Abstract

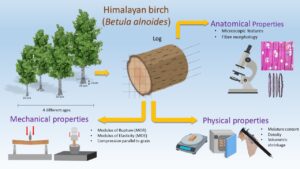

The purpose of this study was to determine the effect of four different age groups on wood properties, i.e., anatomical, physical, and mechanical, of Himalayan birch (Betula alnoides Buch.-H.ex D.Don). The correlation between the properties was also discussed. The results indicated age influences the anatomical, physical, and mechanical properties of Himalayan birch. Results were comparable with other plantation species. Moreover, mechanical properties were highly correlated with the fibre morphology in Himalayan birch. Results from this present study indicate that the 15-, 20-, and 25-year-old Himalayan birch are suitable to be used for parquet, furniture, and other products. Generally, plantation-grown Himalayan birch has the potential to be a raw material to fulfill the demand for the timber industry.

Download PDF

Full Article

Effect of Tree Age on the Properties of Himalayan Birch (Betula alnoides Buch.-H.ex D.Don) Wood

Mohd Khairun Anwar Uyup,a,b Jinfeng Zhang,b Xian Feng,b Zhonghua Chen,b Zhengtao Li,c and Nordahlia Abdullah Siam a

The purpose of this study was to determine the effect of four different age groups on wood properties, i.e., anatomical, physical, and mechanical, of Himalayan birch (Betula alnoides Buch.-H.ex D.Don). The correlation between the properties was also discussed. The results indicated age influences the anatomical, physical, and mechanical properties of Himalayan birch. Results were comparable with other plantation species. Moreover, mechanical properties were highly correlated with the fibre morphology in Himalayan birch. Results from this present study indicate that the 15-, 20-, and 25-year-old Himalayan birch are suitable to be used for parquet, furniture, and other products. Generally, plantation-grown Himalayan birch has the potential to be a raw material to fulfill the demand for the timber industry.

DOI: 10.15376/biores.18.4.8007-8019

Keywords: Himalayan birch; Wood; Anatomy; Mechanical properties

Contact information: a: Forest Products Division, Forest Research Institute Malaysia, 52109 Kepong, Selangor, Malaysia; b: Yunnan Academy of Forestry and Grassland, No 2 Eucalyptus Blue Road, Panlong District, Kunming, China; c: Dehong Forestry and Grassland Bureau. Mangshi, Dehong, China;

*Corresponding authors: mkanwar@frim.gov.my; zhangjinfeng@yafg.ac.cn

GRAPHICAL ABSTRACT

INTRODUCTION

Forest plantations have long been established to ensure a steady supply of raw materials for the wood industry. Forest plantations have become more important sources of timber in some countries to relieve pressure from over-harvesting of natural forest stands because the demand for wood products keeps increasing yearly (West 2006; Alain and Chirstian 2010). Betula spp. from the Betulaceae family is one of the species chosen for forest plantation in Yunnan Province, China, for its timber and other uses. This species is found in the Northern Hemisphere, particularly in northern temperate climate areas such as China. Betula spp., also known as birch, has not only exceptional physical and mechanical properties (Luostarinen and Verkasalo 2000; Collins and Fink 2022), but it is also abundant on the Eurasian continent (Dobrowolska et al. 2020).

Birch wood has been used to make sawn timber, plywood, parquet, furniture, and other items. Birch is a medium density wood with the lightest juvenile wood near the core and the heaviest wood at or near the surface. According to Luostarinen and Verkasalo (2000), this species is durable in dry conditions but is not suitable for outdoor use due to its sensitivity to fungal, decay, and insect damage. However, the properties of wood from plantation species are different from the wood from natural forests, and this leads to limitations in the applications of plantation wood (Jakubowski et al. 2020).

Therefore, it is important to study the properties of wood from forest plantations to ensure the quality of the timber. The properties to study are wood anatomical, physical, and mechanical properties. These properties could be an indicator to the other important properties, such as strength, drying, and machining, and also for the suitable product of the timber (Toong et al. 2014; Nordahlia et al. 2023).

