Abstract

This paper discusses the use of agricultural biomass as a promising resource for renewable energy production, e.g., bio-oil and biogas via pyrolysis and catalysis, among other technologies. In order to prevent the accumulation of agricultural biomass, most countries still use traditional disposal or processing methods, e.g., burning in the field, which not only has a low energy conversion rate, but also releases harmful gases, e.g., CO2, CO, and NH3. These traditional methods are regarded as inefficient with respect to the low utilization of waste; they also pose a threat to human health. The energy conversion of agricultural biomass makes full use of resources and accelerates the development of green energy. In particular, agricultural biomass can lead to the production of high-quality renewable fuels and chemical raw materials through catalytic pyrolysis technologies. The fuel produced using catalytic pyrolysis has a low sulfur and alkali metal contents and techno-economic analysis shows that catalytic pyrolysis greatly reduces the production cost and improves the utilization rate of agricultural biomass. The production of bio-oil and gas via catalytic pyrolysis and agricultural biomass are environmentally friendly and economically feasible for clean energy production. Therefore, additional research is needed to enable the upscaling of renewable energy products.

Download PDF

Full Article

Sustainable Conversion of Agricultural Biomass into Renewable Energy Products: A Discussion

Quan Zhou,a Quyet Van Le,b Han Yang,a Haiping Gu,a Yafeng Yang,a Christian Sonne,c,* Meisam Tabatabaei,d Su Shiung Lam,e Cheng Li,a Xiangmeng Chen,f and Wanxi Peng a,*

This paper discusses the use of agricultural biomass as a promising resource for renewable energy production, e.g., bio-oil and biogas via pyrolysis and catalysis, among other technologies. In order to prevent the accumulation of agricultural biomass, most countries still use traditional disposal or processing methods, e.g., burning in the field, which not only has a low energy conversion rate, but also releases harmful gases, e.g., CO2, CO, and NH3. These traditional methods are regarded as inefficient with respect to the low utilization of waste; they also pose a threat to human health. The energy conversion of agricultural biomass makes full use of resources and accelerates the development of green energy. In particular, agricultural biomass can lead to the production of high-quality renewable fuels and chemical raw materials through catalytic pyrolysis technologies. The fuel produced using catalytic pyrolysis has a low sulfur and alkali metal contents and techno-economic analysis shows that catalytic pyrolysis greatly reduces the production cost and improves the utilization rate of agricultural biomass. The production of bio-oil and gas via catalytic pyrolysis and agricultural biomass are environmentally friendly and economically feasible for clean energy production. Therefore, additional research is needed to enable the upscaling of renewable energy products.

DOI: 10.15376/biores.17.2.Zhou

Keywords: Agriculture; Biomass; Energy; Pyrolysis; Waste

Contact information: a: School of Forestry, Henan Agricultural University, Zhengzhou 450002 China; b: Institute of Research and Development, Duy Tan University, Da Nang 550000 Vietnam; c: Aarhus University, Department of Bioscience, Arctic Research Centre (ARC), Frederiksborgvej 399, PO Box 358, Roskilde DK-4000 Denmark; d: Faculty of Plantation & Agrotechnology, Universiti Teknologi Mara, Shah Alam 40450 Malaysia; e: Pyrolysis Technology Research Group, Higher Institution Centre of Excellence (HICoE), Institute of Tropical Aquaculture and Fisheries (AKUATROP), Universiti Malaysia Terengganu, Kuala Nerus 21030 Terengganu, Malaysia; f: School of Chemical Engineering and Energy, Zhengzhou University, Zhengzhou 450001 China; Corresponding author: cs@bios.au.dk; pengwanxi@163.com

GRAPHICAL ABSTRACT

INTRODUCTION

Biomass is an important natural source used for conversion into renewable energy products in the form of biochar, fuel pellets, bioethanol, and hydrogen fuel, all which help the sustainable development of energy. This is an important research area (as shown in Figs. S1 and S2 in the Appendix). The global potential of biomass energy production is 100 to 440 EJ/year, which accounts for approximately 30% of the total energy needs of the world (Buyanov 2011; Kant et al. 2021; Ferraz et al. 2021; Swetha et al. 2021; Elnajjar et al. 2021). In some developing countries, the direct burning of agricultural biomass is a common practice, but this leads to serious environmental impacts, e.g., the emission of carbon dioxide, nitrogen oxides, and particulate matter (PM2.5) (Bhatia et al. 2020; Khan et al. 2021). The increase in particulate matter (PM2.5) concentration will even lead to the risk of cardiovascular and respiratory diseases (Karanasiou et al. 2021). China is one of the largest agricultural countries in the world, with an annual output of agricultural biomass of 889 million tons, of which 75% is directly combusted (REN21 2018; Wang et al. 2020). India is the second largest agriculture-based economy, growing crops all year round. The agricultural sector produces a large amount of agricultural biomass, and in order to deal with them, India needs to burn approximately 92 million tons of agricultural biomass every year, leading to a considerable impact on air quality and health (Bhuvaneshwari et al. 2019; Dey et al. 2020).

Since 1991, food-based ethanol production accounted for 92% of the actual production capacity, with corn and wheat being the dominating biomass resource (Ingrao et al. 2021). In the EU and North America, approximately 80 megatons/year of straw is available for energy production. For example, wheat production in Canada has great potential for wheat straw recycling into power generation. Such technology has potential to provide ecological benefits from the production of bioethanol and hydrogen fuels (Mupondwa et al. 2018; Havrysh et al. 2021). The annual output of rice and straw in Vietnam reaches 97 million tons, and its energy potential exceeds 380 Twh (Beňová et al. 2021). Many countries have gradually found that agricultural biomass can be used as a substitute for traditional fuels, offering a way to reduce the net amount of pollution caused by incineration (Bot et al. 2021; Rabea et al. 2021).

Table 1. Different Ways to Handle Agricultural Biomass and Development of Energy Products in Seven of the Larger Technology Leading Countries

Among the 17 sustainable development goals proposed by the United Nations in 2015, it was proposed that promoting the development of sustainable agriculture and sustainable modern energy will help to improve rural development, environmental protection, and economic operation. The disposal of agricultural biomass determines the development direction of sustainable energy (Vasileiadou et al. 2021). As a result, countries began to use different methods to treat agricultural biomass (as shown in Table 1).

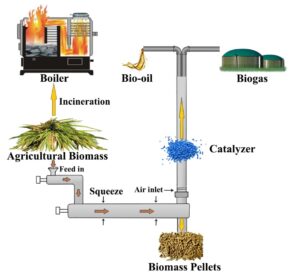

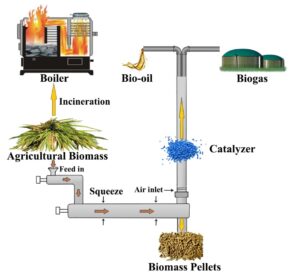

There are various ways to utilize agricultural biomass, and scholars from all over the world are committed to studying the utilization methods of agricultural biomass resources to achieve high output and maximum benefit of products (Zhang et al. 2015; Wang et al. 2020; Li et al. 2021). Straw from corn and wheat, which is used as one of the most important biomass resources, can be used in the production of fuel products through mechanical compaction or pyrolysis technology. In addition to the high-yield of corn and wheat, these agricultural biomasses are used as raw materials for energy production in some areas. For example, sugarcane is widely planted in southeast Brazil, where it is being used for conversion into liquid and gas fuels as well biochar materials (Muigai et al. 2020; Santana et al. 2020; Mohapatra et al. 2021; Rey et al. 2021). Straw, rice husk, bagasse, fruit husk, and crops are converted into biofuels using catalytic cracking, pyrolysis, and anaerobic digestion (as shown in Fig. 1) (Mahari et al. 2018; Lam et al. 2019; Baharin et al. 2020; Miranda et al. 2021). The catalytic cleavage of liquefied products from agricultural biomass under certain temperature and catalyst conditions is also able to produce fuels of higher value. For example, bio-oil can be obtained via the liquefaction process and biogas can be produced via gasification technology (Akhtar et al. 2010).

