Abstract

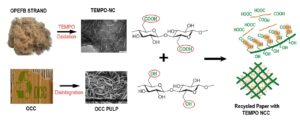

Recycled fibers used in the manufacturing of paper and board are associated with strength deficiencies. This study investigated the use of TEMPO-oxidized nanocellulose from oil palm empty fruit bunch (OPEFB-TEMPO) for reinforcing papers made from such fibers. Strength properties of tensile and tear were enhanced with the addition of OPEFB-TEMPO, with strong correlations, as indicated by the R2 values. The reinforcement capability was supported by the scattering coefficient-percent relationship. The only drawback of the nanocellulose addition is that it reduces pulp drainability, which can be minimized by adding drainage aids. Because only a relatively small amount is required, OPEFB-TEMPO has the potential to be used as paper strengthening agent, particularly in the production of low grammage papers.

Download PDF

Full Article

Enhancing Strength Properties of Recycled Paper with TEMPO-oxidized Nanocellulose

Eti Indarti,a,* Khairul Hafizuddin Abdul Rahman,b Mazlan Ibrahim,b and Wan Rosli Wan Daud b

Recycled fibers used in the manufacturing of paper and board are associated with strength deficiencies. This study investigated the use of TEMPO-oxidized nanocellulose from oil palm empty fruit bunch (OPEFB-TEMPO) for reinforcing papers made from such fibers. Strength properties of tensile and tear were enhanced with the addition of OPEFB-TEMPO, with strong correlations, as indicated by the R2 values. The reinforcement capability was supported by the scattering coefficient-percent relationship. The only drawback of the nanocellulose addition is that it reduces pulp drainability, which can be minimized by adding drainage aids. Because only a relatively small amount is required, OPEFB-TEMPO has the potential to be used as paper strengthening agent, particularly in the production of low grammage papers.

DOI: 10.15376/biores.18.1.1508-1524

Keywords: TEMPO-oxidized nanocellulose; Oil palm empty fruit bunch; Strengthening agents; Recycled paper; Carboxylic acid moieties; Paper strength properties

Contact information: a: Agriculture Product Technology Department, Faculty of Agriculture, Universitas Syiah Kuala. Banda Aceh Indonesia 23111; b: Bioresources Technology Division, School of Industrial Technology, Universiti Sains Malaysia, 11800 Penang Malaysia;

*Corresponding author: eti_indarti@usk.ac.id

GRAPHICAL ABSTRACT

INTRODUCTION

Despite the advent of digital information and online publications, the world’s paper industry continues to expand from an annual production of 323 million tonnes in 2000 (FAO 2001) to 409 million tonnes in 2016 (FAO 2017), with a projected forecast of 482 million tonnes in 2030 (Papernews 2015). This increase is attributed to the growing global demand for packaging and tissue papers (FAO 2017). Although virgin fiber is the predominant raw material for papermaking, recycled fiber (also known as secondary or recovered fiber) has also increased its share as sources for papermaking. It is estimated that in 2017, 56% of recycled fiber is used in the manufacture of paper globally (FAO 2017).

One of the challenges in using recycled fibers is that the strength of paper made from these fibers decreases with the extent of recycling, which is due to the degradation of their fiber properties. This has been associated with the deterioration in the strength of bonds between fibers (Laivins and Scallan 1993). During recycling, fibers undergo various stages of drying and rewetting, and in doing so, they lose some of their conformability and swelling capabilities. Hornification, or the irreversible hardening of fibers (Jayme 1944), was suggested as being accountable for these fibers’ impairment, whereby the inter-fiber hydrogen bonds that were fully formed during the initial papermaking are resistant to being broken during the subsequent rewetting process of recycling. Because some of these bonds remain bonded, the fibers only experience partial swelling, resulting in paper with poorer strength qualities.

To overcome these setbacks, different strategies have been adopted, i.e., mechanical treatment (refining), using of chemical additives, and addition of long fibers so as to increase the strength of paper made from recycled fibers, with the latter method relying on the creation of new fiber-to-fiber interactions (hydrogen bonds). This forms the basis for the use of nanocelluloses as paper strength reinforcement agents. This material is biodegradable (and renewable), with high specific strength and stiffness, high reinforcing potential, and high specific surface area (Guimond et al. 2010; Osong et al. 2014; Kumar et al. 2016; Balea et al. 2018; Viana et al. 2018).

Nanocellulose (NC) is a general term that has been used to describe nanosized elements obtained from cellulose, which includes cellulosic nanofibrillar and nanocrystalline materials (Hamad 2006), cellulose nanocrystals (Habibi et al. 2010; Lin et al. 2011), cellulose nanowhiskers (Chen et al. 2009), cellulose crystallites (Fleming et al. 2001), and nanocrystalline cellulose (Li et al. 2012). The morphology and dimensions are related to the processes used to isolate them, amongst which are acid hydrolysis at elevated temperatures (Hamad 2006; Habibi et al. 2010; Qin et al. 2011; Fan et al. 2020), mechanical treatments such as using a disk grinder (Hu et al. 2015) and high intensity ultrasonication (Wang et al. 2015) of fibers, all of which demands a high energy usage. To mitigate such issues, the fibers are usually chemically pretreated, with 2,2,6,6-tetramethylpiperidine-1-oxy (TEMPO) being one of those successful pretreatments. It is believed that during this TEMPO-mediated oxidation, the hydroxyl primary groups on the cellulose chains (C6) undergo a selective oxidation, during which negatively charged carboxylic moieties are introduced, thus allowing the pretreated fibers to be easily broken down into nanocelluloses that are dispersible in water (Tahiri and Vignon 2000; Saito et al. 2007; Johnson et al. 2009; Isogai et al. 2011). In an attempt to increase the NC yield, Rohaizu and Wanrosli (2017) used two treatment sequences of sono-assisted TEMPO oxidation of the cellulosic material, followed by a highly powered ultrasonication mechanical treatment of the oxidized product, with yields exceeding 90% reported. The resultant NC was shown to be stable over a long period of time; even after 24 hours only partial sedimentation was observed. These observations were most likely due to the increase in the negative charge carboxylate groups generated during the TEMPO oxidation process.

