Abstract

Forest residues are a potentially important source of renewable energy. They are generated as a byproduct of timber harvesting around the world. To optimize the utilization of such biomass, one must know its physical and chemical properties. This paper presents an analysis of comminuted forest residues from Pinus sylvestris L. They were classified into four size fractions for which three density parameters were established pursuant to relevant standards. The mean bulk density of the fractions amounted to 110 to 190 kg/m3, apparent density 725 to 908 kg/m3, and specific density 1111 to 1350 kg/m3. The findings were compared to the results of previous research on other forms of forest biomass. The measured apparent-to-specific density conversion coefficient was β = 0.64. The elementary composition of forest residues measured in this work differed from that of other biomass types described in literature. In terms of carbon, nitrogen, sulfur, oxygen, and ash content, statistical analysis showed that the two compared types of biomass (forest residues and energy wood chips) formed two separate homogeneous groups, while both of these materials constituted one homogeneous group in the case of hydrogen content. The calorific value of the forest residues was 15.78 ± 0.39 MJ/kg.

Download PDF

Full Article

Forest Residues as a Renewable Source of Energy: Elemental Composition and Physical Properties

Tomasz Nurek,a,* Arkadiusz Gendek,a and Kamil Roman b

Forest residues are a potentially important source of renewable energy. They are generated as a byproduct of timber harvesting around the world. To optimize the utilization of such biomass, one must know its physical and chemical properties. This paper presents an analysis of comminuted forest residues from Pinus sylvestris L. They were classified into four size fractions for which three density parameters were established pursuant to relevant standards. The mean bulk density of the fractions amounted to 110 to 190 kg/m3, apparent density 725 to 908 kg/m3, and specific density 1111 to 1350 kg/m3. The findings were compared to the results of previous research on other forms of forest biomass. The measured apparent-to-specific density conversion coefficient was β = 0.64. The elementary composition of forest residues measured in this work differed from that of other biomass types described in literature. In terms of carbon, nitrogen, sulfur, oxygen, and ash content, statistical analysis showed that the two compared types of biomass (forest residues and energy wood chips) formed two separate homogeneous groups, while both of these materials constituted one homogeneous group in the case of hydrogen content. The calorific value of the forest residues was 15.78 ± 0.39 MJ/kg.

Keywords: Forest residues; Density; Chemical composition

Contact information: a: Department of Agricultural and Forestry Machinery, Faculty of Production Engineering, Warsaw University of Life Sciences – SGGW, Nowoursynowska 164, 02-787 Warsaw, Poland; b: Department of Economic and Energetic Analysis, Institute of Technology and Life Sciences, Falenty, Al. Hrabska 3, 05-090 Raszyn, Poland; *Corresponding author: tomasz_nurek@sggw.pl

INTRODUCTION

Recent years have seen an increased demand for biomass used for the production of a variety of liquid and gaseous fuels, improved solid fuels, such as pellets and briquettes, and for direct combustion (Rosendahl 2013; Ociepa-Kubicka 2015; Uliasz-Bocheńczyk and Mokrzycki 2015). This is directly linked to climate change and the effects of acid rain, which motivate scientists to seek and develop new methods of heat and electricity production (Ghaly and Mansaray 1999; Jabłoński and Stempski 2015; Ociepa-Kubicka 2015). According to Cardoso et al. (2011), approximately 14% of the total demand for energy worldwide is covered by biomass. In turn, the International Energy Agency (2017) reports that biomass accounts for 10.3% of the world’s energy production.

Forest residues and other logging byproducts do not seem to be utilized to their full capacity. For sanitary and fire protection reasons, these types of biomass must not be left in forest areas and must be removed before forest regeneration work can begin. Unfortunately, this practice also leads to the removal of mineral substances, which would otherwise enrich the soil and enhance tree growth in the future. According to Gornowicz et al. (2015), the removal of forest residues from 1 ha entails, on average, a loss of 125 kg of nitrogen, 19 kg of phosphorus, 45 kg of potassium, 75 kg of calcium, and 9 kg of magnesium. On the other hand, it should be remembered that over dozens of years of tree stand growth has enriched the soil by other kinds of dead plant matter.

The studied kind of biomass is variously termed in the literature as forest residues, logging residues, or forest harvesting residues. A characteristic feature of such material is its inhomogeneity. In addition to “pure” wood, it contains considerable amounts of bark, conifer needles, and non-lignified shoots (Gendek et al. 2018a). Forest residues are generated during the harvesting of timber, as well as during forest tending treatments such as cleanings and thinnings (Moskalik et al. 2013, 2016). While preparing a forest stand for regeneration, lying branches and tree tops should be removed and stored either on the cleared forest area or at the roadside for further processing (e.g., chipping). They may also be comminuted and mixed with the topsoil using specialized mulching equipment.

The processing of forest residues and their utilization for energy purposes has been pioneered by the Scandinavian countries (Hakkila and Parikka 2002), where the most widely used technologies are terrain and roadside chipping (Stampfer and Kanzian 2006; Yoshioka et al. 2006; Eker 2011; Röser et al. 2012). Similar technologies are used in Polish forests; however, in Poland, forest residues are also sometimes compressed into bundles, which are subsequently comminuted at power plants (Moskalik et al. 2013; Gendek and Nurek 2016; Moskalik et al. 2016).