The objective of this study was to determine the effect of four different age groups on wood properties of Himalayan birch. The anatomical and physical characteristics of Himalayan birch at various ages were determined. Mechanical properties including modulus of rupture (MOR), modulus of elasticity (MOE), and compression strength were also assessed. Moreover, correlation factors between the properties were also presented in this research. It is hoped that these basic properties of Himalayan birch will be useful to wood-based industries in terms of exploring suitable products from this plantation species.

EXPERIMENTAL

Materials

Himalayan birch (Betula alnoides Buch.-H.ex D.Don) of various ages, i.e., 10-, 15-, 20-, and 25-years-old, were harvested from a forest plantation area in DeHong Prefecture (GPS coordinates: 24.398872060 N 97.931232590 E), Yunnan Province, China. Three trees were cut at 15 cm above the ground from each age group. The total number of trees cut in this study was 12. Two 5-cm-thick discs from each tree were used for anatomical and physical properties research, whilst 2 m billet pieces were used for evaluation of mechanical properties. The diameter at breast height (DBH), wood diameter (cm), and bark thickness (mm) of Himalayan birch at 4 different ages are shown in Table 1.

Table 1. Diameter at Breast Height, Wood Diameter, and Bark Thickness of Himalayan Birch at 4 Different Ages

Sapwood percentage

The sapwood percentage of from each stem was determined by measuring the radius of the disc and heartwood portion. The sapwood percentage was calculated using the following Eq. 1,

Sapwood percentage = (R2 – r2) / R2 × 100 (1)

where R is average disc radius (mm), and r is average of heartwood radius (mm).

Anatomical study

Microscope slides were prepared by taking a wooden block of 1.0 x 1.0 x 1.0 cm3 from each species studied and boiling it in distilled water until it was well soaked and sank (Schweingruber et al. 2006). Each block’s transverse, tangential, and radial surfaces were cut into thin sections of 15 to 20 µm using a sledge microtome. The thin sections were then immersed in 1% aqueous of Safranin-O for several minutes before being dehydrated with increasing concentrations of alcohol: 70%, 80%, 90%, and 95% until excess stain was removed. The sections were cleared in clove oil before mounting in Canada balsam and drying for a few days in a 60 °C oven.

The samples for maceration were cut into small matchstick-sized pieces and then placed in a test tube containing of 30% hydrogen peroxide and glacial acetic acid (1:1 mixture) (Wheeler et al. 1989). The test tube was then heated in a 45 °C water bath until the sticks became silvery white. To remove the excess acid, the softened sticks were washed with distilled water. After cleaning the sticks, they were shaken in distilled water to break up the fibres from each other. Finally, one or two drops of Safranin-O were added into the test tubes to stain the fibres for easy observation.

Thirty measurement for each anatomical features were measured using a light microscope (model BX53F; Olympus, Tokyo, Japan) to make microscopic observations. The Runkel and slenderness ratio were calculated based on values derived from the fiber properties (Abara and Bekele 2022). The Runkel ratio (Eq. 2) and slenderness ratio (Eq. 3) ratio was calculated as shown below,

Runkel ratio = 2FWT/d (2)

where FWT is fiber wall thickness and d is lumen width,

Slenderness ratio = L/D (3)

where L is fiber length and D is fiber diameter.

Physical Properties

Moisture content

All specimens for moisture content with dimension of 20 mm x 20 mm x 30 mm were weighed before and after drying in an oven at 103 ± 2 °C until a constant weight was obtained. The specimens were conditioned in desiccators with silica gel and their oven dry weights were determined. The MC was calculated in percentage terms using Eq. 4,

MC (%) = (Wi – Wo) / Wo × 100 (4)

where MC is moisture content (%), Wi is initial weight of samples (g), and Wo is oven dry weight (g).

Oven-dry density

For density determination, 120 specimens with dimensions of 20 mm x 20 mm in x 30 mm (in radial x tangential x longitudinal directions) were cut based on dimensions stipulated in the BS 373 (1957) standard. The samples’ oven dry weight was determined after 48 h of drying in an oven at 103 ± 2 °C. The air dry volume was determined by measuring the samples to the nearest 0.01 mm in the radial (R), tangential (T), and longitudinal (L) directions with digital Vernier calipers. The oven dry density was calculated using oven dry weight and air-dry volume, as shown in Eq. 5,

Oven- dry density (kg/m³) = Wo / Vg (5)

where Wo is oven dry weight (kg) and Vg is air-dry volume (m3).

