Abstract

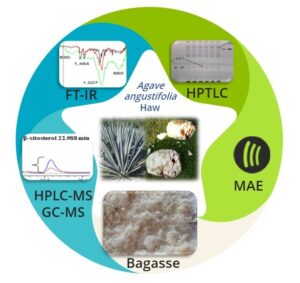

β-sitosterol (BSS) and β-sitosterol glucoside (BSSG) were extracted from Agave angustifolia Haw bagasse using microwave-assisted extraction (MAE). The quantification and characterization of BSS and BSSG were performed through high-performance thin-layer chromatography (HPTLC), Fourier-transform infrared spectroscopy (FT-IR), high-performance liquid chromatography coupled with mass spectrometry (HPLC-MS), and gas chromatography-mass spectrometry (GC-MS). With an extraction time of 9 seconds using MAE, a higher amount of BSS (103.6 mg of β-sitosterol per gram of dry weight of extract) was obtained compared to BSSG (61.6 mg of β-sitosterol glucoside per gram of dry weight of extract). MAE emerges as a promising method for the efficient recovery of β-sitosterol (BSS) and β-sitosterol glucoside (BSSG) from A. angustifolia bagasse. This enriches scientific knowledge regarding phytochemical extraction and holds great potential for various industries, such as pharmaceuticals and nutraceuticals. Additionally, by valorizing the by-products of the agave industry, this research contributes to the sustainable utilization of resources, aligning with the principles of green and circular economy practices.

Download PDF

Full Article

Microwave-Assisted Extraction of β-Sitosterol: A by-Product from Agave angustifolia Haw Bagasse

Herminia López-Salazar,* Brenda Hildeliza Camacho-Díaz, Martha Lucia Arenas Ocampo, Roberto Campos-Mendiola, Rita Martínez-Velarde, Argelia López-Bonilla and Antonio Ruperto Jiménez-Aparicio

β-sitosterol (BSS) and β-sitosterol glucoside (BSSG) were extracted from Agave angustifolia Haw bagasse using microwave-assisted extraction (MAE). The quantification and characterization of BSS and BSSG were performed through high-performance thin-layer chromatography (HPTLC), Fourier-transform infrared spectroscopy (FT-IR), high-performance liquid chromatography coupled with mass spectrometry (HPLC-MS), and gas chromatography-mass spectrometry (GC-MS). With an extraction time of 9 seconds using MAE, a higher amount of BSS (103.6 mg of β-sitosterol per gram of dry weight of extract) was obtained compared to BSSG (61.6 mg of β-sitosterol glucoside per gram of dry weight of extract). MAE emerges as a promising method for the efficient recovery of β-sitosterol (BSS) and β-sitosterol glucoside (BSSG) from A. angustifolia bagasse. This enriches scientific knowledge regarding phytochemical extraction and holds great potential for various industries, such as pharmaceuticals and nutraceuticals. Additionally, by valorizing the by-products of the agave industry, this research contributes to the sustainable utilization of resources, aligning with the principles of green and circular economy practices.

DOI: 10.15376/biores.19.1.568-581

Keywords: Agave biomass waste; Sterols; Valorization of agro-industrial by-products; Sustainable

Contact information: Department of Biotechnology, Centro de Desarrollo de Productos Bióticos, Instituto Politécnico Nacional, P.O. Box 24, Yautepec 62730, Morelos, Mexico;

*Corresponding author: herminia784@gmail.com

GRAPHICAL ABSTRACT

INTRODUCTION

Agave is a versatile plant with significant economic importance in Mexico, as it finds application in various industrial sectors, including beverages, food, biofuels, natural fibers, and secondary metabolites. Agave species are rich sources of diverse secondary metabolites, such as steroidal sapogenins, saponins, sterols, fructans, flavonoids, homoisoflavonoids, phenolic acids, tannins, volatile coumarins, long-chain alkanes, fatty acids, and alcohols. These metabolites exhibit various pharmacological activities, including immunomodulatory, anti-inflammatory, cytotoxic, and antiparasitic effects (Nava-Cruz et al. 2015).

