Abstract

Yeast strains and appropriate hydrolysis conditions were selected for efficient single cell protein (SCP) production from waste rapeseed meal. High potential for effective biomass production was observed for Yarrowia lipolytica LOCK0264 with 10 g of rapeseed meal at 4.9 × 108 ± 1.5 × 108 (2.91 logarithmic units). The highest yeast multiplication rate was obtained for Metschnikowia pulcherrima NCYC747 with 12.5 g of rapeseed meal and with 15 g of rapeseed meal at 1.6 × 108 ± 3.8 × 107 and 4.5 × 108 ± 4.0 × 107 (2.75 and 2.86 logarithmic units, respectively).

Download PDF

Full Article

Conventional and Unconventional Yeasts Able to Grow on Rapeseed Meal Hydrolysates

Dawid Dygas,* Paulina Janicka, Joanna Berłowska, and Dorota Kręgiel *

Yeast strains and appropriate hydrolysis conditions were selected for efficient single cell protein (SCP) production from waste rapeseed meal. High potential for effective biomass production was observed for Yarrowia lipolytica LOCK0264 with 10 g of rapeseed meal at 4.9 × 108 ± 1.5 × 108 (2.91 logarithmic units). The highest yeast multiplication rate was obtained for Metschnikowia pulcherrima NCYC747 with 12.5 g of rapeseed meal and with 15 g of rapeseed meal at 1.6 × 108 ± 3.8 × 107 and 4.5 × 108 ± 4.0 × 107 (2.75 and 2.86 logarithmic units, respectively).

DOI: 10.15376/biores.17.2.3082-3094

Keywords: Rapeseed meal; Enzymatic hydrolysis; Unconventional yeasts

Contact information: Department of Environmental Biotechnology, Lodz University of Technology, 90-924 Lodz, Poland; *Corresponding authors: dorota.kregiel@p.lodz.pl; dawid.dygas@dokt.p.lodz.pl

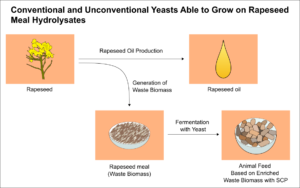

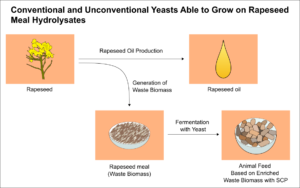

GRAPHICAL ABSTRACT

INTRODUCTION

Rapeseed (Brassica napus) is widely used for oil production across the world. Global production of rapeseed oil reached 27.3 million metric tons in 2019 and 2020. The main provider of rapeseed meal was Canada, at 19 million metric tons. The second largest producer was the European Union, at 16.8 million metric tons. The third was China at 7 million metric tons (Shahbandeh 2021). Rapeseed oil has a high content of vitamins and unsaturated fatty acids and is especially valuable in the food and cosmetics industries. Rapeseed oil may also be used as an additive in diesel fuel or as an independent fuel (Zentková and Cvengrošová 2013; Paciorek-Sadowska et al. 2019).