Traditionally, NC can be obtained from wood; nevertheless they can also be isolated from non-woody materials such as sisal fibers (Moran et al. 2008), kenaf (Kargarzadeh et al. 2012), rice straw (Jiang and Hsieh 2013), sugarcane bagasse (Mandal and Chakrabarty 2011), bamboo (Wang et al. 2015), and oil palm lignocellulosic (OPL) biomass fibers (Fahma et al. 2010; Haafiz et al. 2014; Al-Dulaimi and Wanrosli 2016; Rohaizu and Wanrosli 2017). The latter, which is a by-product of the palm oil industry, is of particular interest in this research due to its abundance, low cost, and the ready availability of renewable cellulosic biomass. OPL consists of various types of residues, viz. trunks, fronds, and empty fruit bunches (OPEFB), which are rich in cellulose. However, because of its distinct advantage of being produced at the mill site, from which it can be easily obtained, OPEFB has been chosen as the material for investigation for the potential as paper strength reinforcement agents.

This study deals with the effects of adding nanocellulose produced via the TEMPO reaction (OPEFB-TEMPO) with recycled fibers (RF) obtained from old corrugated containerboard (OCC) on pulp and paper properties made thereof. It has great potential as strengthening agent; the presence of reactive carboxylic groups in OPEFB-TEMPO will confer a greater degree of inter-fiber (hydrogen) bonding, resulting in better paper qualities. For comparison purposes, microcrystalline cellulose (OPEFB-MCC) that was prepared by acid hydrolysis and beaten bleached OPEFB pulp (OPEFB-B) obtained via totally free chlorine (TCF) processes was used. Paper handsheets were prepared and evaluated according to the appropriate TAPPI Standards (TAPPI 2004).

EXPERIMENTAL

Materials

OPEFB in the form of fibrous strands were obtained from a local Malaysian company. Before use, they were washed with water, air dried, and cut into lengths of 5 cm to ensure better penetration of the pulping chemicals. 4-Acetamido-TEMPO (2,2,6,6-tetramethylpiperidin-1-oxyl) 98% was procured from Sigma-Aldrich (St. Louis, MO, USA). Sodium bromide (NaBr) and other chemicals were obtained from Bendosen and used as received.

Preparation of Bleached Pulp

Bleached OPEFB pulp (OPEFB-B) was prepared using an environmentally benign process as described by WanRosli et al. (2003) and Leh et al. (2008). The two phases were preparation of the unbleached OPEFB pulp (OPEFB-UB), followed by bleaching. In the former, OPEFB fiber strands were pulped via water prehydrolysis followed by soda-anthraquinone pulping, while the latter involves the bleaching of OPEFB-UB pulp using a totally chlorine-free (TCF) bleaching sequence of oxygen (O), ozone (Z), and peroxide (P). The resultant OPEFB-B pulp has a Kappa number of 1.2.

Preparation of Microcrystalline Cellulose

Microcrystalline cellulose (OPEFB-MCC) was prepared by hydrolyzing the above OPEFB-B pulp with 2.5 M HCl while maintaining a solid to liquid ratio of 1:20 at a temperature of 105 ± 2 °C for 15 min. After hydrolysis, the material was thoroughly washed with distilled water before being air-dried and subsequently kept in a desiccator over phosphorous pentoxide until further use.

Preparation of TEMPO Oxidized Nanocellulose

TEMPO oxidized nanocellulose (OPEFB-TEMPO) were prepared based on the procedure described by Rohaizu and Wanrosli (2017), which involves sono-assisted TEMPO-oxidation of the cellulosic material with slight modifications. First, 3 g of OPEFB-UB pulp was suspended in a 1 L glass reactor containing an aqueous mixture of 500 mL water, 0.048 g of 4-acetamido-TEMPO, and 0.48 g sodium bromide, followed by drop-wise addition of a 30 mL solution of sodium hypochlorite with continuous stirring. The oxidation reaction was carried out in an ultrasonic water bath (model Branson 8510) at a frequency of 40 kHz and 320 W output power at a constant temperature of 30 °C, whilst maintaining the pH of 10.0 ± 0.2 by using 0.5 M NaOH for 2 h. The reaction was quenched by adding 30 mL of ethyl alcohol, with the final pH regulated to 5.0 by adding 1.0 M HCl, after which it was centrifuged using a Kubota model 5100 at 3500 rpm for 20 min. To ensure the TEMPO oxidized OPEFB is maximum free from any unreacted TEMPO, superfluous acids and inorganic salts, the water-insoluble product was re-dispersed and re-centrifuged three times using distilled water, followed by sonication in an ice-bath using an ultrasonic probe (Branson sonifier 450) with a 7 mm tip at 20 kHz and 400W output power for 30 min after which a colloidal suspension was obtained.