Fig. 1. Current situation of agricultural biomass utilization. The primary sources of agricultural biomass are straw, chaff, and crop residues (Mittal et al. 2017). (Note: the arrows in different colors indicate a different energy production method, and the arrows point to the target product indicate that the agricultural biomass has rich energy development potential)

CONVERSION OF AGRICULTURAL BIOMASS INTO AN ENERGY SOURCE

The most traditional energy conversion method for biomass is incineration, which has many advantages, i.e., in Japan, the use of incineration reduces the land occupation due to a shortage of land. Incineration refers to the process of thermal decomposition through thermal oxidation under high temperature conditions of 900 °C or higher. Generally, combustible wastes or wastes with high organic content are considered to be the most suitable for incineration (Oppelt et al. 2014). The cost of energy increased in the 1950s, and as a result many countries chose to use the incineration of agricultural biomass to generate household energy and heating (Yui et al. 2018; Nesterovic et al. 2021). The atmospheric pollution generated via incineration, e.g., the open-air combustion of straw, has become a major environmental problem (Zhang et al. 2016; Wu et al. 2020; Guo and Zhao 2021; Huang et al. 2021). Particulate matter, including PM2.5 and PM10, emitted from such incineration increases global warming and reduces air quality, which leads to the premature death of organisms among other effects (Beig et al. 2021; Liu et al. 2021; Manojkumar and Srimuruganandam 2021). The incineration of crop residues is one of the primary sources of atmospheric particulate matter (Song et al. 2021). In Thailand, the incineration of 9 million tons to 14 million tons of straw per year results in approximately 5 million tons to 9 million tons of CO2 emission, and the incineration of agricultural crops in India has been reported to reach 92 million tons per year, with the excess particulate matter emissions causing serious air pollution problems (Suramaythangkoor and Gheewala 2008; Junpen et al. 2018; Bhuvaneshwari et al. 2019). This shows an urgent need for countries worldwide to produce sustainable and renewable energy with considerably less environmental impacts.

Fig. 2. The conversion of agricultural biomass into fuel pellets (Brunerova et al. 2018). It is seen that the five types of agricultural biomass shown in the figure produce biomass pellet fuel via compression, combustion, cutting, and other methods.

Facing the emission of air pollutants, a study in North America used densification, compaction, and agglomeration methods to process biomass into smaller biomass pellets. This study reported that the combustion time of the biomass pellets was shorter than the combustion time of agricultural biomass direct combustion, which effectively reduced the emission of air pollutants (Marrugo et al. 2019; Tan et al. 2020; Yu et al. 2021; Dragutinovic et al. 2021). Biomass pellets also have a small volume, which are more convenient in terms of fuel transportation (Liu et al. 2020). Some countries also gradually began to use local agricultural biomass to make smaller biomass pellets to replace coal and natural gas as fuel for industrial boilers and kilns (as shown in Fig. 2) (Wattana et al. 2017; Dragutinovic et al. 2019; Vamvuka et al. 2020; Brand and Jacinto 2020). For example, bagasse and straw are widely burned as energy in boilers and power plants in Brazil (Kelly et al. 2021). Most straw is directly converted into granular fuel without prior drying due to its low water content (Chico-Santamarta et al. 2013; Djatkov et al. 2018).

Bio-oil

At the end of the 1970s, pyrolysis technology was being applied to the production of bio-oil from agricultural biomass. In the pyrolysis process, in addition to the production of bio oil, there are bio-char and gaseous products. Different raw materials and process conditions affect the yield of each product (Alper et al. 2015). Rapeseed, sunflower (Mathias et al. 2017; Thers et al. 2019; Urrutia et al. 2021), straw (Dimitriadis et al. 2021), rice husk (Das and Goud 2021), cotton stalk (Mandapati and Ghodke 2021), corn stalk (Akhtar et al. 2021), bagasse, and coconut shell have been used as raw materials for bio-oil production (Sarkar and Wang 2020; Almeida and Colombo 2021; Negrao et al. 2021). The production of bio-oil from agricultural biomass is also considerable (Table 2).

Table 2. Oil Production Rate of Agricultural Biomass Pyrolysis, Which Shows that the Oil Yield of Agricultural Biomass Pyrolysis Technology is Greater than 28 wt%, and the Average Yield Reported is 45 wt%

A biofuel refinery uses wheat straw and rice straw to produce bio-oil with an output of 75 million liters. A case study in Argentina shows that the production potential of soybeans used for bio-oil production on 32 Mha land can reach 472 PJ in 2030 (Diogo et al. 2014). The production of bio-oil from agricultural biomass has considerably increased the production of bio-oil in various countries. The bio-oil from bagasse is widely used as light vehicle fuel in Brazil (Stattman et al. 2013), and in Malaysia, bio-oil is used as engine and boiler fuel (Tye 2011; Gao et al. 2018; Sanchez-Borrego et al. 2021). Therefore, more and more countries are expected to produce bio-oil from agricultural biomass (Moghtaderi et al. 2007; Abdullah et al. 2020). The United States has set a target of 136 billion liters of biofuel by 2022 (Lora and Andrade 2009; OECD 2011). Liquefaction technology is another way to prepare high-quality bio-oil. The bio-oil made from agricultural biomass under certain conditions can also replace transportation fuel (Perkins et al. 2019; Cervi et al. 2020; Wang and Tuohedi 2020). In addition, studies have shown that the yield of bio-oil obtained from the liquefaction experiment of agricultural biomass catalyzed by metal oxides is about 1.4 times that without catalysis (Yim et al. 2016). In an experiment using rice husks as a raw material, the bio-oil was liquefied at a temperature of 320 °C for 30 min, and the biomass conversion rate was approximately 83% (Shin et al. 2013).

Biogas

Agricultural biomass can be used to produce biogas through gasification technology. Biomass gasification is a process in which the hydrocarbons that make up the biomass are converted into combustible gases containing CO, H2, and CH4 under certain thermodynamic conditions, and most of the energy in the biomass is transferred to gas. However, in the actual production of biogas, some raw materials will be converted into biochar, which means that 100% biogas production is not possible (Brewer et al. 2009). Compared with the incineration of agricultural biomass, gasification can be more environmentally friendly, as the amount of SO2, NOx, and dust released from the combustion of the biogas generated from gasification can be 90% lower than the amounts released from the incineration of agricultural biomass. Gasification also converts the biomass into a cleaner fuel, e.g., syngas, which is comprised of hydrogen, carbon monoxide, methane, water, and carbon dioxide (Bridgwater 1995; Molino et al. 2016; Okolie et al. 2020a; Reao and Halog 2020). The gas produced via agricultural biomass gasification is widely used for centralized gas supply, power generation, and may even replace fossil fuels (Evaristo et al. 2020; Okolie et al. 2020b; Guo et al. 2021). The biogas produced via straw gasification is used in large biogas plants and as energy for power generation (Chen and Xie 2014; Trivedi et al. 2017; Hoque et al. 2021). In addition, studies have shown that the measures of biogas replacing fossil fuel power generation can greatly reduce the emission of greenhouse gases in the atmosphere (Gosens et al. 2013). Kaspersen et al. (2016) evaluated the carbon dioxide emissions of biogas power plants in the Municipality of Solrød in Denmark and found that biogas power plants can reduce about 40000 tons of carbon dioxide per year through this way of power generation.

