wet-laid nonwoven systems generally omit such devices and employ equipment that has been designed especially for processing of relatively long fibers.

Process Overview

Key steps in the process of manufacturing a wet-laid nonwoven sheet have been reviewed by Angelini (1988). Procedures used during stock preparation, the flow of water in the approach system, and the headbox operations all play a critical role.

As noted by Hutten (1995), the amount of dilution water needed for such operations and initial dispersion and for forming of the sheet increases roughly with the square of fiber length. Thus, relatively large tankage and large pumping capacity is required in comparison to conventional papermaking of the same amount of dry mass per unit of time. The design and layout of equipment such as tanks, agitators, and piping, needs to be well planned to avoid vortices and flow restrictions that could promote entanglement of long fibers (Sholz 1985; Hutten 1995).

Forming section

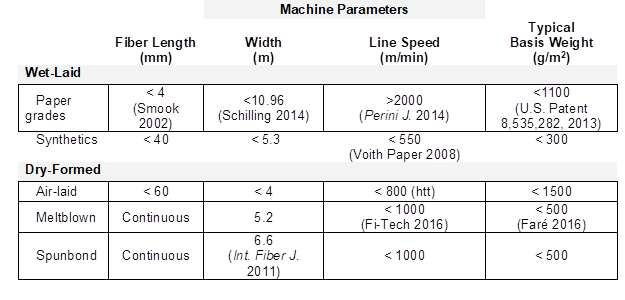

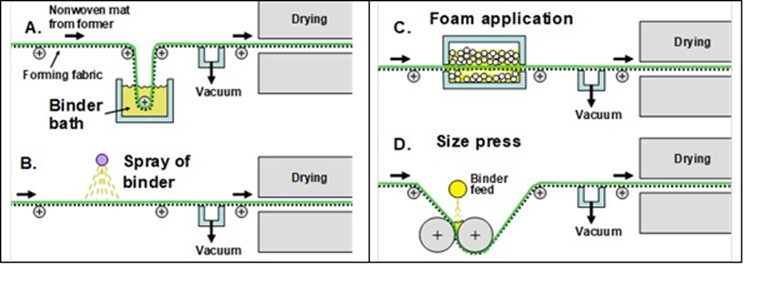

The sheet-forming equipment that is typically used for manufacture of wet-laid nonwoven fabrics differs in some characteristic ways from what is used for ordinary paper or paperboard products. Figure 1 illustrates some essential features of a so-called “inclined-wire Fourdrinier” system. Such devices, as well as some alternative versions of forming devices intended for wet-laid manufacturing, have been described (Saich 1969; Keller and Kroetz 1972; Schoffmann 1980; Scholz and Lasschuit 1981; Ahrens 1982; Fegley 1985; Scholz 1985; Angelini 1988; Dunn and Harke 1991; Schoeffman 1992; Schoffmann and Schwend 1992; Williamson 1993; Hutten 1995, 2007). As shown in Fig. 1, in an incline-wire system the fibers that will comprise the product are deposited onto a moving screen, which is often called the “forming fabric” or “the wire”. Typically such systems are designed so that the velocity of the approach flow approximately corresponds to the velocity of the forming fabric. By such means, the goal is to capture – in two dimensions – the same degree of uniformity that has been achieved in dispersing the fibers in the aqueous medium. Also, as noted by Ahrens (1982), it is possible to achieve an approximately random distribution of fiber orientations within the plane of the sheet (sometimes called a “square sheet”). Vacuum is used to facilitate rapid and controllable dewatering of the web.

Fig. 1. Schematic diagrams of typical equipment for preparation of wet-laid nonwoven fabrics. A: Inclined-wire forming equipment; B: Possible arrangement of chests and recirculation of process water. Figures redrawn based on concepts presented in US Patent 4,200,488 (1980).

Figure 1(B) shows how the forming section of the machine is integrated into a system. The lower right of the figure shows how water is recirculated via a fan pump so that the fibers can be in a highly diluted state during the forming operation. The system also includes tanks for dispersing the fibers (the pulper), for blending different types of fibers, and for feeding the mixture to the forming section.

As alternatives to the inclined-wire Fourdrinier equipment, the wet-laid sheet also can be formed on a rotating cylinder screen, which has provision for vacuum application from its interior (Gill et al. 1972; Dunn and Harke 1991). A variety of other specialized designs of formers have become available (Schoffmann 1980; Elliot 1987; Dunn and Harke 1991), especially for high-speed production of tissue-like products.

Once it is formed, a typical freshly-formed nonwoven sheet, especially if it does not contain cellulosic fibers, will be very weak. In contrast to plant-derived cellulosic fibers, typical synthetic fibers employed in wet-laid nonwoven manufacture are relatively non-conformable, and as a result the areas of close contact between adjacent fibers in a freshly-made nonwoven sheet will be relatively small. Furthermore, most of the synthetic fibers, with the possible minor exception of glass, lack the ability to form hydrogen bonds among the fibers during the drying process. Therefore, most wet-laid nonwoven operations include treatment of the freshly formed web with a bonding agent and/or the use of meltable or otherwise bondable fibers. The unit operations for strength development in wet-laid nonwovens have been reviewed (Scholz 1985; Parsons 1999).

WETTING

The first step in almost every implementation of wet-laid nonwovens processing is the placement of dry fibers into an aqueous solution. This step is reviewed in detail here due to its critical importance, relative to the quality of the final product. If the fibers happen to be cellulosic (from wood, cotton, flax, hemp, etc.), then the fibers may immediately become surrounded intimately on all sides by water. Such behavior can be attributed to the oxygen-rich surfaces of the fibers. Oxygen, often in the form of –OH groups, provides opportunities for numerous hydrogen bond associations with the surrounding water. Other fibers, such as ordinary polypropylene, polyethylene terephthalate (polyester), nylon, etc., generally lack oxygen or other polar groups on their surfaces and therefore do not interact strongly enough with water to promote easy wetting (Ring et al. 1977). If one places pure polypropylene fibers onto the surface of pure water, the fibers will appear to float. Water will not be able to work its way between the adjacent fibers to allow them to sink or to become dispersed. Because of this situation, treatments to increase fiber wettability can be regarded as among the most important of the chemical strategies affecting the overall success of the wet-laid nonwoven processing (Shiffler 1999).

Contact Angles and Wettability

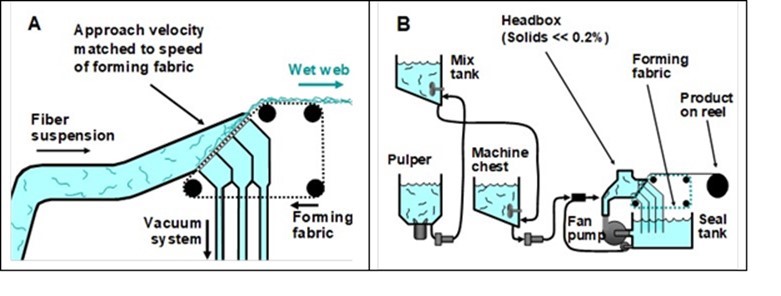

The wettability of a fiber and its ability to form a dispersion can be interpreted in terms of the contact angle of the aqueous solution with the surface of a monofilament fiber (Rebouillat et al. 1999). Figure 2 (A) defines the angle of contact (drawn through the liquid phase) in the case of surfaces that are either wettable of not wettable by pure water. As shown by the data presented in Part B of the figure, typical glass and cellulosic fibers have very low contact angles with water, and they are regarded as hydrophilic. By contrast, conventional polyethylene, polyester, polyamide, and polytetrafluoroethylene fibers yield water contact angles substantially greater than 90 degrees, and they are called hydrophobic.

Fig. 2. Wettability of water droplets on smooth surfaces. A: Definition of wettable vs. non-wettable surfaces; B: Water contact angles on selected surfaces. Data are from Lyne (1993).

