Abstract

Pinus elliottii wood from different radial locations within trees was used to prepare two-layer preservative-treated wood joints with alkaline copper quaternary preservative and emulsion polymer isocyanates (EPI) or resorcinol-phenol-formaldehyde (RPF) adhesives. The radial variations in shear strength and wood failure percentage were analyzed. Radial variations in wood density and average penetration depth (AP) of adhesives were investigated to establish relationships between shear strengths and characteristics of bonded joints. The shear strengths of EPI- and RPF-bonded joints showed similar increasing trends from pith to bark, and they varied in ranges of 2.92 to 8.13 MPa and 2.03 to 7.12 MPa, respectively. The wood failure percentage of EPI joints (93% to 100%) had no significant differences in all the radial locations, but that of RPF joints (60% to 100%) showed a clear decreasing trend from pith to bark. High positive linear correlations were found between the shear strengths and wood density, and Pearson’s correlation coefficients for EPI and RPF were 0.934 (p < 0.01) and 0.931 (p < 0.01), respectively. Wood density is a very important factor influencing radial variations of bonding strengths. The correlation between the AP and shear strength was not significant at the 0.05 level.

Download PDF

Full Article

Radial Variation in Bonding Performance of Preservative-treated Wood within Pinus elliottii Trees and Its Relationships with Wood Density and Adhesive Penetration

La Hu, Lizhe Qin, Dongshan Wu, Huilan Xu, and Zhangqi Yang *

Pinus elliottii wood from different radial locations within trees was used to prepare two-layer preservative-treated wood joints with alkaline copper quaternary preservative and emulsion polymer isocyanates (EPI) or resorcinol-phenol-formaldehyde (RPF) adhesives. The radial variations in shear strength and wood failure percentage were analyzed. Radial variations in wood density and average penetration depth (AP) of adhesives were investigated to establish relationships between shear strengths and characteristics of bonded joints. The shear strengths of EPI- and RPF-bonded joints showed similar increasing trends from pith to bark, and they varied in ranges of 2.92 to 8.13 MPa and 2.03 to 7.12 MPa, respectively. The wood failure percentage of EPI joints (93% to 100%) had no significant differences in all the radial locations, but that of RPF joints (60% to 100%) showed a clear decreasing trend from pith to bark. High positive linear correlations were found between the shear strengths and wood density, and Pearson’s correlation coefficients for EPI and RPF were 0.934 (p < 0.01) and 0.931 (p < 0.01), respectively. Wood density is a very important factor influencing radial variations of bonding strengths. The correlation between the AP and shear strength was not significant at the 0.05 level.

Keywords: Radial variation; Bonding performance; Preservative-treated wood; Pinus elliottii; Wood density; Average penetration depth

Contact information: Guangxi Forestry Research Institute, Guangxi Key Laboratory of Superior Timber Trees Resource Cultivation, Engineering Research Center of Masson Pine of Guangxi, Nanning 530002, Guangxi, China; *Corresponding author: yangzhangqi@163.com

INTRODUCTION

Slash pine (Pinus elliottii) is native to the southeastern United States, and it has been grown in China for over 70 years (Wen et al. 2004). The planting area of slash pine was rapidly expanded in the early 1980s to improve the ecological environment in South China (Ma et al. 2008), and it has become an important endemic plantation tree species in subtropical China (Tu et al. 2017). Although the slash pine is mainly used for resin-tapping because of the high yield and quality of its resin (Lai et al. 2020), it has potential as a raw material for wood construction due to its fast growth rate and high stem straightness (Pérez Zerpa et al. 2017).