The by-product from the production of rapeseed oils is pomace (sometimes referred to as oil cake or rapeseed meal). Currently, the most important application of pomace is for the production of animal feed. Rapeseed meal is a good source of nutritional components, with a high content of methionine and lower content of lysine and isoleucine. Lysine is one of the most important amino acids and is a growth-limiting factor. In comparison to soybean meal, the essential amino acids present in rapeseed meals show lower digestibility. Rapeseed meal contains about 31.6% of neutral detergent fiber, which is about three times more than soybean meal (10.5%). Rapeseed oil contains far more acid detergent fiber (20.7% vs. 5.7%) and lignin (9.7% vs. 0.4% of dry matter) than soybean meal (Table 5). The digestibility of lignin is limited, and this can affect the digestive tract, energy release, and animal growth. In broiler production, excessive ingestion of rapeseed meal produces an off-fishy flavor in eggs. Another problem is increased cases of liver hemorrhaging. Rapeseed meal contains many anti-nutritional substances, such as glucosinolates, phytates, erucic acid, and alkaloids (Bau et al. 1994; Mandiki et al. 2002). Generally, glucosinolates are not toxic. However, their derivatives can have side effects on the liver, kidneys, and thyroid. Damage to the thyroid gland occurs via disturbance of iodine metabolism (Grubb and Abel 2006; Yasumoto et al. 2010). Another anti-nutritional substance is phytic acid. This antioxidant binds with macro elements, such as iron, calcium, magnesium, sodium, and potassium, which are necessary for the health of humans and animals (Thompson 1990). Therefore, the use of rapeseed meal directly in animal nutrition must be limited. Acceptable levels of rapeseed meal in boiler feed range from 5% to 20%, depending on the glucosinolate concentration (Paciorek-Sadowska et al. 2019). New technologies are sought to enrich rapeseed meal with higher doses of proteins.

A new avenue for both increasing the nutritional value of oil cake and managing waste rapeseed material is the production of single cell protein (SCP) for use as animal feed. Through selective use of microorganisms for fermentation, it is possible to increase the nutritional value of waste biomass and enrich its amino acid profile (Fenwick and Curtis 1980; Ritala et al. 2017; Weindl et al. 2018; Górka and Penner 2020). Yeast cells can be used as a protein supplement in animal feed. They provide good nutritional value. This type of protein is inexpensive and competitive with other protein sources. In addition to the high protein content, which ranges between 60% and 82%, yeast SCP contains fats, carbohydrates, vitamins, and minerals. It is also rich in essential amino acids, such as lysine and methionine. Many yeasts are possible sources of SCP, including the genera of non-conventional yeasts (except classical Saccharomyces cerevisiae): Candida, Cryptococcus, Hansenula, Lipomyces, Pichia, Rhodotorula, Torulpsis, Yarrowia, etc. Suitable yeasts are non-pathogenic strains, capable of synthesizing high yields of protein acceptable as feed. High growth rates should not require special conditions and should be obtained in inexpensive agricultural media (Obaida 2021).

This study compared various non-conventional yeasts as candidates for efficient SCP production in different rapeseed meal media after enzymatic hydrolysis. The study is a part of a research project with the aim of developing an animal feed enriched with microbial protein, based on waste biomass from the agro-food industry. The results will enable determination of the proper yeast strain for application in the SCP production process.

EXPERIMENTAL

Aim of study

The aim of this study was to investigate the effect of different portions of rapeseed meal on the growth of yeast.

Yeast Strains

Table 1 lists the tested yeast strains (* = Marcq-en-Barœul, France).

Table 1. List of Tested Yeast Strains

The yeasts were cultured in 50 mL of YPG broth (Yeast extract [1g/100mL], Peptone K [2g/100mL], Glucose [2g/100mL]) (Merck, Darmstadt, Germany) at 25 °C for 24 h on a rotary shaker at 220 rpm.

Rapeseed Meal Biomass Hydrolysis and Yeast Cultivation

Portions containing 10 g (sample A), 12.5 g (sample B), and 15 g (sample C) of rapeseed meal were put into three cylindrical flasks. Each flask was filled with 90 mL of water. Each portion was tested with all yeast strains in three series. Flasks with hydrated rapeseed meal were sterilized for 15 min at 121 °C. After sterilization, enzymatic hydrolysis was performed. Two enzymes were used: Rohament®️ PL and Rohapect®️ PTE (AB Enzyme, Darmstadt, Germany). Rohament®️ PL is a cellulolytic enzyme, produced by AB Enzyme (Buntru et al. 2014) with activity in katals per mL of pectin lyase 2 nkat/mL, pectin methyl esterase 10 nkat/mL, and pectin methyl esterase 46957 nkat/mL (Mieszczakowska-Frąc et al. 2012). This enzyme causes enzymatic hydrolysis of the cellulose contained in rapeseed meal and the release of monosaccharides. Monosaccharides are a source of carbon required for yeast growth. Rohapect®️ PTE is a pectinolytic enzyme produced by AB Enzyme (Buntru et al. 2014). It is characterized by the following activity: pectin lyase 1586 nkat/mL; pectin methyl esterase 131 nkat/mL; and pectin methyl esterase 160 nkat/mL (Mieszczakowska-Frąc et al. 2012).