Capillarity

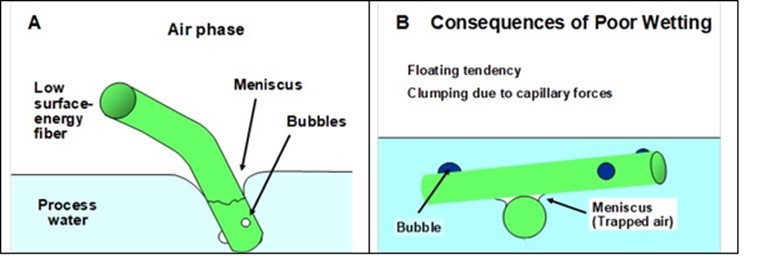

A hydrophobic type of fiber, when placed on the top of pure water, will give a contact angle greater than 90 degrees. This situation is depicted in Fig. 3(A). An adverse consequence of such a non-wetting tendency is that such fibers will tend to remain at the surface of pure water. This tendency can be compounded by the capillary effect illustrated in Fig. 3(B). Note that a trapped bubble of air at the junction between hydrophobic fibers in water will contribute to holding bunches of semi-dry fibers together in an arrangement akin to a floating raft. Interfacial forces, associated with the boundary between air and the aqueous phase, act to pull the adjacent fibers towards each other. The capillary force can be estimated by multiplying the surface tension of the aqueous solution times the estimated length of interfaces that intersect with the plane of interest.

Fig. 3. Schematic illustrations of problems related to the limited wettability by water of synthetic fibers such as polyethylene, polyester, polyamide, etc. A: Meniscus shape and air bubbles at fiber surfaces; B: Role of bubbles in holding hydrophobic fibers together in clumps

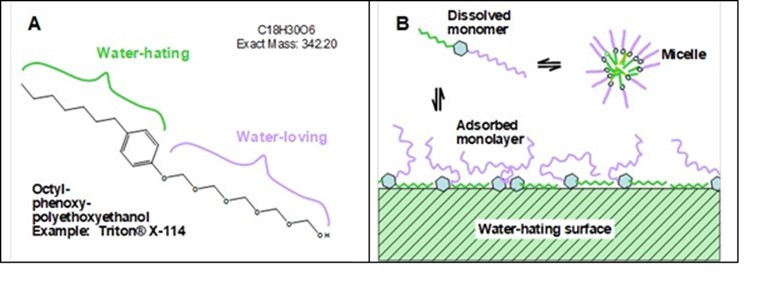

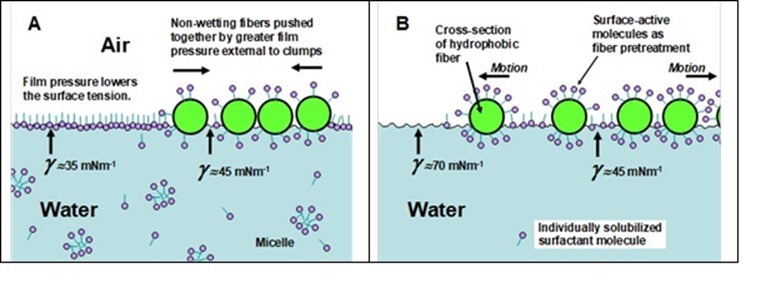

Surfactants

The situation described in the preceding paragraph can be overcome by the judicious use of surface-active agents, i.e. surfactants. Briefly stated, a surfactant is a molecule that contains both hydrophilic and hydrophobic moieties. Applications of surfactants in wet-laid nonwoven production have been explained in earlier articles (Stassen 1983; Cai et al. 2003). Surfactants have been shown to help achieve a good distribution of fibers in wet-laid nonwoven processing (Chakrabarti 1979a,b; Whichard 1985; Jakush 1991; Razak 1994; Ramasubramanian et al. 2008). An example of a surfactant widely used in wet-laid nonwoven manufacture is shown in Fig. 4 (A).

Fig. 4. Example of a surface-active molecule and its role in enhancing wettability. A: Molecular structure of octylphenoxypolyethoxyethanol, a commonly used wetting agent for wet-laid nonwoven fibers; B: Schematic diagram illustrating individually dispersed surfactant molecules, the formation of micelles, and adsorption onto a hydrophobic surface from water

Though in principle the water-loving group can be either ionic (having a fixed charge) or nonionic, it is the nonionic surfactants that are mainly being used as wetting agents in wet-laid nonwoven processing. Relatively short hydrophilic molecular chains having the composition –(CH2CH2O)n – are readily prepared by ring-opening polymerization of ethylene oxide in the presence of acid or base as a catalyst (Harris 1985). A wide range of hydrophobic groups, attached to the hydrophilic group, are in commercial use. Das et al. (2012) described the alternative usage of a cationic surfactant for dispersing of fibers for wet-laid forming.

Figure 4(B) illustrates the manner in which typical surface-active agents interact with the surfaces of hydrophobic solids in an aqueous suspension. As shown, the surfactant molecules can be expected to be present as an equilibrated mixture comprised of individually-dispersed molecules and micelles (Alexandridis and Hatton 1995; Prosser and Franses 2001). The hydrophobic parts of the molecules, represented by zig-zag green tails, tend to self-associate, allowing the hydrophilic portions of the molecule generally to face the aqueous phase. In addition, the surfactant will tend to associate with the hydrophobic solids (Cai et al. 2003), adsorbing in such a way that the hydrophilic parts of the molecules extend into the aqueous phase.

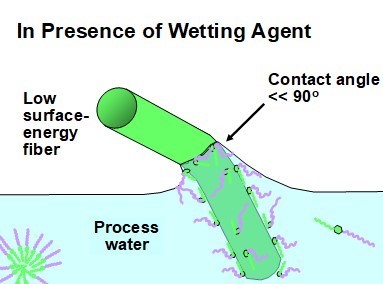

One of the functions of a surfactant (or wetting agent) is to compatibilize the two phases, essentially making the fiber surfaces act as if they had a higher surface free energy and an ability to form hydrogen bonds. Thus, in Fig. 5 one can envision the contact angle as having been transformed into a relatively low value. That situation allows the aqueous fluid (with surfactant present) to surround each fibers. Bundles of fibers are then able to sink into the suspending medium, and air bubbles entrapped within the bundles of chopped synthetic fibers are able to free themselves and rise to the water surface.

Fig. 5. Schematic illustration of the role of a surface-active agent in facilitating the wetting of a hydrophobic fiber

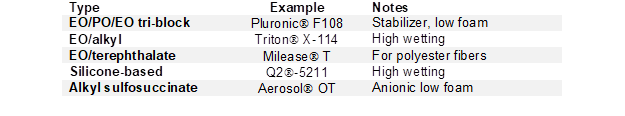

The selection of the type and dosage of surfactant involves a compromise between achieving wetting and excessive stabilization of foam. The combined use of both surfactants and water-soluble polymers (see later) in the aqueous phase can be regarded as being almost the worst situation if one wishes to avoid the stabilization of the foam bubbles (Karakashev and Grozdanova 2012; Fauser and von Klitzing 2014). Fortunately, by the judicious choice of the surfactant, the stabilization of bubbles can be minimized. Table 2 gives examples of some widely used surfactants. In general terms, the characteristics of a surfactant can be predicted by comparing the lengths or efficiencies of the water-hating groups versus the water-loving group, i.e. the hydrophile-lipophile balance (HLB). Good wetting agents for most wet-laid nonwoven applications will have HLB values in the range of 7 to 9 (Swarup and Schoff 1993).