The slash pine is a non-durable wood species, and thus it needs preservative treatment for protection from attacks of wood-decaying fungi and insects if used in outdoor construction (Cookson 2013). Although chemicals such as creosote, pentachlorophenol, and chromate copper arsenate (CCA) are used as wood preservatives in China’s wood industry, low-toxicity water-based preservatives such as alkaline copper quaternary (ACQ) and copper azole (CA) are the leading commercial products (Qin et al. 2019). Glued products such as cross-laminated timber (CLT) are increasingly popular in construction instead of traditional logs and sawn timbers (Li et al. 2019; Lim et al. 2020), as the assembling and gluing processes are greatly beneficial to prepare high-performance and diverse structural products while using fast-growing plantation wood as the main raw materials. Therefore, the bonding performance of preservative-treated slash pine wood plays an important role in its application for timber structures.

The heterogeneity of wood shows great influences on its utilization, especially for structural uses. The radial variability of wood properties within trees is generally significant and attracts more attention, as it reflects different properties of wood formed in different growth periods. For slash pine, there are significant differences in the physical, chemical, and mechanical properties between juvenile wood and mature wood (Bao et al. 2001; Severo et al. 2012). This large variability leads to differences in corresponding bonding strengths, and it needs investigation in order to use slash pine in timber structures.

It is widely believed that adhesive penetration in wood has a substantial effect on the bonding performance of the wood joints (Modzel et al. 2011; Bastani et al. 2016). The penetration affects the bond quality and subsequently the properties of the whole bonding joints, and a deeper penetration generally contributes to a higher bonding strength. The quantitative parameters of adhesive penetration, including the average penetration depth (AP) and the effective penetration depth (EP), have significant correlations (p < 0.01) with the shear strength of ACQ-treated Masson pine (Pinus massoniana) glue joints, and a larger Pearson’s correlation coefficient has been found for AP (0.516) than EP (0.401) (Qin et al. 2019). Thus, the radial variation of adhesive penetration could be a crucial factor accounting for the radial variability of the bonding performance of preservative-treated slash pine wood. To understand the radial variation in bonding performance of preservative-treated wood within Pinus elliottii trees, ACQ preservative and two structural adhesives of emulsion polymer isocyanates (EPI) and resorcinol-phenol-formaldehyde (RPF) were used to prepare two-layer wood joints, and their shear strength and wood failure percentage were evaluated. The changes of bonding performance were further analyzed based on the radial variations of both wood density and adhesive penetration.

EXPERIMENTAL

Materials

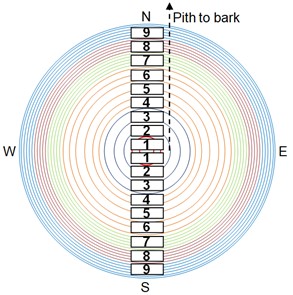

Two 27-year-old slash pine trees with similar diameter at breast height (30.1 cm and 30.0 cm) and tree height (18.3 m, 17.6 m) were felled in Guangxi Hepu Forestry Division, and logs at a height of 1.3 to 5.3 m were collected. Two 40 mm thick timbers across the north-south radial direction were sawn from the logs, with the pith locating near the center of the timbers. The timbers were kiln dried to obtain a moisture content of less than 15%. For each timber, wood strips with a thickness of 8 mm were successively processed from pith to bark with a precision panel saw (MJ6130TD, Qingdao SOSN Machinery CO., LTD., Qingdao, China) (Fig. 1), and numbered 1, 2, 3, 4, 5, 6, 7, 8 and 9, corresponding to the annual rings of 1 to 2 a, 3 to 4 a, 4 to 5 a, 6 to 8 a, 8 to 9 a, 9 to 11 a, 12 to 16 a, 17 to 21 a and 22 to 27 a, respectively. These strips were then cut into small boards with a size of 480 mm (longitudinal) × 30 mm (tangential) × 8 mm (radial) and moved to a humidity chamber (temperature of 20 °C, relative humidity of 65%) for one week.

Fig. 1. Cross-section schematic diagram of the processing of wood strips from logs. Numbers represent radial locations

The solution of ACQ-D preservative was provided by Guangdong Linke Technology Development Co., Ltd. (Guangzhou, China), and the mass fraction of its active ingredients was 15.39%. The ACQ-D consisted of quaternary ammonium salt (expressed as didecyldimethylammonium chloride (DDAC)) and copper compound (expressed as CuO) with a ratio of 4.87:10.52.