CATALYTIC PYROLYSIS CONVERSION OF AGRICULTURAL BIOMASS INTO ENERGY MATERIALS

Bio-oil from agricultural biomass pyrolysis has strong chemical corrosivity; instead, high-quality bio-oil can be prepared via catalytic pyrolysis technology, which is more conducive to energy utilization (Zheng et al. 2019; Moreno et al. 2020; Olatunji et al. 2021). Wang et al. (2015) prepared jet fuel via the catalytic conversion of bio-oil from straw, providing energy for military and commercial aviation fuel applications. Various energy products, e.g., liquid fuel and fuel cells, are produced using a number of different catalysts or reaction conditions of catalytic cracking technology (as shown in Table 3). When the catalytic medium used is steam, a series of reactions, e.g., biomass steam gasification, catalytic cracking, carbon dioxide reforming, and steam reforming, are carried out in a fixed bed gasifier with straw as a raw material. The gasification efficiency can reach 99.93%, and more stable hydrogen rich gas can be obtained compared to using gasification technology (Ma 2016). In a study by Wang et al. (2010), rice husk was catalytically cracked in a continuous pyrolysis unit. During the pyrolysis process, as the pyrolysis temperature increased, the hydrogen production increased, and hydrogen rich gas with a stable yield of approximately 30% was obtained.

However, in the process of catalytic cracking, the alkali metals and alkaline earth metals contained in agricultural biomass may volatilize and deposit on the catalyst, resulting in the reduction of catalyst performance (Mullen et al. 2010). In addition, the deactivation of the catalyst will also affect the performance of the catalyst, including coking deactivation and hydrothermal deactivation. Coking deactivation refers to the rapid formation of coke on the catalyst, which blocks the pores of the catalyst and leads to deactivation (Horne and Williams 1995). The hydrothermal deactivation of the catalyst is caused by the presence of water vapor in the catalytic cracking process and the exposure of the catalyst to high temperature. The water vapor comes from the reactions such as water and thermal decomposition of biomass structure in agricultural biomass raw materials (Stefanidis et al. 2016). Therefore, metal contamination and deactivation of the catalyst will change the functionality of the catalyst.

Table 3. Catalytic Cracking of Agricultural Biomass to Produce Energy Products. Various Types of Fuels can be Obtained from Agricultural Biomass Under the Action of Different Types of Catalysts

CHALLENGES AND FUTURE DIRECTIONS

The burning of agricultural biomass causes serious environmental pollution, which leads to the destruction of the ecosystem and poses a threat to human health. Therefore, countries all over the world need to adopt advanced technologies to obtain renewable bioenergy (Quispe et al. 2018; Duc et al. 2021). The conversion of agricultural biomass into energy related products via different methods will help to reduce greenhouse gas emissions and obtain renewable energy, as well as improve the economic situation of some rural farmers (Bhatia et al. 2020). In addition, converting agricultural biomass into liquid fuel, biogas, and other energy sources also has social benefits, e.g., improving rural living standards, effectively managing agricultural biomass waste, and improving sanitary conditions (Taghizadeh-Alisaraei et al. 2017; Bhatia et al. 2020). The production of fuel from agricultural biomass was improved via catalytic cracking, but the structure or property of fuel may be changed in the process of catalytic cracking (Ong et al. 2019; Yang et al. 2020). Therefore, it is necessary to study the mechanism of catalyst in the process of treating agricultural biomass and determine the factors affecting the quality of fuel in order to obtain high-quality renewable fuels and chemical raw materials.

The way agricultural biomass is converted into energy still faces many challenges. In the gasification process, in addition to gaseous fuel, some toxic pollutants are produced, such as acid gas, tar, and alkaline compounds. These pollutants need to be treated before being released into the atmosphere, so there will be additional costs (Ajay et al. 2009). Moreover, some bio-oil products produced by pyrolysis technology have poor thermal stability, and the product characteristics need to be improved to meet better applications (McKendry 2002). Therefore, in the process of converting agricultural biomass into energy, deeper and broader research solutions are needed to develop efficient and economical new technologies as soon as possible. At the same time, it is also necessary to overcome various social and commercial constraints, properly implement and promote government policies or plans, and contact stakeholders to the greatest extent, e.g., providing preferential treatment for the public and some energy industries in terms of commodities and taxes. This will not only help to ensure the future implementation of agricultural biomass to energy projects but will also achieve sustainable development by protecting the environment (Kumari 2016).

- Atmospheric emissions from the incineration of agricultural biomass increases global warming and air pollution. It is therefore necessary to use advanced technologies to achieve a sustainable energy-based utilization of agricultural biomass. This paper has discussed the application progress of agricultural biomass as biomass fuel, bio-oil, biogas, and the development of catalytic technology. The energy conversion of agricultural biomass improves the utilization rate of agricultural biomass and the output of renewable fuels.

- Agricultural biomass is processed into smaller biomass pellets by mechanical compaction, which not only can simplify the storage and transportation of biomass, but also can shorten the combustion time of agricultural biomass and reduce the emission of pollutants in the combustion process.

- Agricultural biomass is used as raw material to produce bio oil by pyrolysis technology and liquefaction technology, and the conditions suitable for different raw materials are selected to improve the conversion and yield of bio oil.

- The production of biogas can be used in power plants as an energy source through gasification or catalytic pyrolysis, in which the catalytic pyrolysis technology has obtained bio-oil and biogas with high yields and stability. In summary, future work should focus on the promotion of agricultural biomass, catalytic cracking technology, and the pursuit of high-quality products.

ACKNOWLEDGEMENTS

The manuscript was supported by the Program for Innovative Research Team (in Science and Technology) at the University of Henan Province (Grant No. 21IRTSTHN020) and the Central Plain Scholar Funding Project of Henan Province (Grant No. 212101510005). The authors declare no conflict of interest.

REFERENCES CITED

Abdullah, A., Ahmed, A., Akhter, P., Razzaq, A., Hussain, M., Hossain, N., Bakar, M. S. A., Khurram, S., Majeed, K., and Park, Y. K. (2020). “Potential for sustainable utilisation of agricultural residues for bioenergy production in Pakistan: An overview,” Journal of Cleaner Production 287, 1-14. DOI: 10.1016/j.jclepro.2020.125047

Ajay, K., Jones, D. D., and Hanna, M. A. (2009). “Thermochemical biomass gasification: a review of the current status of the technology,” Energies 2(3), 556-581. DOI: 10.3390/en20300556

Akhtar, J., Kuang, S. K., and Amin, N. S. (2010). “Liquefaction of empty palm fruit bunch (EPFB) in alkaline hot compressed water,” Renewable Energy 35(6), 1220-1227. DOI: 10.1016/j.renene.2009.10.003

Akhtar, J., Imran, M., Ali, A. M., Nawaz, Z., Muhammad, A., Butt, R. K., Jillani, M. S., and Naeem, H. A. (2021). “Torrefaction and thermochemical properties of agriculture residues,” Energies 14(14), 1-13. DOI: 10.3390/en14144218

Almeida, M. A. d., and Colombo, R. (2021). “Production chain of first-generation sugarcane bioethanol: Characterization and value-added application of wastes,” BioEnergy Research 1-16. DOI: 10.1007/s12155-021-10301-4

Alper, K., Tekin, K., and Karagz, S. (2015). “Pyrolysis of agricultural residues for bio-oil production,” Clean Technologies and Environmental Policy 17, 211-223. DOI: 10.1007/s10098-014-0778-8