In the literature there are numerous reports concerning biomass of various origins that is produced for energy (i.e. “energy biomass”) (Aniszewska et al. 2018), its parameters, chemical composition, processing (Väisänen 2016), including processing into improved solid fuels (Gendek et al. 2018b), and supply chain optimization (Dessbesell et al. 2016). Miranda et al.(2009) has determined the chemical composition and gross calorific value of pellets made of residues from Pyrenean oak. There are also reports concerning other kinds of biomass (Werther et al. 2000; Phanphanich and Mani 2011; Malat’ak et al. 2018). However, the physical and chemical properties of forest residues from the most popular species in Poland and Europe (Scots pine and Norway spruce) have not been elucidated to date.

In considering the use of forest residues, one needs to take into account their natural composition, which is inhomogeneous. Such material consists of different forms of biomass, including branches, treetops, and bole fragments containing not only wood, but also bark, large amounts of conifer needles, and mineral contaminants (Gendek and Zychowicz 2015). Therefore, it is necessary to elucidate the chemical and physical properties of forest residues as a potential energy feedstock or raw material for the production of improved fuels.

A review of the available literature shows that while energy biomass has been extensively studied in terms of its physical (bulk density, moisture content, and particle size), chemical (carbon (C), hydrogen (H), nitrogen (N), and sulfur (S), oxygen (O), and ash content), and energetic (net and gross calorific value) properties, most papers either deal with only a limited range of those parameters or with biomass of types other than forest residues.

The bulk density of forest wood chips ranges from approximately 110 kg/m3 to 340 kg/m3, depending on their moisture content, composition, and origin (Ragland et al. 1991; Gigler et al.2000; Jensen et al. 2006; Phanphanich and Mani 2009; Sultana and Kumar 2011; Gendek et al. 2018). Of great importance to bulk density is the size and orientation of particles. The size distribution of particles is crucial (Asikainen and Pulkkinen 1998), as it influences effective combustion (Hartmann et al. 2006) and storage properties, affecting the calorific value and durability of the material. The size distribution of wood chips depends on the type and size of the chipper (Spinelli et al. 2005), tree species (Nati et al. 2010; Gendek and Zychowicz 2015), part of the tree (stem or branches), as well as knife wear and mounting (Friedl et al. 2005). According to Barontini et al. (2014) and Gendek and Nawrocka (2014), knife wear and sharpening angle have an effect on particle size variation and distribution. Chipping with a blunt knife leads to smaller chips and a greater proportion of finer particles. While it is the operator who decides on knife replacement, according to Facello et al. (2013) one should avoid a situation in which the knives can no longer produce chips of satisfactory quality.

Oxygen, CHNS, and ash content have been extensively studied in various types of biomass, including many tree species and wood wastes (Friedl et al. 2005; Munalula and Meincken 2009; Reva et al. 2012), as well as different tree parts (Zhao et al. 2014; Wielgosiński et al. 2017) found in forest wood chips (Chandrasekaran et al. 2012; Sulaiman et al. 2017), such as wood, stumps, roots (Uri et al. 2015), bark, conifer needles and cones (Brebu et al. 2010), and seeds (Aniszewska et al. 2017).

The objective of the present study is to determine the physical properties and chemical composition of comminuted forest residues in the aggregate, as a mixture of different parts of trees and types of plant tissue (wood, bark, conifer needles) and mineral matter. The authors’ findings were compared with physical and chemical data for other types of biomass. To the best of the authors’ knowledge, no other work to date has provided such a comprehensive characterization of forest residues. Research results may be the basis for the choice of method for forest residues management. Physical and chemical properties of the residues have an impact on the possibilities and parameters of pressure agglomeration of biomass, as well as on the parameters of the combustion process, which will be the subject of further research. The innovation and originality of this research result from the absence of characteristics of this type of biomass in literature. The obtained results will enable the management of forest residues – by facilitating decisions on whether to leave the comminuted residues on the forest floor or use them as a source of energy.

EXPERIMENTAL

Materials

Material consisted of forest residues generated in the process of timber harvesting from an 80-year-old Scots pine (Pinus sylvestris L.) stand on a lowland mesic dystrophic site (Chojnów Forest District, Żabieniec, Poland). Twenty 2 × 2 m sampling plots were established on the area from which forest residues were to be removed (GPS coordinates of the center of that area are WGS84: 52.0492 N; 21.0563 E). The forest residues collected from the sampling plots were comminuted using a hammer mill that produced wood chips less than 16 mm in size. This size was selected due to the fact that one of the prospective objectives of the study was to examine the process of briquetting the analyzed biomass in a 45-mm chamber. Prior to physical and chemical testing, the material was homogenized by mixing wood chips obtained from all the sampling plots.

Methods

The comminuted biomass was fractionated for 180 s in a screen classifier (Lisowski et al. 2008a,b) according to the procedure described by Rynkiewicz and Śnieg (2015), with the four fractions (size classes) being 0 mm to 1 mm (f1), 1 mm to 4 mm (f2), 4 mm to 8 mm (f3), and 8 mm to 16 mm (f4).

The moisture content of the studied material was determined by weight loss on drying. The weight of samples was measured with an accuracy of 0.01 g on a WSP 600/C laboratory balance (Radwag, Radom, Poland). Sample drying was conducted in accordance with the standard ISO 18134-3: 2015 in a Top+ SLW 115 laboratory oven (Pol-Eko-Aparatura, Wodzisław Śląski, Poland) at 105±1 C until constant weight.

The bulk density of the comminuted pine forest residues was determined pursuant to the standard PN-EN 15103:2010E (2010), using a measuring container described therein. Bulk density was defined as the quotient of biomass weight (difference between the weights of empty and filled measuring containers) and its volume (including the volume of air inside particle pores and between particles).