OPEFB-TEMPO nanocellulose was isolated by re-centrifuging the colloidal suspension at 3500 rpm for 1 h and the ensuing admixture filtered using a 15-µm filter for removal of any unwanted materials comprising of micro-contaminants and fibrous aggregates, and then stored in a refrigerator before further use.

Preparation of Recycled Fiber Pulp

Recycled fiber (RF) pulp was prepared from old corrugated containerboard (OCC) by tearing them into pieces of dimensions 1 cm x 1 cm, followed by soaking in water for 24 hours, after which it is disintegrated for 3000 revolutions in a standard laboratory British disintegrator. After concentrating the pulp to about 20% consistency, they were kept in plastic bags and stored in the refrigerator until further use.

Morphological Analysis

The surface morphology of the samples was investigated using SEM and TEM. For SEM, a SEM Oxford INCA 400 model was used. Prior to scanning, samples were coated with gold sputter in order to avoid charging effect. TEM micrographs were obtained using the transmission electron microscope Phillips CM12 with Docu Version 3.2 image analysis. Drops of the suspension (0.01% of w/v) were deposited on carbon coated electron microscope grids and allowed to dry and stained with phosphotungstic acid (around 2% of wt) for 30 seconds.

The lengths of OPEFB-B fibers were analyzed by the Fiber Quality Analyzer (FQA, Op Test Equipment, Canada), while for OPEFB-MCC and the OPEFB-TEMPO, the sample dimensions were measured directly from the TEM micrographs with the results based on a mean of 50 measurements.

Preparation of Paper Handsheets

One of the challenges regarding the use of specialized cellulosic materials as strengthening agents for papermaking is that it is almost impossible to determine the amount retained during sheet making, unless it is prepared by evaporation, which does not really represent the papermaking process. This is because they all belong to the same group of materials which have practically the same basic fiber properties. Papermaking is a filtration process wherein fibers are collected on a wire mesh. Thus, the objective is to retain as much as possible the fibers and other materials that are added. In designing the experimental procedure, the greatest constraint is to minimize the errors that ensued from the sheet making process and, in this regard, three approaches were considered. It should be emphasized that some amounts of the cellulosic materials, especially the micro- and nano- fractions will definitely be lost during the sheet forming process; however, since all experiments were carried under the same conditions, it can be assumed that the lost proportion will be consistent throughout and the results will be thus comparable.

In the first approach, the normal handsheet making technique, as outlined in the Second Report (Anon., 1936) using a Standard British Laboratory handsheet equipment, was carried out. In the second method, the cellulosic materials were blended for two minutes to ensure proper mixing, followed by handsheet making. In the third procedure, RF fibers were added during the initial stage of the handsheet equipment being filled with water, with the OPEFB cellulosic materials only added after the water had finally reached the maximum level.

Both of the first two methodologies gave unsatisfactory results because of significant variations in handsheet grammage. It is anticipated that the micro- and nanometric small particles of OPEFB-MCC and OPEFB-TEMPO are not trapped in the sheet structure, causing it to pass through the wire mesh as the water is drained. This is partly confirmed by the turbidity of the collected backwater, which can be inferred as resulting from the accumulation of the small particles that easily passed through the wire mesh.

The third procedure gave a more consistent grammage with much lesser turbidity in the backwater; hence it was adopted in this study. It is believed that in this method, the small particles have a better chance of being trapped because by the time they reach the wire mesh, the paper structure has already been formed, hence entrapping them. Nevertheless, it should be emphasized that there is no known technique to determine the exact amount of these cellulosic materials that are retained in the paper structure.

The amount of cellulosic material added is dependent on its type; ranging from 0 to 100% for OPEFB-B, and 0 to 20% for OPEFB-TEMPO and OPEFB-MCC.

Handsheet Making and Testing

Handsheets of 65 ± 2 g/m2 were prepared using the Standard British Laboratory handsheet equipment, as outlined in the Second Report (Anonymous 1936) with slight modifications whereby they were prepared according to the third procedure as discussed above. For OPEFB-B, prior to addition to the recycled fiber, the pulp samples were beaten in a PFI mill for 20,000 revolutions.

Pulp freeness was determined according to TAPPI Standard T227 om-99. Drainage times were expressed as the time taken for the water to drain completely from the maximum level in the handsheet equipment.

The completed handsheet sets were conditioned at 23 °C and 50 % RH for at least 24 hours before testing. Their properties were evaluated following the appropriate TAPPI standard methods (TAPPI 2004), such as: Tensile index (T 494 om-01), Tear index (T 414 om-98), and Opacity, from which scattering coefficients are derived (T425 om-91).

RESULTS AND DISCUSSION

OPEFB cellulosic materials comprising of OPEFB bleached pulp (OPEFB-B), OPEFB microcrystalline cellulose (OPEFB-MCC), and OPEFB nanocellulose produced via the TEMPO oxidation method (OPEFB-TEMPO) were utilized as reinforcing materials for paper using recycled fibers (RF). The effects were compared and discussed in terms of fiber morphology, pulp freeness and drainability, sheet density, tensile, and tear indices.

Morphological Analysis

Figure 1 shows representative SEM and TEM images of various OPEFB cellulosic materials: OPEFB-B pulp, OPEFB-MCC, and OPEFB-TEMPO. The OPEFB-B pulp (Fig. 1a), as expected, demonstrated a fibrous structure. The dimensions were reduced greatly upon conversion into OPEFB-MCC, with the morphology apparently in the form of bundles of rod-like structure, as shown in Fig. 1(b).

