BioResources Early Career Investigator Award

Latest articles

BioResources Early Career Investigator Award

The BioResources Early Career Investigator Award, established in 2021, recognizes novel, impactful, and captivating research from early career scientists in any experimental or theoretical frameworks related to lignocellulosic materials, chemicals, and applications for new uses and new capabilities.

Eligible recipients have earned their Doctorate degree in the last 10 years, or are in the process of earning their Doctorate degree.

Nominees submit their original research, in the scope of materials, wood, and fiber sciences to BioResources, wherein the Editorial Board elects the winner after reviewing the submitted work and the candidate’s curriculum vitae.

The award recipient receives a $1,000 USD honorarium and their research is published free of charge in the open-access, international, and peer-reviewed journal BioResources.

Please see details here: 2025 BioResources Early Career Investigator Award

Congratulations to the Award Winners!

2024 Award

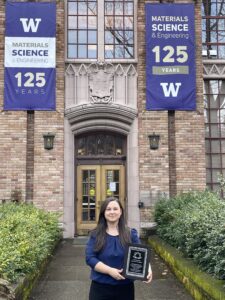

Eleftheria Roumeli, University of Washington

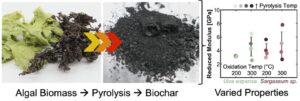

Lou, B., Parker, M., and Roumeli, E. (2025). “Effects of pyrolysis temperature of macroalgal biomass on the structure and mechanical properties of produced biochar,” BioResources 20(2), 4152–4173.

DOI: 10.15376/biores.20.2.4152-4173

Biochars, produced via pyrolysis, are gaining attention in applications ranging from soil amendments to energy storage and environmental remediation. While lignocellulosic biochars from woody biomass are well studied, algal biochars remain comparatively overlooked despite offering diverse organic and inorganic content that may broaden their applications. This study investigates how pyrolysis temperature and oxidative pretreatment affect the structure and properties of biochars derived from two macroalgae, Ulva expansa and Sargassum sp., under various pyrolysis conditions (500 to 900 °C). Using Raman spectroscopy, X-ray photoelectron spectroscopy, X-ray diffraction, scanning electron microscopy, and nanoindentation, it was found that the C-O and C-N surface functional groups decreased in Ulva but the C=O and C-O-C groups increased in Sargassum upon pyrolysis. The reduced modulus ranged between 2.6 to 7.9 GPa and was governed by pyrolytic carbon content and inorganic composition. Of these two factors, the amount and type of pyrolytic carbon were determined by the heating conditions, with oxidation at 200 °C generally preserving more carbon than oxidation at 300 °C. Meanwhile, the final pyrolysis temperature dictated residual carbon content, salt formation, and carbonation. These findings highlight the potential for tailored pyrolysis to produce algal biochars with customizable structures and properties, enabling environmental and industrial applications such as carbon sequestration, filtration, and energy storage.

Biochars, produced via pyrolysis, are gaining attention in applications ranging from soil amendments to energy storage and environmental remediation. While lignocellulosic biochars from woody biomass are well studied, algal biochars remain comparatively overlooked despite offering diverse organic and inorganic content that may broaden their applications. This study investigates how pyrolysis temperature and oxidative pretreatment affect the structure and properties of biochars derived from two macroalgae, Ulva expansa and Sargassum sp., under various pyrolysis conditions (500 to 900 °C). Using Raman spectroscopy, X-ray photoelectron spectroscopy, X-ray diffraction, scanning electron microscopy, and nanoindentation, it was found that the C-O and C-N surface functional groups decreased in Ulva but the C=O and C-O-C groups increased in Sargassum upon pyrolysis. The reduced modulus ranged between 2.6 to 7.9 GPa and was governed by pyrolytic carbon content and inorganic composition. Of these two factors, the amount and type of pyrolytic carbon were determined by the heating conditions, with oxidation at 200 °C generally preserving more carbon than oxidation at 300 °C. Meanwhile, the final pyrolysis temperature dictated residual carbon content, salt formation, and carbonation. These findings highlight the potential for tailored pyrolysis to produce algal biochars with customizable structures and properties, enabling environmental and industrial applications such as carbon sequestration, filtration, and energy storage.