Volumetric shrinkage

The volumetric shrinkage test was carried out under air-dry to oven-dry conditions based on ISO 13061-14:2016 (E) with some modification of initial samples (air-dry) used. In this study, samples measuring 20 mm x 20 mm x 30 mm were used, where the tangential, radial, and longitudinal dimensions of each sample were marked. The measurements were done to the nearest 0.01 mm using digital Vernier calipers. The weight was taken before the samples were dried in an oven at 103 ± 2 °C for 48 h. The volumetric shrinkage of 120 specimens was measured and calculated according to Eq. 6,

ßv (%) = (Vi – Vo) Vi × 100 (6)

where ßv is volumetric shrinkage (%) from the air-dry to oven dry conditions, Di is the volume, in cubic millimeters, of the air-dry test piece, and Do is the volume, in cubic millimeters, of the test piece at absolutely dry (oven-dry).

Mechanical Properties

Bending strength

For mechanical testing, 120 specimens were cut and tested in accordance with BS 373 (1957). The static bending test dimensions were 20 mm x 20 mm x 300 mm. During the test, samples were supported at both ends over a 280 mm span. At mid-span, a load was applied at a constant speed of 6.6 mm min-1.

Compression parallel to grain

The specimens with dimensions of 20 mm (width) x 20 mm (thickness) x 60 mm (length) were used for the compression parallel to the grain. Each specimen was vertically positioned. The bottom end was placed on the flat surface of the strength tester’s hemispherical bearing, while the top end was subjected to a constant applied load. Loading was controlled and applied at a constant cross-head movement rate of 0.6 mm min-1.

Statistical Analysis

An analysis of variance (ANOVA) was used to determine whether or not the differences in means were significant. If the differences were significant, the Least Significant Difference (LSD) at (p ≤ 0.05) test was used to determine which means were significantly different from one another. Pearson correlation analysis was used to examine the relationships between the fibre morphology and mechanical properties. The correlation used the guide established by Evans (1996), which suggests for the absolute value of r: 00 to 0.19 is very weak; 0.20 to 0.39 is weak; 0.40 to 0.59 is moderate; 0.60 to 0.79 is strong; and 0.80 to 1.0 is very strong.

RESULTS AND DISCUSSION

Table 2 depicts the sapwood and heartwood of Himalayan birch at various ages. The colour of the wood distinguishes the sapwood and heartwood of this species. The sapwood is white in colour and heartwood has a light reddish brown colour. The sapwood is the lighter coloured (yellowish white) wood found adjacent to the bark, whereas the heartwood is the darker coloured (pale reddish brown) wood found to the inside of the sapwood (Wiedenhoeft 2010; Nordahlia et al. 2014). According to Table 2, age 10 had the highest percentage of sapwood value, and the value decreased as age increased. In this present study, 10- to 15- year-old Himalayan birch are considered as juvenile wood in which the woods contained more than 50% sapwood. Based on previous studies on juvenile wood, normally, juvenile wood contains more than 50% sapwood, e.g., in 10-year-old Azadirachta excelsa (sentang) (Nordahlia et al. (2014), 8-year-old Malaysian-grown teak (Lim and Gan 2000), and 13-year old teak (Bhat 1995).

Table 2. Sapwood-Heartwood Ratio Between the Age Groups

Microscopic Features

The following description of Himalayan birch is based on microscopic features of a 10- to 25-year-old tree. Cross-section (Fig. 1): Growth rings are present in the cross-section, marked by 2 to 4 rows of radially flattened cells. Wood is diffusely porous, with vessels that are solitary, in radial multiples of 2 to 3, and in clusters. The size of the vessels varies with age, ranging from 88 to 132 µm. There are scalariform perforation plates present. The axial parenchyma diffuses and in marginal. Tangential section (Fig. 2): Rays are 2- to 5-seriate, the average ray height varies with age, ranging from 328 to 450 µm. Radial section (Fig. 3): All ray cells procumbent and non-septate fibres are present.