(a)

(b)

(c)

Fig. 1. (a) SEM of OPEFB-B pulp (x200 magnifications); TEM of (b) OPEFB-MCC (x31000 magnifications), (c) OPEFB-TEMPO (x88000 magnifications)

During the acid hydrolysis process, the amorphous regions were removed, leaving the MCC rod-like structures, and since all contaminants were removed during this treatment, the product was a highly purified cellulose. However, unlike the OPEFB-MCC, OPEFB-TEMPO (Fig. 1c) had distinct rod-like structures resembling the nanocrystalline cellulose crystallites.

The length of OPEFB-B as analyzed by the Fiber Quality Analyzer (FQA, Op Test Equipment, Canada) (expressed as length weighted average) was ca. 1.01 mm, while for the OPEFB-MCC and OPEFB-TEMPO, the lengths were ca. 1875 nm and 76 nm, respectively. The differences in size of these cellulosic materials will have an impact on the pulp and paper properties as will be discussed later.

Freeness and Drainability

Freeness of pulps as measured by Canadian Standard Freeness (CSF) decreased with the addition of OPEFB-MCC and OPEFB-B pulp (Fig. 2a).

Fig. 2. Effect of (a) freeness and (b) drainability on OPEFB cellulosic addition

However, reliable data for OPEFB-TEMPO addition could not be determined due to the very slow drainage rate, which affects the freeness readings. For the OPEFB-TEMPO, the water drained slowly (dripping) through the side walls of the apparatus sample chamber, making it impossible to have accurate CSF readings.

A possible explanation for the changes observed with both OPEFB-MCC and OPEFB-B is that the intrinsic properties of these materials differ greatly from the recycled fibers. The RF, by virtue of being hornified, are stiff fibers, which have markedly reduced swelling and absorption capabilities. This was reflected in the high freeness at zero addition of OPEFB cellulosics. As the virgin OPEFB cellulosics were added, some of the base RF were replaced with the active fibers, and because of their intact internal structure, they can swell and absorb water unhindered to their maximum potential, leading to a CSF reduction. It could also be seen that the freeness with OPEFB-MCC addition decreased at a faster rate than OPEFB-B pulp, which could be related to the size of the cellulosic material, whereby the fiber length of the OPEFB-MCC was much shorter than the OPEFB-B fibers and their fines as discussed above (Morphological analysis). Furthermore, chemical OPEFB-MCC is considered pure cellulose, which has large amounts of hydroxyl groups, which can participate in water absorption. Thus, both the high surface area and greater number of hydroxyl groups in the OPEFB-MCC will absorb more water, resulting in lower freeness as compared to OPEFB-B pulp.

The effect of OPEFB cellulosic additions was investigated in terms of drainage times, which in this study was measured by the time it takes for the pulp to drain from the handsheet machine. As shown in Fig. 2b, OPEFB-TEMPO showed the slowest rate (longer drainage times), followed by OPEFB-B and OPEFB-MCC. It is possible that this is due to the nanometric scale of the OPEFB-TEMPO nanocelluloses, which increases the water retention capacity of the pulp, resulting in slow drainage. It is also probable that these retained nano-sized elements in the fiber matrix could decrease the available pore area through plugging of the inter-fiber pores, hence reducing the drainage rate (Lin et al. 2007; Cole et al. 2008; Rantanen and Maloney 2013). They can penetrate the fiber network, leading to a partial closing of the pores, thus increasing the drainage resistance (Cole et al. 2008). These small particles can migrate in the fiber network, and as they become trapped, they tend to block the flow of water. In addition, since swelling is driven by osmosis, it is therefore dependent on the number of ions trapped in the fibers, and with OPEFB-TEMPO containing substantial amounts of carboxylic groups, this could contribute to increased swelling, leading to slow drainage. Nevertheless, this drawback can be minimized by adding retention aids such as alum, polyamines, or polyethylene imines (PEI).

Paper Density

Figure 3 shows the relationship between the addition of OPEFB cellulosic material and sheet density. It is evident that even though the densities of all sheets increase with all types of OPEFB cellulosics, the effect varied according to the nature of the cellulose, with OPEFB-B highest followed by OPEFB-MCC and OPEFB-TEMPO.

The high increment upon the addition of OPEFB-B pulp is probably a result of the replacement of the more stiffened recycled fiber base pulp with the active virgin OPEFB bleached pulp. The recycled fibers are more rigid because of hornification, whereby bleached fibers are less flexible, thus unable to conform well to each other leading to bulkier (or less dense) sheets. As these recycled fibers are progressively replaced by the active flexible virgin fibers, the conformability of individual fibers in the fibrous structure increases resulting in denser sheets. In addition, the presence of fines in the OPEFB-B pulp will also contribute through the fillings in the voids between fibers, resulting in an increase in sheet density.