Auersvald, M., Shumeiko, B., Vrtiška, D., Straka, P., Staš, M., Šimáček, P., Blažek, J., and Kubička, D. (2019). “Hydrotreatment of straw bio-oil from ablative fast pyrolysis to produce suitable refinery intermediates,” Fuel 238, 98-110. DOI: 10.1016/j.fuel.2018.10.090

Baharin, N. S. K., Koesoemadinata, V. C., Nakamura, S., Yahya, W. J., Yuzir, M. A. M., Akhir, F. N. M., Iwamoto, K., Othman, N., Ida, T., and Hara, H. (2020). “Conversion and characterization of bio-coke from abundant biomass waste in Malaysia,” Renewable Energy 162, 1017-1025. DOI: 10.1016/j.renene.2020.08.083

Beňová, D., Mareš, K., Hutla, P., Ivanova, T., Banout, J., and Kolaříková, M. (2021). “Energy potential of agri residual biomass in southeast Asia with the focus on Vietnam,” Agronomy 11(1), 1-18. DOI: 10.3390/agronomy11010169

Bhatia, R. K., Ramadoss, G., Jain, A. K., Dhiman, R. K., Bhatia, S. K., and Bhatt, A. K. (2020). “Conversion of waste biomass into gaseous fuel: Present status and challenges in India,” BioEnergy Research 13(4), 1046-1068. DOI: 10.1007/s12155-020-10137-4

Bhuvaneshwari, S., Hettiarachchi, H., and Meegoda, J. N. (2019). “Crop residue burning in India: Policy challenges and potential solutions,” Int. Journal of Environmental Research and Public Health 16(5), 1-19. DOI: 10.3390/ijerph16050832

Biswas, B., Pandey, N., Bisht, Y., Singh, R., Kumar, J., and Bhaskar, T. (2017). “Pyrolysis of agricultural biomass residues: comparative study of corn cob, wheat straw, rice straw and rice husk,” Bioresource Technology 237, 57-63. DOI: 10.1016/j.biortech.2017.02.046

Bot, B. V., Sosso, O. T., Tamba, J. G., Lekane, E., Bikai, J., and Ndame, M. K. (2021). “Preparation and characterization of biomass briquettes made from banana peels, sugarcane bagasse, coconut shells and rattan waste,” Biomass Conversion and Biorefinery, 1-10. DOI: 10.1007/s13399-021-01762-w

Brand, M. A., and Jacinto, R. C. (2020). “Apple pruning residues: Potential for burning in boiler systems and pellet production,” Renewable Energy 152, 458-466. DOI: 10.1016/j.renene.2020.01.037

Brewer, C. E., Schmidt-Rohr, K., Satrio, J. A., and Brown, R. C. (2009). “Characterization of biochar from fast pyrolysis and gasification systems,” Environmental Progress & Sustainable Energy 28, 386-396. DOI: 10.1002/ep.10378

Bridgwater, A. V. (1995). “The technical and economic feasibility of biomass gasification for power generation,” Fuel 74(5), 631-653. DOI: 10.1016/0016-2361(95)00001-L

Brunerová, A., Müller, M., Šleger, V., Ambarita, H., and Valášek, P. (2018). “Bio-pellet fuel from oil palm empty fruit bunches (EFB): Using European standards for quality testing,” Sustainability 10(12), 1-19. DOI: 10.3390/su10124443

Buyanov, V. (2011). “BP: Statistical Review of World Energy 2011,” Economic Policy 4, 38-55. (https://ideas.repec.org/a/rnp/ecopol/1149.html), Accessed 3 Mar 2021.

Campos, V. A. F. d., Silva, V. B., Cardoso, J. S., Brito, P. S., Tuna, C. E., and Silveira, J. L. (2021). “A review of waste management in Brazil and Portugal: Waste-to energy as pathway for sustainable development,” Renewable Energy 178, 802-820. DOI: 10.1016/j.renene.2021.06.107

Canadian Bioenergy Association (2010). “Canadian Report on Bioenergy 2010,” (http://www.canbio.ca/upload/documents/canada-report-on-bioenergy-2010-sept-15-2010. pdf), accessed 15 May 2021.

Cervi, W. R., Lamparelli, R. A. C., Gallo, B. C., Bordonal, R. d. O., Seabra, J. E. A., Junginger, M., and Hilst, F. (2020). “Mapping the environmental and techno-economic potential of biojet fuel production from biomass residues in Brazil,” Biofuels Bioproducts and Biorefining 15, 282-304. DOI: 10.1002/bbb.2161

Cheewaphongphan, P., Junpen, A., Kamnoet, O., and Garivait, S. (2018). “Study on the potential of rice straws as a supplementary fuel in very small power plants in Thailand,” Energies 11(2), 1-21. DOI: 10.3390/en11020270

Chen, Y., and Xie, S. (2014). “Characteristics and formation mechanism of a heavy air pollution episode caused by biomass burning in Chengdu, southwest China,” Science of the Total Environment 473-474, 507-517. DOI: 10.1016/j.scitotenv.2013.12.069

Chico-Santamarta, L., Godwin, R. J., Chaney, K., White, D. R., and Humphries, A. C. (2013). “On-farm storage of baled and pelletized canola (Brassica napus L.) straw: Variations in the combustion related properties,” Energy 50, 429-437. DOI: 10.1016/j.energy.2012.11.026

Das, S., and Goud, V. V. (2021). “RSM-optimized slow pyrolysis of rice husk for bio-oil production and its upgradation,” Energy 225, 1-10. DOI:10.1016/j.energy.2021.120161

David, E., and Kopac, J. (2018). “Pyrolysis of rapeseed oil cake in a fixed bed reactor to produce bio-oil,” Journal of Analytical and Applied Pyrolysis 134, 495-502. DOI: 10.1016/j.jaap.2018.07.016

Dey, D., Gyeltshen, T., Aich, A., Naskar, M., and Roy, A. (2020). “Climate adaptive crop-residue management for soil-function improvement; recommendations from field interventions at two agro-ecological zones in South Asia,” Environmental Research 183, 1-9. DOI: 10.1016/j.envres.2020.109164

Dimitriadis, A., Liakos, D., Pfisterer, U., Moustaka-Gouni, M., Karonis, D., and Bezergianni, S. (2021). “Impact of hydrogenation on miscibility of fast pyrolysis bio-oil with refinery fractions towards bio-oil refinery integration,” Biomass Bioenergy 151, 1-11. DOI: 10.1016/j.biombioe.2021.106171

Diogo, V., Hilst, F. v. d., Eijck. J. v., Verstegen, J. A., Hilbert, J., Carballo, S., Volante, J., and Faaij, A. (2014). “Combining empirical and theory-based land-use modelling approaches to assess economic potential of biofuel production avoiding iLUC: Argentina as a case study,” Renewable and Sustainable Energy Reviews 34, 208-224. DOI: 10.1016/j.rser.2014.02.040

Djatkov, D., Martinov, M., and Kaltschmitt, M. (2018). “Influencing parameters on mechanical–physical properties of pellet fuel made from corn harvest residues,” Biomass Bioenergy 119, 418-428. DOI: 10.1016/j.biombioe.2018.10.009

Dragutinović, N., Höfer, I., and Kaltschmitt, M. (2021). “Fuel improvement measures for particulate matter emission reduction during corn cob combustion,” Energies 14(15), 1-23. DOI: 10.3390/en14154548

Dragutinovic, N., Nakomcic-Smaragdakis, B., Djuric, S., and Djordjic, D. (2019). “Investigation of additives in combustion of wheat straw pellets in a small-scale boiler,” Journal of Renewable and Sustainable Energy 11(4), 1-9. DOI: 10.1063/1.5088640