The enzyme dose required to perform enzymatic hydrolysis was calculated based on the dry matter content. The optimal enzyme dose was determined from the liquefaction level (0.5 mL, 0.25 mL, and 0.125 mL per 10 g of dry mass). Pre-hydrolysis was performed for 4 h at 50 °C. However, the enzymes were not deactivated, and simultaneous saccharification and fermentation (SSF) occurred.

To enable simple identification of the samples, the hydrolyzed samples were given new symbols. The sample containing 10 g of waste biomass was labelled sample D. The sample containing 12.5 g of waste biomass was labelled sample E. The sample containing 15 g of waste biomass was labelled sample F.

Following hydrolysis, 0.3 g of ammonium sulfate was added to each sample as a mineral nitrogen source. Inoculation was performed with 2- to 5-day yeast cultures. From each strain, 1 mL of culture suspension was transferred to the previously prepared samples. Each of the flasks was placed on a shaker for 48 h, at room temperature with a shaking speed of 200 to 300 rpm, depending on the density of the flask content.

Liquefaction Level

The enzymatic effect of rapeseed meal hydrolysis (liquefication level) was measured using the following formula:

LL (%) = Δm / M (1)

where LL is the liquefaction level (%), Δm is the difference in the sample mass before and after hydrolysis (g), and M is the primary sample mass (g).

Carbohydrate Content

The monosaccharide profiles of the obtained yeast lysates were analyzed using a UV-spectrophotometer (Thermo Scientific Multiskan GO; Thermo Fisher Scientific, Munich, Germany). Tests were carried out with Megazyme K-ARGA (l-arabinose, d-galactose), K-XYLOSE (d-xylose), K-MANGL (d-mannose, d-fructose, d-glucose) Kits (Bray, Ireland). The assays were conducted according to the manufacturer’s instructions and as described in the literature (Berłowska et al. 2017). The content of sugars was compared before and after pre-hydrolysis.

Efficiency of Yeast Biomass Synthesis

Dilutions were performed on each flask for subsequent analysis by the plate count method. Petri dishes were incubated for 48 h at 30 °C. The numbers of colony-forming units per 1 mL were determined for each of the tested strains at the beginning and end of the bioprocess. Based on the results, microbial growth was calculated in CFU/mL according to the following formula,

Δ log N = log NA – log NI (2)

where Δ log N is microbial growth presented on a logarithmic scale, NA is the number of colony-forming units after 48 h of incubation (cfu/mL), and NI is inoculum density (cfu/mL).

Determination of Amino Acid Profiles

The free amino acids were extracted using hydrochloric acid. Simultaneously, nitrogenous molecules were precipitated with sulfosalicylic acid and eliminated throughout filtration. The filtrate was acidified to pH 2.2. Next, the amino acids were separated by ion exchange chromatography (Shimadzu Corporation, Kyoto, Japan) and identified by reaction with ninhydrin and photometric detection at a wavelength of 570 nm. For proline detection, the wavelength was changed to 440 nm (EC 2009).

Statistics

The results from three independent experiments were averaged, and the standard deviation (SD) was calculated in Microsoft Excel. In the same program, a one-way analysis of variance (ANOVA) and t-test were performed (Microsoft Excel, Microsoft®, v16.0.14827.20028, Redmond, WA, USA).

RESULTS AND DISCUSSION

Table 2 presents the content of carbohydrates in the rapeseed meal samples before and after hydrolysis.