Table 2. Examples of Surface-active Agents Use to Enhance the Wetting of Hydrophobic Fibers Used in Wet-laid Manufacture

Key: EO = ethylene oxide; PO = Propylene oxide

As illustrated in Fig. 6, it can be advantageous in some situations if at least some of the surfactant is initially on the dry fibers rather than all present in the aqueous phase. The key to understanding Fig. 6 is that several seconds may be required for surfactant molecules to migrate from the bulk of solution to a freshly-created air-water interface. Once at the interface, such molecules contribute to a film pressure, which reduces the value of surface tension at that location. Thus, in Fig. 6(A), if there is little or no surfactant initially present on the fiber surfaces, or alternatively if there is a lot of surfactant already in the aqueous system, then there may be a momentarily greater level of surfactant at the air-water interface toward the outside of the fiber bundles, compared to within them. This situation will tend to force the adjacent fibers towards one another during the critical moments when one is attempting to disperse the fibers in water. By contrast, if there is momentarily a higher amount of surfactant within the fiber assembly (as in Part B of the figure), then the film-pressure of surfactant at the water-air interface will tend to force the fiber bundles apart. Note that the two-dimensional pressure of adsorbed surfactant molecules will act to decrease the surface tension of the water at that location. Over a longer period of time the effects just described will diminish to zero as the amounts of surfactant adsorbed at interfaces throughout the system approach equilibrium.

Fig. 6. Schematic illustration showing how (A) a build-up of surface-active molecules in the process water may tend to cause the hard-to-wet fibers to remain as clumps floating on the surface during the critical initial moments of the mixing process, whereas (B) pretreatment of hard-to-wet fibers with surface-active molecules can help push the fiber bundles apart during initial wetting

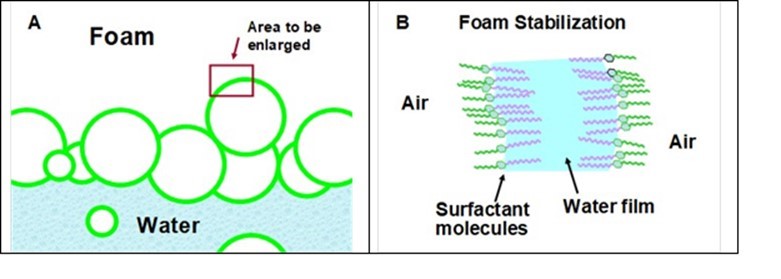

Foam and Defoamers

In addition to the desirable effects of surfactants in promoting the wetting of various hydrophobic fiber materials, surfactants also can stabilize foam bubbles (Avery-Edwards et al. 1994). Foam can be a serious problem in wet-laid nonwoven forming, especially when there is an effort to reuse the process water multiple times. Figure 7 provides a schematic view of how this happens. Part A of the figure envisions a bank of foam floating on the surface of an aqueous system. If one were able to peer within the microscopic scale of the wall of one of the bubbles, a cross-sectional view might resemble what is shown in Fig. 7(B). Note that the wall of a bubble suspended in air will consist of a bi-layer of surfactant molecules enclosing a thin film of water. Given sufficient time, the liquid in the film will tend to drain towards the bottom of a bubble in response to gravity. If one closely observes the kind of bubbles used at parties for children, a floating bubble often will gradually change colors and then turn colorless before it breaks. The colors can be attributed to the interference with certain wavelengths of light that are close to a specific fraction of the thickness of the bubble walls. The changes in color are consistent with decreases in thickness. The transition to colorlessness occurs when the thickness decreases below the lengths associated with visible light. The tendency to stabilize bubbles, either at the surface of water or when the bubbles are entrained in the solution, depends greatly on the detailed characteristics of the surfactant, in addition to other factors such as temperature and the presence of dissolved macromolecules (Karakashev and Grozdanova 2012).

Fig. 7. Schematic illustration of foam bubbles (A) and the manner in which surfactant molecules stabilize foam (B)

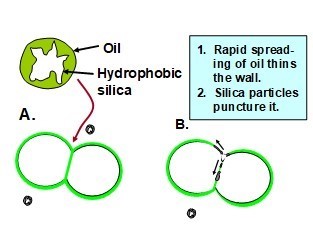

Defoamer chemicals are widely employed in wet-laid nonwoven manufacture in order to avoid excessive levels of entrained bubbles and/or floating foam (Twoomey 1987; Jakush 1991; Avery-Edwards et al. 1994). Figure 8 illustrates the action of a typical droplet of an emulsified defoamer product. As shown in this illustration, the droplet diffuses randomly in the suspension until it contacts the walls of a pair of bubbles in the suspension (Karakashev and Grozdanova 2012). Once reaching the interface, the surface-active compound in the defoamer product will tend to spread very rapidly in the plane of the bubble wall. If the defoamer droplet contains hydrophobic particles, such as hydrophobized silica particles, then the rapid spreading of the defoamer’s surfactant at the interface will cause such particles to pierce the bubble walls and allow adjacent bubbles to coalesce. Such action, when repeated multiple times, will transform small bubbles into large bubbles that rise to the surface of the aqueous phase and pop.

Fig. 8. Schematic illustration (A) of an anti-foam emulsion droplet in the water phase approaching the Plateau border region of a pair of bubbles; and (B) rapid spreading of the water-insoluble surface-active agent within the bubble walls, tearing an opening between the pair of bubbles

While defoamer chemicals can be very helpful for foam management, there can be some downsides, in addition to their cost. Ring et al. (1977) found that unspecified defoaming agents contributed to the flocculation of long fibers. Lickfield and Liu (1993) found that a silicone-based defoamer product interfered with the action of latex binders added later in the process.

DISPERSION OF FIBERS

Once each individual fiber added to the blend chest in a wet-laid processing system has become surrounded on all sides by water, i.e. wetted, the next step is to separate the adjacent fibers from each other. In the case of typical cellulosic fibers, as well as some glass fibers and some fibrillated synthetic fibers (Merriman 1981; Smith 1988a,b; Evans and Pfeiffer 1992), which are generally hydrophilic, such dispersion may occur almost spontaneously as soon as the fibers have been wetted. But in the case of hydrophobic fibers, hydrodynamic shear and the addition of chemical agents known as dispersants are required (Miller 1996).

The kinds of synthetic fibers most often used in wet-laid nonwoven fabrics manufacture are prepared by the chopping of bundles of continuous filaments to produce staple fibers. Thus, even after the wetting of each individual fiber, one still may face a challenge in separating the bundles of fibers (sometimes called “logs”) into separately dispersed fibers (Shiffler 1985, 1986, 1988, 1999; Latifi et al. 2008; Ramasubramanian et al. 2008; Fages et al. 2013). Fiber separation can be especially a problem in the case of crimped fibers (Ring et al. 1997; Reese and Cooper 2002). If efforts to disperse fiber bundles are unsuccessful, then the wet-laid product will appear non-uniform, and its properties may fail to meet expectations. In addition, the mass per unit area of the product may differ from location to location (Keller et al. 2012).

Particular difficulty in dispersing fiber bundles into the components fibers can be encountered if the ends of adjacent cut fibers had become fused together in the course of chopping. The quality of cutting of fibers intended for other usages is often not good enough to meet the demands of wet-laid forming (Bourdon 1971; Brandon et al. 1988; Shiffler 1988, 1999; Williamson 1993; Keith 1994). Fusing of the ends of chopped fiber may happen, for instance, if the temperature of the chopping blades exceeds the melting temperature of the fiber material. Dull chopping equipment can make it more likely that the ends of the fiber bundles become fused and resistant to separation. The critical nature of cut quality tends to raise the costs associated with acquisition of suitable quality fibers for wet-laid nonwoven applications.

Critical Force Concept

Two critical factors in the dispersing of fibers, in preparation for nonwovens processing, are hydrodynamic shear and the use of dispersant chemicals. The topic of hydrodynamic shear will be considered first.

According to Shiffler (1999) the resistance to dispersion of a bundle of chopped fibers can be envisioned as the sum of contributing factors. These factors include adhesive forces between the fibers, capillary effects, inter-fiber friction, and various problems related to the ends of fiber bundles. It follows that there ought to be a certain level of hydrodynamic shear that is just sufficient to cause separation of individual fibers from a typical fiber bundle. Indeed, Shiffler (1985) found that the rate of bundle breakup increased with increasing speed of agitation. Latifi et al. (2008) proposed that for each type of fiber and set of aqueous conditions there is likely to be an optimum level of hydrodynamic shear that is just enough to disperse the fibers. Ideally this can be accomplished without inducing other problems, such as entanglement, which will be considered in a later section. Ramasubramanian et al. (2008) carried out computational fluid dynamics modeling, along with experimental study, to verify and quantify the general concept of fiber dispersion, along with some other concepts. Switzer and Klingenberg (2003) found that shear flow was effective for disrupting fiber bundles, whereas extensional flow resulted in only partial dispersion of fibers, but left many fragments intact. Safavi et al. (2009) found that although the frequency of defects related to fiber entanglement tended to increase with both fiber length and fiber fineness, at constant solids content of the suspension, the speed at which hydrodynamic shear was able to disperse the fibers was also increased with increasing fiber length and fineness.