An example of such biological activities was observed in Agave angustifolia Haw, where an acetonic extract obtained through maceration demonstrated immunomodulatory effects. Further research identified 3-O-[(6′-O-palmitoyl)-β-d-glucopyranosyl] sitosterol, stigmasterol, and β-sitosteryl glucoside as the compounds responsible for this activity. β-sitosterol and its glucoside form, known as β-sitosterol β-d-glucoside (BSSG), are bioactive phytosterols associated with anti-inflammatory activity and immunomodulation (Hernández-Valle et al. 2014).

In another study, a standardized ethanol extract based on β-sitosterol glucoside (BSSG) derived from the stem of A. angustifolia using microwave-assisted extraction (MAE) demonstrated safety for cellular viability, as no cytotoxic effects were observed on human fibroblasts. Moreover, the extract exhibited the ability to stimulate fibroblast proliferation in vitro experiments, indicating its potential as a therapeutic approach for enhancing the wound healing process (López-Salazar et al. 2019).

Phytosterols, including β-sitosterol (BSS), campesterol, and stigmasterol, are crucial constituents of cell membranes in both animals and plants, contributing to membrane stability. BSS, a prominent phytosterol, is naturally present in the diet and synthesized by plants through the mevalonic acid pathway. These compounds are found in more than 500 plant species and can exist as conjugates, particularly as fatty acyl sterol esters within lipid bodies and seeds. Bread, cereals, vegetables, and added fats are the primary dietary sources of phytosterols. β-sitosterol possesses a diverse range of pharmacological activities, including anti-inflammatory, anticancer, antioxidant, and cholesterol-lowering effects. Furthermore, it influences various biological systems, such as the central nervous system, liver function, gastrointestinal tract, and reproductive system. Hence, these compounds hold potential as promising candidates for the treatment of various diseases. These properties make it a recommended nutritional supplement for adults (Ambavade et al. 2014).

As we strive for sustainability, the circular economy and improved waste management play essential roles. Industrial plants generate significant amounts of waste, presenting opportunities for the recovery of valuable resources, including secondary metabolites, thus enhancing their value. Current research focuses on effectively utilizing plant waste in diverse sectors, ranging from human health, the food industry, cosmetics, pharmaceuticals, nutraceuticals, veterinary science, and agriculture, to food additives. Consequently, we anticipate a growing body of research exploring the untapped potential of plant matrices, expanding their applications in various fields. This highlights the significance of adopting environmentally friendly practices within the agricultural sector (Chiocchio et al. 2021).

The production of tequila, mezcal, and agave fructans leads to the generation of waste, including leaves, bagasse, and vinasse. Agave bagasse is the residual material that remains after boiling and shredding the agave heads, followed by the extraction of sugars with water. These fibrous bagasse remnants have significant potential for use in manufacturing a wide range of products, including filters, absorbents, geotextiles, fiberboard, packaging, and molded items. It is estimated that for every liter of mezcal produced, approximately 15 to 20 kg of bagasse is generated. In 2019, a total of 178,625 liters of mezcal were reported to have been produced in the state of Durango, Mexico. During that year, it is estimated that between 2679 and 3572 tons of wet agave bagasse were generated (Moreno-Anguiano et al. 2022).

Agave bagasse in Mexico serves as an alternative income source with diverse applications. Explored uses include animal feed, with observations revealing no digestive issues in sheep when fed chopped bagasse. Tequila industry-generated bagasse, often composted over the course of 6 to 8 months, can be composted within 3 months after pretreatment with the Bjerkandera adusta fungus, followed by vermicomposting with Eisenia fetida. Agave residues, which are renewable and versatile, offer potential in biofuel generation. Utilizing the ammonia fiber expansion process and optimized enzymatic hydrolysis, around ~40g/L of bioethanol can be produced from agave leaf fiber and bagasse, showcasing their biofuel potential. Additionally, bagasse finds applications in manufacturing various products like ropes, baskets, clothing, and crafts (Pérez-Zavala et al. 2020).

Agave bagasse refers to the fibrous residue remaining after the agave stalks undergo various processes to extract sugars for tequila and mezcal production. Agave fructans, on the other hand, are carbohydrates extracted from various agave species, including A. angustifolia, and find applications in diverse non-alcoholic products. Notably, fructans have gained considerable attention due to their prebiotic properties, promoting the growth and activity of beneficial intestinal bacteria (Márquez-López et al. 2022).

