Abstract

Unfinished, polyvinyl chloride-faced (PVC-faced), and melamine-finished particleboards were examined to determine the effects of VOCs released from these particleboards on indoor air quality. A climate chamber and GC/MS was used to analyze the changes in the concentration of volatile organic compounds (VOCs) from these particleboards over a single cycle of 28 days. The main pollutants from the unfinished particleboard were esters, aromatic hydrocarbons, and aldehydes ketones; the pollutants released from the PVC-faced and melamine-finished particleboards were esters, and aldehydes and ketones. The VOCs from the PVC-faced particleboard had the lowest impact on indoor air quality. When the released VOCs from PVC-faced particleboard reached their stable floor-level values, the air quality was grade I, which is suitable for living. When unfinished and melamine-finished particleboards were used individually indoors, the air quality was grade IV and V. After the released VOCs reached their stable floor-level values, the indoor air quality was grade I or II, which met the standards for living conditions. Under the premise of ensuring that the indoor air was not polluted, the maximum loading rates of the unfinished, PVC-faced, and melamine-finished particleboards were 2.0 m2/m3, 3.8 m2/m3, and 3.8 m2/m3, respectively.

Download PDF

Full Article

Effects of Volatile Organic Compounds Released by Different Decorative Particleboards on Indoor Air Quality

Liqun Jiang,a Jun Shen,a* Hongwei Li,b Qifan Wang,a and Xiwei Shen c

Unfinished, polyvinyl chloride-faced (PVC-faced), and melamine-finished particleboards were examined to determine the effects of VOCs released from these particleboards on indoor air quality. A climate chamber and GC/MS was used to analyze the changes in the concentration of volatile organic compounds (VOCs) from these particleboards over a single cycle of 28 days. The main pollutants from the unfinished particleboard were esters, aromatic hydrocarbons, and aldehydes ketones; the pollutants released from the PVC-faced and melamine-finished particleboards were esters, and aldehydes and ketones. The VOCs from the PVC-faced particleboard had the lowest impact on indoor air quality. When the released VOCs from PVC-faced particleboard reached their stable floor-level values, the air quality was grade I, which is suitable for living. When unfinished and melamine-finished particleboards were used individually indoors, the air quality was grade IV and V. After the released VOCs reached their stable floor-level values, the indoor air quality was grade I or II, which met the standards for living conditions. Under the premise of ensuring that the indoor air was not polluted, the maximum loading rates of the unfinished, PVC-faced, and melamine-finished particleboards were 2.0 m2/m3, 3.8 m2/m3, and 3.8 m2/m3, respectively.

Keywords: Decorative particleboards; Volatile organic compounds (VOCs); Indoor air quality; Effect; Evaluation; Maximum loading rate

Contact information: a: College of Material Science and Engineering, Northeast Forestry University, Harbin, China; b: Northeast Forestry University School of Foreign Languages; c: Graduate School of Design, Harvard University, Cambridge, Massachusetts; *Corresponding author: 1126431608@qq.com

INTRODUCTION

With the advancement of society and the improvement of people’s living standards, the decorative activities of architectural engineering that reflect artistic style and aesthetic taste through form, texture, pattern, and color are increasingly important considerations. Building and ornament materials are the material basis for realizing these decorative activities, and they have important roles in decoration, beautification, and protection. The use of building and ornament materials in construction projects is becoming more and more common. In ordinary buildings the cost of decorative materials accounts for about 50% of the cost of all building materials, while in luxury buildings, the proportion is as high as 70% (Ding and Chen 2004). However, a large number of studies have shown that building and ornament materials will release volatile organic compounds such as benzene, aldehydes, and xylenes, which will cause indoor air pollution and affect indoor air quality (Feng et al. 2001; Zhang 2015). Indoor air quality is closely related to people’s health, because people, especially children and the aged, spend most of their time indoors in small, poorly ventilated spaces without well-circulated air (Lan 2003; Madureira et al. 2016). It is generally assumed that indoor air pollution causes an increase in indoor air complaints (Wolkoff 2006), as well as symptoms such as dry cough, fatigue, headaches, dizziness, and irritation of the skin, eyes, and respiratory tract, which jeopardizes human health (Wolkoff 2003; Zhao 2015; Cao et al. 2018). Therefore, accurately assessing the impact of building and ornament materials on indoor air quality is of great significance for improving the quality of indoor air and ensuring the health of residents.