During enzymatic hydrolyzation, polysaccharides are degraded into simple sugars, which are metabolized by microorganisms. As a result of hydrolysis, increases in carbon hydrates were noted for all concentrations of biomass: L-arabinose (Δ 1.184 to 1.957 g/L), D-galactose (Δ 0.784 to 1.390 g/L), D-xylose (Δ 0.279 to 0.638 g/L), and D-glucose (Δ 1.289 to 1.833 g/L). Simultaneously, hydrolyzation led to decreases in two tested carbohydrates: D-fructose (Δ 0.332 to 0.763 g/L) and D-mannose (Δ 0.141 to 0.206 g/L). These results may be due to the continuous release of simple sugars during hydrolysis under conditions of high-load of biomass (Xue et al. 2015).

However, the results of sugar determination do not reflect the actual concentrations of sugars during fermentation. The application of SSF leads to continuous hydrolysis of the substrate and the gradual release of simple sugars, which are subsequently consumed by yeasts (Szambelan et al. 2018).

Table 2. Content of Carbohydrates in Rapeseed Meal Samples Before and After Hydrolysis

Table 3. Liquefaction of Rapeseed Meal at Different Concentrations

To evaluate the effectiveness of the enzymatic process, the liquefaction level (LL) of the waste material was measured (Table 3). The highest liquefaction level was obtained for a biomass concentration of 10 g, with an LL value of 23.7%. The LL for 12.5 g of biomass was 7.2%. The LL for 15 g of biomass was 0.3%. Increasing the amount of waste material led to lower liquefaction after 4 h of hydrolysis. However, the liquefaction level changed throughout the fermentation process. This is because in the SSF process in the study, enzymatic hydrolysis occurs during fermentation with yeast (Szambelan et al. 2018).

Table 4. Proliferation of Yeast Cells (CFU/mL) in Culture Medium with Hydrolyzed Rapeseed Meal (Sample D)

All the tested yeast strains showed the ability to grow on the tested rapeseed meal hydrolysates (Table 4). The highest yeast growth rate was observed on 10 g of rapeseed meal (Δ log N ranged from 0.92 to 2.91 logarithmic units). Yeast growth with 10 g of rapeseed meal was highest for the strain Yarrowia lipolytica ŁOCK0264 (2.91 logarithmic units). The lowest yeast growth was observed for the strain Candida humicola ŁOCK0013 (0.92 logarithmic units). Saccharomyces strains are capable of metabolizing hexoses, which enables them to grow on rapeseed meal. When combining with strains capable of processing pentoses, they are able to completely utilize carbohydrates present in rapeseed waste (Tomás et al. 2013). Yarrowia lipolytica is an oleaginous yeast, capable of the internal accumulation of up to 20% w/w lipids and with high adaptability to various environmental conditions, which may stimulate its growth in rapeseed meal hydrolysate as a culture medium (Carsanba et al. 2018; Patsios et al. 2020). Metschnikowia pulcherrima is also capable of growing on rapeseed meal-based media. It is able to easily metabolize the fiber structure of rapeseed to make it fit for animal consumption (Santomauro et al. 2018). Scheffersomyces stipitis is adapted to the presence of hemicellulose, a biopolymer that appears in most plants, especially rapeseed. These results were thus consistent with data published in the literature (Nigam 2001). Kluyveromyces marxianus can be used for modification of fiber present in rapeseed. According to Wang et al. (2020), this yeast strain can be used to modify insoluble dietary fiber, increasing its possible uses as a functional ingredient. Candida utilis is characterized by the ability to increase protein content.

However, it is not efficient at consuming glucosinolates (Wang et al. 2012). Strains with multiplication efficiency exceeding 100% were chosen for further analysis. Candida humicola was also included to test its multiplication efficiency with higher doses of biomass. The selected yeast strains were cultivated with larger portions of hydrolyzed rapeseed meal. The results of CFU measurements are presented in Table 5.