Microwave-assisted extraction (MAE) has proven to be an efficient and environmentally friendly method for obtaining socially important compounds from plant materials. It enhances extraction efficiency and significantly reduces extraction time compared to traditional methods. This sustainable technique holds great promise for the efficient utilization of natural resources, showcasing its potential for a more efficient extraction process and further exploration in the extraction of socially valuable compounds (Xu et al. 2021). Unlike traditional extraction methods, MAE employs non-toxic solvents and consumes less energy while preserving the integrity of the extracted compounds. Successful microwave extraction requires careful consideration of various factors, including solvent properties, volume, exposure time, temperature, plant material characteristics, power, and equipment type (Belwal et al. 2018; Rodriguez-Padron et al. 2020).

Theoretical mechanisms underlying the MAE process involve the interaction between the magnetic and electric fields of microwave energy with the materials being extracted, resulting in heating caused by magnetic and dielectric losses. Microwaves are electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz, commonly utilizing frequencies of 2.45 GHz in laboratory equipment and 915 MHz in industrial equipment. Microwave heating occurs through two main phenomena: ionic conduction and dipole rotation. Ionic conduction involves the migration of charged carriers, such as ions and electrons, due to the electric field of microwaves. This migration generates heat through the “friction” between the charged particles and the surrounding medium. Dipole rotation occurs when dipolar molecules attempt to align with the alternating electric field of microwaves, resulting in collisions with neighboring molecules and the generation of heat. Both ionic conduction and dipole rotation occur simultaneously, leading to the conversion of microwave energy into thermal energy (Zhang et al. 2011).

This study aimed to identify and quantify β-sitosterol and its glucoside in an ethanol extract obtained from A. angustifolia bagasse using MAE.

EXPERIMENTAL

A. angustifolia Bagasse

The A. angustifolia plant of 5 years old of recorded biological identify was collected in Morelos, Mexico (18°49´33.3´N and 99°06¨21.98W about mean sea level). The A. angustifolia bagasse was obtained through aqueous extraction of fructans (Patent No. MX/ E/ 2015/ 087857) developed at the Center for Biotechnological Product Development (CEPROBI) located in the municipality of Yautepec, Morelos, Mexico. After this process, the A. angustifolia bagasse was collected and dried in an oven at a constant temperature of 40 °C for 72 hours (to prevent the growth of microorganisms). After grinding the dry bagasse (Gutstark, mkz-Molin2000pla), it was sieved using a 100 mesh screen (mesh opening of 0.150 mm), resulting in a final yield of 1000 g.

Microwave-Assisted Extraction (MAE)

The MAE was carried out in a microwave oven (300 W at 2450 MHz), CEM Discover® laboratory equipment, Matthews, NC, USA. The MAE conditions used were an open system (operates in atmospheric conditions), constant radiation power of 300 W, ratio 20:1.6 mL/g liquid/solid, using ethanol as a solvent, and extraction temperature of 21-23 °C, (López-Salazar et al. 2019). García-Ávila et al. (2022) employed the response surface methodology to maximize the extraction yield of phytosterols from A. angustifolia bagasse. The extraction time of 9 seconds was adopted from this study.

High-Performance Thin-Layer Chromatographic (HPTLC) Method

The BSS and BSSG reference standards were acquired from Sima Aldrich Co. (St. Louis, MO, USA). The HPTLC silica gel gas plate 60 F254 with dimensions of 10 cm x 20 cm and a thickness of 250 μm was provided by Merck (Darmstadt, Germany). A mobile phase composed of toluene, ethyl acetate, and formic acid was utilized. Methanol was employed as a diluent for both the standard solutions and experimental samples. The BSS and BSSG standard solutions were prepared by dissolving 250.00 μg/mL of each compound in methanol. To prepare the experimental sample, 5 mg of the ethanolic extract obtained from A. angustifolia was dissolved in 1 mL of methanol.

The extract solutions were applied as 6 mm bands onto HPTLC plates using a CAMAG Linomat V (Muttenz, Switzerland) with a 100 μL microliter syringe and nitrogen gas. The application parameters included 20:10 cm between bands, 10 mm from the lower edge, 8 mm from the left side, and 15 mm from the top. A total of 18 tracks were applied.