An indoor air quality assessment is targeted to examine specific objects; it uses scientific methods to analyze the main factors contributing to indoor air pollution, to predict trends over a certain period, and to create specific control measures (Liu 2012). Decorative particleboards are common building and ornament materials, which are often used in interior decoration. In this study, different types of particleboards were examined as specific objects. A 1-m3 climate chamber was used to simulate the indoor environment. A gas chromatography-mass spectroscopy (GC/MS) instrument was used to examine the concentration of VOCs released from particleboards over 28-d period. A single-factor index model (Shu 2010) was developed to determine the main pollutants released from the different decorative particleboards, and the typical model of Shen (Wang 2006) was used to make a comprehensive evaluation of the possible indoor pollution caused by the decorative particleboards.

EXPERIMENTAL

Materials

Decorative particleboards were produced at Foshan Shunde One Furniture Factory (Guangdong, China). The particleboards had the dimensions of 1200 mm × 1200 mm × 18 mm and had a formaldehyde emission level of E1. The formaldehyde emission rates were less than or equal to 0.124 mg/m3, as determined by Chinese Standard GB 18580 (2017). The particleboard samples had single-sided areas of 1000 mm × 500 mm, with both sides able to release gases. The edges of the samples, except for the board faces, were sealed with foil to prevent VOCs from being released. The particleboards were fabricated in three groups, namely unfinished, PVC-faced, and melamine finished. The following parameters were held constant: thickness = 18 mm; tree species = hardwood; hot-pressing temperature = 190 ºC; hot-pressing time = 80 s; grade = E1; adhesive = urea formaldehyde, glue amount = 10% surface layer and 7.5% core layer; and other additives = paraffin emulsion, 0.5%.

Methods

Collection of VOCs

A 1-m3 climate chamber that was equipped with a temperature control, humidity control, high-temperature cleaning system, and circulatory system was used to collect the gases released from the particleboard samples. Before the start of the experiment, the inner chamber was washed with distilled water, and the high-temperature cleaning system was turned on until the temperature in the chamber reached 240 °C. It was cleaned for 4 h to ensure that the background total volatile organic compound (TVOC) concentration within the climate chamber was less than 20 µg/m3, and that the concentration of each component was less than 2 µg/m3. The parameters for the 1-m3 climate chamber are listed in Table 1. The VOCs were absorbed using Tenax-TA tubes (Markes International, Cardiff, UK). The adsorption tube was 89 mm long and had an outer diameter of 6.4 mm.

Table 1. Parameters for the Climate Chamber

Analysis of the VOCs by GC/MS

The thermal desorption instrument used was a Unity GC/MS system (Markes International, Llantrisant, United kingdom) with a thermal desorption autosampler (Ultra 100, Markes International). Helium was used as the carrier gas, and the equipment reached an analytical temperature of 300 °C and a pipeline temperature of 180 °C. The thermal analysis time was 10 min and the injection time was 1 min. Table 2 presents the basic program parameters used for the GC/MS analysis. The chromatographic column was initially run at 40 °C for 2 min, increased to 50 °C (at 2 ºC/min rate), and maintained at 50 °C for 5 min, and then increased to 150 °C (at 5 °C/min rate) and maintained at 150 °C for 4 min. Finally, the temperature was increased to 250 °C (at 10 °C/min rate) and maintained at 250 °C for 8 min.

Table 2. Basic Parameters for GC/MS Analysis

Experimental Design

Sampling of the 1-m3 climate chamber was based on the ISO 16000-9 (2006) and ISO 16000-6 (2011) standards. The climate chamber parameters were set according to the ASTM D5116 (2010) standard. Three particleboard samples were kept at 23 °C and 45% relative humidity for one week. After one week, the samples were placed horizontally in the center of the climate chamber and the door was closed after ensuring ample airflow around the two sides of each sample. The VOCs released from the specimen surfaces were absorbed using Tenax-TA tubes, and the rates were recorded on day 1, 3, 7, 14, 21, and 28. Purified and humidified air was supplied throughout the experiment. Chinese GB/T 29899 (2013) standard was used for the GC/MS analysis of the VOC release rates, TVOC concentrations, and specific component concentrations for the 28-d cycle. The single-factor index model and the typical model from Shen et al. (2013) were developed to determine the main pollutants released from the particleboards, and to make a comprehensive evaluation of the indoor pollutants originating from the particleboards.