EPI was purchased from Dynea (Shanghai) Co., Ltd. (Shanghai, China), and the weight ratio of its main agent to curing agent was 100:20. The main agent (Prefere 6150) is a milky white viscous liquid with a solid content of 58%, viscosity of 8 Pa·s, and pH of 7.0. The curing agent (Prefere 6653) is a brown liquid with a viscosity of 0.2 Pa·s. RPF was provided by Shenyang AICA-HOPE Chemical Co., Ltd. (Shenyang, China), and the weight ratio of its main agent to curing agent is 100:20. The main agent (PR-1HSE) is a reddish brown viscous liquid with a solid content of 65%, viscosity of 15 Pa·s, and pH of 7.5. The curing agent (PRH-10A) is a reddish brown powder.

Methods

Preservative treatment

Slash pine boards were treated with a conventional vacuum-pressure impregnation method. The boards were placed into a stainless box with ACQ solution (1.5%wt), and the box was then transferred into a pressure tank. A preliminary vacuum was applied at -0.08 to -0.09 MPa for 30 min, and pressure was then applied up to 1.2 MPa for 60 min. The retention of wood preservatives was calculated as (m2 – m1) · C / V, where m1 and m2 are the masses of the wood specimens before and after impregnation treatment, respectively, and C and V are the concentration of preservation solution and the volume of wood specimens before impregnation treatment, respectively. ACQ retentions of wood boards from locations 1 and 2 were 8.88 kg/m3 and 8.02 kg/m3, respectively, which were slightly higher than that from locations 3 to 9 (7.09 to 7.49 kg/m3). The treated boards were dried in an oven at 50 °C for 3 d and moved to a humidity chamber (temperature of 20 °C, relative humidity of 65%) for two weeks. The density of each treated board was simply obtained by its mass divided by its volume.

Bonding test

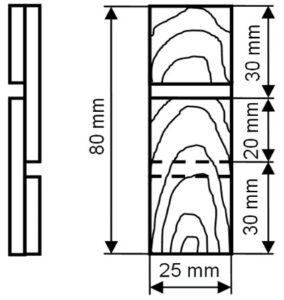

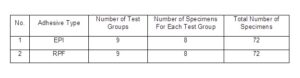

The bonding performance of the preservative-treated boards was evaluated according to ISO 6237 (2017). The treated boards were planed and sawn to thinner blocks with a size of 400 mm (longitudinal) × 30 mm (tangential) × 5 mm (radial), with a single-sided planer at a spindle speed of 9100 r/min (MB103G-3F2, Jincheng Woodworking Machinery Co., Ltd, Yantai, China) and a precision panel saw. The block surfaces to be glued were carefully cleaned by a dust-blow gun. Two-layer wood joints were assembled at glue-spread rates of 305.1 g/m2 and 263.1 g/m2 for EPI and RPF, respectively. Wood joints with EPI as the adhesive were prepared under unit pressure of 1.3 MPa for 2 h, while wood joints with RPF as the adhesive were prepared under unit pressure of 0.8 MPa for 3 h. Each set of tests was repeated four times, and two specimens were cut from each joint (Fig. 2). The number of specimens used in the test is shown in Table 1. The shear strength was measured by a universal mechanical testing machine with loading speed of 5 kN/min, and the wood failure percentage was obtained by visual observations. The appearance of the fracture surfaces of bonding joints was observed by a Nikon stereo microscope (SMZ 745T, Japan).