2024 Early Career Award Winner Paper

Q&A. What inspired you to enter your research field?

“Receiving this award from the bioresources science community is immensely gratifying. Our interdisciplinary approach blends biomass utilization with polymer physics, mechanics, and lifecycle analysis, bridging various scientific domains. Recognition from the biomass field validates the relevance and impact of our work, highlighting its integration and innovation at the crossroads of multiple disciplines.”

Q&A. What was the most challenging part of the process that led to this award?

“Initiating our algal biomass biochar project under the tight timeline of the award nomination was exceptionally challenging yet profoundly motivating. This opportunity became the reason to launch a project I had long envisioned but had not yet pursued. The complexity of macroalgal biomass—with its diverse organic and inorganic structures—added layers of intricacy to our studies, particularly in managing the overlapping thermal and chemical transformations during pyrolysis. However, it was this very challenge, spurred by the nomination process, that excited our team to break new ground. I deeply value this experience, as it not only kick-started an innovative research thrust in my group but also demonstrated the transformative potential of embracing new opportunities in science.”

Q&A. What advice would you give to someone just entering the field?

“Pursue research topics that genuinely interest you and you find meaningful and worth your while. The path of research is filled with challenges and failures, and passion for your work provides the resilience needed to navigate these hurdles. Choose projects that inspire you, as they will sustain your motivation through the ups and downs inherent in scientific inquiry.”

2023 Award

Nawa Raj Baral, Lawrence Berkeley National Laboratory

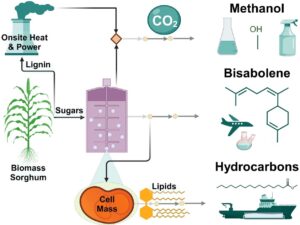

Baral, N. R., Banerjee, D., Mukhopadhyay, A., Simmons, B. A., Singer, S. W., and Scown, C. D. (2024). “Integration of genome-scale metabolic model with biorefinery process model reveals market-competitive carbon-negative sustainable aviation fuel utilizing microbial cell mass lipids and biogenic CO2,” BioResources 19(3), 4056-4086.

DOI: 10.15376/biores.19.3.4056-4086

Producing scalable, economically viable, low-carbon biofuels or biochemicals hinges on more efficient bioconversion processes. While microbial conversion can offer robust solutions, the native microbial growth process often redirects a large fraction of carbon to CO2 and cell mass. By integrating genome-scale metabolic models with techno-economic and life cycle assessment models, this study analyzes the effects of converting cell mass lipids to hydrocarbon fuels, and CO2 to methanol on the facility’s costs and life-cycle carbon footprint. Results show that upgrading microbial lipids or both microbial lipids and CO2 using renewable hydrogen produces carbon-negative bisabolene. Additionally, on-site electrolytic hydrogen production offers a supply of pure oxygen to use in place of air for bioconversion and fuel combustion in the boiler. To reach cost parity with conventional jet fuel, renewable hydrogen needs to be produced at less than $2.2 to $3.1/kg, with a bisabolene yield of 80% of the theoretical yield, along with cell mass and CO2 yields of 22 wt% and 54 wt%, respectively. The economic combination of cell mass, CO2, and bisabolene yields demonstrated in this study provides practical insights for prioritizing research, selecting suitable hosts, and determining necessary engineered production levels.