Fig. 3. Effect of density on OPEFB cellulosic addition

With regards to OPEFB-TEMPO and OPEFB-MCC, the increase is a consequence of their dimensional properties; being infinitesimal, they could easily fill in the empty spaces and gaps between the rigid recycled fibers leading to sheet density increase. Further, these micro- and nano-sized particles could also contribute to a compacting effect which increases the amount of inter-fiber bonds, resulting in a higher sheet density (Retulainen 1997). It could also be seen that sheets containing OPEFB-MCC were denser than sheets containing OPEFB-TEMPO. This behavior could be related to the retention of the cellulosic materials by virtue of the bigger dimensions of OPEFB-MCC which are easier to be retained in the sheet. It could also be that since the OPEFB-MCC size is larger, they are heavier than the smaller particles of OPEFB-TEMPO, thus contributing to a higher density of OPEFB-MCC.

Strength Properties

There are various types of mechanical tests used to evaluate the strength properties of paper, of which tensile and tear are the most common. Hence, both were used to describe the effects of OPEFB cellulosic addition on paper strength properties. To minimize the influence of grammage variations, they were expressed in terms of their indices.

Tensile strength

The response of tensile strength on addition of OPEFB cellulosic materials shows a strong positive correlation as indicative from the R2 values (Fig. 4).

Fig. 4. Effect of tensile index on OPEFB cellulosic addition

Although all of them were found to be capable of providing a positive impact, the degree of their effectiveness was dependent on the type of cellulosic material used, with OPEFB-TEMPO giving better enhancement than OPEFB-MCC. Nevertheless, both of these materials were better in comparison to OPEFB-B pulp in affecting the strength improvement. Considering that OPEFB-B were first beaten in a PFI mill for 20,000 revolutions before being added to the recycled fiber, these results are of immense significance, since it could possibly mitigate the industrial practice of beating and refining to increase the paper’s strength properties.

Paper derives its strength from both the strengths of individual fibers and the strengths of the bonds between them (Page 1969); hence, any treatments that can increase these factors, especially the strengthening of bonds (since bonds are normally weaker than the fibers), will improve the strength properties of paper.

A significant factor that influences paper strength development is fiber swelling, since it increases fiber flexibility and surface area, consequently enhancing the inter-fiber bonding (H-bonds). The observed increase in tensile strength in OPEFB-B could be due to the substitution of the passive recycled fibers with the more active fibers of the virgin pulp (Wanrosli et al. 2005) that are able to swell and increase the fibers flexibility, which in turn generates new additional inter-fiber bonding resulting in an increase of tensile strength. Furthermore, since these virgin OPEFB-B fibers have undergone bleaching, the hydroxyl groups residing in the cellulose chains are more exposed, and consequently more inter-fiber bonds are formed. All of these possibilities will lead to a greater number of the H-bonds being formed, thus a higher tensile strength.

It is evident from Fig. 4 that OPEFB-TEMPO and OPEFB-MCC showed a remarkable increase in tensile index as compared to OPEFB-B. Although there are several reasons that can be proposed, they are all based on the concept of inter-fiber bond creation. Since they are small, they can penetrate into the fiber network and fill in the voids, and in doing so form new inter-fiber bonds. Furthermore, by being elements of micro- and nano- dimensions, these particles have a greater surface area as compared to pulp fibers, hence increasing the bonding area which further facilitates inter-fiber bond development. Another possibility is related to their increase bonding potentials by virtue of their functional groups. OPEFB-MCC being a very pure cellulosic material is composed almost entirely of cellulose with massive amounts of unobstructed hydroxyl groups which can contribute towards the formation of hydrogen bonds leading to tensile strength increment. This is unlike the OPEFB-B which apart from cellulose, also consists of some lignin which can mask the hydroxyl groups from participating in inter-fiber bonding.

OPEFB-TEMPO provided a better strengthening effect than OPEFB-MCC. There are several possible explanations, but all revolve around the central inherent feature of TEMPO modified fibers, which is that, in addition to the hydroxyl groups that are already present in the cellulose chains, it has also the carboxylic groups (-COOH) resulting from the TEMPO-oxidation process as shown in Fig. 5 (Isogai et al. 2011). These carboxylic acid groups are known to be significantly more reactive than the alcoholic OH groups due to the presence of the carboxyl groups (DeRuiter 2005), which could promote greater inter-fiber bonds. Barzyk et al. (1997) reported that acidic acid groups (which were introduced by various chemical treatments onto the pulp fibers) promote swelling and inter-fiber hydrogen bonding. Furthermore, these carboxylic moieties can form three hydrogen bonds simultaneously as compared to one with the hydroxyl groups, which could contribute to an improvement in the paper tensile strength. Additionally, it is reported that the strength of hydrogen bonds in carboxylic acids is about 13 kcal/mol, while those in alcohol is about 4-5 kcal/mol (Jones et al. 1952; Biermann 1996), suggesting that the H-bonds between the COOH groups are much stronger as compared to H-bonds formed through OH groups, resulting in an increase in paper tensile strength when OPEFB-TEMPO is added. All of these OPEFB-TEMPO attributes will positively contribute to the observed tensile strength enhancement in comparison to OPEFB-MCC.

Fig. 5. Generation of the carboxylic acid groups via TEMPO-oxidation (Isogai et al. 2011)

To form the inter-fiber bonds (hydrogen bonds), the distance between the cellulosic material surfaces has to be within about 0.27 nm (Linhart 2005; Hubbe 2006). Because the OPEFB-TEMPO nanocelluloses are of nano-sized dimensions, this would greatly increase the probability of the formation of new inter-fiber bonds resulting in higher tensile strength.