The anatomical properties of Himalayan birch at four different ages are tabulated in Tables 3 and 4. The fibre length of either sapwood or heartwood increased as the tree grew older. However, after 10 years, the fibre length at sapwood reached a plateau. The highest value obtained for heartwood at age 25-year-old was 1673 µm, From the result obtained, Himalayan birch of all ages studied showed longer fibre than Hevea brasiliensis (Naji et al. 2013) and Eucalyptus grandis (Palermo et al. 2015). The diameter and lumen of Himalayan birch fibres ranged from 29 to 33 µm and 18 to 23 µm, respectively.

Fig. 1. Cross-section: Growth rings present, marked by 2 to 4 rows of radially flattened cells (yellow arrow). Wood diffuse-porous, vessels solitary and in radial multiples of 2 to 3, scalariform perforation plate (blue arrow)

Fig. 2. Tangential section: Rays 2- to 5-seriate (arrow)

Fig. 3. Radial section: All ray cells procumbent (arrows) and non-septate fibres present

Table 3. Fibre Morphology of Himalayan birch at Four Different Ages

1. InsideWood. 2004-onwards. Published on the Internet. http://insidewood.lib.ncsu.edu/search

2. Naji et al. (2013)

3. Palermo et al. (2015)

Note: Swd: Sapwood, Hwd: Heartwood; Values in parentheses are standard deviations. Cell values differing by a letter (a, b, c) in the superscript in each column are significantly different at p ≤ 0.05.

Table 4. Anatomical Properties, Runkel Ratio, and Slenderness Ratio of Himalayan birch at Four Different Ages

1InsideWood. 2004-onwards. Published on the Internet. http://insidewood.lib.ncsu.edu/search

Note: Swd: Sapwood, Hwd: Heartwood;

Values in parentheses are standard deviations. Cell values differing by a letter (a,b,c) in the superscript in each column are significantly different at p ≤ 0.05.

In contrast, the vessel diameter and ray height significantly increased with the age (Table 4). The anatomical properties of Himalayan birch of all ages were larger in the sapwood compared to heartwood. Sapwood generally has higher anatomical properties than the heartwood. This is because sapwood is the actively conducting portion of the stem in which parenchyma cells are still alive and metabolically active. Meanwhile, heartwood is the dead, inner wood portion of a stem that often accounts for the majority of its cross-section (Wiedenhoeft 2010).

Table 4 also shows the Runkel ratio and slenderless ratio for Himalayan birch. The highest mean value was observed at the age of 25 years, which was 0.74 and 0.67 for sapwood and heartwood, respectively. The Runkel ratio for Himalayan birch was less than 1 (< 1) until the age of 25. Fibre with a Runkel ratio less than 1 is considered fine raw material and is suitable for the papermaking industry. Fibres with a Runkel ratio less than 1 (< 1) produce high-quality pulp and paper because they have a large surface area for bonding (Jang and Seth 1998; Kiaei 2011). This species’ slenderness ratio is greater than 33, which indicates that it will provide better forming and well-bonded paper (Xu et al. 2006; H’ng et al. 2016; Nordahlia et al. 2022).

Physical and Mechanical Properties

Table 5 summarises the results of physical and mechanical properties. Based on the findings, the density of Himalayan birch increases with age, with values of 432, 538, 552, and 578 kg/m3 for 10-, 15-, 20-, and 25-year-olds, respectively. The density of Himalayan birch was significantly different between the ages of 10 and 15, but not between the ages of 15 and 25. There is no significant difference in moisture content and volumetric shrinkage observed.

Table 5. Physical and Mechanical Properties of Himalayan birch

1 Sun et al. (2006), 2Eric (2015) 3 Naji et al. (2013), 4 Palermo et al. (2015), 5 Liao et al. (2013),

6 Zhao and Qiu (2021)

Values in parentheses are standard deviations. Cell values differing by a letter (a,b,c) in the superscript in each column are significantly different at p ≤ 0.05.