Duc, H. N., Bang, H. Q., Quan, N. H., and Quang, N. X. (2021). “Impact of biomass burnings in southeast Asia on air quality and pollutant transport during the end of the 2019 dry season,” Environ. Monit. Assess. 193(9), 1-28. DOI: 10.1007/s10661-021-09259-9

Elnajjar, E., Syam, M. M., and Al-Omari, S. A. B. (2021). “Experimental investigations of bio-syngas production using microwave pyrolysis of UAE’s palm date seed pits,” Fuel 303, 1-16. DOI: 10.1016/j.fuel.2021.121348

Evaristo, R. B. W., Viana, N. A., Guimãres, M. G., Vale, A. T. d., and Ghesti, G. F. (2020). “Evaluation of waste biomass gasification for local community development in central region of Brazil,” Biomass Conversion and Biorefinery, 1-12. DOI: 10.1007/s13399-020-00821-y

Field, J. L., Tanger, P., Shackley, S. J., and Haefele, S. M. (2016). “Agricultural residue gasification for low-cost, low-carbon decentralized power: An empirical case study in Cambodia,” Applied Energy 177, 612-624. DOI: 10.1016/j.apenergy.2016.05.100

Fleig, O. P., Raymundo, L. M., Trierweiler, L. F., and Trierweiler, J. O. (2021). “Study of rice husk continuous torrefaction as a pretreatment for fast pyrolysis,” Journal of Analytical and Applied Pyrolysis 154, 1-9. DOI: 10.1016/j.jaap.2020.104994

Gao, N., Quan, C., Ma, Z., and Wu, C. (2018). “Thermal characteristics of biomass pyrolysis oil and potential hydrogen production by catalytic steam reforming,” Energy & Fuels 32(4), 5234-5243. DOI: 10.1021/acs.energyfuels.8b00365

Gosens, J., Lu, Y., He, G., Bluemling, B., and Beckers, T. A. M. (2013). “Sustainability effects of household-scale biogas in rural China,” Energy Policy 54, 273-287. DOI: 10.1016/j.enpol.2012.11.032

Guo, L., and Zhao, J. (2021). “Effect of burning straw in rural areas on ecological environment quality,” Arabian Journal of Geosciences 14(14), 1-10. DOI: 10.1007/s12517-021-07797-7

Guo, X., Zhang, Y., Guo, Q., Zhang, R., Wang, C., Yan, B., Lin, F., Chen, G., and Hou, L. (2021). “Evaluation on energetic and economic benefits of the coupling anaerobic digestion and gasification from agricultural wastes,” Renewable Energy 176, 493-503. DOI: 10.1016/j.renene.2021.05.097

Hai, A., Bharath, G., Daud, M., Rambabu, K., Ali, I., Hasan, S. W., Show, P., and Banat, F. (2021). “Valorization of groundnut shell via pyrolysis: product distribution, thermodynamic analysis, kinetic estimation, and artificial neural network modeling,” Chemosphere 283, 1-9. DOI: 10.1016/j.chemosphere.2021.131162

Havrysh, V., Kalinichenko, A., Brzozowska, A., and Stebila, J. (2021). “Agricultural residue management for sustainable power generation: The Poland case study,” Applied Sciences 11(13), 1-16. DOI: 10.3390/app11135907

Hoque, M. E., Rashid, F., and Aziz, M. (2021). “Gasification and power generation characteristics of rice husk, sawdust, and coconut shell using a fixed-bed downdraft gasifier,” Sustainability 13(4), 1-18. DOI: 10.3390/su13042027

Horne, P. A., and Williams, P. T. (1995). “The effect of zeolite ZSM-5 catalyst deactivation during the upgrading of biomass-derived pyrolysis vapours,” Journal of Analytical & Applied Pyrolysis 34(1), 65-85. DOI: 10.1016/0165-2370(94)00875-2

Huang, L., Zhu, Y., Wang, Q., Zhu, A., Liu, Z., Wang, Y., Allen, D. T., and Li, L. (2021). “Assessment of the effects of straw burning bans in China: Emissions, air quality, and health impacts,” Science of the Total Environment 789(4), 1-12. DOI: 10.1016/j.scitotenv.2021.147935

Ingrao, C., Matarazzo, A., Gorjian, S., Adamczyk, J., Failla, S., Primerano, P., and Huisingh, D. (2021). “Wheat-straw derived bioethanol production: A review of life cycle assessments,” Science of the Total Environment 781, 1-20. DOI: 10.1016/j.scitotenv.2021.146751

Junpen, A., Pansuk, J., Kamnoet, O., Cheewaphongphan, P., and Garivait, S. (2018). “Emission of air pollutants from rice residue open burning in Thailand,” Atmosphere 9(11), 1-23. DOI: 10.3390/atmos9110449

Kant, B. S., Palai, A. K., Kumar, A., Bhatia, R. K., Patel, A. K., Thakur, V. K., and Yang, Y.-H. (2021). “Trends in renewable energy production employing biomass-based biochar,” Bioresource Technology 340, 1-12. DOI: 10.1016/j.biortech.2021.125644

Karanasiou, A., Alastuey, A., Amato, F., Renzi, M., Stafoggia, M., Tobias, A., Reche, C., Rorastiere, F., Gumy, S., Mudu, P., et al. (2021). “Short-term health effects from outdoor exposure to biomass burning emissions: A review,” Science of the Total Environment 781, 1-21. DOI: 10.1016/j.scitotenv.2021.146739

Kaspersen, B. S., Christensen, T. B., Fredenslund, A. M., Møller, H. B., Butts, M. B., Jensen, N. H., and Kjaer, T. (2016). “Linking climate change mitigation and coastal eutrophication management through biogas technology: Evidence from a new Danish bioenergy concept,” Science of the Total Environment 541, 1124-1131. DOI: 10.1016/j.scitotenv.2015.10.015

Kelly, R. P. d., Edson, T., Soria-Verdugo, A., and Silva, M. A. (2021). “The influence of the elemental and structural chemical composition on the ash fusibility of sugarcane bagasse and sugarcane straw,” Fuel 304, 1-14. DOI: 10.1016/j.fuel.2021.121404

Khan, J. Z., Sun, L., Tian, Y., Shi, G., and Feng, Y. (2021). “Chemical characterization and source apportionment of pm1 and PM2.5 in Tianjin, China: Impacts of biomass burning and primary biogenic sources,” Journal of Environmental Sciences 99, 196-209. DOI: 10.1016/j.jes.2020.06.027

Kumari, S., and Das, D. (2016). “Biologically pretreated sugarcane top as a potential raw material for the enhancement of gaseous energy recovery by two stage biohythane process,” Bioresource Technology 218, 1090-1097. DOI: 10.1016/j.biortech.2016.07.070

Lam, S. S., Mahari, W. A. W., Ok, Y. S., Peng, W., Chong, C. T., Ma, N. L., Chase, H. A., Liu, Z. L., Yusup, S., Kwon, E. E., et al. (2019). “Microwave vacuum pyrolysis of waste plastic and used cooking oil for simultaneous waste reduction and sustainable energy conversion: Recovery of cleaner liquid fuel and techno-economic analysis,” Renewable and Sustainable Energy Reviews 115, 1-13. DOI: 10.1016/j.rser.2019.109359

Li, S., and Song, X. (2018). “Study on the preparation and production factors of a direct lignocellulose biomass fuel cell,” Journal of Electroanalytical Chemistry 810, 55-61. DOI: 10.1016/j.jelechem.2017.12.085