Apparent density was calculated using a modified measuring container from the standard PN-EN 15103:2010E (2010) and chemically pure water, based on Eq. 1,

(1)

where a is apparent density (kg/m3), Vw is the volume of water added to the measuring container filled with wood chips (m3), Vc is the volume of the measuring container (m3), m1 is the weight of the measuring container (kg), and m2 is the weight of the measuring container filled with wood chips (kg).

Material swelling or shrinking was not taken into account during measurement because, according to the literature (Hartmann et al. 2004), it amounted to 0.7%. Because the test lasted for a short time, water absorption by the wood chips was not taken into consideration either.

The specific density (ρs) of comminuted forest residues was determined using a helium pycnometer (Ultrapycnometer 1200e with an accuracy of 0.03%) (Quantachrome Instruments, Boynton Beach, USA) according to the methodology described by Lisowski et al. (2011) and Aniszewska and Gendek (2016).

The apparent-to-specific density conversion coefficient β, was calculated from the two values defined above, according to Eq. 2, which is shown below.

(2)

Specific and apparent density was determined for unfractionated biomass and for all four wood chip fractions individually. Bulk density was determined for each wood chip fraction. The moisture content of the material was approx. 15%.

Comparative chemical analysis encompassed energy wood chips. Carbon, hydrogen, nitrogen, and sulfur content were determined using an Elementar Vario Macro apparatus (Elementar Americas Inc., Ronkonkoma, USA) pursuant to the protocol given by Sadhukhan et al. (2009). Dried samples with a weight of 200 mg were prepared according to the requirements of the apparatus. Following determination of elemental carbon, hydrogen, sulfur, and nitrogen content, the samples were incinerated to measure the relative proportions of ash and oxygen. The latter was determined by subtracting the content of the other chemical elements and ash from the material analyzed.

The percentage shares of the chemical elements and ash represent the mean values obtained from the measurements on a dry basis (db).

The chemical composition results for the forest residues were compared with energy wood chips, which were collected from a container ready to be shipped to a power plant.

Ash content was determined by slow incineration in a muffle furnace at 815 C ± 10 C, according to the ISO standard ISO 1928 (2009). Samples with a weight of 2 g were weighed with an accuracy of 0.0001 g.

Gross calorific value measurement of fractions of chipped forest residues was conducted according to the standard PN-ISO 1928 (2009) using a KL-11 Mikado calorimeter (Precyzja-Bit, Bydgoszcz, Poland). Distilled water at 20 C was used and the mass of a single sample was 1 g, weighed on a WPS 210S laboratory balance (Radwag, Radom, Poland) with an accuracy of 0.0001 g.

While there are many models for calculating calorific value (Zhu and Zhuang 2012), the present study employed the widely used formula specified in an international ISO standard. On the basis of obtained gross calorific value results, the net calorific value (Qnet) was determined using Eq. 3, according to ISO 1928 (2009),

(3)

where Qgross is gross calorific value (kJ/kg), RH is relative humidity (%), and H is hydrogen content (%). Statistical analyses were performed using Statistica software (Dell Inc., v. 13, Landolock, TX, USA) at a significance level of α = 0.05. The obtained results were analyzed statistically, and analysis of variance (ANOVA) was performed to determine the significance of the tested parameter.

RESULTS AND DISCUSSION

The applied hammer mill produced wood chips with a maximum size of less than 16 mm. According to the adopted methodology, the material was separated into four fractions (0 mm to 1 mm, 1 mm to 4 mm, 4 mm to 8 mm, and 8 mm to 16 mm), which were weighed (mfi) to determine their mean percentage shares (αfi). The results are given in Table 1.

Gendek and Nawrocka (2014) have reported that forest residues comminuted using a Bruks 805CT chipper had a mean geometric size of 10.8 mm to 14.4 mm for blunt knives and 15.3 mm to 17.3 mm for sharp knives. The maximum size of the obtained wood chips was 63 mm, with the largest share in the 6 mm to 23 mm fraction. In turn, Spinelli et al. (2005), who examined nine types of wood chippers, obtained a mean geometric particle size of 14 mm to 30 mm, with the most abundant fractions being 3 mm to 16 mm and 16 mm to 45 mm. These results are consistent with the studies of Barontini et al. (2014) and Nati et al. (2010), who reported the largest relative proportions of wood chips in the size classes of 3 mm to 8 mm, 8 mm to 16 mm, and 16 mm to 45 mm.

As shown in Table 1, the relative proportions of the finest f1 (0 mm to 1 mm) and coarsest f4 (8 mm to 16 mm) fractions were the lowest (at 6.32% and 25.02%, respectively). The largest mean percentage share by weight (36.1%) was found for f3 (4 mm to 8 mm). This was consistent with the reports of other authors (Spinelli et al. 2005; Nati et al. 2010; Barontini et al.2014; Gendek and Nawrocka 2014). However, one should take into account the type and size of the applied hammer mill and the maximum size of material that can be fed. It was noteworthy that almost 70% of the wood chips ranged from 1 mm to 8 mm.

The size and fraction structure of wood chips make it possible to produce briquettes with a diameter of >40 mm in further studies. In addition, the fraction structure may be modified with a view to optimizing the quality of the fuel.