Table 5. Proliferation of Yeast Cells (CFU/mL) in Culture Media with Hydrolyzed Rapeseed Meal (Sample E and Sample F)

The highest yeast growth in the 12.5% rapeseed meal hydrolysates was noted for Metschnikowia pulcherrima NCYC747 (3.5 × 108/mL). The lowest yeast growth was noted for Kluyveromyces marxianus ŁOCK0024 (8.3 × 106/mL). Yeast growth on the 15% hydrolysates was also the highest for the Metschnikowia pulcherrima NCYC747 strain (CFU 4.5 × 108/mL). It was lowest for Saccharomyces bayanus BC S103 (1.0 × 108/mL). To compare microbial growth on media with different waste concentrations, multiplication efficiency was calculated (Fig. 1).

Fig. 1. Increase in logarithmic units of living yeast cells in various portions of rapeseed meal

Inhibitory compounds present in rapeseed meal can have a negative effect on yeast growth. Rapeseed meal contains antinutritional compounds including glucosinolates, sinapine, sinapic acid, tannin, phytic acid, and crude fiber (Dingyuan et al. 2007). According to the literature, glucosinolates decrease the microbial growth of fungi (Calmes et al. 2015). The phenolic derivatives sinapine and sinapic acid are capable of reducing yeast growth (Câmara et al. 2019). Similar reduction of yeast growth has been noticed for tannins (Ishida et al. 2006). There is currently no data on the direct influence of antinutritional compounds on the tested yeast species. This may be the focus of future work.

The highest multiplication rate in the presence of 10% of hydrolyzed waste material was noted for Yarrowia lipolytica (2.91 logarithmic units). Supplementation of larger biomass portions of substrate led to improvement of microbial growth expressed in logarithmic units for Metschnikowia pulcherrima NCYC747 (2.86 logarithmic units). The lowest microbial growth among all the tested strains was observed for Candida humicola ŁOCK0013. Increasing the concentration of waste material led to lower growth of all four tested strains: Saccharomyces bayanus, Yarrowia lipolytica, Kluyveromyces marxianus, and Scheffersomyces stipitis. This effect was especially noticeable for Yarrowia lipolytica. However, two tested strains, Metschnikowia pulcherrima and Candida humicola, were characterized by good adaptation to higher rapeseed meal concentrations. Metschnikowia pulcherrima is usually isolated from fruits or vegetables, and can be used as SCP producers in waste biomass valorization (Abeln et al. 2020; Němcová et al. 2021). This strain was characterized by a wide spectrum of enzymatic activity. In addition, Metschnikowia pulcherrima showed strong biocontrol activity against various microorganisms (Pawlikowska et al. 2019). This quality may be an added advantage for SCP production in waste plant materials. In turn, C. humicola is known for its high proteolytic activity, which may contribute to produce SCP with better feed qualities (Ray et al. 1992).

Table 6 presents the amino acid profiles of waste material samples cultivated with the industrial yeast strain Saccharomyces cerevisiae Ethanol Red (Leaf/Lesaffre Advanced Fermentation). The authors compared the results with standards for Ajinomoto Eurolysine, a commercial animal feed (Table 6).

Table 6. Amino Acid Profiles of Samples Cultivated with Saccharomyces cerevisiae Ethanol Red

Humans and animals cannot synthesize all amino acids required for normal functioning. Some, called essential amino acids, are delivered with food. Essential amino acids are marked in bold in Table 6 (Hou et al. 2015). Cultivation increased the amounts of essential amino acids and enriched the total amino acid profile. Comparison with the standards for Ajinomoto Eurolysine demonstrated the effectiveness of the revalorization of waste material for animal feed purposes. The levels of amino acids, also lysine and isoleucine, in rapeseed meal hydrolysates after yeast cultivation were higher than the standards for Ajinomoto Eurolysine.