RESULTS AND DISCUSSION

VOC Emission Rates from the Decorative Particleboards

Chinese GB/T 18883 (2002) standard was used to quantify the indoor air quality. VOCs were determined as the peak areas in the range of hexane (C6) and hexadecane (C16). In accordance with this standard, toluene-d8 was used as the internal standard. Individual VOC constituents were identified by comparing their retention times with those in a standard mass-spectra library using a match quality of no less than 90%. The VOCs were quantified based on the response factors derived from standardized curves. The relationship between the concentrations of the VOCs in the chamber and amount released per unit area of the particleboard was determined as,

(1)

where ![]() is the quantity of VOCs released per unit area of particleboard per unit time (µg/m2/h), C is the concentration of VOCs in the climate chamber (µg/m3), and q is the ventilation volume per unit area (m3/(m2h)). The VOC emission rates from the particleboards are shown in Fig. 1.

is the quantity of VOCs released per unit area of particleboard per unit time (µg/m2/h), C is the concentration of VOCs in the climate chamber (µg/m3), and q is the ventilation volume per unit area (m3/(m2h)). The VOC emission rates from the particleboards are shown in Fig. 1.

Fig. 1. Emission rates of VOCs from the various decorative particleboards

Differences were observed in the VOC emission rates from the various particleboard types (Fig. 1). The greatest VOC emission rate was from the unfinished particleboard, which was followed by the melamine-finished particleboard. The lowest VOC emission rate came from the PVC-faced particleboard. The generalized trends for the VOC emission rates for the various particleboards types were similar. The rates gradually decreased with time until a stable floor-level value was reached. During the first 7 days, the VOC emission rates were high, but they then decreased rapidly afterwards. The emission rates were slower and more stable during day 7 to 28.

Major VOC Pollutants Released from the Particleboard

An objective evaluation method is an important way to evaluate indoor air quality. The single-factor index model is a frequently used model. This model was used to determine the primary indoor air pollutants by calculating the index of pollutants, multiple of exceed standard, etc. The single-factor index model was used to analyze major pollutants from the VOCs released from the various decorative particleboards. The equation used to calculate the index is,

(2)

where Ii is the single-factor index, Ci is the concentration of a particular type of VOC released by the particleboard (µg/m3), and Cvi is the limited concentration of that type of VOCs indoors (µg/m3). When Ii is less than 1, it that the VOC did not contribute to indoor air pollution, whereas when Ii is greater than 1, it indicates a substance that contributes to indoor air pollution and the pollution level is proportional to the value of Ii.

The limited concentrations that were utilized in this investigation are taken from the Zhao (2015) study. The indoor limited concentrations of alkanes, aromatic hydrocarbons, aldehydes and ketones (excluding formaldehyde), esters, olefins, and TVOC were 100 µg/m3, 50 µg/m3, 20 µg/m3, 20 µg/m3, 30 µg/m3, and 300 µg/m3, respectively. The major pollutants in the VOCs released from the unfinished particleboards on the first day are analyzed and are shown in Table 3.

Table 3. Single-Factor Indices of the Various VOC Types from the Unfinished Particleboard Samples on Day 1

In the indoor environment of the climate chamber, the single-factor indices for esters and for aldehydes and ketones that were released from the unfinished particleboards were all greater than 1 (4.25 and 1.06, respectively), which represented exceeded concentrations. Therefore, the main contaminants in the VOCs released from the particleboards on the first day were esters, aldehydes and ketones, where the release of esters were much higher than the aldehydes and ketones based on the index values. The main pollutants from the various particleboards for one cycle were analyzed using the same method and are compared in Table 4.