Table 1. Mean Percentage (± SD) Shares of the Various Fractions in Forest Residue Samples

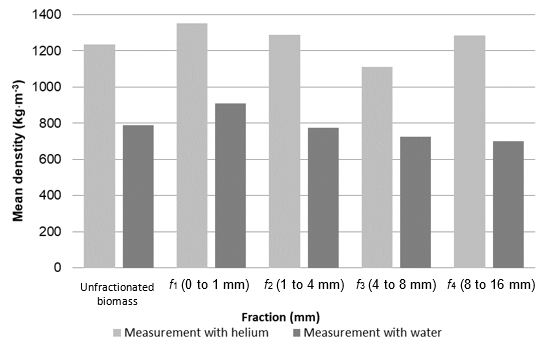

Biomass density measurements for the four fractions and unfractionated wood chips are given in Table 2. The mean apparent density of the unfractionated comminuted pine forest residues measured with water was 787.3 kg/m3, while the specific density obtained using a helium pycnometer model Ultrapycnometer 1200e (Quantachrome Instruments, Boynton Beach, FL, USA) was 1234.0 kg/m3. In turn, specific density for the various fractions ranged from 1111 to 1350 kg/m3 and apparent density from 725 to 908 kg/m3.

Table 2. Mean (± SD) Density of Comminuted Pine Forest Residues and the Apparent-to-Specific Density Conversion Coefficient (β)

Statistical analysis (ANOVA, p<0.05) showed that the densities obtained by the two methods applied were significantly different, with an average absolute difference of 474.3 kg/m3. Similar differences were found for each of the designated fractions. In the measurements with water, apparent density decreased with fraction size, while in pycnometric measurements the lowest specific density was found for the 4 mm to 8 mm fraction. The individual fractions and unfractionated material were also assigned to homogeneous groups. Four such groups were found for specific density, with fractions f2 (1 mm to 4 mm) and f4 (8 mm to 16 mm) being classified in the same group. Apparent density measurements revealed two homogeneous groups, with the fraction f1 (0 mm to 1 mm) forming a group of its own. This meant that there were no significant differences between the other three fractions and unfractionated biomass.

An analysis of the data given in Table 2 showed that differences between the specific and apparent density measurements of unfractionated wood chips and the four fractions were of similar magnitude. As shown in Fig. 1, both types of density measurements for the various fractions and unfractionated material followed a similar trend. The conversion coefficient ranged from 0.55 for fraction f4 (8 mm to 16 mm) to 0.67 for fraction f1 (0 mm to 1 mm), with that for unfractionated biomass being 0.64. These results indicate that it is possible to determine specific density on the basis of tests performed using water for preliminary measurements, while the coefficient defined in this paper allows for correcting the results of the “water” method.

Fig. 1. Wood chip density obtained by different methods

The measured mean bulk density for the various fractions was as follows: 190 kg/m3 for f1 (0 mm to 1 mm), 170 kg/m3 for f2 (1 mm to 4 mm), 120 kg/m3 for f3 (4 mm to 8 mm), and 110 kg/m3 for f4 (8 mm to 16 mm).

The chemical composition of the studied biomass is given in Table 3. Energy wood chips were also tested according to the adopted methodology.

Table 3. Percentage Shares (± SD) of Chemical Elements and Ash in the Studied Forest Residues and Energy Wood Chips (db)

The analyzed forms of raw material were characterized by remarkable differences in chemical compounds, which could be explained by the place of obtaining individual samples, as well as different compositions of the examined matter. The forest residues contained a large number of needles and a small number of branches and bark (non-lignified). For tests, they were manually collected directly from the forest surface onto the transport means. This noticeably reduced biomass contamination with the mineral fraction. The energy wood chips, in addition to pure wood, also contained various types of contamination, but in a much smaller amount than logging residues. They were characterized by high shares of mineral compounds. This was related to the technology of obtaining them, given that the residues were taken from the ground with a hydraulic crane grab, loaded onto the forest tractor, and then moved from the stack prepared for chipping to the wood chipper chute, also with a crane. During both operations, a large amount of soil and sand was collected along with the biomass.

According to the results of the tests conducted, the carbon content in the chipped logging residues was 50.8%. Thus, ANOVA indicated major differences between the studied biomass types, and the Duncan test was used to assign the materials to homogeneous groups. Each of the materials formed a separate homogeneous group, which confirmed considerable differences in carbon content between the tested materials. The significance level (p < 0.0001) for carbon content was much lower than the empirical statistic F(1, 7) = 310.99.

The percentage share of hydrogen in the chemical structure of the analyzed materials was much lower (approximately 6%). Its content was within the upper limit given by Friedl et al.(2005) for wood and wood wastes (5.7% to 6%) and at the same time within the lower limits reported by Munalula and Meincken (2009) as well as Reva et al. (2012) (6.0% to 6.9%). It was slightly higher than the hydrogen content in conifer seeds (5.6% to 5.8%) determined by Aniszewska et al. (2017) or that in pine cones (5.56%) studied by Brebu et al. (2010) (it should be noted that cones are part of forest residues).

Statistical analysis revealed that the observed differences in oxygen content between the various biomass types were not significant at p = 0.6595, which was higher than the statistic F(1, 7) = 0.21. This meant that all the materials belonged to one homogeneous group.

The percentage shares of nitrogen and sulfur in the structure of the analyzed material might have been influenced by silvicultural practices, site conditions, soil quality, and other environmental parameters.

According to the available literature (Friedl et al. 2005; Munalula and Meincken 2009; Reva et al. 2012), nitrogen and sulfur content in the wood and wood wastes ranges from 0.07% to 3.02% and from 0.0% to 0.22%, respectively. Similarly, Brebu et al. (2010) have reported the percentage share of nitrogen and sulfur in pine cones at 0.8% and 0.05%, respectively. Aniszewska et al. (2017), who studied the elemental composition of conifer seeds, found that they contain 0.6% to 2.6% of nitrogen and 0.2% to 0.3% of sulfur. In the forest residues examined herein, nitrogen and sulfur content was 0.66% and 0.25%, respectively, which was consistent with the literature data. However, those values deviated from those reported for other types of biomass, such as pine cones or conifer seeds (it should be noted that forest residues consist mostly of wood, bark, and needles, along with small amounts of cones and seeds).