Fig. 2. Two-ply tensile shear specimen. Width of the sawcut is 3 mm

Table 1. Number of Tensile Shear Specimens Used in the Bonding Test

Adhesive penetration measurement

AP was measured according to the method used by Qin et al. (2019). Two blocks with length of 20 mm were cut across the longitudinal direction from each wood joint. The blocks were then processed to thinner blocks with a thickness of 7 mm, ensuring that the bondline was located nearly in the center of the blocks. Two small sample blocks with a width of 7 mm were finally cut from the thinner blocks and were impregnated in water for 3 d. Transverse sections with a thickness of 25 μm were cut from the sample blocks using a sliding microtome and dehydrated by placing them in an alcohol solution under progressively increasing concentrations (30%, 50%, 70%, 95%, 100%) for 10 min. The dehydrated slices were fixed between a glass slide and a cover glass with a drop of Canada balsam. The gross penetration was measured by a Nikon microscope (Eclipse Ni-E, Japan). The AP was calculated according to Eq. 1, and it represents the average depth of penetration for several column tissues within the entire measurement length,

![]() (1)

(1)

where yi is the penetration depth of adhesives in column tissue (μm), and N is the total column number of tissues in measurement length.

Statistical analysis

Duncan multiple comparisons were conducted to test the significance of the difference between radial locations with SPSS Statistics (International Business Machines Corporation, Armonk, NY, USA). Pearson correlation analysis and least squares regression analysis were used to investigate the relationship between wood density (AP) and shear strength with SPSS Statistics.

RESULTS AND DISCUSSION

Radial Variation of Bonding Performance

The shear strength and wood failure percentage of EPI/RPF bonded preservative-treated wood joints are shown in Fig. 3. The shear strengths of EPI and RPF bonded joints showed similar increasing trends from pith to bark, with variation ranges of 2.92 to 8.13 MPa and 2.03 to 7.12 MPa, respectively. According to the results from Duncan multiple comparisons, the wood formed in early growth periods had significantly lower shear strength, and the shear strength of the joints became generally stable from location 5 to location 9, which was consistent with the reported better mechanical properties (such as modulus of rupture, modulus of elasticity, compression parallel-to-grain and tensile strength) of mature slash pine wood than juvenile wood (Bao et al. 2001). The average shear strength of EPI joints (6.56 MPa) was higher than that of RPF joints (5.35 MPa), and close to that of Vacsol Azure-treated Scotch pine joints with poly(vinyl acetate) (6.74 MPa), urea-formaldehyde (7.04 MPa), and phenol-formaldehyde (6.40 MPa) as adhesives (Keskin et al. 2009).

Fig. 3. Radial variations in the bonding performance of EPI/RPF bonded preservative-treated wood joints. The same letter indicates no significant difference (p < 0.05) in Duncan multiple comparisons.

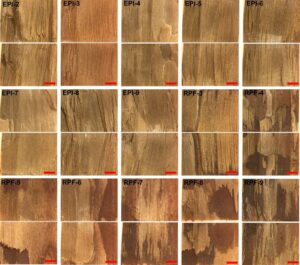

The failure region of EPI joints from location 1 and RPF joints from locations 1and 2 appeared in wood cross sections near the sawcut rather than in shearing sections, indicating a very low mechanical strength of the wood in these locations. The wood failure percentages of these joints were counted as 100%. The wood failure percentages of EPI joints fluctuated from 93% to 100%, and showed no significant differences in all radial locations (Figs. 3 and 4). However, the wood failure percentages of RPF joints (60% to 100%) presented a clear decreasing trend from pith to bark, and the wood failure percentages of specimens from locations 1 to 3 (92% to 100%) were significantly higher than that from locations 7 to 9 (60% to 65%). As compared with EPI joints, the lower wood failure percentages of RPF joints accounted for their lower shear strengths.

Fig. 4. The appearance of the fracture surfaces of bonding joints. The scale bar represents 5 mm.