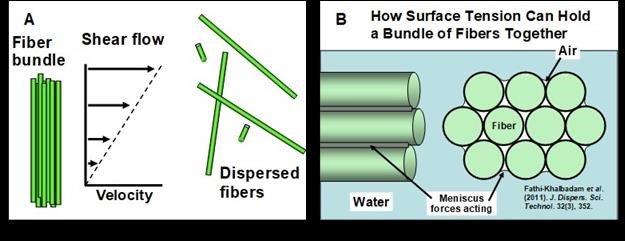

Figure 9(A) presents an idealized view of the actions of localized hydrodynamic shear flow in bringing about dispersion of bundles of parallel chopped synthetic fibers. The idealized shear flow assumes a steady gradient of velocity with distance perpendicular to the axis of flow.

Fig. 9. Schematic illustration of bundles of chopped fibers. A: Hydrodynamic shear forces help separate such bundles by overcoming the mechanical factors, adhesion forces, and capillary forces holding them together; B: Illustration of how surface tension forces tend to hold a bundle of fibers together, especially if they are difficult to wet by water.

In theory, the separation will take place quickly if and when the applied hydrodynamic force exceeds the combined effects of mechanical fusion, attractive forces, capillary effects, and friction. Figure 9(B) illustrates how pockets of air located within a bundle of hydrophobic fibers can be expected to act in holding the bundle together. The attractive force will be approximately proportional to the surface tension of the aqueous phase, as affected by surfactants and other solutes.

Fiber dimensions

As one would expect from the mechanism just described, fiber dispersion has been found to vary a lot between different types and batches of synthetic fibers that have been prepared for wet-laid nonwoven applications. In general, the length of fibers used in wet-laid forming is restricted to about 10 mm or less (Lichstein 1988). The presence of even a minority of excessively long fibers can give rise to a kind of defect known as “dumbbells” or “double-knubs” (Schoeffmann 1992; Shiffler 1988, 1999). Such defects consist of pairs of clumps of fibers joined together by at least one over-length fiber.

Thicker fibers tend to be more difficult initially to disperse (Safavi et al. 2009). Likewise, Fathi-Khalfbadam et al. (2011) found that with increasing fiber diameter it was necessary to apply agitation for a longer time in order to adequately disperse the fibers. This tendency can be attributed to increased stiffness of the thicker fibers.

Clark and Shiffler (1985) proposed that the cross-sectional shape of a fiber can influence its ability to disperse in water. Fibers prepared with a scalloped-oval cross-section were found to disperse in water more readily than similar fibers having a round cross-section. Other properties that can be affected by fiber cross-sectional shape include softness and the wicking of water in absorbent products (Clark and Shiffler 1985; Ezaki 1988; Haile and Phillips 1995).

Capillary forces

If air remains within the fiber bundle, then the hydrodynamic force needed to separate the fibers can be estimated based on the situation illustrated in Fig. 9(B). As shown, one can expect that the surface tension at the air-water interface will be acting to hold the fibers together as a bundle. The difference in pressure tending to hold a bundle of fibers together can be estimated from the relationship,

DP £ 2g/RL (1)

where P is the pressure difference pulling adjacent fibers together, g is the surface tension of the aqueous solution, and RL is the radius of the fiber bundle, which is treated as being cylindrical. Also, the fibers are assumed to be sufficiently hydrophobic such that the contact angle of aqueous solution on the fibers surfaces is 90 degrees or higher.

Capillary forces, as just described, can be expected to oppose separation of fiber bundles in two ways. On the one hand, they can act to prevent outward lifting or peeling of a fiber away from the perimeter of the bundle. In addition, due to friction between the fibers, the inward-directed capillary forces also will tend to resist a sliding mechanism of fiber separation. Ideally, frictional resistance to sliding can be expected to be governed by the product of the capillary force drawing the fiber bundle together and a coefficient of friction (Shiffler 1999).

Though it may be unrealistic to attempt to calculate the precise hydrodynamic conditions needed to separate a bundle of chopped fibers, all of the mechanisms summarized above point to a common theme: There ought to be a threshold of force needed to separate individual fibers from the bundle. Alternatively, a random distribution of resistance to detachment may make it necessary to exceed the highest threshold in the distribution.

Time and flow patterns

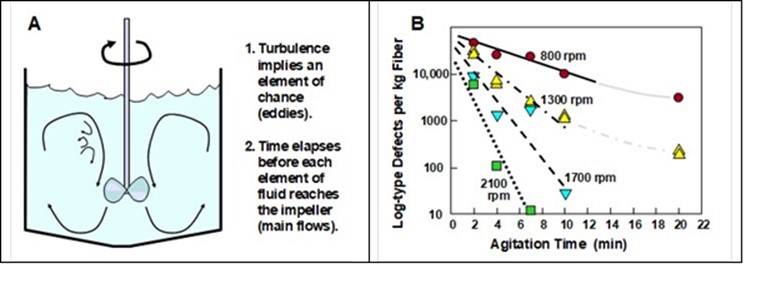

The force-threshold concept, as just introduced, suggests that one ought to apply a very short spurt of agitation at high intensity. In practice, however, it has been observed that several minutes of agitation with an impeller may be needed to achieve nearly complete dispersion of fiber bundles in a tank (Shiffler 1988; Latifi et al. 2008; Safavi et al. 2009; Fathi-Khalfbadam et al. 2011). The likely reason for this time dependency can be understood by considering the diagram in Fig. 10(A).

As shown, at any given time only a small fraction of the fibers in the mixing tank can be near to the impeller, which would be the point of greatest hydrodynamic force. In addition, the presence of eddies of turbulent flow introduce an element of chance. With the passage of time it becomes more and more likely that each fiber in the mixture has come close to the impeller. However, as will be discussed later, an excessive amount of time of agitation can be expected to lead to fiber entanglement and to formation of flocs (Das et al. 2012). Thus, one can expect that both the intensity and duration of agitation will need to be optimized in typical cases in order to meet the goals for fiber dispersion in a given application (Shiffler 1988; Richardson et al. 1988; Latifi et al. 2008).

Fig. 10. Effect of time on the dispersion of bundles of chopped fibers. A: Schematic explanation of why time is required for essentially all parts of the mixture to have been exposed to high hydrodynamic shear at the tips of the impeller. B: Data showing effects of agitation speed and mixing time on the numbers of bundle-type defects observed in wet-laid product (replotted from the findings of Shiffler 1988).

The concept just introduced is supported by the data shown in Fig. 10(B), which is replotted from the work of Shiffler (1988). As shown, the frequency of bundle-type defects in a nonwoven product decreased sharply with increasing time of agitation during preparation of the slurries. In addition, the rate of decrease in defects was a found to be a strong function of the speed of agitation. This makes sense because stronger agitation will tend to bring different parts of the suspended material more quickly to the neighborhood of the impeller blades, and also a higher volume of the system, at any one time, will be exposed to shear forces exceeding a threshold level.

Chemical Aspects

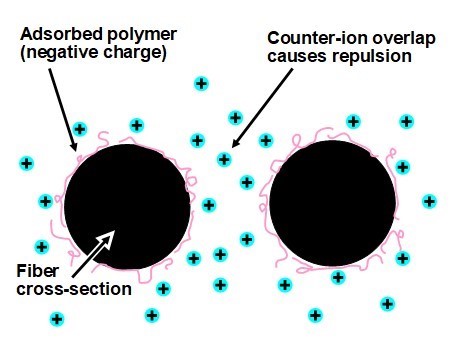

One of the most fundamental mechanisms by which solids in a suspension can be kept from agglomerating together involves electrostatic repulsive forces. This charge stabilization mechanism is important, for instance, in the case of glass fibers in aqueous suspension. Glass develops a negative ionic charge at its surface due to dissociation of silanol groups (Berli et al. 2003; Atalay et al. 2014). However, charge-stabilization can be achieved with essentially any kind of fiber, since a negative charge can arise by adsorption of anionic dispersants or adsorption of certain kinds of surface-active agents.