All the types of biomass considered in this paper revealed low levels of sulfur and nitrogen, which indicated good environmental properties of those materials. Statistical analysis revealed that the significance level for nitrogen was very low (p < 0.0001) compared to the empirical statistic F(1, 7) = 215.10, while that level for sulfur was p = 0.0455 compared to the empirical statistic F(1, 7) = 5.90. Because the calculated significance levels for nitrogen and sulfur content in the various materials were less than 0.05, the Duncan test was performed to determine the homogeneous groups (Table 3).

In the case of ash content, statistical analysis revealed significant differences between the various biomass types, with p < 0.0001 and F(1, 7) = 158.42. Due to the obtained differences for the materials, further statistical analysis was conducted and two distinct homogeneous groups were determined (Table 3). According to Friedl et al. (2005), ash content in wood and wood waste amounts to 2.9% and 1.5%, respectively, while Font et al. (2009) found 4.5% and 0.8% of ash in pine needles and cones, respectively. Munalula and Meincken (2009) have reported that the ash content in several tree species ranges from 0.34% to 2.79%. The ash content found in the present study (1.07%) differed from the literature data for pine needles and cones, but remained within the cited range for wood and wood wastes.

The relatively low ash content in the examined forest residues was probably attributable to the high percentage share of bark and non-lignified shoots. As shown in Table 3, the differences in ash content between the two studied types of biomass were statistically significant, with the highest value found for energy wood chips (1.91%). This fact might have been due to the high degree of biomass contamination during storage in forest areas, transportation, and comminution. These results are consistent with the findings of Gendek et al. (2018b), who reported that mean ash content (1.4–5.9%) depends on the composition of forest residues and on the impurities that they contain. It should be noted that the studied forest residues fall within the maximum ash content threshold allowed by Polish energy companies for this kind of fuel, which is 5% (Gendek and Nurek 2016).

The percentage share of ash in the examined forest residues was consistent with the data for Scots pine (Pinus sylvestris) and Norway spruce (Picea abies) branches (Moriana et al. 2016). The results for energy chips did not correspond to any literature values. It should be remembered that the analyzed materials were collected from different locations and tree stands, and so the identified differences were difficult to explain.

The mean oxygen content (41.46%) was calculated by subtracting the percentage shares of the other chemical elements and ash. For all of the studied types of biomass, oxygen content was slightly lower that that reported for spruce wood (43.6% to 45.6% (Bach et al. 2016) and 43.2% (Kajda-Szcześniak 2013)). The percentage share of oxygen found herein for the forest residues was within the range reported for wood and wood wastes by Friedl et al. (2005) (41.0% to 41.9%) and Munalula and Meincken (2009) (39.7% to 41.8%), but at the same time it was higher than the values given by Font et al. (2009) for pine cones (38.7%) and needles (37.9%). Statistical analysis revealed significant differences in oxygen content between the various types of materials, which were classified into distinct homogeneous groups (Table 3). Oxygen was the second most abundant element in the studied samples.

The significance level for oxygen content was very low (p < 0.0001) with the empirical statistic amounting to F(1, 7) = 186.19, which indicated significant differences between the compared types of biomass. The results of gross and net calorific values of chipped logging residues are presented in Table 4.

Table 4. Gross and Net Calorific Values of Logging (Unfractionated Biomass)

As reported by Stolarski et al. (2007), the net calorific value of wood materials ranges from 19.12 MJ/kg to 20.08 MJ/kg, while the tested logging residues are characterized by a lower net calorific value (15.78 MJ/kg), which is affected by the biomass composition. The value obtained in the present study is similar to that reported by Barontini et al. (2014) for comminuted wood after a period of storage (approximately 16 MJ/kg). Ingredients, such as pine needles, bark, and minerals, reduce the net calorific value. According to Zhao et al. (2014), calorific value varies among stem wood, bark, branch, and foliage components, ranging from 18.9 to 20.6 MJ/kg. In turn, the study of Gendek et al. (2018b) shows that the calorific value of wood chips is affected not only by their composition, but also by harvesting technology and the presence of impurities. Nevertheless, the obtained results indicate the possibility of using logging residues as a solid fuel. It should also be remembered that this biomass could be further aggregated to obtain more favorable energy parameters.

CONCLUSIONS

- Density measurement of comminuted forest residues with water may be deemed a good and economical preliminary method, for it does not require a specialized apparatus. The conversion coefficient defined and determined in this study makes it possible to estimate the specific density of wood chips.

- The composition of the studied wood chips was compared with data for other types of biomass and considerable differences were identified. Those differences are attributable to the inhomogeneity of the studied wood chips, which contained a substantial amount of conifer needles, bark, and mineral matter.

- The studied material is characterized by lower net and gross calorific values (15.78 MJ/kg and 18.75 MJ/kg, respectively) as compared to other wood materials.

- The results of the present study indicate that it is advisable to collect forest residues for energy purposes. Irrespective of the logging technique applied, considerable amounts of forest residues remain on cleared forest areas. In addition to wood, those residues contain a substantial proportion of bark, conifer needles, and mineral matter. The present findings show that forest residues may be used as a source of thermal energy due to a high content of carbon and a low content of nitrogen and sulfur. However, given the low density of the studied material both before and after comminution, pressure aggregation of wood chips should be considered as an option.

REFERENCES CITED

Aniszewska, M., and Gendek, A. (2016). “Logistics of the supplies of selected forest tree species’ cones. Part 1. Cone density and substitution coefficient,” Ann. Warsaw Univ. Life Sci. – SGGW, Agric. 67, 121-130.