Radial Variation in Wood Density and Its Correlation with Shear Strength

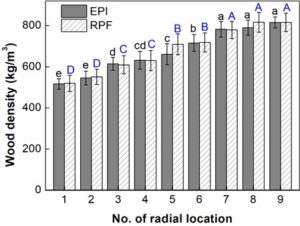

Radial variations in wood density of the two trees are displayed in Fig. 5. The densities of wood blocks for bonding with EPI and RPF showed similar increasing trends from pith to bark, which was consistent with the radial variation of wood density of Masson pine (Pinus massoniana) (Wassenberg et al. 2015). Variation ranges of wood density for EPI and RPF were 516.6 to 816.2 kg/m3 and 519.7 to 816.5 kg/m3, respectively. The wood specimens from locations 7 to 9 had significantly higher densities than those from other locations, while the wood specimens from locations 1 and 2 showed significantly lower densities. Basing on the radial variation of wood density, blocks from locations 1 to 6 belonged to juvenile wood, and blocks from locations 7 to 9 were classified as mature wood. The juvenile period of the slash pine used in this study should be about 11 to 12 years, which was similar to the result from Xu et al. (1993).

Fig. 5. Radial variations in the density of wood blocks for bonding with EPI and RPF adhesives. The same letter indicates no significant difference (p < 0.05) in Duncan multiple comparisons.

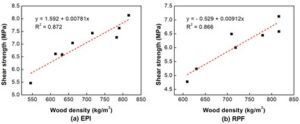

Considering the abnormal failure pattern for EPI joints from locations 1 and RPF joints from locations 1 and 2, the data from these locations were not used to conduct correlation analysis. As shown in Fig. 6, high positive linear correlations were found between the shear strength and wood density of joints from different radial locations, and the Pearson’s correlation coefficients of EPI and RPF were 0.934 (p < 0.01) and 0.931 (p < 0.01), respectively. The wood density was demonstrated to be a very important factor accounting for the radial variation of bonding strength. Similar significant correlations were found between air-dried density and the compression strength parallel to the grain of Casuarina equisetifolia (Chowdhury et al. 2009), as well as between the wood density obtained from soft X-ray analysis with Young’s modulus and strength in static bending, compressive Young’s modulus, compressive strength, and compressive proportional limit (Kubojima et al. 2008).

Fig. 6. Linear regression for wood density and shear strength of joints from different radial locations

Radial Variation in Adhesive Penetration and Its Correlation with Shear Strength

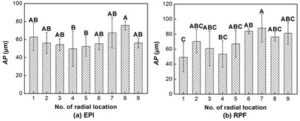

As shown in Fig. 7, the AP of EPI and RPF fluctuated within ranges of 49.88 to 75.65 μm and 49.20 to 87.83 μm, respectively. The average AP of RPF (70.08 μm) was higher than that of EPI (58.94 μm), possibly due to the lower molecular weight of RPF. The AP of EPI in location 8 was significantly higher than that in locations 4 and 5, while the AP of RPF in location 7 was significantly higher than that in locations 1 and 4. The average AP of EPI (54.41 μm) and RPF (66.36 μm) in juvenile wood was significantly (p < 0.05) lower than that in mature wood (61.84 μm and 82.44 μm for EPI and RPF, respectively). However, no obvious trend from pith to bark was observed for the AP of EPI and RPF.

Fig. 7. Radial variations in the AP of EPI and RPF adhesives. The same letter indicates no significant difference (p < 0.05) in Duncan multiple comparisons.

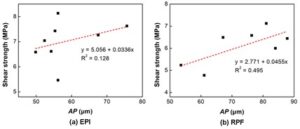

Although positive linear correlations were observed for the AP and shear strength (Fig. 8), no significant (p < 0.05) correlation was found in Pearson correlation analysis.

Fig. 8. Linear regression analysis for AP and shear strength of joints from different radial locations

The AP of EPI and RPF was substantially higher than AP (30.6 to 35.8 μm) of aqueous polymer isocyanate (API) in a previous similar study referring to Masson pine (Qin et al. 2019). These findings is indicated that both EPI and RPF penetrated easily in preservative-treated slash pine wood, and thus the adhesive penetration is not a significant factor influencing the radial variation of bonding strength.