Producing scalable, economically viable, low-carbon biofuels or biochemicals hinges on more efficient bioconversion processes. While microbial conversion can offer robust solutions, the native microbial growth process often redirects a large fraction of carbon to CO2 and cell mass. By integrating genome-scale metabolic models with techno-economic and life cycle assessment models, this study analyzes the effects of converting cell mass lipids to hydrocarbon fuels, and CO2 to methanol on the facility’s costs and life-cycle carbon footprint. Results show that upgrading microbial lipids or both microbial lipids and CO2 using renewable hydrogen produces carbon-negative bisabolene. Additionally, on-site electrolytic hydrogen production offers a supply of pure oxygen to use in place of air for bioconversion and fuel combustion in the boiler. To reach cost parity with conventional jet fuel, renewable hydrogen needs to be produced at less than $2.2 to $3.1/kg, with a bisabolene yield of 80% of the theoretical yield, along with cell mass and CO2 yields of 22 wt% and 54 wt%, respectively. The economic combination of cell mass, CO2, and bisabolene yields demonstrated in this study provides practical insights for prioritizing research, selecting suitable hosts, and determining necessary engineered production levels.

2023 Early Career Award Winner Paper

Q&A. What inspired you to enter your research field?

“During my freshman year of undergraduate studies in Mechanical Engineering, I was primarily focused on becoming a successful designer of mechanical engineering systems. However, as I progressed and learned about economic design, my focus shifted towards designing cost-effective mechanical engineering systems. This shift sparked my interest in exploring economically viable solutions. Later, during my Master’s degree in Renewable Energy Engineering, I learned about the importance of alternative energy systems in addressing global climate change challenges. This led me to explore the design of low-carbon, economically viable, diverse alternative energy systems, including solar photovoltaic systems, biomass-based fuels or chemicals production systems, micro hydropower, and geothermal energy systems. My research is now focused on the food, water, and energy nexus, examining a range of environmental, economic, and social sustainability indices to inform and improve decisions at individual, organizational, and societal levels. This is all possible due to two very inspiring individuals I have met: my current supervisor, Corinne Scown, Staff Scientist at Lawrence Berkeley National Laboratory, and my former supervisor, Thomas Bradley, Woodward Professor and Department Head at the Department of Systems Engineering, Colorado State University. I would like to express my gratitude to them for their continuous support and encouragement, always motivating me to conduct research that benefits research communities, investors, policymakers, and the public as a whole.”

Q&A. What advice would you give to someone just entering the field?

“One piece of advice I would offer to someone just entering the field is to carefully plan the beginning of their research, rather than focusing solely on the desired outcome. Establishing a strong research foundation is crucial for generating successful outcomes. Staying updated with research conducted by peers and remaining open to interdisciplinary collaborations are also important for conducting impactful and successful research.”

2022 Award

Björn Sjöstrand, Kemiteknik Karlstad University

Björn Sjöstrand, Kemiteknik Karlstad University

Sjöstrand, B., Danielsson, M., and Lestelius, M. (2023). “Method for studying water removal and air penetration during Through Air Drying of tissue in laboratory scale,” BioResources 18(2), 3073-3088.

DOI: 10.15376/biores.18.2.3073-3088

Energy use, together with consumption of raw materials, machine clothing, and wet end chemicals, are some of the most critical aspects in successful tissue making today. This work was aimed at developing a laboratory-scale method of estimating dewatering mechanisms, vacuum efficiency, and energy use of Through Air Drying (TAD) of tissue. When compared to pilot data, the results of the new laboratory method for investigating dewatering during TAD were in the same magnitude, around 24 to 26% dryness after vacuum dewatering, and 27 to 29% dryness after TAD molding. Sheet properties, such as caliper and surface profile, were evaluated and compared to commercial tissue sheets. The results indicate that it will be possible to precisely measure accurate dryness development and penetrated air volume for tissue sheet forming and TAD molding at a laboratory scale. This can contribute to the efforts of implementing a circular forest-based bioeconomy by increasing the fundamental understanding of dewatering of tissue paper materials, which is facilitated by improvements in energy use. The new method developed in this work will make it easier to assess ideas that are difficult to bring to pilot scale or full scale before learning more of the dewatering capabilities. The authors are convinced that improved knowledge of tissue dewatering mechanisms, forming, and material transport during and after TAD dewatering can increase the efficiency of the industrial manufacturing processes.