Figure 11 illustrates the manner in which ions of opposite charge, i.e. counter-ions, tend to gather adjacent to a charged surface in aqueous solution. Here we imagine ions such as sodium, potassium, and calcium ions in the solution very close to the surfaces of synthetic fibers that have been stabilized by the adsorption of negatively charged polyelectrolyte molecules. The figure represents only those positively charged ions that are playing the role of balancing the net negative charge of the surface. The positions of such ions are governed by two opposing tendencies: Electrostatic attraction causes the ions to migrate in the direction of the opposite charges at the fiber surfaces. But thermal energy causes the ions to diffuse randomly in all directions. The net effect is that counter-ions will be present as a type of “atmosphere” at the fiber surfaces. In principle, electrostatic repulsion can be expected whenever like-charged double-layers come close enough (generally within a few nanometers) to overlap significantly.

Fig. 11. Schematic illustration of overlap of ionic double-layers, resulting in charge-induced repulsion between fibers immersed in aqueous solution

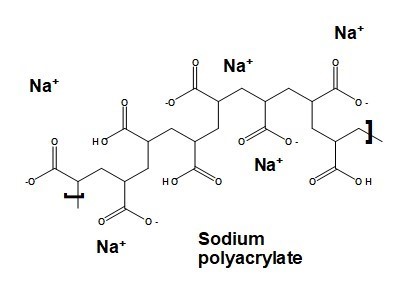

Dispersants

Chemical-based strategies to promote the dispersal of fibers from each other after wetting has been achieved generally rely on electrostatic forces of repulsion. Addition of dispersants, such as polyacrylates, to the aqueous solution can be quite effective (Jansma and Smith 1993; Miller 1996). In principle, the negatively charged polymer chains adsorb onto fiber surfaces in sufficient amount to impart a strong negative charge. Addition of a dispersant at an excessively high concentration can actually decrease its effectiveness (Huang et al. 1991; Briscoe et al. 1998; Chen et al. 2014). The dosages of dispersing agents need to be optimized, since excess dispersant in the process water can be regarded as a contribution to the pollution load when the water is eventually discharged from the system.

Figure 12 illustrates the structure of a typical polyacrylate dispersant. In this figure some of the carboxyl groups are shown as being protonated, whereas others of them are shown in their dissociated, sodium acrylate form. The ratio between the two forms of carboxyl groups on such a molecule will depend on the pH. When the pH equals the pKa value, which is typically near to 6.8 for this kind of macromolecule, there will be an equal number of negatively charged and uncharged carboxyl functions (Charman et al. 1991). As the pH is increased above that point, the dispersant molecule becomes more fully anionic.

Fig. 12. Typical molecular structure of a sodium polyacrylate dispersing agent

Order of addition

Because conventional wet-laid nonwoven production can include addition of several different additives, such as dry fibers, surfactants, dispersants, and thickeners, among others, it is reasonable to expect that somewhat different results can be achieved depending on the order of addition (Richardson et al. 1988). Brandon et al. (1985) patented a process in which fibers were added to a solution containing only water and a dispersant, for the purpose of maximizing the effectiveness of breakup of bunches of fibers, and then a thickener was added later. Likewise, Jakush (1991) stated that thickener products tend to impede the action of dispersants. Nonetheless, they found that the ratio between the two kinds of additives could be adjusted to achieve more favorable results.

Sizing agent and spin finishing

In light of the challenges just discussed in bringing about the initial dispersion of fibers, many suppliers of chopped synthetic fibers intended for wet-laid processing treat the fiber surfaces in advance to promote dispersibility. The pre-application of surface-active agents was already suggested in Fig. 6 and the related discussion. In addition, lubricants may be applied to the fiber surfaces (Reese and Cooper 2002). The fiber-dispersion-promoting agents listed as background information in the cited patent range from surfactants to block co-polymers having pendant ethylene-oxide chains. Clark and Shiffler (1985), likewise, give citations supporting the use of block copolymers of ethyleneterephthalate and ethylene oxide as sizing agents to promote later dispersion of dry fibers after their delivery to the point of use.

Spin finishing (also referred to as lubrication) is a well-known process for modifying the physical properties of synthetic fibers before they are chopped (McIntyre 1968). Bajaj (1997) has reviewed of spin finishing methods and chemistries and states that it is one of the most important variables influencing the performance, quality and uniformity of processing synthetic fibers. Typical chemistries used in spin finishing include lubricants, emulsifiers, and antistatic agents (EPA 1997). Lubricating agents include animal, vegetable, and minerals oils; fatty acid esters such as methyl oleate and butyl stearate; non-ionic surface active agents such as ethylene oxide adducts of fatty acids or fatty acid esters of higher or polyhydric alcohols; and anionic surface active agents such as alkyl sulfates, alkyl phosphates, and fatty acid salts. Antistatic agents include alkyl phosphates and sulfates, as well as cationic surface active agents such as quaternary ammonium salts (Kawanaka et al. 1974). Water-soluble polymers such as polypropylene glycol and polyalkylene glycol can also be used impart lubricity to the fiber (Dow 2106). Add-on weights of active ingredients in spin finishing are typically less than 5% by weight. Lubricating agents modify fiber-to-fiber friction and are used to minimize falling-out of fibers during the drawing process (Kawanaka et al. 1974). In wet-lay applications, it has been shown that staple fibers spin finished with an emulsion made principally from an ethoxylated castor oil promoted fiber dispersion (Hawkins 1979).

AVOIDANCE OF ROPING

One of the great challenges inherent in wet-laid nonwoven processing is that the same hydrodynamic forces that are essential for initial dispersion of synthetic fibers can also promote fiber entanglement and the formation of ropes (Shiffler 1988; Smith 1992; Ramasubramanian et al. 2008). In particular, vortexes of flow are known to favor rope formation (Shiffler 1986, 1988; Ramasubramanian et al. 2008). Depending on the nature of the fibers, such entanglement may be difficult or impossible to reverse. It has been recommended, therefore, to avoid or suppress vortex flow (Ramasubramanian et al. 2008). Also, it has been recommended to avoid application of shear stress that is in excess of what is needed to disperse the fibers (Das et al. 2012). In principle, high levels or shear, beyond what are needed, will tend to momentarily bend the fibers. Then, as the elasticity of the fibers acts to straighten them again, they may become locked into persistent floc structures that are held together by a combination of elastic forces and friction between the adjacent fibers (Parker 1972; Hubbe 2007).

Crowding Factor Concepts

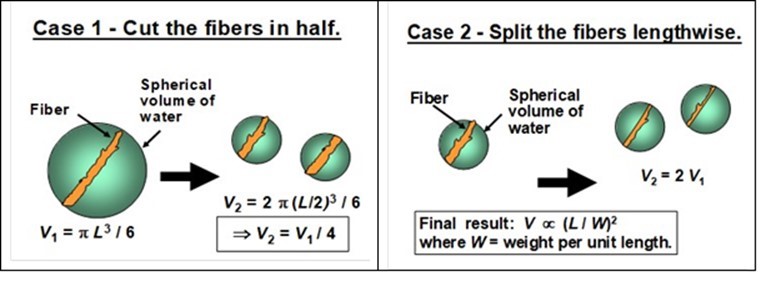

In principle, entanglement among fibers in suspension can be avoided by providing each fiber with sufficient space so that it can rotate in any direction without coming into contact with any of its neighbors. In practice, it is seldom practical to employ such a high dilution of fibers as implied by that statement. However, the idea of having enough volume so that each fiber can rotate freely without colliding with other fibers has been found useful for predicting the flocculation tendency of different fiber suspensions (Kerekes and Schell 1992, 1995; Williamson 1993; Hutten 1995). Kerekes and Schell (1992, 1995) showed that a crowding factor can be defined as follows,

NC = (2/3) Cv (L / d )2 (2)

where Cv is the volume-based concentration of fiber material in the suspension, L is the fiber length (assumed to be uniform), and d is the fiber diameter. It was predicted that an NC value of 60 was sufficient for there to be an average of three contact points per fiber, allowing the onset of structure formation (Kerekes and Schell 1992).