Fig. 6. Effect of scattering coefficient on OPEFB cellulosic addition

This enhancement of interfiber bonding is collaborated with the scattering coefficient-percent relationship (Fig. 6). Scattering coefficient is related to the area of bonding between the fibers, and it is thus generally a measure of the degree of bonding (Gurnagul 1995). It was first proposed by Ingmanson and Thode (1959), which is based on the assumption that it is proportional to the area available for light scattering, and since only free fiber surface scatters light, sheets which have a greater number of bonds will give a higher scattering coefficient. OPEFB-TEMPO showed the lowest scattering coefficient, followed by OPEFB-MCC and OPEFB-B, which correlates very well with the relationship observed in Fig. 4 (tensile index versus OPEFB cellulosic additions). The lowest scattering coefficient plot of OPEFB-TEMPO is indicative of the highest degree of inter-fiber bonding that occurs in this type of cellulosic, leading to a higher paper strength.

Tear strength

The effects of OPEFB cellulosics addition on tearing strength (Fig. 7) shows a similar positive trend as observed previously with tensile strength. It is speculated that such increases in tear index were induced by greater inter-fiber bonding capability, with active virgin fibers in OPEFB-B and the presence of greatly exposed hydroxyl groups in OPEFB-MCC and carboxylic groups in OPEFB-TEMPO. Earlier studies using CNF hardwood Eucalyptus kraft pulp (Gonzalez et al. 2012; Viana et al. 2018) and Balea et al. (2018) using CNFs obtained from three different cellulose residues, eucalyptus sawdust, pine sawdust, and triticale straw have also shown that tear index increases with addition of these cellulosic materials.

Fig. 7. Effect of tear index on OPEFB cellulosic addition

These results suggest that although tearing strength is highly dependent on fiber length (Page and MacLeod 1992), the role of inter-fiber bonding in governing tear resistance needs also to be appreciated. During tearing, apart from fiber pull-out, the sheet failure also involves breaking down of the inter-fiber bonds, and as more of these are needed to be broken, the greater the tear strength.

However, unlike tensile index, which does not show a maximum, tear index on the contrary shows an upper limit at ca. 15% addition, after which the effect was small (the slope leveled off) for both OPEFB-MCC and OPEFB-TEMPO. It is possible that a negative impact of fiber length on tear strength had begun to be operative. At higher addition, the incorporation of these micro- and nano- particles significantly neutralized the positive effects of interfiber bonding, whereby paper with shorter fibers exhibited a lower tear index.

Figure 7 shows that the OPEFB-TEMPO had a greater influence than OPEFB-MCC. This can be explained in terms of the presence of carboxylic groups, which have the potential to create more hydrogen bonds leading to higher tear index.

CONCLUSIONS

- Morphologically, bleached oil pulp empty fruit bunch (OPEFB-B) consisted of fibrous materials, the corresponding microcrystalline cellulose (OPEFB-MCC) was in the form of rod-like structure bundles, and the corresponding TEMPO-oxidized nanocellulose (OPEFB-TEMPO) was comprised of individualized rod-like structures.

- Pulp drainage was fastest in the presence of OPEFB-MCC, even surpassing the more fibrous OPEFB-B, with the OPEFB-TEMPO the slowest. However this slow drainage can be minimized by adding drainage aids. As for density, OPEFB-B achieved the highest followed by OPEFB-MCC and OPEFB-TEMPO.

- The addition of all OPEFB cellulosics was accompanied with an increase in tensile and tear indices, with the OPEFB-TEMPO showing the greatest effect. A scattering coefficient-percent addition relationship suggests that this enhancement was due to the increase in inter-fiber bonding, as indicated by a bigger reduction in the scattering for OPEFB-TEMPO, as compared to OPEFB-MCC and OPEFB-B. This inter-fiber bonding augmentation is also evident from the tear strength correlation, where again the OPEFB-TEMPO displayed a higher increase in comparison to the other OPEFB cellulosics.

ACKNOWLEDGMENTS

The authors express their gratitude to Universitas Syiah Kuala for Research Contract No. 266/UN11/SPK/PNBP/2020, Universiti Sains Malaysia for the Research University Grant No. 1001/PTEKIND/814240, and to the Ministry of Higher Education Malaysia and Yayasan Pahang for sponsoring the postgraduate studies of Khairul Hafizuddin Abdul Rahman.

REFERENCES CITED

Al-Dulaimi, A., and Wanrosli, W. D. (2016). “Isolation and characterization of nanocrystalline cellulose from totally chlorine free oil palm empty fruit bunch pulp,” Journal of Polymers and the Environment 25, 192-202. DOI: 10.1007/s10924-016-0798-z

Anon. (1936). “The second report of the pulp evaluation committee to the technical section,” The Paper Makers ‘Association of Great Britain and Ireland, London, 1936.

Balea, A., Merayo, N., Fuente, E., Negro, C., Delgado-Aguilar, M., Mutje, P., and Blanco, A. (2018). “Cellulose nanofibers from residues to improve linting and mechanical properties of recycled paper,” Cellulose 25, 1339-1351. DOI: 10.1007/s10570-017-1618-x.

Barzyk, D., Page, D. H., and Ragauskas, A. (1997). “Acidic group topochemistry and fibre-to-fibre specific bond strength,” J. Pulp Pap. Sci 23, J59-J61.

Biermann, C. J. (1996). “Wood and fiber fundamentals,” in: Handbook of Pulping and Papermaking, C. J. Biermann (ed.), Academic Press, San Diego, pp. 13-54.