Yeasts are among the most important groups of biotechnological microorganisms. The traditional industrial attributes of classical yeasts include primary roles in the fermentation of various foods, such as beers, cider, wines, and bakery products. More recently, non-Saccharomyces yeasts have been considered as industrial organisms for a variety of biotechnological roles, including SCP production (Johnson 2013). Their good adaptation abilities, wide spectra of enzymatic activity, assimilation profiles, and biocontrol features make them suitable candidates for use in SCP production from rapeseed meal.

In this study, hydrolyzed rapeseed meal was shown to be a suitable feedstock for both conventional and unconventional yeasts. The results pave the way for future research on (1) the valorization of waste biomass with the use of selected yeast and carefully chosen mixed populations; (2) techno-economic analysis of microbial protein production on a larger scale.

CONCLUSIONS

- Simultaneous saccharification and fermentation enables a gradual release of carbohydrates metabolized by yeast.

- The liquefaction level of rapeseed meal depends on its concentration in the hydrolyzed mixture.

- The tested yeast strains showed different abilities to grow on rapeseed meal hydrolysates.

- The highest growth on medium with 10 g of rapeseed meal was noted for Yarrowia lipolytica. With higher portions of waste biomass, the highest efficiency was observed for Metschnikowia pulcherrima.

ACKNOWLEDGMENTS

The authors are grateful for the support of Wojewodzki Fundusz Ochrony Srodowiska i Gospodarki Wodnej w Lodzi (Grant no. 157/BN/D/2020).

REFERENCES CITED

Abeln, F., Hicks, R. H., Auta, H., Moreno-Beltrán, M., Longanesi, L., Henk, D. A., and Chuck, C. J. (2020). “Semi-continuous pilot-scale microbial oil production with Metschnikowia pulcherrima on starch hydrolysate,” Biotechnology for Biofuels, BioMed Central, 13(1), 127. DOI: 10.1186/S13068-020-01756-2

Bau, H., Villaume, C., Lin, C., Evrard, J., Quemener, B., Nicolas, J., and Méjean, L. (1994). “Effect of a solid‐state fermentation using Rhizopus oligosporus sp.T‐3 on elimination of antinutritional substances and modification of biochemical constituents of defatted rapeseed meal,” Journal of the Science of Food and Agriculture 65(3), 315-322. DOI: 10.1002/jsfa.2740650309

Berłowska, J., Dudkiewicz-Kołodziejska, M., Pawlikowska, E., Pielech-Przybylska, K., Balcerek, M., Czysowska, A., and Kregiel, D. (2017). “Utilization of post-fermentation yeasts for yeast extract production by autolysis: The effect of yeast strain and saponin from Quillaja saponaria,” Journal of the Institute of Brewing 123(3), 396-401. DOI: 10.1002/jib.438

Buntru, M., Vogel, S., Spiegel, H., and Schillberg, S. (2014). “Tobacco BY-2 cell-free lysate: An alternative and highly-productive plant-based in vitro translation system,” BMC Biotechnology 14. DOI: 10.1186/1472-6750-14-37

Câmara, C. R. S., Shi, Q., Pedersen, M., Zbasnik, R., Nickerson, K. W., and Schlegel, V. (2019). “Histone acetylation increases in response to ferulic, gallic, and sinapic acids acting synergistically in vitro to inhibit Candida albicans yeast-to-hyphae transition,” Phytotherapy Research, John Wiley & Sons, Ltd, 33(2), 319–326. DOI: 10.1002/PTR.6222

Carsanba, E., Papanikolaou, S., and Erten, H. (2018). “Production of oils and fats by oleaginous microorganisms with an emphasis given to the potential of the nonconventional yeast Yarrowia lipolytica,” Critical Reviews in Biotechnology, Taylor & Francis. DOI: 10.1080/07388551.2018.1472065

European Commission (EC) Regulation 152/2009 (2009). “Commission Regulation (EC) No 152/2009 of 27 January 2009 laying down the methods of sampling and analysis for the official control of feed” European Union, Brussels, Belgium.