The density of Himalayan birch from this study was lower than what was reported by Sun et al. (2006) (Betula alnoides) and Eric 2015 (B. alleghaniensis). However, the value was higher than other plantation species such as Hevea brasiliensis (Naji et al. 2013) and Eucalyptus grandis (Palermo et al. 2015). Table 5 also summarized some information from other studies for comparison.

Mechanical properties, such as bending strength (MOR, MOE) and compression parallel to grain, of Himalayan birch increased with age. At 25 years old, the highest values for MOR, MOE, and compression parallel to the grain were 126 N/mm2, 12124 N/mm2, and 58.6 N/mm2, respectively. There is a significant difference in MOR between 10 and 15 years old, and a highly significant difference between 25 years old.

Figure 4, 5, and 6 shows the relationship between the age of Himalayan birch and mechanical strength (MOR, MOE, compression). The regressions lines that were fitted to data indicate a positive relationship between age and mechanical strength. The coefficients of determination (R2) for MOR, MOE and compression strength were 0.72, 0.76 and 0.74, respectively.

Fig. 4. Relationship between age and MOR of Himalayan birch

Fig. 5. Relationship between age and MOE of Himalayan birch

Fig. 6. Relationship between age and compression strength of Himalayan birch

This difference is caused by the increased density of older trees (Bijak and Lachowicz 2021). Hassani et al. (2022) found that the mechanical properties of Populus nigra increased when the age of tree increased. They related it with the fiber length and cell wall thickness, which affect the increasing of density of the wood. Similar findings were also obtained from the research conducted by Bijak and Lachowicz (2021).

The findings in this study also revealed that the mechanical properties of 20-year-old Himalayan birch are almost similar to that of mechanical properties of 19-year-old Himalayan birch reported by Sun et al. (2006). As comparisons, the average values of MOR, MOE, and compression parallel of Himalayan birch in this study also were higher than other plantation species for example Hevea brasiliensis (Naji et al. 2013), Eucalyptus grandis (Palermo et al. 2015), Pinus yunnanensis (Liao et al. 2013), and Cunninghamia lanceolata (Zhao and Qiu 2021).

Correlation Analysis Between Fibre Morphology and Mechanical Properties

Table 6 shows the results of the correlation between fibre morphology and mechanical properties. A very strong correlation was observed between fibre morphology with MOR, where the r value is more than 80 (r ≥ 80). A strong correlation was observed between fibre morphology with MOE and compression parallel to grain, where the r value is 0.60 to 0.79 (r: 0.60 to 0.79).

Table 6. Correlation Factors Influencing MOR, MOE, and Compression of Himalaya Birch

Based on the obtained results, mechanical properties were highly correlated with the fibre morphology in Himalayan birch. This was in good agreement with the conclusions reached by Hamdan et al. (2020) and Adeniyi et al. (2013) who also reported that fibre structure was the factor that primarily affected the mechanical properties of wood.

CONCLUSIONS

- The age of Himalayan birch trees affects the fibre length (heartwood), fibre wall thickness (sapwood), vessel diameter, and ray height.

- This species is suitable as a raw material for the pulp and paper industry as shown by its suitable anatomical properties based on Runkel and Slenderness ratio.

- The density, bending strength and compression strength of the Himalayan birch increased as the age increased.

- Based on the result obtained, 15-, 20-, and 25-year-old timber of Himalayan birch is suitable to use for parquet, furniture, and other wood based products.

- Finally, plantation-grown Himalayan birch have the potential to be a raw material for the timber industry.

ACKNOWLEDGEMENTS

This research was funded by APFNet Visiting Scholar Program (APFNet-ENSTRUMENT-2020-006) and International (Foreign) Science and Technology Cooperation Base (GHJD-2020031). The author also would like to thank Yunnan Academy of Forestry and Grassland (YAFG) for the facilities provided during this study and Forest Research Institute Malaysia (FRIM) for their support.