Table 4. Major Pollutants from Various Decorative Particleboards over One Cycle Based on Single-Factor Indices

Note: Single-factor indices are given in parentheses

In the indoor environment of the climate chamber, the single-factor indices of the VOC types released from the three kinds of decorative particleboards were all less than 1 after day 14, which indicated that the mass concentration of each of the tested substances was less than the limiting concentration (i.e., nonpolluting). During the first 14 d, the major pollutants released by the unfinished particleboard were esters, aromatic hydrocarbons, and aldehydes and ketones, with single-factor indices that exceeded unity (1). The major pollutants released by the PVC-faced particleboard were esters. The major pollutants released by the melamine-finished particleboard were esters, and aldehydes and ketones. According to the value of the single-factor indices, the pollution degrees of the esters released from the unfinished and melamine-finished particleboards were higher than those from the PVC-faced particleboard.

Comprehensive Evaluation of the Impact of VOCs from the Particleboards on the Indoor Environment

The comprehensive index evaluation method is generally composed of single-factor indices that comprehensively reflect the indoor air quality. The most widely used comprehensive index evaluation method is the one proposed by Shen et al. (2013), which considers the largest single-factor index, the arithmetic average index and accurately reflects the indoor air quality. In this study, the indoor environment was assumed to be the same as the environment in the climate chamber used for testing. A comprehensive index evaluation method was conducted to assess the impact of VOCs released from the decorative particleboards on the indoor air quality. The equation for the comprehensive index (I) is given as,

(3)

where max Ii represents the maximum single-factor index value, and represents the arithmetic average for the single-factor indices. The maximum single-factor index and arithmetic average index of the various decorative particleboards are given in Table 5.

Table 5. Maximum Single-factor Index and Arithmetic Average Index of the Various Particleboards over One Cycle

The comprehensive index for indoor air quality can be broken down into five different categories according to the value of the calculated comprehensive index (Table 6). The value of the comprehensive index reflects the indoor air quality. When the comprehensive index is below 1, the indoor air quality is free of VOC pollution, and thus, suitable for human habitation. When the comprehensive index is 1.5 or higher, the indoor air quality was polluted with VOCs, and it indicates a health hazard risk to humans (i.e., grades IV and V).

Table 6. Indoor Air Quality Grades and Their Meanings

A sample calculation of the comprehensive index for unfinished particleboard for day 1 is given as follows.

- max Ii = 4.25 and

= 1.33 (Table 6)

- I ≈ 2.38 corresponds to grade V (Table 7)

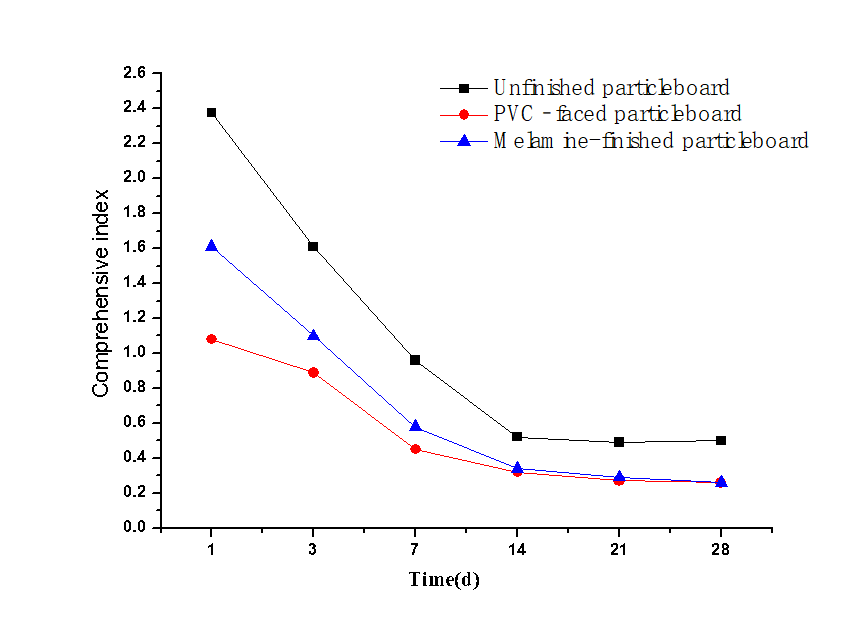

Hence, when the indoor environment of the climate chamber was tested for the VOCs released on the first day from the unfinished particleboard, the particleboard contributed to heavy pollution of the indoor air at a very high level. The comprehensive indices of the VOCs on day 1, 3, 7, 14, 21, and 28 were calculated and are given in Table 7.