It follows from Eq. 2 that the required amount of dilution water to keep the value of NC below a defined limit will increase as the square of the ratio of L over d (Hutten 1995). To illustrate how the equation can be used, Fig. 13 considers two examples. In “Case 1” one imagines what would happen if it were possible to reduce the length of each fiber by cutting them in the middle. As indicated in the figure, the net volume of rotation occupied by all of the fibers in the suspension would then be decreased by a factor of four. By contrast, “Case 2” shows that the net volume occupied by the rotating fibers would be doubled if each fiber in the suspension were to be split lengthwise.

Fig. 13. Illustration of ways in which “cutting” of fibers can be expected to affect the crowding factor, hence affecting the clumping tendency and the required dilution. Case 1: Cutting all the fibers in half would decrease the occupied volume due to rotation of fibers by a factor of four. Case 2: Length-wise splitting of fibers would increase the occupied volume by a factor of two.

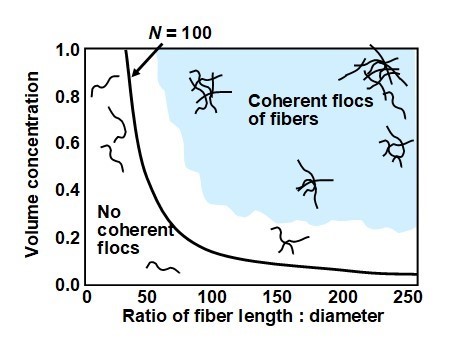

Based on the analysis just presented, it follows that one of the most promising ways to decrease the flocculation tendency of a fiber suspension would be to shorten the fibers, assuming that other parameters, including that the volumetric content of fiber material, remains constant. Alternatively, one could utilize coarser fibers of the original length. But when product goals require the usage of long, slender fibers, then high levels of dilution would be essential. Figure 14 gives an example of calculated results corresponding to a crowding number of 100 (Soszynski and Kerekes 1988). Above that number it is assumed that coherent flocs will become common in the fiber suspension. Below that number one expects there to be few persistent flocs. As shown in the figure, the ratio of fiber length to diameter, i.e. the aspect ratio, plays a very large role in determining whether coherent flocs of fibers are likely to be important at a given level of fiber solids.

Though most published literature related to the crowding factor concept has been aimed at conventional papermaking applications, various studies dealing with wet-laid nonwovens have provided support for the concept of fiber crowding (Scholz and Lasschuit 1981; Kinn and Mate 1986; Keith 1994; Ramasubramanian et al. 2008). For instance, Das et al. (2012) showed that nonwoven fabrics made up of shorter and coarser fibers tended to be more uniform in comparison with those prepared with fibers that were longer and finer.

Fig. 14. Effects of fiber volume concentration and aspect ratio on whether or not persistent flocs are present. Data replotted from the work of Soszynski and Kerekes (1988)

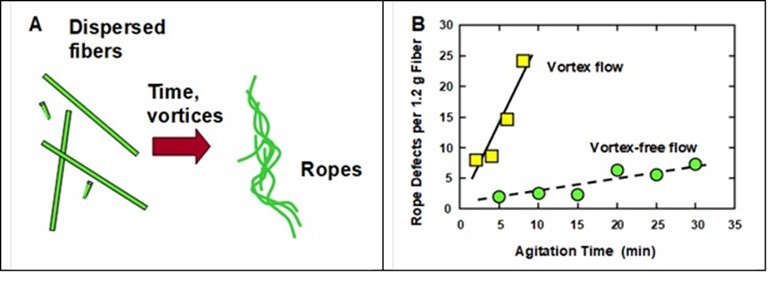

Vortex Effects

A vortex can be defined as a cyclone-like twirling motion of fluid surrounding a funnel-shaped core of air. Vortex flow can easily form in stirred tanks, especially if a centrally located impeller draws fluid downward with a high enough rate of rotation. It has been reported that vortex flow can be a cause of rope formation during preparation of fiber suspensions for wet-laid processing (Tafreshi and Pourdeyhimi 2003; Ramasubramanian et al. 2008). This is illustrated schematically in Fig. 15(A). It is possible that such ropes could form by the kind of twisting mechanism suggested by Nanko and associates (Nanko et al. 2006; Hubbe et al. 2009). Tafreshi and Pourdeyhimi (2003) carried out numerical simulations and experimental tests to help clarify the mechanisms underlying such observations.

Fig. 15. A: Illustration of the formation of “ropes” due to entanglement of long fibers, especially in cases where vortex flow is present during mixing. B: Effect of agitation time on the frequency of rope-type defects, in the presence or absence of vortex flow. Data replotted from Shiffler (1999)

Evidence of the role of vortex flow in generating rope defects in a wet-laid nonwoven system is presented in Fig. 15(B) (Shiffler 1999). As shown, in the presence of a distinct vortex a rapid increase was observed in the number of rope defects for a given mass of fibers. Stirring in the absence of vortex flow also gave an increase in rope defects with time, but the rate of rope formation was very much smaller.

It has been reported that vortex development can be inhibited by increasing the viscosity of the fluid (Wilharm 1986). While there is no reason to doubt the validity of using thickeners to repress vortex flow, it is worth keeping in mind that flow patterns are highly dependent on the setup of the equipment. A vortex is less likely to develop, at a given speed of rotation, if the axis of rotation of the impeller is placed away from the center of the tank. Ramasubramanian et al. (2008) carried out experiments to determine the relative state of entanglement of fibers collected from different parts of a stirred tank that was provided with baffles. Samples were collected onto screens dipped quickly into different locations of a stirred tank. Defects related to entanglement were 43% more frequent in the region behind the baffles, where vortex flow was present, in comparison with the center of the tank.

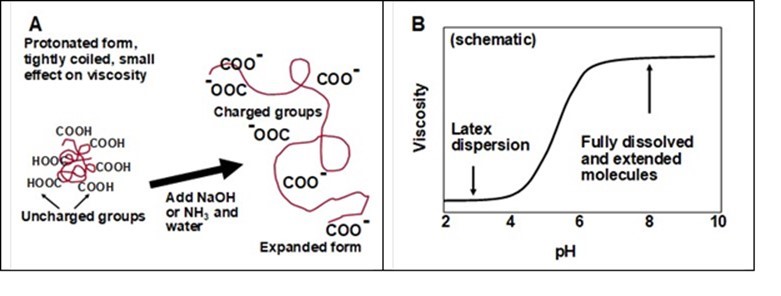

Thickeners

Many studies have shown that one of the most effective ways to reduce the tendency of long fibers to form ropes and fiber bundles is to add very-high-mass soluble polymers, i.e. thickeners, to the aqueous medium (Wasser 1978; Wilharm 1986, 1990; Wilharm et al. 1987; Richardson and Smith 1989; Smith 1992; Miller 1996; Nedwick and Greenblatt 1996; Farer et al. 1998). Further evidence of the effectiveness of thickeners in making wet-laid products more uniform is provided in patents (Brandon et al. 1980a,b, 1985; Richardson et al. 1990). One of these patents specifies ranges of viscosity that should be achieved in the solution (Brandon et al. 1980a). As summarized in the subsections below, thickening agents can have a variety of chemical compositions. Some are ionically charged – usually anionic. But a common feature is that they are highly water-soluble and capable of increasing the solution viscosity. Acrylamide copolymers, carboxymethylcellulose (CMC), and various natural gums have been considered as thickeners for formation of sheets from long fibers.