REFERENCES CITED

Abara, L., and Bekele, T. (2022). “Evaluation of fiber characteristics and basic density of Acacia melanoxylon (R. Br.) grown in Ethiopia for pulp and paper making,” Annals of Civil and Environmental Engineering 6(1), 053-061

Adeniyi, I. M., Adebagbo, C. A., Oladapo, F. M., and Ayetan, G. (2013). “Utilization of some selected wood species in relation to their anatomical features,” Global Journal of Science Frontier Research Agriculture and Veterinary 13(9), 2249-4626

Alain, P., and Christian, M. (2010). “The role of plantations in managing the world’s forests in the Anthropocene,” Frontiers in Ecology and the Environment 8(1), 27–34. DOI: 10.1890/080116

Bhat, K. M. (1995). “A note on heartwood proportion and wood density of 8-year-old teak,” The Indian Forester 121(6), 514-517.

Bijak, S., and Lachowicz, H. (2021). “Impact of tree age and size on selected properties of black locust (Robinia pseudoacacia L.) Wood,” Forests 12, article 632. DOI:10.2290/f12050634

BS 373 (1957). “Methods of testing small clear specimens of timber,” British Standards Institution, London, England.

Collins, S., and Fink, G. (2022). “Modelling the tensile mechanical properties of silver birch timber boards,” Construction and Buildings Materials 344, article ID 128147. DOI: 10.1016/j.conbuildmat.2022.128147

Dobrowolska, E., Wroniszewska, P., and Jankowska A. (2020). “Density distribution in wood of European birch (Betula pendula Roth.),” Forests 11(4), article 445. DOI: 10.3390/f1104044

Eric, M. (2015). Wood: Identifying and Using Hundreds of Woods Worldwide, Wood Database, United States of America.

Evans, J. D. (1996). Straightforward Statistics for the Behavioral Sciences, Brooks/Cole Publishing, Pacific Grove, CA, USA.

Hamdan, H., Nordahlia, A. S., Anwar, U. M. K., Iskandar, M. M., Omar, M. K. M., and Tumirah, K. (2020). “Anatomical, physical, and mechanical properties of four pioneer species in Malaysia,” Journal of Wood Science 66, 1-9. DOI: 10.1186/s10086-020-01905-z

Hassani, S., Talaeipour, M., Bazyar, B, Hemmasi A. H., Mahdavi, S. (2022). “The effect of tree age, thickness, and depth of timber on density and mechanical properties of heat-treated black poplar wood (Populus nigra),” BioResources 17(3), 4086-4097. DOI: 10.15376/biores.17.3.4086-4097

H`ng, P. S., Li, K. L., Cheng, Z. Z., Tang, C. H., Wong, Y. S, Foo, S. L, Aw, T. H., and Wan, K. F. (2016). “Anatomical features, fibre morphological, physical and mechanical properties of three years old new hybrid paulownia: Green paulownia,” Research Journal of Forestry 10, 30-35. DOI: 10.3923/rjf.2016.30.35

InsideWood. (2004). “The InsideWood database,” (http://insidewood.lib.ncsu.edu/search)

ISO 13061-14 (2016). “Physical and mechanical properties of wood – Test methods for small clear wood specimens – Part 14: Determination of volumetric shrinkage”.

Jakubowski, M., Tomczak, A., and Jelonek, T. (2020). “Variations of wood properties of birch (Betula pendula Roth) from a 23-year old seed orchard,” Wood Research 65(1), 75-86. DOI: 10.37763/wr.1336-4561/65.1.075086

Jang, H. F., and Seth, R. S. (1998). “Using confocal microscopy to characterize the collapse behavior of fibres,” TAPPI Journal 81(5), 167-174.

Kiaei, M. (2011). “Anatomical, physical and mechanical properties of Eldas Pine (Pinus eldarica Medw.) grown in the Kelardasht region,” Turkish Journal Agriculture and Forestry 35, 3-42. DOI: 10.3906/tar-1001-552

Liao, S. X., Cui, K., Sun Q. F., Liu F. Y., and Liu, Y. J. (2013). “Comparative study on physical and mechanical properties of normal and compressed wood from Pinus yunnanensis plantation,” Journal of Northwest Forestry University 28(6), 161-164.