Table 7. Comprehensive Index Values of the Various Decorative Particleboards at Various Days over One Cycle

In the indoor environment of the climate chamber, the VOCs released from the unfinished and the melamine-finished particleboards during the early stages of the cycle had a high impact according to the calculated comprehensive index values. The most serious indoor air pollution occurred on the first day, when the air quality showed heavy pollution and reached a grade V. Starting on the day 7, the VOCs released from the various particleboards decreased and the air quality gradually improved to grade II and then to grade I, which represented unpolluted and suitable for living, respectively. When compared with the unfinished and melamine-finished particleboards, the VOCs released from the PVC-faced particleboard had a lower impact on the indoor environment. On day 1 and 3, the impact of the VOCs on the indoor environment was relatively large, and the air quality was grade II. Starting on day 7, the indoor air quality gradually improved to grade I and reached a stable state that was suitable for human habitation.

Fig. 2. Calculated comprehensive indices for the various decorative particleboards over time

The trends for the comprehensive index values are shown in Fig. 2 for the different decorative particleboards. The comprehensive indices of the VOCs gradually decreased over time until they reached a floor-level value. The impact of the VOCs released by the different particleboard types on the indoor environment decreased over time and the indoor air quality increased over time.

Estimated Maximum Loading Rate of the Decorative Particleboards

Based on the mass concentration of the VOCs released on day 28 at steady-state, the maximum loading rates for the particleboards were calculated under the premise of no indoor air pollution. On day 28, the maximum single-factor index value of 0.77 and the arithmetic average index value of 0.33 was observed for the unfinished particleboard (Table 6). When the comprehensive index is less than 1, there was no indoor air pollution (Table 7). The maximum loading rate for a particular decorative particleboard (i.e., m2 of exposed particleboard area per m3 of indoor environment) can be calculated by dividing the comprehensive index value at day 28 into the upper limiting value for non-polluting grade level (i.e., 1 with grade II). For example, the maximum loading rate for unfinished particle board is 2.0 m2/m3 (= 1/( ![]() ) ≈ 1/0.5 = 2). Similarly, the maximum loading rates for the PVC-faced and the melamine-finished particleboards at day 28 were calculated. The maximum loading rates for both decorative particleboards were both 3.8 m2/m3. Hence, when unfinished particleboard, melamine-finished particleboard, and PVC-faced particleboard are used indoors, their exposure areas must lower than 2.0 m2, 3.8 m2, and 3.8 m2 per m3 of indoor room volume, respectively, in order for them to be non-polluting.

) ≈ 1/0.5 = 2). Similarly, the maximum loading rates for the PVC-faced and the melamine-finished particleboards at day 28 were calculated. The maximum loading rates for both decorative particleboards were both 3.8 m2/m3. Hence, when unfinished particleboard, melamine-finished particleboard, and PVC-faced particleboard are used indoors, their exposure areas must lower than 2.0 m2, 3.8 m2, and 3.8 m2 per m3 of indoor room volume, respectively, in order for them to be non-polluting.

CONCLUSIONS

- The VOC emission rates from the various decorative particleboard types examined in this study were different, but the overall trends for the VOC emission rates were the same. They gradually decreased over time until they reached a floor-level value. The VOC emission rates sharply decreased from day 1 to day 7, after which the emission rate declined slowly.

- In the environment of the climate chamber, which simulated the indoor environment, the main pollutants released from the unfinished particleboard were esters, aromatic hydrocarbons, and aldehydes and ketones, while the main pollutants released from the PVC-faced and melamine-finished particleboards were esters, and aldehydes and ketones.

- In the environment of the climate chamber, the VOCs released from the PVC-faced particleboard had the lowest impact on the indoor air quality. After the VOC release reached its equilibrium floor-value for the PVC-faced particleboard, the indoor air quality was grade I, which is suitable for living. The VOCs released from the unfinished and melamine-finished particleboards had the greatest influence on the indoor air quality. During the initial stage of VOCs release, when the unfinished and melamine-finished particleboards were used indoors individually, the indoor air quality was grade V and IV, heavy polluted. After the VOC reached their stable floor-level values, the indoor air quality was grade II or grade I, which met the standards for living conditions.