Aniszewska, M., Gendek, A., Drożdżek, M., Bożym, M., and Wojdalski, J. (2017). “Physicochemical properties of seed extraction residues and their potential uses in energy production,” Rocz. Ochr. Śr. 19, 302-334.

Aniszewska, M., Gendek, A., and Zychowicz, W. (2018). “Analysis of selected physical properties of conifer cones with relevance to energy production efficiency,” Forests 9(7), 405. DOI: 10.3390/f9070405

Asikainen, A., and Pulkkinen, P. (1998). “Comminution of logging residues with Evolution 910R chipper, MOHA chipper truck, and Morbark 1200 tub grinder,” Int. J. For. Eng. 9(1), 47-53.

Bach, Q.-V., Chen, W.-H., Chu, Y.-S., and Skreiberg, Ø. (2016). “Predictions of biochar yield and elemental composition during torrefaction of forest residues,” Bioresource Technol. 215, 239-246. DOI: 10.1016/j.biortech.2016.04.009

Barontini, M., Scarfone, A., Spinelli, R., Gallucci, F., Santangelo, E., Acampora, A., Jirjis, R., Civitarese, V., and Pari, L. (2014). “Storage dynamics and fuel quality of poplar chips,” Biomass Bioenerg. 62, 17-25. DOI: 10.1016/j.biombioe.2014.01.022

Brebu, M., Ucar, S., Vasile, C., and Yanik, J. (2010). “Co-pyrolysis of pine cone with synthetic polymers,” Fuel 89(8), 1911-1918. DOI: 10.1016/j.fuel.2010.01.029

Cardoso, C. R., Miranda, M. R., Santos, K. G., and Ataíde, C. H. (2011). “Determination of kinetic parameters and analytical pyrolysis of tobacco waste and sorghum bagasse,” J. Anal. Appl. Pyrol. 92(2), 392-400. DOI: 10.1016/j.jaap.2011.07.013

Chandrasekaran, S. R., Hopke, P. K., Rector, L., Allen, G., and Lin, L. (2012). “Chemical composition of wood chips and wood pellets,” Energ. Fuel. 26(8), 4932-4937. DOI: 10.1021/ef300884k

Dessbesell, L., Xu, C., Pulkki, R., Leitch, M., and Mahmood, N. (2016). “Forest biomass supply chain optimization for a biorefinery aiming to produce high-value bio-based materials and chemicals from lignin and forestry residues: A review of literature,” Can. J. For. Res. 47(3), 277–288. DOI: 10.1139/cjfr-2016-0336

Eker, M. (2011). “Assessment of procurement systems for unutilized logging residues for Brutian pine forest of Turkey,” Afr. J. Biotechnol. 10(13), 2455-2468. DOI: 10.5897/AJB10.2059

Facello, A., Cavallo, E., Magagnotti, N., Paletto, G., and Spinelli, R. (2013). “The effect of knife wear on chip quality and processing cost of chestnut and locust fuel wood,” Biomass Bioenerg. 59, 468-476. DOI: 10.1016/j.biombioe.2013.07.012

Font, R., Conesa, J. A., Moltó, J., and Muñoz, M. (2009). “Kinetics of pyrolysis and combustion of pine needles and cones,” J. Anal. Appl. Pyrol. 85(1-2), 276-286. DOI: 10.1016/j.jaap.2008.11.015

Friedl, A., Padouvas, E., Rotter, H., and Varmuza, K. (2005). “Prediction of heating values of biomass fuel from elemental composition,” Anal. Chim. Acta 544(1-2), 191-198. DOI: 10.1016/j.aca.2005.01.041

Gendek, A., Aniszewska, M., Malaťák, J., and Velebil, J. (2018a). “Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species,” Biomass and Bioenergy 117, 173-179. DOI: 10.1016/j.biombioe.2018.07.025

Gendek, A., and Nawrocka, A. (2014). “Effect of chipper knives sharpening on the forest chips quality,” Ann. Warsaw Univ. Life Sci. – SGGW, Agric. 64, 97-107.

Gendek, A., and Nurek, T. (2016). “Variability of energy woodchips and their economic effects,” Folia For. Pol., Ser. A 58(2), 62-71. DOI: 10.1515/ffp-2016-0007

Gendek, A., Nurek, T., Zychowicz, W., and Moskalik, T. (2018). “Effects of intentional reduction in moisture content of forest wood chips during transport on truckload price,” BioResources 13(2), 4310-4322. DOI: 10.15376/biores.13.2.4310-4322

Gendek, A., Malaťák, J., and Velebil, J. (2018b). “Effect of harvest method and composition of wood chips on their caloric value and ash content,” Sylwan 162(3), 248-257.

Gendek, A., and Zychowicz, W. (2015). “Analysis of wood chippings fractions utilized for energy purposes,” Ann. Warsaw Univ. Life Sci. – SGGW, Agric. 65, 79-91.

Ghaly, A. E., and Mansaray, K. G. (1999). “Comparative study on the thermal degradation of rice husks in various atmospheres,” Energ. Source. 21(10), 867-881. DOI: 10.1080/00908319950014254

Gigler, J. K., Van Loon, W. K. P., Seres, I., Meerdink, G., and Coumans, W. J. (2000). “PH–Postharvest technology: Drying characteristics of willow chips and stems,” J. Agr. Eng. Res. 77(4), 391-400. DOI: 10.1006/jaer.2000.0590

Gornowicz, R., Gałązka, S., Kuźmiński, R., Kwaśna, H., Łabędzki, A., Łakomy, P., Pilarek, Z., and Polowy, K. (2015). “Forest biomass as a bioenergy source and important element of the forest ecosystem,” in: Challenges and Opportunities for 21st-century Forestry, Z. Sierota (ed.), Forest Research Institute, Sękocin Stary, Poland, pp. 61–67.