CONCLUSIONS

The shear strengths of emulsion polymer isocyanates (EPI) and resorcinol-phenol-formaldehyde (RPF) bonded alkaline copper quaternary (ACQ)-treated slash pine joints showed similar increasing trends from pith to bark, and varied in ranges of 2.92 to 8.13 MPa and 2.03 to 7.12 MPa, respectively. The wood failure percentage of EPI joints showed no significant difference in all radial locations, but that of RPF joints presented clear decreasing trend from pith to bark.

The wood density gradually increased from pith to bark, and varied in ranges of 516.6 to 816.2 kg/m3 and 519.7 to 816.5 kg/m3 for EPI and RPF, respectively. High positive linear correlations were found between the shear strength and wood density of joints from different radial locations, and the Pearson’s correlation coefficients of EPI and RPF were 0.934 (p < 0.01) and 0.931 (p < 0.01), respectively.

The average penetration depth (AP) of EPI and RPF fluctuated within ranges of 49.88 to 75.65 μm and 49.20 to 87.83 μm, respectively, and no obvious trend from pith to bark has been observed. The correlations between the AP and shear strengths were not significant at the 0.05 level.

The average shear strength and wood failure percentage of EPI joints (6.56 MPa and 98.52%) were higher than that of RPF joints (5.35 MPa and 79.98%), while the average AP of RPF (70.08 μm) was higher than that of EPI (58.94 μm). The EPI showed stronger adhesion to ACQ-treated slash pine wood than the RPF.

The preservative-treated Pinus elliottii wood from the early growth periods showed poor bonding performance, and thus the wood over 10 years old was recommended as the raw material for producing glued products.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Fundamental Research Funds for Guangxi Forestry Research Institute (Grant No. 201803), the Science and Technology Major Project of Guangxi (Grant No. GUIKE AA17204087-16), the Guangxi Natural Science Foundation (Grant No. 2018GXNSFBA281108), and the Guangxi Science and Technology Base and Talent Special Project (Grant No. GUIKE AD19254004).

REFERENCES CITED

Bao, F. C., Jiang, Z. H., Jiang, X. M., Lu, X. X., Luo, X. Q., and Zhang, S. Y. (2001). “Differences in wood properties between juvenile wood and mature wood in 10 species grown in China,” Wood Sci. Technol. 35, 363-375. DOI: 10.1007/ s002260100099

Bastani, A., Adamopoulos, S., Koddenberg, T., and Militz, H. (2016). “Study of adhesive bondlines in modified wood with fluorescence microscopy and X-ray micro-computed tomography,” Int. J. Adhes. Adhes. 68, 351-358. DOI: 10.1016/j.ijadhadh. 2016.04.006

Chowdhury, M. Q., Ishiguri, F., Iizuka, K., Takashima, Y., Matsumoto, K., Hiraiwa, T., Ishido, M., Sanpe, H., Yokota, S., and Yoshizawa, N. (2009). “Radial variations of wood properties in Casuarina equisetifolia growing in Bangladesh,” J. Wood Sci. 55, 139-143. DOI: 10.1007/s10086-008-1004-2

Cookson, L.J. (2013). “Durability of light organic solvent preservative (LOSP) treatments for softwood glulam,” Int. Biodeter. Biodegr. 80, 41-47. DOI: 10.1016/j.ibiod. 2013.02.003

ISO 6237 (2017). “Adhesives – Wood-to-wood adhesive bonds – Determination of shear strength by tensile loading,” International Organization for Standardization, Geneva, Switzerland.