For centuries practitioners of certain handcraft papermaking traditions have employed natural gums, including slime from the roots of Hibiscus manihot. These gums have been used to prepare high-quality paper from relatively long bast fibers (Swanson 1950; Huber and Weigl 1970; Seibert and Bähr 1970; Hubbe and Bowden 2009). Among natural gums, deacetylated karaya gum has been found to be especially effective as a formation aid (Hervey et al. 1975). Dissolved CMC has also been shown to be effective as a thickener (Giri et al. 2000). The cited authors showed that CMC remained effective even in the presence of moderate concentrations of salt ions.

In modern times various acrylamide copolymers have emerged as the most widely used agents to suppress fiber entanglement in wet-laid manufacture (Wasser 1978; Smith 1986; Wilharm 1986; Richardson et al. 1988; Lee and Lindström 1989; Farer et al. 1998). Richardson et al. (1988) showed that polymer ionic charge, molecular mass, and especially that dosage all had important effects.

Figure 16 represents the chemical composition and swelling tendency of a typical thickener macromolecule. In some important aspects, the chemistry of such a thickener molecule is similar to that of the dispersant molecule represented earlier in Fig. 12. Key differences are that a typical thickener can contain about 50 to 95% of neutral, unsubstituted acrylamide monomer units and the molecular mass can reach up to 20 million Daltons (Lee and Lindström 1989). As shown in Part A of the figure, the molecular extension in solution is expected to be highly pH-dependent. The net effect will be an increased viscosity with increasing pH in a range of about 4 to 8, as shown in Part B of the figure.

Fig. 16. Effect of pH on the macromolecular chain extension (A) and viscosity (B) of a solution of anionic high-mass polyelectrolyte (thickener)

It has been reported that the effectiveness of thickening agents can be decreased markedly in the presence of salt, with particularly adverse effects attributable to divalent cations such as Ca2+ (Wilharm et al. 1987; Charman et al. 1991; Shiffler 1999). Such effects are attributable to the kind of conformational change illustrated in Fig. 17. A condensed conformation of the macromolecule will express itself as a much lower contribution to the viscosity of a solution. Also, there will be a reduced ability of the solution to resist the formation of ropes in an agitated suspension of long fibers.

Fig. 17. Schematic diagram illustrating the expected effect of salt addition on the conformation of a very-high-mass anionic polyelectrolyte (thickener)

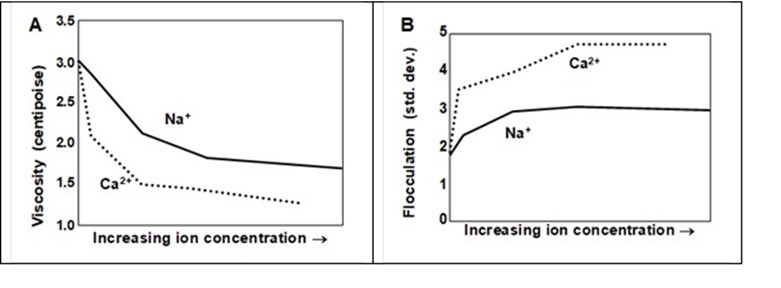

Figure 18 compares the effects of Na+ and Ca2+ ions with respect to solution viscosity (Part A) and the degree of fiber flocculation (Part B) (Shiffler 1999). A greater adverse effect of the divalent cation is apparent.

Fig. 18. Effect of monovalent and divalent ion concentration on the viscosity of the solution (A) in a long-fibers suspension stabilized by anionic very-high-mass polyelectrolyte, and (B) the corresponding degree of flocculation

Associative thickeners

One strategy to boost the effectiveness of thickeners is to modify the copolymerization so that some long-chain alkyl (hydrophobic) groups are included, along with anionic or neutral hydrophilic acrylamide units. Such products, called associative thickeners, have been shown to be effective for inhibiting the entanglement of long fibers (Tse et al. 1989; Nedwick and Greenblatt 1996). Because such products have a surface-active character, it may be unnecessary or even unhelpful to separately add surfactants to achieve initial wetting of the fibers (Tse et al. 1989).

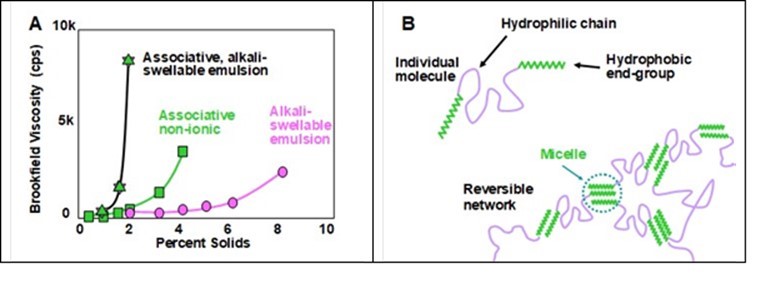

Figure 19 (Part A) redrawn from Rohm & Haas product literature shows some examples of how the viscosity of an aqueous solution was increased with increasing concentration of different macromolecular thickening agents.

Fig. 19. Associative thickener effects. A: Example in which an anionic associative thickener achieved a higher viscosity at lower solids compared to a non-ionic associative thickener and an ordinary alkali-swellable emulsion; B: Principle by which transient cross-linking among molecules of an associative thickener induce high viscosity

Fig. 19. Associative thickener effects. A: Example in which an anionic associative thickener achieved a higher viscosity at lower solids compared to a non-ionic associative thickener and an ordinary alkali-swellable emulsion; B: Principle by which transient cross-linking among molecules of an associative thickener induce high viscosity

Notably, in the cases shown, a specific associative, alkali-swellable thickener outperformed a non-ionic associative thickener and an ordinary alkali-swellable emulsion product. Part B of the figure provides a mechanistic explanation. As shown, the hydrophobic groups of the thickener molecules are able to form transient cross-link points, which make the molecules behave like they are part of a huge interconnecting network.

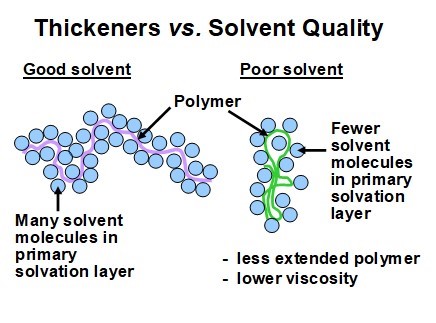

Nonionic thickeners

All of the thickeners discussed so far have been ionically charged. Such products have an inherent tendency to be adversely affected by ions – especially multivalent ions of opposite charge – in the aqueous solution (Shiffler 1999). One strategy to avoid such problems is to employ a non-ionic polymer thickener such as polyethylene oxide (Seibert and Bähr 1970; Ashikaga 1972). Seibert and Bähr (1970) found that PEO was more effective than many other prospective polymer solutions for the preparation of handmade paper from long fibers. The work by Ashikaga (1972) showed that PEO use tended to make the fiber mat sticky, and it was necessary to use a release agent to be able to separate the product from dryer can surfaces.

Formation-aid Mechanisms

There are at least three concepts that have been invoked in order to explain the ability of very-high-mass water-soluble polymers to repress the tendency for entanglement of fibers. These will be briefly stated, and then explained:

- The thickener increases the bulk viscosity of the solution enough to inhibit the formation of a vortex.

- The thickener adsorbs onto fibers and provides steric stabilization, thus reducing inter-fiber friction to a very low level and letting the fibers slide easily past each other.

- The thickener macromolecules dissolved within the solution phase increase the solution’s extensional viscosity, which results in a lubrication effect between fibers during agitation.

Suppression of vortex formation

The hypothesis based on the suppression of vortex flow is consistent with the earlier-cited evidence indicating that vortex flow is involved in the creation of rope defects in nonwoven products. Increased viscosity is known to reduce the tendency for a vortex to form (Wilharm 1986; Scargiali et al. 2013). However, the present literature search did not reveal a specific study showing a case where addition of thickener was reported to change the flow regime in a tank being used for wet-laid nonwovens processing.