Li, Y., Shaheen, S. M., Rinklebe, J., Ma, N. L., Yang, Y., Ashraf, M. A., Chen, X. M., and Peng, W.-X. (2021). “Pyrolysis of Aesculus chinensis Bunge seed with Fe2O3/Nio as nanocatalysts for the production of bio-oil material,” Journal of Hazardous Materials 416, 1-10. DOI: 10.1016/j.jhazmat.2021.126012

Liu, X., Feng, X., Huang, L., and He, Y. (2020). “Rapid determination of wood and rice husk pellets’ proximate analysis and heating value,” Energies 13(14), 1-12. DOI: 10.3390/en13143741

Liu, Y., Zhang, J., and Zhuang, M. (2021). “Bottom-up re-estimations of greenhouse gas and atmospheric pollutants derived from straw burning of three cereal crops production in China based on a national questionnaire,” Environmental Science and Pollution Research 28, 65410-65415. DOI: 10.1007/s11356-021-15658-9

Lora, E. S., and Andrade, R. V. (2009). “Biomass as energy source in Brazil,” Renewable and Sustainable Energy Review 13(4), 777-788. DOI: 10.1016/j.rser.2007.12.004

Ma, C. (2016). “Influence of dolomite on straw steam gasification,” Biomass Chemical Engineering 50(1), 45-49. DOI: 10.3969 /j.issn.1673-5854.2016.01.009

Mahari, W. A. W., Chong, C. T., Cheng, C. K., Lee, C. L., Hendrata, K., Yek, P. N. Y., Ma, Y. L., and Lam, S. S. (2018). “Production of value-added liquid fuel via microwave co-pyrolysis of used frying oil and plastic waste,” Energy 162, 309-317. DOI: 10.1016/j.energy.2018.08.002

Mandapati, R. N., and Ghodke, P. K. (2021). “Kinetics of pyrolysis of cotton stalk using model-fitting and model-free methods,” Fuel 303(29), 1-9. DOI: 10.1016/j.fuel.2021.121285

Manojkumar, N., and Srimuruganandam, B. (2021). “Size-segregated particulate matter and health effects in air pollution in India: A review,” Environmental Chemistry Letters 19, 3837-3858. DOI: 10.1007/s10311-021-01277-w

Marrugo, G., Valdés, C. F., Gómez, C., and Chejne, F. (2019). “Pelletizing of Colombian agro-industrial biomasses with crude glycerol,” Renewable Energy 134, 558-568. DOI: 10.1016/j.renene.2018.11.004

Mathias, J.-D., Alzina, A., Grédiac, M., Michaud, P., Roux, P., Baynast, H. D., Delattre, C., Dumoulin, N., Faure, T., Larrey-Lassalle, P., et al. (2017). “Upcycling sunflower stems as natural fibers for biocomposite applications,” BioResources 10(4), 8076-8088. DOI: 10.15376/biores.10.4.8076-8088

McKendry, P. (2002). “Energy production from biomass (part 2): Conversion technologies,” Bioresource Technology 83(1), 47-54. DOI: 10.1016/S0960-8524(01)00119-5

Miranda, N. T., Motta, I. L., Filho, R. M., and Maciel, M. R. W. (2021). “Sugarcane bagasse pyrolysis: A review of operating conditions and products properties,” Renewable and Sustainable Energy Reviews 149, 1-20. DOI: 10.1016/j.rser.2021.111394

Mittal, S., Ahlgren, E. O., and Shukla, P. R. (2017). “Barriers to biogas dissemination in India: A review,” Energy Policy 112, 361-370. DOI: 10.1016/j.enpol.2017.10.027

Moghtaderi, B., Sheng, C., and Wall, T. F. (2007). “An overview of the Australian biomass resources and utilization technologies,” BioResources 1(1), 93-115.

Mohapatra, S. S., Rath, M. K., Singh, R. K., and Murugan, S. (2021). “Performance and emission analysis of co-pyrolytic oil obtained from sugarcane bagasse and polystyrene in a CI engine,” Fuel 298(8), 1-9. DOI: 10.1016/j.fuel.2021.120813

Molino, A., Chianese, S., and Musmarra, D. (2016). “Biomass gasification technology: The state of the art overview,” Journal of Energy Chemistry 25(1), 10-25. DOI: 10.1016/j.jechem.2015.11.005

Moreno, V. C., Iervolino, G., Tugnoli, A., and Cozzani, V. (2020). “Techno-economic and environmental sustainability of biomass waste conversion based on thermocatalytic reforming,” Waste Management 101, 106-115. DOI: 10.1016/j.wasman.2019.10.002

Morrissey, K. G., Thoma, G., and López, D. E. (2021). “Life cycle impact assessment of biofuels derived from sweet sorghum in the U.S.,” Biotechnology for Biofuels 14(1), 1-11. DOI: 10.1186/S13068-021-02009-6

Muigai, H. H., Bordoloi, U., Hussain, R., Ravi, K., Moholkar, V. S., and Kalita, P. (2020). “A comparative study on synthesis and characterization of biochars derived from lignocellulosic biomass for their candidacy in agronomy and energy applications,” Int. J. Energy Research 45(10), 4765-4781. DOI: 10.1002/er.6092

Mullen, C. A., Boateng, A. A., Hicks, K. B., Goldberg, N. M., and Moreau, R. A. (2010). “Analysis and comparison of bio-oil produced by fast pyrolysis from three barley biomass/byproduct streams,” Energy Fuel 24, 699-706. DOI: 10.1021/ef900912s

Mullen, C. A., Boateng, A. A., Goldberg, N. M., Lima, I. M., Laird, D. A., and Hicks, K. B. (2010). “Bio-oil and bio-char production from corn cobs and stover by fast pyrolysis,” Biomass & Bioenergy 34(1), 67-74. DOI: 10.1016/j.biombioe.2009.09.012

Mupondwa, E., Li, X., and Tabil, L. (2018). “Integrated bioethanol production from triticale grain and lignocellulosic straw in western Canada,” Industrial Crops and Products 117, 75-87. DOI: 10.1016/j.indcrop.2018.02.070

Negrão, D. R., Grandis, A., Buckeridge, M. S., Rocha, G. J. M., Leal, M. R. L. V., and Driemeier, C. (2021). “Inorganics in sugarcane bagasse and straw and their impacts for bioenergy and biorefining: A review,” Renewable and Sustainable Energy Reviews 148, 1-14. DOI: 10.1016/j.rser.2021.111268

Nesterovic, A., Djatkov, D., Viskovic, M., Martinov, M., and Adamovic, D. (2021). “Air pollutants emissions from biomass combustion in the city of Novi Sad, Serbia,” Biomass Conversion and Biorefinery, 1-12. DOI: 10.1007/s13399-021-01882-3

OECD (2011). “Database-OECD-FAO Agricultural Outlook 2011–2020,” (https://stats. oecd.org/Index.aspx?DataSetCode=HIGH_AGLINK_2011), accessed 13 May 2021.