Chen, Y., Liu, C. H., Chang, P. R., Cao, X. D., and Anderson, D. P. (2009). “Bionanocomposites based on pea starch and cellulose nanowhiskers hydrolyzed from pea hull fibre: Effect of hydrolysis time,” Carbohydr. Polym 76, 607-615. DOI: 10.1016/j.carbpol.2008.11.030

Cole, C., Hubbe, M., and Heitmann, J. (2008). “Water release from fractionated stock suspensions. Part 1 – Effects of the amounts and types of fiber fines,” TAPPI J 7, 28-32.

DeRuiter, J. (2005). “Carboxylic acid structure and chemistry: Part 2,” Principles of Drug Action 1, Auburn University, Alabama, pp. 1-10.

Fahma, F., Iwamoto, S., Hori, N., Iwata, T., and Takemura, A. (2010). “Isolation, preparation, and characterization of nanofibers from oil palm empty-fruit-bunch (OPEFB),” Cellulose 17, 977-985. DOI: 10.1007/s10570-010-9436-4

Fan, L., Zhang, H., Gao, M., Zhang, M., Liu, P., and Liu, X. (2020). “Cellulose nanocrystals/silver nanoparticles: In-situ preparation and application in PVA films,” Holzforschung 74, 523-528. DOI: 10.1515/hf-2018-0251.

FAO (2001). Survey of World Pulp and Paper Capacities 2001-2005, FAO Forestry Department Rome, Italy.

FAO (2017). Survey of World Pulp and Paper Capacities 2013-2018, FAO Forestry Department Rome, Italy.

Fleming, K., Gray, D.G., and Matthews, S. (2001). “Cellulose crystallites,” Chem. A Eur. J 7, 1831-1835. DOI: 10.1002/1521-3765(20010504)7:93.3.CO;2-J

González, I., Boufi, S., Pèlach, M.À., Alcalà, M., Vilaseca, F., and Mutjé, P. (2012). “Nanofibrillated cellulose as paper additive in Eucalyptus pulps,” BioResources 7, 5167-5180. DOI: 10.15376/biores.7.4.5167-5180

Guimond, R., Chabot, B., Law, K.N., and Daneault, C. (2010). “The use of cellulose nanofibres in papermaking,” Journal of Pulp and Paper Science 36, 55-61.

Gurnagul, N. (1995). “Sodium hydroxide addition during recycling: Effects on fiber swelling and sheet strength,” TAPPI J 78, 119-124.

Haafiz, M. K. M., Hassan, A., Zakaria, Z., and Inuwa, I. M. (2014). “Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose,” Carbohydr. Polym 103, 119-125. DOI: 10.1016/j.carbpol.2013.11.055

Habibi, Y., Lucia, L. A., and Rojas, O. J. (2010). “Cellulose nanocrystals: Chemistry, self-assembly, and applications,” Chem. Rev 110, 3479-3500. DOI: 10.1021/cr900339w

Hamad, W. (2006). “On the development and applications of cellulosic nanofibrillar and nanocrystalline materials,” Can. J. Chem. Eng 84, 513-519. DOI: 10.1002/cjce.5450840501

Hu, C., Zhao, Y., Li, K., Zhu, J.Y. and Gleisner, R. (2015). “Optimizing cellulose fibrillation for the production of cellulose nanofibrils by a disk grinder,” Holzforschung 69(8), 993-1000. DOI: 10.1515/hf-2014-0219.

Hubbe, M.A. (2006). “Bonding between cellulosic fibers in the absence and presence of dry strength agents – A review,” BioResources 1, 281-318.

Ingmanson, W., and Thode, E. (1959). “Factors contributing to the strength of a sheet of paper: II. Relative Bonded Area,” TAPPI J. 42, 83-94.

Isogai, A., Saito, T., and Fukuzumi, H. (2011). “TEMPO-oxidized cellulose nanofibers,” Nanoscale 3, 71-85. DOI: 10.1039/C0NR00583E

Jayme, G. (1944). “Mikro-Quellungsmessungen an Zellstoffen,” Papier-Fabr./ Wochbl. Papier-fabr 6, 187-194.

Jiang, F., and Hsieh, Y. L. (2013). “Chemically and mechanically isolated nanocellulose and their self-assembled structures,” Carbohydr. Polym 95, 32-40. DOI: 10.1016/j.carbpol.2013.02.022

Johnson, R. K., Zink-Sharp, A., Renneckar, S. H., and Glasser, W. G. (2009). “A new bio-based nanocomposite: Fibrillated TEMPO-Oxidized celluloses in hydroxypropylcellulose matrix,” Cellulose 16, 227-238. DOI: 10.1007/s10570-008-9269-6

Jones, M. M., Gilkerson, W. R., and Gallup, G. A. (1952). “Hydrogen bond energies in carboxylic acids,” The Journal of Chemical Physics. 20, 1048. DOI: 10.1063/1.1700640

Kargarzadeh, H., Ahmad, I., Abdullah, I., Dufresne, A., Zainudin, S. Y., and Sheltami, R. M. (2012). “Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers,” Cellulose 19, 855-866. DOI: 10.1007/s10570-012-9684-6

Kumar, A., Singh, S., and Singh, A. (2016). “Comparative study of cellulose nanofiber blending effect on properties of paper made from bleached bagasse, hardwood and softwood pulps,” Cellulose 23, 2663-2675. DOI: 10.1007/s10570-016-0954-6.