Keskin, H., Atar, M., and Akyildiz, M. H. (2009). “Bonding strengths of poly(vinyl acetate), Desmodur-VTKA, phenol-formaldehyde and urea-formaldehyde adhesives in wood materials impregnated with Vacsol Azure,” Mater. Design 30, 3789-3794. DOI: 10.1016/j.matdes.2009.01.032

Kubojima, Y., Kanetani, S., Fujiwara, T., Suzuki, Y., Tonosaki, M., Yoshimaru, H., and Ikegame, H. (2008). “Radial variations of wood properties of an endangered species, Pinus armandii var. amamiana,” J. Wood Sci. 54, 443-450. DOI: 10.1007/ s10086-008-0986-0

Lai, M., Zhang, L., Lei, L., Liu, S., Jia, T., and Yi, M. (2020). “Inheritance of resin yield and main resin components in Pinus elliottii Engelm. at three locations in southern China,” Ind. Crop. Prod. 144, 112065. DOI: 10.1016/j.indcrop.2019.112065

Li, H., Wang, B. J., Wei, P., and Wang, L. (2019). “Cross-laminated timber (CLT) in China: A state-of-the-art,” J. Bioresour. Bioprod. 4(1), 22-30. DOI: 10.21967/ jbb.v4i1.190

Lim, H., Tripathi, S., and Tang, J. D. (2020). “Bonding performance of adhesive systems for cross-laminated timber treated with micronized copper azole type C (MCA-C),” Constr. Build. Mater. 232, 117208. DOI: 10.1016/j.conbuildmat.2019.117208

Ma, Z. Q., Liu, Q. J., Wang, H. M., Li, X. R., Zeng, H. Q. and Xu, W. J. (2008). “Observation and modeling of NPP for Pinus elliottii plantation in subtropical China,” Sci. China Ser. D 51(7), 955-965. DOI: 10.1007/s11430-008-0075-7

Modzel, G., Kamke, F. A., and Carlo, F. De. (2011). “Comparative analysis of a wood: Adhesive bondline,” Wood Sci. Technol. 45(1), 147-158. DOI: 10.1007/s00226-010-0354-2

Pérez Zerpa, J. M., Castrillo, P., and Baño, V. (2017). “Development of a method for the identification of elastoplastic properties of timber and its application to the mechanical characterization of Pinus taeda,” Constr. Build. Mater. 139, 308-319. DOI: 10.1016/j.conbuildmat.2017.02.058

Qin, L., Hu, L., Yang, Z., and Duan, W. (2019). “Effect of the ACQ preservative on the bonding strength of aqueous polymer isocyanate bonded masson pine joints and on the adhesive penetration into wood,” BioResources 14(2), 2610-2621. DOI: 10.15376/biores.14.2. 2610-2621

Severo, E. T. D., Calonego, F. W., and Sansígolo, C. A. (2012). “Physical and chemical changes in juvenile and mature woods of Pinus elliottii var. elliottii by thermal modification,” Eur. J. Wood Wood Prod. 70, 741-747. DOI: 10.1007/s00107-012-0611-1

Tu, J., Wei, X., Fan, H., Wu, J., Hao, L., and Pei, Q. (2017). “Disentangling critical drivers of stem CO2 efflux from Pinus elliottii trees in Subtropical China,” Agr. Forest Meteorol. 237-238, 296-302. DOI: 10.1016/j.agrformet.2017.02.013

Wassenberg, M., Chiu, H. S., Guo, W., and Spiecker, H. (2015). “Analysis of wood density profiles of tree stems: Incorporating vertical variations to optimize wood sampling strategies for density and biomass estimations,” Trees 29(2), 551-561. DOI: 10.1007/s00468-014-1134-7

Wen, X., Kuang, Y., Shi, M., and Li, H. (2004). “Biology of Hylobitelus xiaoi (Coleoptera: Curculionidae), a new pest of slash pine, Pinus elliottii,” J. Econ. Entomol. 97, 1958-1964. DOI: 10.1093/jee/97.6.1958

Xu, Y., Shen, M., Wen, J., Zhao, D., and Huang, T. (1993). “Variation in wood characteristics of slash pine for pulpwood,” Journal of Huazhong Agricultural University 12(2), 147-153. DOI: 10.13300/j.cnki.hnlkxb.1993.02.011 (In Chinese)

Article submitted: October 29, 2020; Peer review completed: December 6, 2020; Revised version received and accepted: December 31, 2020; Published: February 1, 2021.

DOI: 10.15376/biores.16.2.2204-2214