Fenwick, G. R., and Curtis, R. F. (1980). “Rapeseed meal and its use in poultry diets. A review,” Animal Feed Science and Technology 5(4), 255-298. DOI: 10.1016/0377-8401(80)90016-4

Górka, P., and Penner, G. B. (2020). “Rapeseed and canola meal as protein sources in starter diets for calves: Current knowledge and directions of future studies,” Ankara Universitesi Veteriner Fakultesi Dergisi 67(3), 313-321. DOI: 10.33988/auvfd.712730

Grubb, C. D., and Abel, S. (2006). “Glucosinolate metabolism and its control,” Trends in Plant Science 11(2), 89-100. DOI: 10.1016/j.tplants.2005.12.006

Hou, Y., Yin, Y., and Wu, G. (2015). “Dietary essentiality of ‘nutritionally non-essential amino acids’ for animals and humans,” Experimental Biology and Medicine 240(8), 997-1007. DOI: 10.1177/1535370215587913

Johnson, E. A. (2013). “Biotechnology of non-Saccharomyces yeasts – The ascomycetes,” Applied Microbiology and Biotechnology 97(2), 503-517. DOI: 10.1007/s00253-012-4497-y

Mandiki, S. N. M., Derycke, G., Bister, J. L., Mabon, N., Wathelet, J. P., Marlier, M., and Paquay, R. (2002). “Chemical changes and influences of rapeseed antinutritional factors on gestating and lactating ewes: 1. Animal performances and plasma hormones and glucose,” Animal Feed Science and Technology 98(1-2), 25-35. DOI: 10.1016/S0377-8401(01)00298-X

Mieszczakowska-Frac, M., Markowski, J., Zbrzeźniak, M., and Płocharski, W. (2012). “Impact of enzyme on quality of blackcurrant and plum juices,” LWT – Food Science and Technology, Academic Press, 49(2), 251-256. DOI: 10.1016/J.LWT.2011.12.034

Němcová, A., Szotkowski, M., Samek, O., Cagáňová, L., Sipiczki, M., and Márová, I. (2021). “Use of waste substrates for the lipid production by yeasts of the genus metschnikowia—screening study,” Microorganisms, MDPI, 9(11). DOI: 10.3390/microorganisms9112295

Nigam, J. N. (2001). “Development of xylose-fermenting yeast Pichia stipitis for ethanol production through adaptation on hardwood hemicellulose acid prehydrolysate,” Journal of Applied Microbiology 90(2), 208-215. DOI: 10.1046/j.1365-2672.2001.01234.x

Obaida, B. M. (2021). “Yeasts as a source of single cell protein production: A review,” Plant Archives 21(Supplement 1), 324-328. DOI: 10.51470/plantarchives.2021.v21.s1.051

Paciorek-Sadowska, J., Borowicz, M., Isbrandt, M., Czupryński, B., and Apiecionek, Ł. (2019). “The use of waste from the production of rapeseed oil for obtaining of new polyurethane composites,” Polymers 11(9), article no. 1431. DOI: 10.3390/polym11091431

Patsios, S. I., Dedousi, A., Sossidou, E. N., and Zdragas, A. (2020). “Sustainable animal feed protein through the cultivation of YARROWIA lipolytica on agro-industrial wastes and by-products,” Sustainability 12(4), article no. 1398. DOI: 10.3390/su12041398

Pawlikowska, E., James, S. A., Breierová, E., Antolak, H., and Kregiel, D. (2019). “Biocontrol capability of local Metschnikowia sp. isolates,” Antonie van Leeuwenhoek 112, 1425-1445. DOI: 10.1007/S10482-019-01272-W/FIGURES/10

Ray, M. K., Devi, K. U., Kumar, G. S., and Shivaji, S. (1992). “Extracellular protease from the antarctic yeast Candida humicola,” Applied and Environmental Microbiology 58(6), 1918-1923. DOI: 10.1128/aem.58.6.1918-1923.1992