Hakkila, P., and Parikka, M. (2002). “Fuel resources from the forest,” in: Bioenergy from Sustainable Forestry: Guiding Principles and Practice, J. Richardson, R. Björheden, P. Hakkila, A. T. Lowe, C. T. Smith (eds.), Kluwer Academic Publishers, Dordrecht, Netherlands, pp. 19-48. DOI: 10.1007/0-306-47519-7_2

Hartmann, H., Böhm, T., Jensen, P. D., Temmerman, M., Rabier, F., and Golser, M. (2006). “Methods for size classification of wood chips,” Biomass Bioenerg. 30(11), 944-953. DOI: 10.1016/j.biombioe.2006.06.010

Hartmann, H., Böhm, T., Jensen, P. D., Temmerman, M., Rabier, F., Jirjis, R., Burvall, J., Hersener, J.-L., and Rathbauer, J. (2004). “Methods for bulk density determination of solid biofuels,” in: 2nd World Conference and Technology Exhibition on Biomass for Energy, Industry and Climate Protection, W. P. M. Van Swaaij, T. Fjällström, P. Helm, A. Grassi (eds.), Rome, Italy, pp. 662-665.

International Energy Agency (IEA) (2017). Key World Energy Statistics, International Energy Agency, Paris, France.

ISO 18134-3:2015 – “Solid biofuels — Determination of moisture content — Oven dry method — Part 3: Moisture in general analysis sample. International Organization for Standardization,” Geneva, Switzerland.

ISO 1928 (2009). “Solid mineral fuels — Determination of gross calorific value by the bomb calorimetric method and calculation of net calorific value,” International Organization for Standardization, Geneva, Switzerland.

Jabłoński, K., and Stempski, W. (2015). “Demand for forest biomass and possibilities for its harvesting in Poland,” Acta Sci. Pol. Silv. Colendar. Rat. Ind. Lignar. 14(1), 31-38. DOI: 10.17306/J.AFW.2015.1.0

Jensen, P., Hartmann, H., Böhm, T., Temmerman, M., Rabier, F., and Morsing, M. (2006). “Moisture content determination in solid biofuels by dielectric and NIR reflection methods,” Biomass Bioenerg. 30(11), 935-943. DOI: 10.1016/j.biombioe.2006.06.005

Kajda-Szcześniak, M. (2013). “Evaluation of the basic properties of the wood waste and wood based wastes,” Archives of Waste Management and Environmental Protection, 15(1), 1-10.

Lisowski, A., Sar, Ł., Świątek, K., and Kostyra, K. (2008a). “Separator sitowy do analizy rozkładu długości sieczki [Sieve separator to analysis of chaff length distribution],” Technika Rolnicza Ogrodnicza Leśna 2, 17-19.

Lisowski, A., Świątek, K., Kostyra, K., and Chlebowski, J. (2008b). “Methods for evaluation of breaking up of maize chaff separated on the sieve separator,” Ann. Warsaw Univ. Life Sci. – SGGW, Agric. 52, 23-30.

Lisowski, A., Świętochowski, A., Szulc, K., and Lenart, A. (2011). “Density and porosity of the cut and ground material of energy plants,” Ann. Warsaw Univ. Life Sci. – SGGW, Agric. 58, 21-28.

Malat’ak, J., Bradna, J., Velebil, J., Gendek, A., and Ivanova, T. (2018). “Evaluation of dried compost for energy use via co-combustion with wood,” Agron. Res. 16(1), 157-166. DOI: 10.15159/ar.18.022

Miranda, M. T., Arranz, J. I., Rojas, S., and Montero, I. (2009). “Energetic characterization of densified residues from Pyrenean oak forest,” Fuel 88(11), 2106-2112. DOI: 10.1016/j.fuel.2009.05.015

Moriana, R., Vilaplana, F., and Ek, M. (2016). “Cellulose nanocrystals from forest residues as reinforcing agents for composites: A study from macro- to nano-dimensions,” Carbohyd. Polym. 139, 139-149. DOI: 10.1016/j.carbpol.2015.12.020

Moskalik, T., Sadowski, J., Sarzyński, W., and Zastocki, D. (2013). “Efficiency of slash bundling in mature coniferous stands,” Sci. Res. Essays 8(31), 1478-1486. DOI: 10.5897/SRE2013.5562

Moskalik, T., Sadowski, J., and Zastocki, D. (2016). “Some technological and economic aspects of logging residues bundling,” Sylwan 160(1), 31-39.

Munalula, F., and Meincken, M. (2009). “An evaluation of South African fuelwood with regards to calorific value and environmental impact,” Biomass Bioenerg. 33(3), 415-420. DOI: 10.1016/j.biombioe.2008.08.011

Nati, C., Spinelli, R., and Fabbri, P. (2010). “Wood chips size distribution in relation to blade wear and screen use,” Biomass Bioenerg. 34(5), 583-587. DOI: 10.1016/j.biombioe.2010.01.005

Ociepa-Kubicka, A. (2015). “The use of biomass in energy companies,” Proceedings of ECOpole 9(1), 279-286. DOI: 10.2429/proc.2015.9(1)036

Phanphanich, M., and Mani, S. (2009). “Drying characteristics of pine forests residues,” BioResources 5(1), 108-121. DOI: 10.15376/biores.5.1.108-121

Phanphanich, M., and Mani, S. (2011). “Impact of torrefaction on the grindability and fuel characteristics of forest biomass,” Bioresource Technol. 102(2), 1246-1253. DOI: 10.1016/j.biortech.2010.08.028

PN-EN 15103:2010E (2010). “Solid biofuels – Determination of bulk density,” Polish Committee for Standardization, Warsaw, Poland.