To quantify BSS and BSSG, a calibration curve was constructed using standard solutions with six different volumes (0.5, 1.0, 2.0, 2.5, 3.0 μL). For the determination of BSS and BSSG, 4.0 μL of the ethanolic extract from A. angustifolia bagasse was applied six times on each plate at a constant application rate of 150 nL/s. It is important to note that the application volume of the ethanolic extract was determined in preliminary experiments, which confirmed that 4 μL volumes fell within the range of the calibration curve.

Chromatography was conducted using a 60 F254 silica gel plate measuring 20 x 10 cm. The development process took place in the CAMAG Automatic Developing Chamber 2 (ADC 2) in Muttenz, Switzerland, at a temperature of 26 °C and a relative air humidity of 39%. The mobile phase consisted of a mixture of toluene, ethyl acetate, and formic acid in a ratio of 5:5:0.7 (v/v/v). The migration distance was 70 mm, and the migration time was 22 minutes. After development, the plate was air-dried for 5 minutes. Following the HPTLC plate development, since BSS and BSSG displayed no sensitivity in the UV detector, the plate was sprayed with the Komarowsky reagent. Subsequently, it was heated for 3 minutes in the CAMAG TLC Plate Heater III in Muttenz, Switzerland at a temperature of 110°C. For plate image evaluation, a CAMAG TLC Visualizer Documentation System in Muttenz, Switzerland was utilized, featuring a high-performance 12-bit CCD digital camera known for its excellent linearity. All images were captured in a reflected manner under UV wavelength at λ 540 nm, with an exposure time of 2 minutes. The obtained data were processed using VisionCATS 2.4 software.

The densitometric evaluation was carried out using a CAMAG TLC Scanner 4 in Muttenz, Switzerland. Absorption measurements of the derivatized plate with the Komarowsky reagent were recorded under UV light at λ 540 nm.

Fourier-Transform Infrared (FT-IR) Spectroscopic

Fourier-transform infrared (FT-IR) spectroscopy was employed, utilizing a Shimadzu spectrophotometer model IRAffinity-1S (Shimadzu Corporation, Kyoto, Japan) equipped with an attenuated total reflection accessory. This method facilitated the identification of the functional groups present in BSS and BSSG, allowing for analysis of the samples in the medium infrared (MIR) range.

HPLC

The HPLC-MS analysis of the ethanolic extract obtained from A. angustifolia bagasse (ExtBag) was carried out using the following equipment and methodology: a CBM-20 system controller, 2 LC-20AD binary pumps, a DGY-20A5R degasser, SIL-20AC autosampler, a CTO20A column oven, an SPD-M20A UV-Vi’s photodiode array detector, and an LCMS-2020 Mass Spectrometer equipped with an electrospray ionization source (ESI). The separation process utilized an RP-18 reverse-phase column (Lichrospher 100.250 × 4 mm, RP-18, 5 µm) from Merck (Darmstadt, Germany), and isocratic elution was performed using a mobile phase of methanol:water Mili Q (98:2). The sample was injected with a volume of 20 µL and run at a flow rate of 1 mL/min for 40 minutes, maintaining a column temperature of 30 °C. Detection was carried out at a wavelength of 205 nm. Phytosterols were analyzed in the m/z range of 50 to 1000 and 400 to 900 using the negative ionization mode. The capillary voltage was set at 4.5 L/min, and nitrogen gas was used as the nebulizing gas.

GC-MS

The ExtBag underwent analysis using GC-MS. Two milligrams of the extract were dissolved in 100 μL of toluene. The reaction mixture was heated to 50 °C and stirred for 30 minutes on a heating plate. The derivatized extracts (1 μL) were immediately injected into an Agilent 6890 instrument coupled with an Agilent-Technologies 5973N Network Mass Selective Detector (GC-MS). Electron impact was used as the ion source at 70 eV within a mass range of 20 to 600 DA. The capillary column employed was an HP-5 MS (30 m × 0.25 mm, 0.25 μm film thickness: Agilent-Technologies, Little Falls, CA, USA). The oven temperature was programmed at 100 °C for 1 minute, followed by a rate of 10°C/min until reaching 150 °C, and then a rate of 3 °C/min until reaching 300 °C, which was maintained for 4 minutes. Helium gas was used as the carrier with a flow rate of 1.0 mL/min, and the injector temperature was set at 250 °C. Compound identification was achieved by comparing their mass spectra with the NIST library version 1.7a.