Okolie, J. A., Nanda, S., Dalai, A. K., and Kozinski, J. A. (2020a). “Hydrothermal gasification of soybean straw and flax straw for hydrogen-rich syngas production: experimental and thermodynamic modeling,” Energy Conversion and Management 208, 1-13. DOI: 10.1016/j.enconman.2020.112545

Okolie, J. A., Nanda, S., Dalai, A. K., Berruti, F., and Kozinski, J. A. (2020b). “A review on subcritical and supercritical water gasification of biogenic, polymeric and petroleum wastes to hydrogen-rich synthesis gas,” Renewable and Sustainable Energy Reviews 119, 1-15. DOI: 10.1016/j.rser.2019.109546

Ong, H. C., Chen, W.-H., Farooq, A., Gan, Y. Y., Lee, K. T., and Ashokkumar, V. (2019). “Catalytic thermochemical conversion of biomass for biofuel production: a comprehensive review,” Renewable and Sustainable Energy Reviews 113, 1-16. DOI: 10.1016/j.rser.2019.109266

Oppelt, T. E. (2014). “Incineration of hazardous waste,” Energy & Energy Conservation 37, 558-586. DOI: 10.1080/08940630.1987.10466245

Perkins, G., Batalha, N., Kumar, A., Bhaskar, T., and Konarova, M. (2019). “Recent advances in liquefaction technologies for production of liquid hydrocarbon fuels from biomass and carbonaceous wastes,” Renewable and Sustainable Energy Reviews 115, 1-23. DOI: 10.1016/j.rser.2019.109400

Qamar, M. A., Javed, A., Liaquat, R., and Hassan, M. (2021). “Techno-economic modeling of biomass gasification plants for small industries in Pakistan,” Biomass Conversion and Biorefinery, 1-11. DOI: 10.1007/s13399-021-01767-5

Quispe, I., Navia, R., and Kahhat, R. (2018). “Life cycle assessment of rice husk as an energy source. A Peruvian case study,” Journal of Cleaner Production 209, 1235-1244. DOI: 10.1016/j.jclepro.2018.10.312

Rabea, K., Bakry, A. I., Khalil, A., El-Fakharany, M. K., and Kadous, M. (2021). “Real-time performance investigation of a downdraft gasifier fueled by cotton stalks in a batch-mode operation,” Fuel 300, 1-11. DOI: 10.1016/j.fuel.2021.120976

Reaño, R. L., and Halog, A. (2020). “Analysis of carbon footprint and energy performance of biohydrogen production through gasification of different waste agricultural biomass from the Philippines,” Biomass Conversion and Biorefinery, 1-15. DOI: 10.1007/s13399-020-01151-9

Ren, J., Yu, P., and Xu, X. (2019). “Straw utilization in China—Status and recommendations,” Sustainability 11(6), 1-17. DOI: 10.3390/su11061762

REN21 (2018). “Renewables 2018 global status report.” (https://www.ren21.net/gsr-2018/), accessed 3 Mar 2021.

Rey, J. R. C., Pacheco, J. J. T., Tarelho, L. A. d. C., Silva, V., Cardoso, J. S., Silveira, J. L., and Tuna, C. E. (2021). “Evaluation of cogeneration alternative systems integrating biomass gasification applied to a Brazilian sugar industry,” Renewable Energy 178, 318-333. DOI: 10.1016/j.renene.2021.06.053

Sahu, S. K., Mangaraj, P., Beig, G., Samal, A., Pradhan, C., Dash, S., and Tyagi, B. (2021). “Quantifying the high resolution seasonal emission of air pollutants from crop residue burning in India,” Environmental Pollution 286, 1-11. DOI: 10.1016/j.envpol.2021.117165

Sanchez-Borrego, F. J., Alvarez-Mateos, P., and Garcia-Martin, J. F. (2021). “Biodiesel and other value-added products from bio-oil obtained from agrifood waste,” Processes 9(5), 1-15. DOI: 10.3390/pr9050797

Santana, D. A. R., Scatolino, M. V., Lima, M. D. R., Junior, U. d. O. B., Garcia, D. P., Andrade, C. R., Carneiro, A. d. C. O., Trugilho, P. F., and Protásio, T. d. P. (2020). “Pelletizing of lignocellulosic wastes as an environmentally friendly solution for the energy supply: Insights on the properties of pellets from Brazilian biomasses,” Environ. Sci. Pollution Research 28(9), 1-20. DOI: 10.1007/s11356-020-11401-y

Sarkar, J. K., and Wang, Q. Y. (2020). “Different pyrolysis process conditions of south Asian waste coconut shell and characterization of gas, bio-char, and bio-oil,” Energies 13(8), 1-14. DOI: 10.3390/en13081970

Shah, Z., Veses, R. C., Vaghetti, J. C. P., Amorim, V. D. A., and Silva, R. d. (2019). “Preparation of jet engine range fuel from biomass pyrolysis oil through hydrogenation and its comparison with aviation kerosene,” International Journal of Green Energy 16(4), 350-360. DOI: 10.1080/15435075.2019.1566730

Shin, J. D., Hong, S.-G., Choi, W.-S., and Park, S. K. (2013). “Crude oil production and classification of organic compounds on super-critical liquefaction with rice hull,” Biotechnology and Bioprocess Engineering 18(5), 956-964. DOI: 10.1007/s12257-013-0122-xSong, W., He, Y., Wu, Y., and Qu, W. (2021). “Characterization of burning behaviors and particulate matter emissions of crop straws based on a cone calorimeter,” Materials 14(12), 1-13. DOI: 10.3390/ma14123407

Stattman, S. L., Hospes, O., and Mol, A. P. J. (2013). “Governing biofuels in Brazil: A comparison of ethanol and biodiesel policies,” Energy Policy 61, 22-30. DOI: 10.1016/j.enpol.2013.06.005

Stefanidis, S. D., Kalogiannis, K. G., Pilavachi, P. A., Fougret, C. M., Jordan, E., and Lappas, A. A. (2016). “Catalyst hydrothermal deactivation and metal contamination during the in situ catalytic pyrolysis of biomass,” Catalysis Science & Technology, 6. DOI: 10.1039/C5CY02239H

Styks, J., Wróbel, M., Frączek, J., and Knapczyk, A. (2020). “Effect of compaction pressure and moisture content on quality parameters of perennial biomass pellets,” Energies 13(8), 1-20. DOI: 10.3390/en13081859

Suramaythangkoor, T., and Gheewala, S. H. (2008). “Potential of practical implementation of rice straw-based power generation in Thailand,” Energy Policy 36(8), 3193-3197. DOI: 10.1016/j.enpol.2008.05.002

Swetha, A., Shrivigneshwar, S., Gopinath, K. P., Sivaramakrishnan, R., Shanmuganathan, R., and Arun, J. (2021). “Review on hydrothermal liquefaction aqueous phase as a valuable resource for biofuels, bio-hydrogen and valuable bio-chemicals recovery,” Chemosphere 283, 1-11. DOI: 10.1016/j.chemosphere.2021.131248

Taghizadeh-Alisaraei, A., Assar, H. A., Ghobadian, B., and Motevali, A. (2017). “Potential of biofuel production from pistachio waste in Iran,” Renewable and Sustainable Energy Reviews 72, 510-522. DOI: 10.1016/j.rser.2017.01.111

Tan, M., Luo, L., Wu, Z., Huang, Z., Zhang, J., Huang, J., Yang, Y., Zhang, X., and Li, H. (2020). “Pelletization of Camellia oleifera Abel. shell after storage: Energy consumption and pellet properties,” Fuel Processing Technology 201, 1-10. DOI: 10.1016/j.fuproc.2020.106337

Thers, H., Djomo, S. N., Elsgaard, L., and Knudsen, M. T. (2019). “Biochar potentially mitigates greenhouse gas emissions from cultivation of oilseed rape for biodiesel,” Science of the Total Environment 671, 180-188. DOI: 10.1016/j.scitotenv.2019.03.257

Thomsen, T. P., Ravenni, G., Holm, J. K., Ahrenfeldt, J., Hauggaard-Nielsen, H., and Henriksen, U. B. (2015). “Screening of various low-grade biomass materials for low temperature gasification: Method development and application,” Biomass Bioenergy 79, 128-144. DOI: 10.1016/j.biombioe.2014.12.019