Ragland, K. W., Aerts, D. J., and Baker, A. J. (1991). “Properties of wood for combustion analysis,” Bioresource Technol. 37(2), 161-168. DOI: 10.1016/0960-8524(91)90205-X

Reva, V., Fonseca, L., Lousada, J. L., Abrantes, I., and Viegas, D. X. (2012). “Impact of the pinewood nematode, Bursaphelenchus xylophilus, on gross calorific value and chemical composition of Pinus pinaster woody biomass,” Eur. J. For. Res. 131(4), 1025-1033. DOI: 10.1007/s10342-011-0574-5

Rosendahl, L. (Ed.). (2013). Biomass Combustion Science, Technology and Engineering – 1st Edition, Woodhead Publishing Series in Energy No 40, Woodhead Publishing, Oxford Cambridge Philadelphia New Delhi.

Röser, D., Mola-Yudego, B., Prinz, R., Emer, B., and Sikanen, L. (2012). “Chipping operations and efficiency in different operational environments,” Silva Fenn. 46(2), 275-286. DOI: 10.14214/sf.60

Rynkiewicz, M., and Śnieg, M. (2015). “Principal component analysis in assessment of relations to some pelleted feed characteristics,” Acta Sci. Pol. Zootechnica 14(3), 85-96.

Sadhukhan, A. K., Gupta, P., and Saha, R. K. (2009). “Modelling of pyrolysis of large wood particles,” Bioresource Technol. 100(12), 3134-3139. DOI: 10.1016/j.biortech.2009.01.007

Spinelli, R., Hartsough, B. R., and Magagnotti, N. (2005). “Testing mobile chippers for chip size distribution,” Int. J. For. Eng. 16(2), 29-36.

Stampfer, K., and Kanzian, C. (2006). “Current state and development possibilities of wood chip supply chains in Austria,” Croat. J. For. Eng. 27(2), 135-145.

Stolarski, M., Szczukowski, S., and Tworkowski, J. (2007). “Charakterystyka wybranych biopaliw z biomasy stałej [Characteristics of selected biofuels produced from solid biomass],” Problemy Inżynierii Rolniczej 15(4), 21-26.

Sulaiman, S. A., Roslan, R., Inayat, M., and Yasin Naz, M. (2017). “Effect of blending ratio and catalyst loading on co-gasification of wood chips and coconut waste,” J. Energy Inst. (In press). DOI: 10.1016/j.joei.2017.05.003

Sultana, A., and Kumar, A. (2011). “Optimal configuration and combination of multiple lignocellulosic biomass feedstocks delivery to a biorefinery,” Bioresource Technol. 102(21), 9947-9956. DOI: 10.1016/j.biortech.2011.07.119

Uliasz-Bocheńczyk, A., and Mokrzycki, E. (2015). “Biomasa jako paliwo w energetyce [Biomass as a Fuel in Power Industry],” Rocznik Ochrona Srodowiska, 17(part 2), 900–913.

Uri, V., Aosaar, J., Varik, M., Becker, H., Kukumägi, M., Ligi, K., Pärn, L., and Kanal, A. (2015). “Biomass resource and environmental effects of Norway spruce (Picea abies) stump harvesting: An Estonian case study,” Forest Ecol. Manag. 335, 207-215. DOI: 10.1016/j.foreco.2014.10.003

Werther, J., Saenger, M., Hartge, E.-U., Ogada, T., and Siagi, Z. (2000). “Combustion of agricultural residues,” Prog. Energ. Combust. Sci. 26(1), 1-27. DOI: 10.1016/S0360-1285(99)00005-2

Wielgosiński, G., Łechtańska, P., and Namiecińska, O. (2017). “Emission of some pollutants from biomass combustion in comparison to hard coal combustion,” J. Energy Inst. 90(5), 787-796. DOI: 10.1016/j.joei.2016.06.005

Väisänen, T., Haapala, A., Lappalainen, R., and Tomppo, L. (2016). “Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review,” Waste Management 54, 62–73. DOI: 10.1016/j.wasman.2016.04.037

Yoshioka, T., Aruga, K., Nitami, T., Sakai, H., and Kobayashi, H. (2006). “A case study on the costs and the fuel consumption of harvesting, transporting, and chipping chains for logging residues in Japan,” Biomass Bioenerg. 30(4), 342-348. DOI: 10.1016/j.biombioe.2005.07.013

Zhao, D., Kane, M., Teskey, R., Markewitz, D., Greene, D., and Borders, B. (2014). “Impact of management on nutrients, carbon, and energy in aboveground biomass components of mid-rotation loblolly pine (Pinus taeda L.) plantations,” Ann. For. Sci. 71(8), 843-851. DOI: 10.1007/s13595-014-0384-2

Zhu, J. Y., and Zhuang, X. S. (2012). “Conceptual net energy output for biofuel production from lignocellulosic biomass through biorefining,” Progress in Energy and Combustion Science 38(4), 583–598. DOI: 10.1016/j.pecs.2012.03.007

Article submitted: July 19, 2018; Peer review completed: September 17, 2018; Revised version received and accepted: October 22, 2018; Published: November 5, 2018.

DOI: 10.15376/biores.14.1.6-20