Statistical Analysis

The obtained data underwent analysis through one-way ANOVA. To identify significant differences between each group (p < 0.001), the Holm−Sidak Test was employed. Statistical analysis was performed using the SigmaPlot 11.0 software program.

RESULTS AND DISCUSSION

The ExtBag yield from the dried plant was 0.5%. The identification and quantification of β-sitosterol and its glucoside obtained in ExtBag were performed through HPTLC, FT-IR, HPLC, and GC-MS analyses.

HPTLC Analysis

This research aimed to compare the levels of BSS, one of the most common dietary phytosterols, and its glycoside in the bagasse of A. angustifolia. Up until now, there have been no reports on the evaluation of BSS content in A. angustifolia bagasse. Our group has previously developed an HPTLC method to estimate BSS and its glycoside in A. angustifolia bagasse derived from the stem of A. angustifolia. However, the mobile phase used in this method consisted of the mixture toluene: ethyl acetate: formic acid in a ratio of 5:5:0.7 (v/v/v). Upon derivatizing the plate with Komarowsky’s reagent, the terpene bands exhibited a purple color. On the HPTLC plate, a more pronounced intensity of the purple band corresponding to BSS was observed in comparison to the relatively faint band of BSSG. The identification of BSS and BSSG was determined in the experimental extract samples, yielding the same retention factors (rf) of 0.8 ± 0.04 for the reference standard BSS, while BSSG exhibited a rf of 0.3 ± 0.03, as shown in Fig. 1.

Fig. 1. HPTLC plate derivatized with Komarovsky reagent; Tracts 1-6 calibration curve of BSSG, Tracks 7- 12 tracks represent the ethanolic extract obtained by MAE in 9; Tracks 13-18 calibration curve of BSS, with white light and mobile phase toluene: ethyl acetate: formic acid (5:5:0.7 v/v/v).

Fig. 2. 3D densitograms; Tracks 1- 6 show the standard solutions for BSSG; Tracks 7- 12 represent the ExtBag obtained by MAE in 9 s; Tracks 13-18 represent the standard solution of BSS. The measurements were taken at 540 nm.

To facilitate the comparison between the extracted samples and the standard solutions, integration was performed to isolate the chromatographic region containing BSS and BSSG in the extracts. Figure 2 displays the dendrograms of the BSS and BSSG standards, as well as those of BSS and BSSG present in the extract, emphasizing the similarity in their rf.

The results of BSS and BSSG quantification are shown in Table 1. Recoveries ranged from 103.6 mg /g dry weight of extract for BSS and 61.6 mg/g dry weight of extract for BSSG.

Table 1. Quantification of BSS (β-sitosterol) and BSSG (β-sitosterol glucoside) in ExtBag (ethanolic extract of the bagasse of A. angustifolia)

Note: Average ± SD, n=6. p<0.001 according to the Holm-Sidak method

In a previous study conducted by this research group (López-Salazar et al. 2019), an ethanolic extract was obtained from the stem of A. angustifolia by microwave-assisted extraction (MAE), obtaining a BSSG yield of 124.8 mg/g dry weight of the extract. The MAE process had an extraction time of 5 seconds, using an ethanolic solution of KOH as catalyst and a radiation power of 300 W.

The amount of BSSG obtained was higher than that found in the present research. However, it is important to consider that waste material obtained from a heating process was used in this study, which could explain the difference in the amounts of BSSG obtained. It is possible that the heating process applied to the bagasse of A. angustifolia caused damage to the tissue structure, including the cell walls, and the breaking of bonds in the cell wall components (Ngadze et al. 2018). These changes may increase the susceptibility to mechanical rupture, especially upon application of microwave energy, leading to more effective exposure of the compounds of interest. Therefore, the combination of modifications in the bagasse resulting from the processing it undergoes, along with exposure to microwave energy, may have facilitated the degradation of the BSSG.