- Under the premise of the indoor air not being polluted, the maximum loading rates for the unfinished, PVC-faced, and melamine-finished particleboards were determined to be 2.0 m2/m3, 3.8m2/m3, and 3.8 m2/m3, respectively.

ACKNOWLEDGMENTS

This study was supported by the National Key Research and Development Program of China (Grant 2016YFD0600706).

REFERENCES CITED

ASTM D5116 (2010). “Standard guide for small-scale environmental chamber determinations of organic emissions from indoor materials/products,” ASTM International, West Conshohocken, PA.

Cao, T., Shen, J., Liu, W., and Shao, Y. (2018). “Effect of environment on the release of VOCs from wood-based panel which detected by DL-SW Micro-cabin,” J. Northeast Forestry Univ. 46(02), 72-76.

Ding, H., and Chen, R. K. (2004). “Manufacturing and use characteristics of building decoration materials and indoor air quality,” J. Architecture Decoration Culture & Creation. 4(6), 66-69.

Feng, F., Zhang, Z. E., and Zhang, L. J. (2001). “Research on indoor pollution caused by building and decorative materials,” J. New Building Materials 1(12), 39-41.

GB 18580 (2017). “Indoor decorating and refurbishing maters – Limit of formaldehyde emission of wood-based panels and finishing products,” Standardization Administration of China, Beijing, China.

GB/T 29899 (2013). “Determination of the emission of volatile organic compounds from wood-based panels and furnishing. Small chamber method,” Standardization Administration of China, Beijing, China.

GB/T 18883 (2002). “Indoor air quality standard,” Standardization Administration of China, Beijing, China.

ISO 16000-6 (2011). “Indoor air – Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS or MS-FID,” International Organization for Standardization, Geneva, Switzerland.

ISO 16000-9 (2006). “Indoor air – Part 9: Determination of the emission of volatile organic compounds from building products and furnishing—Emission test chamber method,” International Organization for Standardization, Geneva, Switzerland.

Lan, X. (2003). “Indoor air quality and the human health in civil architecture,” Environ. Prot. Sci. 6(120), 7-10.

Liu, S. (2012). “Indoor air quality detection and evaluation method,” Fujian Build. Mater. 7(07), 22-25.

Madureira, J., Paciência, I., Pereira, C., Teixeira, J. P., and Fernandes Ede, O. (2016). “Indoor air quality in Portuguese schools: Levels and sources of pollutants,” Indoor Air 26(4), 526-537. DOI: 10.1111/ina.12237

Shen, J., Liu, Y., and Zhang, W. C. (2013). Study on VOCs Release of Particleboard, Science Press, Beijing, China.

Shu, A. (2010). “Application of comprehensive index evaluation method in indoor air quality evaluation,” Chem. Equip. Technol. 31(2), 60-62.

Wang, Z. (2006). Indoor Air Environment, Chemical Industry Press, Harbin, China.

Wolkoff, P. (2003). “Trends in Europe to reduce the indoor air pollution of VOCs,” Indoor Air 13(S6), 5-11. DOI: 10.1034/j.1600-0668.13.s.6.1.x

Wolkoff, P., Wilkins, C. K., Clausen, P. A., and Nielsen, G. D. (2006). “Organic compounds in office environments—Sensory irritation, odor, measurements and the role of reactive chemistry,” Indoor Air 16(1), 7-19. DOI: 10.1111/j.1600-0668.2005.00393.x

Zhao, Y. (2015). “Measuring the VOC emission-releasing and assessment of the impact of plywood on the indoor environment,” J. Saf. Environ. 15(01), 316-319.

Zhang, Y. M. (2015). “Influence of building materials on indoor air quality and its evaluation,” J. Chemical Enterprise Management 15(17), 220-221.

Article submitted: June 29, 2018; Peer review completed: August 10, 2018; Revised version received and accepted: August 18, 2018; Published: August 22, 2018.

DOI: 10.15376/biores.13.4.7595-7605