Lim, S. C., and Gan, K. S. (2000). “Density and sapwood variation of Malaysian-grown teak,” Paper presented at the XXI IUFRO World Congress, Kuala Lumpur, Malaysia, pp. 1-11.

Luostarinen, K., and Verkasalo, E. (2000). “Birch as sawn timber and in mechanical further processing in Finland, A literature study,” Silva Fennica Monographs 1, 1-40. DOI: 10.14214/sf.sfm1

Naji, H. R., Sahri, M. H., Nobuchi, T., and Bakar, E. S. (2013). “Intra- and interclonal variation in anatomical properties of Hevea brasiliensis Muell,” Wood and Fibre Science 45(3), 268–278.

Nordahlia, A. S., Anwar, U. M. K., Hamdan, H., Zaidon, A., and Mohamad Omar, M. K. (2014). “Mechanical properties of 10-year-old sentang (Azadirachta excelsa) grown from vegetative propagation,” Journal of Tropical Forest Science 26(2), 240-248.

Nordahlia A. S., Shahlinney, L., Anwar, U. M. K., Muhammad Amirul-Aiman, A. J., Noraini, T., Che Nurul-Aini, C. A., and Nor Azahana, A. (2022). “Anatomical and physical properties of three lesser-known timber species from Malaysia,” BioResources 17(1), 1090-1105. DOI: 10.15376/biores.17.1.1090-1105

Nordahlia, A. S., Nor Azahana, A., Anwar, U. M. K., Che Nurul-Aini, C. A., Muhammad Amirul-Aiman, A. J., and Noraini, T. (2023). “Wood anatomical features of Anacardiaceae from Malaysia,” BioResources 18(1), 1232-1250. DOI: 10.15376/biores.18.1.1232-1250

Palermo, G. P. M., Latorraca, J. V. F., Carvalho, A. M., Calonego, F. W., and Severo, E. T. D. (2015). “Anatomical properties of Eucalyptus grandis wood and transition age between the juvenile and mature woods,” European Journal of Wood and Wood Products 73, 775-780. DOI: 10.1007/s00107-015-0947-4

Schweingruber, F. H., Börner, A., and Schulze, E.-D. (2006). Atlas of Woody Plant Stems: Evolution, Structure and Environmental Modifications, Springer-Verlag, Berlin, Germany. DOI: 10.3170/2008-8-18577

Sun, Q. F., Chen, T., and Wang, C. M. (2006). “Studying on difference in wood properties from varied aged plants of Betula alnoides,” Journal of Southwest Forestry College 26(6), 79-81.

Toong, W., Ratnasingam, J., Roslan, M. K. M., and Halis, R. (2014). “The prediction of wood properties from anatomical characteristics: The case of common commercial Malaysian timbers,” BioResources 9(3), 5184-5197. DOI: 10.15376/biores.9.3.5184-5197

West, P. W. (2006). “Plantation forest,” in: Growing Plantation Forests, Springer-Verlag Berlin Heidelberg, Germany, pp. 1-7. DOI: 10.1007/3-540-32479-8_1

Wheeler, E. A., Baas, P., and Gasson, P. E. (1989). “IAWA list of microscopic features for hardwood identification,” IAWA Bull 10(3), 219-332.

Wiedenhoeft, A. (2010). “Structure and function of wood (FPL: GTR-190),” in: Wood Handbook: Wood as an Engineering Material, Centennial Ed., U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI, USA, pp. 3.1-3.18.

Xu, F., Zhong, X. C., Sun, R. C., and Lu, Q. (2006). “Anatomy, ultrastructure and lignin distribution in cell wall of Caragana Korshinskii,” Industrial Crops and Products. 24, 186-193. DOI: 10.1016/j.indcrop.2006.04.002

Zhao, L. F., and Qiu, X. Y. (2021). “Study on the variation of physical and mechanical properties of Chinese fir seedling forest in different stand ages,” Journal of Anhui Agricultural University 48(5), 726-732.

Article submitted: June 6, 2023; Peer review completed: August 5, 2023; Revised version received: September 12, 2023; Accepted: October 2, 2023; Published: October 9, 2023.

DOI: 10.15376/biores.18.4.8007-8019