Several factors must be considered to achieve successful microwave extraction, with the characteristics of the plant material being of great importance (Zill-E-Huma et al. 2011). Furthermore, understanding the cellular structure of the plant is essential, as secondary metabolites often have specific locations within tissues, cells, or organelles where their biosynthesis, transport, and accumulation take place. For instance, steroid glycosides and acyl glycoside sterols are known to accumulate in specialized microdomains known as lipid rafts within the plant’s plasma membrane (Ferrer et al. 2017) Therefore, it is crucial to comprehend the organization and distribution of these specific sites within the cellular structure to optimize microwave extraction methods and ensure the efficient recovery of target compounds (Zill-E-Huma et al. 2011).

There are reports of studies using waste materials and microwave energy to obtain compounds of interest. One such example is the use of cocoa shell waste to extract β-sitosterol by microwave-assisted extraction (MAE). According to the OFAT (One-Factor-at-a-Time) method, the concentration of β-sitosterol in cocoa husk residues was 3550 mg/100g after extraction. Based on this study, the optimal conditions for the extraction of β-sitosterol from cocoa husk residues were an extraction time of 10 min, a microwave power of 500 W, and a microwave temperature of 70 °C. The microwave equipment used was an adaptation (Ibrahim et al. 2020).

Identification of the Functional Groups of BSS and BSSG by FT-IR

The FT-IR analysis involved comparing the ExtBag sample with the presence of functional groups found in the FT-IR spectra of BSS and BSSG. Figure 3A, B (FT-IR zoom) shows BSS FT-IR absorbance bands (cm-1) at 3320, which is attributed to stretching vibration of CH alkane (symmetric and asymmetric), 2932 (CH2)-CH, 1628 for unconjugated olefinic C=C, stretching vibration of an aromatic ring, 1465 cyclic methylene groups (CH2)n, 1376 gem-dimethyl (–CH(CH3)2) group, 1054 C–OH of secondary alcohol and, 663 a group -C=C-, possibly of simple glycoside. This last functional group corresponds to the BSSG.

(A)

(B)

Fig. 3. (A) FT-IR spectra of BSS (β-sitosterol) and BSSG (β-sitosterol glucoside) and ExtBag (ethanolic extract of the bagasse of A. angustifolia); (B) enlargement of Fig. 3B in the region from 600 to 1800 cm-1

These data were also compared with spectral data for BSS and BSSG reported by different authors, which are shown in Table S1. A C=C double bond in the structure, a distinguishing feature of BSS and BSSG, was detected in the FT-IR spectrum of ExtBag. The data presented offers compelling evidence for the identification of the distinctive functional groups of BSSS and BSSG in the FT-IR spectrum of ExtBag

The HPLC-MS analysis of the ExtBag resulted in the identification of two compounds, BSS and BSSG, based on their retention times (Rt) and characteristic UV absorption spectra. BSS eluted at 22.988 min, with a precursor ion at m/z 414.71 g/mol [M-H]-, while BSSG eluted at 9.788 min, with a precursor ion at m/z 577 g/mol [M-H]-. These results are displayed in Fig. S1. The identification of these compounds was further confirmed by comparing their retention times, UV spectra, and ion masses with reference standards. These findings provide valuable insights into the composition and characteristics of the ethanolic extract derived from the bagasse of A. angustifolia obtained by MAE.

HPLC-MS is effective in identifying and quantifying BSS. This technique separates components within a sample, which are then subjected to analysis using mass spectrometry. Multiple studies have emphasized the remarkable utility of HPLC-MS in the identification of BSS due to its ability to provide comprehensive insights into the structure and chemical composition of the compounds under investigation. By examining the obtained mass spectra, researchers can verify the distinct molecular characteristics and specific fragments associated with BSS, facilitating its differentiation from other compounds present in the sample. Moreover, HPLC-MS offers exceptional sensitivity and selectivity, enabling accurate detection and quantification even when dealing with minute quantities of BSS. This feature is particularly advantageous when working with complex samples or those with low concentrations of BSS (Ambavade et al. 2014).

GC-MS Analysis

The presence of BSS in the ExtBag was confirmed through GC-MS analysis, where it exhibited a retention time (Rt) of 18.960 min. These findings offer substantiating proof of the presence of the compound in the ExtBag acquired through MAE.

CONCLUSIONS

- Microwave-assisted extraction (MAE) was successfully employed to extract β-sitosterol (BSS) and its glucoside (BSSG) from A. angustifolia bagasse.