Trivedi, A., Verma, A. R., Kaur, S., Jha, B., Vijay, V., Chandra, R., Vijay, V. K., Subbarao, P. M. V., Tiwari, R., Hariprasad, P., et al. (2017). “Sustainable bio-energy production models for eradicating open field burning of paddy straw in Punjab, India,” Energy 127, 310-317. DOI: 10.1016/j.energy.2017.03.138

Tye, Y. Y., Lee, K. T., Abdullah, W. N. W., and Leh, C. P. (2011). “Second-generation bioethanol as a sustainable energy source in Malaysia transportation sector: Status, potential and future prospects,” Renewable and Sustainable Energy Reviews 15(9), 4521-4536. DOI: 10.1016/j.rser.2011.07.099

Urrutia, R. I., Yeguerman, C., Jesser, E., Gutierrez, V. S., Volpe, M. A., and Gonzalez, J. O. W. (2021). “Sunflower seed hulls waste as a novel source of insecticidal product: Pyrolysis bio-oil bioactivity on insect pests of stored grains and products,” Journal of Cleaner Production 287, 1-11. DOI: 10.1016/j.jclepro.2020.125000

Vamvuka, D., Loukeris, D., Stamou, E., Vlasiadis, A., Sfakiotakis, S., and Bandelis, G. (2020). “Development and performance of a multi-fuel residential boiler burning agricultural residues,” Frontiers in Energy Research 8, 1-10. DOI: 10.3389/fenrg.2020.00136

Vasileiadou, A., Zoras, S., and Iordanidis, A. (2021). “Fuel quality index and fuel quality label: Two versatile tools for the objective evaluation of biomass/wastes with application in sustainable energy practices,” Environmental Technology & Innovation 23, 1-15. DOI: 10.1016/j.eti.2021.101739

Wang, M., Liu, M., Xu, X., Li, B., Zhang, Q., and Jian, E. (2010). “Biomass catalytic pyrolysis with Ni based catalyst to produce hydrogen rich gas,” Journal of Northeast Agricultural University 17, 43-49. DOI: CNKI:SUN:DBYN.0.2010-04-009

Wang, J., Bi, P., Zhang, Y., Xue, H., Jiang, P., Wu, X., Liu, J., Wang, T., and Li, Q. (2015). “Preparation of jet fuel range hydrocarbons by catalytic transformation of bio-oil derived from fast pyrolysis of straw stalk,” Energy 86, 488-499. DOI: 10.1016/j.energy.2015.04.053

Wang, D., Li, Q., Shen, G., Deng, J., Zhou, W., Hao, J., and Jiang, J. (2020). “Significant ultrafine particle emissions from residential solid fuel combustion,” Science of the Total Environment 715, 1-7. DOI: 10.1016/j.scitotenv.2020.136992

Wang, Q., and Tuohedi, N. (2020). “Polyurethane foams and bio-polyols from liquefied cotton stalk agricultural waste,” Sustainability 12(10), 1-13. DOI: 10.3390/su12104214

Wang, Z., Wang, Z., Xu, G., Ren, J., Wang, H., and Li, J. (2020). “Sustainability assessment of straw direct combustion power generation in China: From the environmental and economic perspectives of straw substitute to coal,” Journal of Cleaner Production 273, 1-14. DOI: 10.1016/j.jclepro.2020.122890

Wattana, W., Phetklung, S., Jakaew, W., Chumuthai, S., Sriam, P., and Chanurai, N. (2017). “Characterization of mixed biomass pellet made from oil palm and para-rubber tree residues,” Energy Procedia 138, 1128-1113. DOI: 10.1016/j.egypro.2017.10.218

Wu, H.-Y., Chen, S. S., Liao, W., Wang, W., Jang, M.-F., Chen, W.-H., Ahamad, T., Alshehri, S. M., Hou, C.-H., Lin, K.-S., et al. (2020). “Assessment of agricultural waste-derived activated carbon in multiple applications,” Environmental Research 191. DOI: 10.1016/j.envres.2020.110176

Yang, L., and Liu, Y. (2018). “Analysis of rice husk direct liquefaction and catalytic cracking products,” Environmental Science & Technology 41(9), 48-54. DOI: 10.19672/j.cnki.1003-6504.2018.09.008

Yang, X., Zhao, J., Liang, J., and Zhu, J. (2020). “Efficient and selective catalytic conversion of hemicellulose in rice straw by metal catalyst under mild conditions,” Sustainability 12(24), 1-14. DOI: 10.3390/su122410601

Yim, S. C., Quitain, A. T., Yusup, S., Sasaki, M., Uemura, Y., and Kida, T. (2016). “Metal oxide-catalyzed hydrothermal liquefaction of Malaysian oil palm biomass to bio-oil under supercritical condition,” Journal of Supercritical Fluids 120(Part 2), 384-394. DOI: 10.1016/j.supflu.2016.05.044

Younas, R., Hao, S., Zhang, L., and Zhang, S. (2017). “Hydrothermal liquefaction of rice straw with NiO nanocatalyst for bio-oil production,” Renewable Energy 113, 532-545. DOI: 10.1016/j.renene.2017.06.032

Yu, Y., Lau, A., and Sokhansanj, S. (2021). “Improvement of the pellet quality and fuel characteristics of agricultural residues through mild hydrothermal treatment,” Industrial Crops and Products 169, 1-10. DOI: 10.1016/j.indcrop.2021.113654

Yui, K., Kuramochi, H., and Osako, M. (2018). “Understanding the behavior of radioactive cesium during the incineration of contaminated municipal solid waste and sewage sludge by thermodynamic equilibrium calculation,” ACS Omega 3(11), 15086-15099. DOI: 10.1021/acsomega.8b01113

Zhang, H., Zhang, Z., and Liu, K. (2016). “Regenerated lignocellulose beads prepared with wheat straw,” BioResources 11(2), 4281-4294. DOI: 10.15376/biores.11.2.4281-4294

Zhang, S., Dong, Q., Zhang, L., and Xiong, Y. (2015). “High quality syngas production from microwave pyrolysis of rice husk with char-supported metallic catalysts,” Bioresource Technology 191, 17-23. DOI: 10.1016/j.biortech.2015.04.114

Zheng, J. (2007). “Bio-oil from fast pyrolysis of rice husk: Yields and related properties and improvement of the pyrolysis system,” Journal of Analytical and Applied Pyrolysis 80(1), 30-35. DOI: 10.1016/j.jaap.2006.12.030

Zheng, Y., Tao, L., Yang, X., Huang, Y., Liu, C., and Zheng, Z. (2019). “Comparative study on pyrolysis and catalytic pyrolysis upgrading of biomass model compounds: thermochemical behaviors, kinetics, and aromatic hydrocarbon formation,” Journal of the Energy Institute 92(5), 1348-1363. DOI: 10.1016/j.joei.2018.09.006

Article submitted: December 8, 2021; Peer review completed: January 29, 2022; Revised version received and accepted: March 10, 2022; Published: March 14, 2022.

DOI: 10.15376/biores.17.2.Zhou

APPENDIX

Supplementary

Fig. S1. Number of scientific publications, citations, and total link strength in the area of agricultural biomass energy conversion. The blue bars indicate the number of published articles; the yellow line indicates the number of articles in this field quoted by each country; and the red line show the number of co-occurrences of key words related to agricultural biomass energy in published articles in various countries. (Note: Key words used in searching articles on the Web of Science are TS = agriculture or TS = straw or TS = rice or TS = wheat or TS = wheat or TS = crops)

Fig. S2. Network visualization of the keywords related to agricultural biomass energy production