Energy use, together with consumption of raw materials, machine clothing, and wet end chemicals, are some of the most critical aspects in successful tissue making today. This work was aimed at developing a laboratory-scale method of estimating dewatering mechanisms, vacuum efficiency, and energy use of Through Air Drying (TAD) of tissue. When compared to pilot data, the results of the new laboratory method for investigating dewatering during TAD were in the same magnitude, around 24 to 26% dryness after vacuum dewatering, and 27 to 29% dryness after TAD molding. Sheet properties, such as caliper and surface profile, were evaluated and compared to commercial tissue sheets. The results indicate that it will be possible to precisely measure accurate dryness development and penetrated air volume for tissue sheet forming and TAD molding at a laboratory scale. This can contribute to the efforts of implementing a circular forest-based bioeconomy by increasing the fundamental understanding of dewatering of tissue paper materials, which is facilitated by improvements in energy use. The new method developed in this work will make it easier to assess ideas that are difficult to bring to pilot scale or full scale before learning more of the dewatering capabilities. The authors are convinced that improved knowledge of tissue dewatering mechanisms, forming, and material transport during and after TAD dewatering can increase the efficiency of the industrial manufacturing processes.

2022 Early Career Award Winning Paper

Q&A. What inspired you to enter the field of papermaking and wood products?

“I was interested in science in general and particularly chemistry, and started my undergraduate education in chemical engineering. At Karlstad University, I met several inspiring researchers teaching my classes, and they introduced me to the existing industry of converting biomass from forest into paper and board products. The most important teacher I had was Dr. Christophe Barbier, who later became my supervisor during my PhD education. Dr Barbier introduced the complexity of the processes and the wonderful connection between properties of the wood fibers, layout of the papermaking process, and the optical and mechanical performance of the paper and board products.

The appeal of the field for me is both the exciting high technological processes and that we make products that are renewable, biodegradable, and recyclable and with the potential of competing with fossil-based plastics.”

2021 Award

Nanci Ehman, Materials Institute of Misiones (IMAM, CONICET – UNaM)

Nanci Ehman, Materials Institute of Misiones (IMAM, CONICET – UNaM)

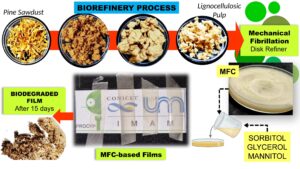

Ehman, N., Ponce de León, A., Felissia, F. E., and Area, M. C. (2022). “Towards biodegradable barrier packaging: Production of films for single-use primary food liquid packaging,” BioResources 17(3), 5215-5233.

DOI: 10.15376/biores.17.3.5215-5233

This research aimed to obtain bio-degradable microfibrillated cellulose (MFC) films from a pine sawdust pulp for use as liquid containers. The films were combined with food-grade polyols (sorbitol, glycerol, and mannitol) to improve the hydrophobicity and provide barrier properties. Pine sawdust (a by-product of primary wood industrialization, highly available, and inexpensive) was treated with soda-ethanol and a 2-stage oxygen sequence. The resulting pulps were mechanically fibrillated to produce MFC with a disk refiner. The polyols were added to improve crosslinking and achieve a plasticizing effect. The films were dried at 25, 50, and 60 °C. The mechanical and barrier properties (tensile strength, elongation, vapor permeability, and water absorption), the crystallinity, and the transparency of the films were evaluated. Total migration tests were carried out to verify the compliance of the films with current regulations. Finally, the film’s biodegradation properties in soil under normal climatic conditions were evaluated.

2021 Early Career Award Winning Paper

Q&A. What does winning this award mean to you?

“I am very grateful and happy!. This award is a great incentive for me. It boosts confidence to continue working on the research. The topic of my research deals with a current problem: non-biodegradable plastics. I consider that, as young researchers, it is crucial to become aware of the current problems related to plastic pollution, and to offer solutions to society.

I am grateful to the BioResources Journal for the award. For helping and for encouraging young researchers, and for also making our research studies reach internationally renowned colleagues.

I would also like to thank my director, Ph.D. Cristina Area, for the nomination, and for always giving me the freedom to investigate such interesting topics related to the pulp and paper field. I greatly appreciate that you have given me an opportunity in research and that you have always trusted me.”