- Quantification and characterization of BSS and BSSG were carried out using various analytical techniques, including high-performance thin layer chromatography (HPTLC), Fourier transform infrared (FT-IR) spectrometry, high-performance liquid chromatography – mass spectrometry (HPLC-MS), and gas chromatography with mass spectrometry (GC-MS).

- The study demonstrated that a 9 s MAE extraction yielded a higher quantity of BSS (103.6 mg of β-sitosterol per gram of dry weight of extract) compared to BSSG (61.6 mg of β-sitosterol glucoside per gram of dry weight of extract).

- MAE stands out as a promising method for the efficient recovery of BSS and BSSG from A. angustifolia bagasse, which has significant implications for various industries.

- This research promotes the sustainable utilization of agave by-products, aligning with the principles of green and circular economy practices, thus contributing to the responsible and efficient management of resources.

ACKNOWLEDGMENTS

The authors express their sincere gratitude to the Consejo Nacional de Humanidades Ciencias, y Tecnologías (CONAHCYT), Mexico, for their generous support through the Postdoctoral Fellowship for México 2022 awarded to Dr. Herminia López Salazar at the Centro de Desarrollo de Productos Bióticos, Instituto Politécnico Nacional. The authors thank the members of the chromatography laboratory at the same institution, particularly M.C. Alma Rosa López Laredo and M.C. Virginia Medina Perez, for their assistance and expertise throughout the course of this research work.

REFERENCES CITED

Ambavade, S. D., Misar, A. V., and Ambavade, P. D. (2014). “Pharmacological, nutritional, and analytical aspects of β-sitosterol: A review,” Oriental Pharmacy and Experimental Medicine 14, 193-211. DOI: 10.1007/s13596-014-0151-9

Azeez, R. A., Abaas, I. S., and Kadhim, E. J. (2018). “Isolation and characterization of β-sitosterol from Elaeagnus angustifolia cultivated in Iraq,” Asian J Pharm Clin Res, 11(11), 442-446. DOI: 10.22159/ajpcr.2018.v11i11.29030

Belwal, T., Ezzat, S. M., Rastrelli, L., Bhatt, I. D., Daglia, M., Baldi, A., and Atanasov, A. G. (2018). “A critical analysis of extraction techniques used for botanicals: Trends, priorities, industrial uses and optimization strategies,” TrAC Trends in Analytical Chemistry 100, 82-102. DOI: 10.1016/j.trac.2017.12.018

Chiocchio, I., Mandrone, M., Tomasi, P., Marincich, L., and Poli, F. (2021). “Plant secondary metabolites: An opportunity for circular economy,” Molecules 26(2), article 495. DOI: 10.3390/molecules26020495

Ferrer, A., Altabella, T., Arró, M., and Boronat, A. (2017). “Emerging roles for conjugated sterols in plants,” Progress in Lipid Research 67, 27-37. DOI: 10.1016/j.plipres.2017.06.002

García-Ávila, E. E., Arenas-Ocampo, M., and Camacho-Díaz, B. (2022). “Obtención de fitoesteroles de bagazo residual de Agave angustifolia Haw con extracción asistida por microondas,” [Tesis de maestría, Instituto Politécnico Nacional].

Hernández-Valle, E., Herrera-Ruiz, M., Rosas Salgado, G., Zamilpa, A., Arenas Ocampo, M. L., Jiménez Aparicio, A., and Jiménez-Ferrer, E. (2014). “Anti-inflammatory effect of 3-O-[(6′-O-palmitoyl)-β-D-glucopyranosyl sitosterol] from Agave angustifolia on ear edema in mice,” Molecules 19(10), 15624-15637. DOI: 10.3390/molecules191015624

Ibrahim, N. H., Mahmud, M. S., and Nurdin, S. (2020, December). “Microwave-assisted extraction of β-sitosterol from cocoa shell waste,” in: IOP Conference Series: Materials Science and Engineering 991, article 012106. IOP Publishing. DOI: 10.1088/1757-899X/991/1/012106

López-Salazar, H., Camacho-Díaz, B. H., Ávila-Reyes, S. V., Pérez-García, M. D., González-Cortazar, M., Arenas Ocampo, M. L., and Jiménez-Aparicio, A. R. (2019). “Identification and quantification of β-sitosterol β-D-glucoside of an ethanolic extract obtained by microwave-assisted extraction from Agave angustifolia Haw,” Molecules 24(21), article 3926. DOI: 10.3390/molecules24213926