Laivins, G. V., and Scallan, A. M. (1993). “The mechanism of hornification of wood pulps,” in: Proceedings of the 10th Fundamental Research Symposium, Oxford, UK. 1235-1260.

Leh, C. P., Wanrosli, W. D., Zainuddin, Z., and Tanaka, R. (2008). “Optimisation of oxygen delignification in production of totally chlorine-free cellulose pulps from oil palm empty fruit bunch fibre,” Ind. Crops Prod 28, 260-267. DOI: 10.1016/j.indcrop.2008.02.016

Li, W., Yue, J. Q., and Liu, S. X. (2012). “Preparation of nanocrystalline cellulose via ultrasound and its reinforcement capability for poly(vinyl alcohol) composites,” Ultrason. Sonochem 19, 479-485. DOI: 10.1016/j.ultsonch.2011.11.007

Lin, T., Yin, X., Retulainen, E., and Nazhad, M. M. (2007). “Effect of chemical pulp fines on filler retention and paper properties,” Appita J 60, 469-473.

Lin, N., Huang, J., Chang, P. R., Feng, J., and Yu, J. (2011). “Surface acetylation of cellulose nanocrystal and its reinforcing function in poly(lactic acid),” Carbohydrate Polymers 83, 1834-1842. DOI: 10.1016/j.carbpol.2010.10.047

Linhart, F. (2005). “Some thoughts on the mode of action of paper strength agents,” Przeglad Papierniczy 61, 449-456.

Mandal, A., and Chakrabarty, D. (2011). “Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization,” Carbohydr. Polym 86, 1291-1299. DOI: 10.1016/j.carbpol.2011.06.030

Moran, J. I., Alvarez, V.A., Cyras, V. P., and Vazquez, A. (2008). “Extraction of cellulose and preparation of nanocellulose from sisal fibers,” Cellulose 15, 149-159. DOI: 10.1007/s10570-007-9145-9

Osong, S. H., Norgren, S., and Engstrand, P. (2014). “Paper strength improvement by inclusion of nano-ligno-cellulose to chemi-thermomechanical pulp,” Nordic Pulp and Paper Research Journal 29, 309-316. DOI: 10.3183/npprj-2014-29-02-p309-316

Page, D. H. (1969). “A theory for the tensile strength of paper,” TAPPI J. 52, 674-81.

Page, D. H., and MacLeod, J. M. (1992). “Fiber strength and its impact on tear strength,” TAPPI J. 75, 172-174.

Papernews. (2015) https://www.papnews.com/paper-and-paperboard-market-demand-is-forecast-to-grow-by-nearly-a-fifth-by-2030/. Accessed 28 October 2022.

Qin, Z. Y., Tong, G. L., Chin, Y. C. F., and Zhou, J. C. (2011). “Preparation of ultrasonic-assisted high carboxylate content cellulose nanocrystals by TEMPO oxidation,” BioResources 6, 1136-1146.

Rantanen, J., and Maloney, T. C. (2013). “Press dewatering and nip rewetting of paper containing nano- and microfibril cellulose,” Nordic Pulp & Paper Research Journal 28, 582-587. DOI: 10.3183/NPPRJ-2013-28-04-p582-587

Retulainen, E. (1997). The Role of Fibre Bonding in Paper Properties, Ph.D. Dissertation, Helsinki University of Technology, Espoo, Finland.

Rohaizu, R., and Wanrosli, W. D. (2017). “Sono-assisted TEMPO oxidation of oil palm lignocellulosic biomass for isolation of nanocrystalline cellulose,” Ultrasonics Sonochemistry 34, 631-639. DOI: 10.1016/j.ultsonch.2016.06.040

Saito, T., Kimura, S., Nishiyama, Y., and Isogai, A. (2007). “Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose,” Biomacromolecules 8, 2485-2491. DOI: 10.1021/bm0703970

Tahiri, C., and Vignon, M. R. (2000). “TEMPO-oxidation of cellulose: Synthesis and characterisation of polyglucuronans,” Cellulose 7, 177-188. DOI: 10.1023/A:1009276009711

TAPPI Standard (2004). “TAPPI Test Methods,” TAPPI Press, Atlanta, USA.

Viana, L. C., Potulski, D. C., Muniz, G. I. B., Andrade, A. S., and Silva, E. L. (2018). “Nanofibrillated cellulose as an additive for recycled paper,” CERNE 24, 140-148. DOI: 10.1590/01047760201824022518

Wang, H., Zhang, X., Jiang, Z., Yu, Z., and Yan Yu, Y. (2015). “Isolating nanocellulose fibrils from bamboo parenchymal cells with high intensity ultrasonication,” Holzforschung 70, 401-409. DOI: 10.1515/hf-2015-0114

WanRosli, W. D., Leh, C. P., Zainuddin, Z., and Tanaka, R. (2003). “Optimisation of soda pulping variables for preparation of dissolving pulps from oil palm fibre,” Holzforschung 57, 106-113. DOI: 10.1515/HF.2003.017

Wanrosli, W. D., Zainuddin, Z., and Roslan, S. (2005). “Upgrading of recycled paper with oil palm fiber soda pulp,” Industrial Crops and Products 21, 325-329. DOI: 10.1016/j.indcrop.2004.04.026

Article submitted: November 8, 2022; Peer review completed: December 31, 2022; Revised version received and accepted: January 2, 2023; Published: January 10, 2023.

DOI: 10.15376/biores.18.1.1508-1524