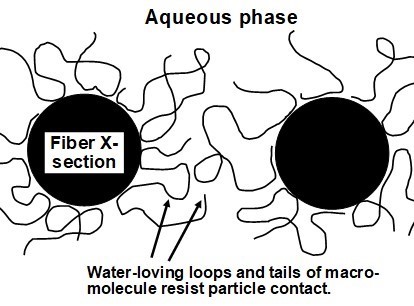

Adsorption and steric stabilization

If fibers in a suspension are somehow prevented from coming close together, then it makes sense that friction between the fibers can be avoided and that there might be less entanglement as a consequence. It is well known that solid surfaces in aqueous solution can be held apart from each other by a steric stabilization mechanism (Sato 1993; Dickinson 2003). Huber and Weigl (1970) proposed that such a mechanism can account for the effect of thickeners in improving the formation uniformity of wet-laid nonwovens.

As a further contributing factor, the negative charge of adsorbed CMC chains will give rise to an electrostatic component of repulsive force between such fibers (Huber and Weigl 1970). Steric stabilization happens when essentially all the surfaces are coated with protruding loops and tails of water-loving polymer or long-chain surfactant molecules. Such a situation is illustrated in Fig. 20.

Fig. 20. Concept of steric stabilization, in which repulsion between fibers in a suspension is achieved by adsorption of either polymers or block surfactants that have extended water-loving chains extending into the aqueous solution

Zauscher and Klingenberg (2000) showed that such effects could be achieved by adsorption of carboxymethyl cellulose (CMC) onto cellulosic surfaces. A similar mechanism of adsorption and steric stabilization also may account for improvements in sheet uniformity when very-high-mass anionic polyelectrolytes are being used as “formation aids” when preparing sheets from suspensions of long fibers (Giri et al. 2000). Thus, Giri et al. (2000) proposed that the amount of adsorbed CMC was the critical factor in their work related to dispersion of fibers. The cited authors observed that the uniformity of dispersion of the fiber slurries increases with increasing molecular weight of the CMC. Also, it appears that the effect requires there to be sufficient addition of thickener to at least coat essentially all of the external surface area of fibers with an extended monolayer of the additive (Sato 1993). Important improvements in mat uniformity have been reported in some cases at relatively low levels of thickener addition – perhaps not sufficient to significantly increase the bulk viscosity of the solution (Giri et al. 2000).

An adsorption-based mechanism also fits well with established practices of “sizing” of fibers intended for wet-laid practices (Hawkins 1979). Such treatment implies placement of various soluble polymers, or other substances, onto the fiber surfaces, so that when the dried fibers are later placed into aqueous solution they will behave differently during processing.

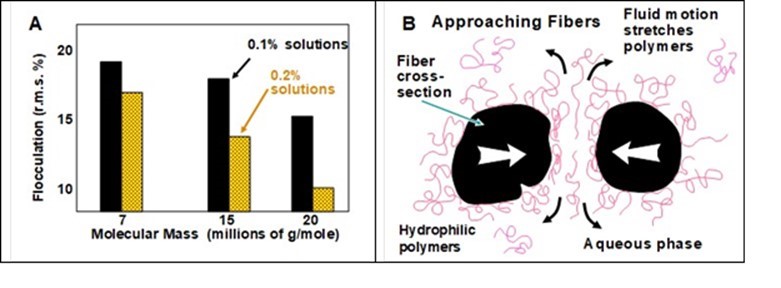

Extensional viscosity

Lee and Lindström (1989) found that the effectiveness of very-high-mass anionic acrylamide copolymers in improving the uniformity of long-fibered handsheets was strongly increased with increases in both dosage and molecular mass. Some of their key results are shown in Fig. 21 (Part A). Both of those factors are consistent with a central role of the bulk viscosity of the solution. However, rather than the shear viscosity, which is much more commonly evaluated, the cited authors proposed that the anti-entanglement capability of very-high-mass polyelectrolytes is due to their effects on extensional viscosity.

The definition and importance of extensional viscosity has been reviewed by Petrie (2006). To evaluate this quantity, liquid at a known pressure is forced through a contracting orifice and the flow rate is quantified. Studies have shown that high-mass polyelectrolytes generally have a much higher relative effect on extensional viscosity compared to their effects on shear viscosity (Gupta et al. 2000; Larson 2005). The sensitivity of extensional viscosity to dissolved polymers has been attributed to the polymers’ resistance to deformation or stretching (Larson 2005). Indeed, as illustrated in Fig. 21(B), a linear polyelectrolyte will tend to become stretched out as it passes into and through a sufficiently long zone of contracting flow (Hsieh et al. 2005; May and Moore 2013). In cases where the solution phase contains a sufficient concentration of very-mass-mass soluble polymer, it has been proposed that the molecules delay the close approach of fiber surfaces toward each other. The result is a lubrication effect that does not depend on any of the polymer having become adsorbed onto the fiber surfaces.

Fig. 21. Effects of very-high-mass anionic acrylamide copolymer on formation uniformity. A: Effects of molecular mass and dosage. Figure redrawn from the results of Lee and Lindström (1989), B: Explanation of the effect based on extensional flow

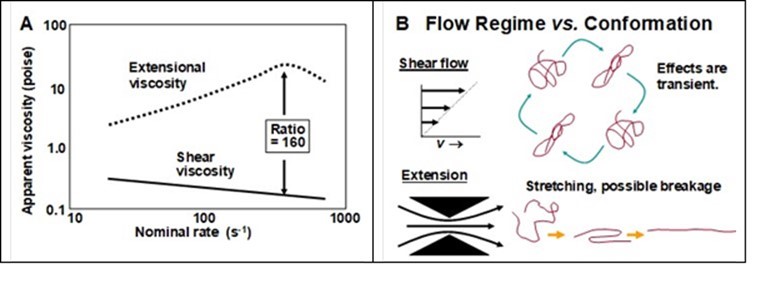

As shown in Fig. 22(A), the relative importance of extensional viscosity in the presence of high-mass soluble polymers will depend on the nominal rate of the local flow event. Thus, Cai (1992) predicted a ratio of as high in 160 when comparing the apparent extensional viscosity vs. the apparent shear viscosity in such systems at a relatively high nominal rate. This ratio also has been called Trouton’s factor (Larson 2005).

Figure 22(B) represents the kinds of conformational changes likely to be induced in the semi-random coils of a long linear polymer in solution when experiencing the two kinds of local flow regimes. The stretching effect of extensional flow has been shown by the breakage of polyelectrolyte chains exposed to such regimes (Nguyen and Kausch 1992).

The importance of extensional flow relative to the dispersion of long fibers in a suspension is also consistent with the tendency of such flow events in stretching of bunches of entangled fibers (Higashitani et al. 1989; Li and Ödberg 1997). Thus, Kerekes (1983) found that fiber flocs passing into the entrance to a tube often were stretched to the point of becoming dispersed.

Fig. 22. Relative effects of very-high-mass polyelectrolytes on two aspects of viscosity – extensional vs. shear. A: Apparent viscosity (depending on measurement method) vs. nominal rate of extension or shear. Figure redrawn form the data of Cai (1992). B: Schematic diagram of expected effects of two types of idealized flow on macromolecular conformation

Which of the mechanisms just described best accounts for the main effects in a given system of wet-laid nonwoven processing probably depends on how serious is the need to resist fiber entanglement. When preparing ordinary paper from wood-derived pulp fibers, it is best to avoid high amounts of very-high-mass polymers, since such polymers, due to the increased bulk viscosity, can be expected to lower the rate of water release during the forming process. Papermakers commonly use very-high-mass polyelectrolytes, but only at the rather low addition levels suitable to impart a bridging mechanism of flocculation, thus helping to retain fine particles in the sheet during its formation (Hubbe et al. 2009). The pronounced slowing of dewatering rates from paper sheets when such polyelectrolytes are being used at the higher concentrations sufficient to improve formation uniformity can probably be attributed to the extensional viscosity effects mentioned earlier (Lee and Lindström 1989).