Márquez-López, R. E., Santiago-García, P. A., and López, M. G. (2022). “Agave fructans in Oaxaca’s emblematic specimens: Agave angustifolia Haw. and Agave potatorum Zucc.,” Plants 11(14), 1834. DOI: 10.3390/plants11141834

Moreno-Anguiano, O., Cloutier, A., Rutiaga-Quiñones, J. G., Wehenkel, C., Rosales-Serna, R., Rebolledo, P., and Carrillo-Parra, A. (2022). “Use of Agave durangensis bagasse fibers in the production of wood-based medium density fiberboard (MDF),” Forests 13(2), 271. DOI: 10.3390/f13020271

Nava-Cruz, N. Y., Medina-Morales, M. A., Martinez, J. L., Rodriguez, R., and Aguilar, C. N. (2015). “Agave biotechnology: An overview,” Critical Reviews in Biotechnology 35(4), 546-559. DOI: 10.3109/07388551.2014.923813

Ngadze, R. T., Verkerk, R., Nyanga, L. K., Fogliano, V., Ferracane, R., Troise, A. D., and Linnemann, A. R. (2018). “Effect of heat and pectinase maceration on phenolic compounds and physicochemical quality of Strychnos cocculoides juice,” PloS One 13(8), article e0202415. DOI: 10.1371/journal.pone.0202415

Ododo, M. M., Choudhury, M. K., and Dekebo, A. H. (2016). “Structure elucidation of β-sitosterol with antibacterial activity from the root bark of Malva parviflora,” SpringerPlus 5(1), 1-11. DOI: 10.1186/s40064-016-2894-x

Pérez‐Zavala, M. D. L., Hernández‐Arzaba, J. C., Bideshi, D. K., and Barboza‐Corona, J. E. (2020). “Agave: A natural renewable resource with multiple applications,” Journal of the Science of Food and Agriculture 100(15), 5324-5333. DOI:10.1002/jsfa.10586

Rodriguez-Padron, D., Zhao, D., Garin Ortega, R. N., Len, C., Balu, A. M., García, A., and Luque, R. (2020). “Characterization and antioxidant activity of microwave-extracted phenolic compounds from biomass residues,” ACS Sustainable Chemistry & Engineering 8(3), 1513-1519. DOI: 10.1021/acssuschemeng.9b06002

Xu, J., Wu, J., Qi, J., Li, J., Liu, Y., Miao, Z., and Jia, W. (2021). “Microwave-assisted extraction of flavonoids from Phyllostachys heterocycla leaves: Optimization, mechanism, and antioxidant activity in vitro,” BioResources 16(4), 8060-8081. DOI: 10.15376/biores.16.4.8060-8081

Zhang, H. F., Yang, X. H., and Wang, Y. (2011). “Microwave assisted extraction of secondary metabolites from plants: Current status and future directions,” Trends in Food Science & Technology 22(12), 672-688. DOI: 10.1016/j.tifs.2011.07.003

Zill-E-Huma, Vian, M.A., Fabiano-Tixier, A.-S., Elmaataoui, M., Dangles, O., and Chemat, F. (2011). “A remarkable influence of microwave extraction: Enhancement of antioxidant activity of extracted onion varieties,” Food Chemistry 127 (4), 1472-1480. DOI: 10.1016/j.foodchem.2011.01.112

Article submitted: October 18, 2023; Peer review completed: November 11, 2023; Revised version received and accepted: November 21, 2021; Published: November 29, 2023.

DOI: 10.15376/biores.19.1.568-581

APPENDIX

Supplementary Information

Table S1. Comparison of FT-IR Spectra of β-Sitosterol (BSS) and β-Sitosterol Glucoside (BSSG) Reported in Different Studies

Fig. S1. RP–HPLC chromatogram recorded at a wavelength of 205 nm for the identification of BSS (β-sitosterol) in Rt: 22.988 min and BSSG (β-sitosterol glucoside) in Rt: 9.788 min in the ExtBag (ethanolic extract of the bagasse of A. angustifolia) and Mass spectrum.