Ritala, A., Häkkinen, S. T., Toivari, M., and Wiebe, M. G. (2017). “Single cell protein-state-of-the-art, industrial landscape and patents 2001-2016,” Frontiers in Microbiology 8, article no. 2009. DOI: 10.3389/fmicb.2017.02009

Santomauro, F., Fan, J., Budarin, V. L., Parsons, S., Clark, J., Miller, T., and Chuck, C. J. (2018). “Microbial oil produced from the fermentation of microwave-depolymerised rapeseed meal,” Bioresource Technology Reports 4, 159-165. DOI: 10.1016/j.biteb.2018.10.008

Shahbandeh, M. (2021). “Leading producing countries of rapeseed in 2019/2020 (in million metric tons),” (https://www.statista.com/statistics/263930/worldwide-production-of-rapeseed-by-country/#statisticContainer), Accessed 5 May 2021.

Szambelan, K., Nowak, J., Szwengiel, A., Jeleń, H., and Łukaszewski, G. (2018). “Separate hydrolysis and fermentation and simultaneous saccharification and fermentation methods in bioethanol production and formation of volatile by-products from selected corn cultivars,” Industrial Crops and Products 118, 355-361. DOI: 10.1016/j.indcrop.2018.03.059

Thompson, L. U. (1990). “Phytates in canola/rapeseed,” in: Canola and Rapeseed, Springer, F. Shahidi (ed.), Springer, Boston, MA, USA, pp. 173-192. DOI: 10.1007/978-1-4615-3912-4_10

Tomás, A. F., Karagöz, P., Karakashev, D., and Angelidaki, I. (2013). “Extreme thermophilic ethanol production from rapeseed straw: Using the newly isolated Thermoanaerobacter pentosaceus and combining it with Saccharomyces cerevisiae in a two-step process,” Biotechnology and Bioengineering 110(6), 1574-1582. DOI: 10.1002/bit.24813

Türkel, S., and Ener, B. (2009). “Isolation and characterization of new Metschnikowia pulcherrima strains as producers of the antimicrobial pigment pulcherrimin,” Zeitschrift fur Naturforschung – Section C Journal of Biosciences 64(5–6), 405-410. DOI: 10.1515/znc-2009-5-618

Wang, X., Jin, Q., Wang, T., Huang, J., Xia, Y., Yao, L., and Wang, X. (2012). “Screening of glucosinolate-degrading strains and its application in improving the quality of rapeseed meal,” Annals of Microbiology 62(3), 1013-1020. DOI: 10.1007/s13213-011-0341-3

Wang, X., Zhang, Y., Li, Y., Yu, H., Wang, Y., and Piao, C. (2020). “Insoluble dietary fibre from okara (soybean residue) modified by yeast Kluyveromyces marxianus,” LWT Food Science and Technology 134, article ID 110252. DOI: 10.1016/j.lwt.2020.110252

Weindl, P., Plesch, P., Windisch, W., and Bellof, G. (2018). “Einsatz von Erbsen und Rapsextraktionsschrot in der intensiven Broilermast [Effects of increasing levels of pea and rapeseed meal in broiler diets],” European Poultry Science, article no. 82. DOI: 10.1399/eps.2018.229

Yasumoto, S., Matsuzaki, M., Hirokane, H., and Okada, K. (2010). “Glucosinolate content in rapeseed in relation to suppression of subsequent crop,” Plant Production Science 13(2), 150-155. DOI: 10.1626/pps.13.150

Zentková, I., and Cvengrošová, E. (2013). “The utilization of rapeseed for biofuels production in the EU,” Visegrad Journal on Bioeconomy and Sustainable Development 2(1), 11-14. DOI: 10.2478/vjbsd-2013-0002

Article submitted: February 3, 2022: Peer review completed: March 12, 2022; Revised version received and accepted: April 8, 2022; Published: April 18, 2022.

DOI: 10.15376/biores.17.2.3082-3094